Hemodialyzer with polypropylene material outer shell and manufacturing method thereof

A technology of hemodialysis and polypropylene, applied in the field of hemodialysis, can solve the problems of uneven fastening, sealing failure, looseness, etc., and achieve the effect of short molding cycle, good sealing and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

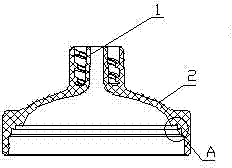

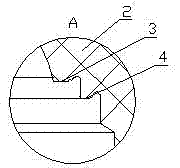

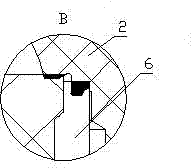

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 The hemodialyzer with a polypropylene shell as shown includes an outer shell and a membrane wire. The two ends of the membrane wire are fixed on the inner sides of the two ends of the outer shell by resin glue. The resin glue is usually made of polyurethane resin, which is non-toxic to hemodialysis. Side effects, good bonding performance and biocompatibility, fast curing time, low curing shrinkage, and low cost. The outer shell includes an end cover 2 and a tubular main body 6. The tubular main body 6 is provided with a dialysate input connection port 5 and a dialysate output connection port 7. The end caps 2 are arranged at both ends of the tubular main body, and the centers of the two end covers are respectively provided with blood The input connection port 8 and the blood output connection port 1; the above structure is the same as that of the prior art, and will not be repeated here. The present invention is ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com