A steel-plastic composite pipe skeleton positioning device and method without secondary processing

A steel-plastic composite pipe, secondary processing technology, applied in the direction of tubular objects, household appliances, other household appliances, etc., can solve the problems of pipeline leakage, increase the production cost of pipe fittings, etc., achieve uniform distance, ensure stability, and pipe wall uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

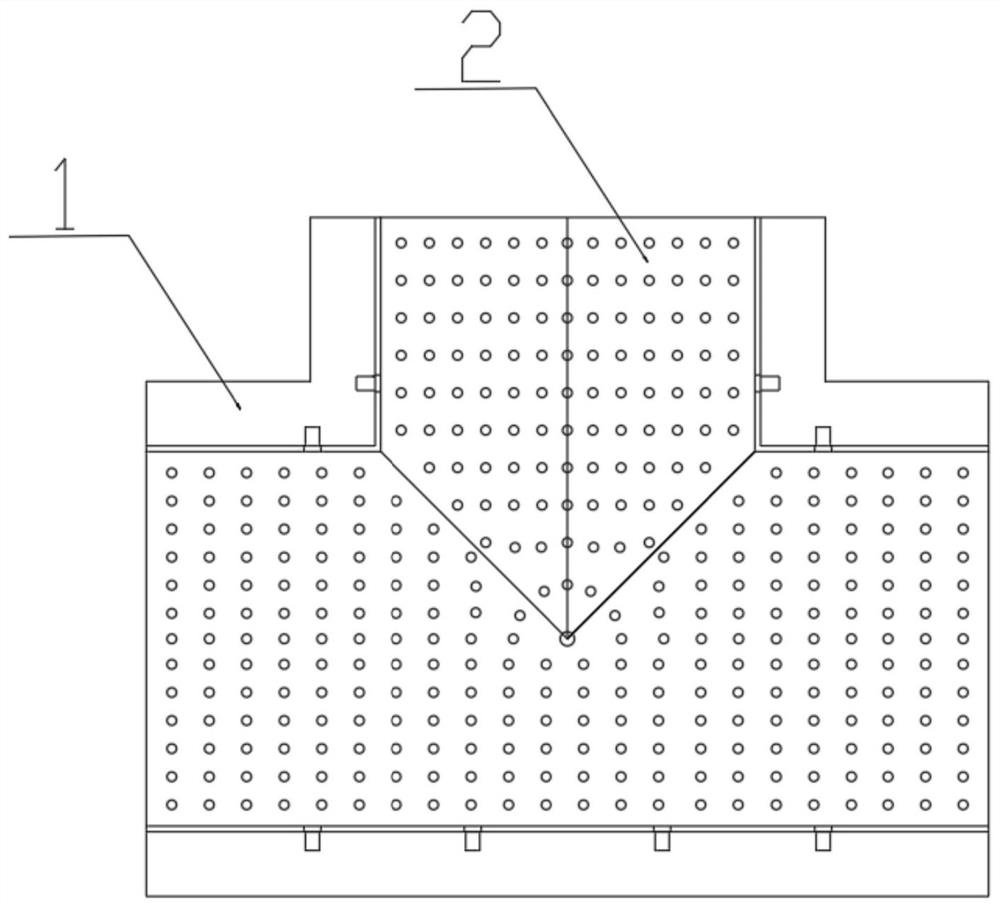

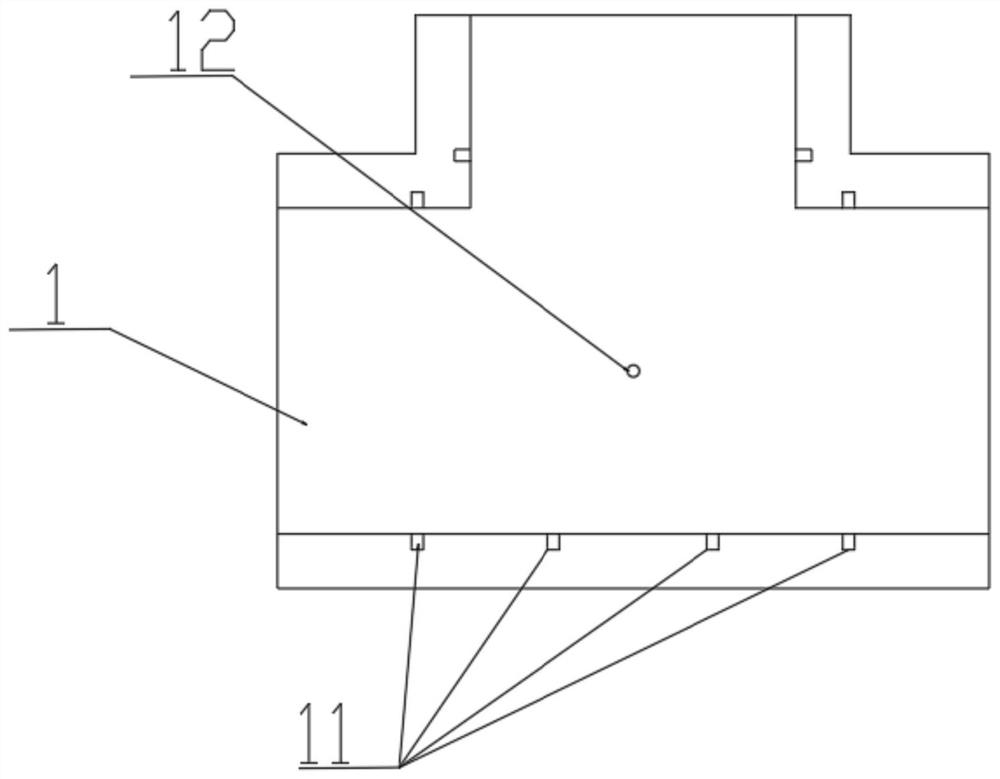

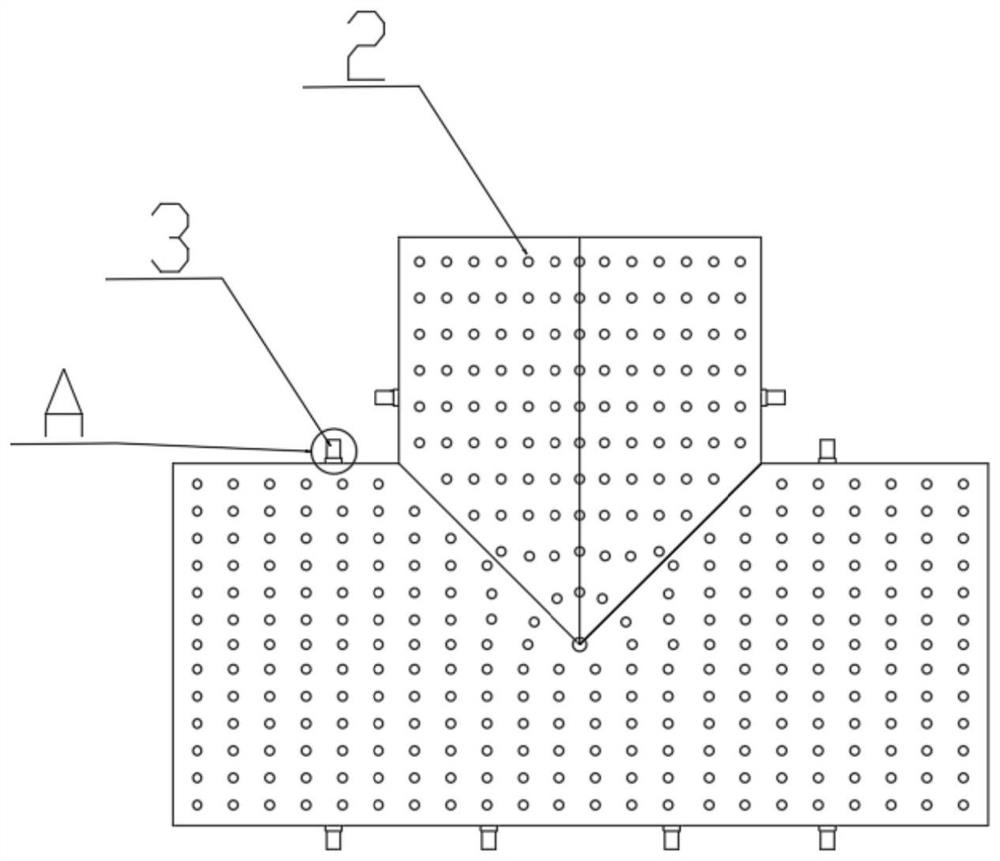

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] like Figure 1-8 As shown, the present invention provides a steel-plastic composite pipe skeleton positioning device that does not require secondary processing, including a mold 1, a skeleton body 2, and a plastic positioning nail 3; the mold 1 is detachably divided into upper and lower parts, and the mold 1 is provided with a mold cavity suitable for placing the skeleton body 2 inside; a placement groove 11 is arranged around the mold cavity of the mold 1; a support nut 21 is fixedly arranged on the surface of the skeleton body 2; the plastic positioning nail 3 is fixed on the support nut 21; When the skeleton body 2 is placed in the mold cavity, the plastic positioning nail 3 is inserted into the placement groove 11 to realize the positioning of the skeleton body 2, and the skeleton body 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com