A kind of high-strength gypsum thermal insulation putty and its preparation method

A technology of high-strength gypsum and heat-insulating putty, which is applied in filling slurry and other directions, can solve the problem that the heat-insulation and mechanical strength of putty cannot be improved at the same time, and achieve the effect of avoiding the decrease of heat-insulating effect, fine scraping and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

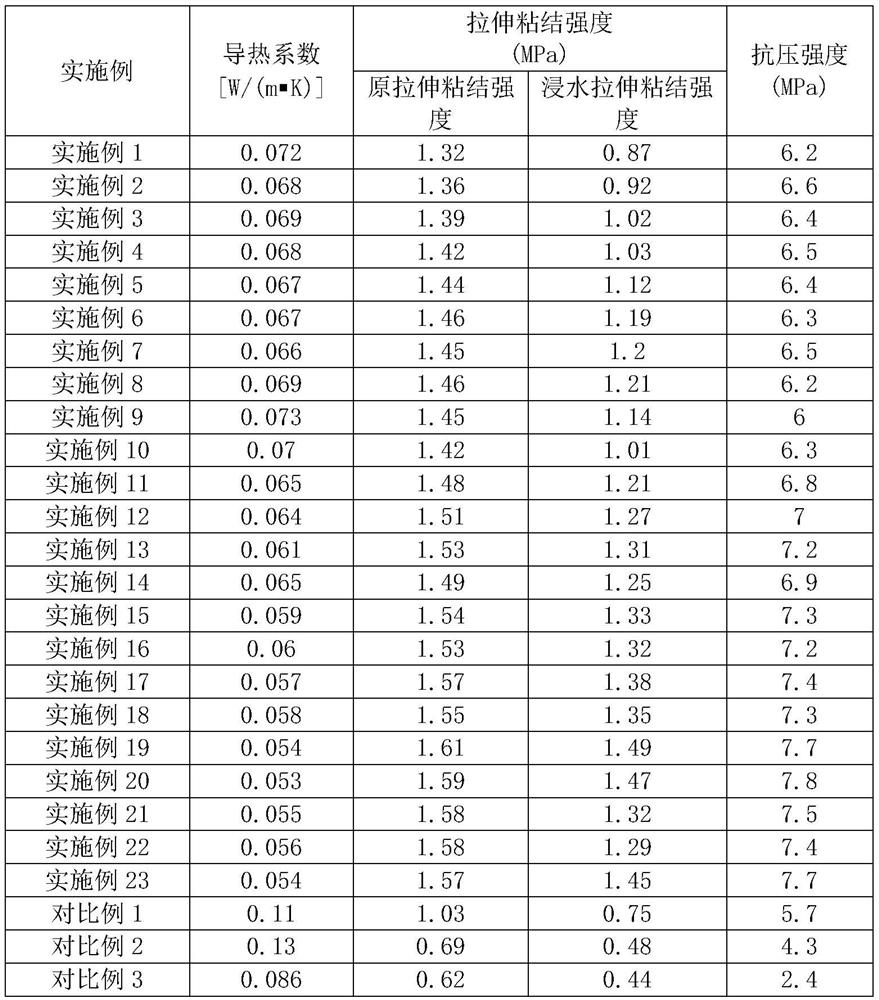

[0039] Embodiments 1-23 provide a new type of high-strength gypsum thermal insulation putty, which will be described below by taking Embodiment 1 as an example.

[0040] A kind of novel high-strength gypsum thermal insulation putty that embodiment 1 provides, its preparation steps are:

[0041] S1: Mix and stir 50g of α-high-strength gypsum and 7g of vitrified microspheres evenly to obtain a mixture 1;

[0042]S2: Add 1kg of water to the mixture 1, mix and stir evenly, then add 1g redispersible latex powder, 0.1g retarder, 0.1g thixotropic agent and 0.01g air-entraining agent, mix evenly, and Mix and stir for 40min at a stirring rate of 50rpm to obtain a mixture 2;

[0043] S3: Add 0.1 g of cellulose ether to the mixture 2, mix evenly, put it in a shearing machine, shear and disperse at a speed of 2000 rpm for 20 minutes, and obtain a new type of high-strength gypsum thermal insulation putty;

[0044] Wherein, the mesh number of the α-high-strength gypsum is 200;

[0045] T...

Embodiment 2-4

[0051] Examples 2-4 are the same as Example 1, except that the quality of the raw materials for the preparation of the novel high-strength gypsum thermal insulation putty is different, see Table 2 for details.

[0052] Table 2

[0053] components Example 1 Example 2 Example 3 Example 4 α-high strength gypsum (g) 50 70 60 65 Vitrified beads (g) 7 10 8 9 water (kg) 1 1.5 1.3 1.4 Redispersible latex powder (g) 1 2 1.5 1.7 Retarder (g) 0.1 0.5 0.3 0.4 Thixotropic agent (g) 0.1 0.5 0.3 0.4 Air-entraining agent (g) 0.01 0.05 0.03 0.04 Cellulose ether (g) 0.1 0.3 0.2 0.25

[0054] Examples 5-10 are the same as Example 4, except that the cellulose ethers are different, see Table 3 for details.

[0055] table 3

[0056] Example Cellulose ether Example 4 Walocel XM 20000PV Example 5 Walocel XM 20000PV and HK75000S are mixed at a mass ratio of 1:2 Example 6 Waloc...

Embodiment 11

[0057] Example 11 is the same as Example 7, except that the α-high-strength gypsum is DLJ-02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com