Epoxy pouring type solid insulation switch with three-cabin

A solid insulated switch, epoxy casting technology, applied in the direction of electric switches, grounding switches, switchgear, etc., can solve the problems of large volume of switches and switch cabinets, inconvenient installation, poor scalability, etc., to achieve reliable overall performance, protection The effect of strictness and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

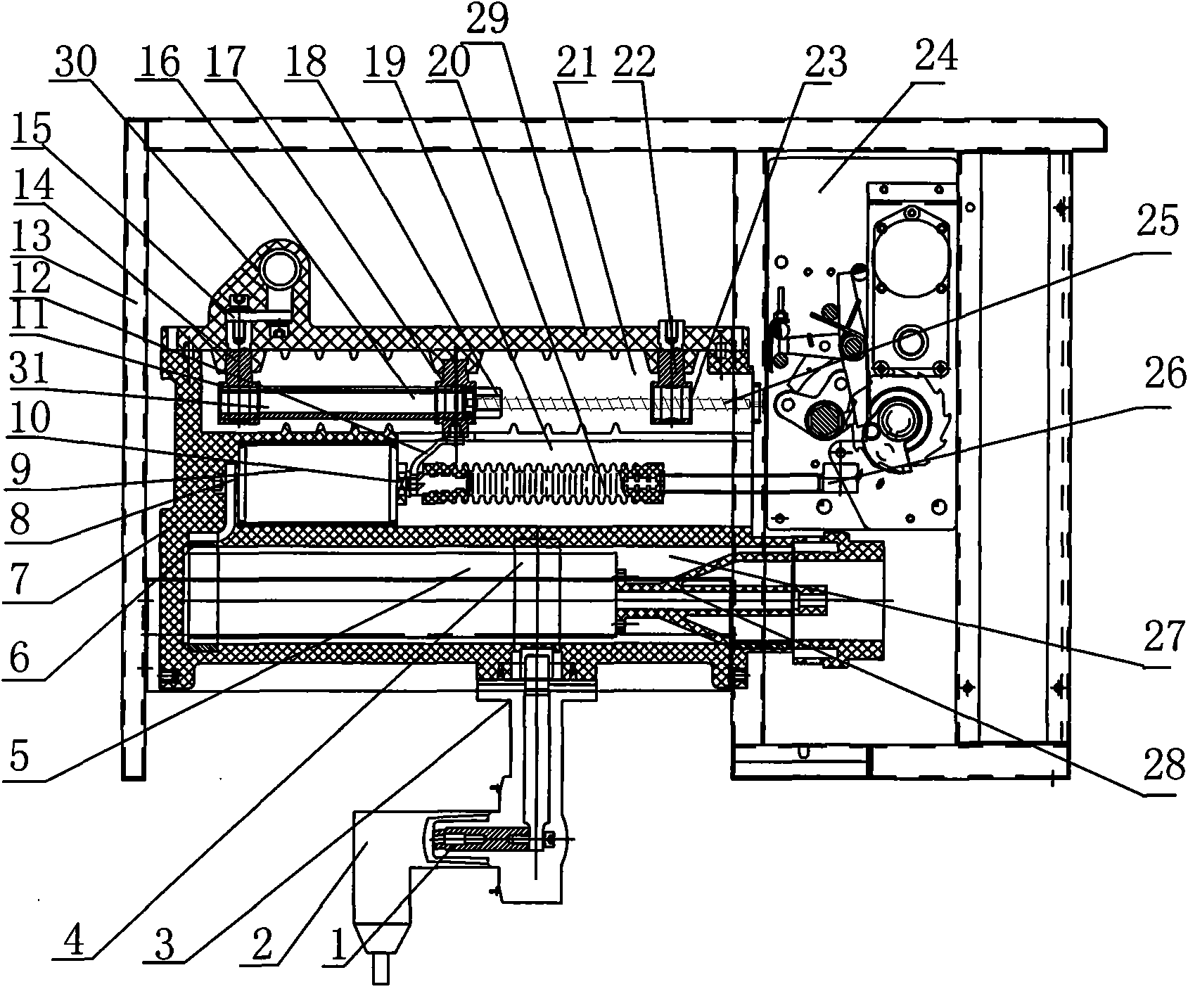

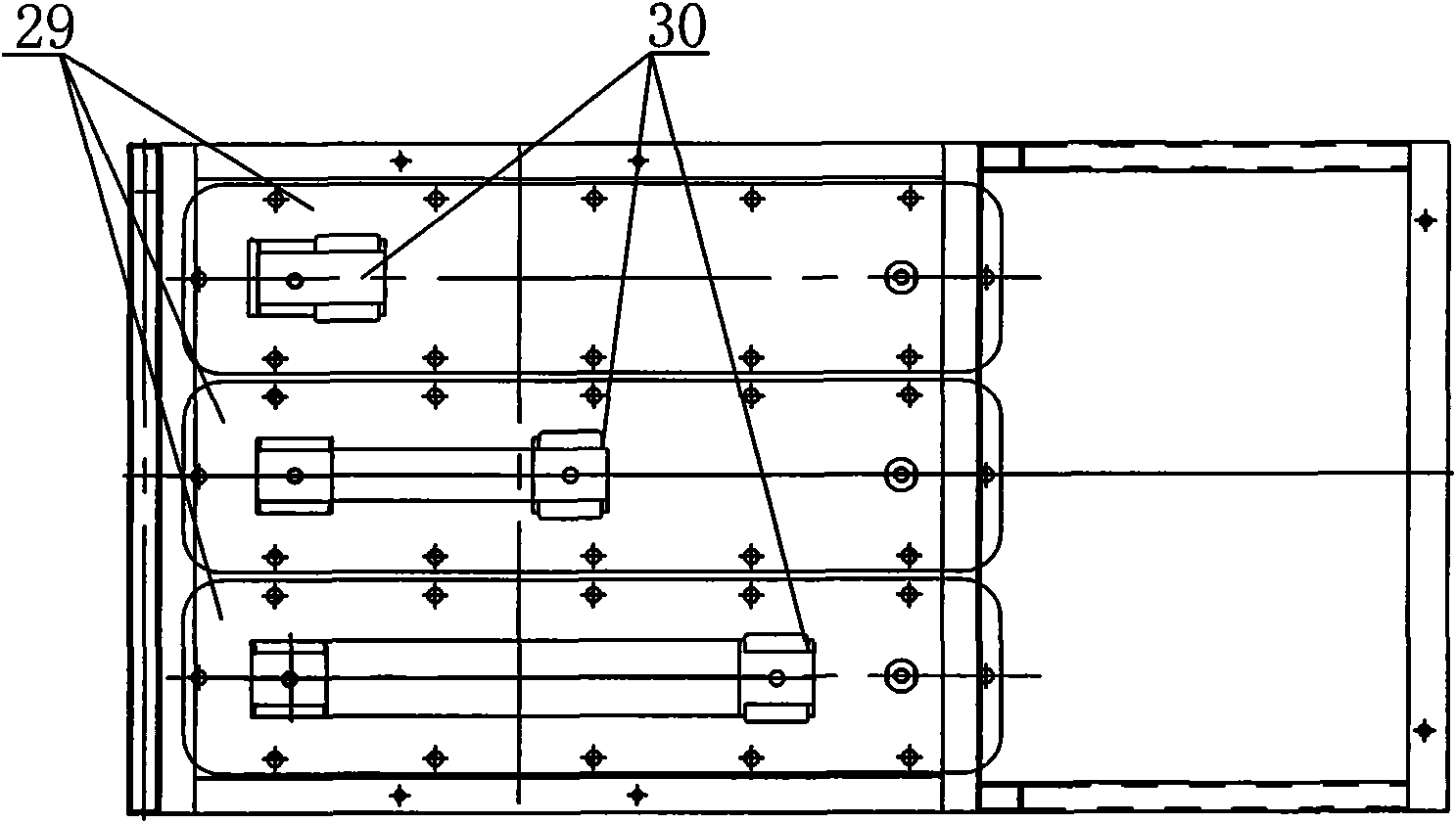

[0028] The manufacture and installation of the three-chamber epoxy cast solid insulated switch is very technical and manufacturable, and the whole switch is separated from the surrounding environment by processing the metal sheet of the shell 13 to play a role of protection and isolation. as attached figure 1 , 2 shown. The epoxy cast three-chamber solid insulated switch includes a housing 13 and three switch bodies 7 with the same structure corresponding to AC three-phase A, B and C installed in the housing 13 .

[0029] The switch body 7 includes an isolation compartment 21, a vacuum interrupter compartment 19 and a fuse compartment 27; the vacuum interrupter compartment 19 is located in the middle of the switch body 7, the isolation compartment 21 is located above the vacuum interrupter compartment 19, and the fuse compartment 27 Located below the vacuum interrupter cabin 19; the isolation cabin 21 includes an isolation switch 29, a bus contact 30, an isolation movable co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com