Tee extrusion method

A technology of extrusion forming and tee, which is applied in the field of metal pipe fittings processing, can solve the problems of inconsistent wall thickness of workpieces, low processing qualification rate, and waste products, so as to reduce product scrap rate, high appearance quality, and clean working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

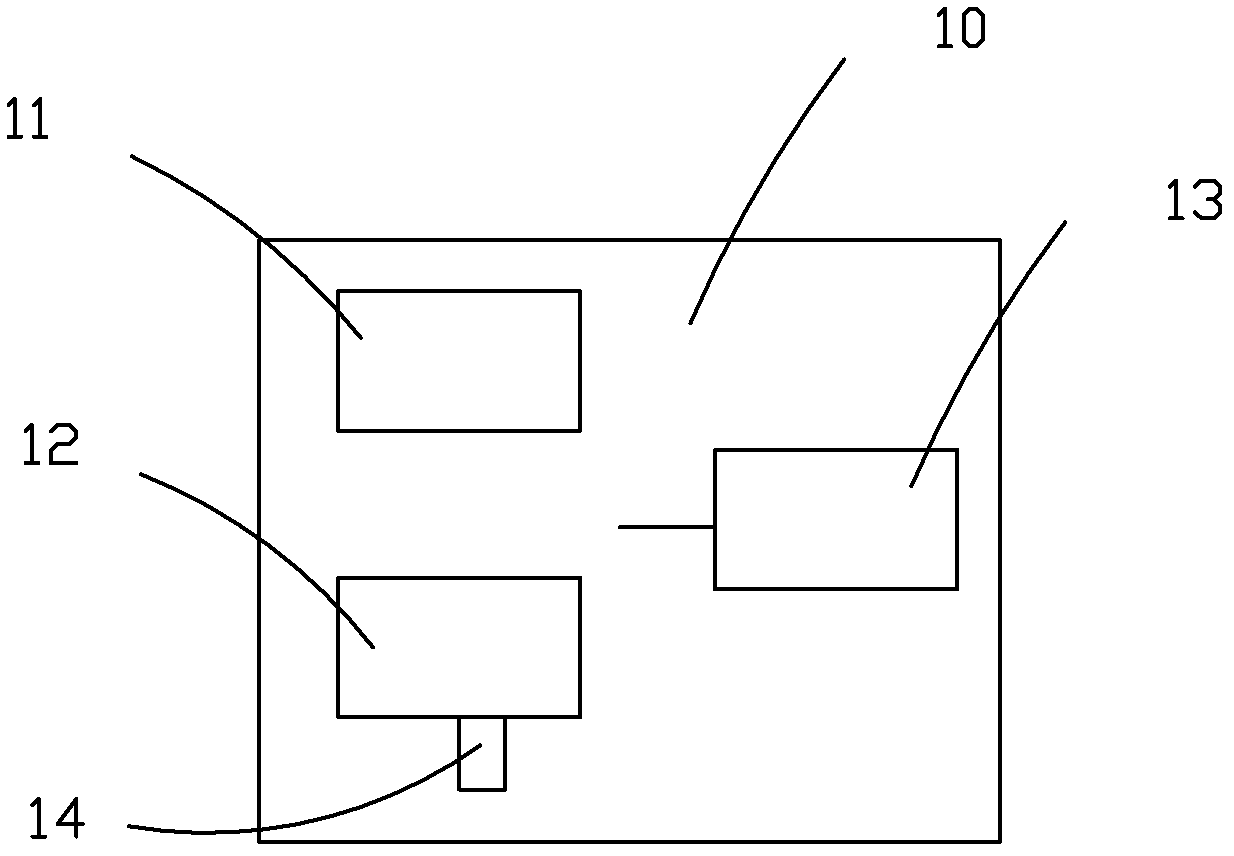

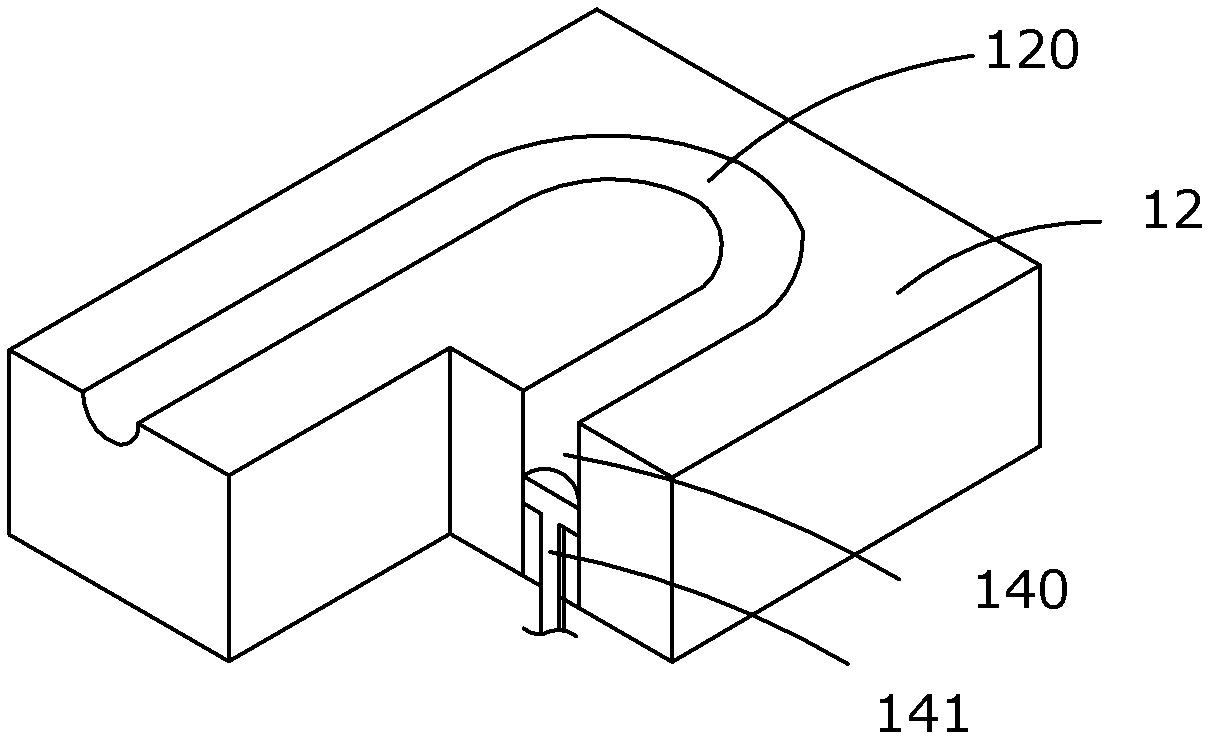

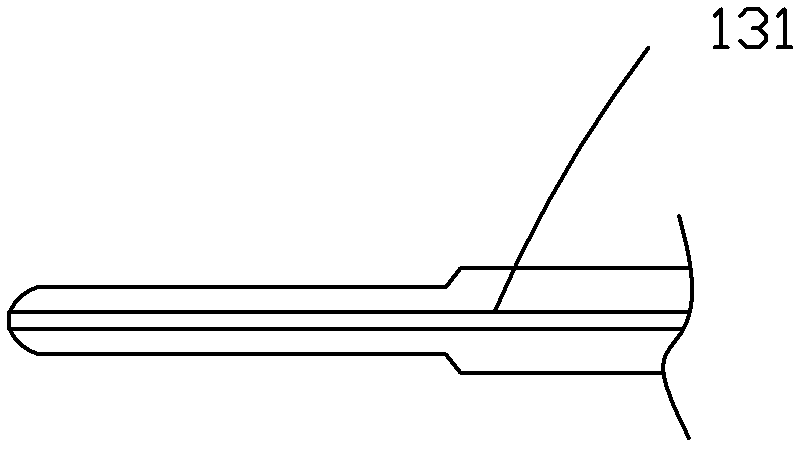

[0032] The three-way extrusion forming equipment of the present invention consists of an upper die 11 and a lower die 12 . See Figure 1-4 , The three-way forming equipment also includes a hydraulic press 10, a side cylinder 13, a thimble 131, a support cylinder 14 and a control system. The upper mold 11 is installed on the upper cylinder of the hydraulic press 10 and is controlled by the control system to move up and down in the vertical direction. The lower mold 12 is placed on the platform of the hydraulic press. The support cylinder 14 is an oil cylinder that provides a constant thrust F1 for the support rod. The role of the thimble 131 It is to completely block the two main ports of the workpiece clamped and fixed by the upper and lower dies, and perform the liquid filling process to squeeze the three-way workpiece to form the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com