Automatic quantitative power filling equipment for novel heat tube

A powder filling and heat pipe technology, applied in the field of heat pipe production equipment, can solve the problems of low production efficiency, large dust in the working environment, waste of copper powder, etc., to improve production efficiency and automation, improve equipment automation, and improve work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below.

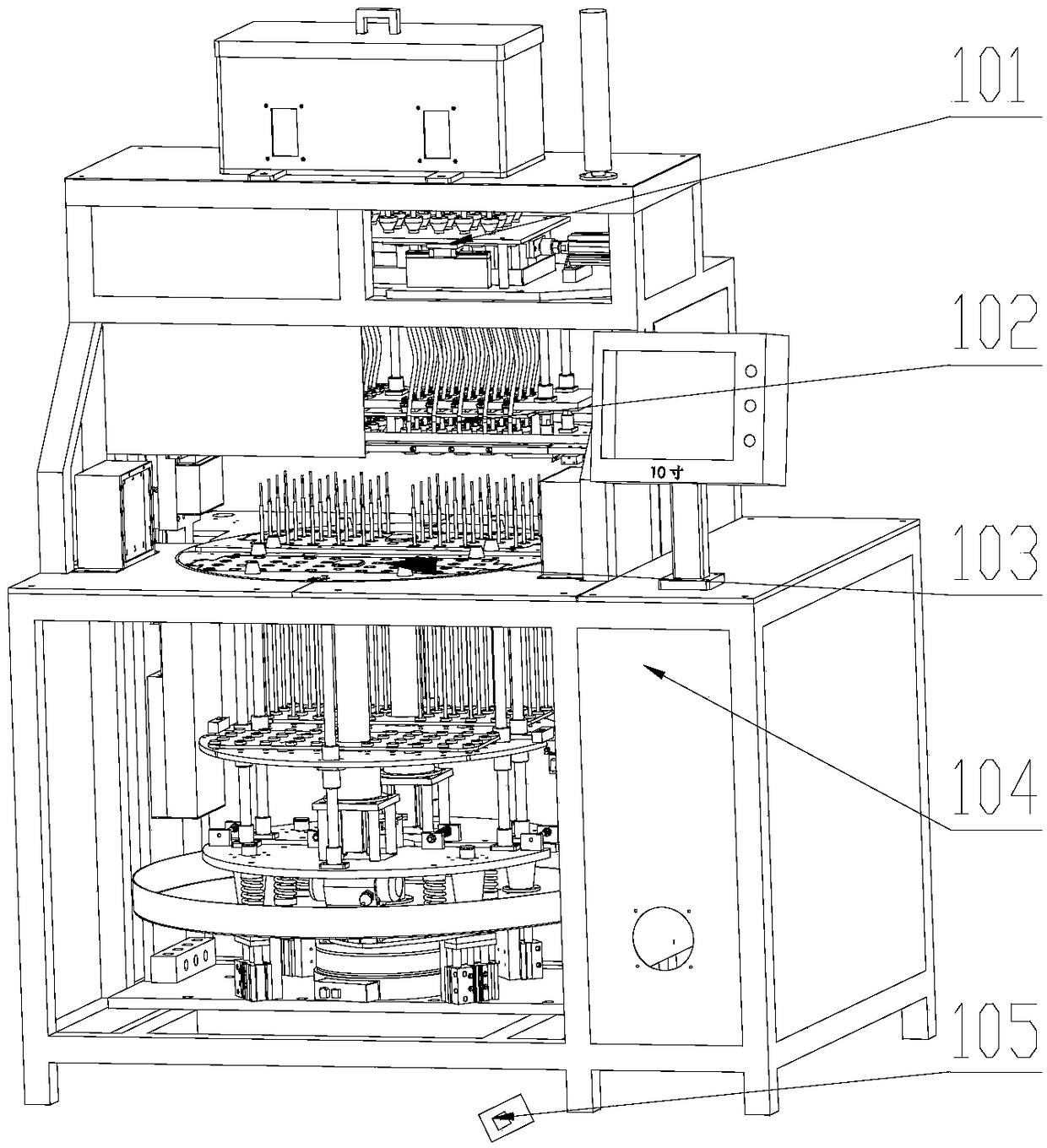

[0039] Such as figure 1 As shown, a new heat pipe automatic quantitative powder filling equipment includes a frame 104, a control device, a powder precise quantitative mechanism 101 and a lifting powder filling mechanism 102 arranged in the frame 104 in isolation from top to bottom. and the rotary table mechanism 103,

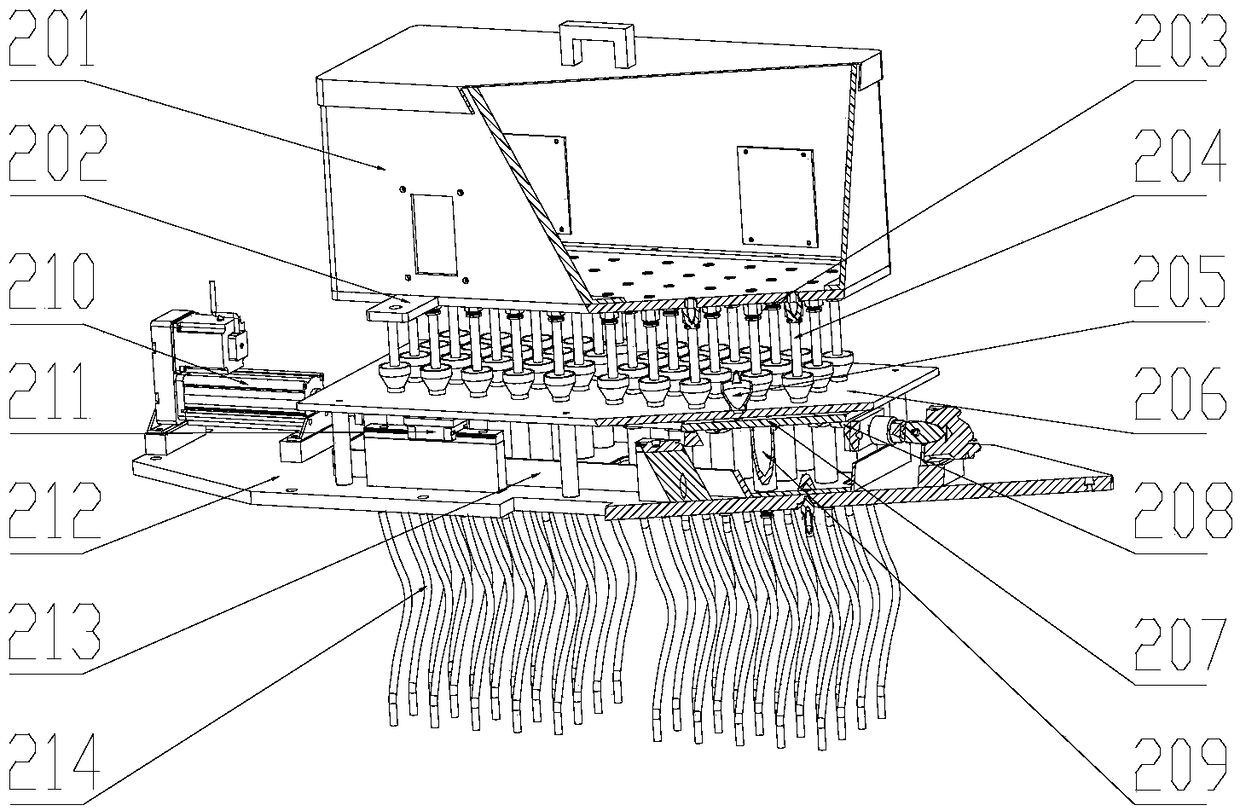

[0040] Such as figure 2 As shown, the powder precise quantification mechanism 101 is sequentially provided with a powder storage box 201, a powder storage box bottom plate 202, a fixed powder funnel 205 for powder quantification, an upper fixing plate 206, and a symmetrically distributed intermediate movement from top to bottom. plate 207, lower fixing plate 212, the powder storage box bottom plate 202 is fixed on the frame 104 for fixing the powder storage box 201, and the bottom of the powder storage box bottom plate 202 is uniformly provided with several threaded holes for fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com