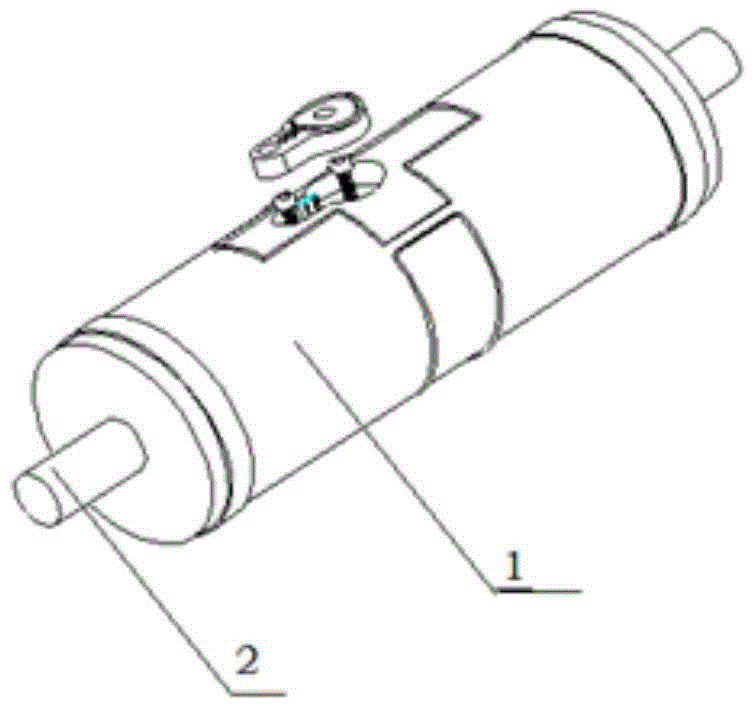

A rotary die cutting machine knife roller waste discharge device

A technology of a waste discharge device and a die-cutting machine, which is applied in metal processing and other directions, can solve the problems of incomplete waste discharge, extrusion and collapse of the knife edge, impracticality, etc., and achieve the effects of reducing production costs, convenient use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

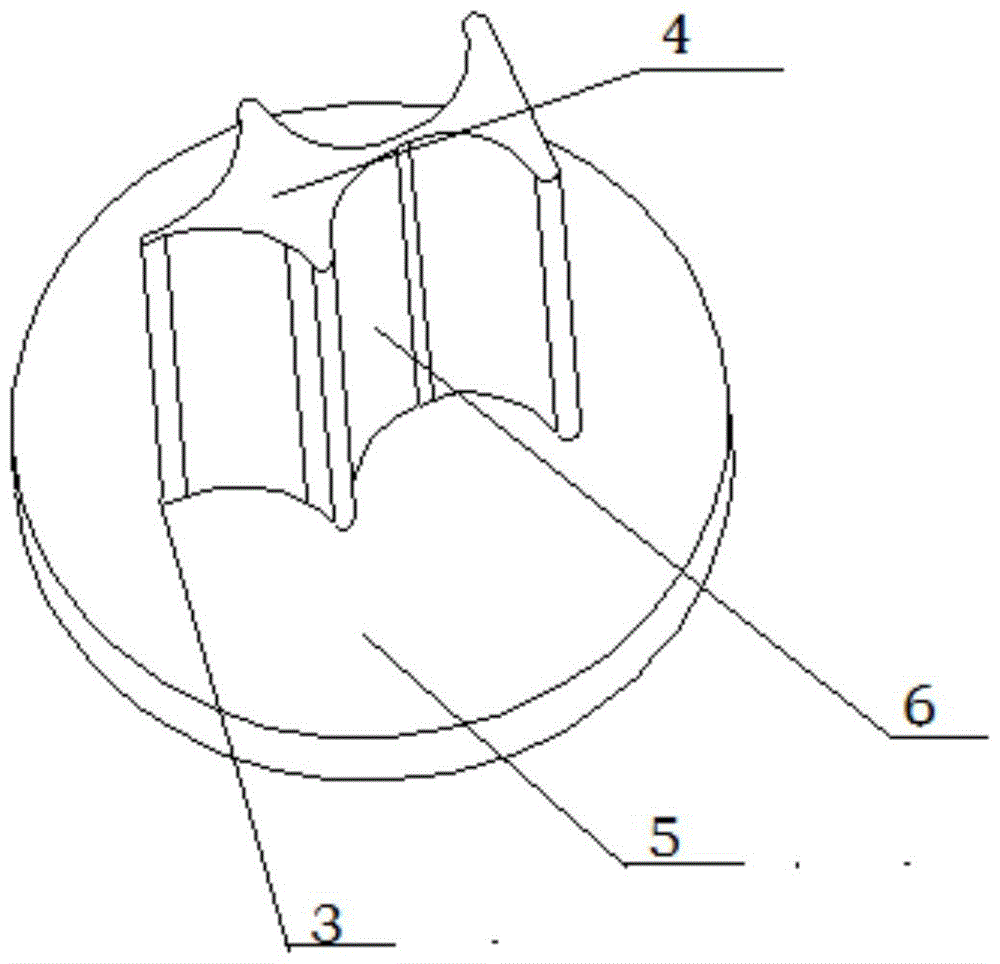

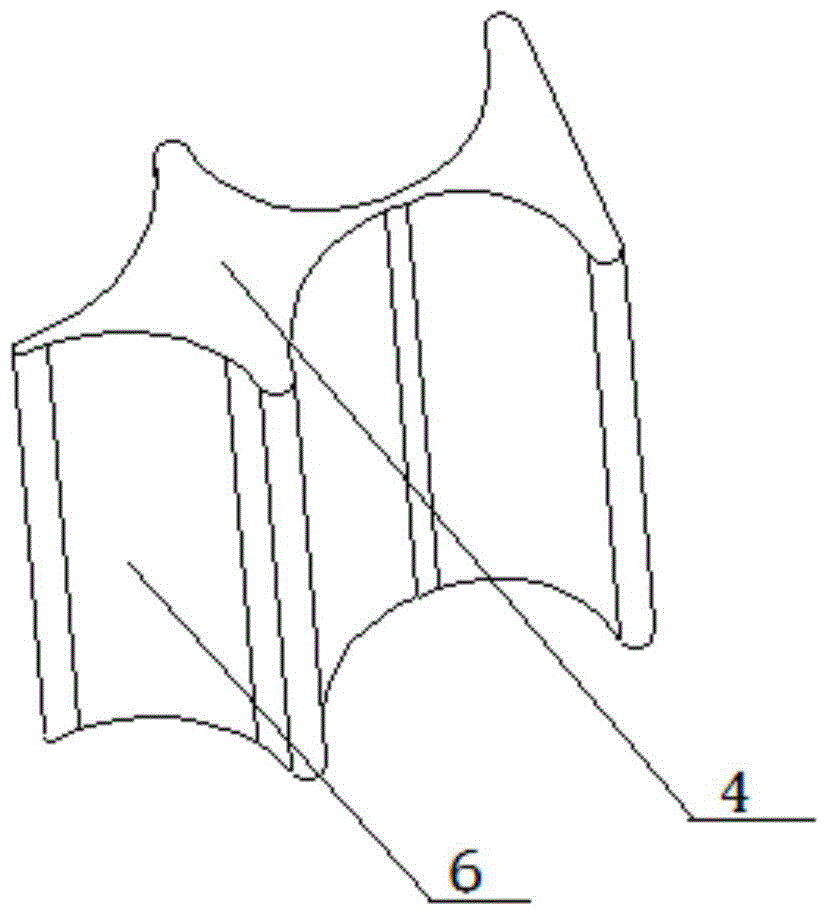

[0017] In view of the diversification of market products, ordinary switchblades can no longer meet the requirements. As the gap between products is getting smaller and smaller, the graphics are becoming more and more irregular. Common thimbles require a gap of more than 0.8mm, while products with a gap between 0.2-0.8mm More and more, because ordinary thimbles are a whole, it is not practical for products with various shapes and small gaps, and the waste discharge is not complete, which indirectly affects the service life of the knife roller and reduces work efficiency. The waste discharge requirement is imminent. The common thimble is a whole, and the special-shaped thimble of the present invention is divided into two parts, one part is the needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com