Marine exhaust gas after-treatment method

A ship exhaust gas and gas technology, which is applied in the post-treatment of ship exhaust gas and the field of ship exhaust gas treatment, can solve the problems of short life, only use low-sulfur oil, low catalytic activity, etc., to achieve increased concentration, low primary investment cost, The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

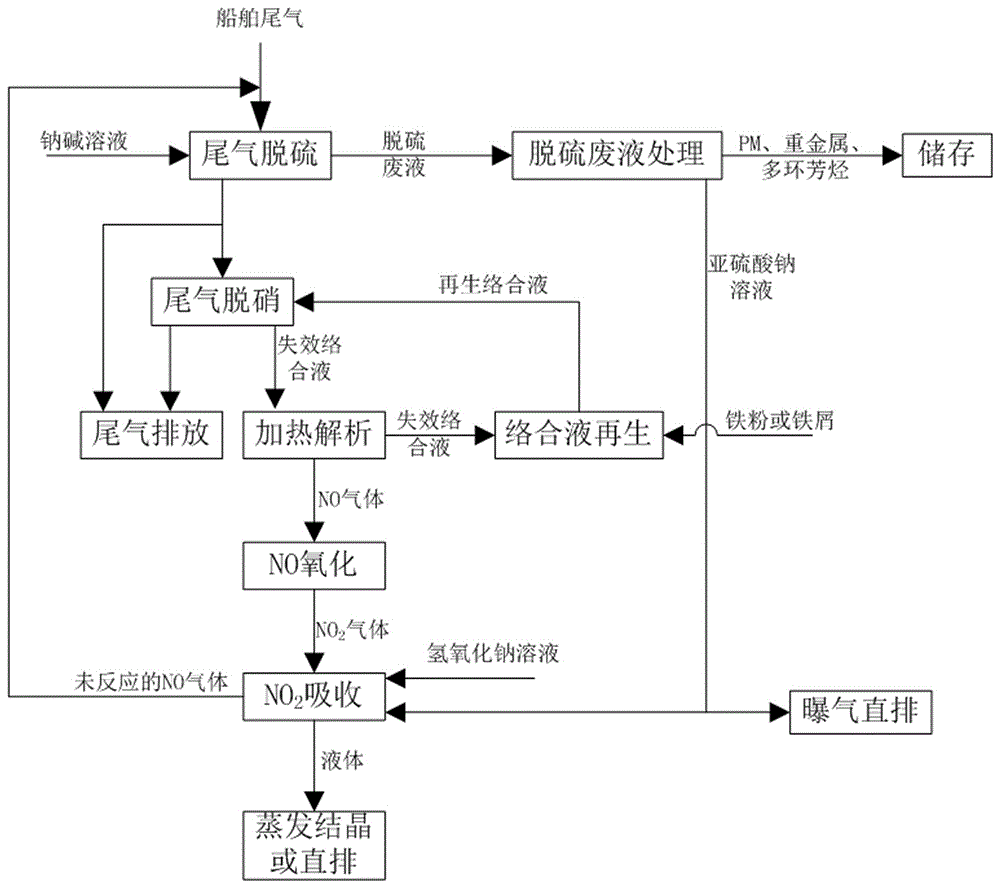

[0045] Such as figure 1 As shown, the present invention provides a kind of aftertreatment method of ship exhaust gas, comprises the following steps:

[0046] When desulfurization and denitration of ship exhaust gas are required, the following steps are included:

[0047] 1) A step of desulfurizing the tail gas of the ship, inputting the tail gas of the ship into the lower part of the desulfurization and denitrification comprehensive tower, and spraying the lower part of the desulfurization and denitrification comprehensive tower with sodium hydroxide solution to absorb SOx to form desulfurization waste liquid;

[0048] 2) A step of treating the desulfurization waste liquid. The desulfurization waste liquid is flocculated, flotation, and filtered to complete the purification of desulfurization washing water, and the purified sodium sulfite solution is used for subsequent NO 2 Absorption of gases; storage of particulate matter, heavy metals, and polycyclic aromatic hydrocarbons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com