Mining explosion-proof all-insulation dry type transformer with amorphous alloy iron core for mobile transformer substation

A mobile substation and dry-type transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the problem of increased operating costs, poor operational reliability, and difficult Combustion and fire prevention and other issues, to achieve the effect of low noise, strong overload capacity, and small partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

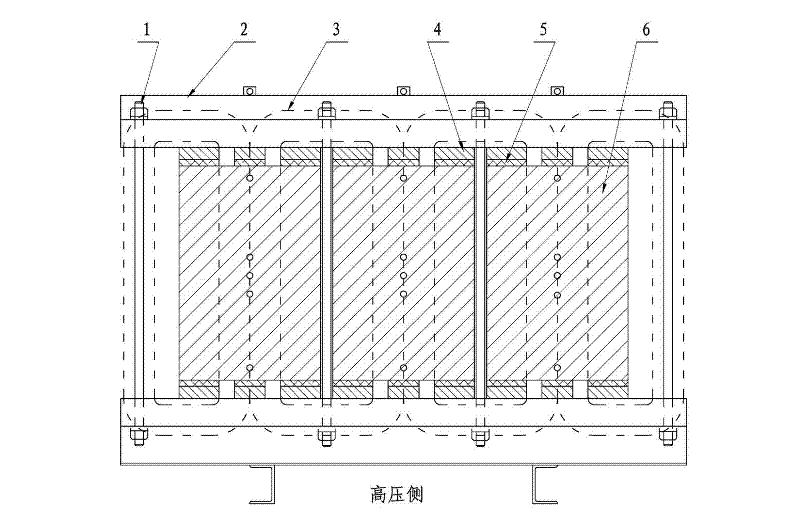

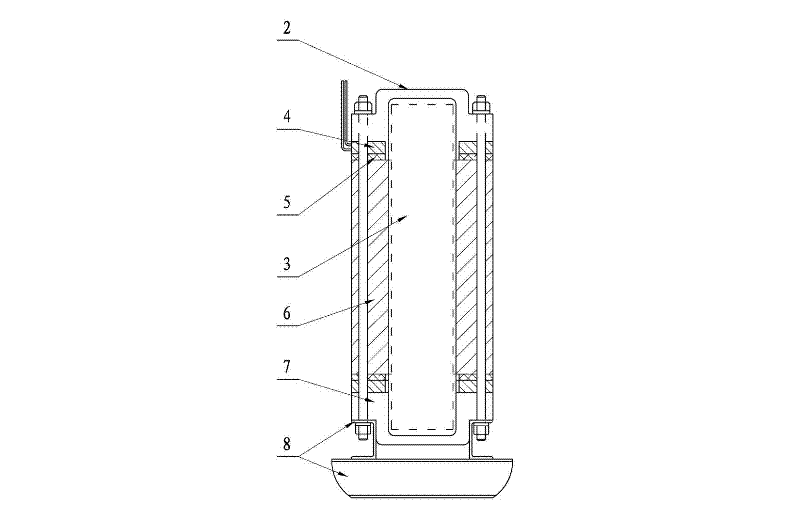

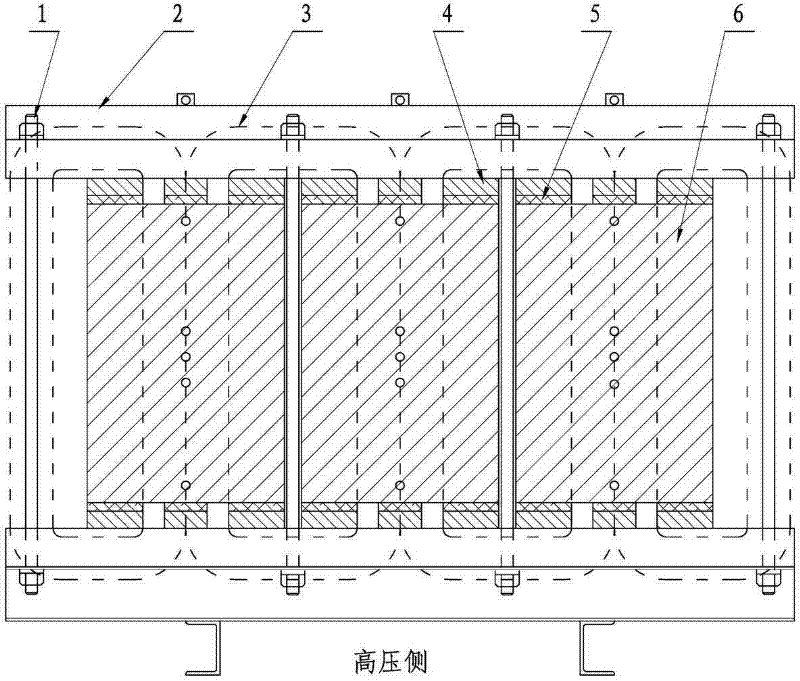

[0022] Below in conjunction with the present invention provide embodiment KBSHQG-T-630 / 10 type "amorphous alloy iron core epoxy resin casting fully insulated dry-type transformer" to further illustrate the concrete technical scheme of the present invention: as Figure 1 ~ Figure 2 As shown, this kind of amorphous alloy iron core fully insulated dry-type transformer for mining explosion-proof mobile substation includes an integral winding coil 6 composed of a low-voltage coil and a high-voltage coil, an iron core 3, an upper clamp 2, a lower Clamp 7, iron yoke pad 4, silicone rubber pad 5, pad 8 and the shell, wherein the iron core 3 is a three-phase five-column type, and the three central columns are respectively equipped with integral winding coils 6 and integral winding coils 6 The inner layer is provided with a low-voltage coil, and a high-voltage coil is installed on the outer layer of the low-voltage coil. The upper clamping piece 2 and the lower clamping piece 7 are buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com