Patents

Literature

315results about How to "No risk of leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

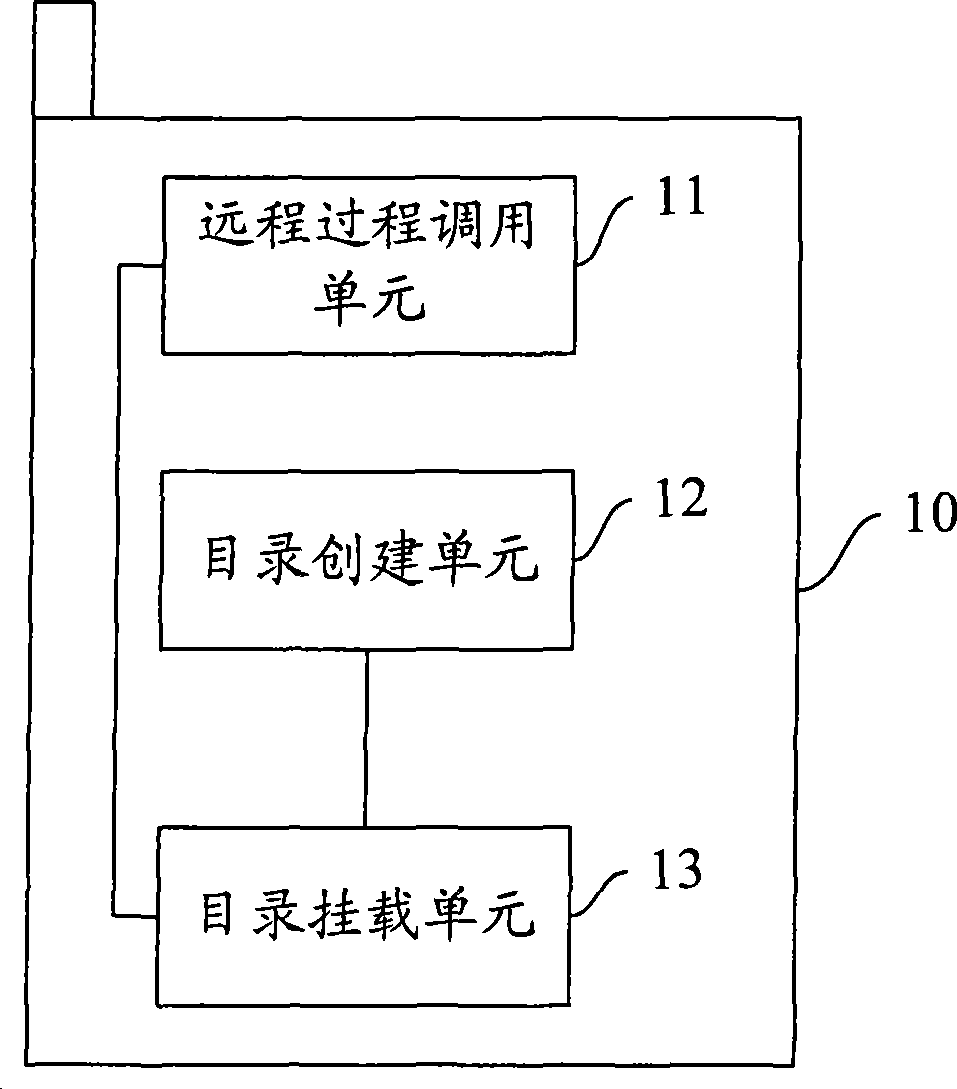

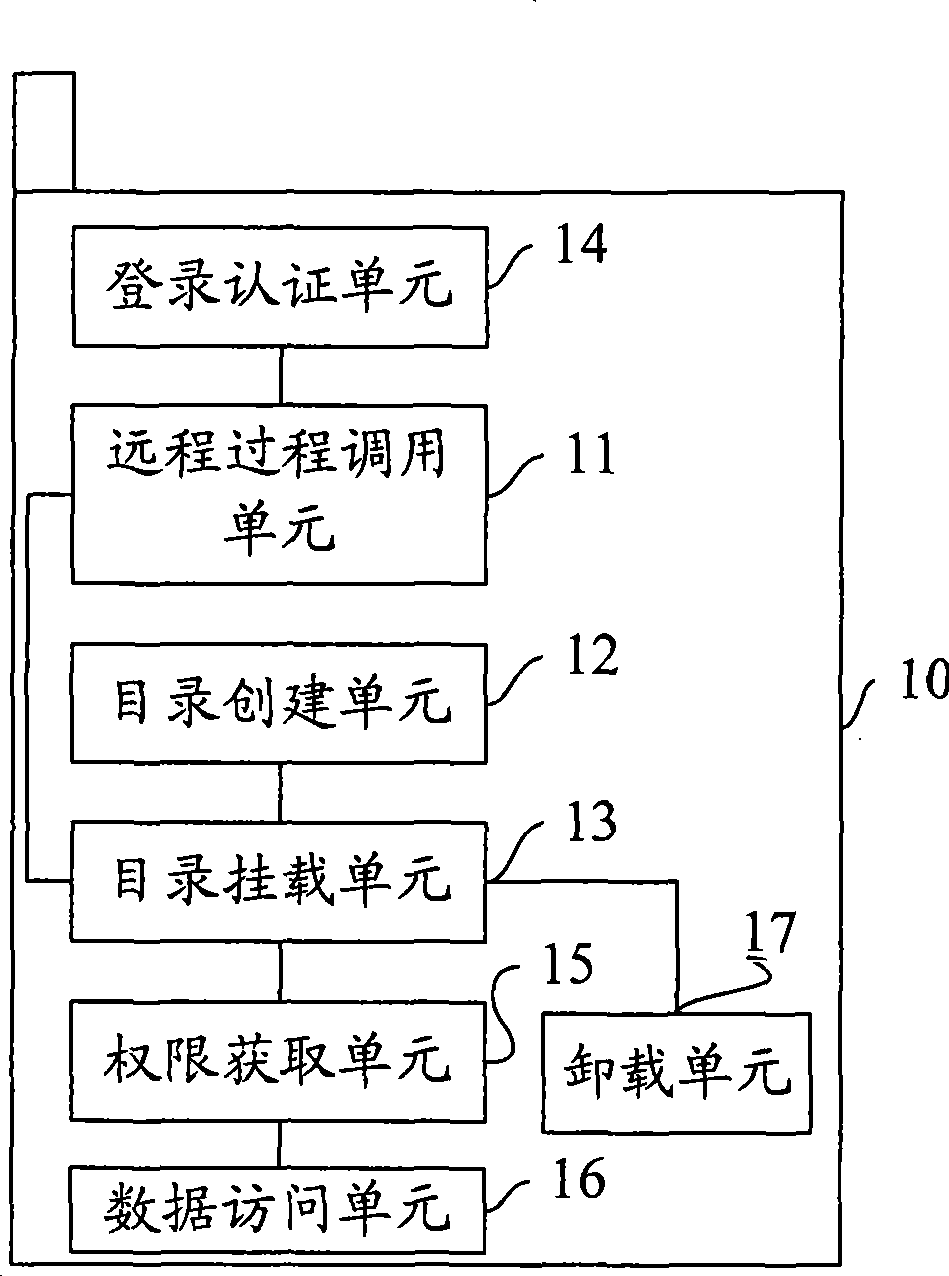

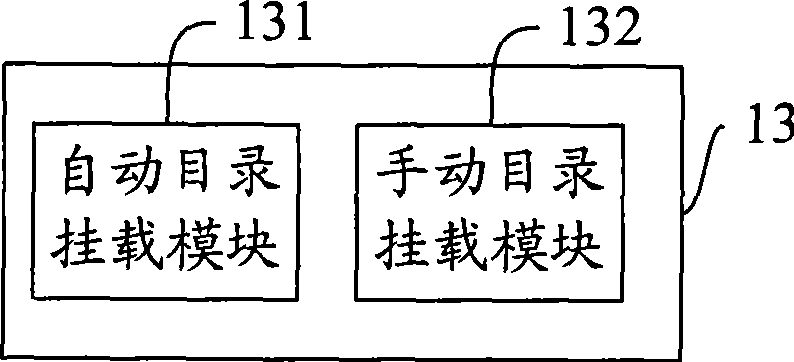

Mobile terminal, server and data access method

ActiveCN101378411ANo risk of leakageThere is no risk of being leakedRadio/inductive link selection arrangementsData switching networksAccess methodData access

The invention provides a movable termination, a server and a data access method, wherein, the movable termination comprises: a remote procedure call unit used for consulting with a remote server and determining a port adopted by a local movable termination for being connected with the remote server, a directory creating unit used for establishing a mount point directory estimated to be mounted on the local movable termination, and a directory mounting unit used for directly mounting a share file directory of the remote server into the mount point directory through the ports. The proposal causes the movable termination to directly access the data in the server, without being limited by the storage capacity of the movable termination.

Owner:HUAWEI DEVICE CO LTD

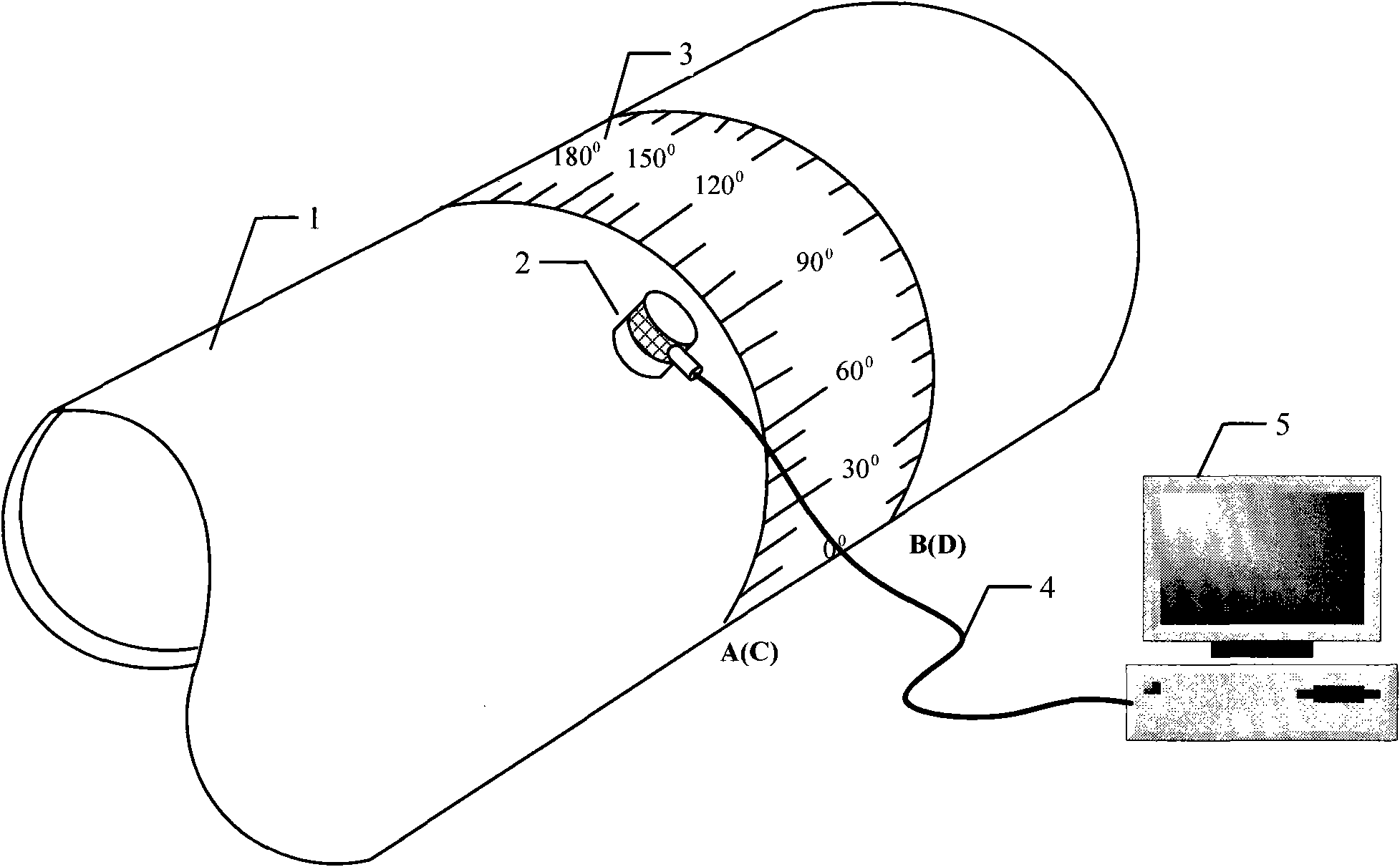

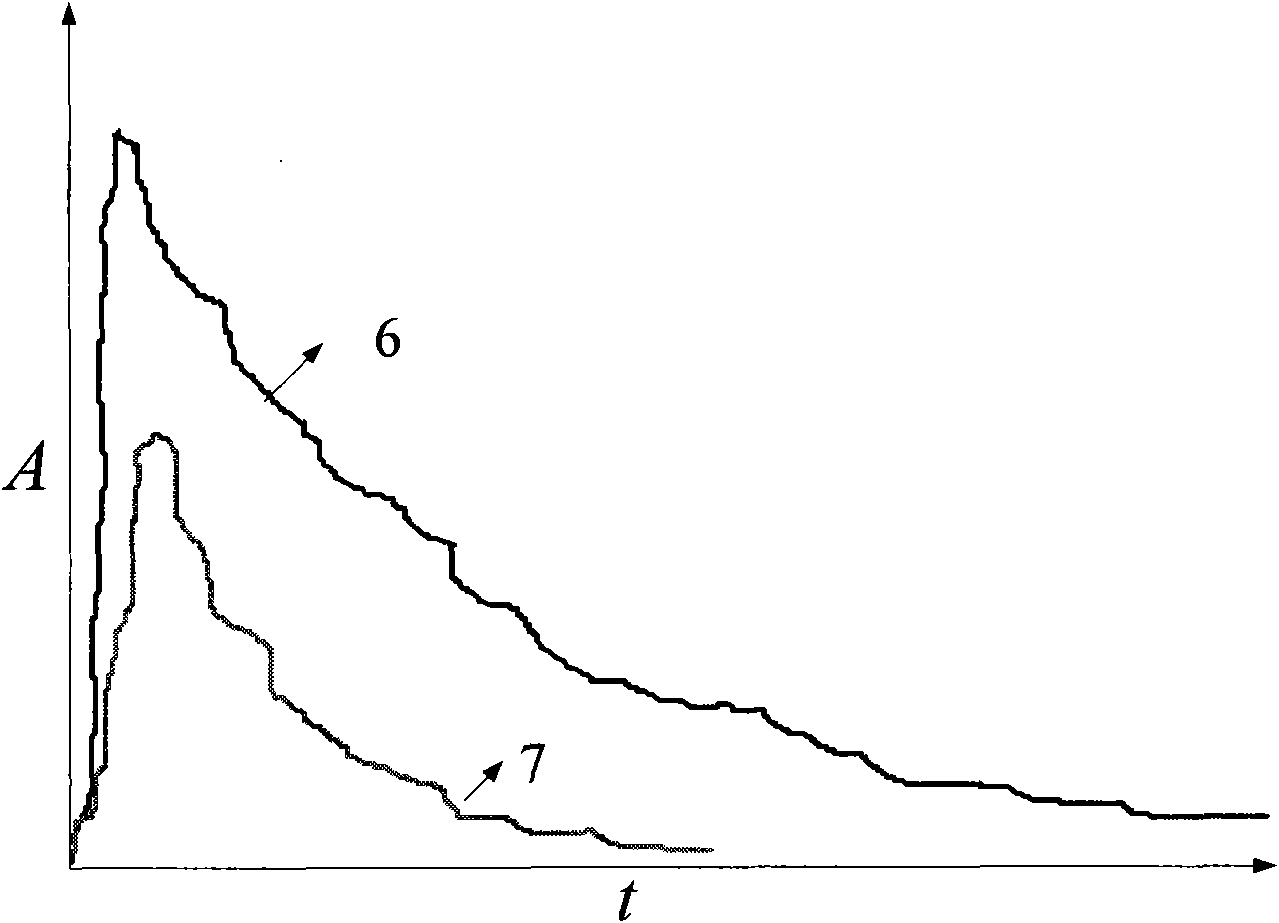

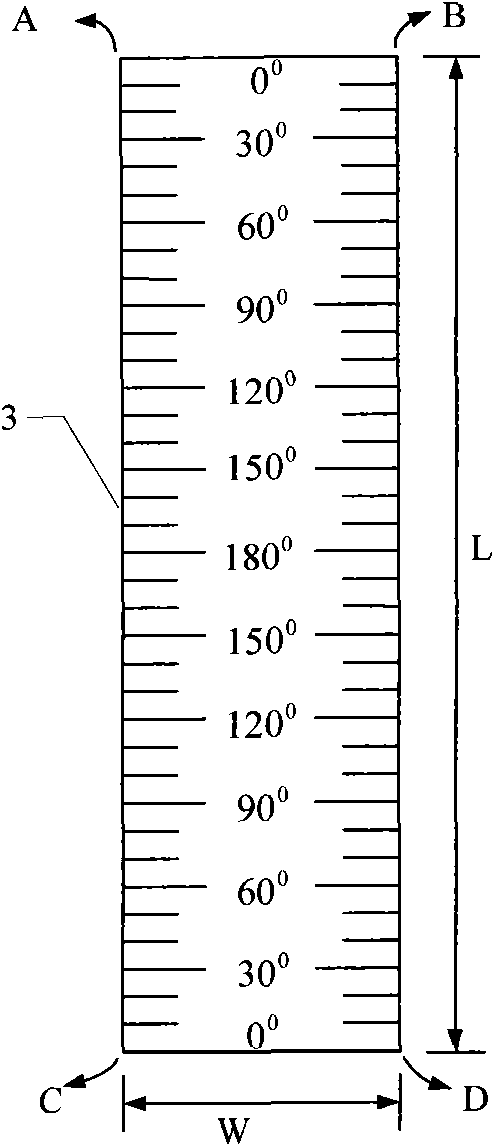

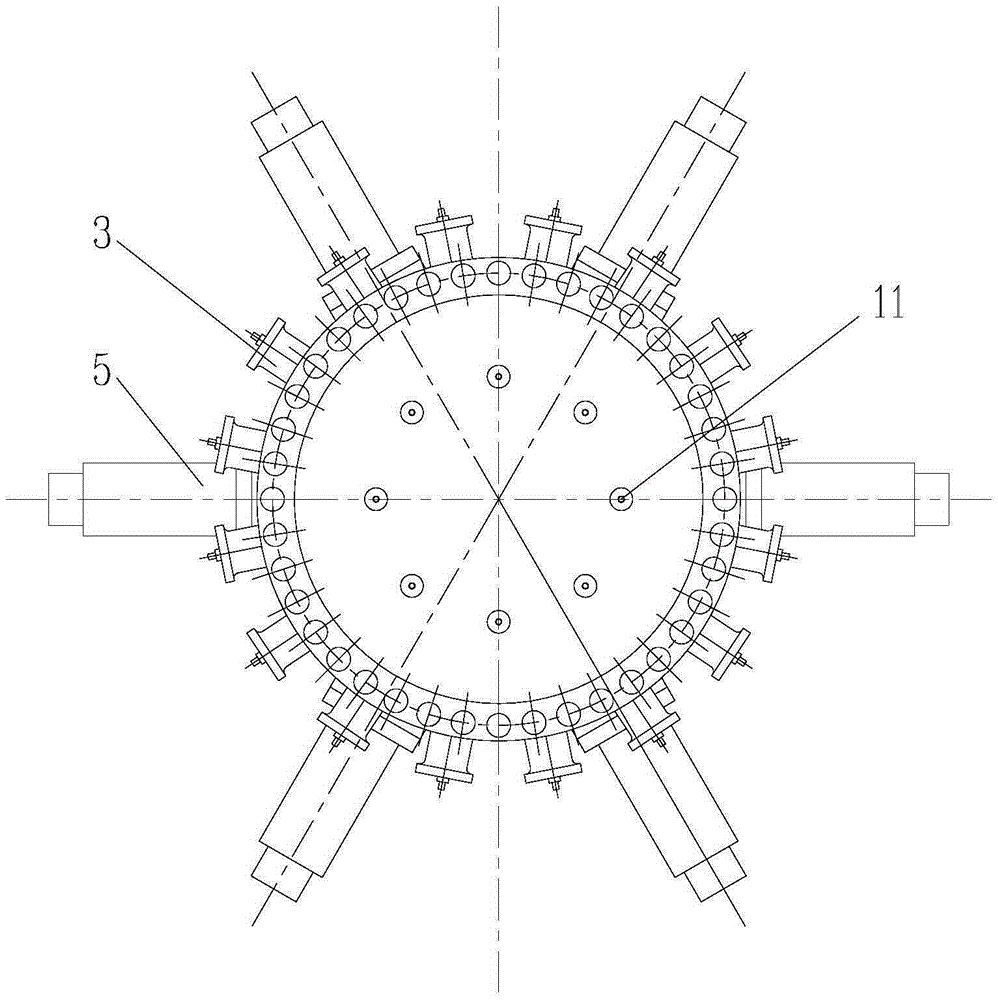

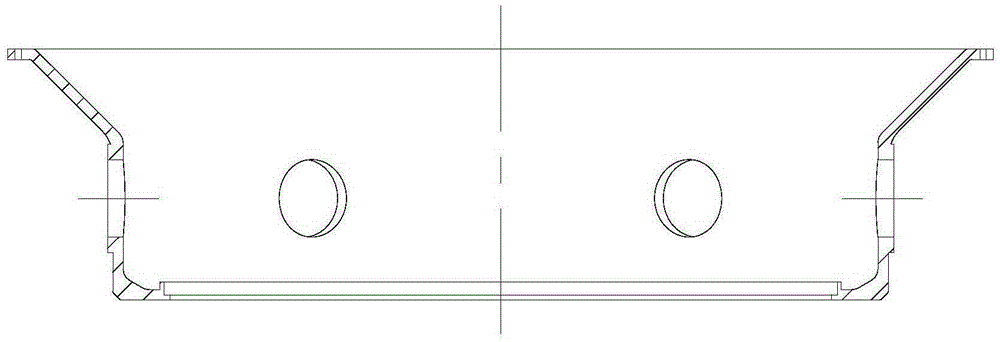

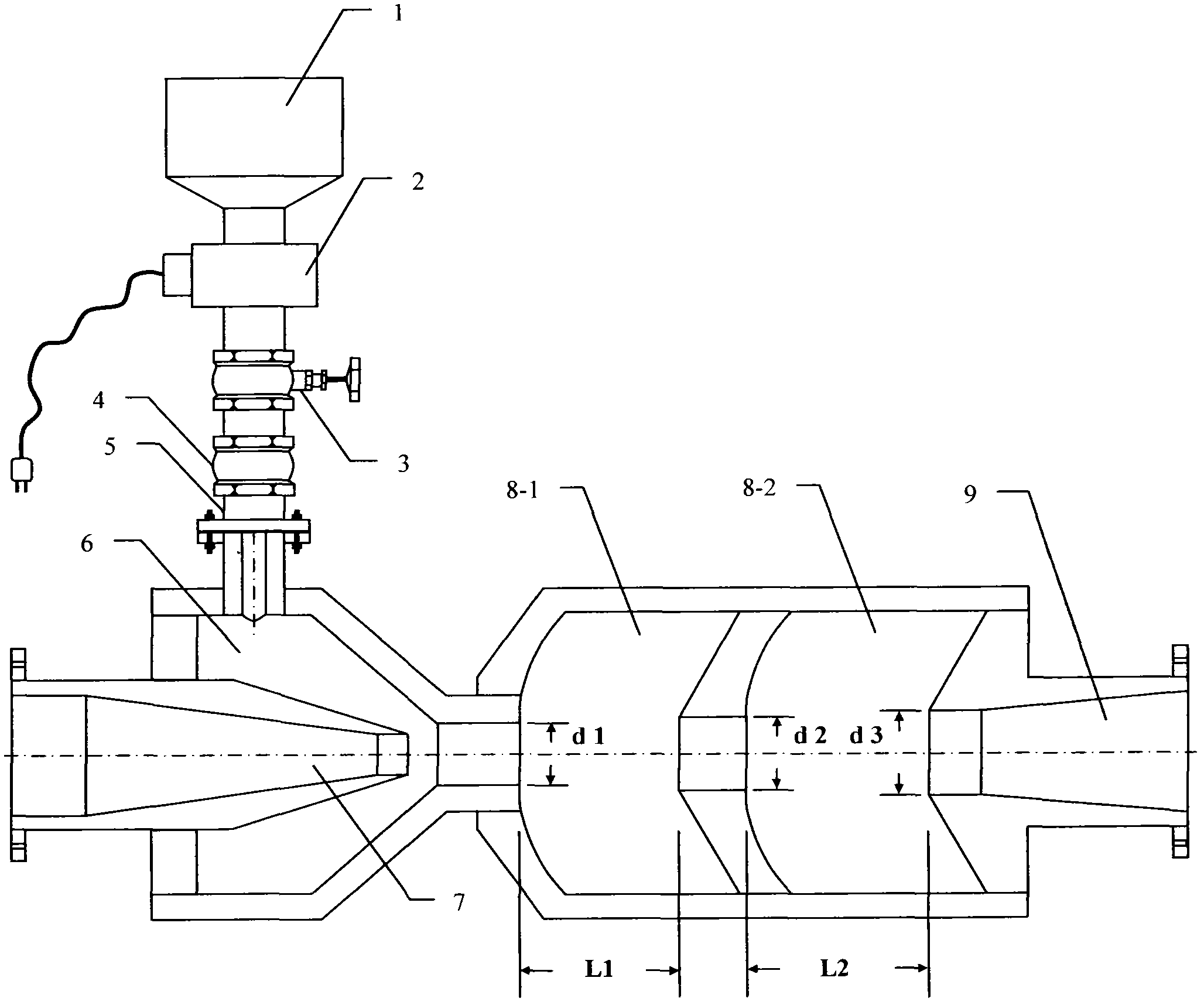

Method and device for measuring accumulated liquid of natural gas pipeline

InactiveCN101839746ASave energyNo security issuesMachines/enginesLevel indicatorsLiquid mediumLine tubing

The invention discloses a method and a device for measuring accumulated liquid of a natural gas pipeline. The method comprises the following steps of: vertically transmitting high-frequency ultrasonic wave into the pipeline by an ultrasonic probe coupled to the outer wall of the measured pipeline, wherein the energy of reflection echo has great difference due to different properties of gas and liquid media; judging that the pipe inner wall is contacted with gas or liquid at the position of the probe according to the characteristic of echo received by the ultrasonic probe and reflected by the pipe inner wall; gradually adjusting the measurement position of the ultrasonic probe on the pipe outer wall along the circumferential direction; and recording a circumferential angle of the ultrasonic probe by a circumferential angle ruler when the echo has mutation, and further calculating the height of the accumulated liquid. The method is a non-intrusive accumulated liquid measurement method, does not change the structure of the conventional pipeline, has no medium leakage risk, does not affect the operation such as cleaning the pipeline and the like, meanwhile is not affected by the composition of gas and liquid phase media in the pipeline and parameters such as temperature, pressure and the like, overcomes the defect that the conventional ultrasonic technology needs complex sound velocity correction, and is particularly suitable for measuring the accumulated liquid inside the pipeline for conveying corrosive and toxic media.

Owner:SINOPEC ZHONGYUAN PETROLEUM ENG DESIGN

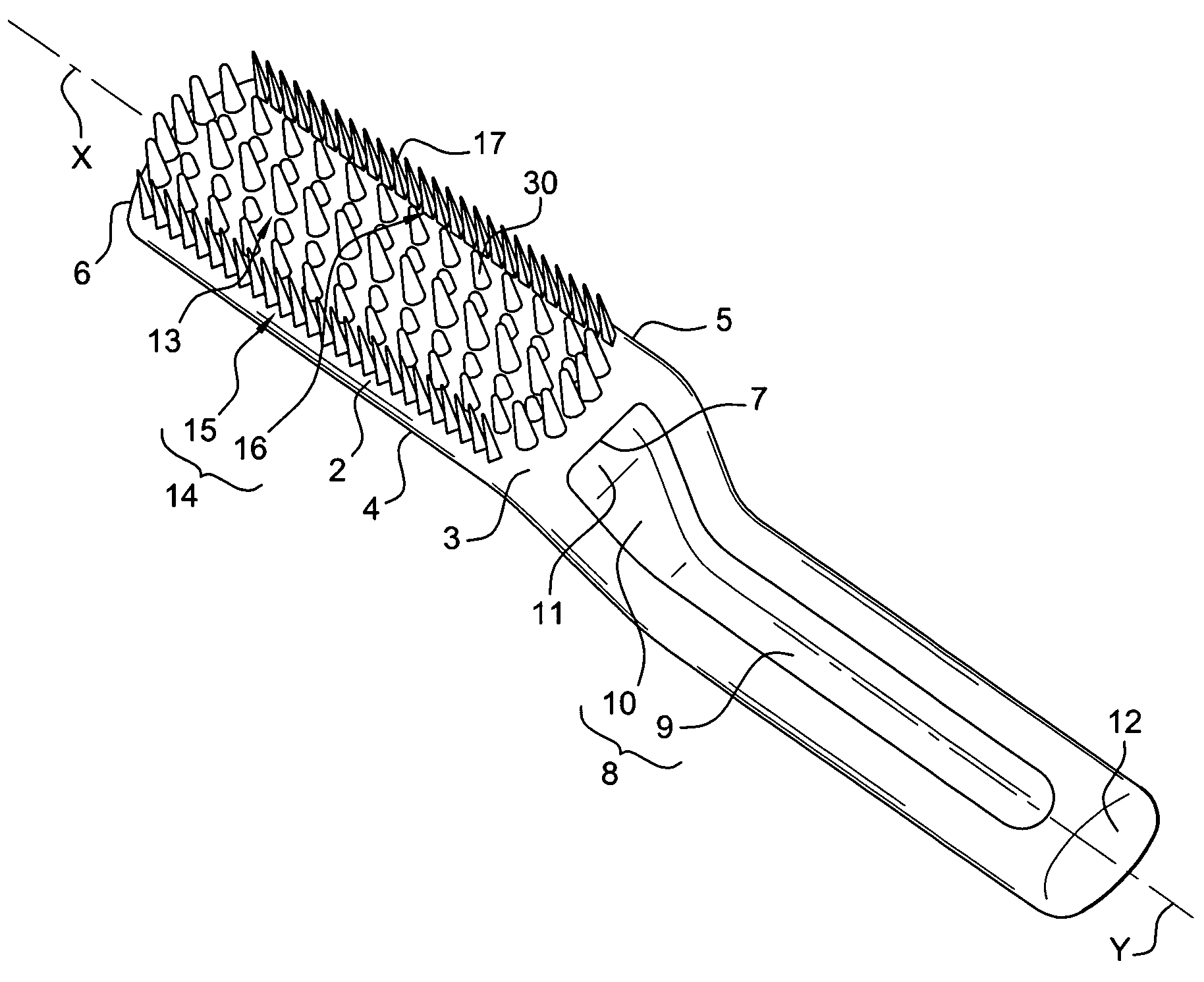

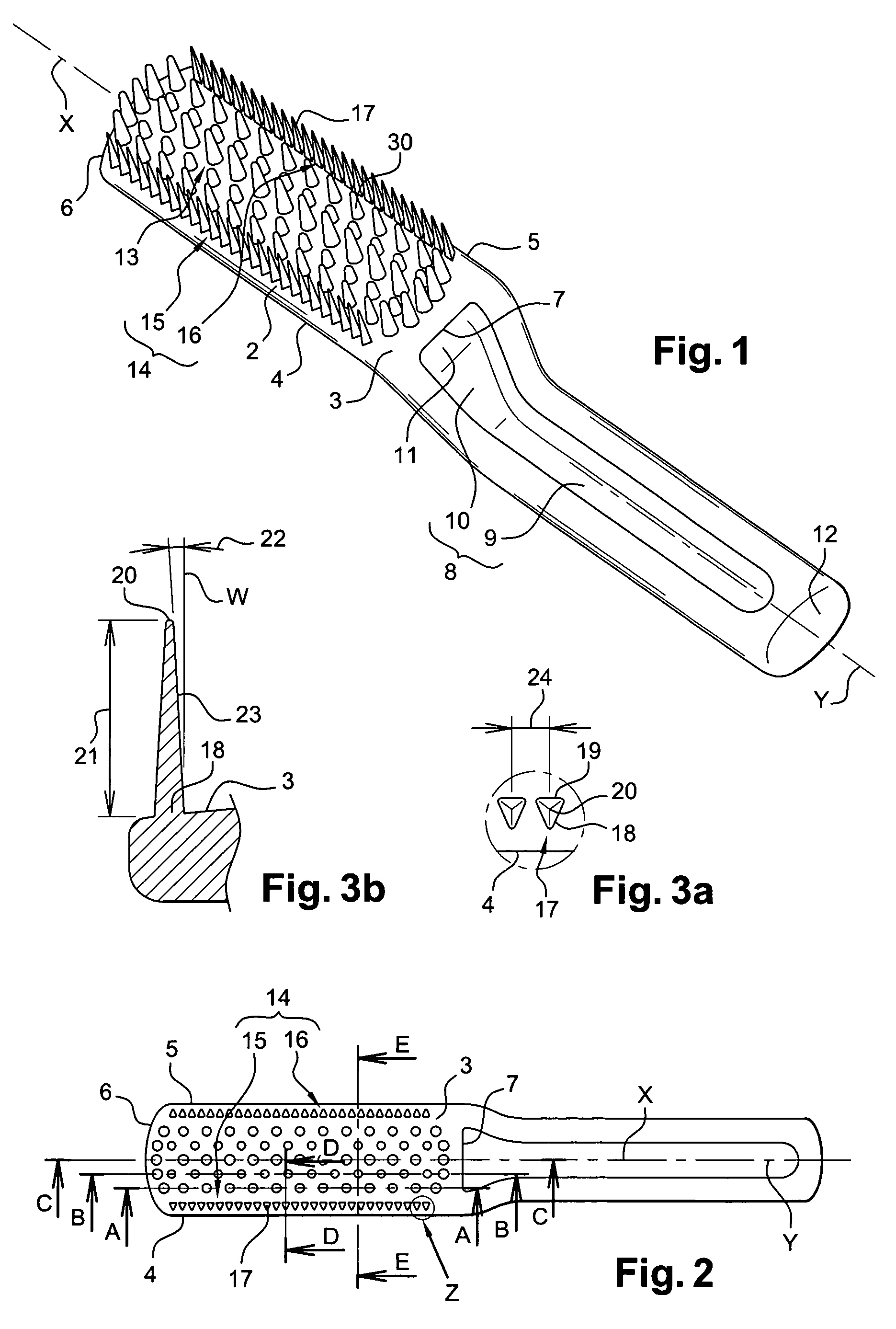

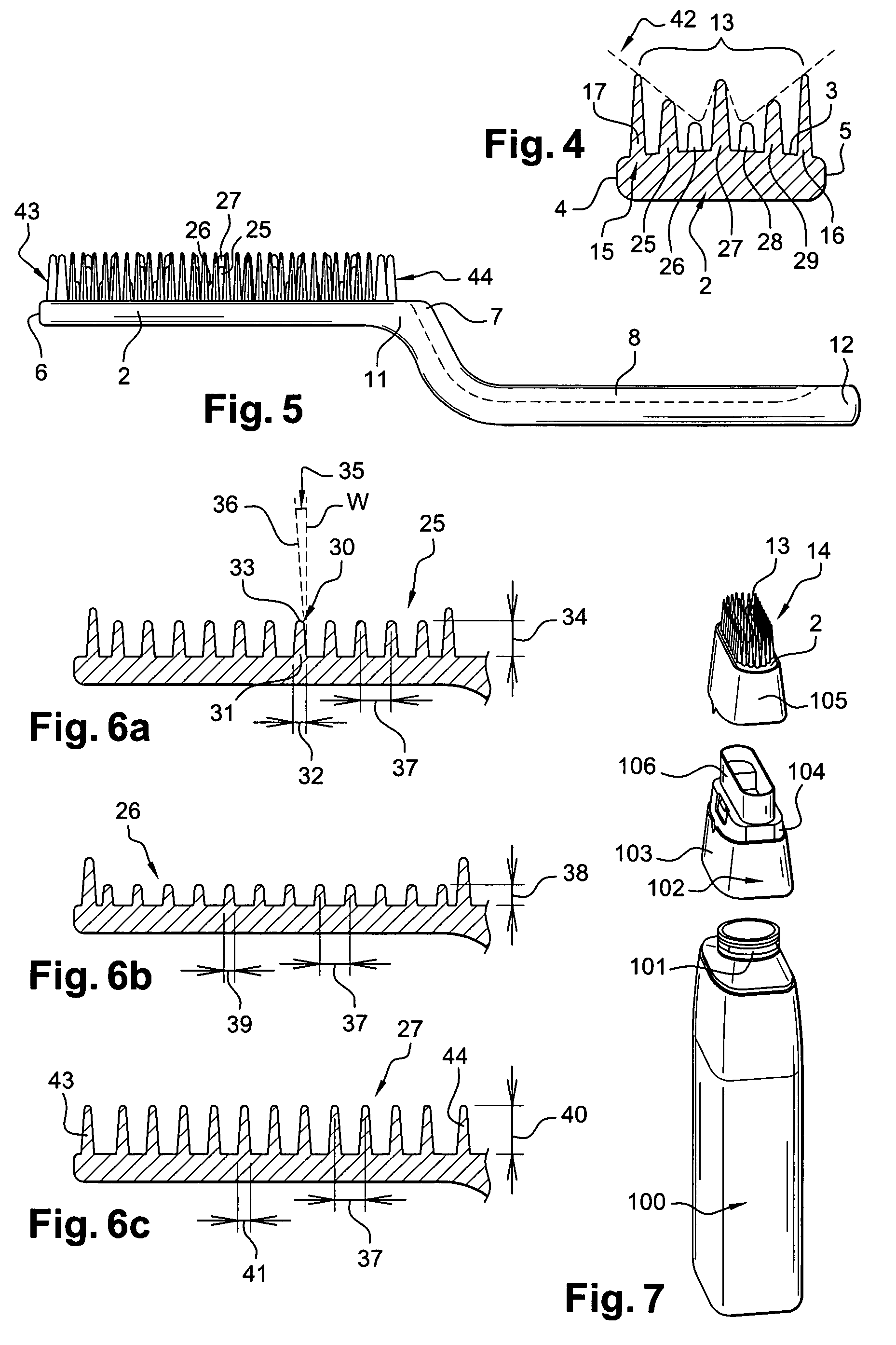

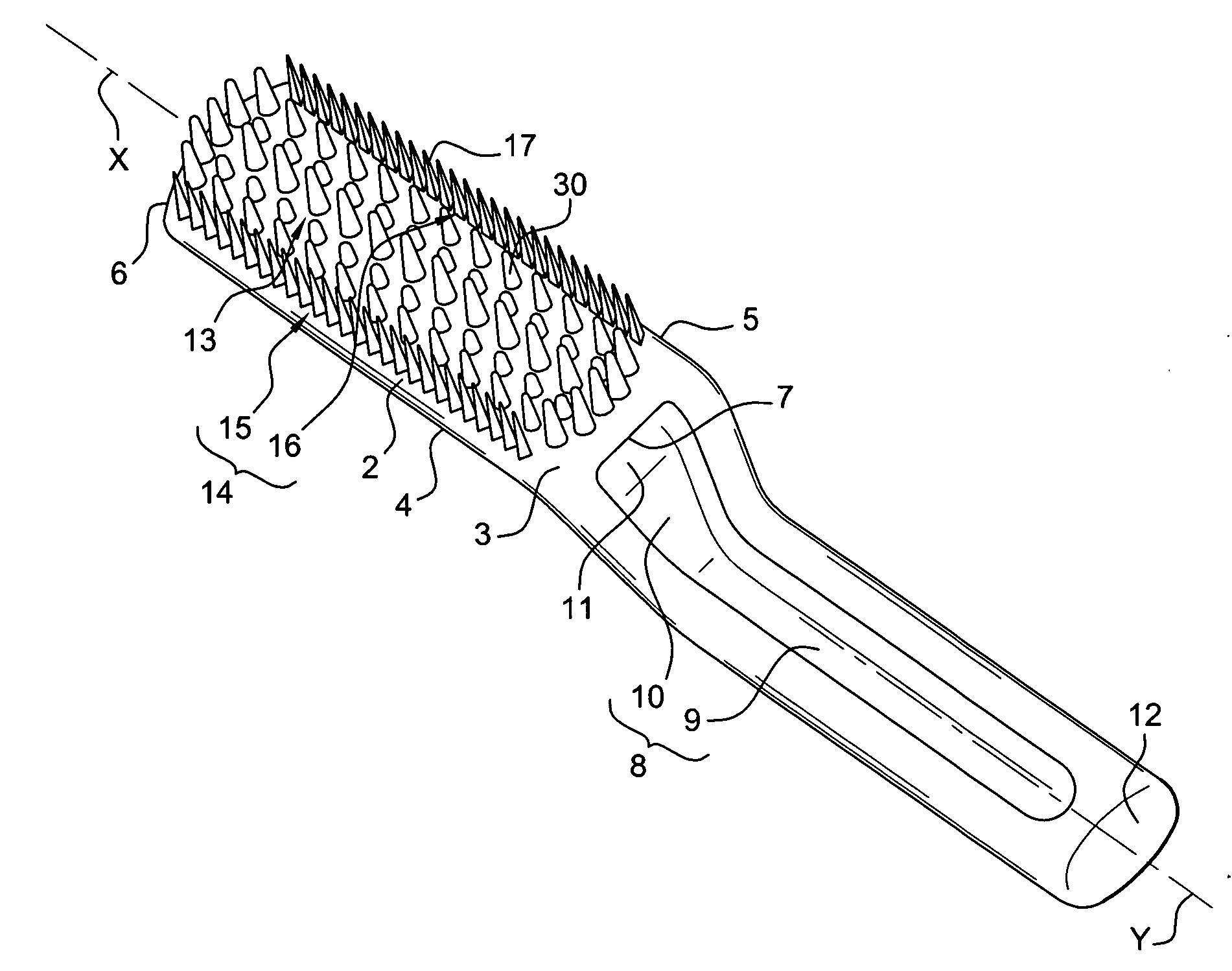

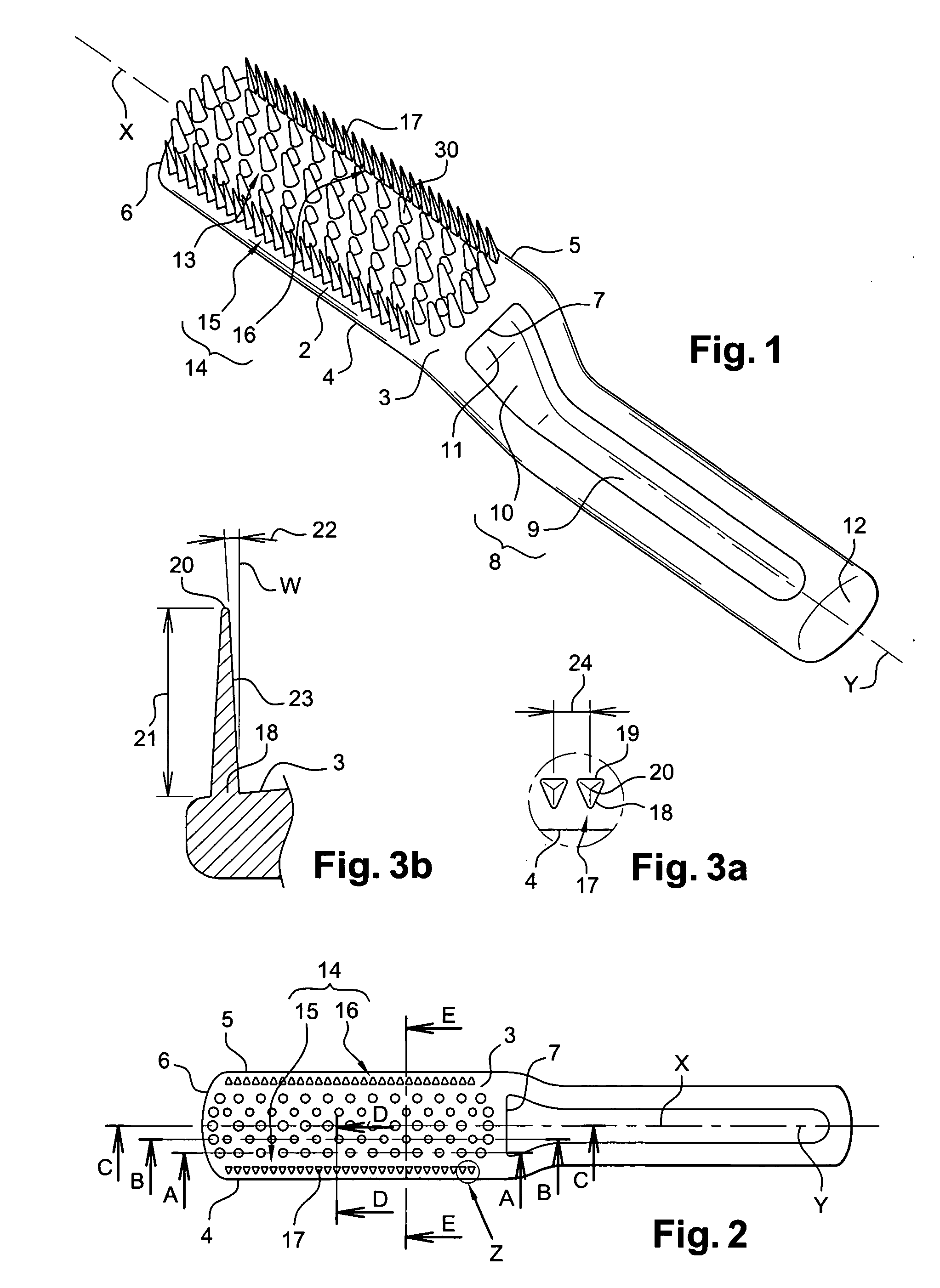

Device for applying a hair product

Owner:LOREAL SA

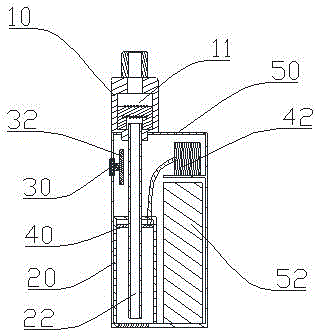

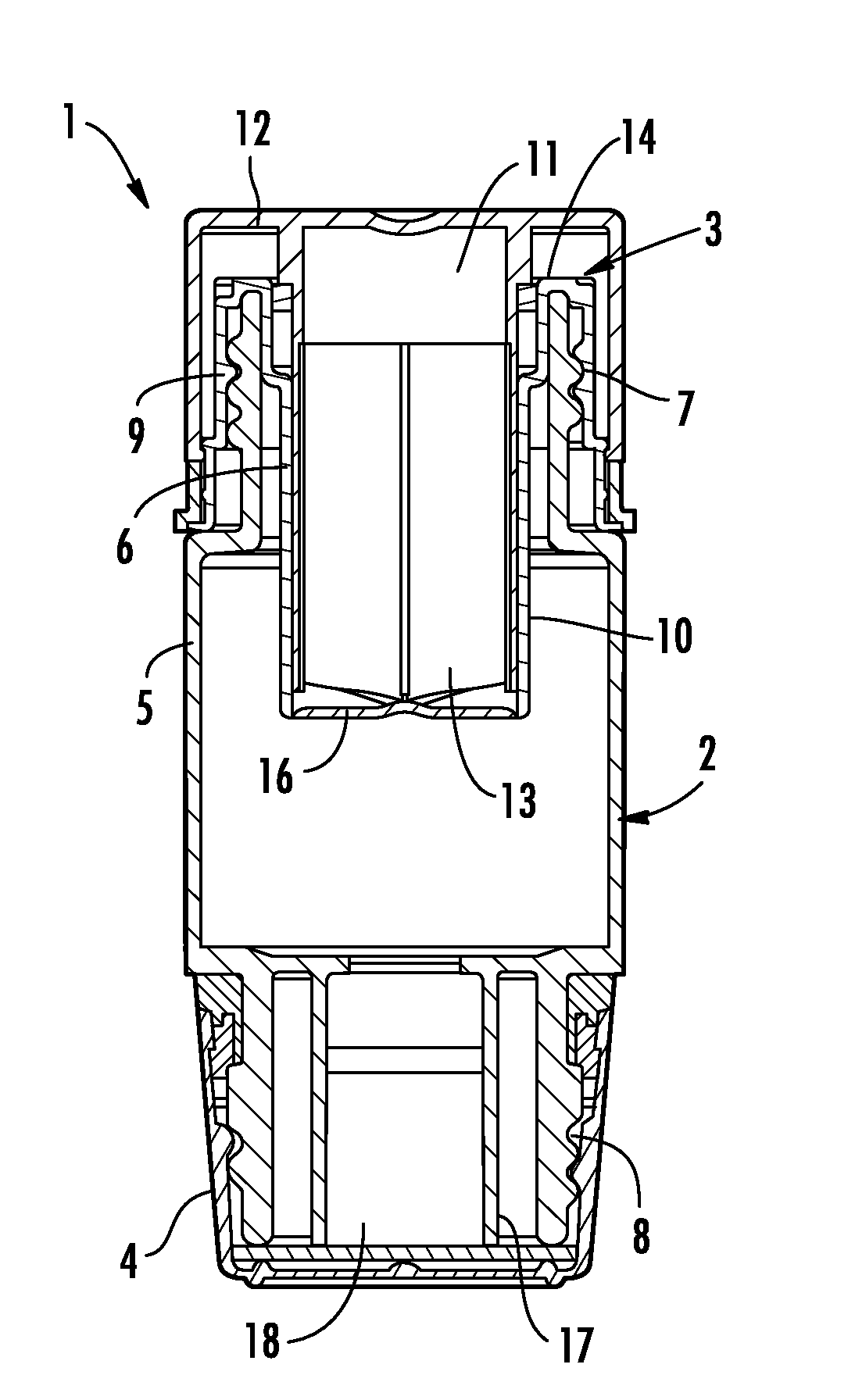

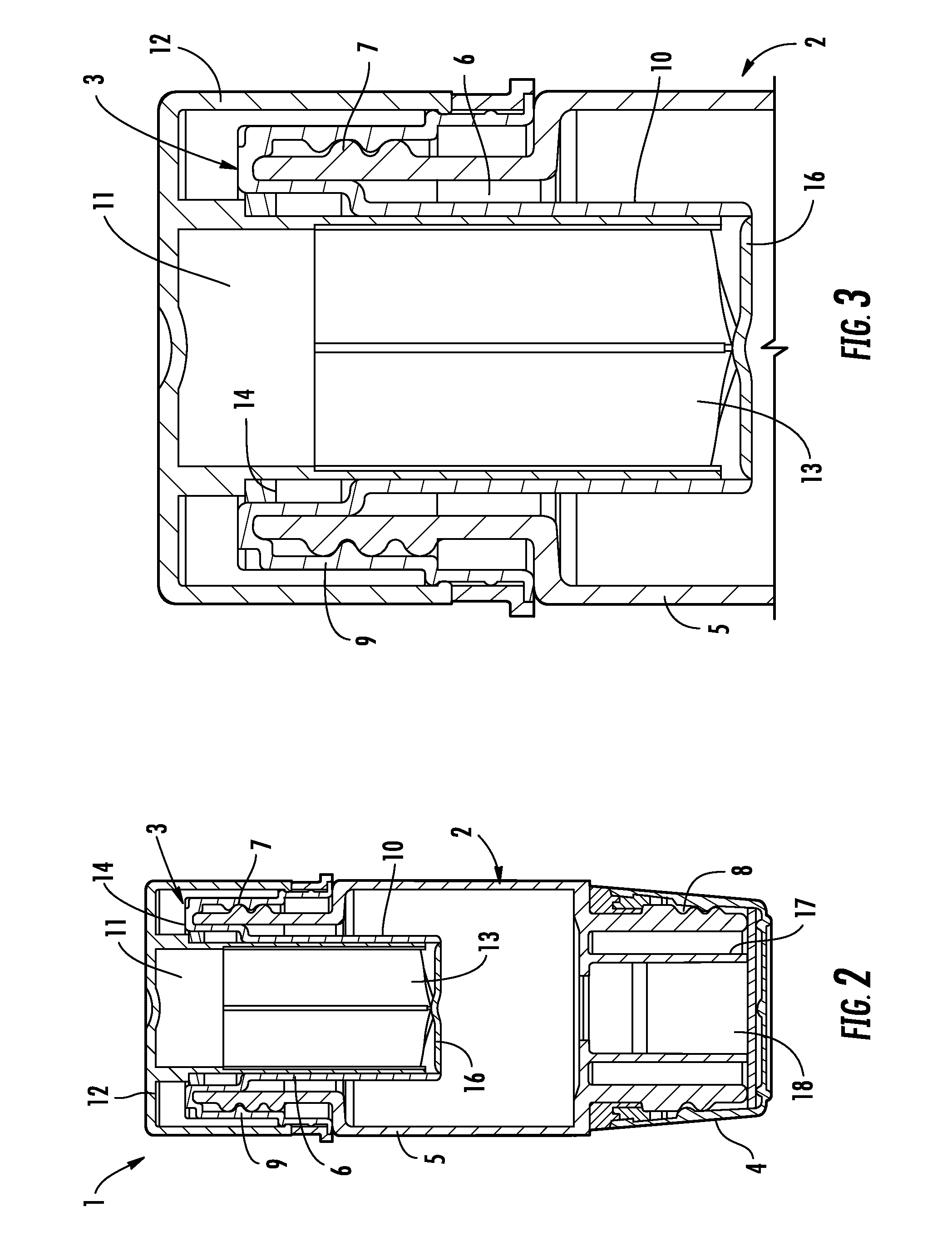

Electronic cigarette

InactiveCN106108121ASolve the problem of dry burningSolve the problem of leakageRespiratorsMedical devicesElectricityEngineering

The invention discloses an electronic cigarette. The electronic cigarette comprises an atomization device and a liquid storage device, wherein the atomization device comprises an atomization cavity; the electronic cigarette further comprises a control unit and a drive mechanism, wherein the control unit controls the liquid inlet of the electronic cigarette, the liquid storage device comprises a liquid inlet pipe and a liquid storage cavity, the first end of the liquid inlet pipe communicates with the atomization cavity, the second end of the liquid inlet pipe communicates with the liquid storage cavity, and the control unit and the drive mechanism are electrically connected with each other, and linkage control is adopted; when the control unit controls the liquid inlet of the electronic cigarette, the control unit controls the drive mechanism to drive tobacco juice in the liquid storage cavity to enter the atomization cavity through the liquid inlet pipe. With the adoption of the technical scheme, the electronic cigarette has the advantages that the condition that an appropriate amount of tobacco juice is in the atomization cavity is guaranteed, so that the burning phenomenon can be avoided, and meanwhile, the risk of liquid leakage caused by the fact that too much tobacco juice soaking a liquid guide element can not be consumed in time in the prior art can be also avoided.

Owner:JOYETECH EURO HLDG

Device for applying a hair product

Owner:LOREAL SA

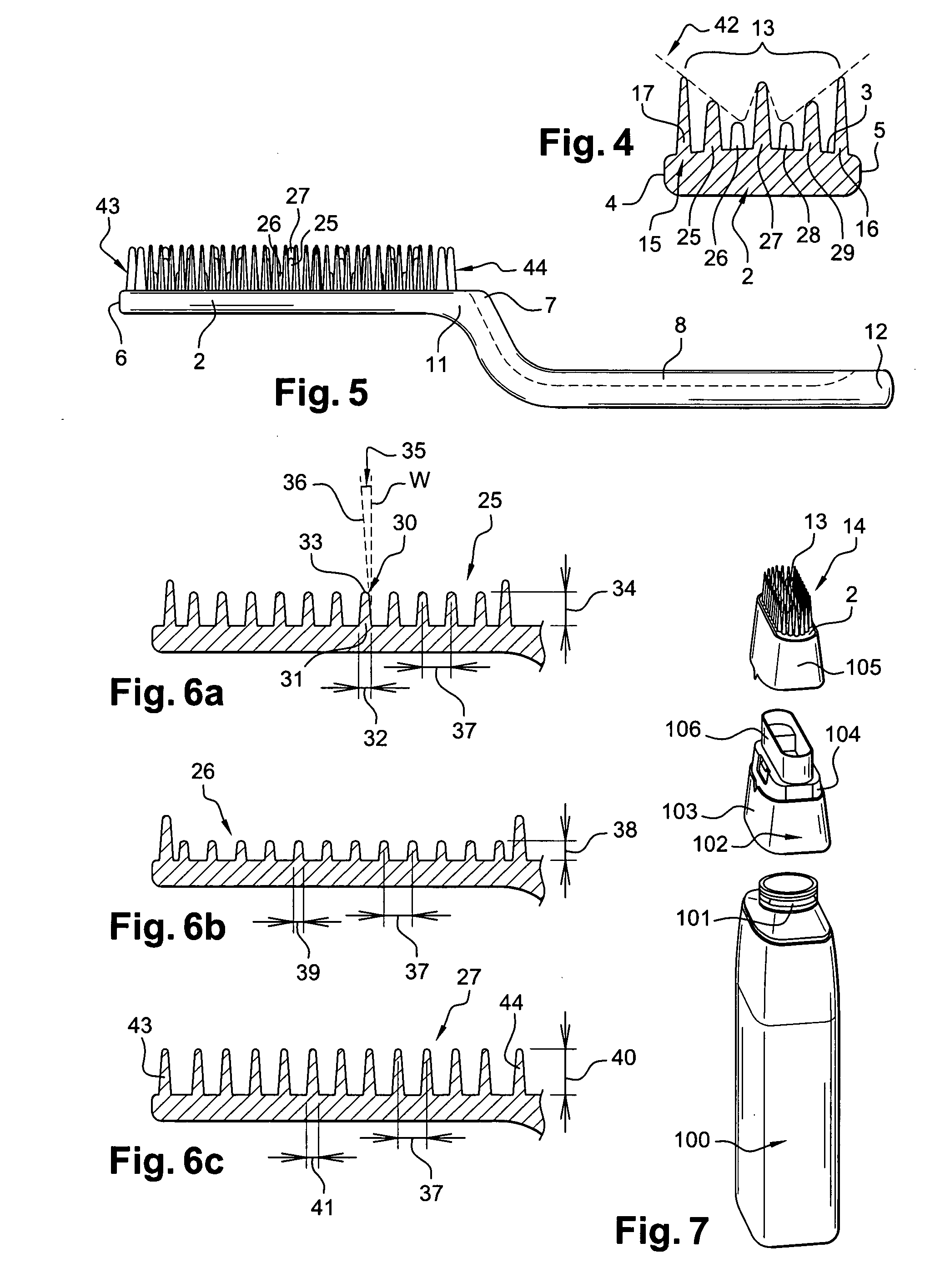

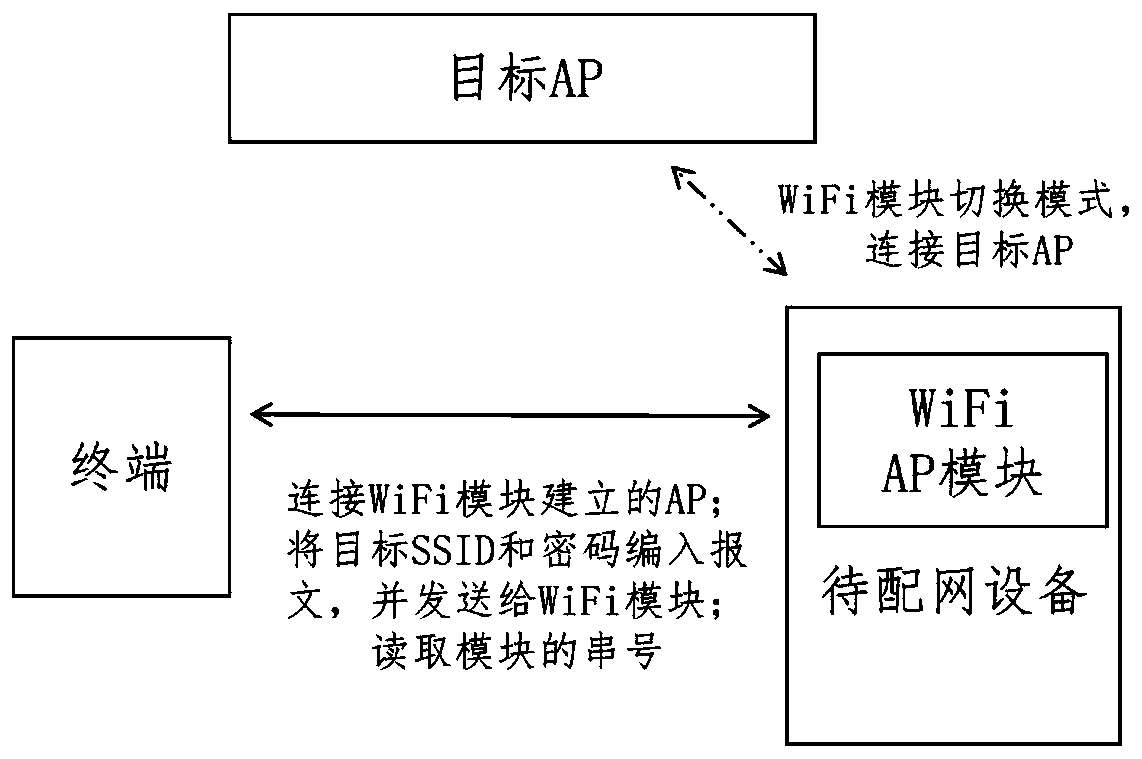

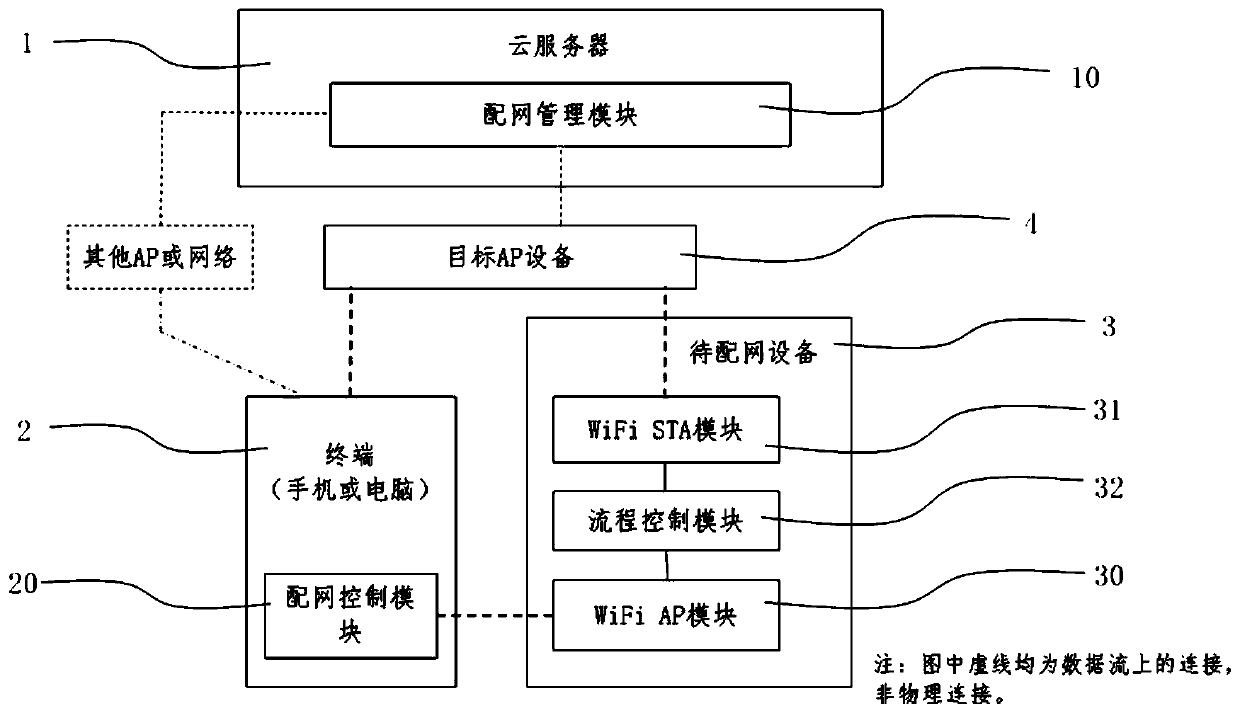

System and method for binding WiFi distribution network and equipment

InactiveCN111565137AUnified experienceNo risk of leakageConnection managementHome automation networksEngineeringDistribution networks

The invention relates to a system and method for binding a distribution network and equipment, in particular to a system and a method for binding a WiFi distribution network and equipment, and belongsto the technical field of smart home. The binding process of the distribution network and the equipment is realized through the cooperation of the terminal, the to-be-distributed network equipment and the cloud server; in the network distribution and binding process, two-way communication is completed between the terminal and the equipment 3 to be subjected to network distribution in an AP connection mode, and therefore data can be exchanged rapidly and reliably and cannot be affected by external factors. In addition, the STA mode is used for scanning and connecting a target AP, and invalid APs are ensured to be filtered, so the experience on different terminals is unified, and the success rate is also greatly improved. According to the method, a mode of combining a distribution network flow identifier Session ID with high randomness with AP connection is used, so the whole flow is unique, independent and closed, the risk of WiFi password leakage is avoided, and the possibility of illegal binding at the cloud is also avoided.

Owner:北京芯创睿胜科技有限公司

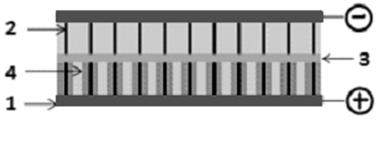

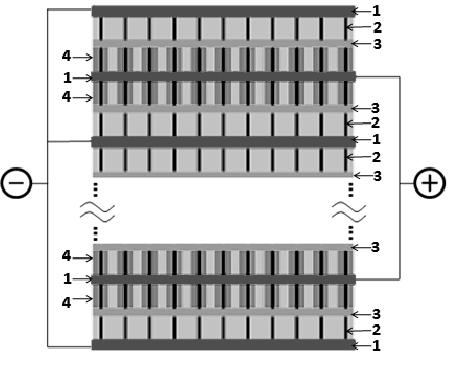

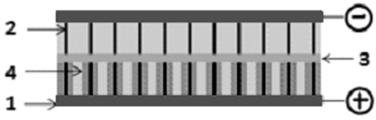

Hybrid solid state supercapacitor

InactiveCN102509637AReduce contact resistanceSolve reunionSolid electrolytic capacitorsCapacitor electrolytes/absorbentsSolid state electrolyteHybrid type

The invention discloses a hybrid solid-state supercapacitor based on an oriented carbon nano tube material, which comprises a positive pole, a negative pole and solid-state electrolyte dissepiments between the positive pole and the negative pole. The positive pole is composed of oriented carbon nano tube arrays and polyaniline films directly arranged on a conductive substrate in a compounding manner; the negative pole is composed of the oriented carbon nano tube arrays also directly arranged on the conductive substrate; and the solid-state electrolyte dissepiments are polymer gel or solid-state electrolytes containing H2SO4. Based on the oriented carbon nano tube material, the positive pole and the negative pole are assembled with the solid-state electrolyte dissepiments in an overlapping manner. The hybrid solid-state supercapacitor provided by the invention has the advantages of high energy concentration, high power concentration, high safety, lower cost and no pollution.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

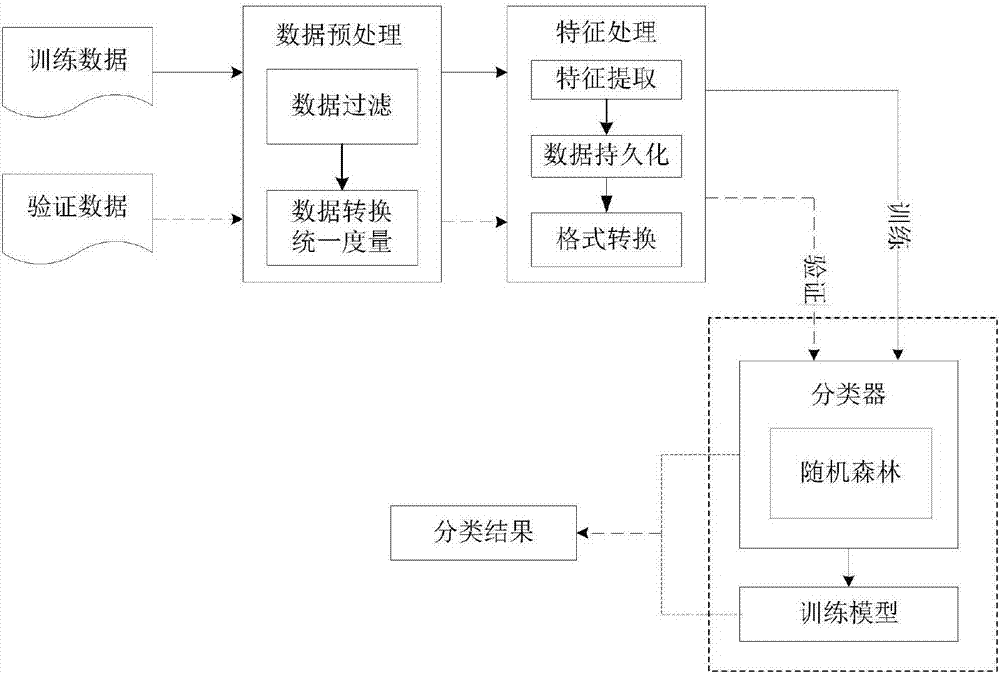

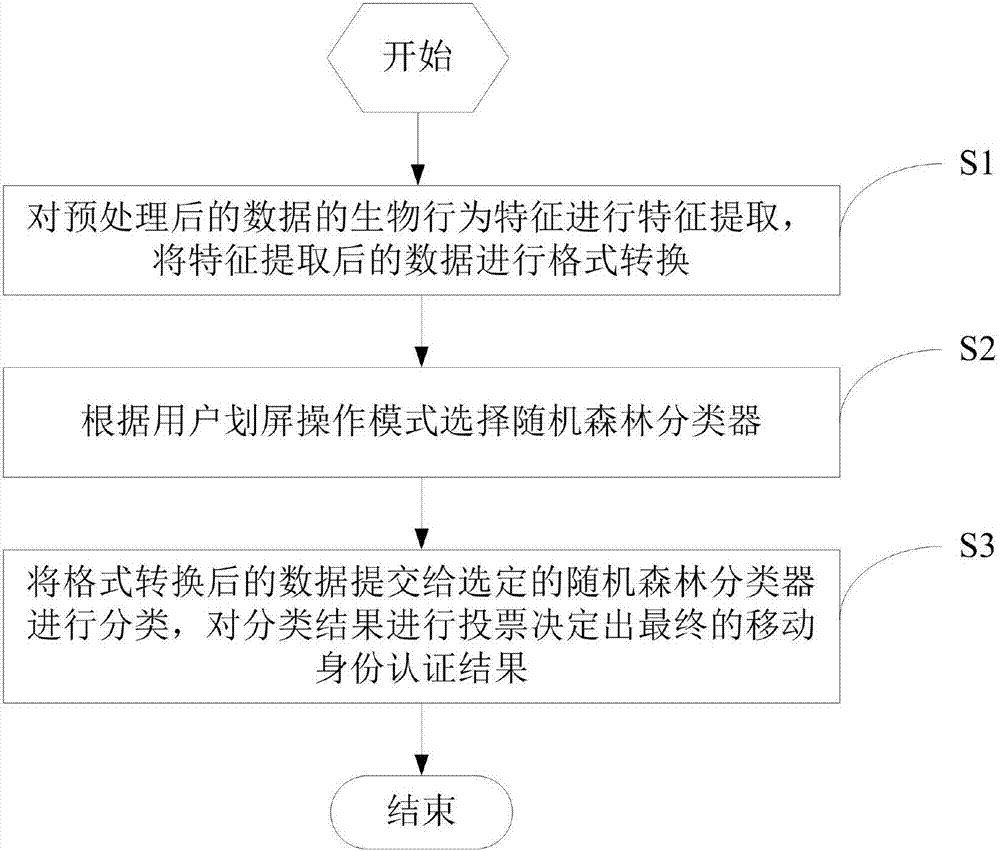

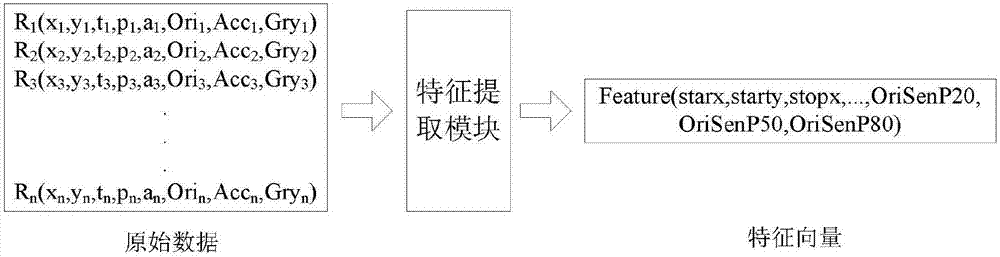

Mobile identity authentication method and system based on screen-sliding habit of user

InactiveCN107194216ANot easy to forgeNo risk of leakageCharacter and pattern recognitionDigital data authenticationClassification resultFeature extraction

The invention discloses a mobile identity authentication method and system based on screen-sliding habit of a user. The method comprises the following steps: S1, carrying out feature extraction on biological behavior features of data after pre-processing, and carrying out format conversion on data after the feature extraction; S2, selecting a random forest classifier according to screen-sliding operation modes of the user; and S3, submitting data after the format conversion to the selected random forest classifier for classification, and carrying out voting on classification results to determine a final mobile identity authentication result. The system of the invention corresponds to the above-mentioned method. The method and system have the characteristics of being able to easily cope with an identity authentication requirement under free screen-sliding operation modes, a high classification accuracy rate and the like.

Owner:CENT SOUTH UNIV

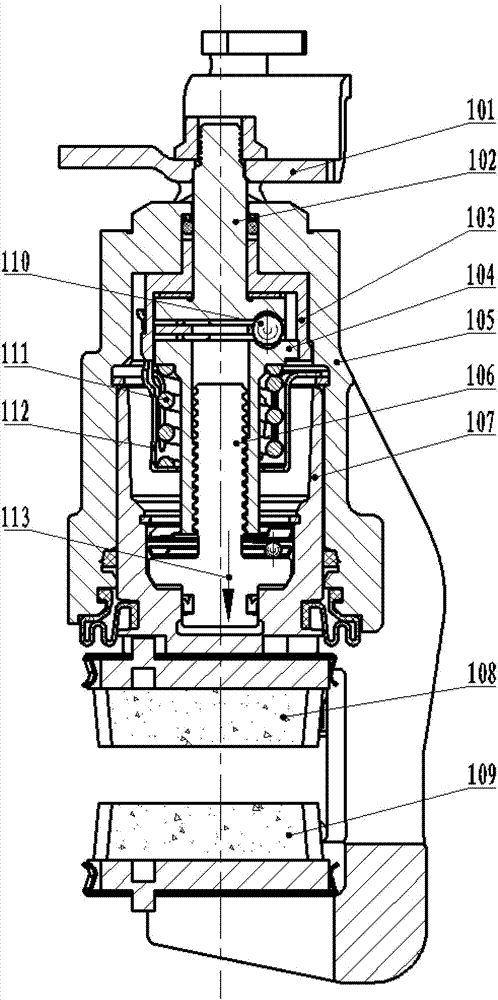

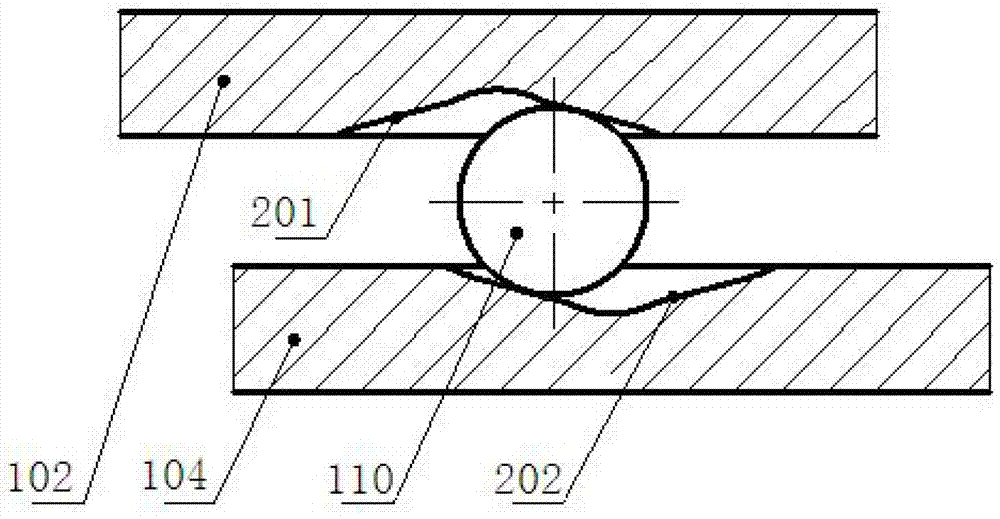

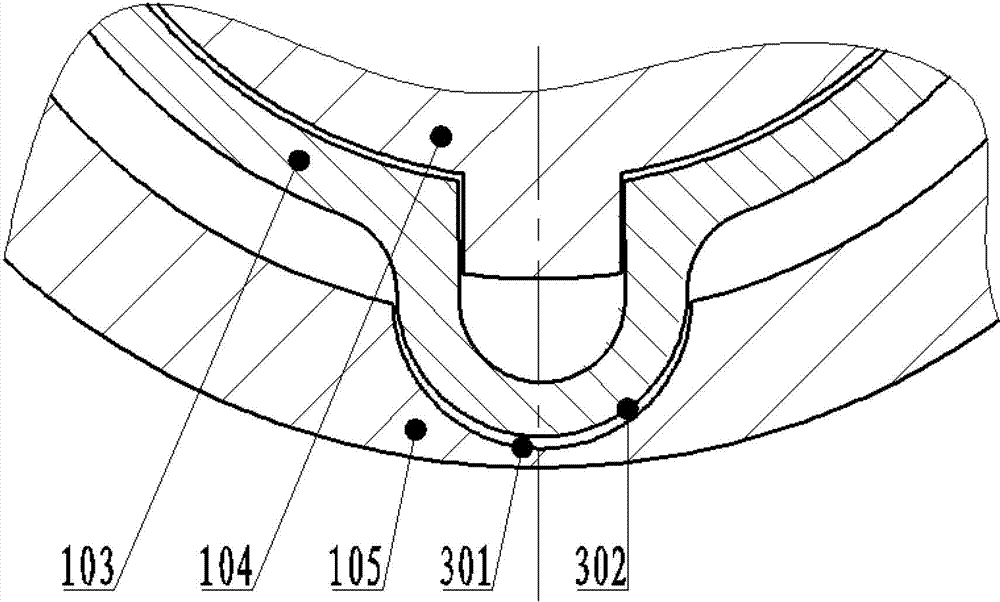

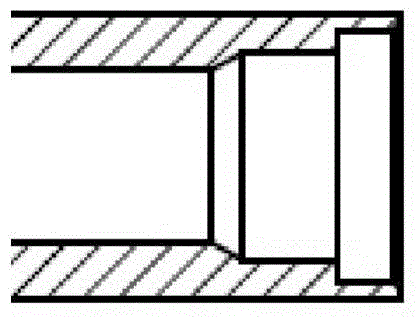

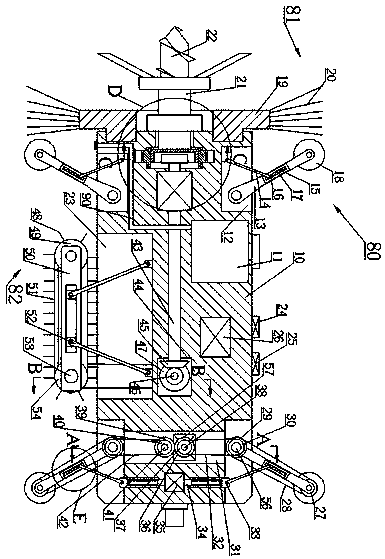

Brake calipers with parking braking mechanism

InactiveCN102865321ANo external impactThere is absolutely no risk of leakage due to external impactBrake actuating mechanismsActuatorsSteel ballCalipers

The invention relates to brake calipers with a parking braking mechanism. The brake calipers comprise a brake caliper cylindrical body, a piston assembly, a parking braking mechanism and a parking braking pulling arm which is connected with the parking braking mechanism, wherein the parking braking mechanism comprises a parking shaft, a steel ball, an anti-rotating lining and a parking nut, an arc-shaped groove is arranged on a circumference of the inner wall of the brake caliper cylindrical body, an arc-shaped protrusion is arranged on a circumference of the outer wall of the anti-rotating lining, the arc-shaped protrusion is embedded in the arc-shaped groove, so that the anti-rotating lining can not rotate relative to the brake caliper cylindrical body, but the anti-rotating lining can move downward along a shaft of the brake caliper cylindrical body, the anti-rotating mechanism is not embedded from the outside of the brake caliper cylindrical body and works inside the cylindrical body, no impact force of external force is provided, no leakage risk exists, the safety factor is high, and the performance is reliable. Beside the product structure of the brake calipers is impact.

Owner:GUANGZHOU ZHONGBO BRAKE SYST CO LTD

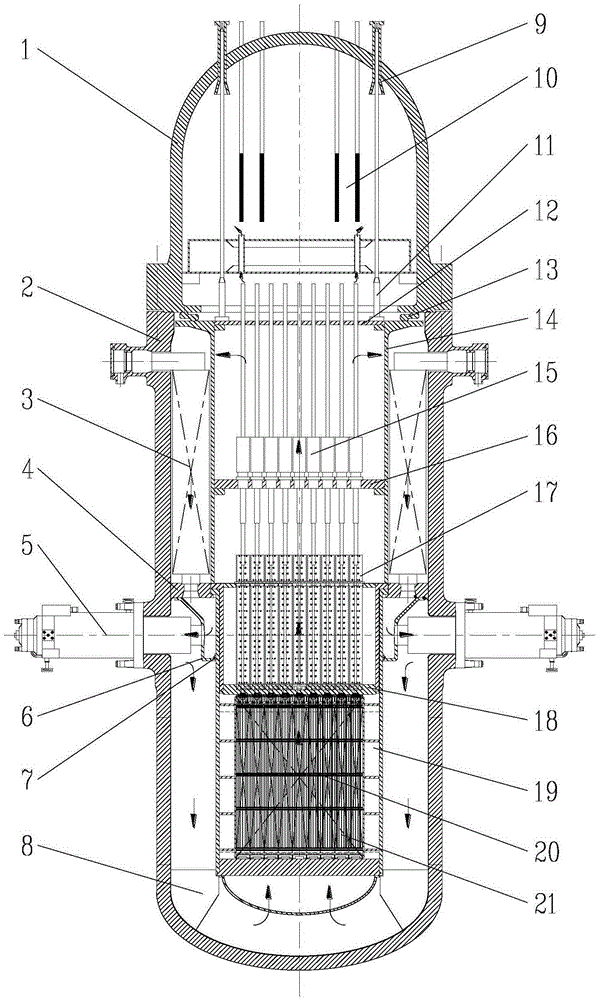

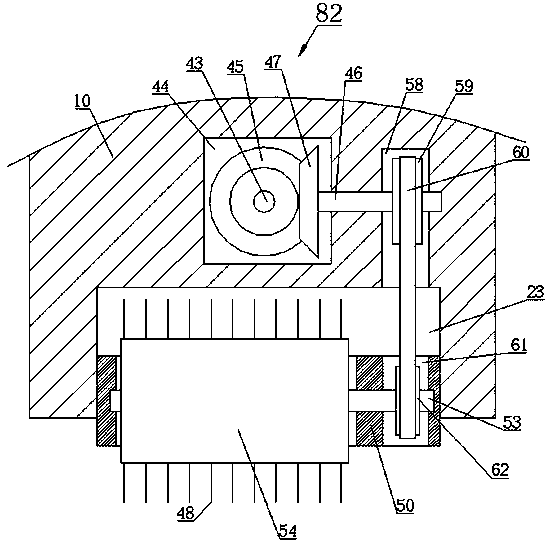

Integrated small reactor

ActiveCN105280257AEliminate large breach accidentsEliminate bouncing accidentsNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention belongs to the pressurized water reactor overall structure design technology, and specifically discloses an integrated small reactor. The integrated small reactor comprises a pressure vessel, and a reactor core, a compressing assembly, a control rod assembly, a guide assembly, a control rod driving mechanism and a once-through steam generator which are arranged inside the pressure vessel, and further comprises a main pump directly connected with a cylindrical body of the pressure vessel, wherein the reactor core comprises a reactor core barrel and a fuel assembly; the compressing assembly and the control rod assembly are arranged inside the reactor core barrel; and the pressure vessel is directly connected with the main pump, the main pump is horizontally installed, and an inlet thereof is provided with a flow distribution device. Heating equipment is arranged on a top cover of the pressure vessel, a coolant inside the pressure vessel is subjected to pressure control directly through temperature adjustment, that is, main equipment such as the steam generator, voltage-stabilizing equipment and the control rod driving mechanism are arranged inside the pressure vessel of the reactor at the same time. According to the integrated small reactor, the external loop pipeline is omitted, large break accidents are eliminated, and the structure is compact; and the control rod driving mechanism is arranged internally, the rod ejection accident is eliminated, and the fixation safety is greatly improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

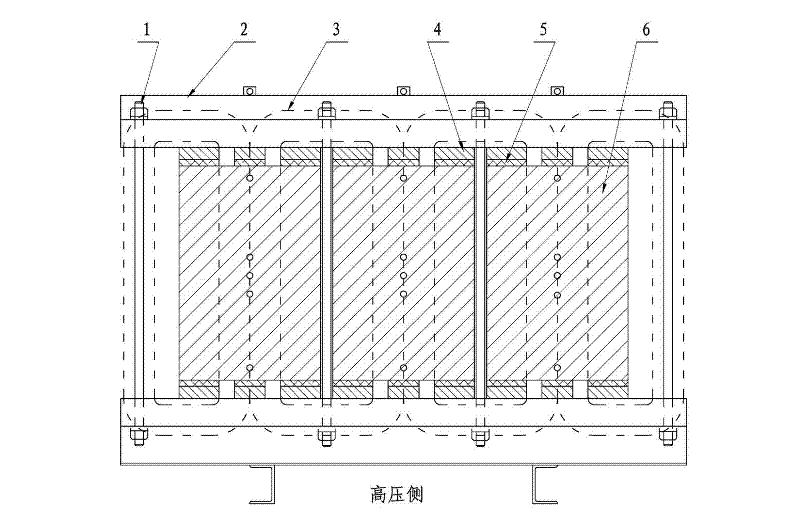

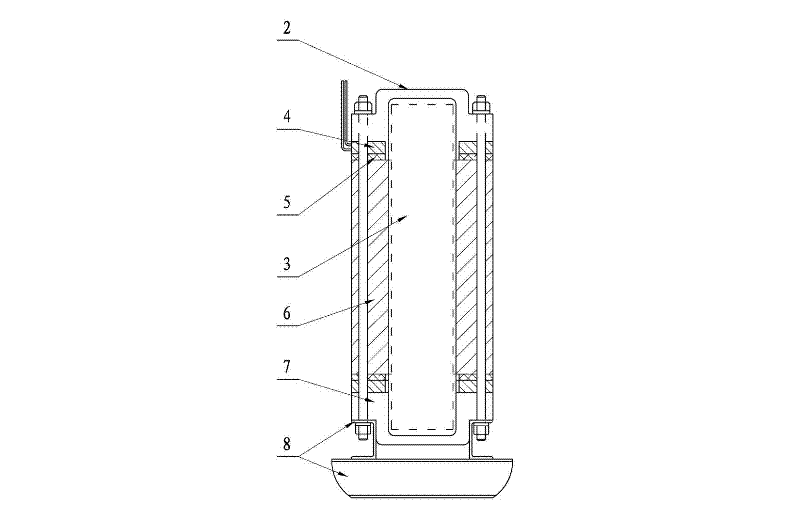

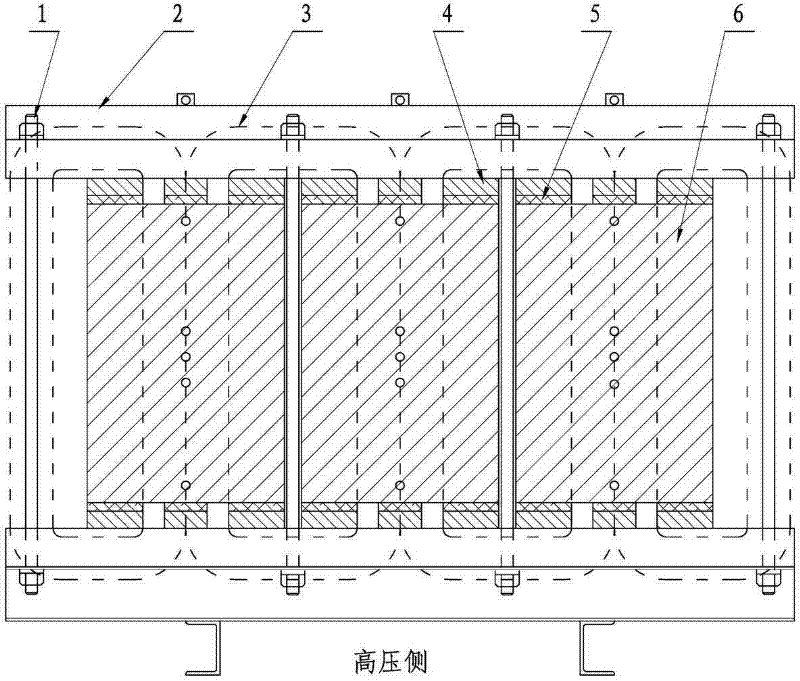

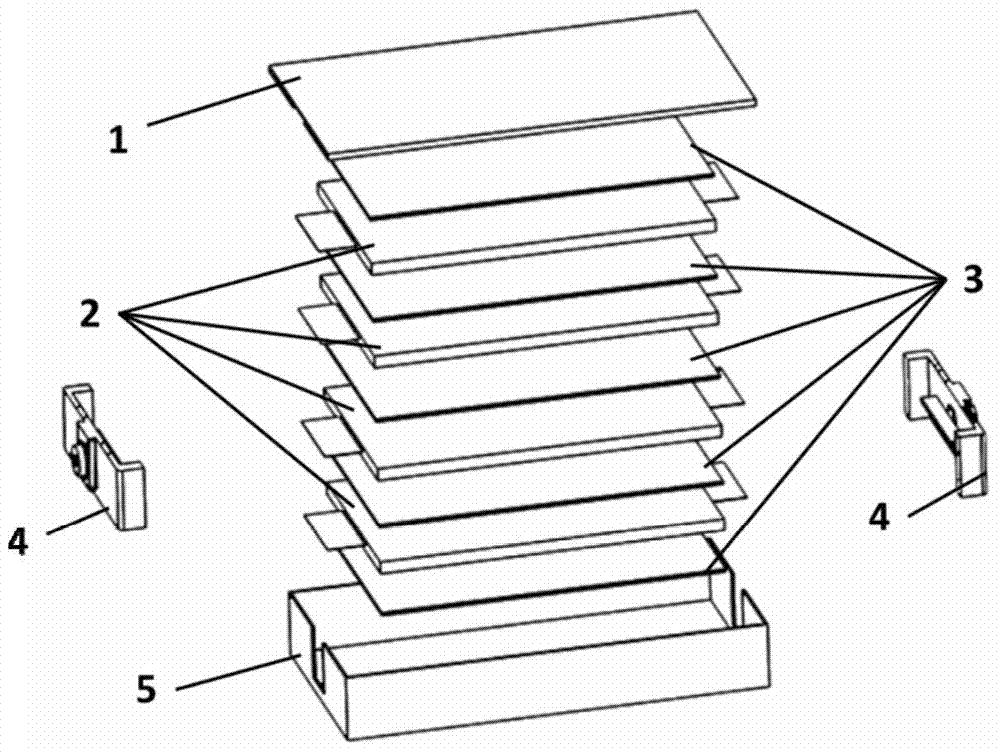

Mining explosion-proof all-insulation dry type transformer with amorphous alloy iron core for mobile transformer substation

InactiveCN102543384AGood energy saving effectReduce lead insulation distanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLap jointLow noise

A mining explosion-proof all-insulation dry type transformer with an amorphous alloy iron core for a mobile transformer substation comprises an integral winding, the iron core, an upper clamp, a lower clamp and a shell, wherein the integral winding includes low-voltage coils and high-voltage coils. The mining explosion-proof all-insulation dry type transformer is characterized in that insulation layers are arranged among layers of the low-voltage coils, the high-voltage coils are arranged on the outer layer of the low-voltage coils, each insulation layer is arranged between each two adjacent layers of the high-voltage coils, an outer insulation layer covers the high-voltage coil, and the integral winding has the square section. The iron core is the amorphous alloy iron core, and an assembling lap joint of the iron core is arranged on the lower portion. The upper clamp and the lower clamp are non-metallic parts cast by epoxy resin and reinforced by filled glass fibers, the U-shaped sections of the upper clamp and the lower clamp cap the upper yoke and the lower yoke to press the upper end face and the lower end face of the winding and are fastened by pull bolts, and the pull bolts are symmetrically mounted on the low-voltage side and the high-voltage side to fasten the upper clamp and the lower clamp. The mining explosion-proof all-insulation dry type transformer has the advantages of long service life, low loss, low noise, no maintenance or pollution, high reliability, flame retardance, fire resistance, recyclability after being used up and the like.

Owner:沈阳幸森电气设备有限公司

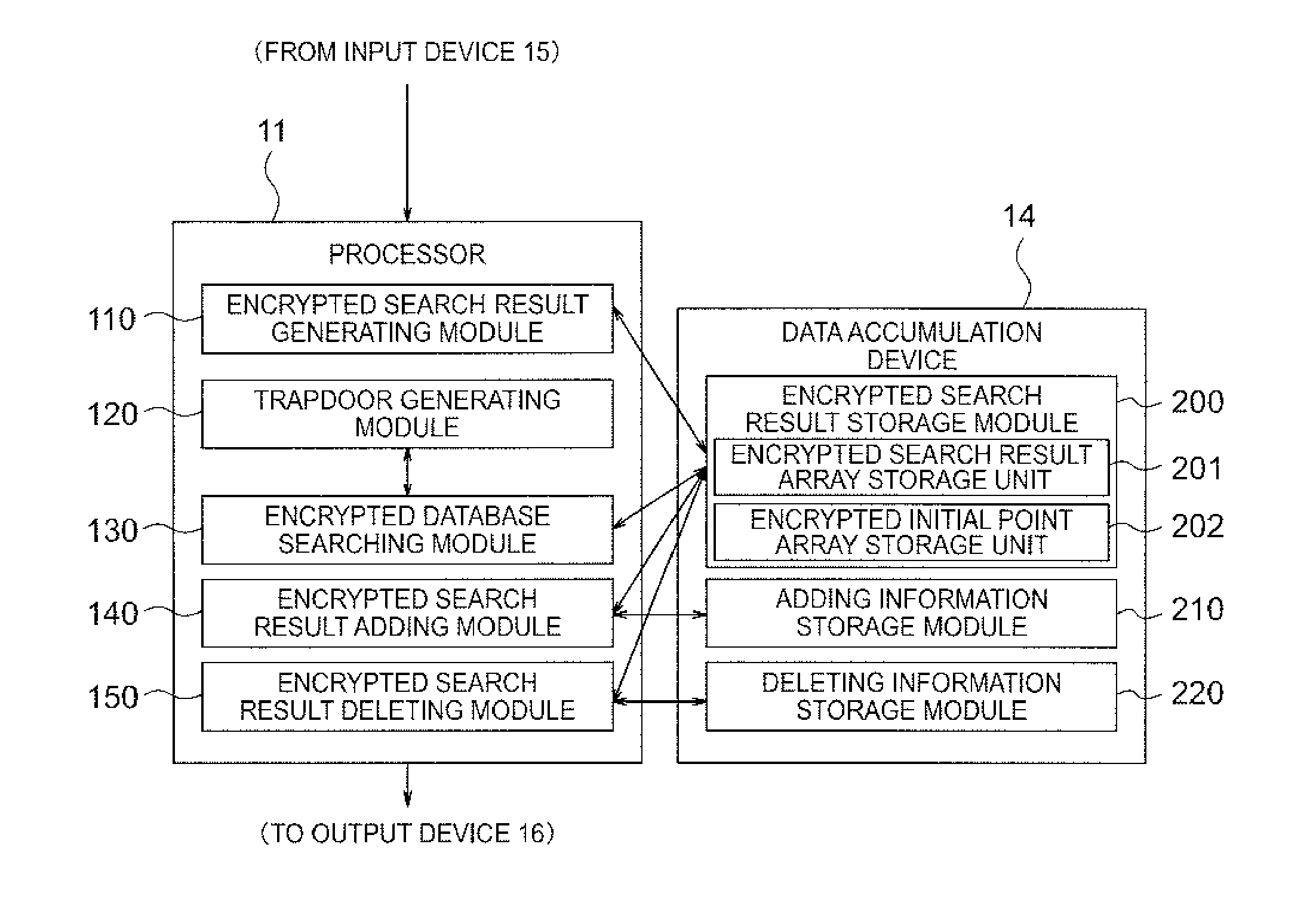

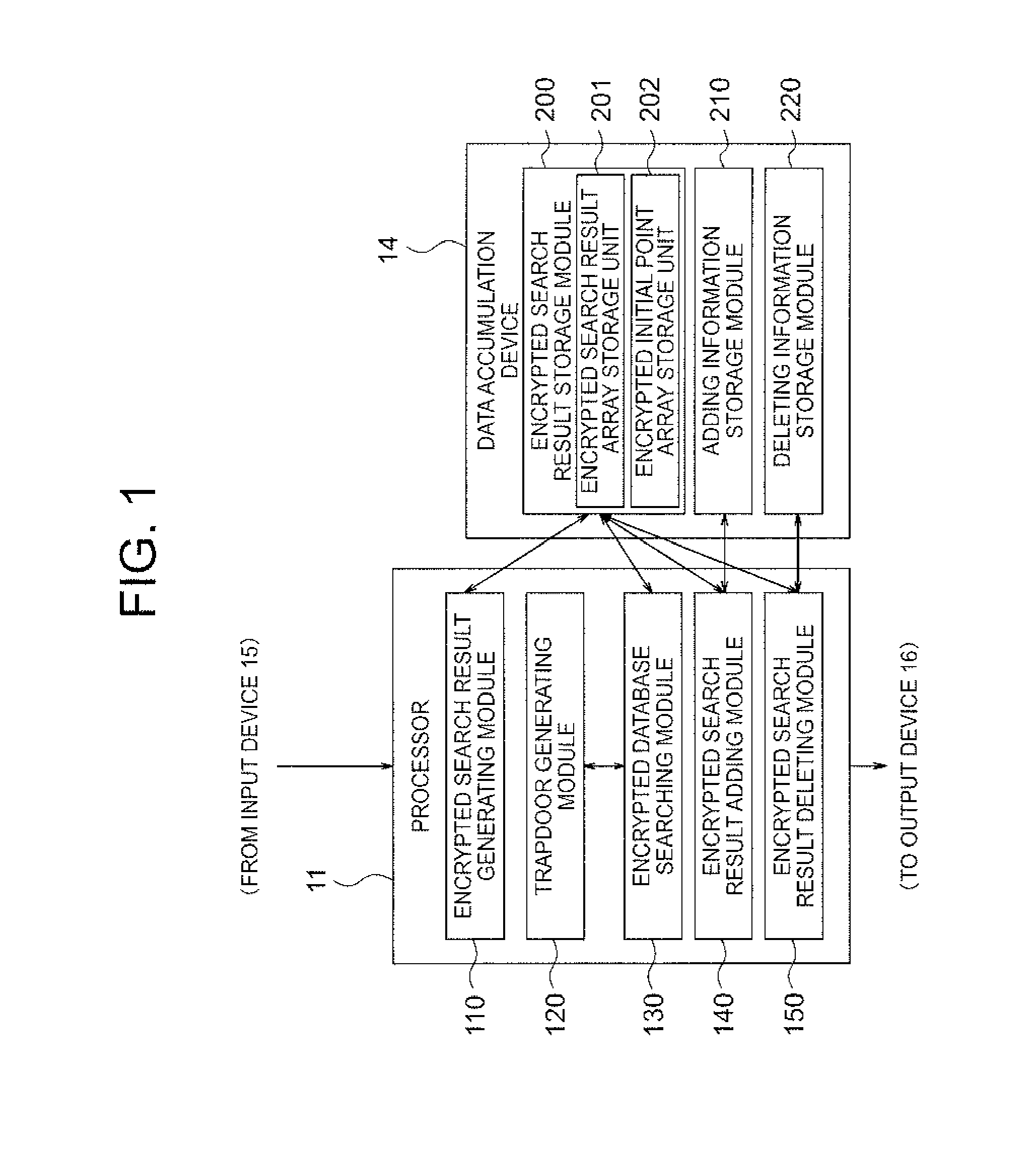

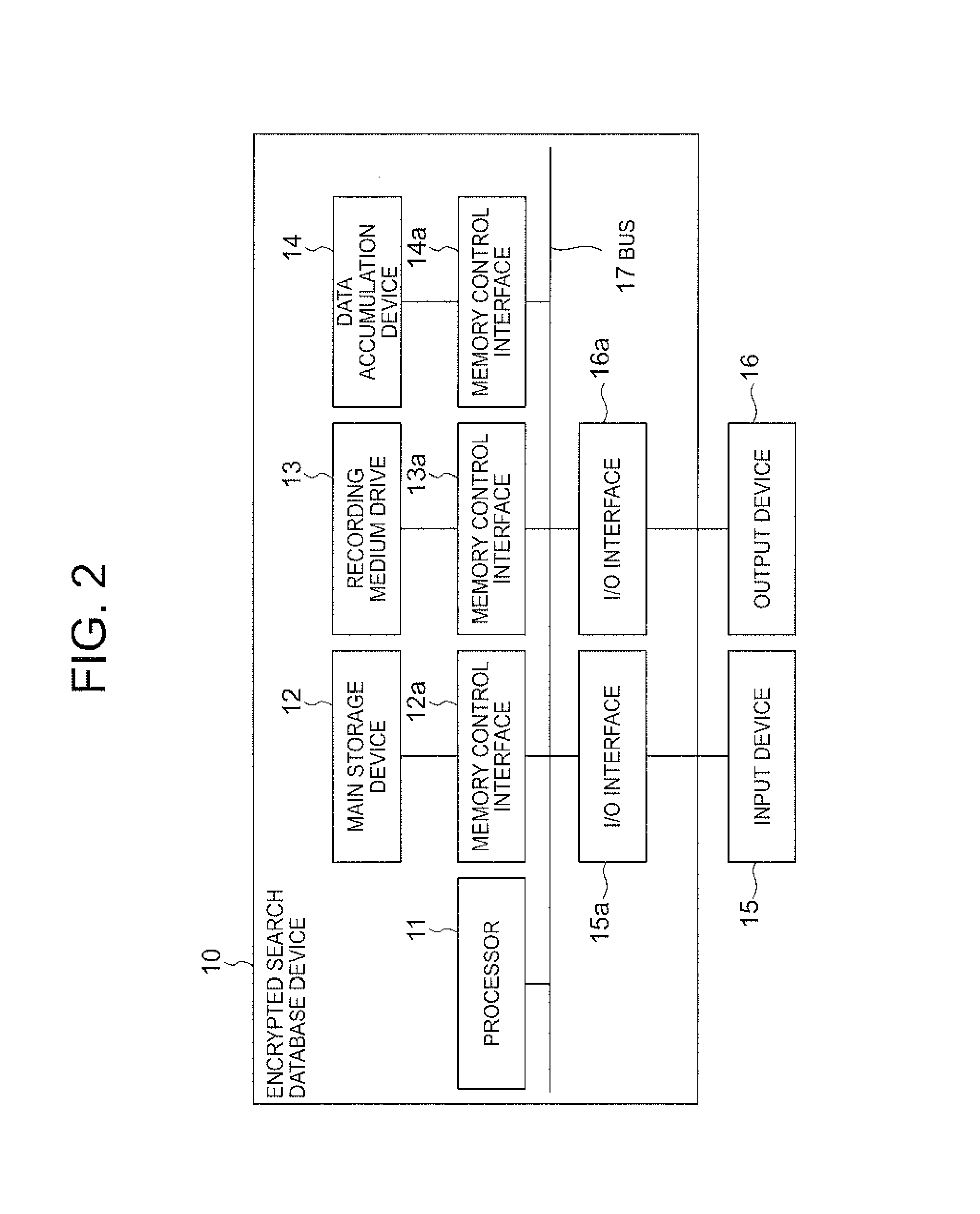

Encrypted search database device, encrypted search data adding/deleting method and adding/deleting program

ActiveUS20140095889A1No risk of leakageDatabase management systemsUnauthorized memory use protectionData miningDatabase

The encrypted search result adding module of the encrypted search database device includes: a search result generating unit which generates a linear list as a list of search results for newly registered document data; an initial point information generating unit which generates initial point information as address of first data corresponding to a keyword; an initial point information encrypting unit which encrypts and adds / stores generated initial point information with an encryption key; and an encrypted linear list adding unit which generates and adds / stores an encrypted linear list by encrypting the linear list with the encryption key, and stores each keyword and final point information as the address of last data in the encrypted linear list for the keyword as adding information.

Owner:NEC CORP

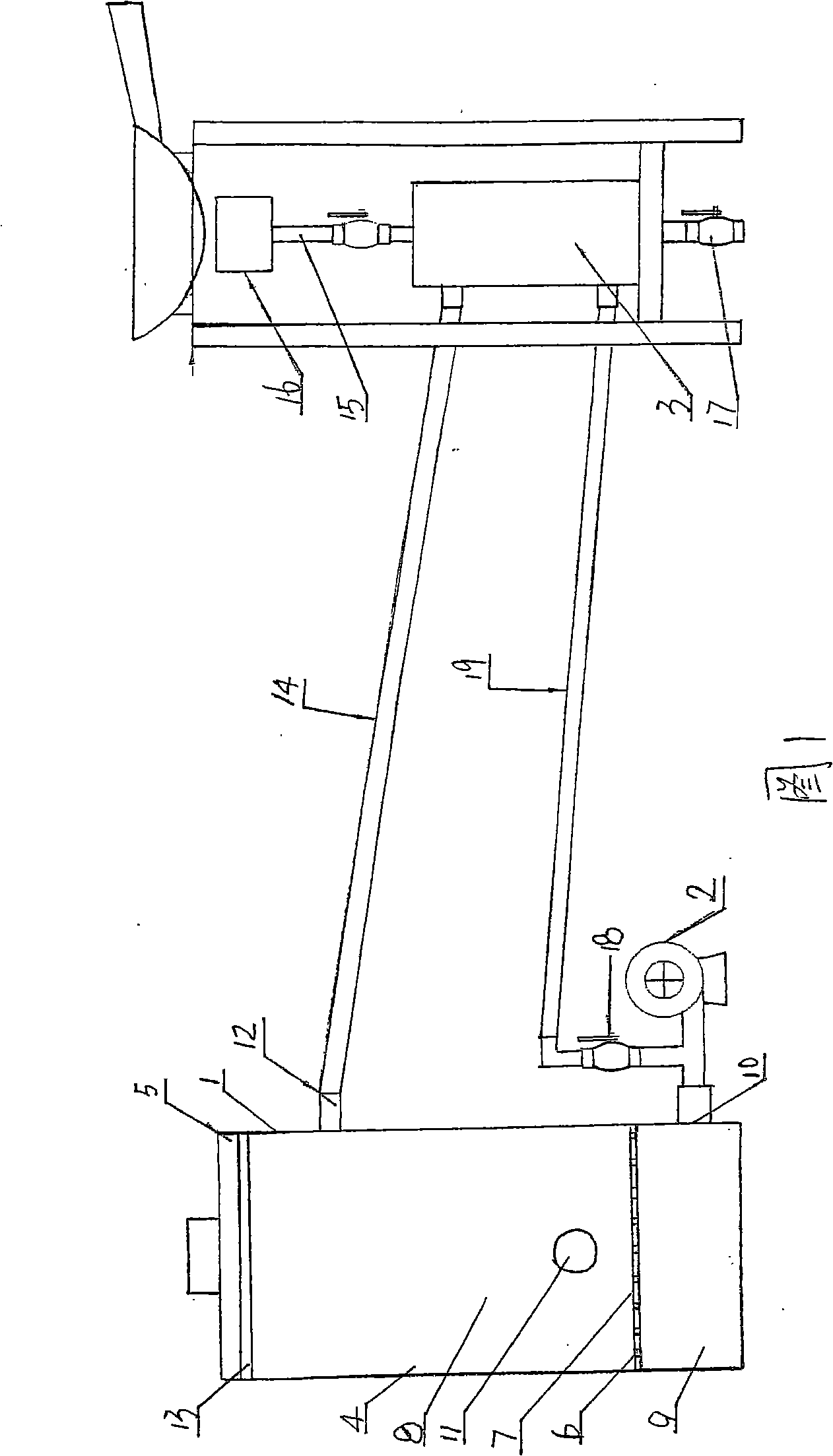

Biomass gasification stoves

InactiveCN101275752AZero costSuitable for gas demandDomestic stoves or rangesLighting and heating apparatusCarbonizationEngineering

The invention discloses a biomass gasifier, wherein the propellant bottle is composed of a barrel (4) and a barrel cover (5), the berrel is divided into an upper carbonization gas making chamber (8) and a lower air chamber (9) through a clapboard (7) with ventholes (6), the turnnel wall of an air chamber (10) is provided with an air inlet (10), a fan (2) is arranged on the air inlet (10), the upper turnnel wall of the carbonization gas making chamber (8) is provided with an air supply opening (12), the top of the barrel (4) is equipped with the barrel cover (5) through a water seal trough (13), an air supply tube (14) on the air supply opening (12) is connected with a fuel gas filtering pot (3), which is connected with an oven (16) through a hose (15). The invention performs the deep exploitation and use on the agricultural resources, changes wastes into valuables, which can increase the utilance of the agricultural resources.

Owner:曾明友

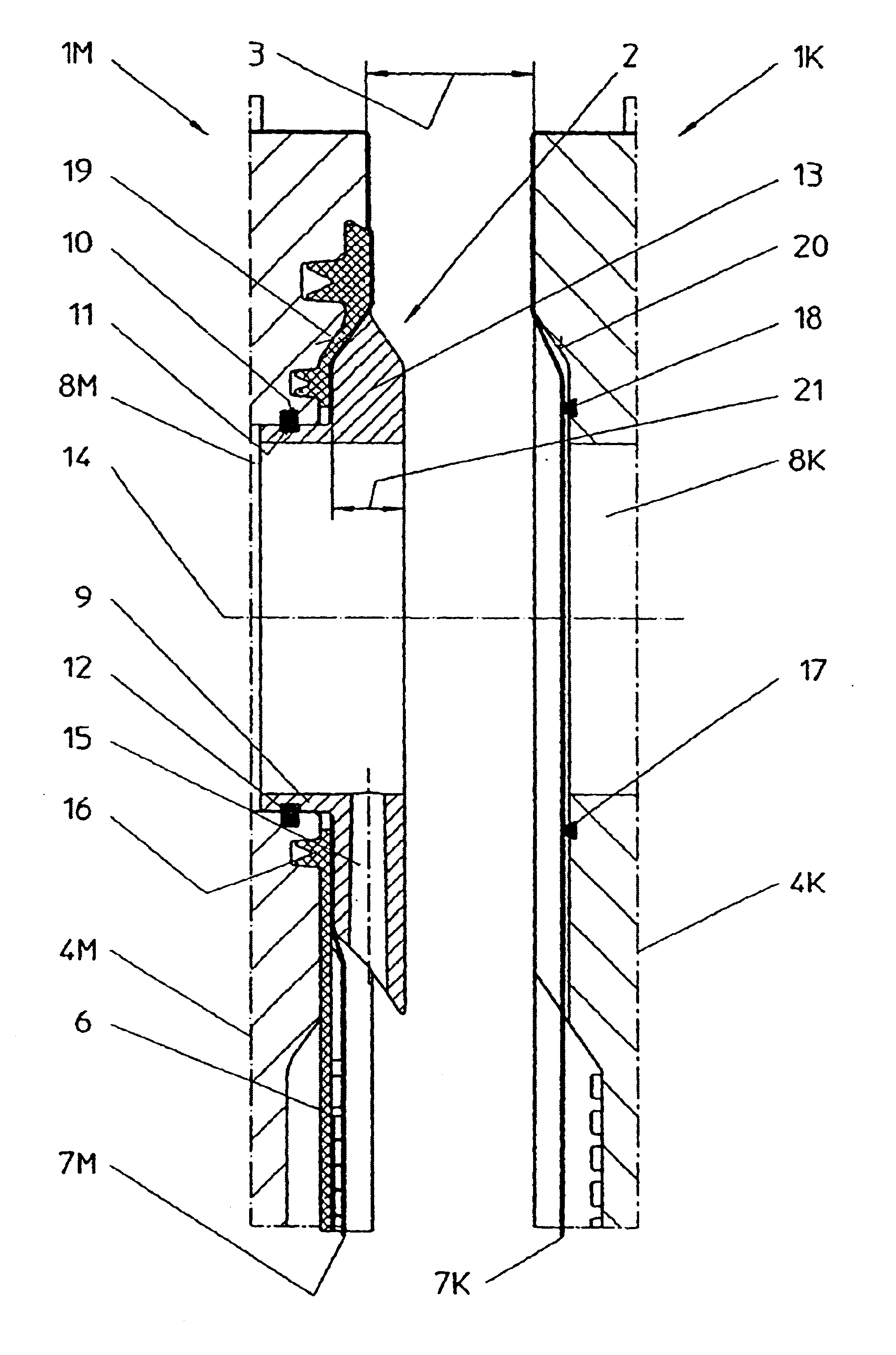

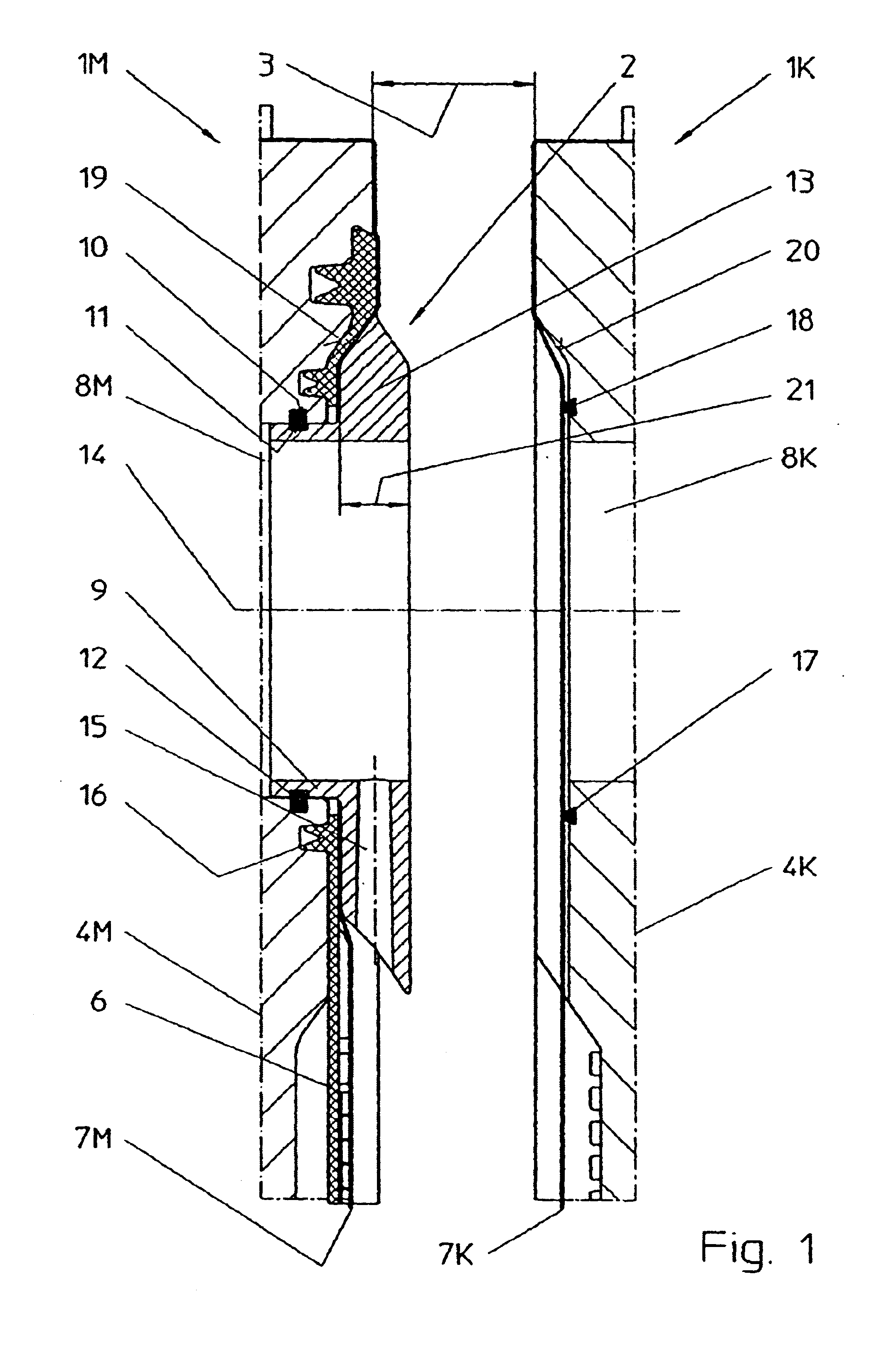

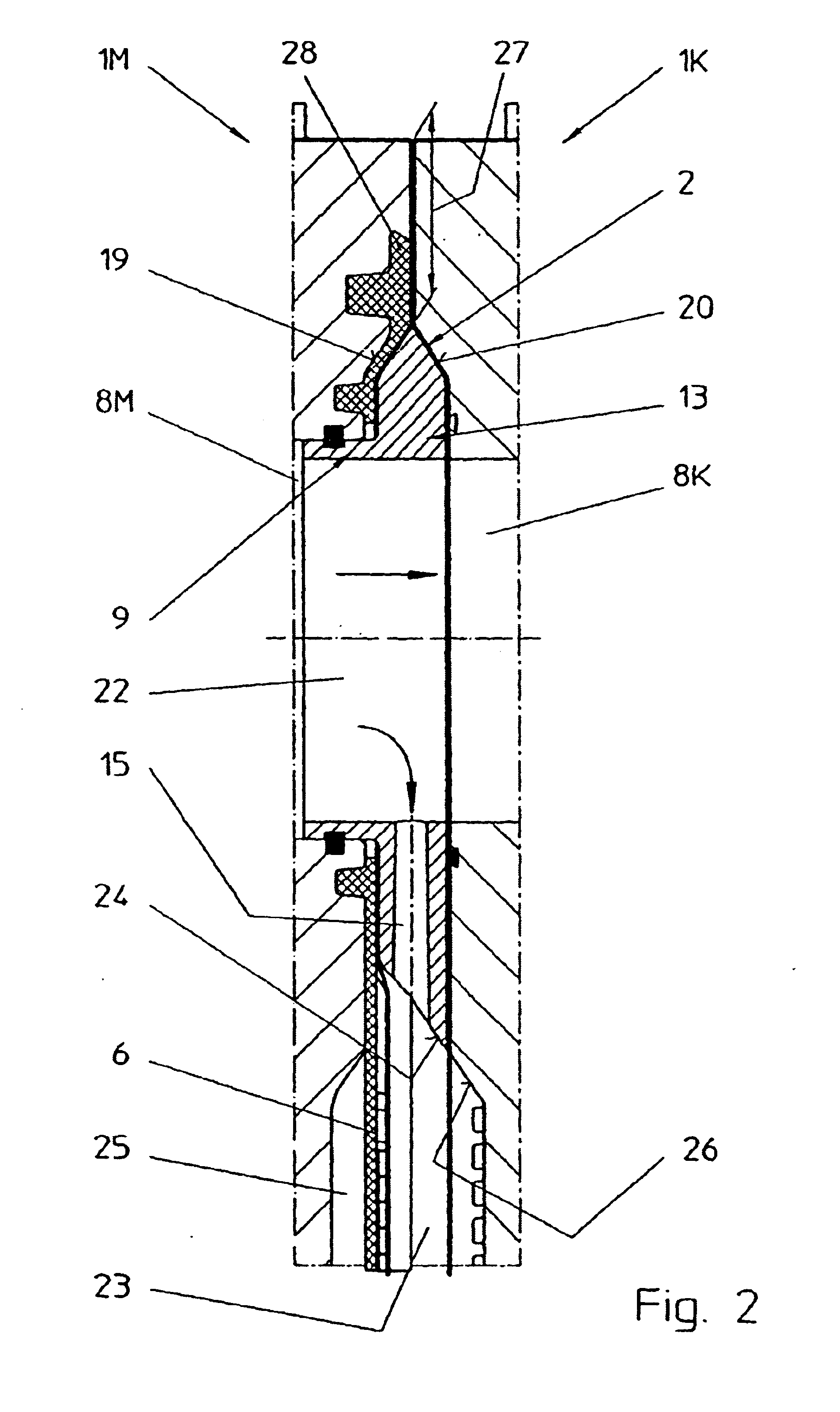

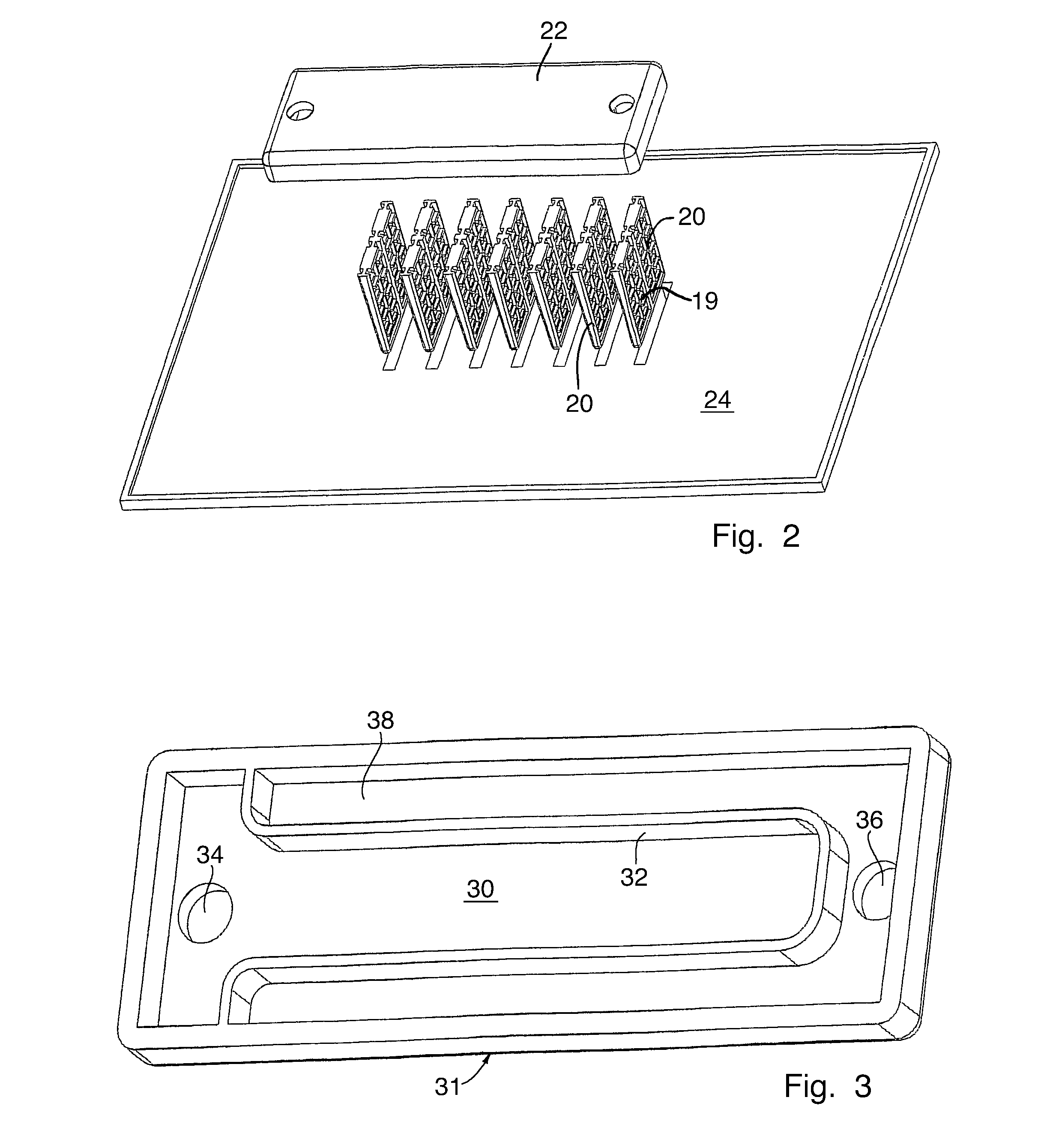

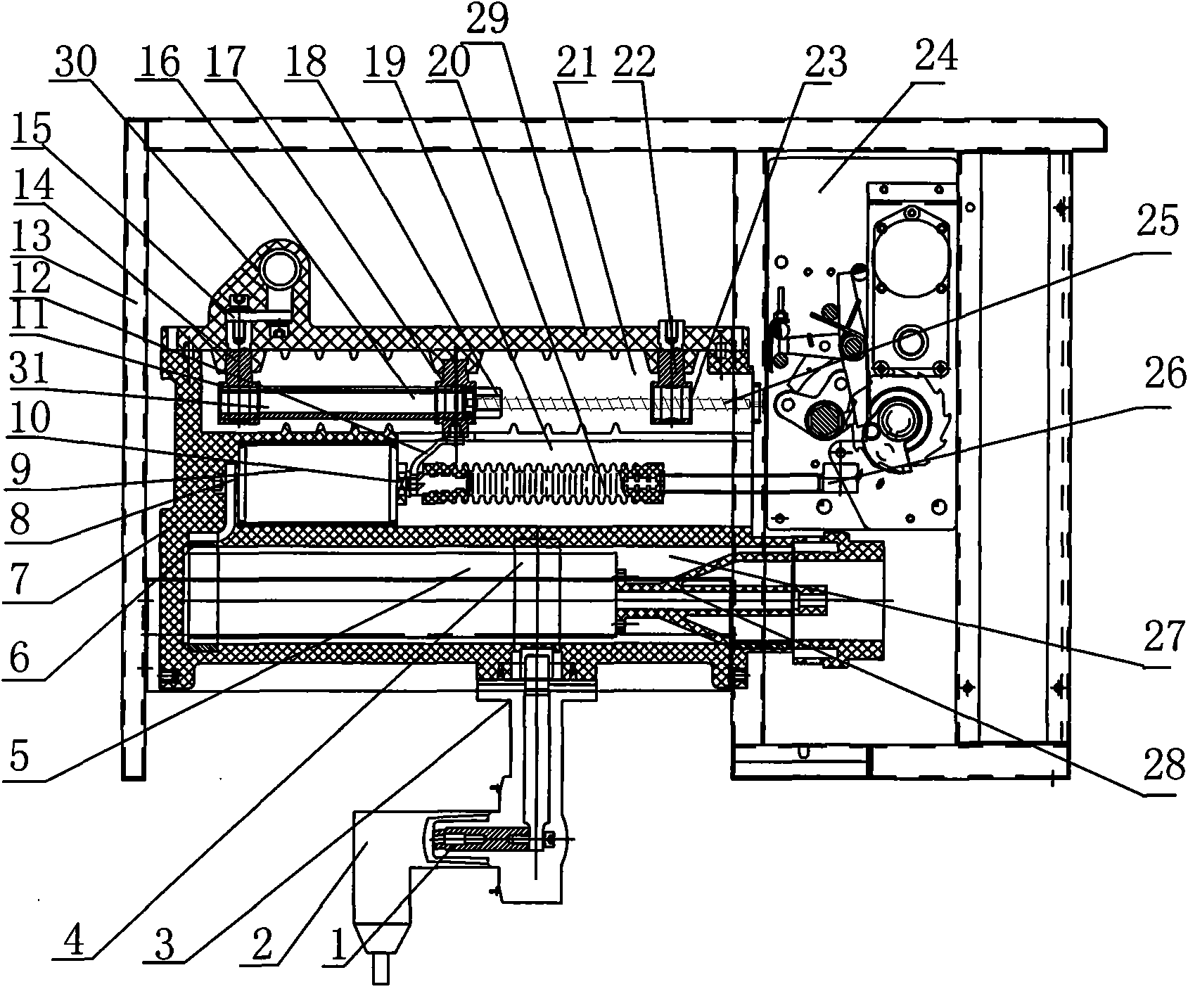

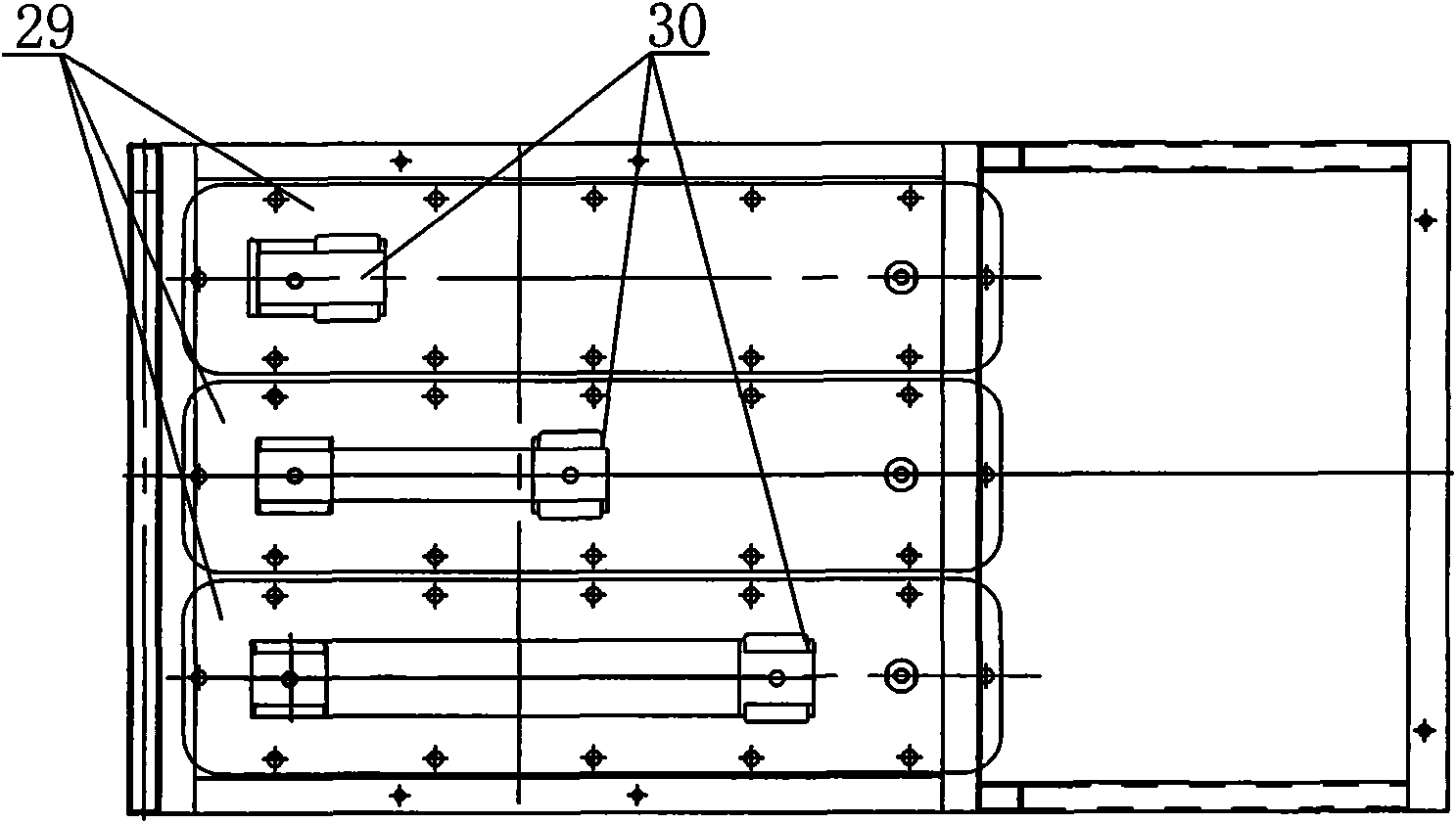

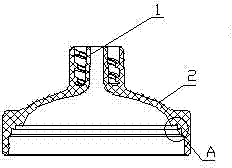

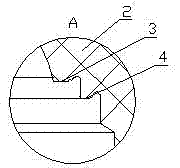

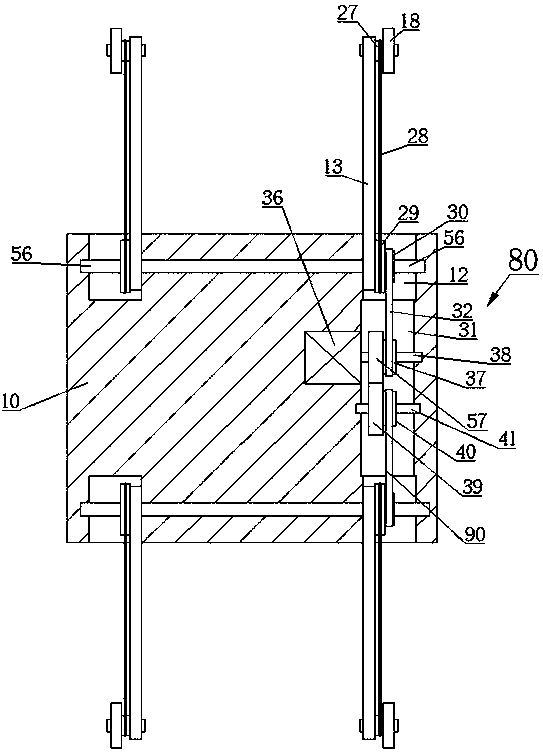

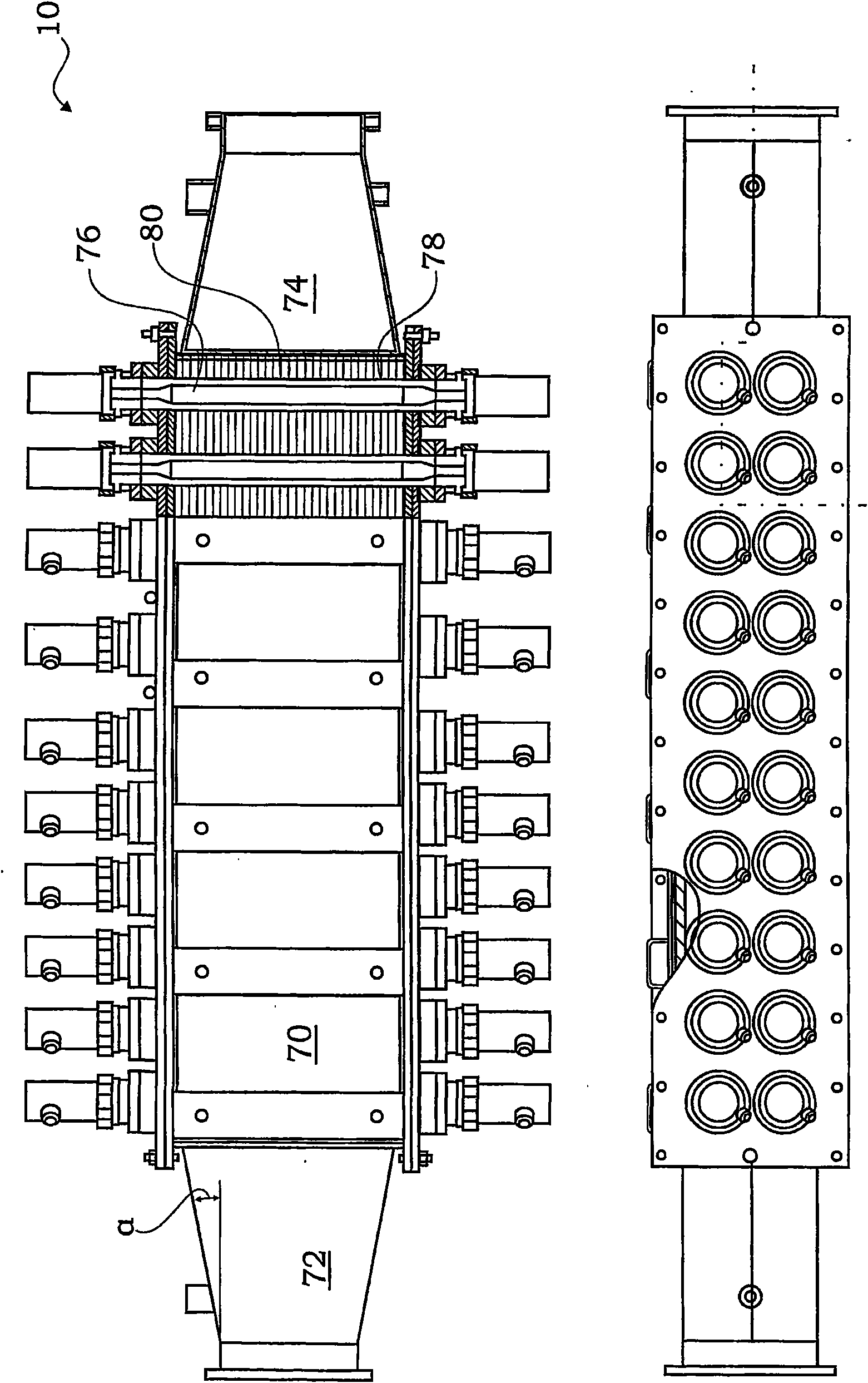

Filter plate of a filter press

InactiveUS6852220B1Low costEasy to manufactureSettling tanks feed/dischargeLoose filtering material filtersFilter pressMechanical engineering

A filter press for filtering suspensions includes plural parallel filter plates that can be displaced relative to one another. In a filtering position, the filter plates are compressed to a package that forms a filter chamber provided with at least one filter cloth between neighboring filter plates. In a discharge position, neighboring filter plates are moved apart by a discharge distance so that a filter cake adhering to the filter cloth can be discharged. Every filter chamber is provided with at least one filling element for feeding the suspension to the filter chamber. The filling element is disposed on a protruding part that protrudes beyond a plate body face or contour and within a sealing edge on the periphery of the filter plates. In the filtering position, the filling elements are sealingly clamped between neighboring filter plates and form a suspension supply channel that extends through the filter plate package.

Owner:OUTOKUMPU OY

Anti-biological blocking device for drip irrigation system

InactiveCN102283080ANo residueNo troubleClimate change adaptationWatering devicesAir filterHazardous substance

The invention relates to an anti-biological clogging device for a drip-irrigation system. The drip-irrigation system is started, an air intake brake valve is opened, an ozone generator is started, and compressed water which comes from the head part of the drip-irrigation system is sprayed at high speed from a jet orifice of a jet nozzle so as to form the negative pressure in a gas injection cavity; and under the action of the negative pressure, the ozone generator ensures that ozone generated through air ionization enters the gas injection cavity through the air intake brake valve, a check valve and an air inlet pipe along with the air filtered by an air filter, and enters an oscillating cavity for vortex oscillation, stirring and aerification along with the high-speed water flow sprayed by the jet nozzle so as to form 'ozone water' of which gas and liquid are distributed uniformly, and the 'ozone water' enters the drip-irrigation system to kill microorganisms in flow channels and cansynchronously inhibit crop root systems from growing toward the direction of a water outlet of a drip irrigation emitter in an underground drip-irrigation system, so that the aim of biological clogging resistance of the drip-irrigation system is fulfilled. Compared with a method of injecting a chemical agent into irrigation water, the invention has the advantages that: the residue of harmful substances which can pollute the environment is not produced, and the risk of using dangerous chemical agents is avoided.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

Device for packaging two products to be mixed and for dispensing the mixture of these products

InactiveUS20110147333A1No risk of leakageEliminate riskClosuresClosure using stoppersBottleBiomedical engineering

Device including a bottle having two open ends and a central body receiving a first product, one end of the bottle has an orifice receiving a stopper which contains a second product to be mixed with the first, another end of the bottle has an orifice receiving a removable cap provided for withdrawing the mixture after removal of the cap.

Owner:ONLY FOR CHILDREN PHARMA

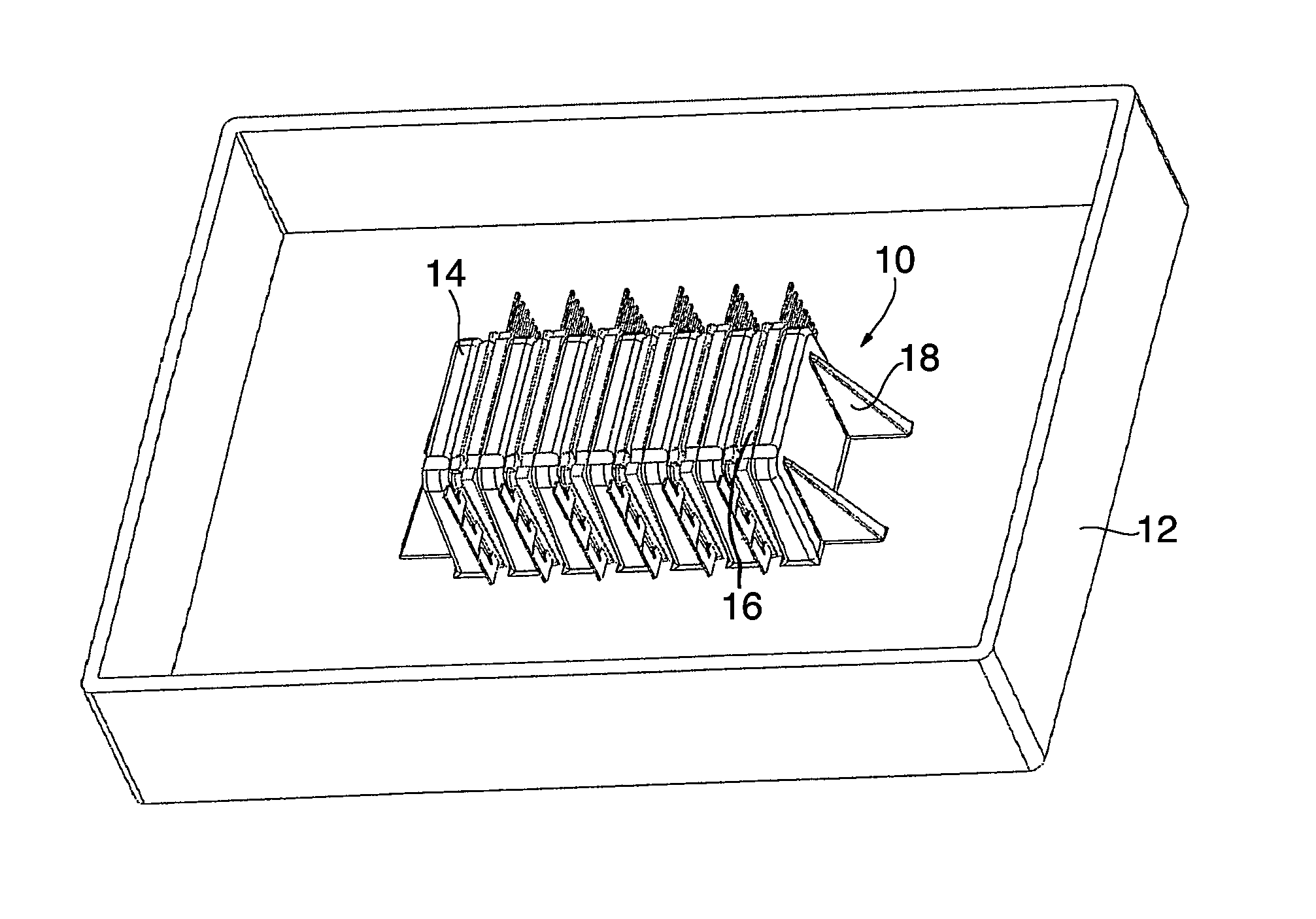

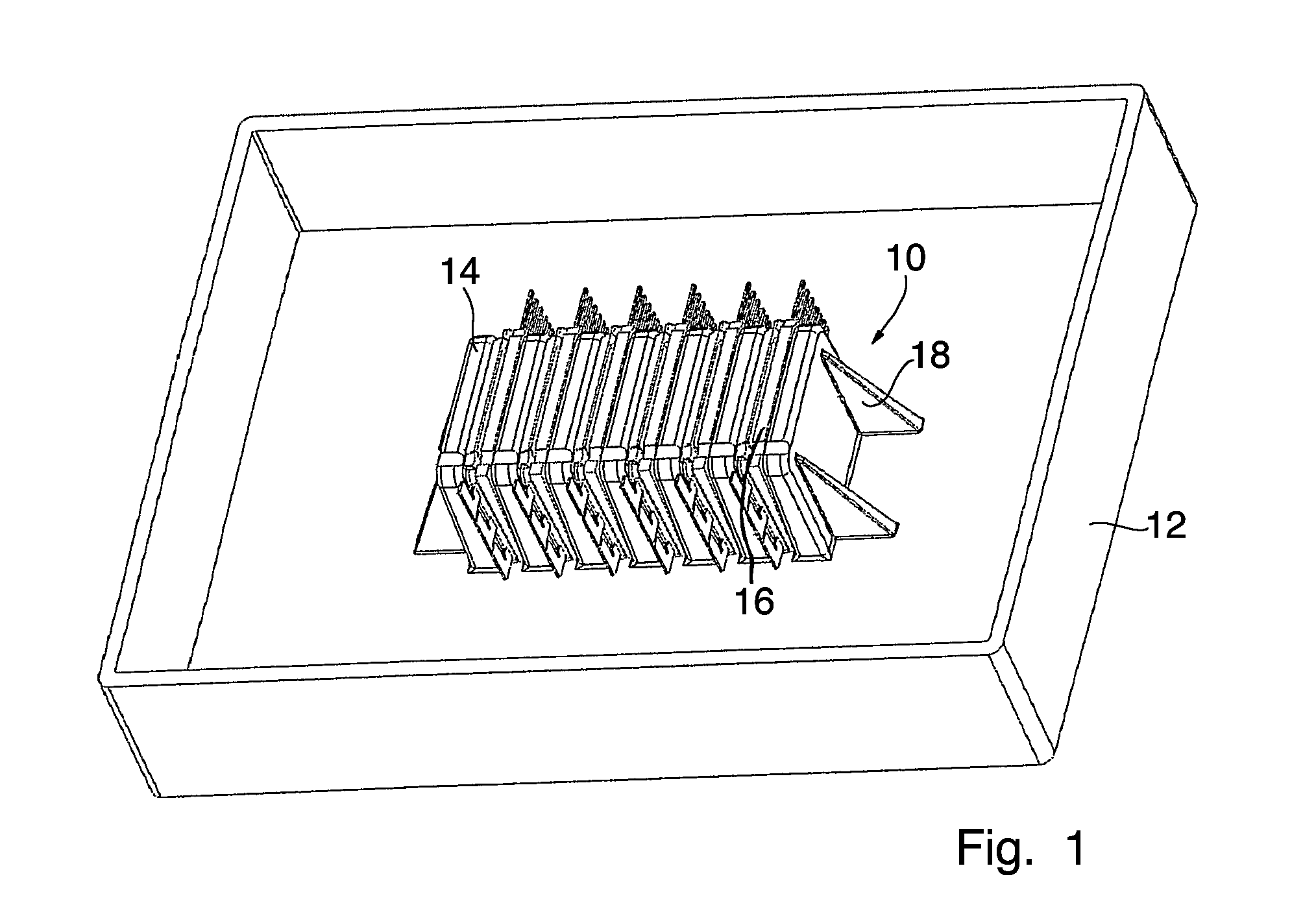

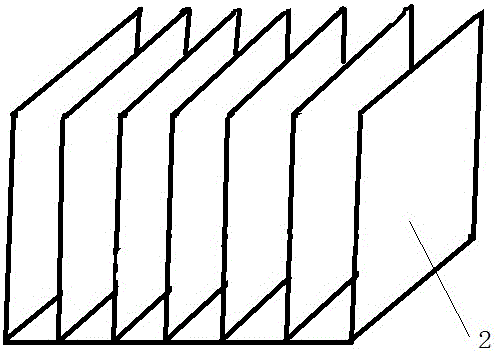

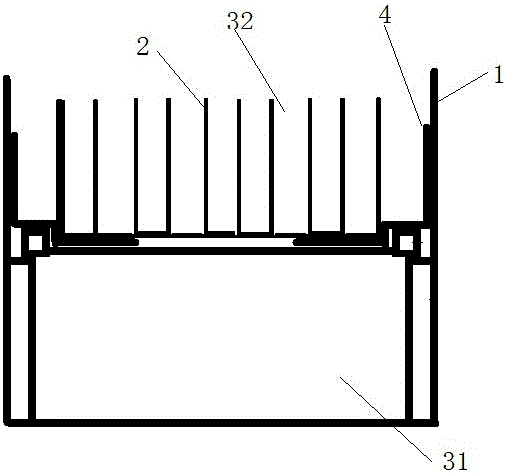

Cooling device for a plurality of power modules

InactiveUS8451609B2Easy to assembleUniform cooling effectSemiconductor/solid-state device detailsSolid-state devicesHeat conductingCoolant flow

The invention relates to a cooling device for a plurality of power modules (16), comprising a heat-conducting body (15) through which a coolant flows. The cooling device comprises external cooling ribs (14) on a first housing shell of the body through which a coolant flows for receiving the plurality of power modules adjacent to each other. Each individual cooling rib is aligned to come into fixed heat-conducting contact on at least one upper or lower side of one of the plurality of power modules, and the housing shell, on the inner side in the region of the respective cooling rib(s), comprises means for the fluidic communication with the volume of the coolant in the inside the body through which the coolant flows.

Owner:DANFOSS SILICON POWER

Epoxy pouring type solid insulation switch with three-cabin

ActiveCN101677177ANo risk of leakageUndisturbedBus-bar/wiring layoutsSwitchgear arrangementsEngineeringElectrical and Electronics engineering

The present invention provides an epoxy pouring type solid insulation switch with three-cabin which is composed of three switch bodies having same structure. The switch body comprises an isolation cabin, a vacuum explosion-chamber cabin and a fuse cabin; a bus contact is arranged on the top of the isolation switch, the bus contact fixedly connects with an isolation contact through a master row; agrounding contact and the isolation contact are arranged on two ends of the isolation switch, a middle contact is in the middle; three contacts have same contact bases, sliding guide holes are arranged on the centre of the bases; the front connects with an insulation nut, the rear end connects with an operating mechanism. a through hole is arranged on the centre of the isolation moving contact andfixedly connects with the insulation nut, the insulation nut is sheathed on the nut and rotately connects with the nut; the vacuum explosion-chamber cabin and the fuse cabin are arranged below the isolation cabin respectively. The switch provided by the invention has advantages of reasonable design, higher electric safety performance, little volume, light weight, stable performance, reliable motion, stronger practicability and advancement. The switch provides assurance for reliability of electric supply, which is a precondition condition for reducing user investment.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

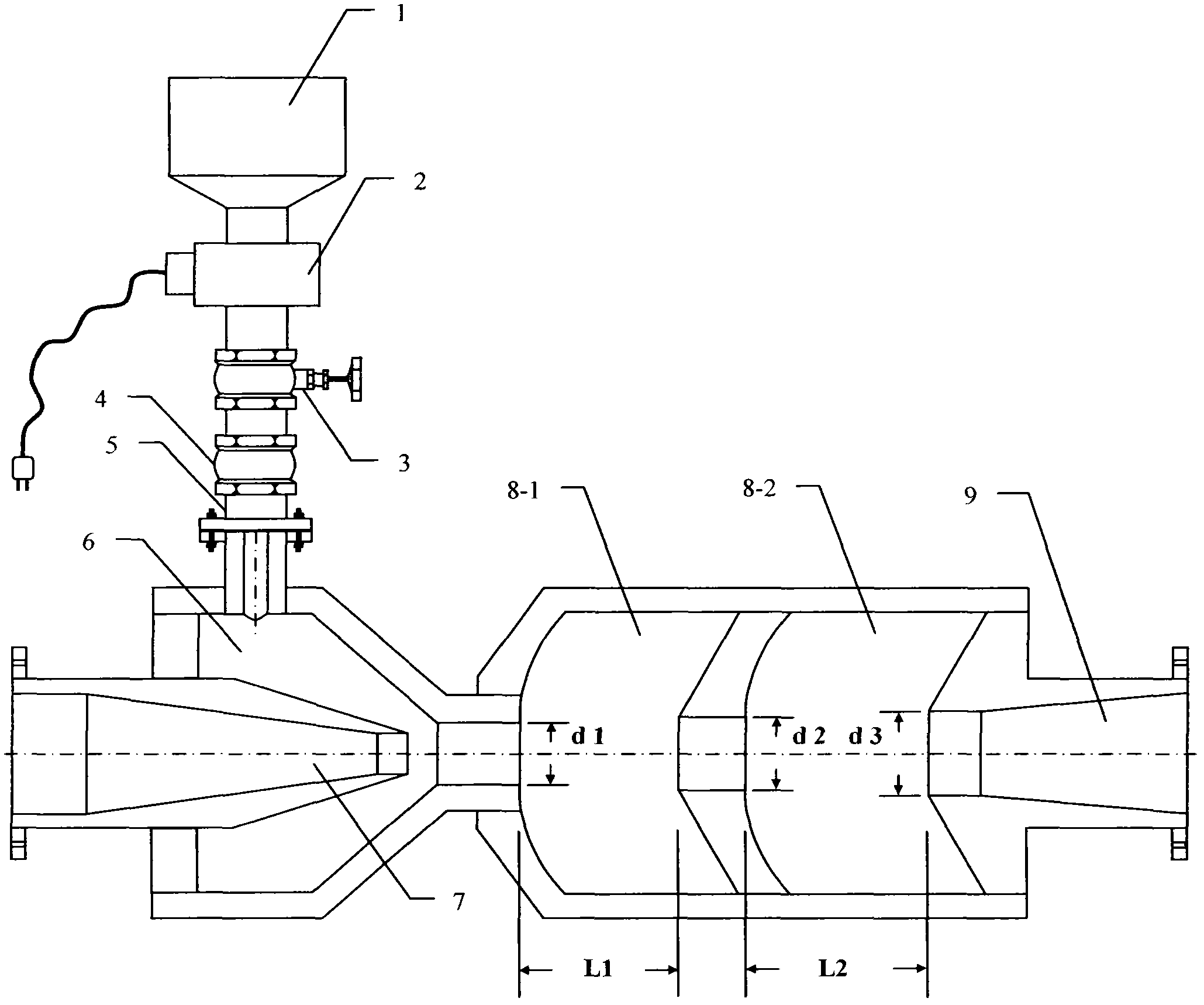

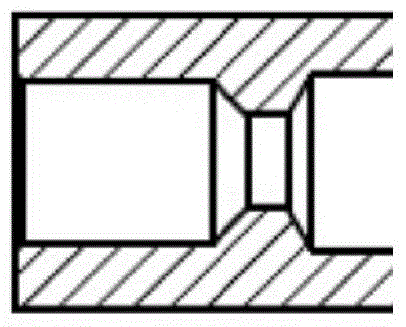

Hemodialyzer with polypropylene material outer shell and manufacturing method thereof

The invention discloses a hemodialyzer with a polypropylene material outer shell and a manufacturing method thereof, and relates to the field of hemodialysis. The hemodialyzer comprises an outer shell body and membrane fibers. The outer shell body comprises an end cover and a tubular body, and the outer shell body is made of polypropylene. A welding bulge loop which is matched with the end face of the body is arranged at the position, opposite to the end face of the tubular body, of the end cover. The welding bulge loop of the end cover and the tubular body are welded together through ultrasonic waves. The manufacturing method of the hemodialyzer with the polypropylene material outer shell includes the steps that injection molding, pre-assembling, sintering, centrifugal can sealing and cropping of the end cover and the tubular body are conducted, the end cover is fixedly mounted on the tubular body, and leak hunting, drying and assembling are carried out on a dust cap. Plasma activating treatment is conducted on the end cover and the tubular body. The outer shell body is not poisonous, using is safe, the cost of raw materials is low, the molding cycle is short, and the preparation efficiency is high. The manufacturing method saves time and labor, improves efficiency, lowers manufacturing cost, and prevents a sealing ring from releasing substances harmful to the health of people when the end cover and the tubular body are in ultrasonic welding.

Owner:WEIHAI WEIGAO BLOOD PURIFICATION PROD

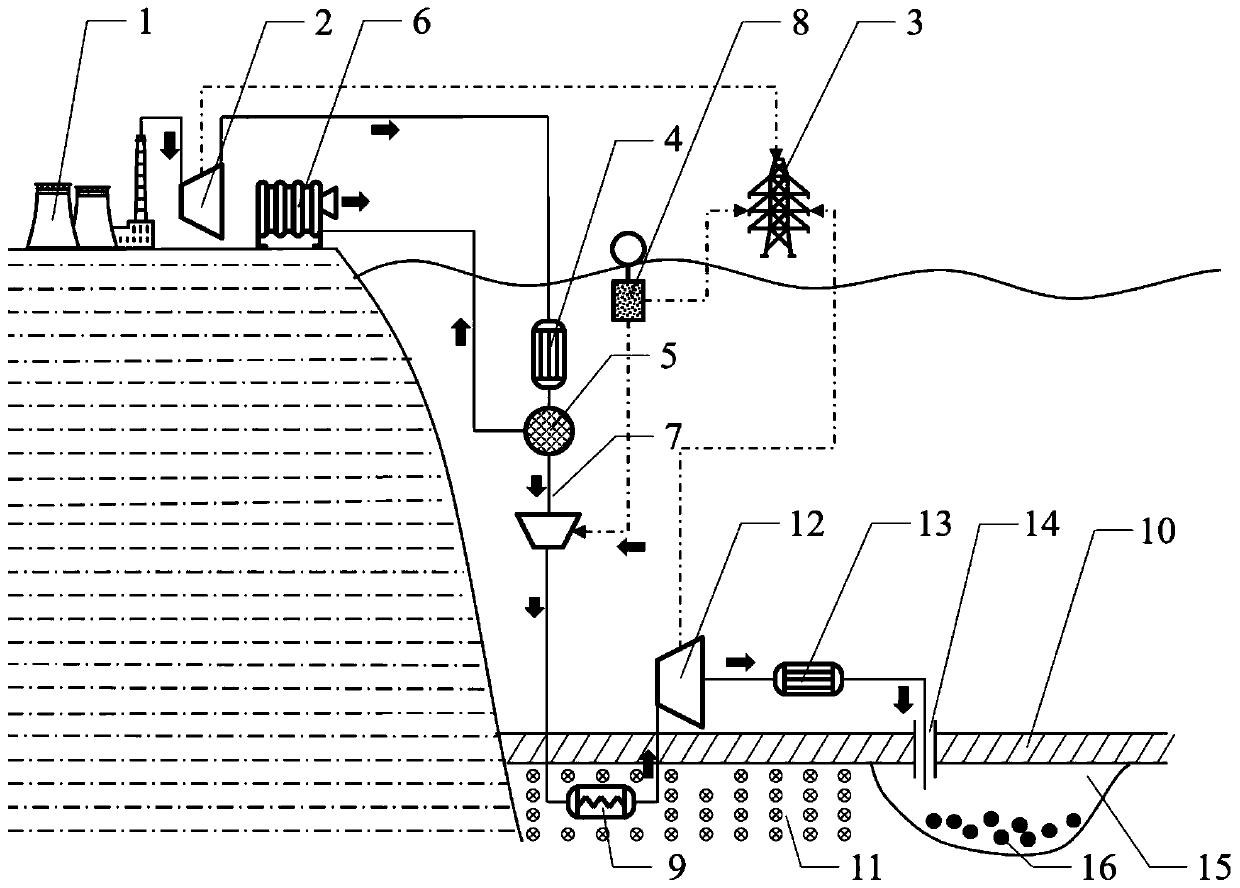

Deep-sea carbon storage and power generation system

The invention discloses a deep-sea carbon storage and power generation system. The deep-sea carbon storage and power generation system comprises a waste heat turbine, a waste gas heat exchanger, a gasstripping device, a waste gas treatment device, a supercritical carbon dioxide compressor, wave energy power generation equipment, a geothermal heat exchanger, a supercritical carbon dioxide turbineand a seabed cooler. According to the deep-sea carbon storage and power generation system disclosed by the invention, waste heat power generation and carbon dioxide stripping are performed on power plant waste gas, and the stripped carbon dioxide is applied to a seabed geothermal Brayton cycle, and is finally stored in deep-sea storage holes. The system is compact in structure, is small in size and is high in efficiency. Rich seabed geothermal energy is used as a heat source, is free of pollution and is low in cost; carbon dioxide is stored in the form of carbon dioxide hydrate, is relativelylow in cost, is environmentally-friendly and is good in leakproofness; and a dried oilfield, gas field or natural hole with a good storage cover in a seabed geologic body is utilized as a carbon storage site, so that the storage effect is good, and later-period maintaining and monitoring cost is reduced, and therefore, the system has a wide application prospect.

Owner:XI AN JIAOTONG UNIV

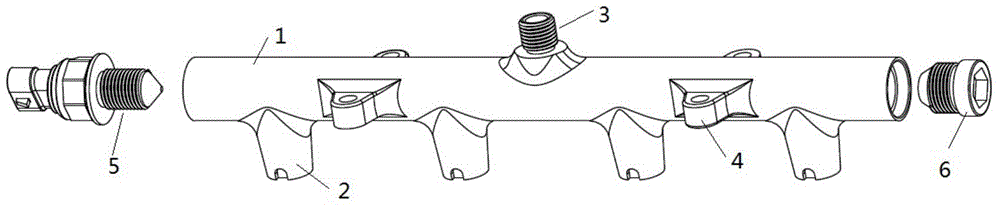

Gasoline direct injection high-pressure fuel distribution pipe manufacturing method

InactiveCN104863769AImprove pressure resistanceImprove sealingFuel injection apparatusMachines/enginesGasoline direct injectionFuel distribution

The invention relates to a gasoline direct injection high-pressure fuel distribution pipe manufacturing method. The method includes the specific steps that 1, hot forging forming is conducted on a main rail blank; 2, the plane and holes are machined in mounting supports; 3, the planes of the two ends of the main rail blank are machined, the forged surface is removed, the two ends are made to be circular planes, and the planes are perpendicular to the center line of a main pipe; 4, deep hole machining is conducted, 5, the sensor corresponding side on the main rail blank is machined, 6, the plug corresponding side on the main rail blank is machined; 7, an oil injection connector on the main rail blank is machined; 8, oil spray device bases are machined; 9, cleaning is conducted; 10, a plug is mounted; 11, a sensor is arranged; 12, a product obtained after sealing detection is conducted is sealed. The product obtained through the method is good in sealing performance, relatively small in part number, free of risk of deformation and leakage due to rack of fusion, relatively simple in process and free of brazing process and the like, energy sources are saved, and the potential safety hazards existing in machining are reduced.

Owner:SHANGHAI USUI ENGINE PARTS

Solid-solid phase change material and preparation method thereof

ActiveCN110669475AHigh latent heat of phase changeLow costHeat-exchange elementsFiberInorganic salts

The invention relates to a solid-solid phase change material and a preparation method thereof, and belongs to the field of phase change energy storage materials. The solid-solid phase change materialcomprises a component A and a component B, wherein the addition amount of the component A is 50-97% and the addition amount of the component B is 3-50% according to the percentage of the total mass ofthe raw materials, wherein the component A is a phase change material component, and comprises the following components in percentage by mass: 0-30% of an inorganic salt, 41-96.8% of water, 1-8% of fiber, 0.1-2% of a dispersant, 0.5-5% of a nucleating agent, 1-8% of a thickening agent and 0.5-6% of a heat conducting medium, wherein the component B is a curing component and comprises the followingcomponents in percentage by mass: 3-25% of isocyanate, 75-97% of hydrophilic polyether polyol and 20 ppm-200 ppm of A retarder accounting for the total mass of the component B. Compared with the existing water-based phase change material, the solid-solid phase change material provided by the invention not only furthest retains the characteristics of high phase change latent heat and low cost of the water-based phase change material, but also has no leakage risk and better heat conductivity.

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

Electric vehicle power battery box with efficient thermal dissipation

InactiveCN105742540ASmall temperature differenceImprove waterproof and dustproof performanceSecondary cellsCell component detailsPower batteryElectrical battery

The invention discloses an electric vehicle power battery box with efficient thermal dissipation. The electric vehicle power battery box comprises a battery box body, wherein multiple side-by-side grids used for placing single batteries are arranged in the battery box body; the grids and the single batteries form power battery modules; the grids are machined and shaped by thermal conducting aluminum sheets; preferably, the power battery modules are mounted in two layers in the battery box; the lower layer power battery module is mounted on the bottom plate of the battery box; the bottom surface of the upper layer power battery module and a thermal conducting apparatus are sealed; and a thermal conducting channel between the bottom surfaces of the power battery modules and the battery box is established through the thermal conducting apparatus. According to the electric vehicle power battery box provided by the invention, the single batteries are placed in the side-by-side grids; the thermal environments of each single battery are same; and therefore, the temperature differences of the single batteries in the battery box is reduced, and high thermal dissipation efficiency is achieved.

Owner:HIGER

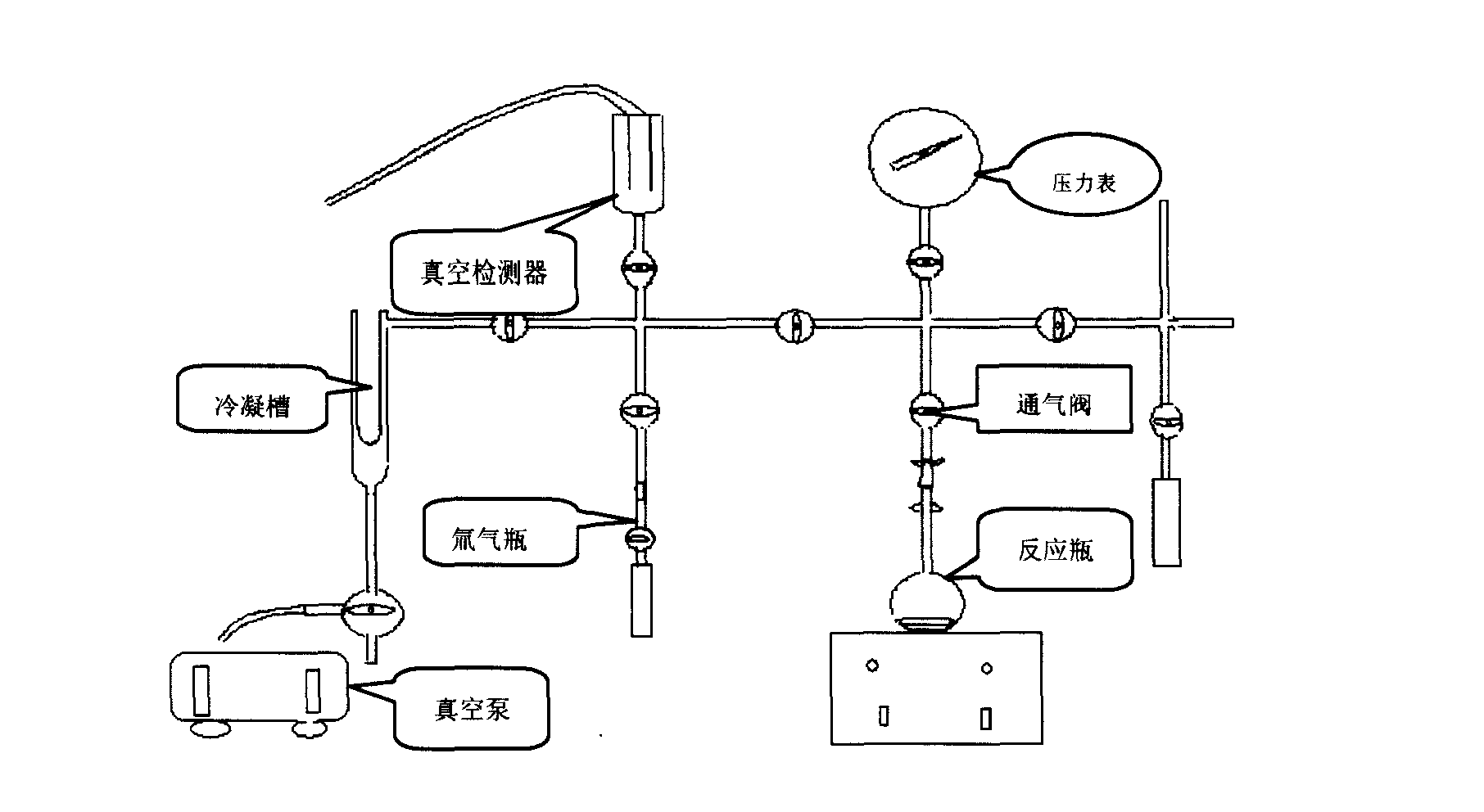

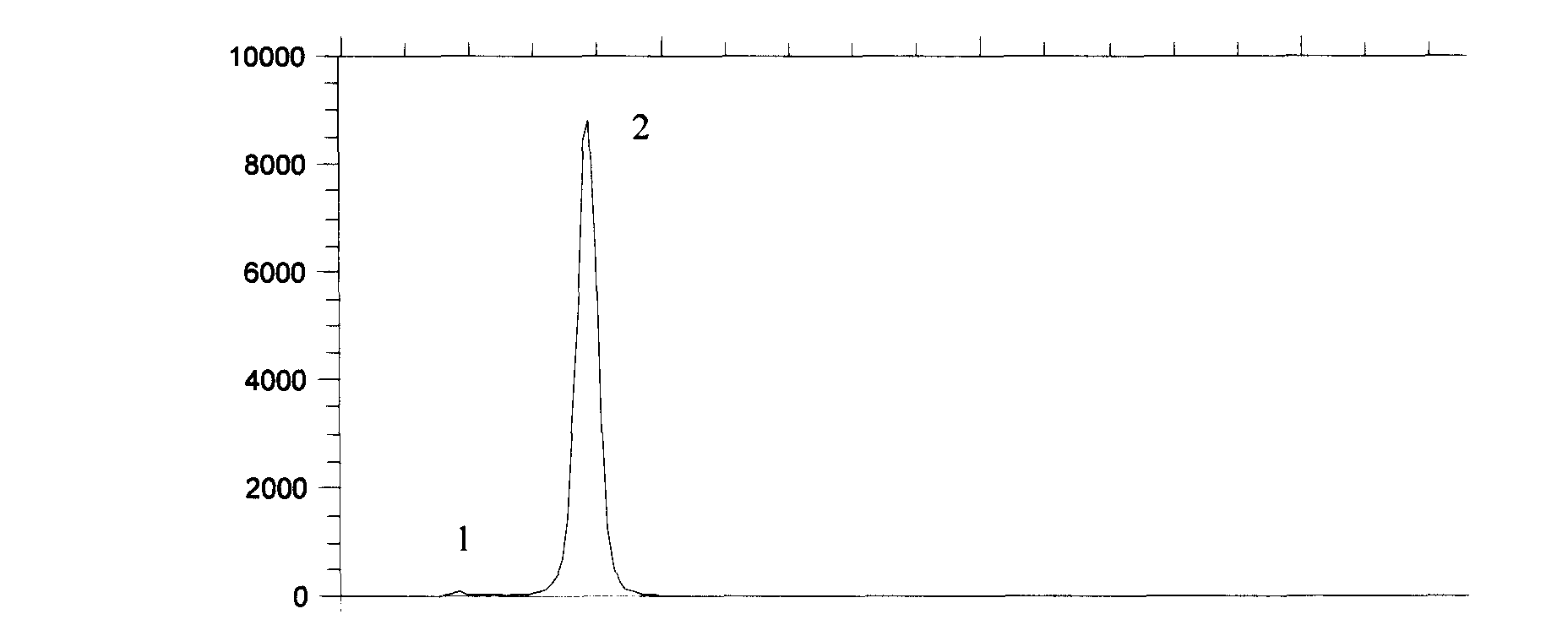

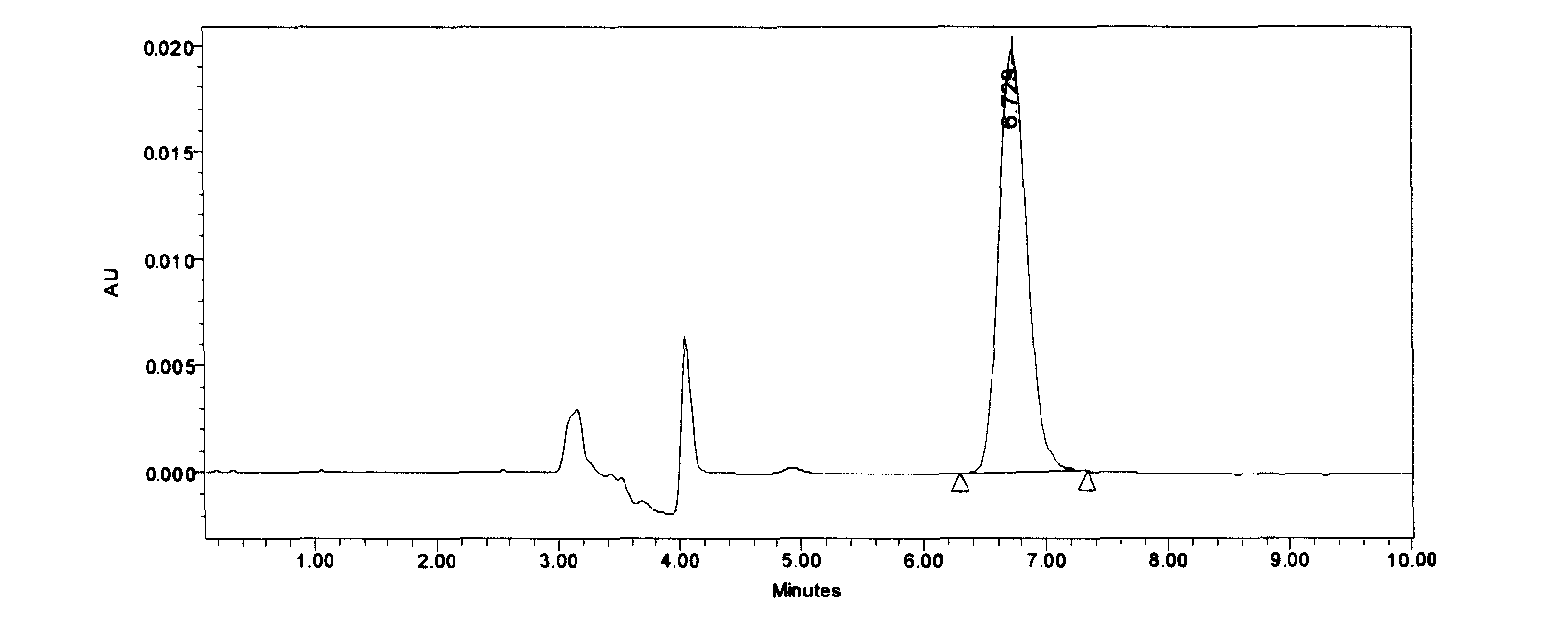

Preparation method of tritium or deuterium-labeled cyadox

InactiveCN101538249ARaw materials are easy to getReduce pollutionOrganic chemistryIn-vivo radioactive preparationsQuinoxalineDrug additive

The invention relates to a preparation method of a feed drug additive cyadox by tritium or deuterium labeling. The preparation method comprises the following steps: dehalogenating 4-bro-2-nitroaniline or 4-iodo-2-nitroaniline to exchange with tritium or deuterium in tritium gas or deuterium gas in the presence of a catalyst and an acid receptor to produce 4-[3]H-2-nitroaniline or 4-[2]H-2-nitroaniline; and preparing the tritium or deuterium-labeled cyadox by microsynthesis after an oxidation reaction, a Beirut reaction and a hydrazone forming reaction so as to obtain the tritium-labeled cyadox with high specific activity (12.63Ci / mmol), high radiochemical purity (above 98%) and high chemical purity (above 99.5%) or the deuterium-labeled cyadox with high chemical purity (above 99.5%). The method provides a material basis for systematic development of rules of absorption, distribution and metabolism of the cyadox in animals. The prepared 4-[3]H-2-nitroaniline or 4-[2]H-2-nitroaniline can be taken as a starting material for synthesizing all tritium or deuterium-labeled quinoxaline drugs without other substituents at the sixth place of a quinoxaline ring and is an important substance for synthesizing the tritium or deuterium-labeled drugs.

Owner:HUAZHONG AGRI UNIV

Dredging device for industrial drainage pipeline

The invention discloses a dredging device for an industrial drainage pipeline. The dredging device comprises a device box body. The left side and the right side of the device box body are provided with eight hinge spaces in left-right symmetry with openings facing the upper side and the lower side. When the device box body is put into the drainage pipeline, supporting rods can make contact with the pipe wall to make the device box body supported in the pipeline, when the device box body is put into another pipeline with a different diameter, a first motor is started to drive threaded slide rods to move up and down to be adjusted, the supporting rods can adjust the opening angle, inner blocking objects can be cleaned up as much as possible, some stubborn blocking objects left in the inner wall of the pipeline can be cleaned up through chemical reaction after chemicals are sprayed, the dredging device can perform quality detecting on the inner wall of the drainage pipeline in the advancing process, and it is ensured that the pipeline is free of leakage risk.

Owner:南京幸庄科技创新产业园管理有限公司

Power battery module

ActiveCN104716402AIncrease temperatureReduce the temperatureBattery isolationSecondary cellsPower batteryElectricity

The invention relates to a power battery module, mainly comprising monomer power batteries, an electric connection piece, a battery module casing cover and a casing; the monomer power batteries are stacked and installed in the casing, electrodes on both ends of the battery are respectively connected with the electric connection piece, the electric connection piece is insulatingly fixed on the casing, one end of the electric connection piece extends out of the casing, the casing and the casing cover are fixedly matched to form a module, endothermic gaskets are placed between the monomer power batteries, and the endothermic gaskets and the monomer power batteries are in mutual interval stacked arrangement. The power battery module can effectively control the module temperature in the appropriate operating temperature range, and improves the uniformity of the temperature. The power battery module can be widely used in the battery system of hybrid electric vehicles and pure electric vehicles, and also can be used as an energy storage unit in an energy storage system.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

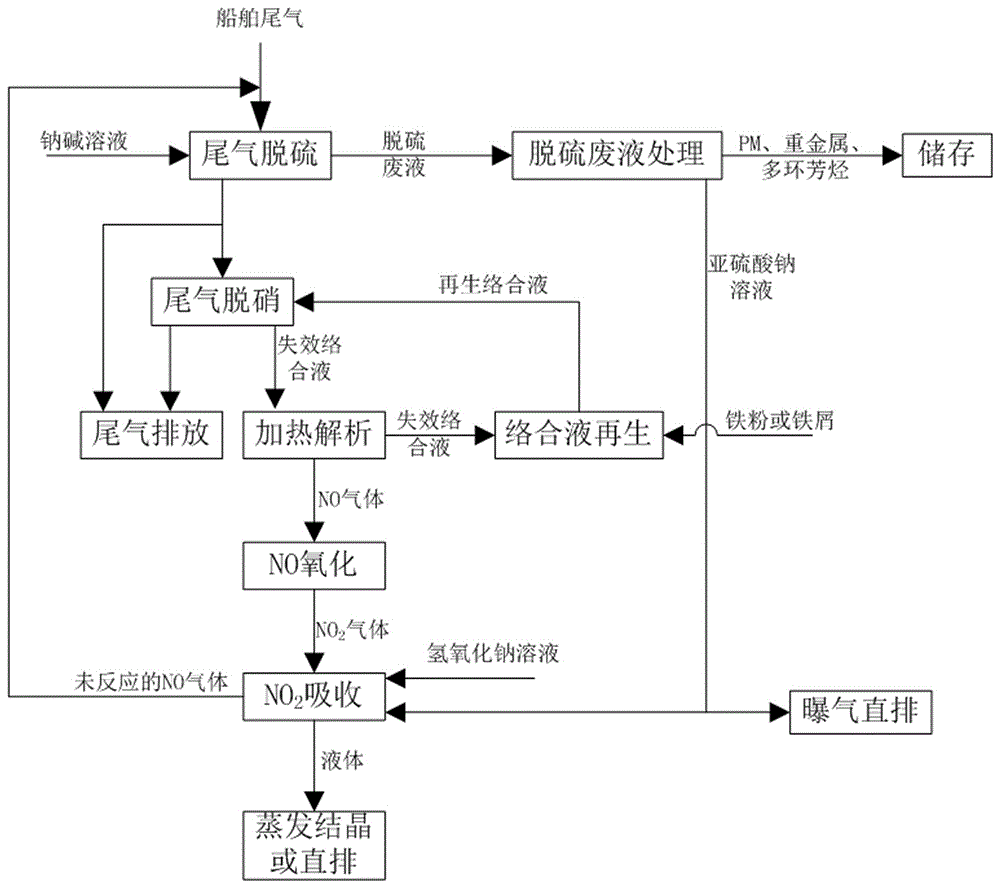

Marine exhaust gas after-treatment method

InactiveCN106237802ALow running costMild reaction conditionsGas treatmentDispersed particle separationChemistrySeawater

The invention discloses a marine exhaust gas after-treatment method. Exhaust gas generated by ships is introduced into a desulfurization and denitrification unified tower, absorbing desulfurization is conducted on the lower portion of the tower by means of sodium hydroxide solution, complexing denitrification can be achieved with complexing liquid on the upper portion of the tower, and exhaust gas up to standard after desulfurization and denitrification treatment is heated and then discharged out of a chimney; the complexing liquid after NO complexing is heated so that NO can be extracted; No extracted through heating is oxidized to be NO2 through catalytic oxidation or plasma oxidization, and then absorbed by sodium hydroxide solution or sodium sulfite solution. When ship usage meets the requirement for low-sulfur oil according to IMO convention, desulfurization is not needed, sodium alkali desulfurization section spraying liquid is changed to be seawater, and exhaust gas is cooled to prevent the temperature of a tower body from becoming too high. When ships sail in an area which does not need denitrification, a denitrification section complexing liquid sprinkling system is closed, and exhaust gas is heated and then directly discharged out of the chimney. In this way, separation and enrichment of NOX from exhaust gas is achieved, the concentration of NOx is improved, and the conversion rate of catalytic oxidation and plasma oxidization is increased.

Owner:SHANGHAI HENGYUAN MARINE EQUIP

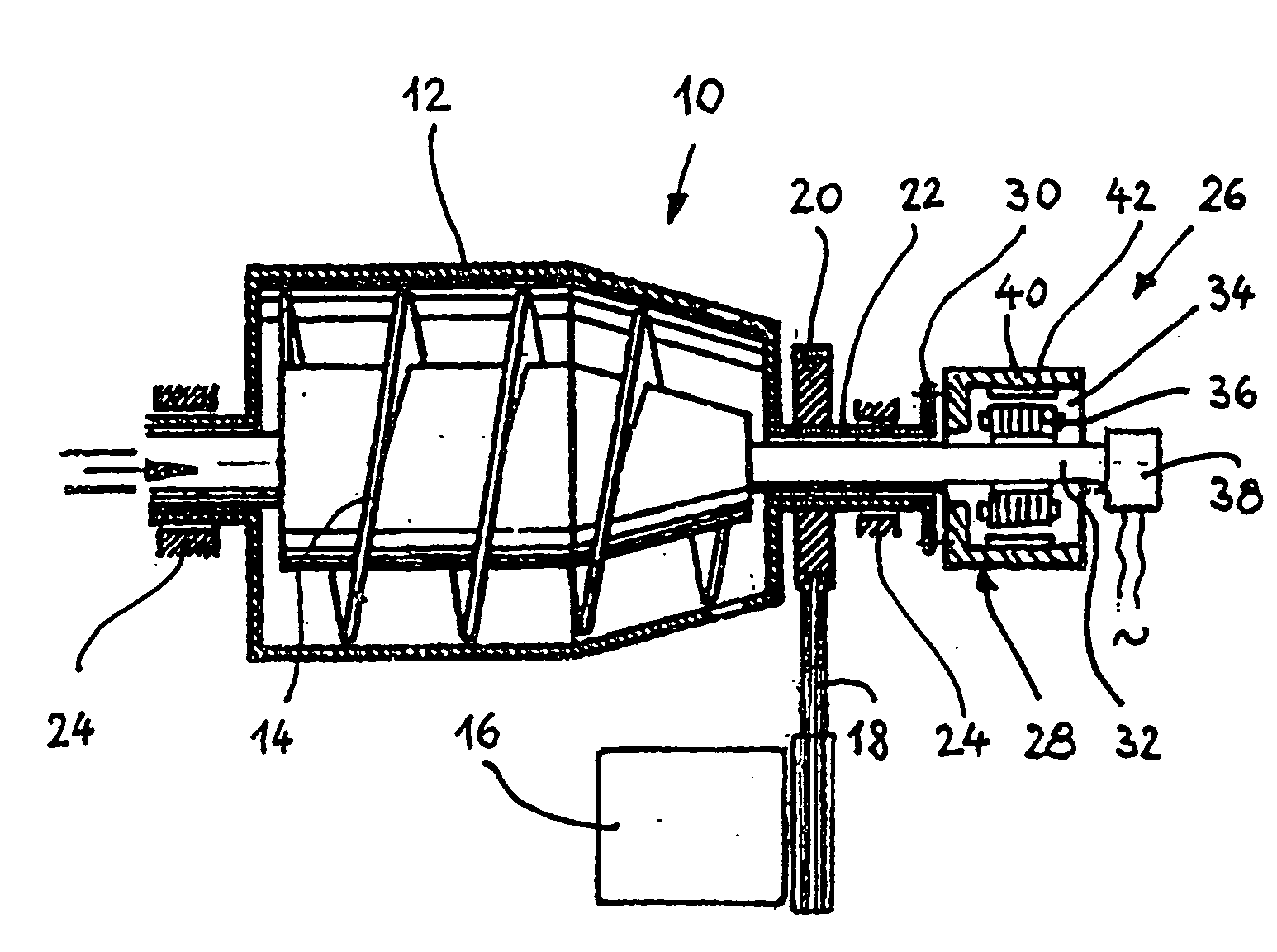

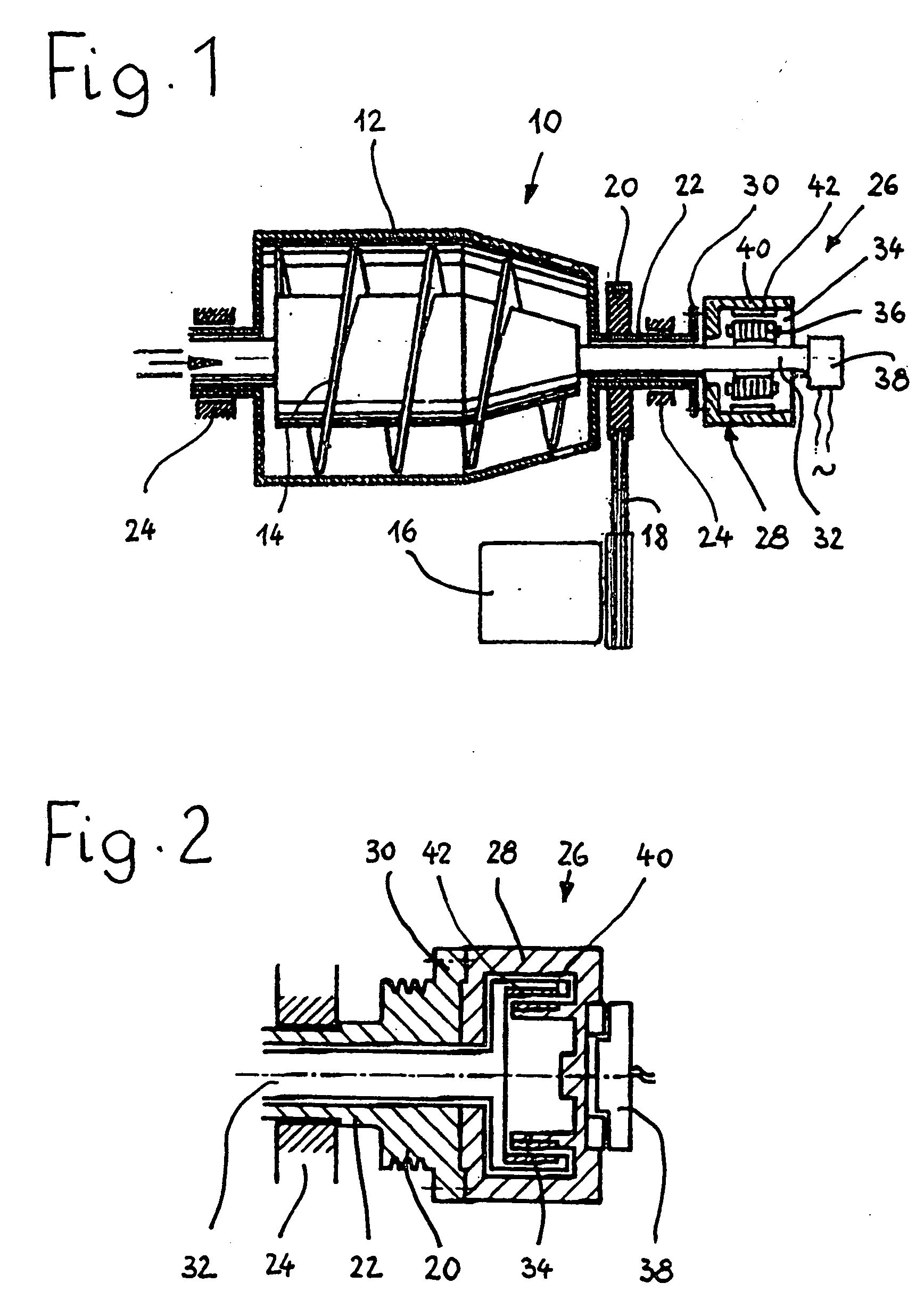

An agitator and a method of replacing a shaft seal of an agitator

ActiveCN104107649AQuick repairNo risk of leakageEngine sealsRotary stirring mixersDrive shaftCoupling

Owner:SULZER MANAGEMENT AG

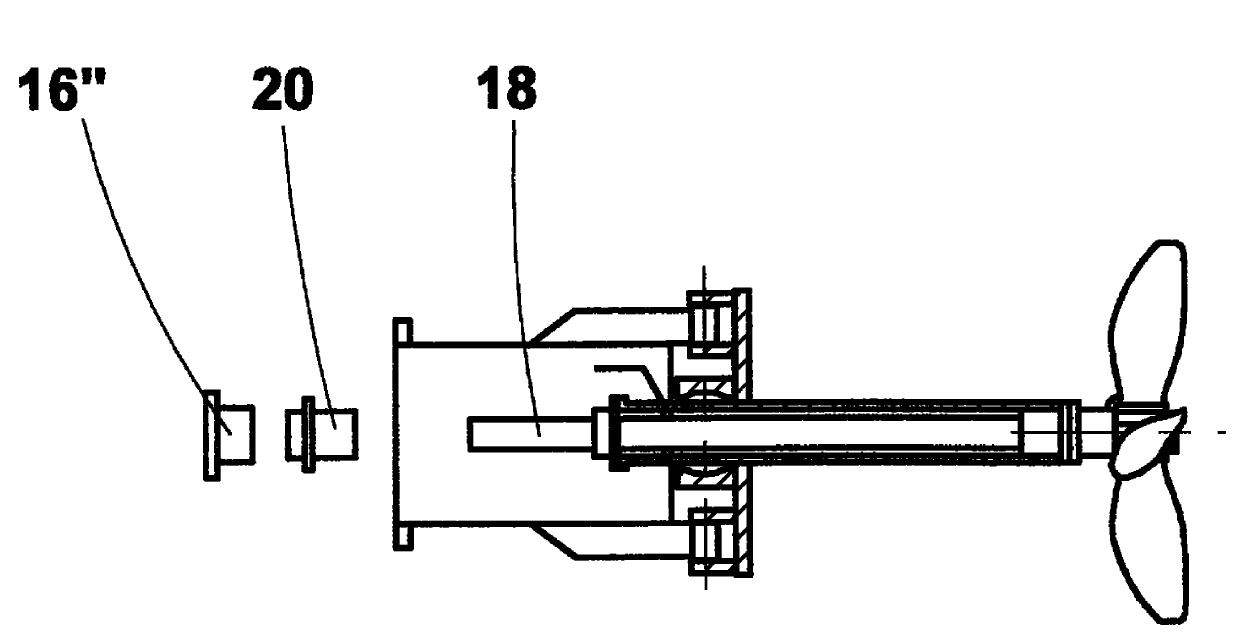

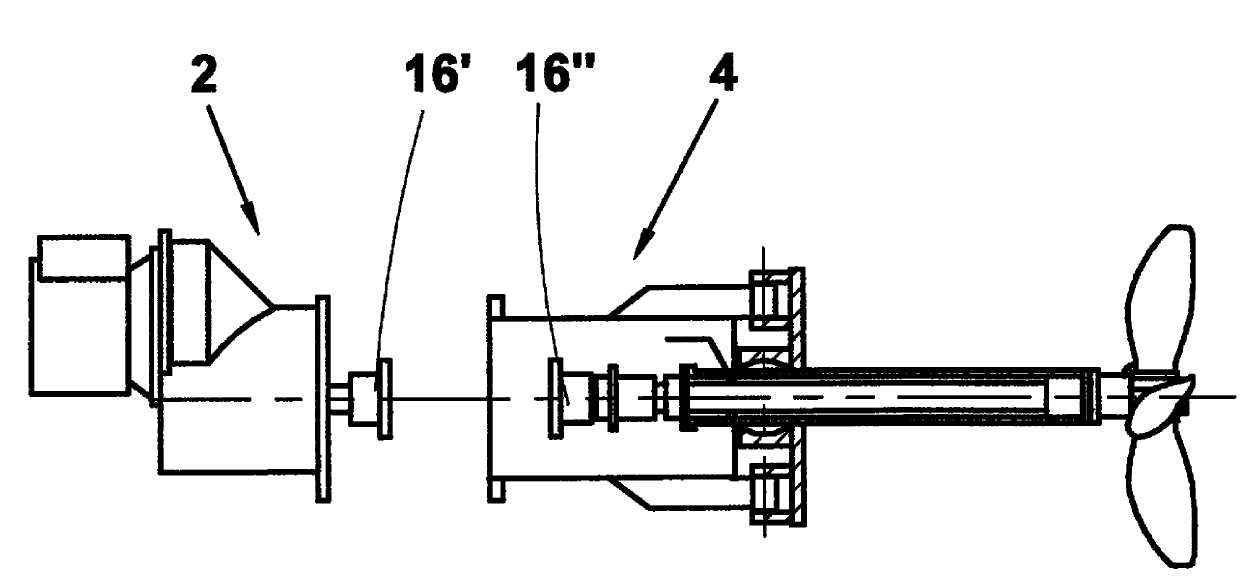

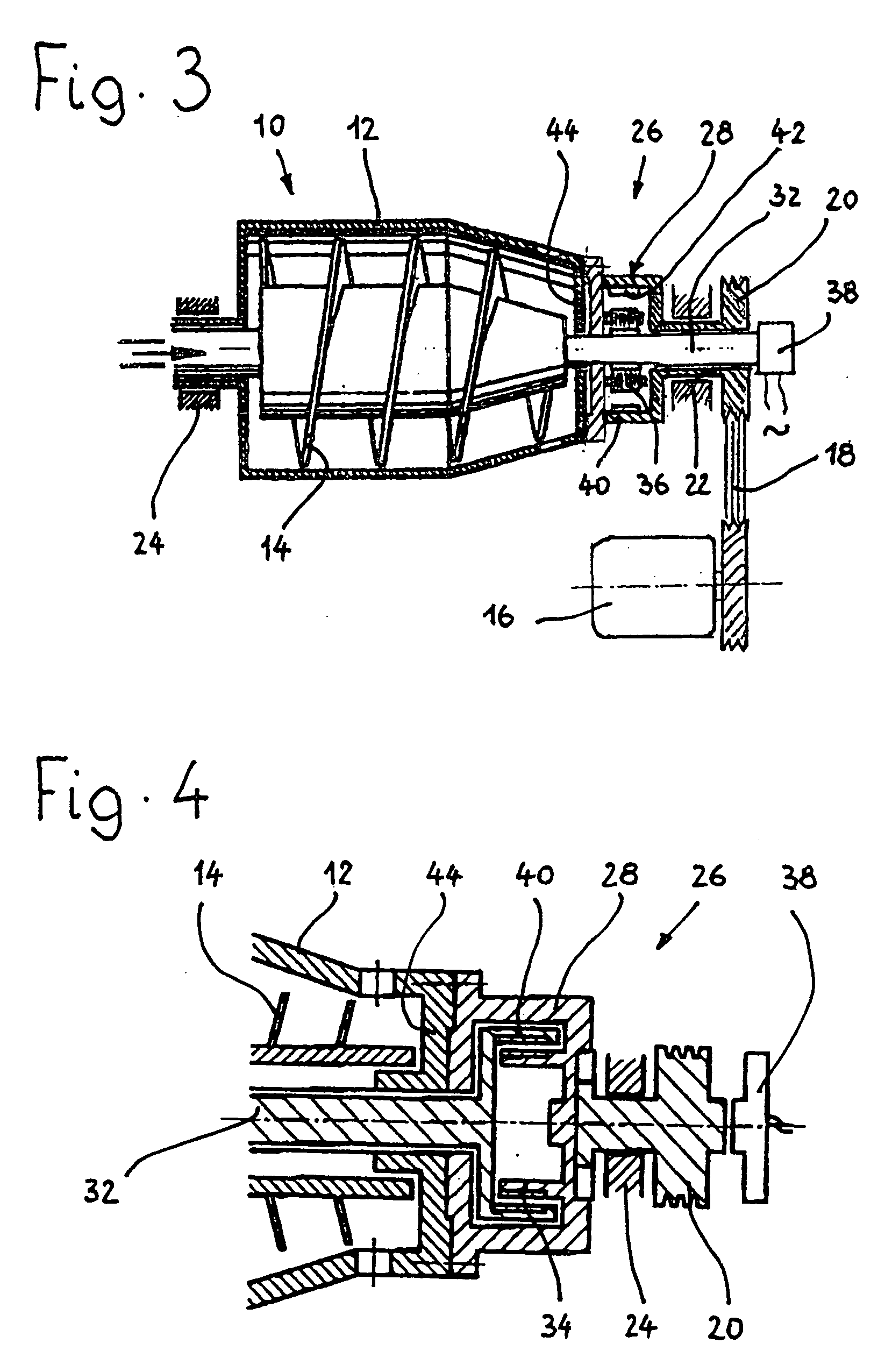

Drive device for screw centrifuges

InactiveUS20060014619A1Improve efficiencyIncrease flexibilityRotary centrifugesTorque motorEngineering

A drive device for screw centrifuges has a rotating drum driven by a drum driving motor, and a screw mounted coaxially in the drum and having a screw shaft. A screw drive motor for rotating the screw has a housing rotatably fixed to the drum and an electric torque motor rotatably fixed to the screw shaft and disconnected from the drum driving motor.

Owner:HILLER

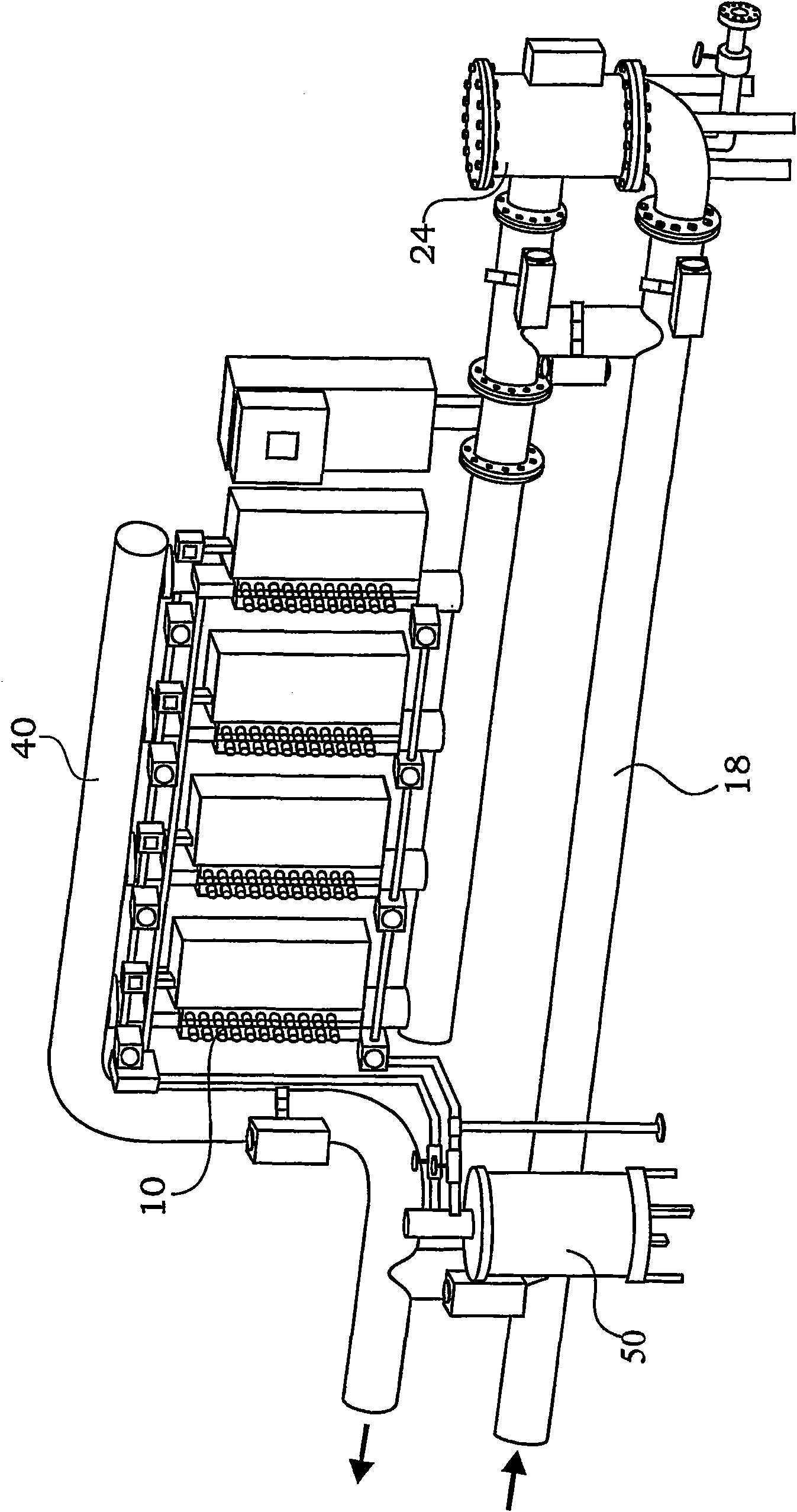

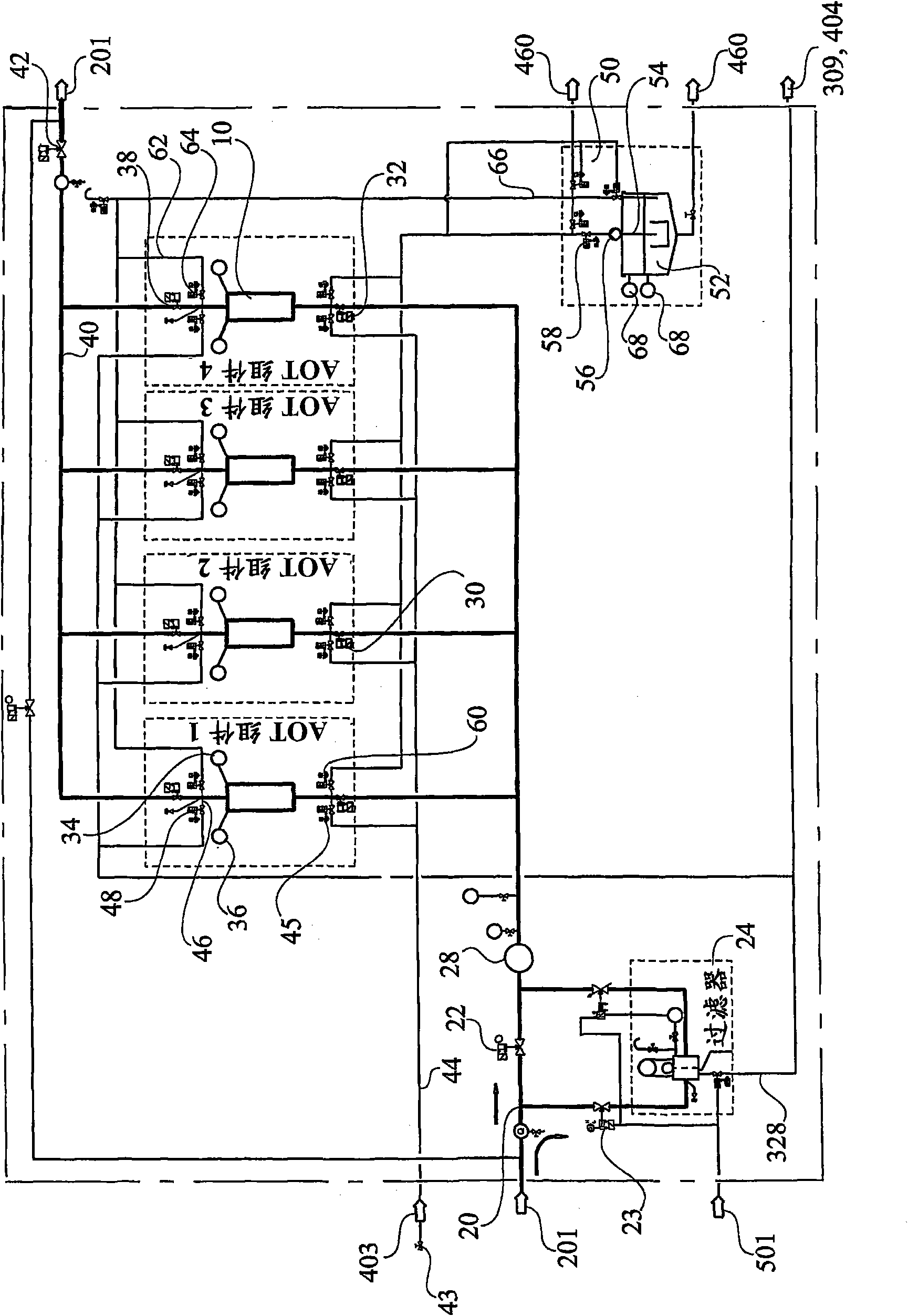

System of water treatment

InactiveCN101668706AReduce riskNo risk of leakageWater/sewage treatment by irradiationAuxillariesContaminated waterPiping

The present invention relates to a system for treating ballast water, comprising water inlets and outlets, piping connected to said inlets and outlets, at least one treatment unit connected to said piping, capable of, during operation, treating ballast water flowing through said unit, filter means for said ballast water and valve means for controlling the flow through said piping, treatment unit and filter means. The system is characterised in a control unit arranged and capable of managing and controlling all the different process sequences during start-up, ballasting, deballasting and cleaning as well as all failure functions and situations, whereby contaminated water is prevented from leaving the system. The present invention also relates to a process for treating ballast water, a method for controlling the process and software for performing the method.

Owner:ALFAWALL AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com