Gasoline direct injection high-pressure fuel distribution pipe manufacturing method

A technology of high-pressure fuel oil and in-cylinder direct injection, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of low structural pressure bearing capacity, achieve high pressure resistance, good sealing performance, and reduce safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

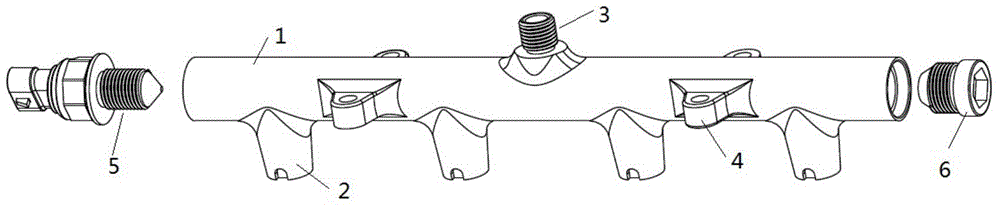

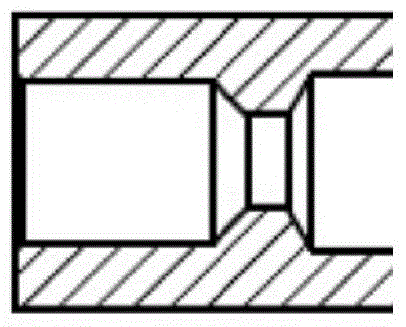

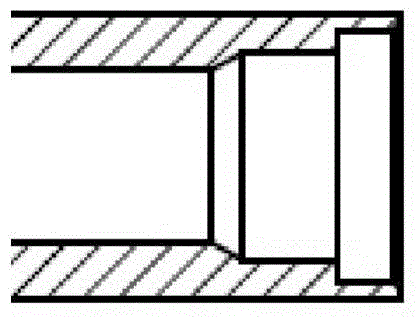

[0047] Please see attached figure 1 , 2, 3, 4, 5, 6, a kind of manufacture method of direct injection gasoline engine high-pressure fuel distribution pipe in cylinder, its specific steps are:

[0048] (1) Hot forging the main rail blank, the shape of the main rail blank is a round solid stainless steel metal rod with an outer diameter of 15-40mm;

[0049] The main rail is composed of the main pipe, injector seat, oil inlet joint and mounting bracket;

[0050] The main body of the main rail is a tube type.

[0051] (2) Process the plane and holes of the mounting brackets: the mounting brackets are evenly distributed on the main rail blank, the interval between adjacent mounting brackets is 10-200mm, and the number of mounting brackets is 2-10;

[0052] The center of the mounting bracket is provided with a circular hole, such as Figure 6 shown;

[0053] (3) Process the planes at both ends of the main rail blank, remove the forging surface, and make the two ends form a circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com