Anti-biological blocking device for drip irrigation system

An anti-biological and ozone generator technology, applied in watering devices, botanical equipment and methods, climate change adaptation, etc., can solve the problem that the anti-biological clogging effect and durability cannot be guaranteed, affect the efficiency and quality of drip irrigation, Limit the popularization and application of drip irrigation technology and other issues, and achieve the effect of improving convection and diffusion capacity, simple structure and less mechanical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

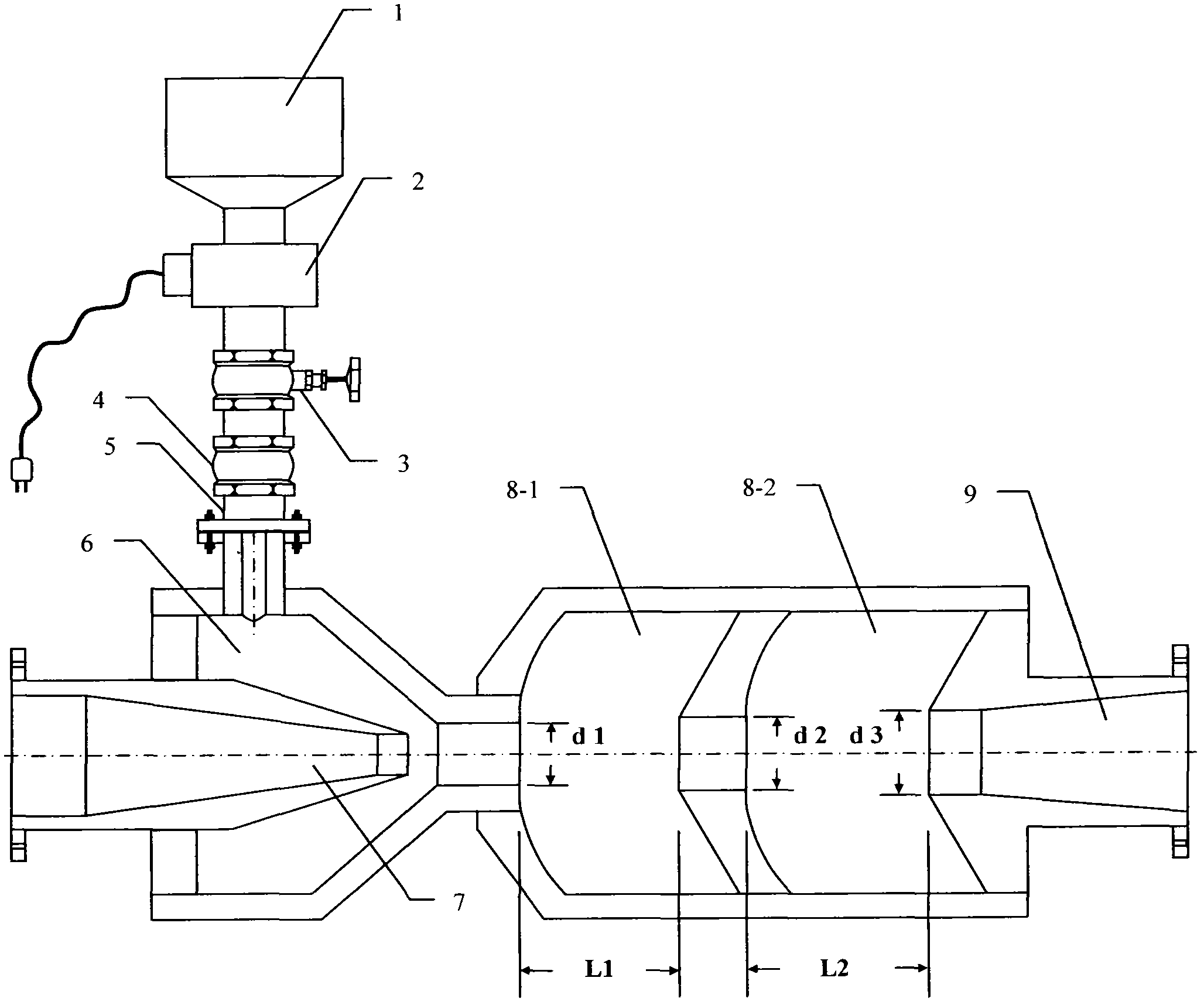

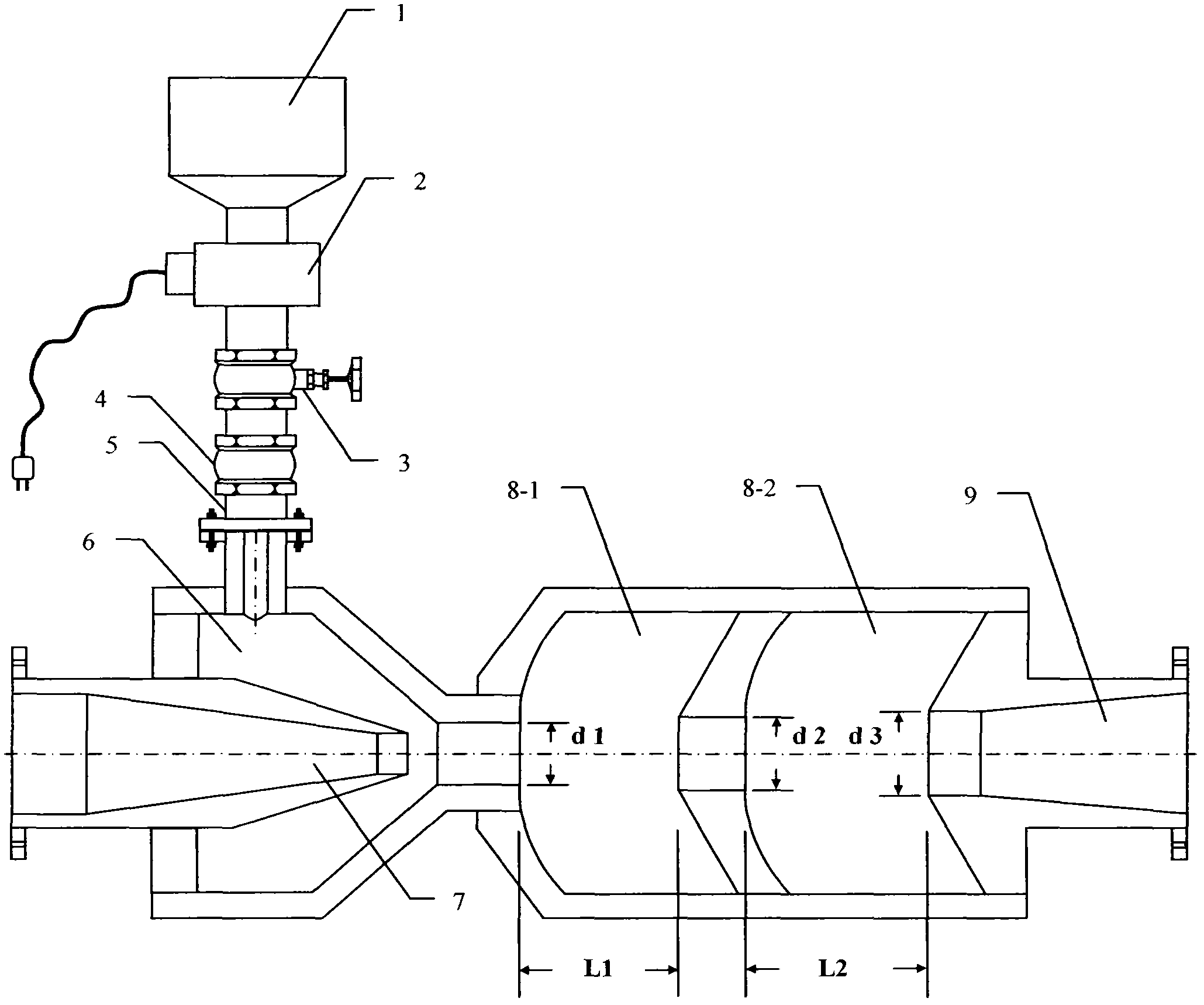

[0023]An anti-biological clogging device for a drip irrigation system, as shown in the accompanying drawings, including: an air filter 1, an ozone generator 2, an air intake gate valve 3, a check valve 4, an air intake pipe 5, an air injection chamber 6, and a jet nozzle 7 , a primary oscillation chamber 8-1, a secondary oscillation chamber 8-2, a gradual change channel 9, the outlet end of the air filter 1 passes through the ozone generator 2, the intake gate valve 3, the check valve 4, the intake pipe 5 and The air inlet end of the upper part of the gas injection chamber 6 is connected, and the end with a large flow section of the jet nozzle 7 is connected to the filter outlet end located at the head of the drip irrigation system. Inside the chamber 6, the horizontal outflow end of the gas injection chamber 6 is connected to the horizontal inflow end of the first-stage oscillation chamber 8-1 through a circular throat with a diameter of d1, and the injection port of the jet n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com