Production technology for quick coupling tube

A production process and quick connection technology, applied in the field of connecting pipes, can solve the problems of cumbersome production steps, increase production cost, short service life, etc., and achieve the effects of low cost, high firmness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

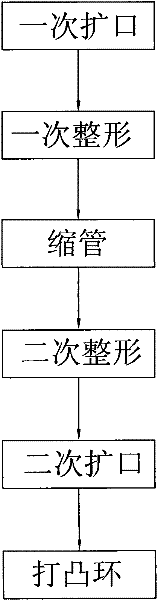

[0025] The present invention will be further described below with specific embodiment, see Figure 1-8 :

[0026] A production process for quick-connect pipes, comprising the following steps:

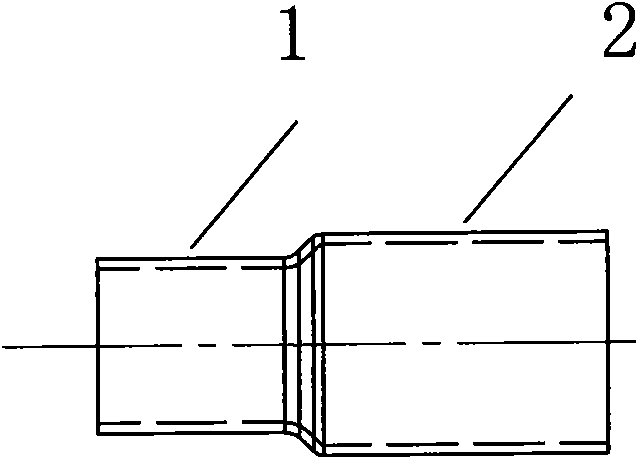

[0027] 1) One-time flaring: one end of the round pipe is flaring, and the round pipe becomes a large-diameter round pipe 2 at one end and a small-diameter round pipe 1 at the other end;

[0028] 2) One-time shaping: the round tube made in step 1) is shaped, and two sections of round tubes with different diameters are adjusted in place according to the length requirements;

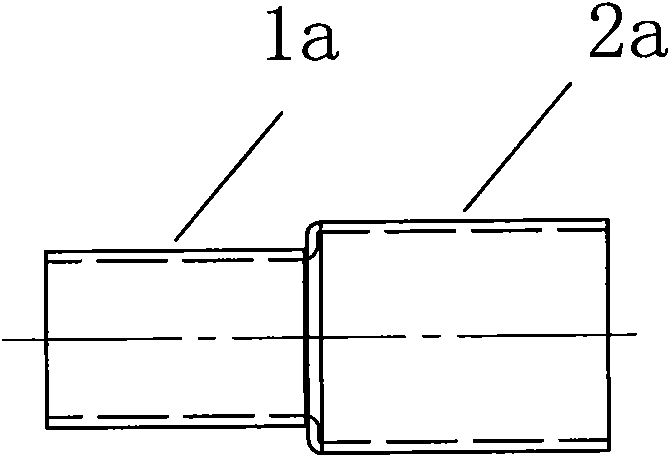

[0029] 3) Tube shrinking: shrink the right side of the large-diameter circular tube 2a made in step 2) according to the diameter of the small-diameter circular tube 1a to form a tube-shrinking section 2b, and the left side of the large-diameter circular tube 2a has an outward protrusion The large convex ring 3;

[0030] 4) secondary shaping: carry out secondary shaping to the circular tube made in step 3), and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com