An ultra-purification column of a laboratory water purifier

A technology of water purifier and purification column, applied in non-polluting water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of large volume, difficult installation and maintenance, leakage of resin debris, etc. The wall thickness is uniform, the pressure bearing capacity is strong, and the welding effect is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

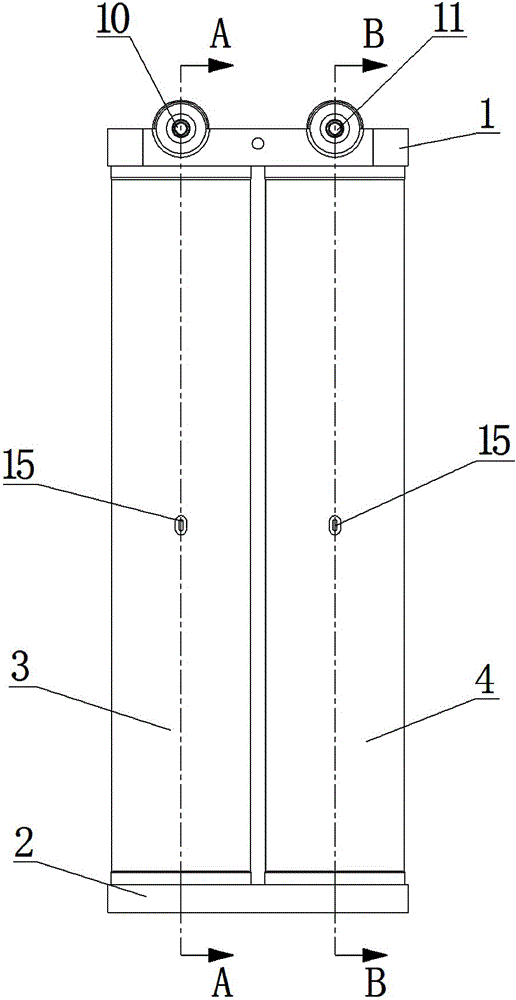

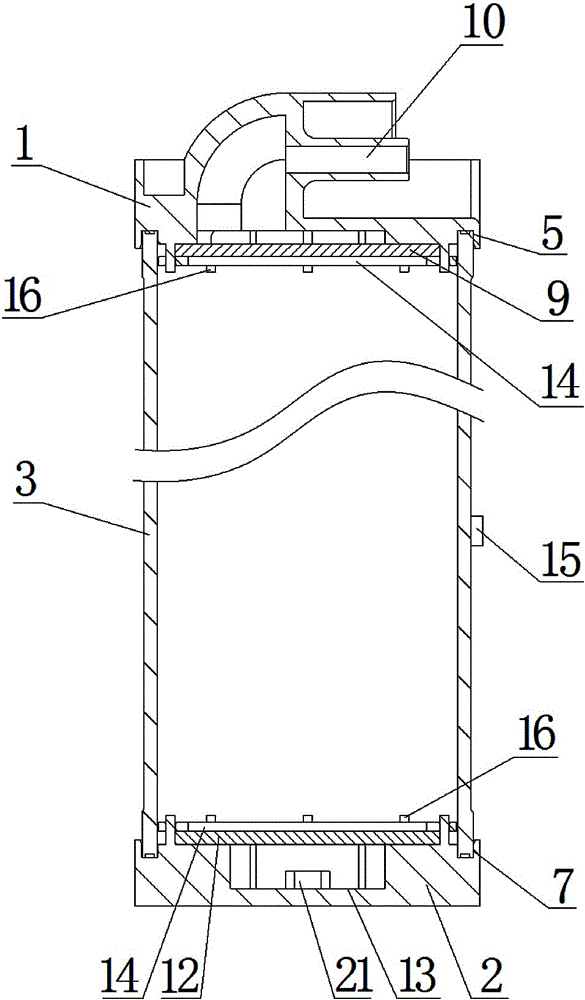

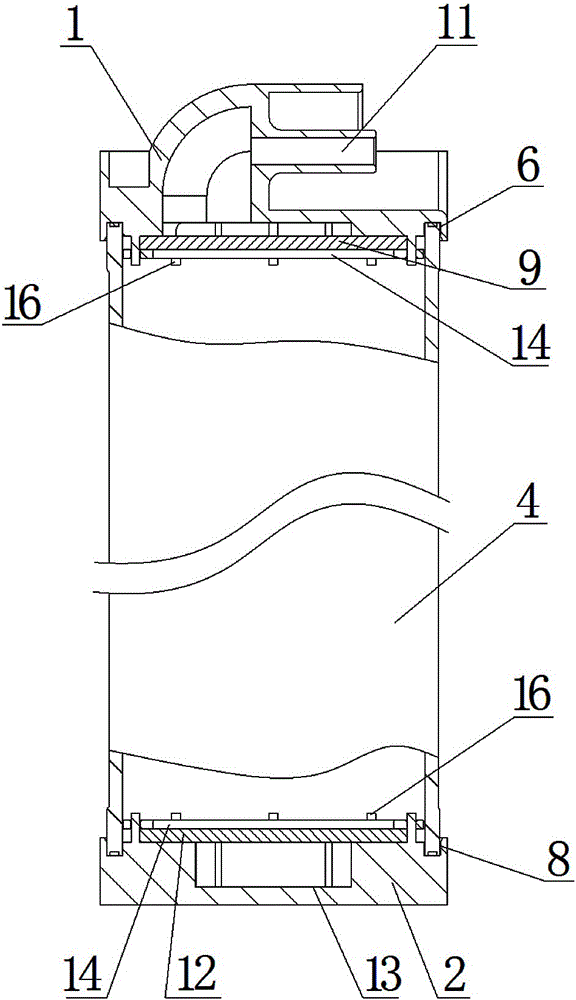

[0021] Such as Figure 1-4 As shown, an ultra-purification column of a laboratory water purifier includes an upper end cover 1, a lower end cover 2, a purification column A3 and a purification column B4, and the bottom surface of the upper end cover 1 is provided with an annular groove a5 and an annular groove b6, an annular groove c7 and an annular groove d8 are arranged on the top surface of the lower end cover 2, and the top and bottom ends of the purification column A3 are respectively welded in the annular groove a5 and the annular groove c7, and the top and bottom ends of the purification column B4, The bottom ends are respectively welded in the annular groove b6 and the annular groove d8, the bottom surface of the upper end cover 1 is provided with a microporous filter sheet I9 located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com