Joint type mechanical arm rapid disassembling and assembling system under nuclear radiation environment

A robotic arm and articulated technology, which is applied in the field of quick disassembly and assembly system of articulated robotic arms, can solve problems such as high operator fatigue, complex structural design, and intricate pipelines, and achieve shortened maintenance, large movement space, and simple process maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

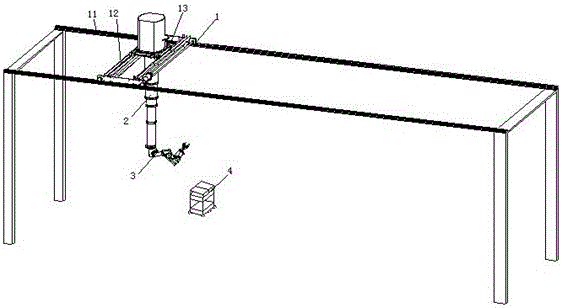

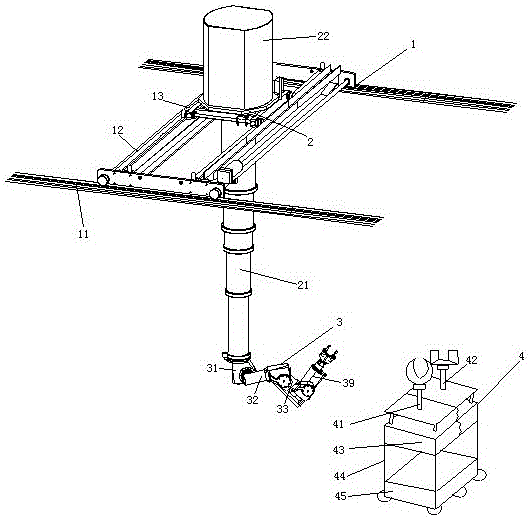

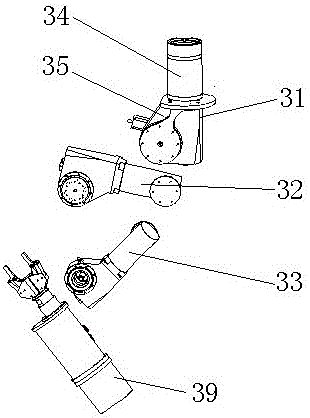

[0033]A fast disassembly and assembly system for an articulated manipulator in a nuclear radiation environment. The disassembly system works in a nuclear radiation environment. It is characterized in that the disassembly system mainly includes a manipulator linkage system and a manipulator assembly 3 , the loading and unloading mechanism 4 and the control system, the linkage system of the mechanical arm is linked with the mechanical arm assembly 3, the loading and unloading mechanism 4 is a disassembly tool for the mechanical arm assembly 3, and the activities are set in the working environment;

[0034] The mechanical arm linkage system is mainly composed of a cantilever type linkage mobile frame 1, a hanging type linkage telescopic tube 2 and a coupler, wherein the linkage mobile frame 1 mainly includes a straight rail fixed frame 11, a whole frame type mobile frame 12 and a sliding The support frame 13 and the straight rail fixed frame 11 are mainly arranged in parallel with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com