An agitator and a method of replacing a shaft seal of an agitator

一种搅拌器、轴封的技术,应用在化学仪器和方法、具有旋转搅拌装置的混合机、搅拌机配件等方向,能够解决增加驱动装置成本、支撑轴承受损、减速范围不能被应用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

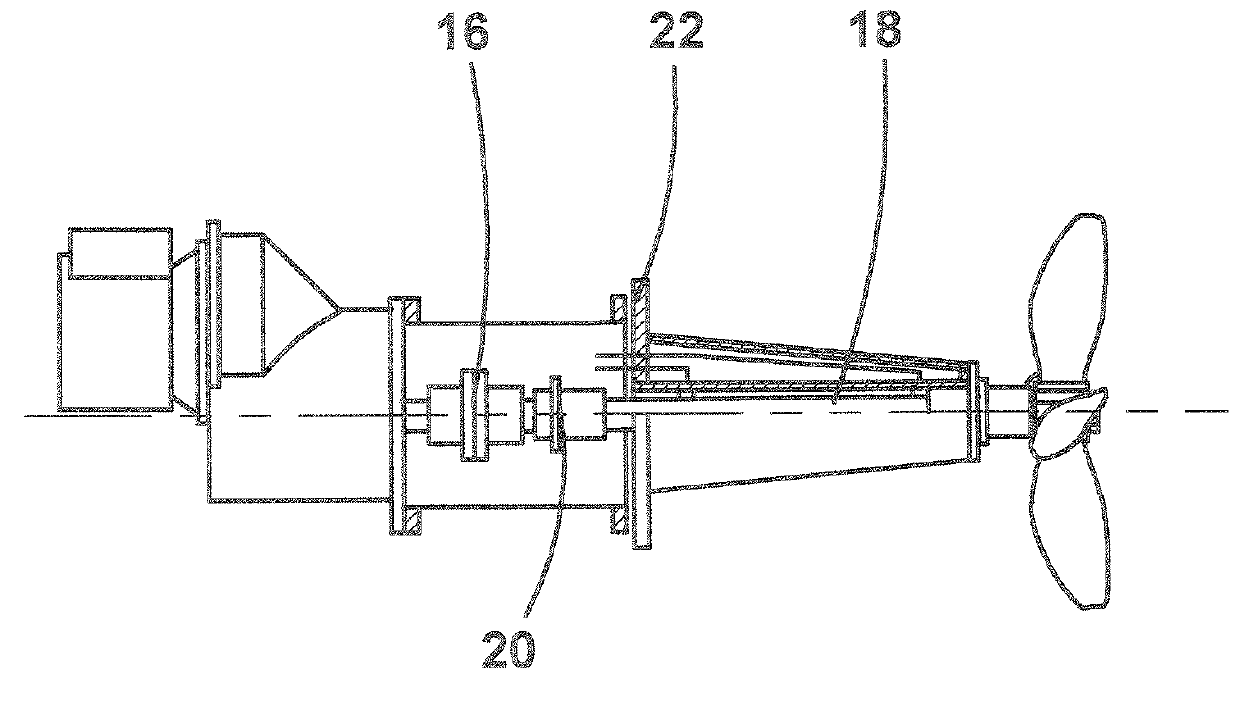

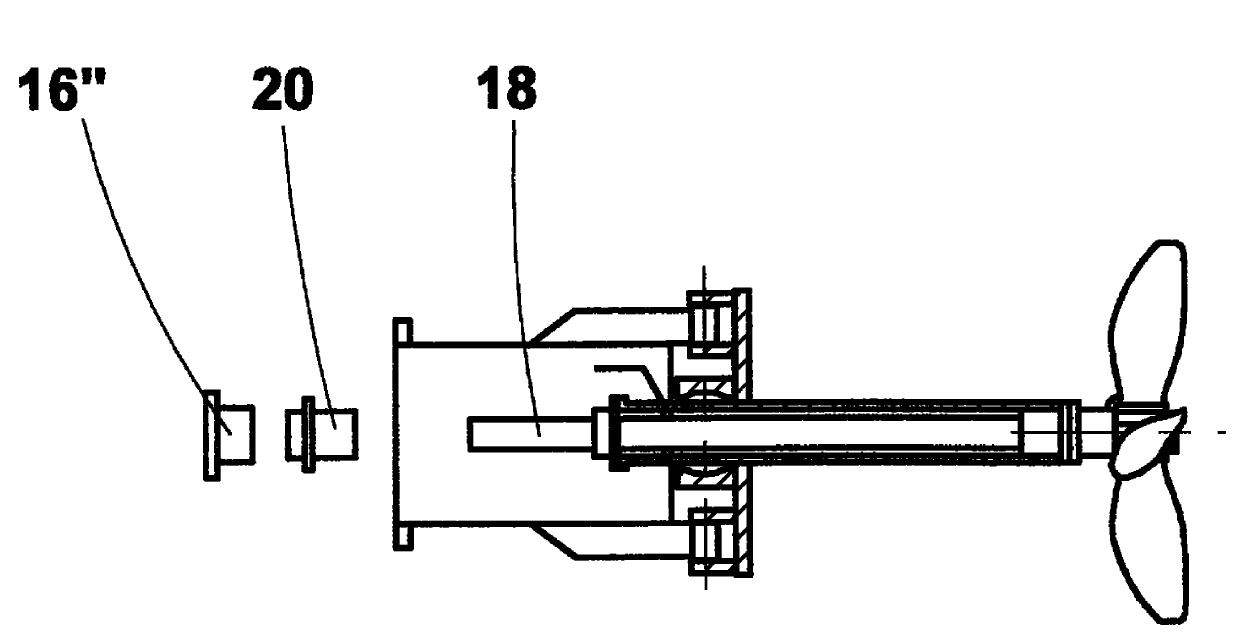

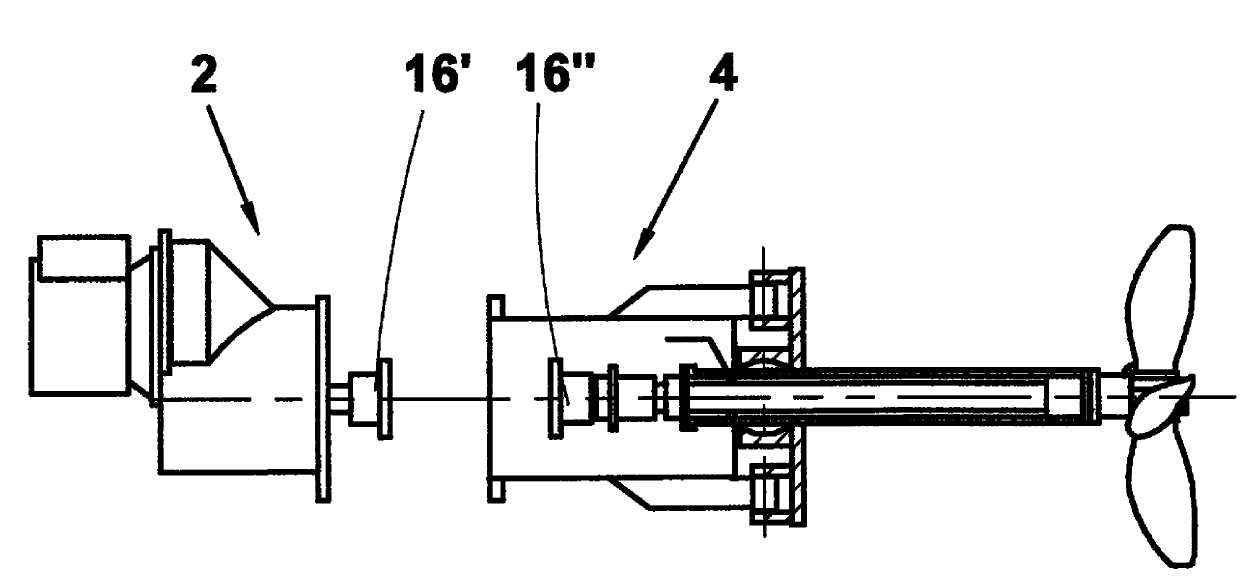

[0037] figure 1 A stirrer in its normal operating state according to a first preferred embodiment of the present invention is disclosed. The stirrer is formed by a drive unit 2 , an intermediate frame 4 , a support frame 6 and paddles 8 . The drive unit 2 comprises an electric motor 10, a reduction gear 12, a first drive shaft 14 (when a certain type of reduction gear is used) and the first half of a coupling 16 (when a certain type of coupling is used) . However, it must be understood that the coupling 16 may be any prior art coupling including, but not limited to, sleeve couplings, split sleeve couplings, and bushing couplings, whereby the coupling can All are considered to belong to the drive unit 2 or to the second drive shaft 18 . There are two basic types of reduction gears that can be used for this application. The first type shown has a first drive shaft extending from the gearbox so that the flange of a split sleeve coupling can be used. The second type has only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com