Winding device

A technology of winding and guiding devices, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc. It can solve the problems of uncertain timing of cutting fiber strips and interruption of fiber strip process, so as to avoid cracking and splice effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

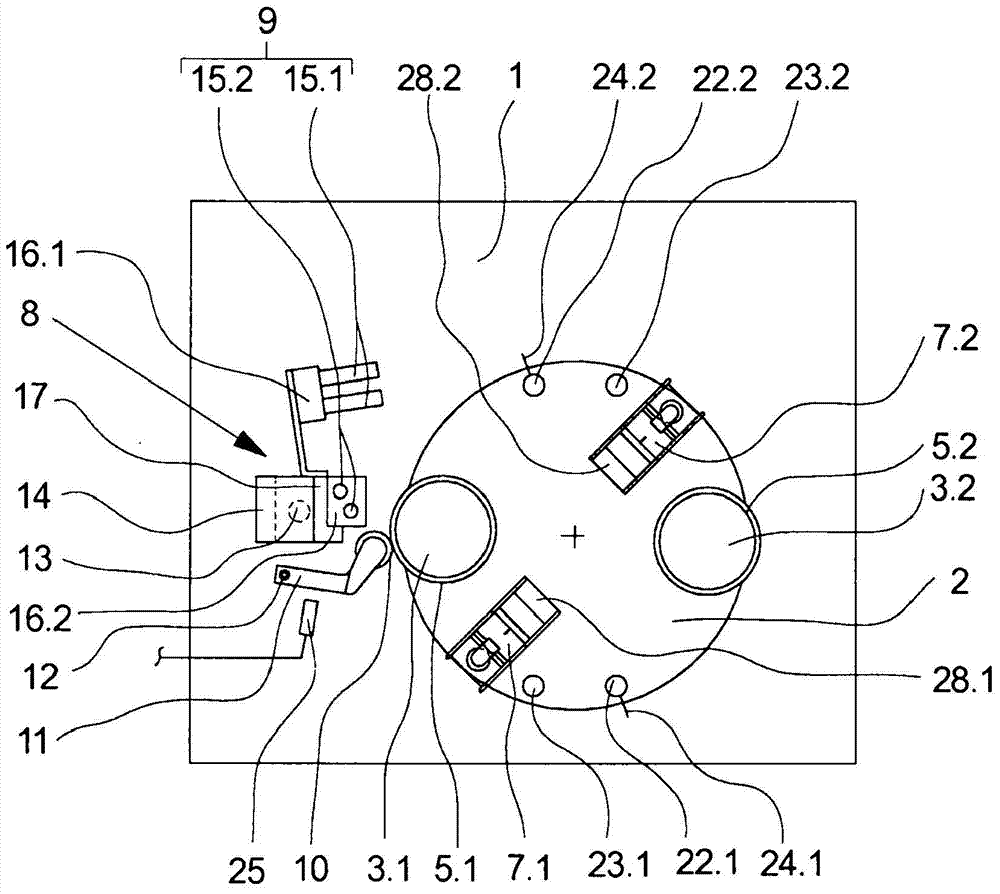

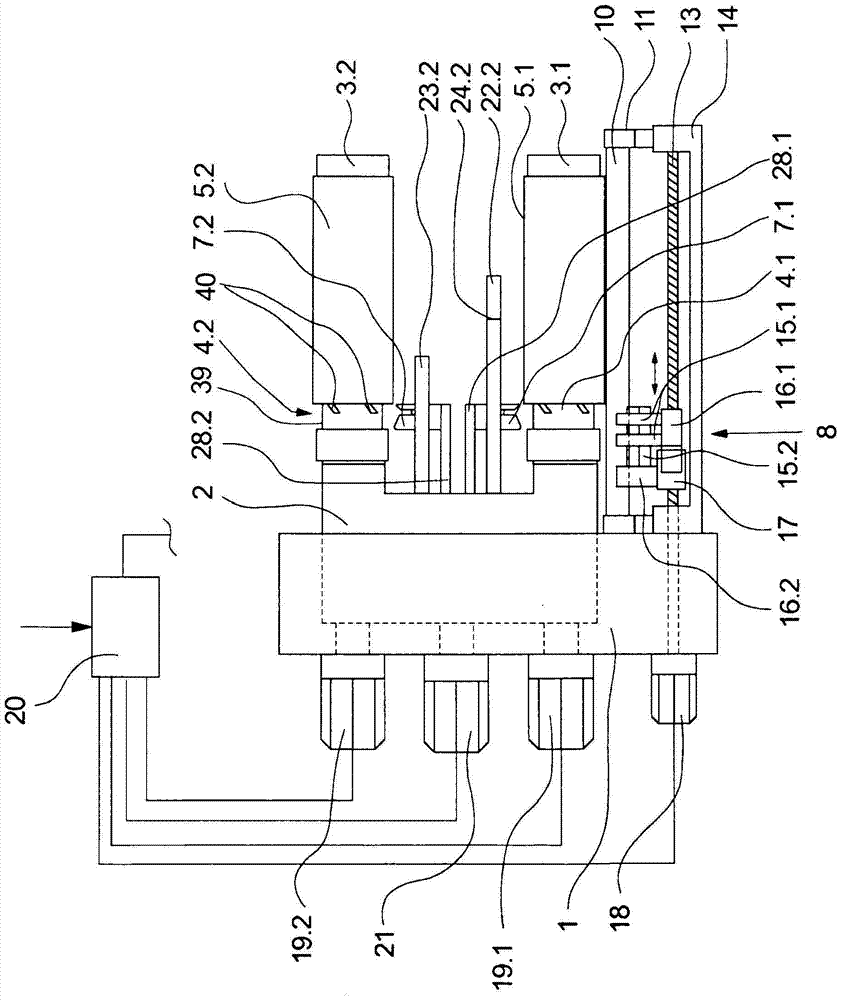

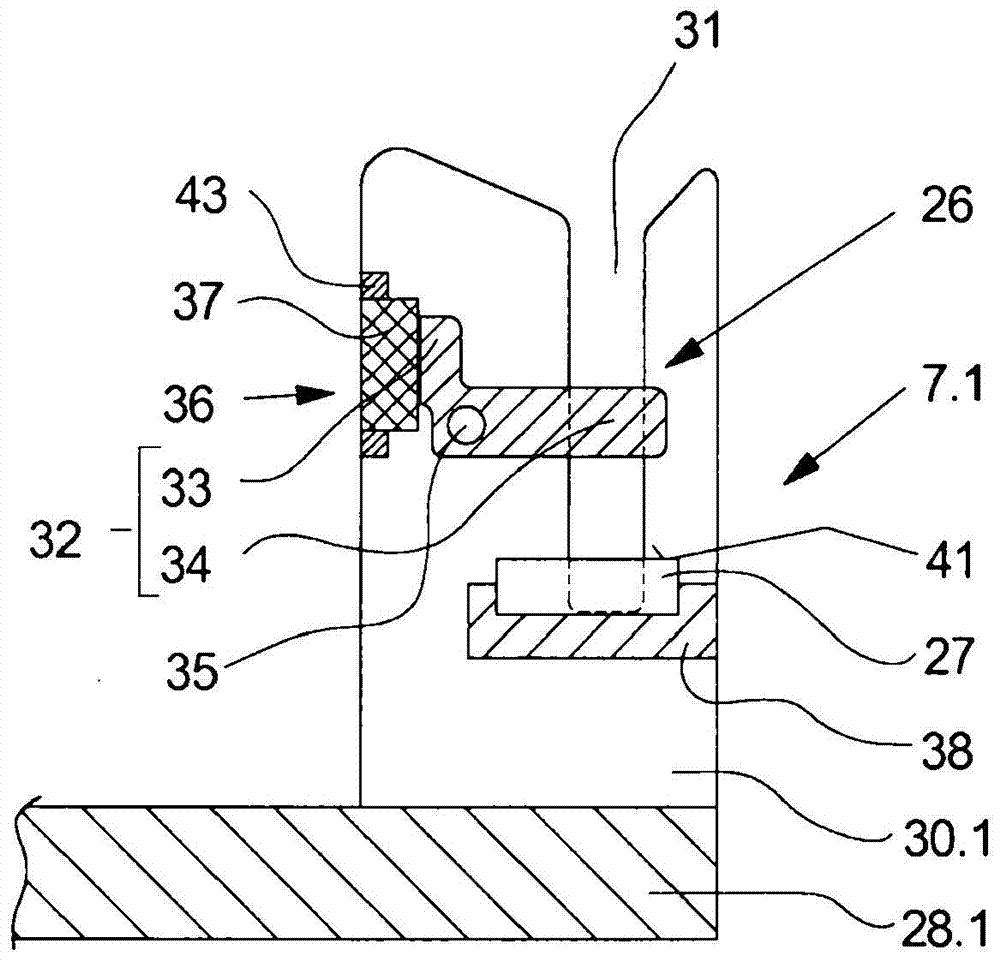

[0026] figure 1 and 2 An embodiment of a winding device according to the invention is shown in several views. figure 1 The front view shows the embodiment and figure 2 This embodiment is shown in plan view. The following description applies to both figures, as long as there is nothing more particularly emphasized about one of the figures.

[0027] This exemplary embodiment of the winding device has a bobbin turret 2 which is rotatably mounted in a machine frame wall 1 and which can be rotated counterclockwise via a turret drive. The bobbin turret has two rotatably mounted bobbin spindles 3.1 and 3.2, which are each held with a free end projecting. The bobbin spindles 3.1 and 3.2 are held on the bobbin turret 2 offset from one another by 180°. Each bobbin spindle 3.1 and 3.2 is connected in a drive device such as figure 2 As shown in , each can be formed by a spindle drive 19.1 and 19.2.

[0028] The bobbin spindles 3.1 and 3.2 each have a bobbin 5.1 and 5.2, around wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com