Calcining process of synthesizing hollow silica alumina ball

A technology for calcining and synthesizing hollow spheres, applied in the field of refractory materials, can solve problems such as poor fluidity, uneven wall thickness of hollow spheres, and rough surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

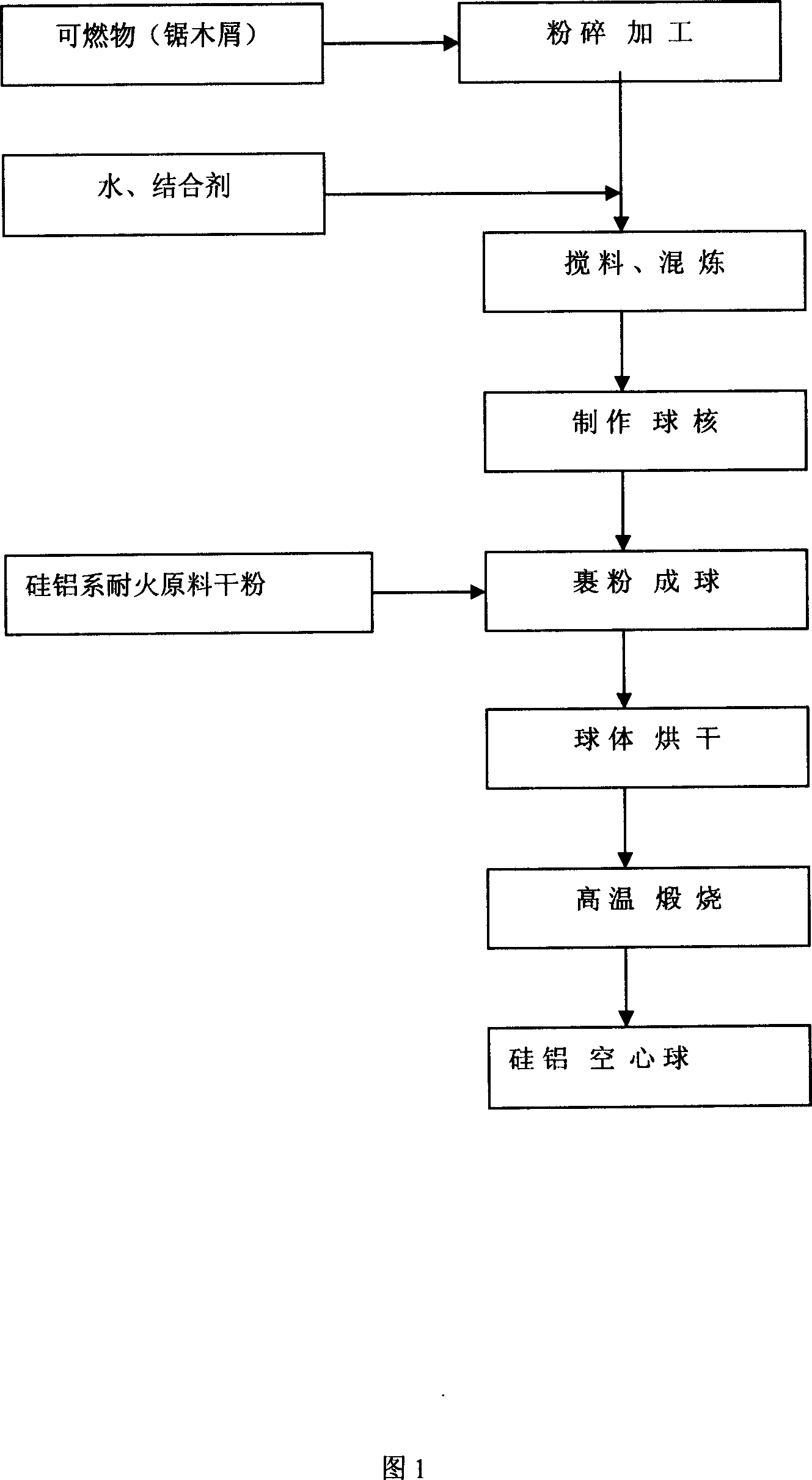

[0018] As shown in Figure 1, after the sawdust is crushed and processed, water and a binder are added, stirred and kneaded to make a wet ball core, and then the wet ball core containing about 60% to 65% of water is placed in the forming machine. In the ball machine, adjust the rotation speed to 28-32 rpm. While the wet bulb core is turning and rolling, sprinkle the dry powder of silicon-aluminum refractory raw materials. The moisture content of the dry powder of silicon-aluminum series refractory raw materials is not more than 5%. ~ 12 minutes, wrap powder into balls, then dry the balls and calcined at high temperature to make silicon-aluminum hollow balls.

[0019] This process can produce clay hollow balls, high alumina hollow balls, and mullite hollow balls. It not only has high ball forming rate, uniform ball wall, small bulk density, high service temperature, and low thermal conductivity, but also has simple process and low cost. Low, solves the long-standing problem of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com