Preparation method of tubular metal catalyst

A metal catalyst and tubular technology, which is applied in the field of preparation of tubular metal catalysts, can solve the problems of complex synthesis method, limited application, tube wall thickness of platinum nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention discloses a method for preparing a tubular metal catalyst, comprising:

[0044] Step a) the first metal salt and sodium nitrate (NaNO 3 ) was dissolved in dimethylsulfoxide (DMSO) to obtain a mixed solution;

[0045] Step b) using the alumina porous mold with nanoscale pores as a template, performing electrochemical deposition of the mixed solution at the nanoscale pores, and obtaining a tubular metal catalyst after removing the template, the work of the electrochemical deposition The voltage is -0.8V ~ -1.8V.

[0046] In the present invention, the first metal salt is preferably platinum dichloride (PtCl 2 ), palladium dichloride (PdCl 2 ), chloroauric acid (AuCl 3 ·HCl·4H 2O), silver nitrate (AgNO 3 ) and cuprous bromide (CuBr) in one or more. Since the method provided by the invention can prepare single-component tubular metal catalysts and multi-component metal tubular catalysts, when preparing single-component metal tubular catalysts, the first ...

Embodiment 1

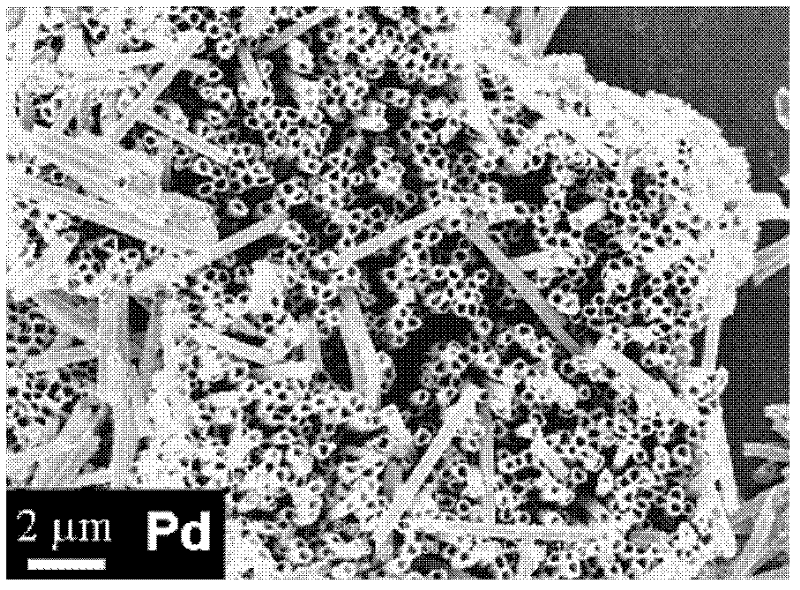

[0056] The electrochemical synthesis of embodiment 1 single-component palladium tubular metal catalyst

[0057] Add 0.177g PdCl to a 100mL beaker 2 With 50mL DMSO (Shanghai Sinopharm Group), dissolve part of PdCl with mechanical stirring 2 Afterwards, keep it sealed for an hour until the undissolved PdCl 2 After turning into white, stir and dissolve again, and so on, until all PdCl 2 After the dissolution is complete, add 100mM / L NaNO 3 Supporting electrolyte, sealed and left overnight to obtain the first mixed solution;

[0058] One side of the commercially available alumina template produced by British Whatman Company is steamed with a gold layer with a thickness of 40nm to form a ring-shaped base electrode, and the alumina template has a hole diameter of about 300nm (obtained by scanning electron microscopy);

[0059] A 100mL beaker was used as an electrolytic cell, and the above-mentioned alumina template was used as a template, and the first mixed solution was subject...

Embodiment 2~4

[0063] Using the same preparation method as in Example 1, using PtCl 2 , AuCl 3 ·HCl·4H 2 O and AgNO 3 It is a metal salt, the working voltage of electrochemical deposition is -1.3V, -1.5V, -1.0V respectively; the electrochemical deposition time is 6h, 5h, 1h respectively; the number of moles of sodium hydroxide solution used is 1M / L ; One-component Pt tubular metal catalyst, Au tubular metal catalyst and Ag tubular metal catalyst were prepared respectively. The scanning electron microscope pictures of the Pt tubular metal catalyst, Au tubular metal catalyst and Ag tubular metal catalyst prepared by embodiments 2~4 are as follows respectively Image 6 , Figure 7 with Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com