Molding process of header body

A molding process and box technology, which is applied in the direction of boiler drum/box header, fluid heater, lighting and heating equipment, etc., can solve the problems of inapplicability, and achieve good tightness, stable quality and uniform pipe wall Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

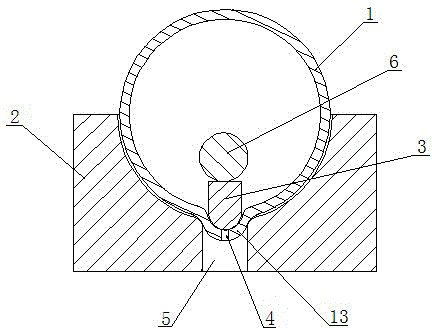

[0061] The molding process of the boiler header body includes the following steps:

[0062] Step 1. Use steel ingot as the material for the header body, heat it at 1000°C for 1.5 hours, and then forge it into a round steel column.

[0063] Step 2. Put the forged round steel column into the heating furnace for heating, the heating temperature is 1300°C, take out the round steel column after burning red, put it on the punching machine, and punch out a through hole 11 along the central axis of the round steel column , and make the tube blank 10.

[0064] Step 3: Send the tube blank 10 into the heating furnace, heat it at 1030°C for 1 hour, take it out, insert a central shaft 12 into the through hole in the center of the tube blank 10, and then send the tube blank 10 into the forging machine , forged into a round tube with the required wall thickness, and the central shaft is drawn out after forging.

[0065] Step 4: Put the round tube forged in Step 3 into the heating furnace, ...

Embodiment 2

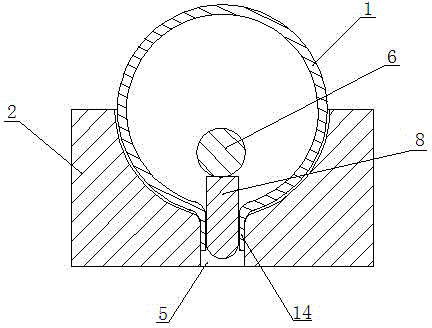

[0077] The molding process of the boiler header body includes the following steps:

[0078] Step 1. Use steel ingot as the material for the header body, heat it at 1030°C for 2 hours, and then forge it into a round steel column.

[0079] Step 2. Send the forged round steel column into the heating furnace for heating. The heating temperature is 1350°C. After burning red, take out the round steel column. The specific heating time is determined according to the size of the round steel column to meet the needs of subsequent punching operations. Accurate, take it out and place it on a punching machine, and punch out a through hole 11 along the central axis of the round steel column to make a tube blank 10.

[0080] Step 3: Send the tube blank 10 into the heating furnace, heat it at 1050°C for 2 hours, take it out, insert a central shaft 12 into the through hole in the center of the tube blank 10, and then send the tube blank 10 into the forging machine , forged into a round tube w...

Embodiment 3

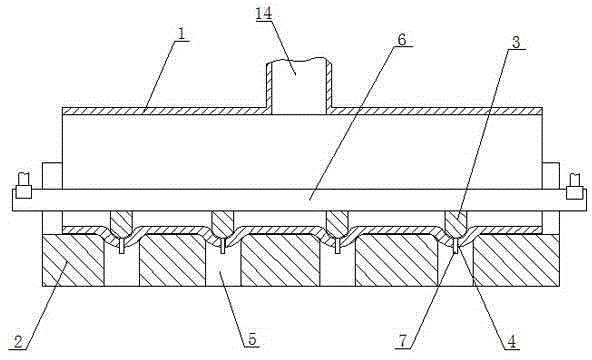

[0093] The molding process of the boiler header body. The header body is provided with a branch pipe interface with a larger diameter, and a row of branch pipe connections with a smaller diameter is provided on both sides of the pipe wall opposite to the interface. The molding process includes the following step:

[0094] Step 1. Steel ingots are used as the material for the header body, heated at 1100° C. for 2.5 hours, and then forged into round steel columns.

[0095] Step 2. Send the forged round steel column into a heating furnace for heating at a temperature of 1500°C. After burning red, take out the round steel column, put it on a punching machine, and punch a through hole 11 along the central axis of the round steel column. The tube blank 10 is made.

[0096] Step 3: Send the tube blank 10 into the heating furnace, heat it at 1100°C for 1 hour, take it out, insert a central shaft 12 into the through hole in the center of the tube blank 10, and then send the tube blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com