Method for preparing Nano tube of zirconium dioxide

A technology of zirconium dioxide and nanotubes, which is applied in the field of preparation of zirconium dioxide nanotubes, can solve the problems of poor uniformity of the tube wall of nanotubes, complex process, environmental pollution, etc. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

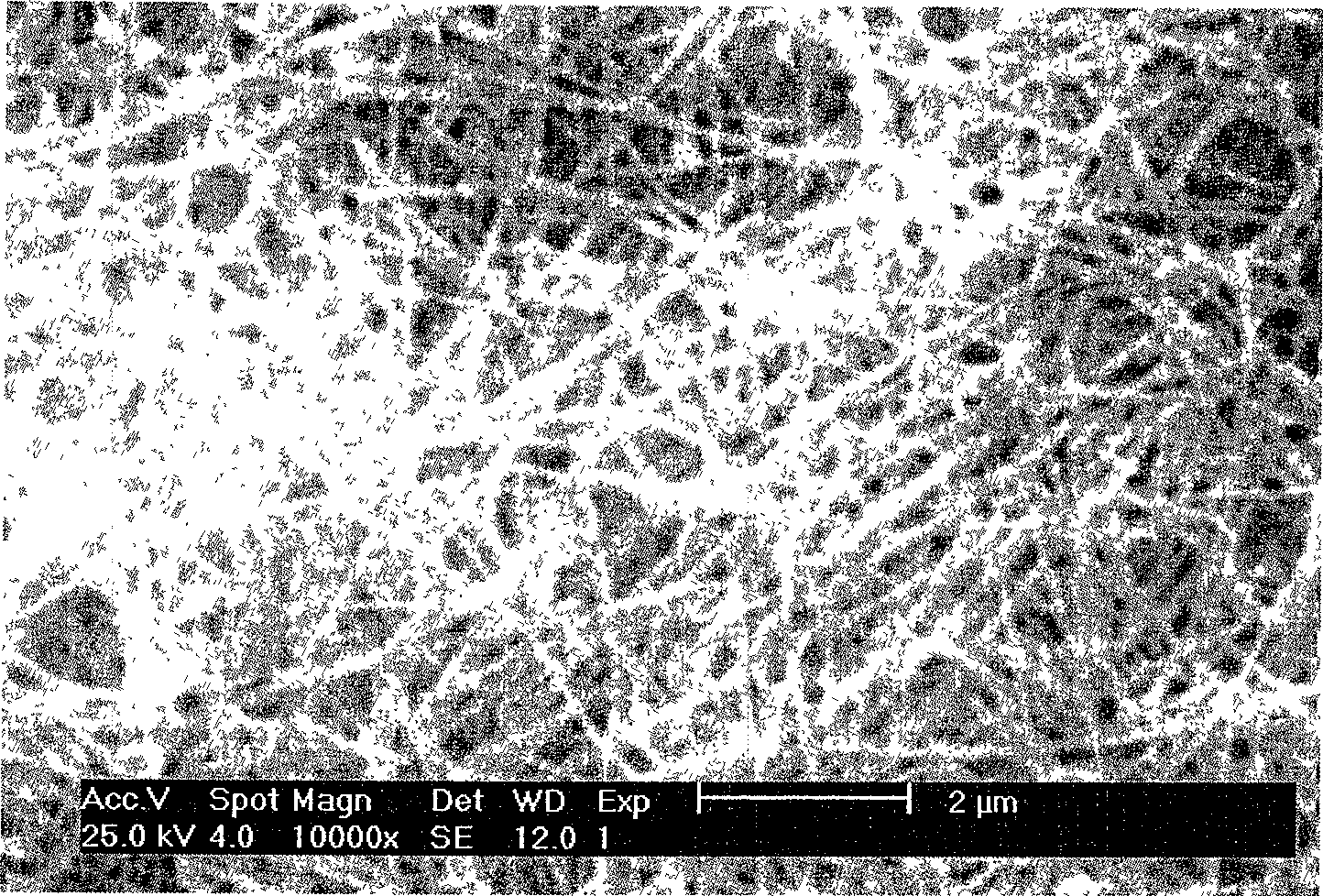

Image

Examples

Embodiment 1

[0019] Mix formamide and glycerin at a volume ratio of 1:1, use the mixed solvent to prepare a sodium fluoride solution with a concentration of 0.5% by weight, put the sodium fluoride solution into the reaction vessel, use the zirconium sheet as the anode, and the platinum sheet as the cathode , the distance between the anode and the cathode is 1.5cm, and the anodic oxidation reaction is carried out at room temperature with 90V direct current, and zirconia nanotubes are formed on the surface of the zirconium sheet. As the reaction progresses, the zirconia nanotubes formed on the surface of the zirconium sheet continue to fall off. After the reaction, the zirconium dioxide nanotubes sinking to the bottom of the reaction vessel were separated, washed with water, and dried at 105° C. to obtain the zirconium dioxide nanotube product.

Embodiment 2

[0021] Mix formamide and ethylene glycol at a volume ratio of 2:1, use the mixed solvent to prepare a solution of 0.5% potassium fluoride and 0.5% ammonium fluoride by weight, and add the fluoride solution to the reaction vessel. The platinum sheet was used as the anode, and the platinum sheet was used as the cathode, the distance between the anode and the cathode was 1.5 cm, and the anodic oxidation reaction was carried out at room temperature with 30V direct current. After the reaction, the zirconium dioxide nanotubes sinking to the bottom of the reaction vessel were separated, washed with water, and dried at 105° C. to obtain the zirconium dioxide nanotube product.

Embodiment 3

[0023] Mix formamide and ethanol at a volume ratio of 3:1, use the mixed solvent to prepare an ammonium fluoride solution with a concentration of 1.5% by weight, put the ammonium fluoride solution into the reaction vessel, use the zirconium sheet as the anode, and the graphite sheet as the cathode , the distance between the anode and the cathode is 1.5cm, and the anodic oxidation reaction is carried out at room temperature with 10V direct current. After the reaction, the zirconium dioxide nanotubes sinking to the bottom of the reaction vessel were separated, washed with water, and dried at 105° C. to obtain the zirconium dioxide nanotube product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com