Induction hardening tooling for outer shell of disc six-hole type cage constant velocity universal joint

A constant velocity universal joint, induction hardening technology, applied in the direction of quenching equipment, manufacturing tools, process efficiency improvement, etc., can solve the problem of unaffected heating temperature, etc., to achieve lower temperature, uniform cooling water pressure, uniform water volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

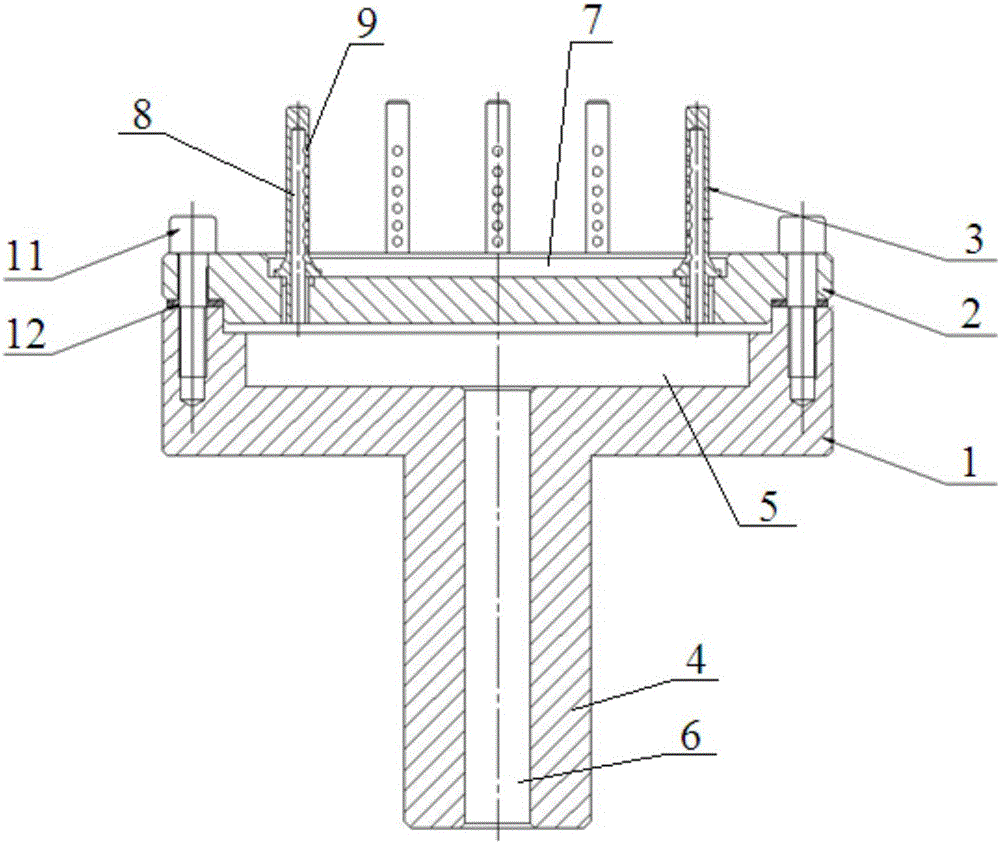

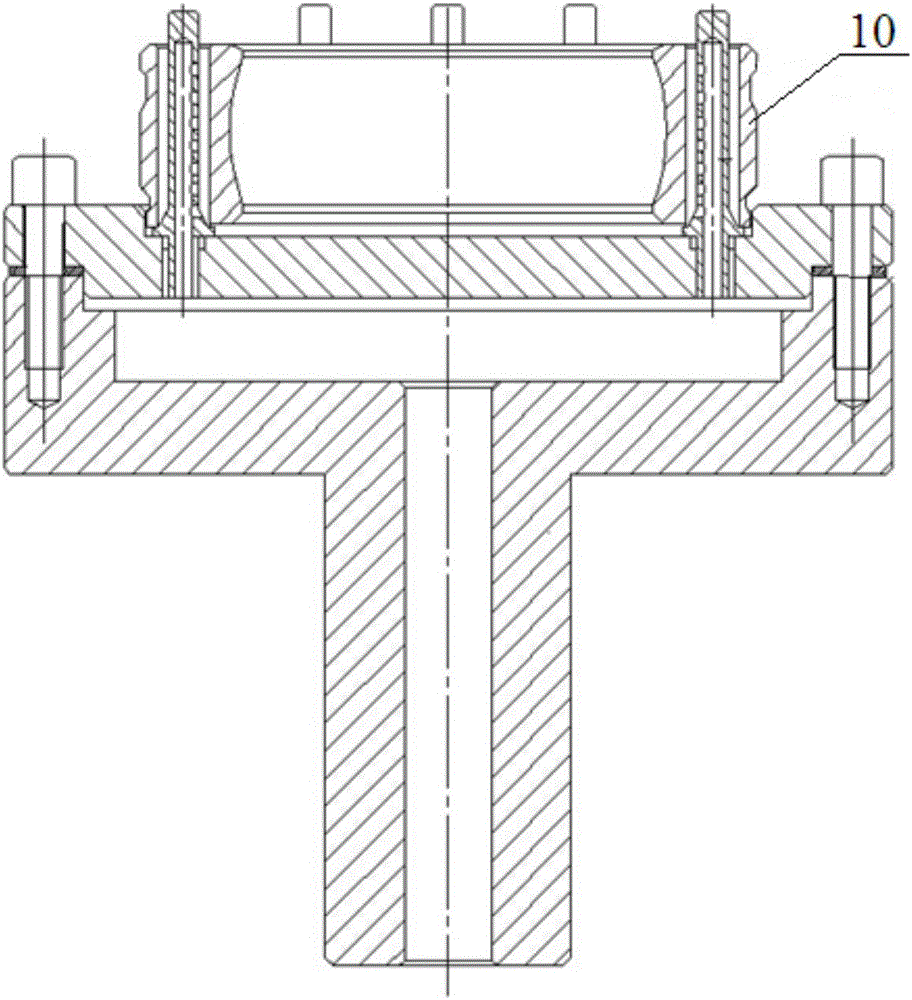

[0016] see figure 1 , 2 , a disc six-hole type ball cage constant velocity universal joint shell induction hardening tooling, including a base 1 and a sealing disc 2, the bottom of the base 1 has a straight handle 4 connected and installed with a quenching machine tool, and the sealing disc 2 is fixedly installed on the base 1 and the base 1 is provided with a cavity 5 below the sealing disc 2, the straight handle 4 is provided with a through hole 6 communicating with the cavity 5, and the sealing disc 2 is provided with a counterbore 7 for positioning the workpiece 10, Six water spray columns 3 are fixedly connected around the counterbore 7, blind holes 8 communicating with the cavity 5 are respectively arranged in the six water spray columns 3, and the inner walls of the six water spray columns 3 are respectively provided with There are water spray holes 9 that are densely distributed and communicate with the blind holes 8 .

[0017] In the present invention, six threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com