Novel high-strength gypsum thermal insulation putty and preparation method thereof

A technology of high-strength gypsum and thermal insulation putty, which is applied in the direction of filling slurry, etc., can solve the problem that the thermal insulation and mechanical strength of the putty cannot be improved at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

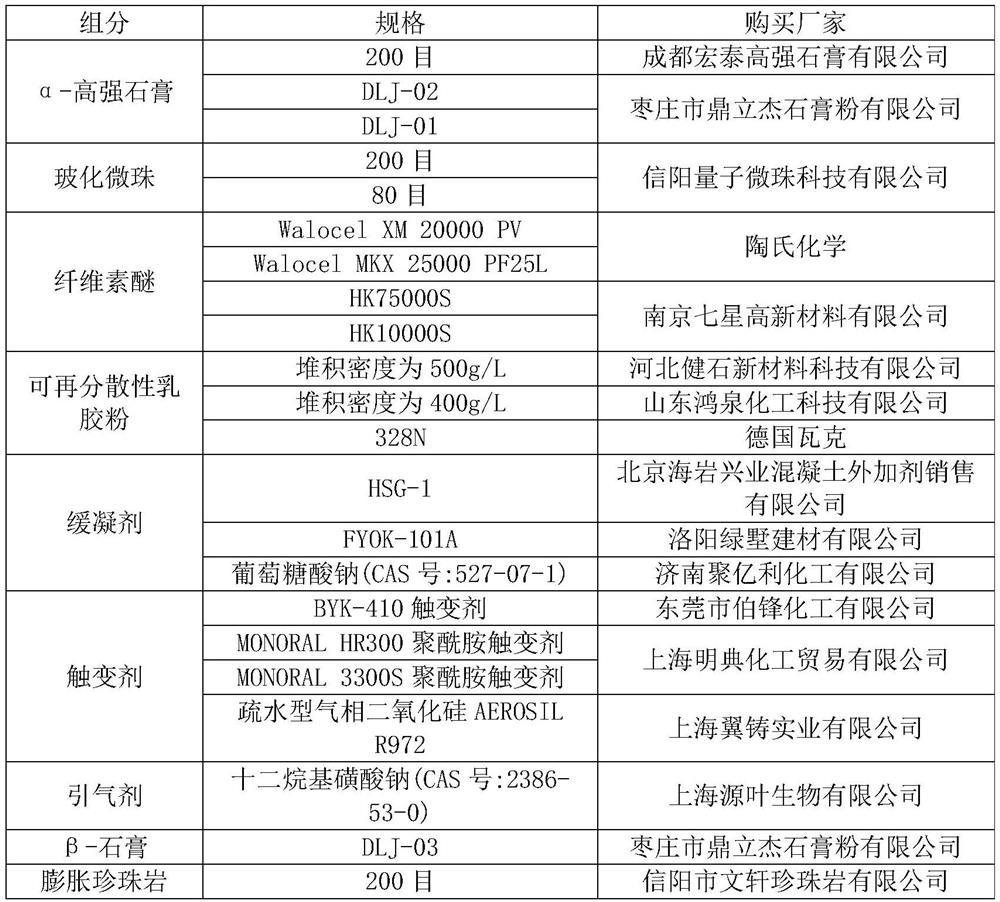

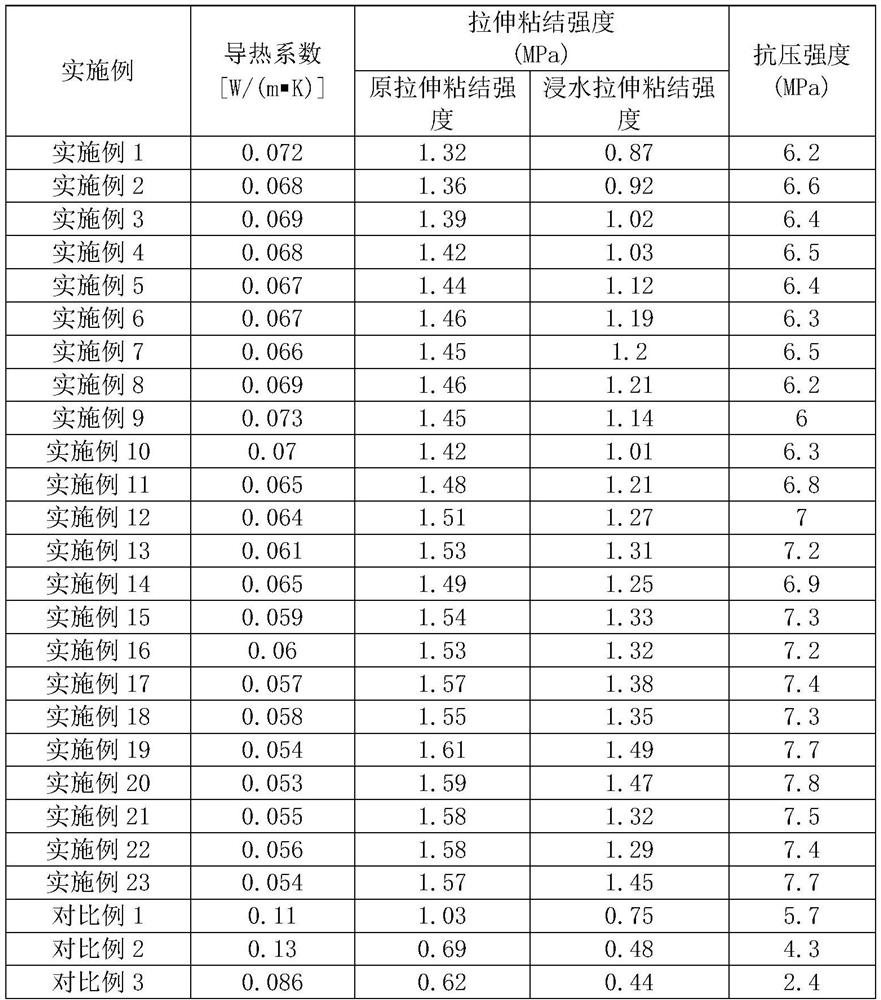

[0039] Embodiments 1-23 provide a new type of high-strength gypsum thermal insulation putty, which will be described below by taking Embodiment 1 as an example.

[0040] A kind of novel high-strength gypsum thermal insulation putty that embodiment 1 provides, its preparation steps are:

[0041] S1: Mix and stir 50g of α-high-strength gypsum and 7g of vitrified microspheres evenly to obtain a mixture 1;

[0042]S2: Add 1kg of water to the mixture 1, mix and stir evenly, then add 1g redispersible latex powder, 0.1g retarder, 0.1g thixotropic agent and 0.01g air-entraining agent, mix evenly, and Mix and stir for 40min at a stirring rate of 50rpm to obtain a mixture 2;

[0043] S3: Add 0.1 g of cellulose ether to the mixture 2, mix evenly, put it in a shearing machine, shear and disperse at a speed of 2000 rpm for 20 minutes, and obtain a new type of high-strength gypsum thermal insulation putty;

[0044] Wherein, the mesh number of the α-high-strength gypsum is 200;

[0045] T...

Embodiment 2-4

[0051] Examples 2-4 are the same as Example 1, except that the quality of the raw materials for the preparation of the novel high-strength gypsum thermal insulation putty is different, see Table 2 for details.

[0052] Table 2

[0053] components Example 1 Example 2 Example 3 Example 4 α-high strength gypsum (g) 50 70 60 65 Vitrified beads (g) 7 10 8 9 water (kg) 1 1.5 1.3 1.4 Redispersible latex powder (g) 1 2 1.5 1.7 Retarder (g) 0.1 0.5 0.3 0.4 Thixotropic agent (g) 0.1 0.5 0.3 0.4 Air-entraining agent (g) 0.01 0.05 0.03 0.04 Cellulose ether (g) 0.1 0.3 0.2 0.25

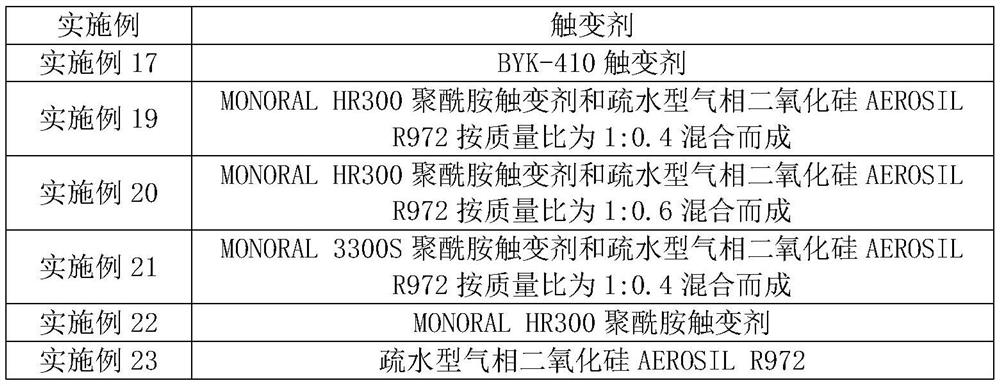

[0054] Examples 5-10 are the same as Example 4, except that the cellulose ethers are different, see Table 3 for details.

[0055] table 3

[0056] Example Cellulose ether Example 4 Walocel XM 20000PV Example 5 Walocel XM 20000 PV and HK75000S are mixed at a mass ratio of 1:2 Example 6 Walo...

Embodiment 11

[0057] Example 11 is the same as Example 7, except that the α-high-strength gypsum is DLJ-02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com