Electric vehicle power battery box with efficient thermal dissipation

A technology for power batteries and electric vehicles, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as performance degradation, liquid leakage, combustion and explosion, and achieve good waterproof and dustproof effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

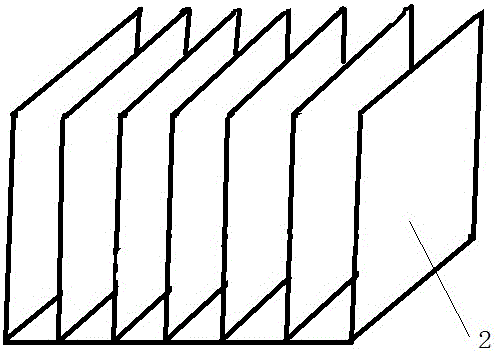

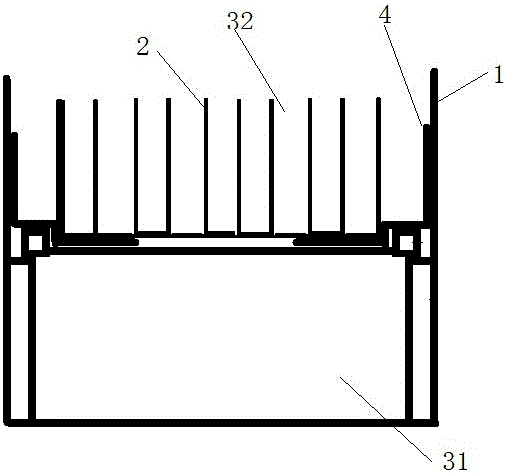

[0018] like figure 1 and 2 As shown, the high-efficiency heat dissipation electric vehicle power battery box disclosed by the present invention includes a battery box 1, and the battery box 1 is provided with a plurality of side-by-side grids 2 for placing single batteries respectively. The power battery module 3 is composed of a single battery, and the grid 2 is processed and formed by a heat-conducting aluminum sheet.

[0019] The upper end surface of the grid is not higher than the upper edge of the single battery. When using a plastic shell on the surface of the single battery, put it directly into the grid; when using a metal shell on the surface of the single battery, cover the surface of the single battery with a thin layer of heat-conducting insulating bag, and then put it into the grid.

[0020] The battery power battery modules 3 can all be installed on one layer of the bottom plate of the battery box. The bottom surface of each power battery module is in close con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com