Patents

Literature

77results about How to "Reduce manual steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

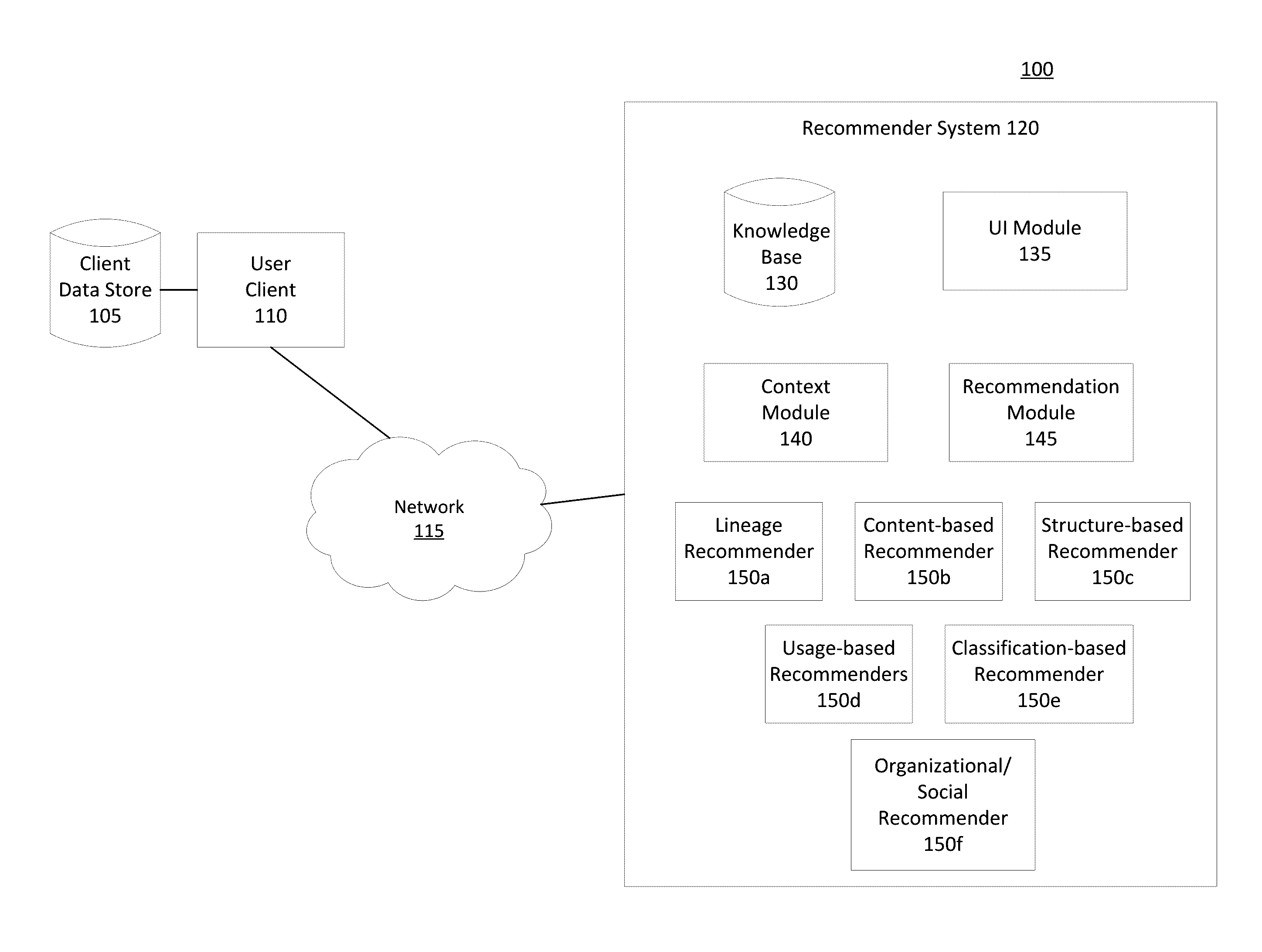

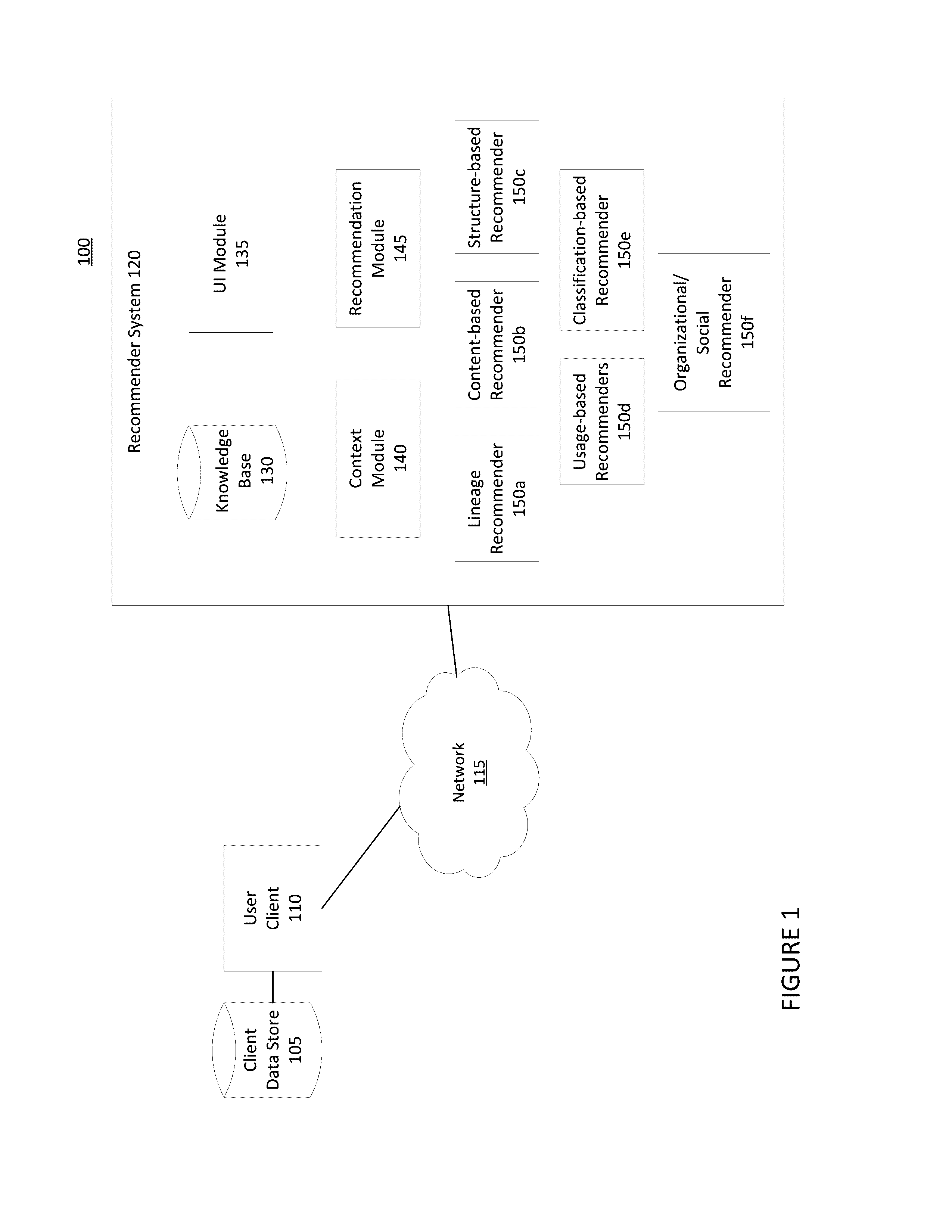

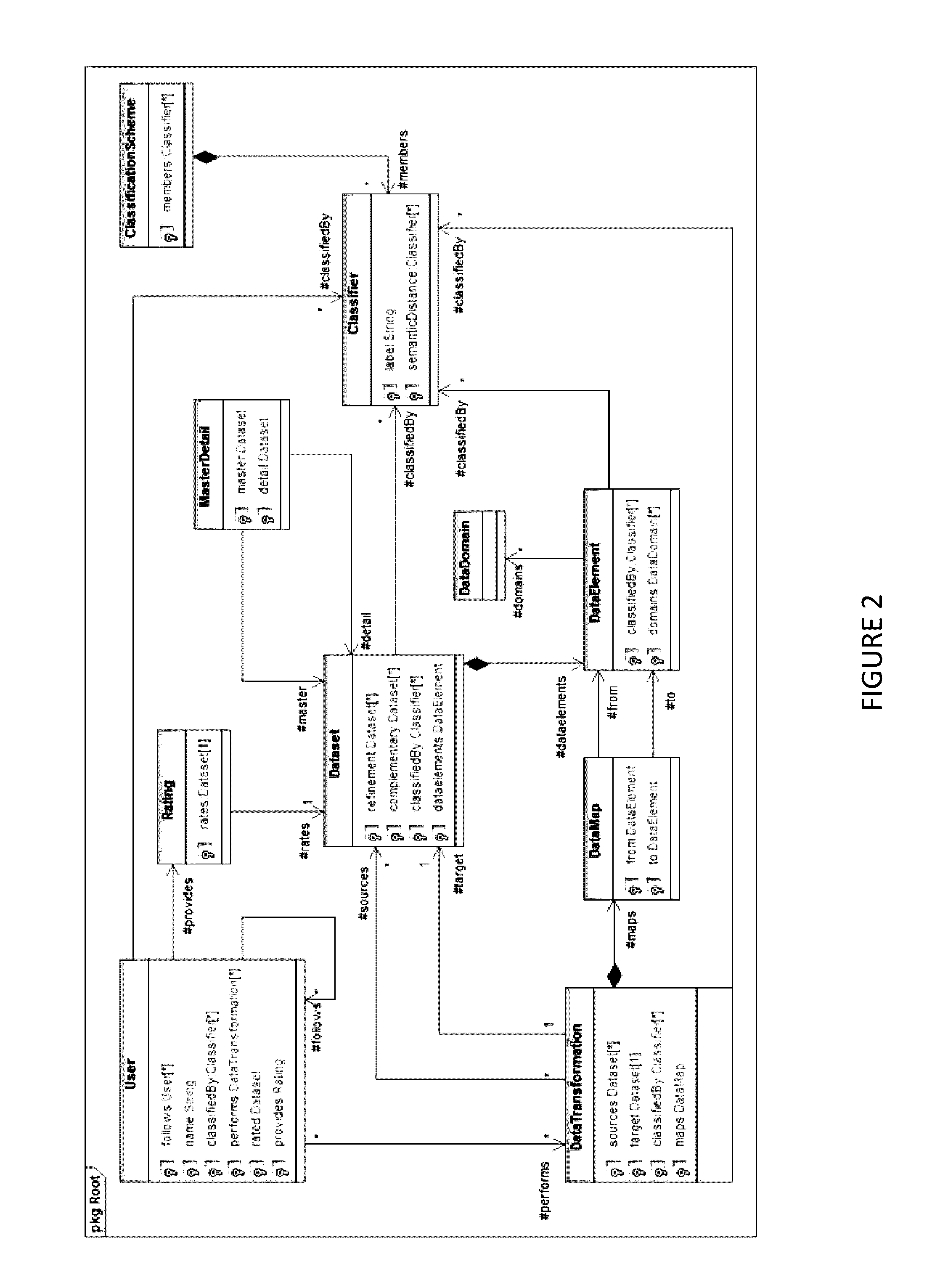

Interactive recommendation of data sets for data analysis

InactiveUS20160328406A1Shorten the timeIncrease awarenessDigital data information retrievalSpecial data processing applicationsData setData profiling

A data analysis platform provides recommendations for datasets for analysis. Given a user selected dataset, for example resulting from a search,automatically identifies other datasets based a variety of different types of relationships, including lineage, structural, content, usage, classification, and organizational / social. Datasets for each type of relationship are identified and scored for relevance, and ranked. Selected ones of the ranked data sets are presented in a recommendation interface. As the user selects from recommended dataset, additional datasets are automatically recommended based in inferences made according to the selected dataset and relationship.

Owner:INFORMATICA CORP

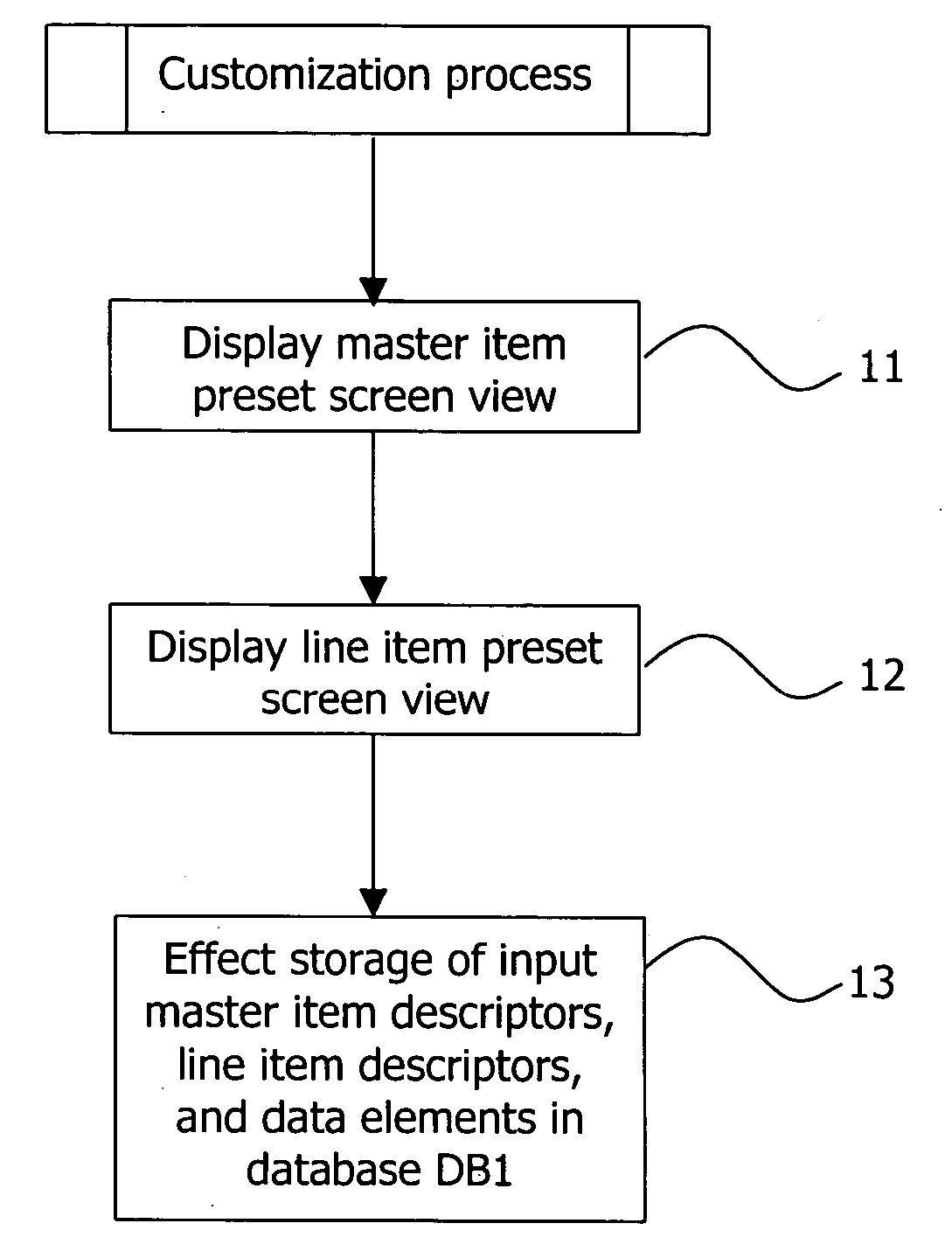

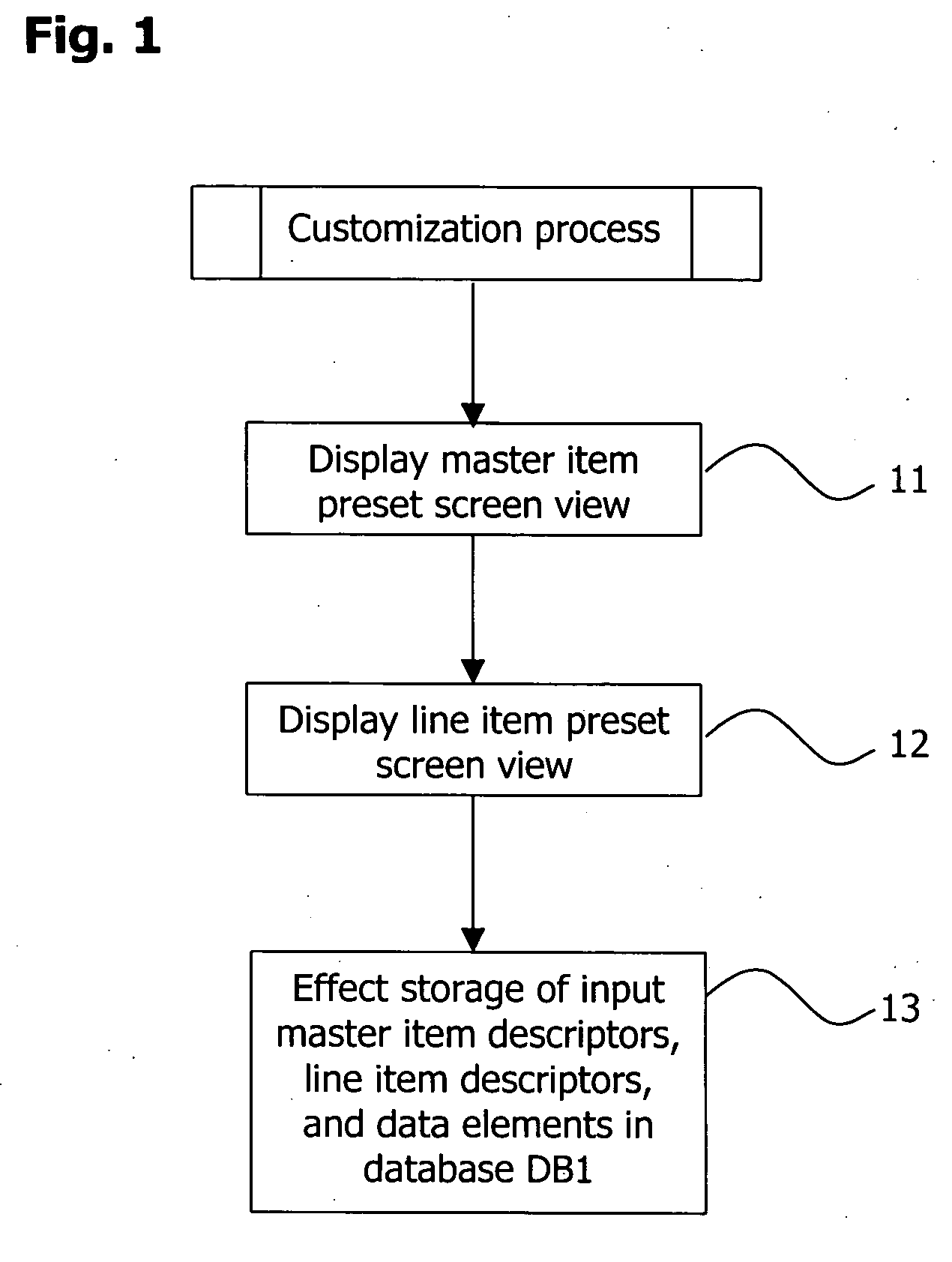

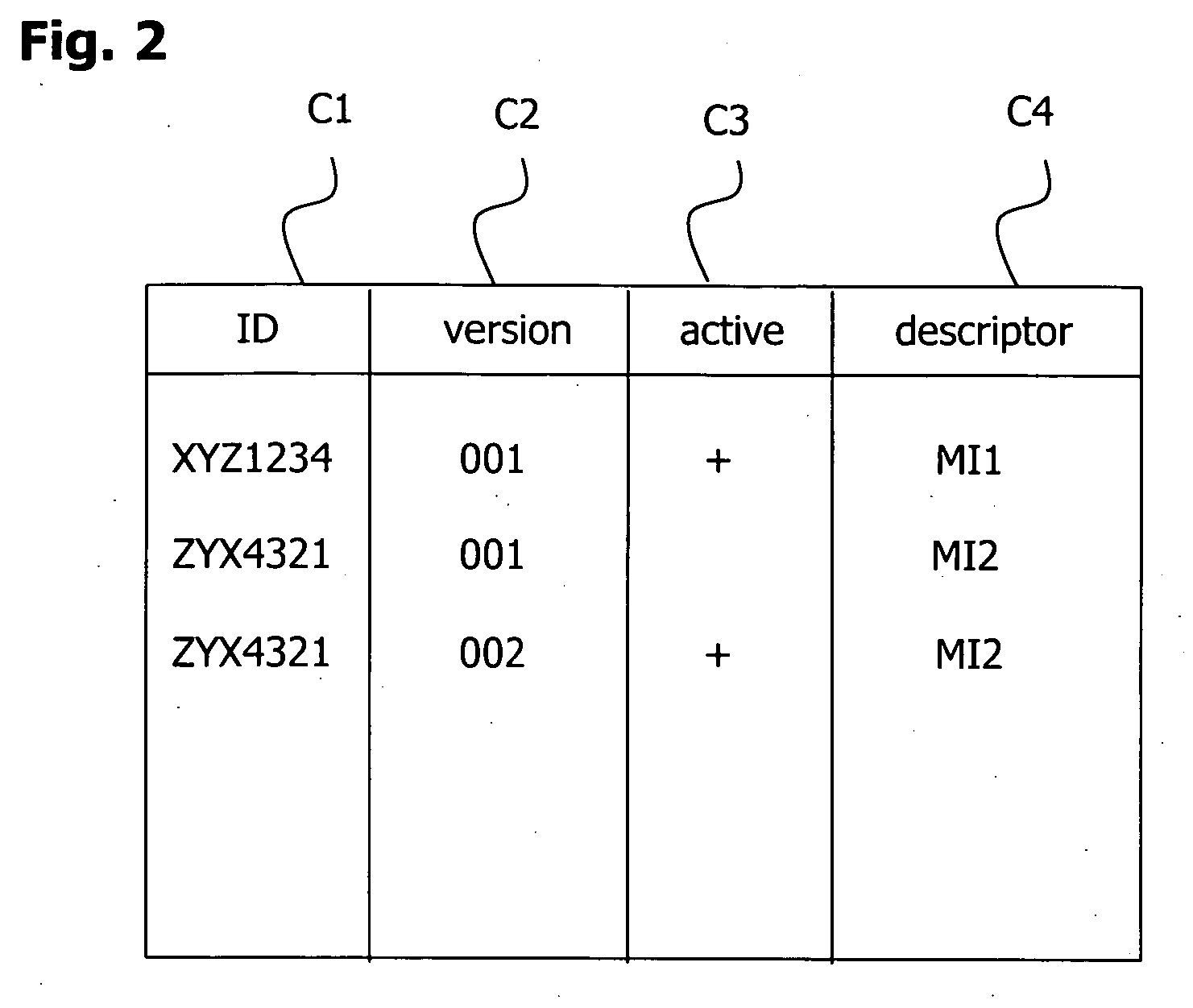

Computer-implemented system and method for creating an electronic document and computer program product therefor

InactiveUS20050155000A1Reduce in quantitySimplify workNatural language data processingSpecial data processing applicationsOutput devicePaper document

A computer-implemented system for creating an electronic document is provided wherein the document is generated based on data added to an electronic form by a user through interaction with a computer. In one embodiment, the system is programmed to perform the steps of: (a) displaying a first screen view on a graphical output device, said first screen view including an entry area arranged to allow a user to enter through an input device one or more line item descriptors and one or more first data elements in association with each line item descriptor; (b) sending off every entered line item descriptor and every entered first data element for storage in a first database; (c) displaying a second screen view on a graphical output device, said second screen view including said form and being arranged to allow a user to add data to said form; (d) displaying in said second screen view one or more control elements each associated with a respective line item descriptor stored in said first database, each control element being configured to be activated through user operation of an input device; (e) upon activation of a control element by a user, submitting a request to said first database to read said one or more first data elements associated with said line item descriptor corresponding to said activated control element; and (f) adding data derived from said read one or more first data elements to said form.

Owner:SAP AG

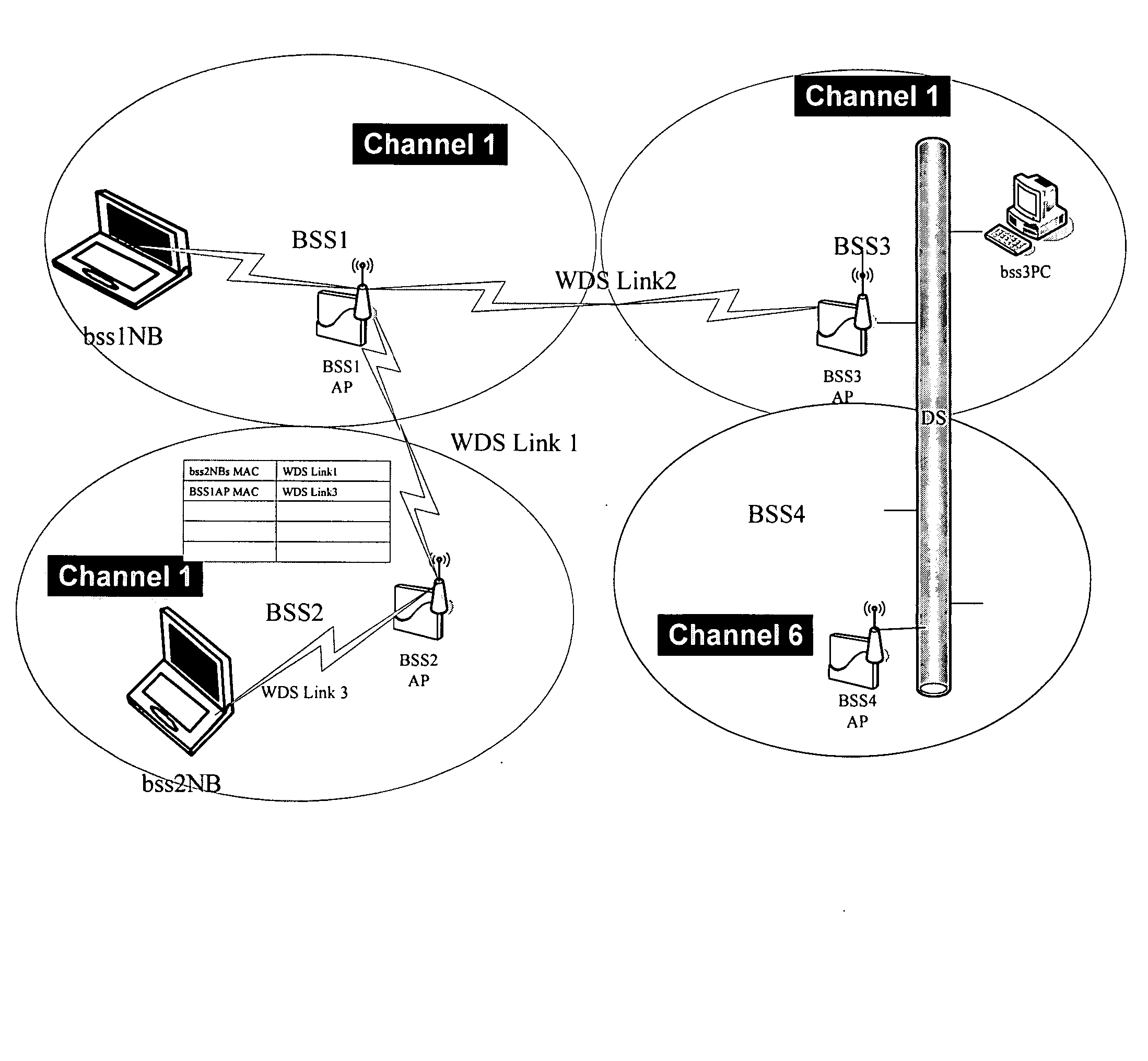

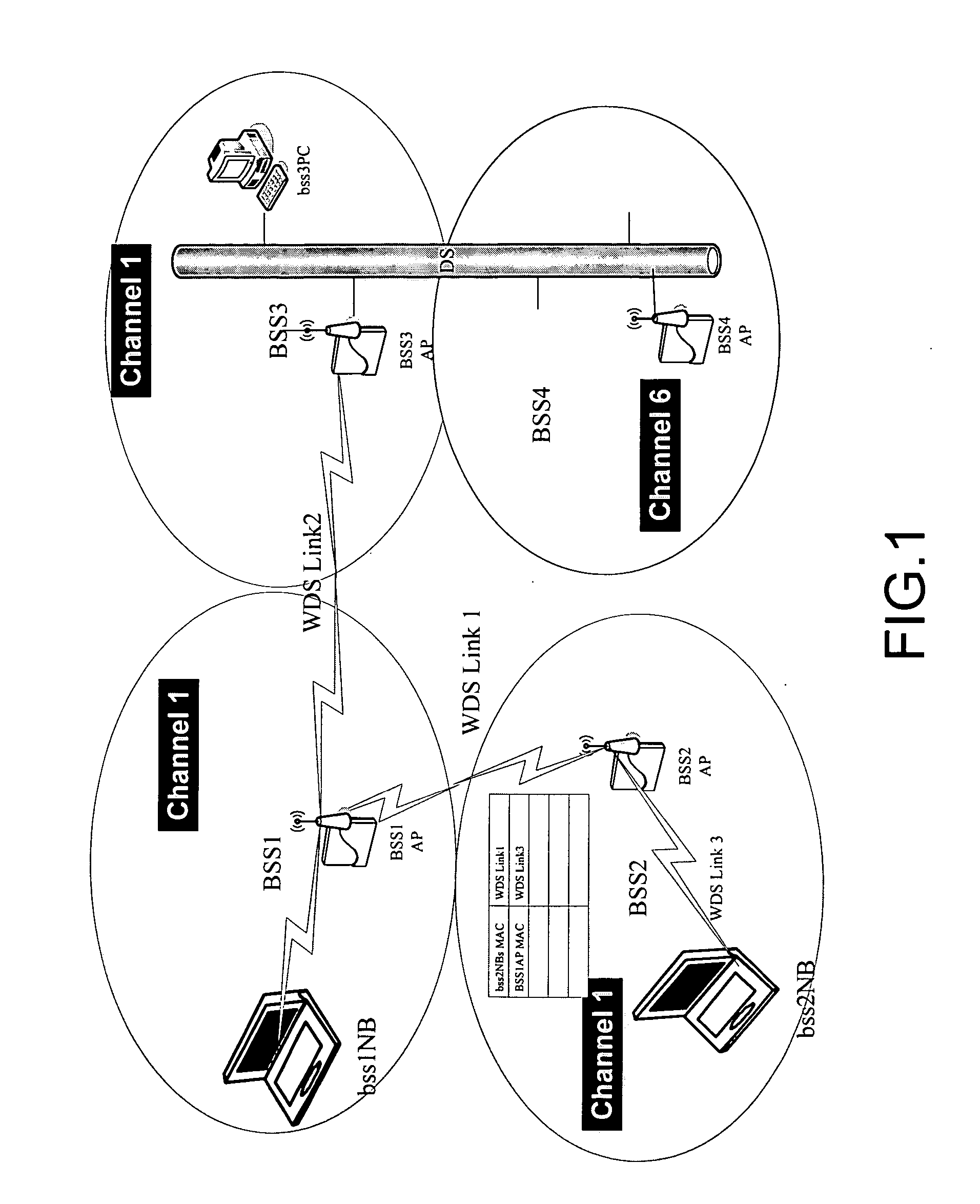

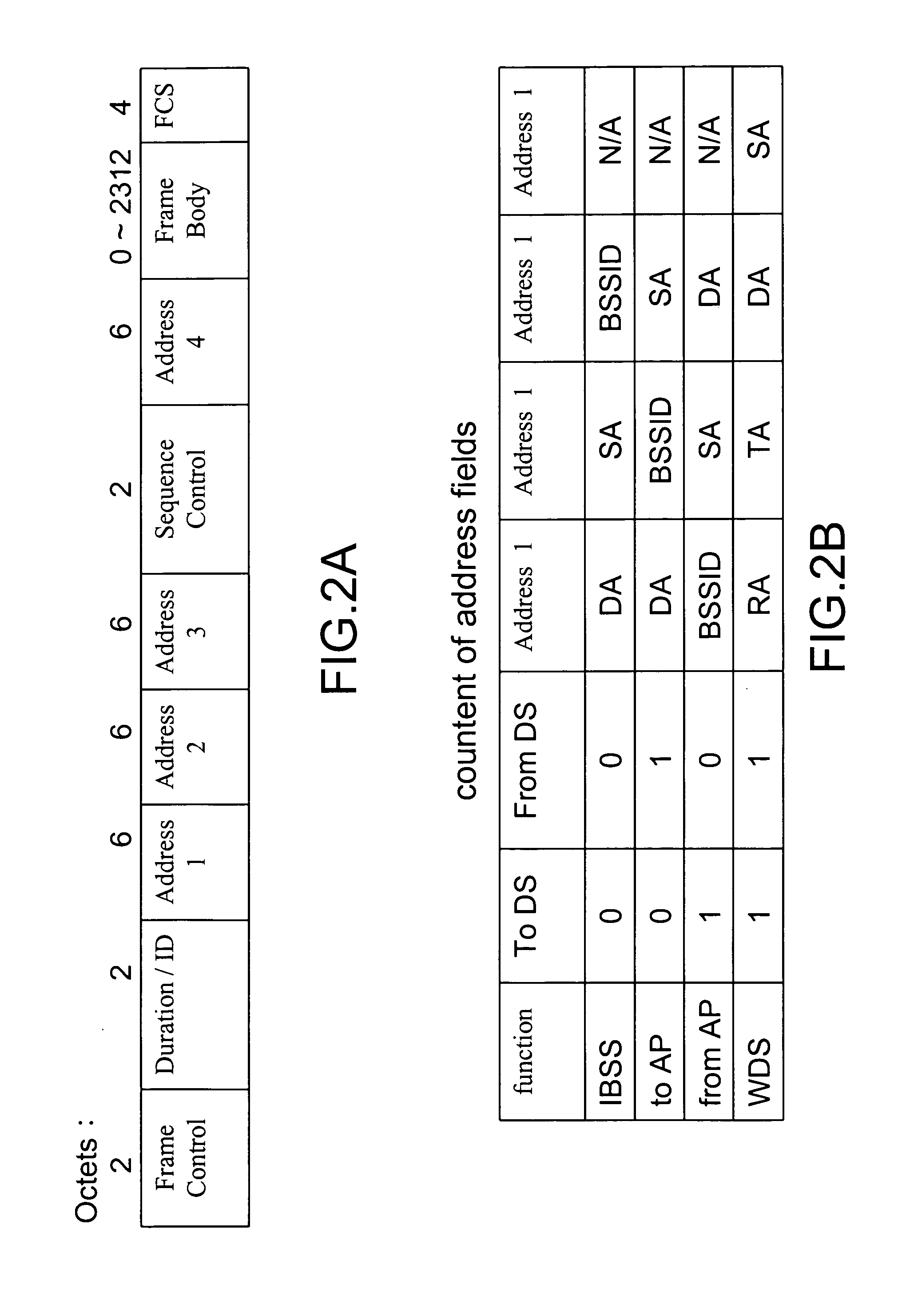

Method for configuring a wireless distribution system and optimize method thereof

InactiveUS20070076642A1Step be reduceOptimize performanceRadio transmissionWireless commuication servicesChannel useMAC address

A method for configuring a wireless distribution system is provided. In the method, a target node starts a building procedure and begins to broadcast a building information. A joining node starts a scanning procedure for scanning all channels available and locks one channel used by the target node. The joining node sends a connect request signal and a channel assign request to the target node. The target node selects one link and one channel available for the joining node for communication, and sends a channel reset signal to the joining node. The MAC address of the joining node is added into an internal table of the target node. After the joining node has received the channel reset signal, the MAC address of the target node is stored into an internal table of the joining node, and the designated link channel is configured.

Owner:IND TECH RES INST

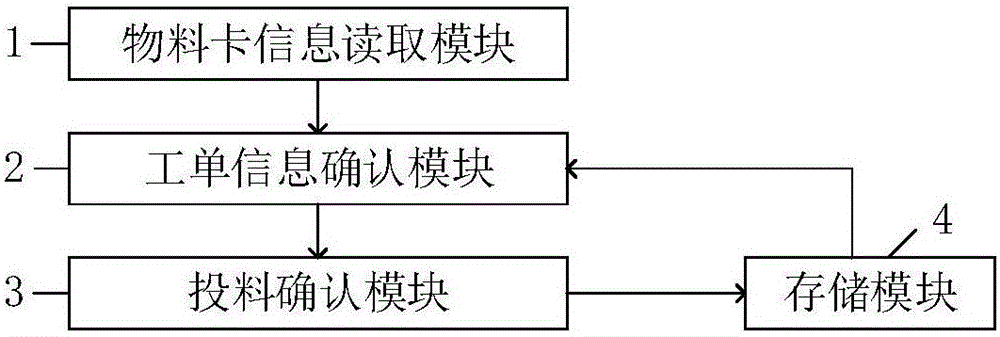

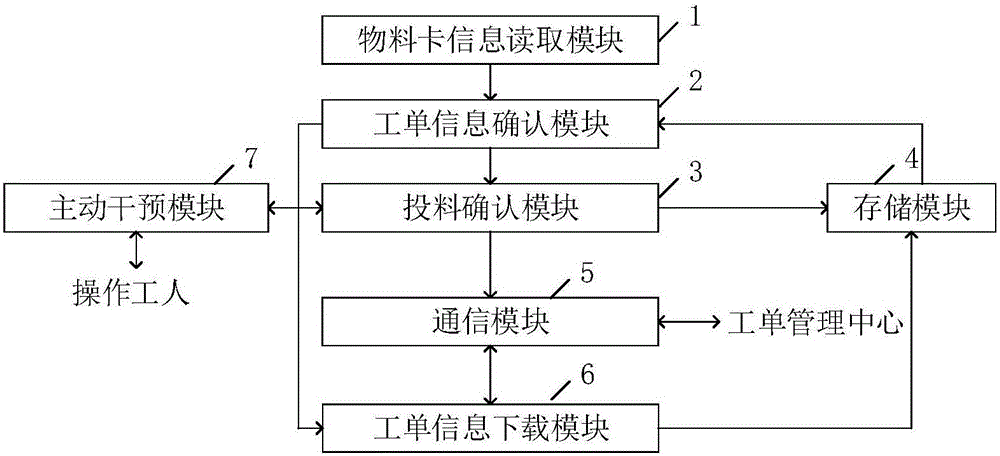

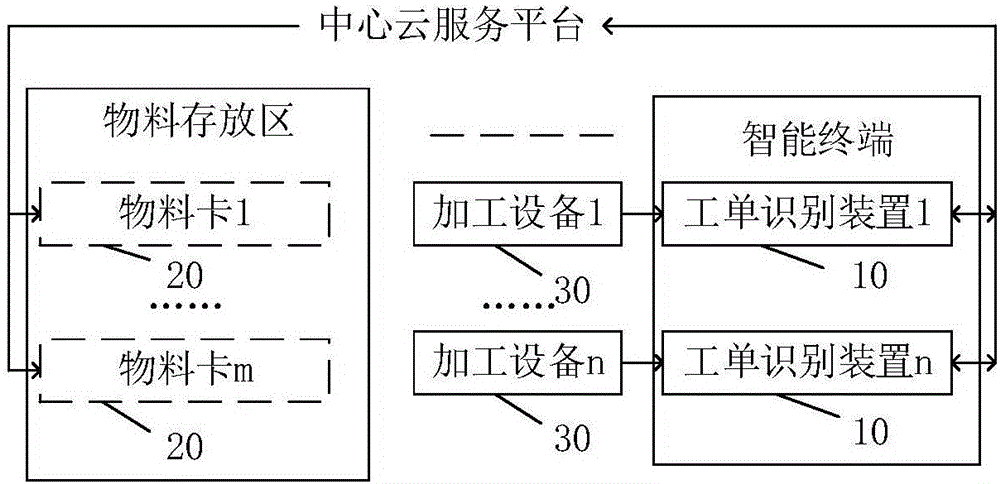

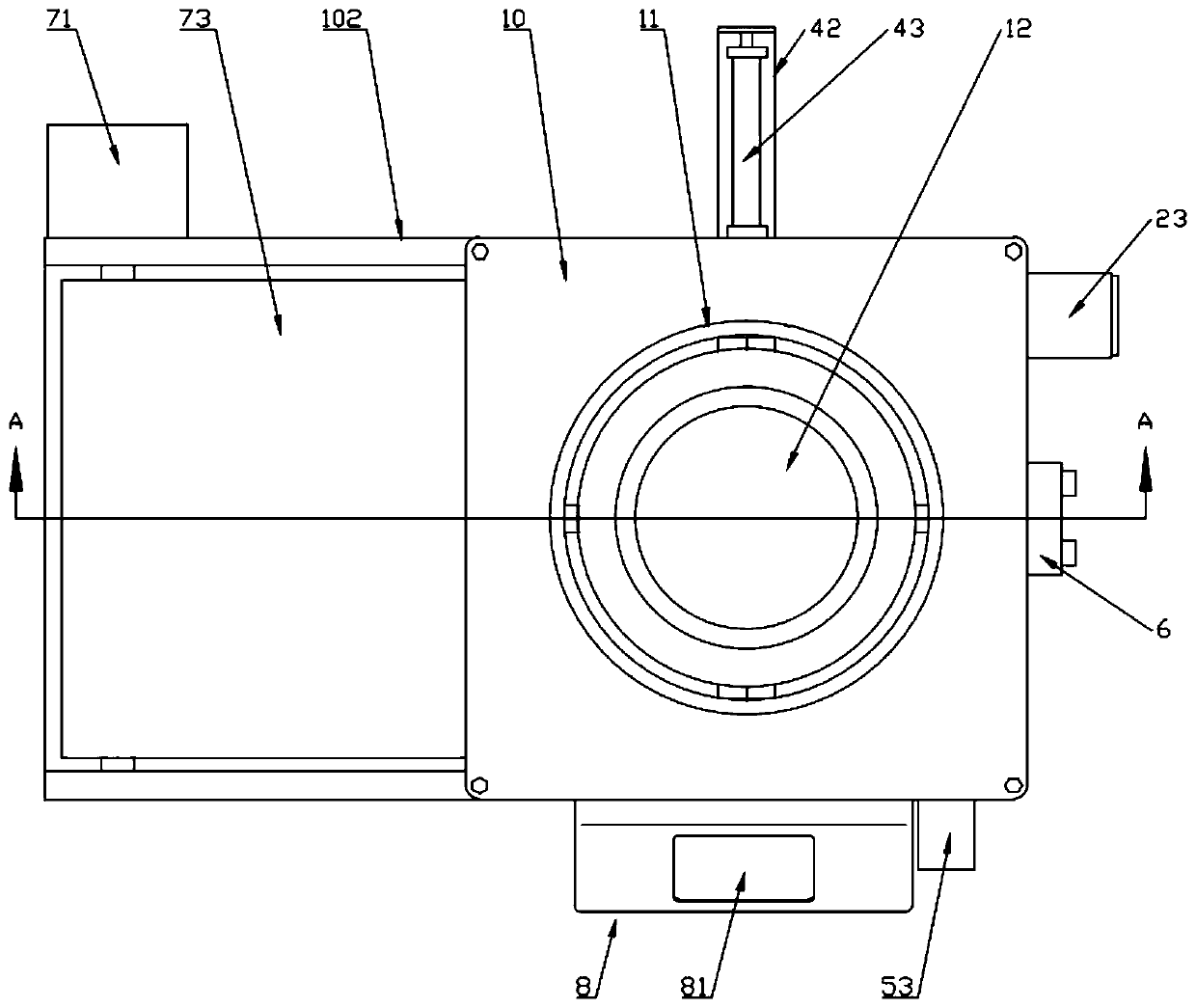

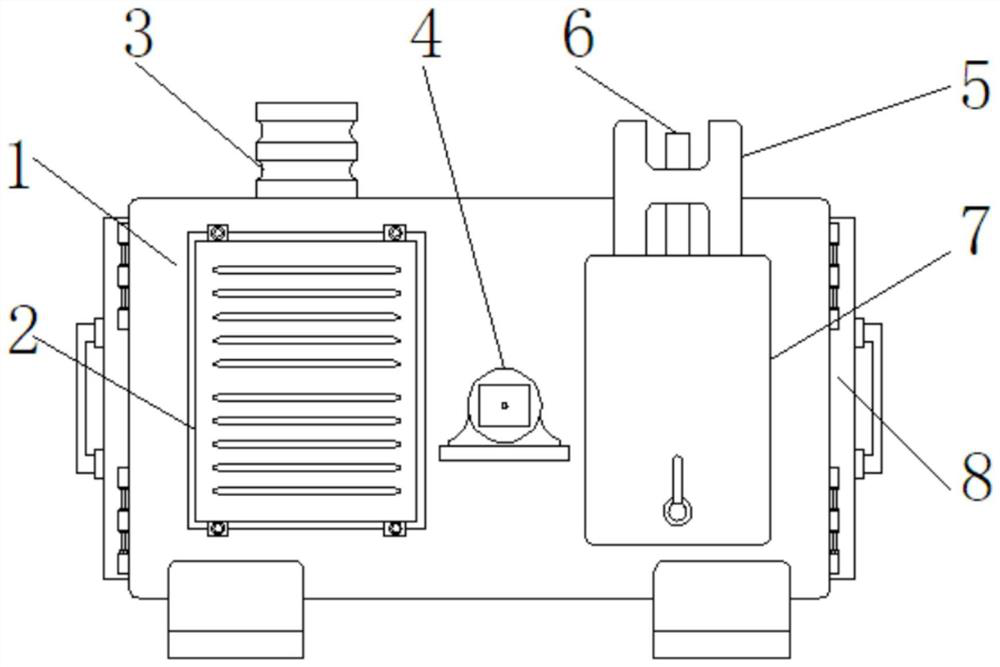

Work order identifying device

InactiveCN106022410AShorten production timeReduce manual stepsData processing applicationsCo-operative working arrangementsIdentification deviceComputer science

The invention belongs to the production automation technology field, especially relates to a work order identifying device. The work order identifying device is disposed on a processing device, and comprises a material card information reading module, a work order information confirmation module, a material feeding confirmation module, and a storage module. The work order identifying device is used to select a work order corresponding to the processing device by scanning material card work order information of a plurality of material frames disposed in a material area, and is used to notifying workers of feeding materials in the material frame corresponding to the work order, and therefore production preparation time for correcting errors occurred during the manual selection of the work order and the material feeding process is reduced.

Owner:杭州塔网科技有限公司

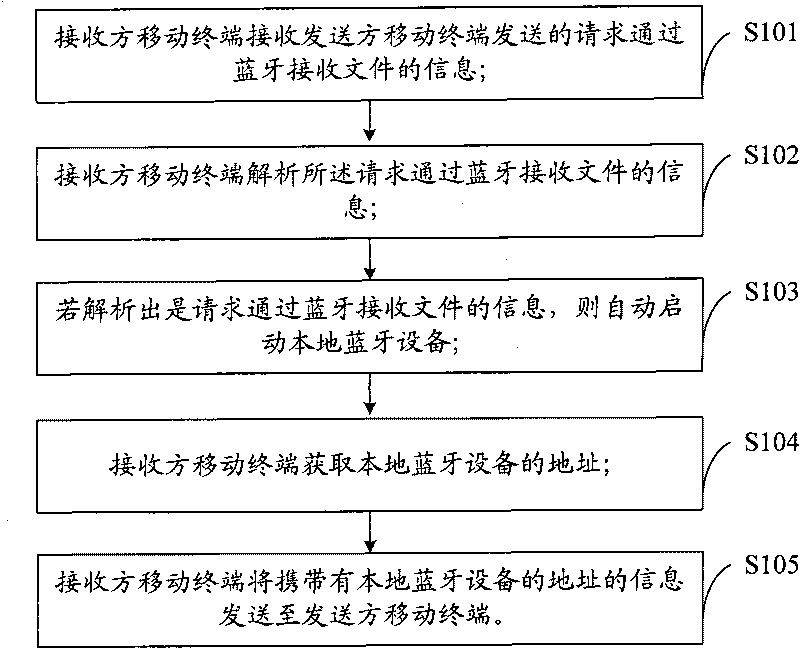

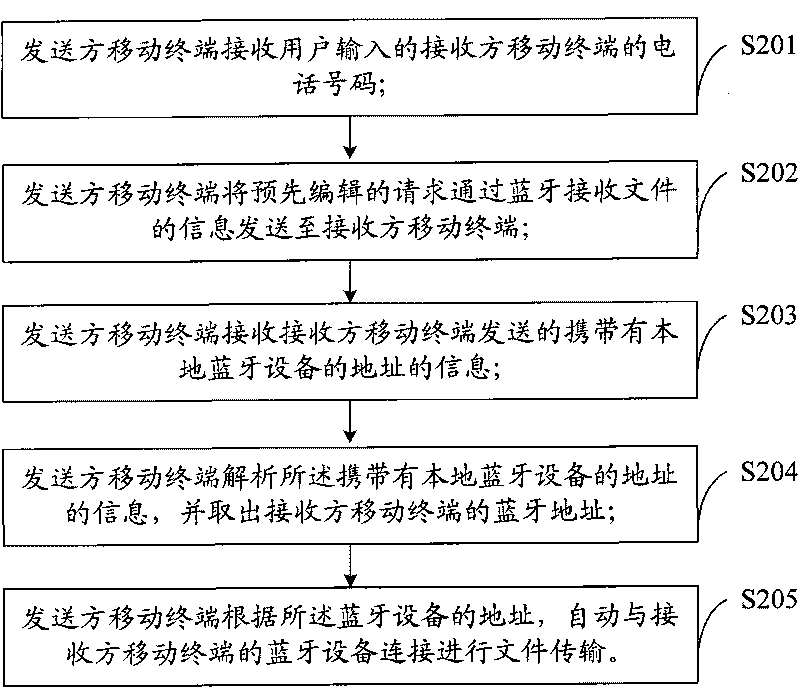

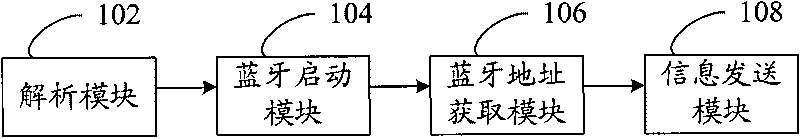

File transmission method based on Bluetooth transmission protocol, system and mobile terminal

InactiveCN101754421AReduce manual stepsImprove convenienceNear-field transmissionWireless network protocolsTelecommunicationsUtilization rate

The invention is applicable to the technical field of wireless communication and provides a file transmission method based on a Bluetooth transmission protocol, a system and a mobile terminal. The method comprises the following steps: a receiver mobile terminal receives the information of requesting to receive a file through a Bluetooth sent by a sender mobile terminal; the receiver mobile terminal analyzes the information of requesting to receive the file through the Bluetooth and automatically starts a local Bluetooth device if the information of requesting to receive the file through the Bluetooth is analyzed; the receiver mobile terminal obtains the address of the local Bluetooth device; and the receiver mobile terminal sends the information carrying the address of the local Bluetooth device to the sender mobile terminal. The sender mobile terminal and the receiver mobile terminal in the invention trigger to automatically start the Bluetooth device for the transmission of the file by interacting information mutually, the steps of human intervention in a file transmission process are reduced, and the file can be transmitted to the Bluetooth devices of a plurality of different mobile terminals each time, and the use convenience and utilization rate are improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

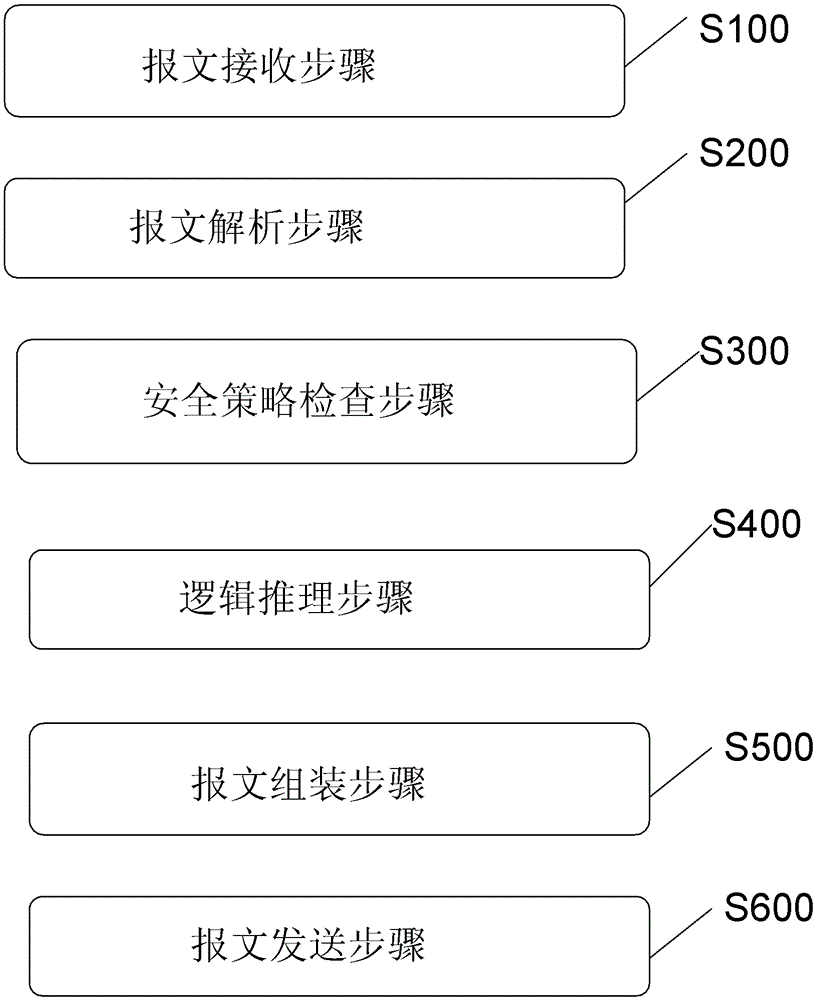

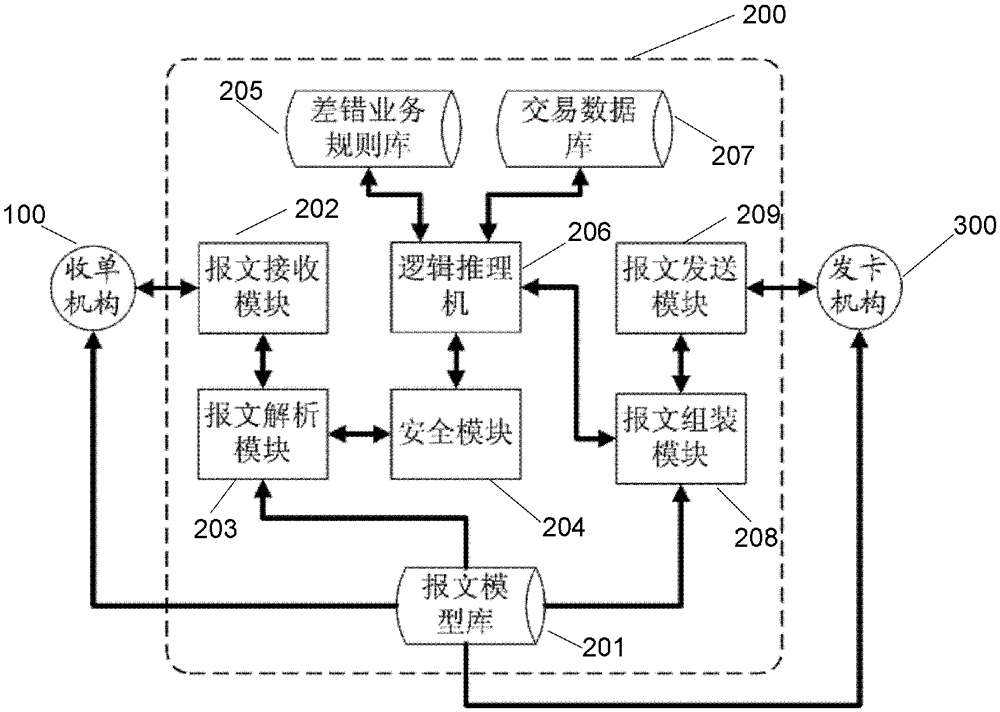

Device and method for data processing on-line processing of date mistakes between mechanisms

ActiveCN105590215AReduce manual stepsAvoid long processing timesTransmissionSpecial data processing applicationsBusiness ruleSecurity policy

The present invention relates to a device and method for data processing on-line processing of date mistakes between mechanisms. The device comprises: a message model base configured to store uniform mistake business message models; a message receiving module configured to receive request message data from a first mechanism; a message analysis module configured to analyze the request message date from the message receiving module; a safety module configured to check the safety strategy of the request message date according to the analysis result; a mistake business rule base configured to store mistake business rules; a logic theory machine configured to perform logical processing of the business date in the request message data and generate business transaction data according to the analysis result and the mistake business rules; a transaction database configured to store business transaction data; a message assembly module configured to assemble the mistake business message model in the business transaction data and message model base to be a request message; and a message sending module configured to send the request message to a second mechanism.

Owner:CHINA UNIONPAY

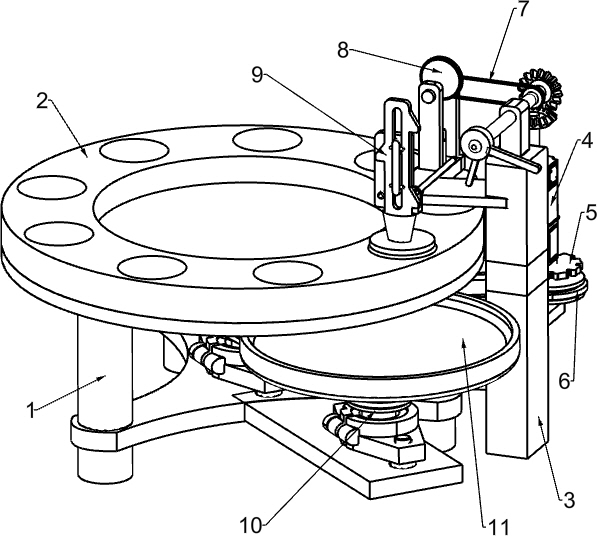

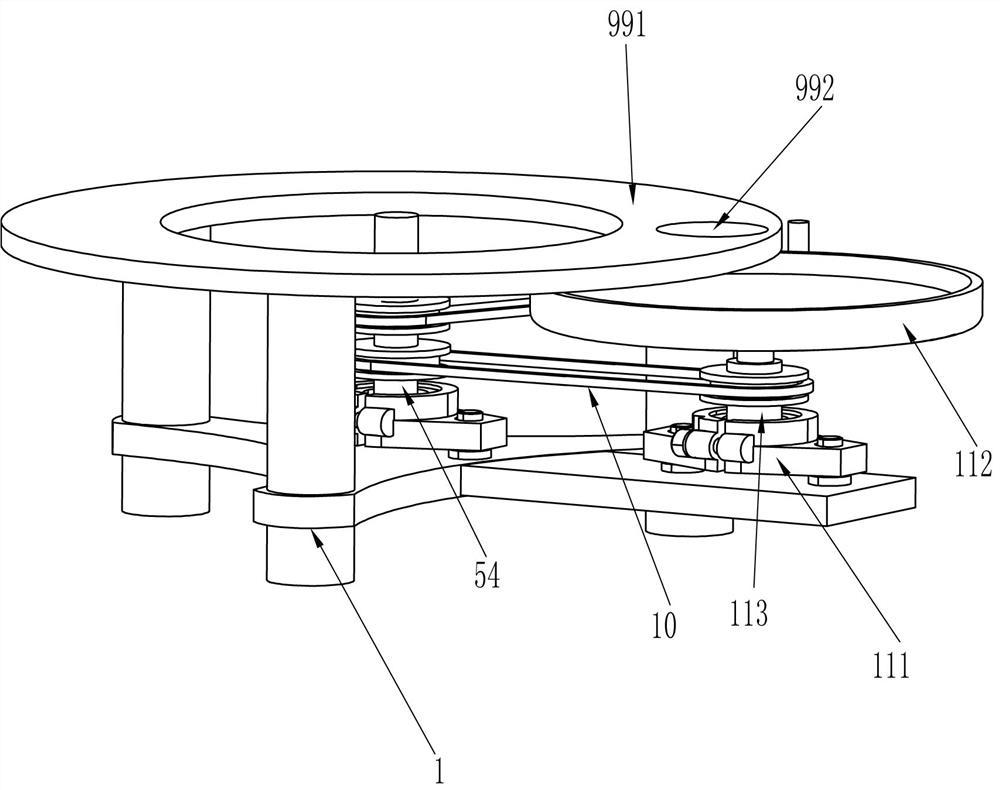

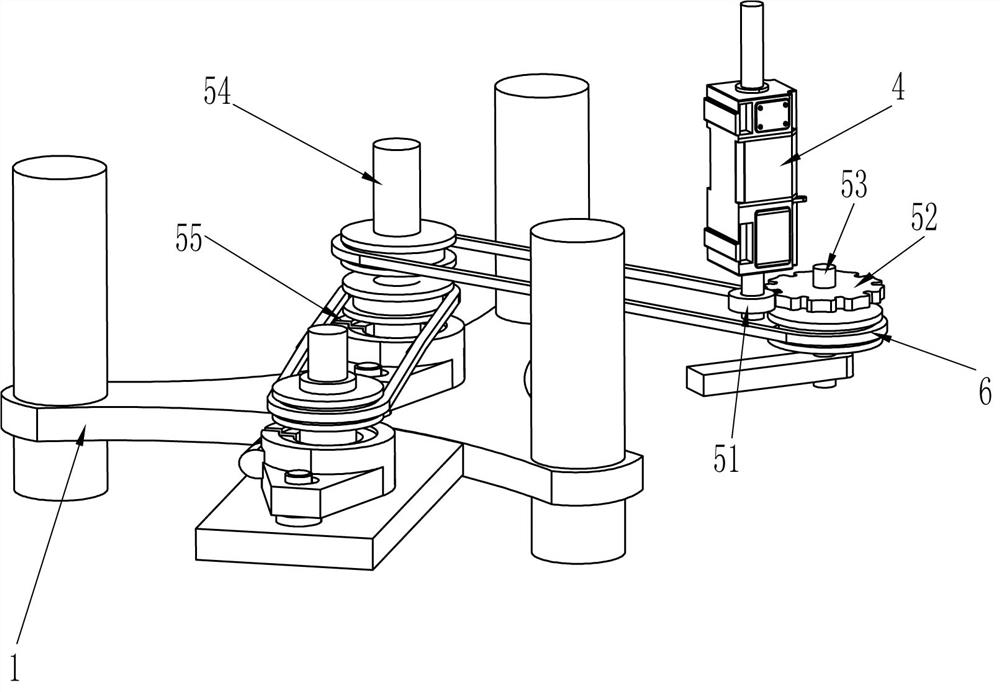

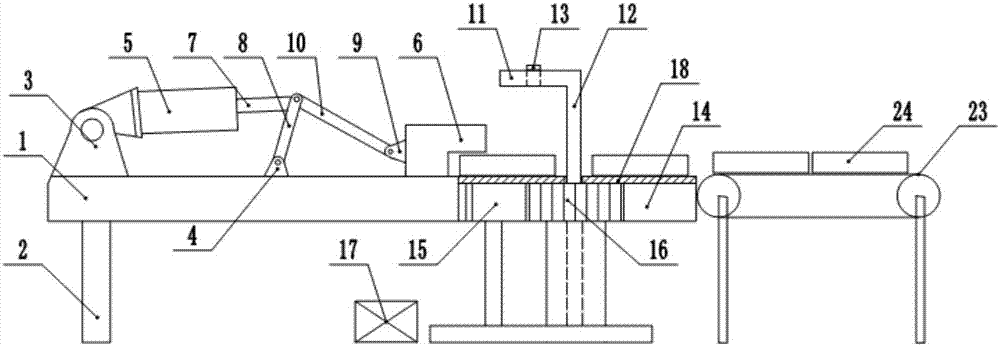

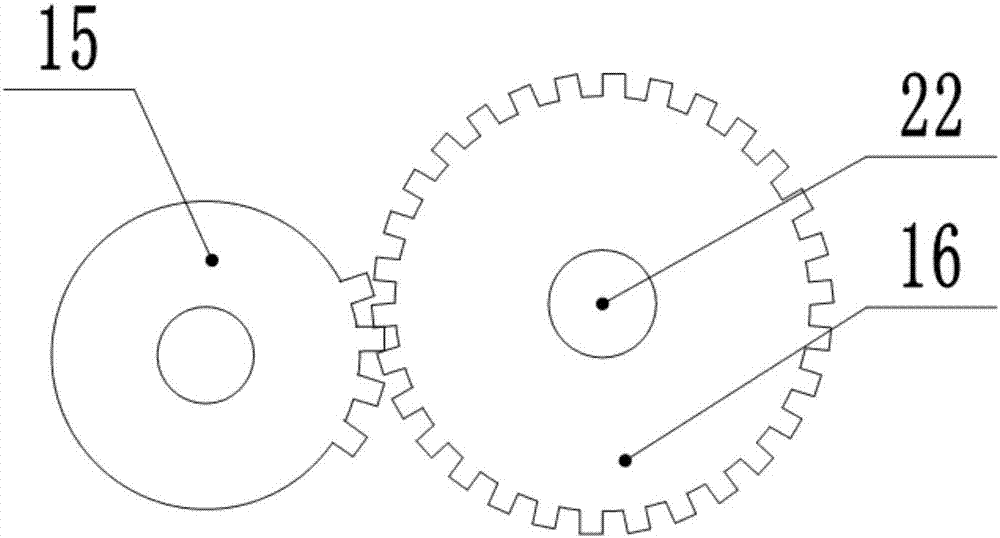

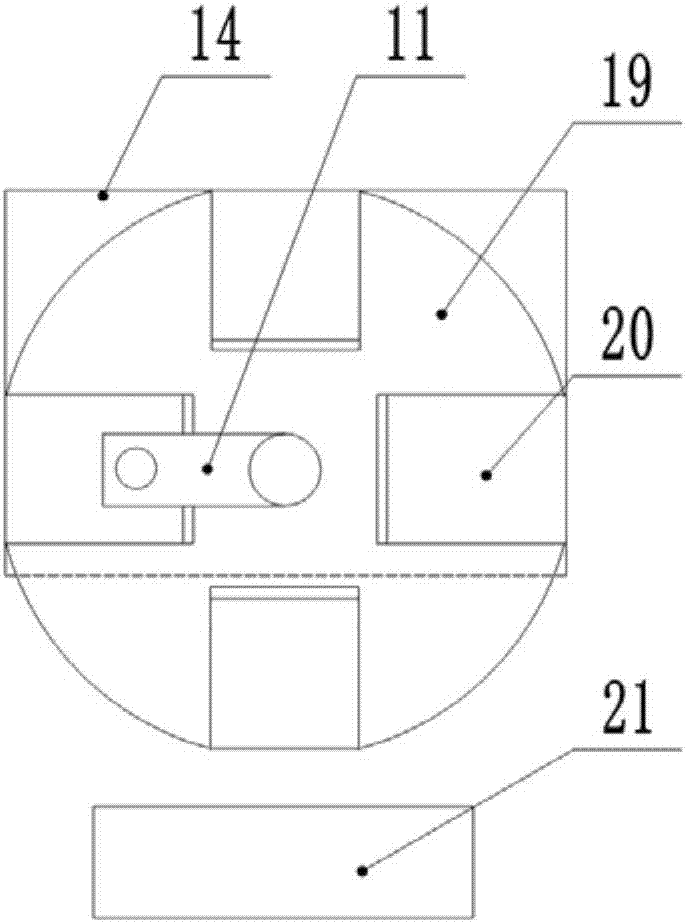

Tengxian rice cake pressing device

The invention relates to a pressing device, in particular to a Tengxian rice cake pressing device. The technical problem is to provide a Tengxian rice cake pressing device which can automatically press rice cakes, collects prepared rice cakes, and reduces manual operations. According to the technical scheme the Tengxian rice cake pressing device comprises a base and a support frame, wherein the top part of the base is rotationally provided with a worktable; the top part of the worktable is evenly provided with a plurality of circular grooves for holding the rice cakes; the support frame is arranged on one side of the base; and the upper part of the side part of the support frame is provided with a dual-axis motor. According to the Tengxian rice cake pressing device, through an intermittentrotating mechanism, the worktable automatically rotates intermittently; without manually replacing and taking the rice cakes repeatedly during pressing, through a pressing mechanism, automation of rice cake pressing is realized, manual operation steps are reduced, and the efficiency of rice cake pressing is increased; and through a poking mechanism, after being pressed, the rice cakes on the worktable can automatically separate from the worktable without manually taking out the rice cakes.

Owner:董永辉

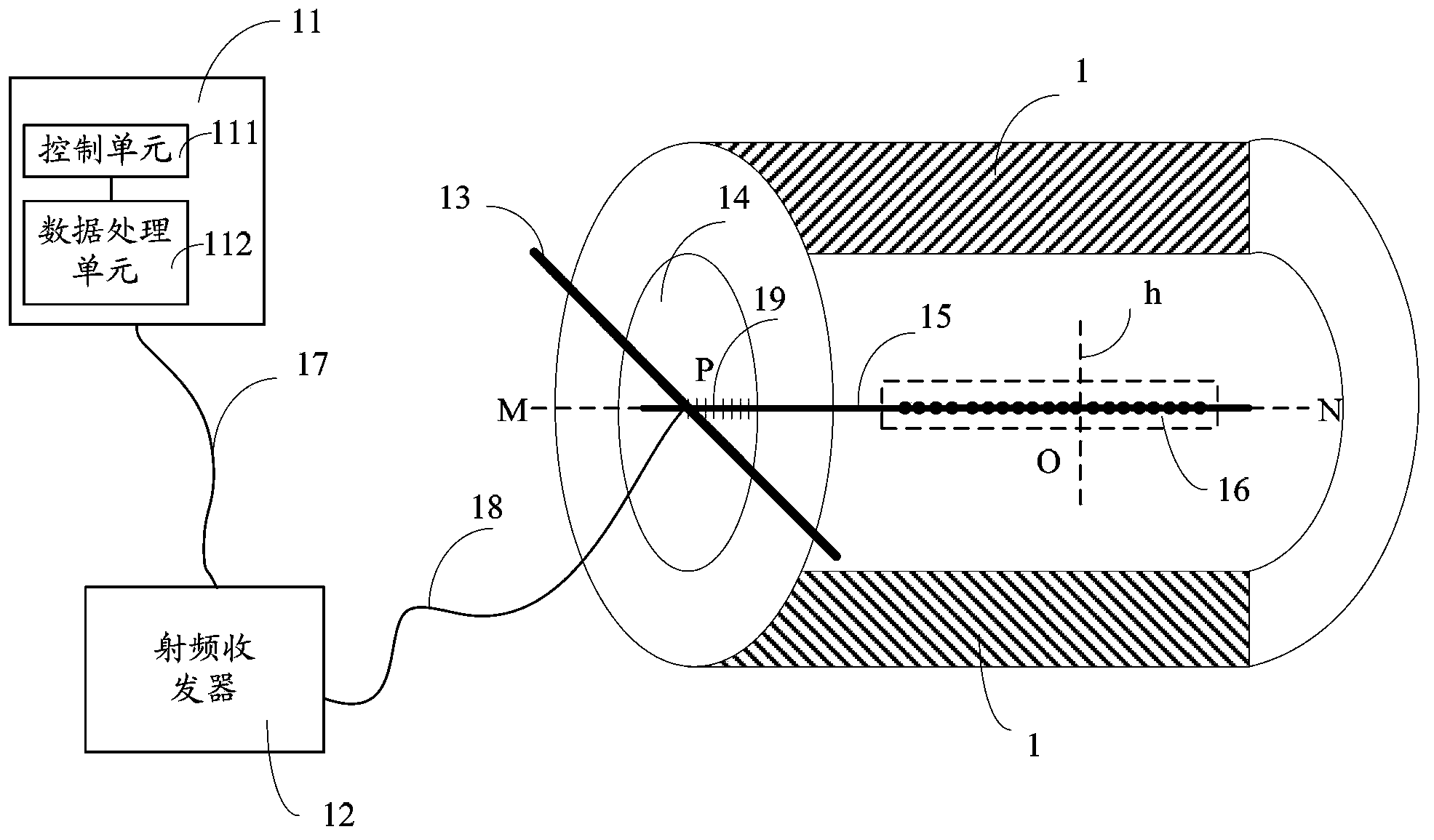

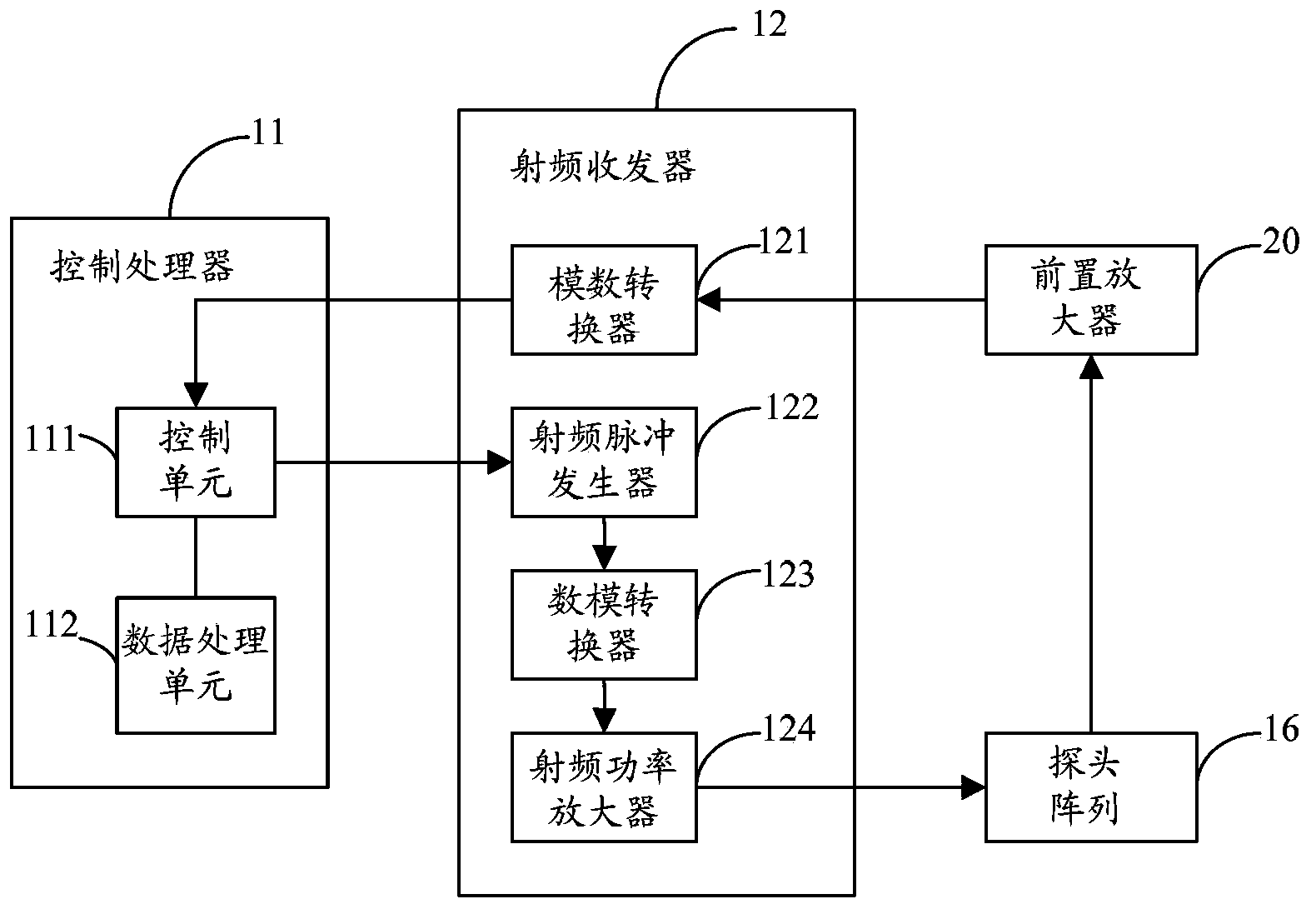

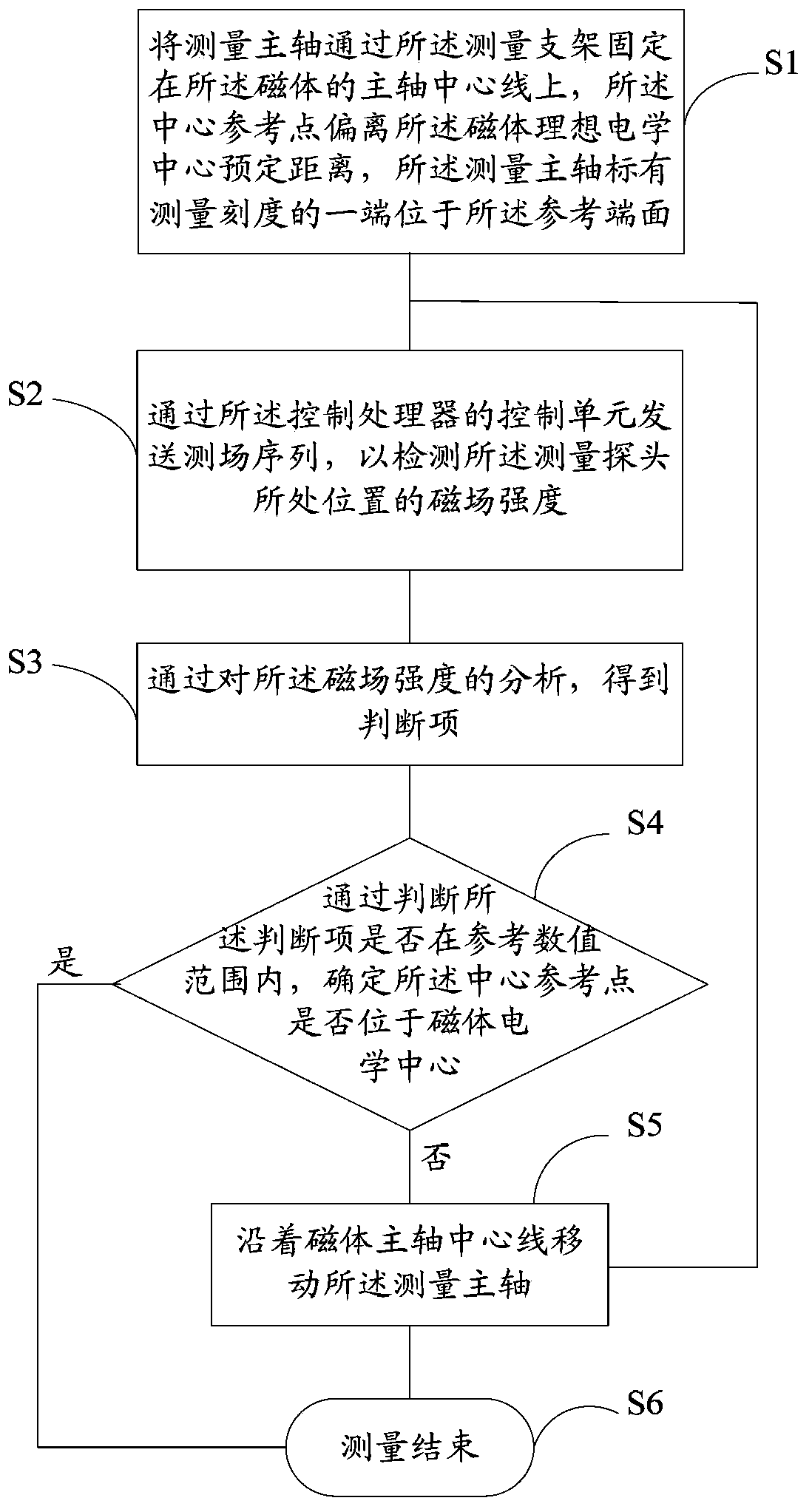

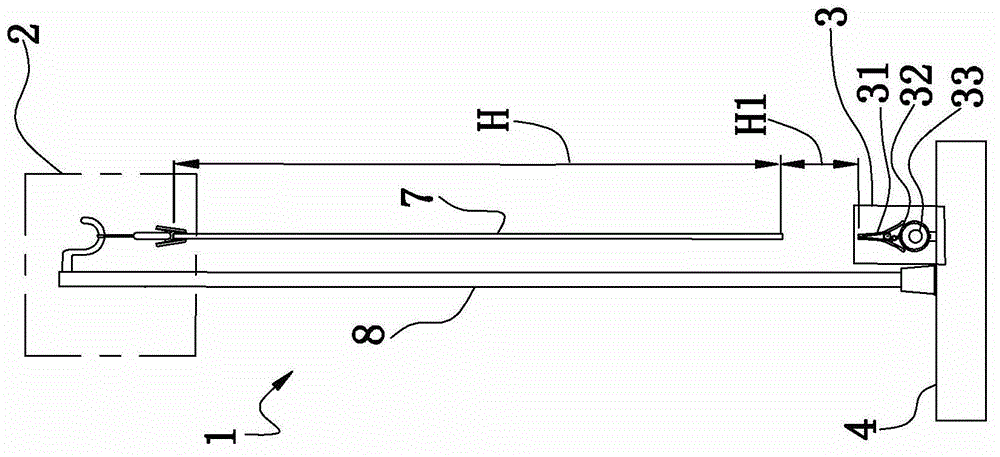

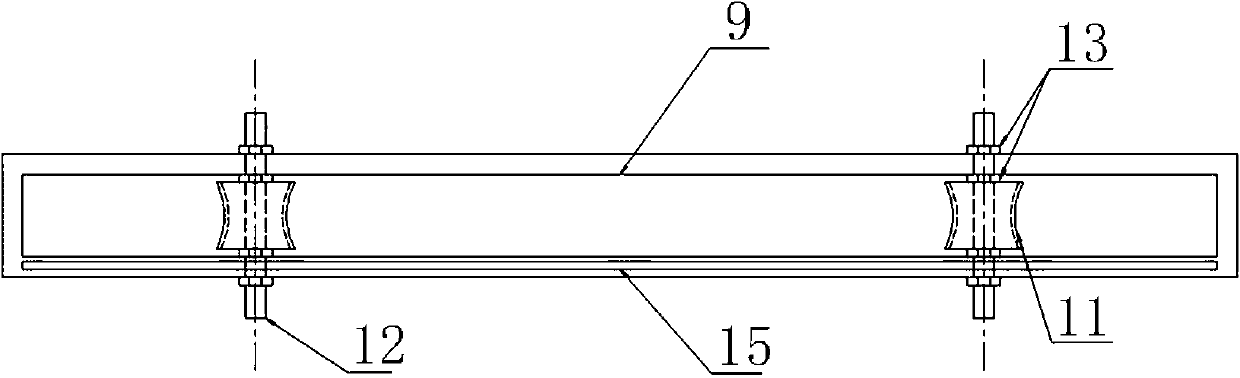

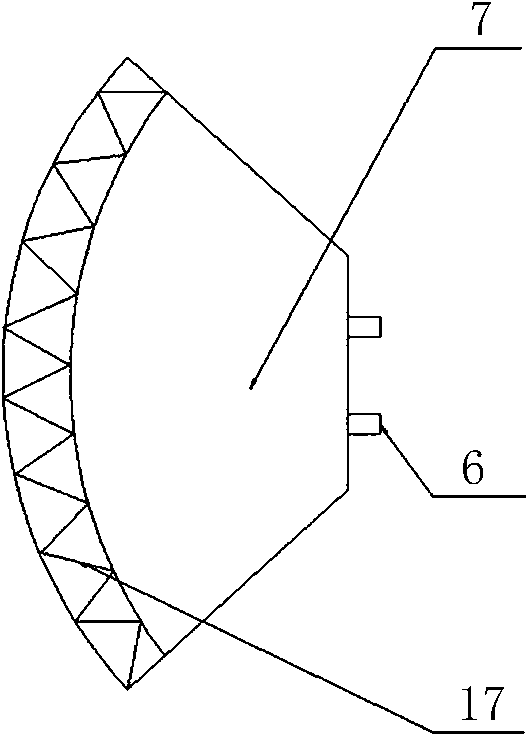

Detection device and method for magnetic-body electrical center

The invention discloses a detection device and method for a magnetic-body electrical center. The detection device comprises a probe array, a main measuring shaft, a radio frequency transceiver and a control processor, wherein the probe array comprises a preset number of measuring probes which are arranged in a linear manner; the probe array is arranged on the main measuring shaft; measuring scales relative to the position of a central reference point are formed at one end of the main measuring shaft; the central reference point is any point on the main measuring shaft, where the probe array is located; the radio frequency transceiver is used for transmitting a radio frequency pulse signal and receiving an analog voltage signal; the control processor comprises a control unit and a data processing unit. By adopting the technical scheme of the invention, the time for measuring the magnetic body electrical center is shortened, the operation complexity caused by too much manual operation is reduced, and the precision of the measurement result is improved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

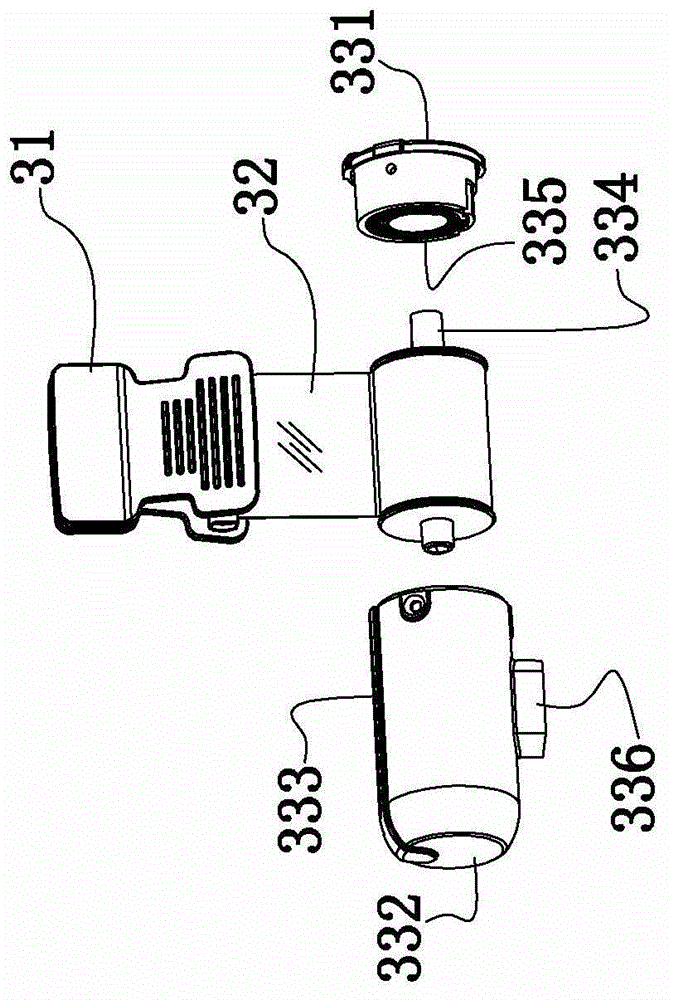

Clothing stretching device and clothing caring machine with same

InactiveCN104372596AImprove nursing efficiencyReduce manual stepsIroning apparatusOther drying apparatusMechanical engineeringEngineering

The invention discloses a clothing stretching device used for a clothing caring machine comprising a body. The clothing stretching device comprises an upper clothing support unit located on the upper portion of the body and a lower clothing clamping unit located under the upper clothing support unit (2), located on the lower portion of the body and used for fixing the lower portion of clothing; the lower clothing gripping unit comprises a grip and an automatic retraction unit provided with a retraction belt, one end of the grip is connected on the outer section of the retraction belt, and the automatic reaction unit has the tensile force enabling the retraction belt to be pulled outward by a preset length dimension and always kept in retraction. When clothing is hung on the upper clothing support unit, the lower end of the clothing is gripped by the grip, pulling upwards by proper distance, of the automatic retraction unit and is held by the retraction belt, and the clothing can be kept in stretched and tightened. Various tension-resistance clothing fabric can be taken into consideration of the clothing stretching device, so that clothing with wide difference in poor tension resistance and good tension resistance can be joint used on the clothing stretching device.

Owner:NINGBO JIMU ELECTRICAL APPLIANCE

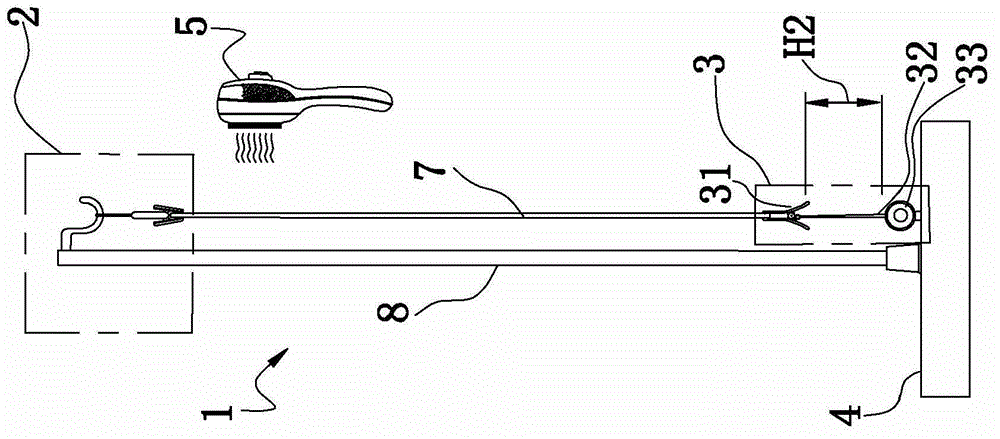

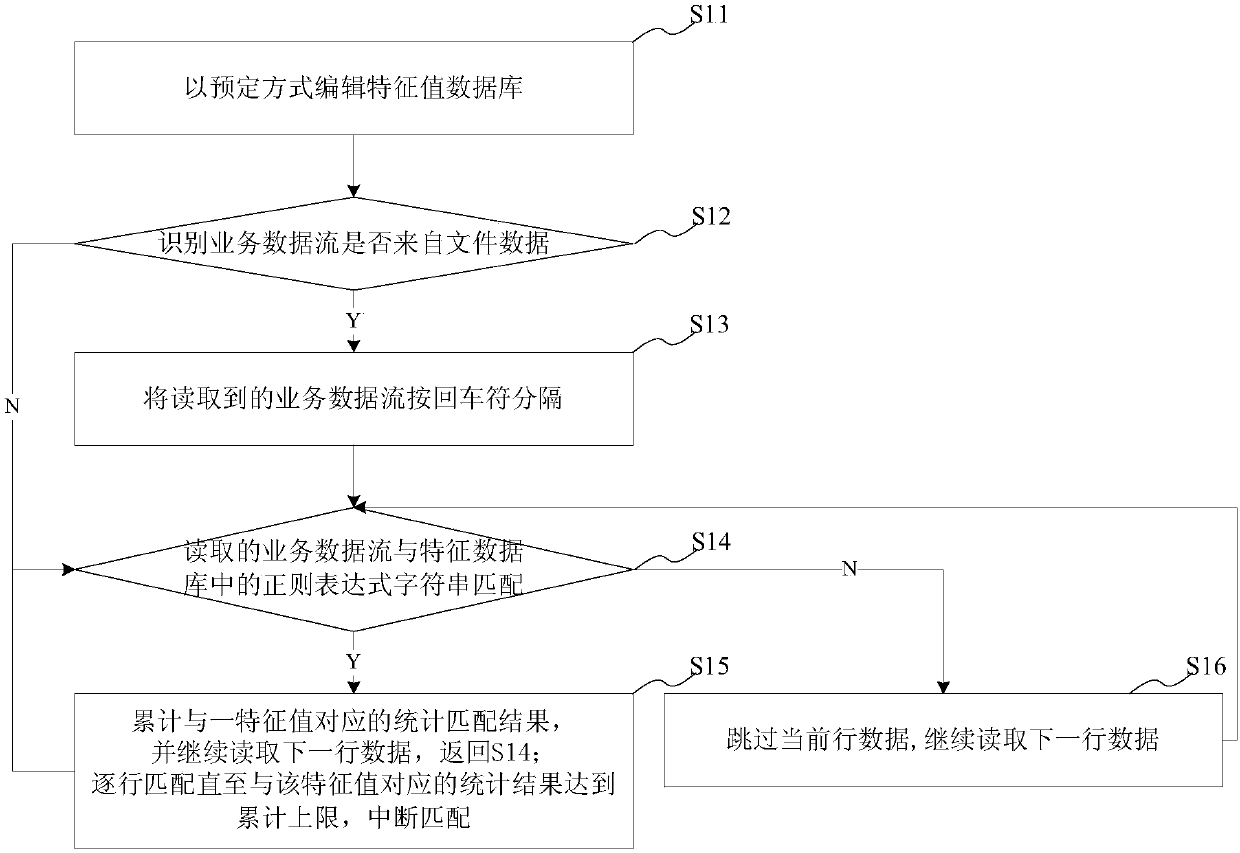

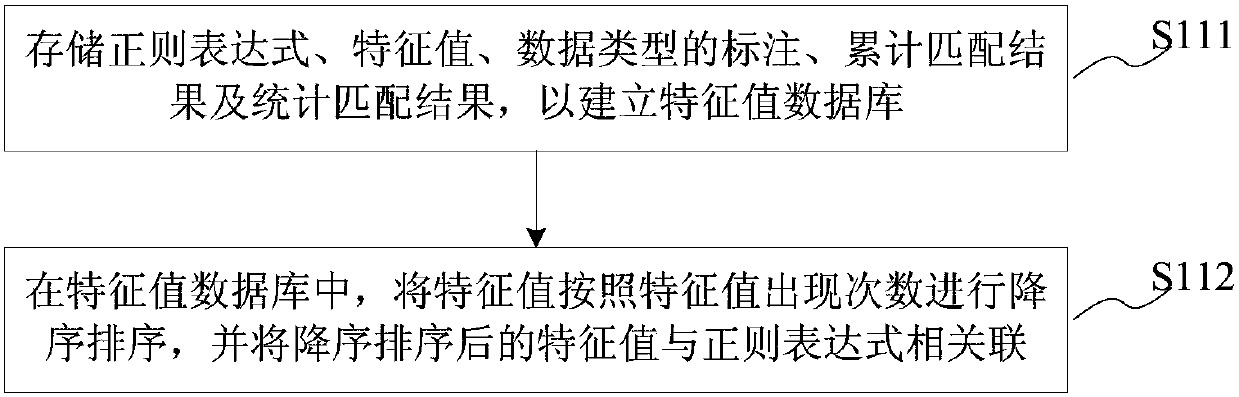

Data type identification method and system, computer readable storage medium and equipment

InactiveCN107766466AAutomate processingRealize agile manufacturingSpecial data processing applicationsData streamBusiness data

The invention provides a data type identification method, a data type identification system, a computer readable storage medium and equipment. The identification method comprises the steps of editinga characteristic value database, wherein the characteristic value database includes regular expressions for judging data types of business data flows and characteristic values associated with the regular expressions, and different business data flows correspond to different regular expressions; reading the received business data flows line-by-line, carrying out string matching with the regular expressions in the edited characteristic value database; if matching, accumulating statistical matching results corresponding to one characteristic value; continuously reading data in a next row; carrying out string matching between the data in the next row and the regular expressions in the characteristic value database; and matching line by line until the statistical result corresponding to the characteristic value reaches a cumulative threshold, and interrupting the matching. According to the data type identification method, the data type identification system, the computer readable storage medium and the equipment, the error rate of manual identification is reduced, the identification efficiency is improved, and the automatic processing of data in a manufacturing process is realized, thereby being beneficial to promoting an intelligent process in the electronic industry.

Owner:VAYO SHANGHAI TECH

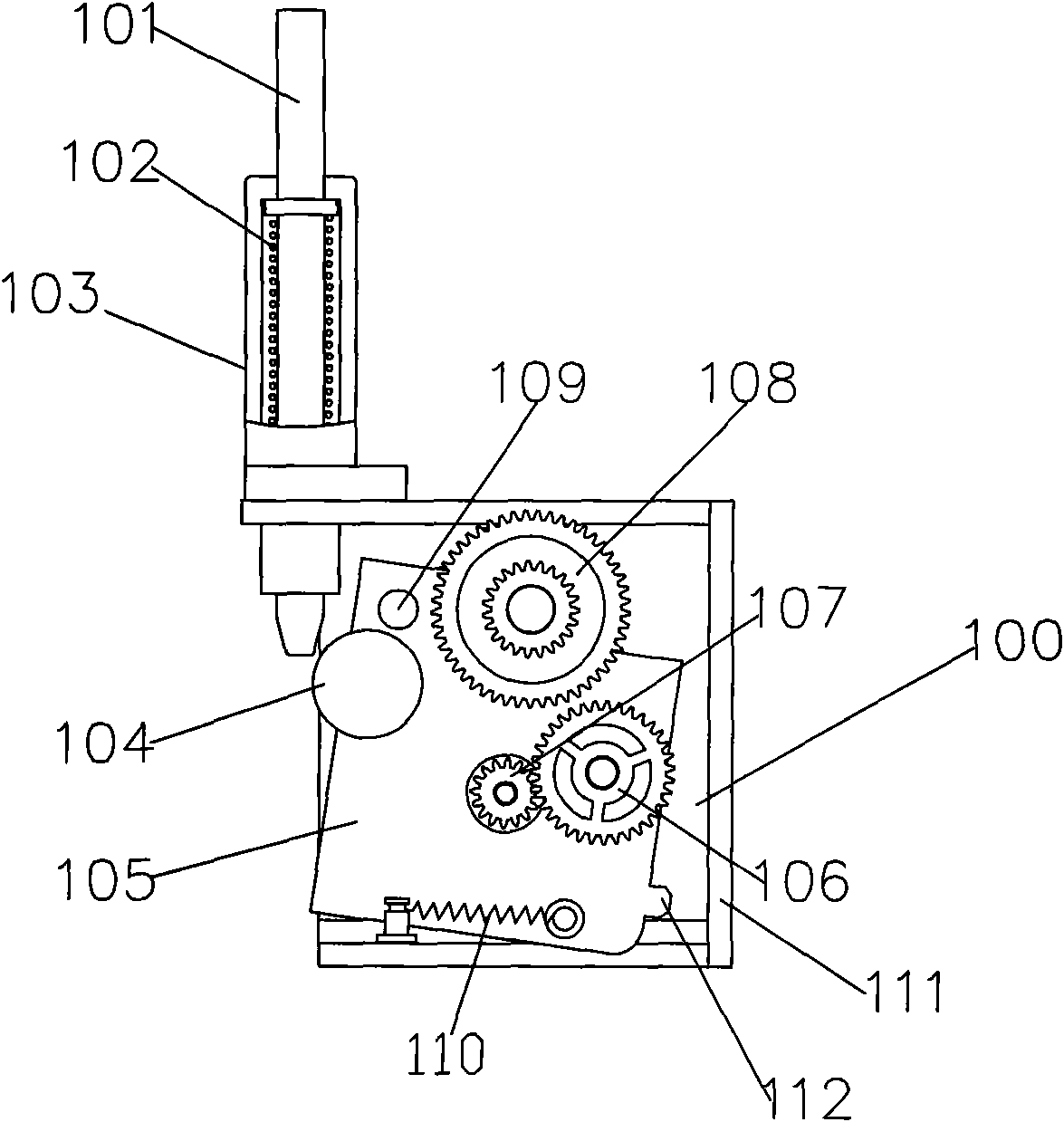

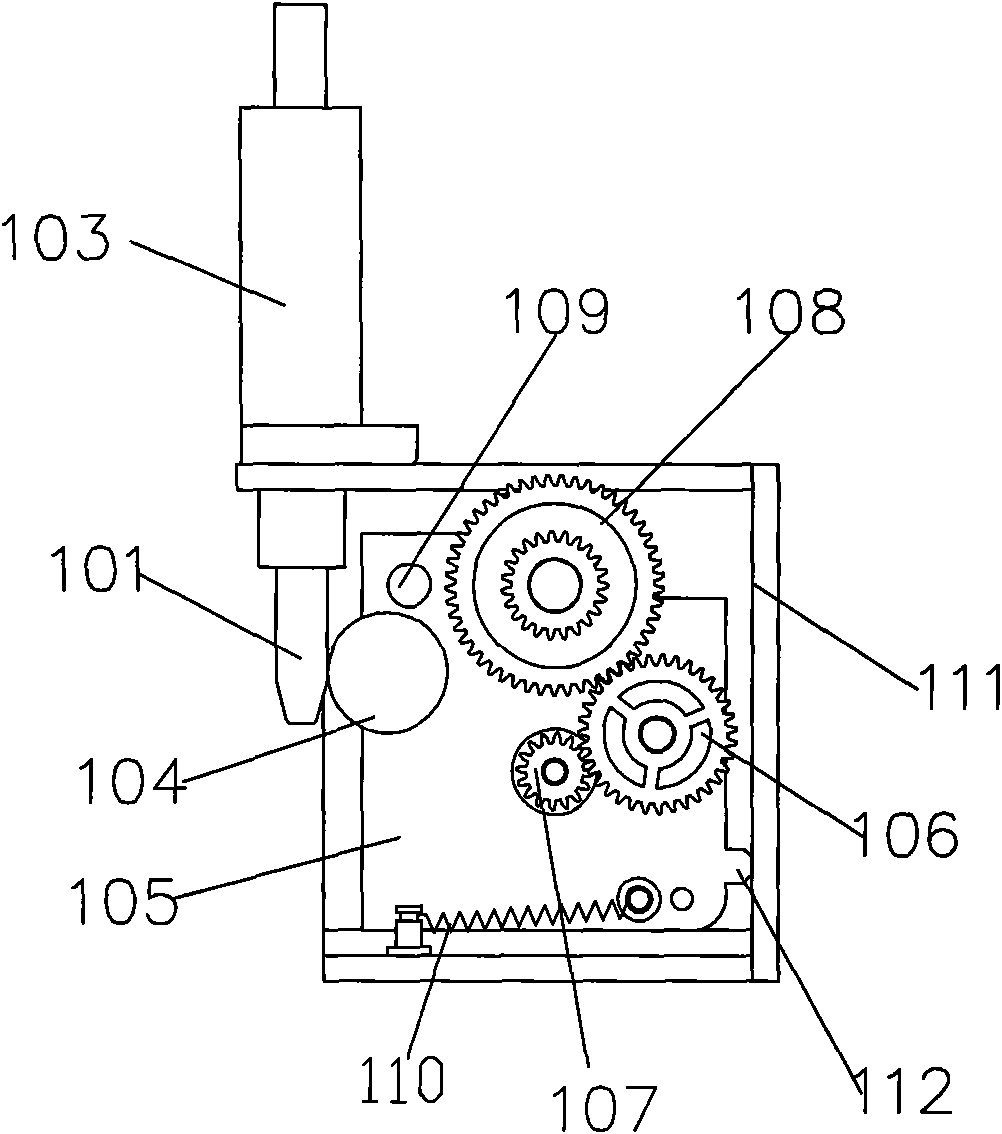

Motor clutch device for money box

The invention discloses a motor clutch device for a money box, comprising a base, a motor closed mandril and a money pressing transmission shaft gear which are arranged on the base, and a motor locating plate rotating shaft used for rotatablely connecting; the motor locating plate rotating shaft is provided with a motor locating plate which can rotate around the motor locating plate rotating shaft; the motor locating plate is fixed with a clutch bearing, a clutch gear, a money pressing motor gear and a tension spring, wherein, the clutch gear is meshed with the money pressing motor gear, one end of the tension spring is fixed on the motor locating plate, and the other end thereof is fixed on the base. In a separating state, the clutch gear is not meshed with the money pressing transmission shaft gear, thus avoiding the gears being collided and prolonging the service lives of the gears; when a cover of the money box is opened, the gears are automatically separated, the step of hand pushing for adding money can be omitted, and the step of adding money is also reduced, so that the time for adding money is shortened.

Owner:HANGZHOU EASTCOM FINANCIAL TECH +1

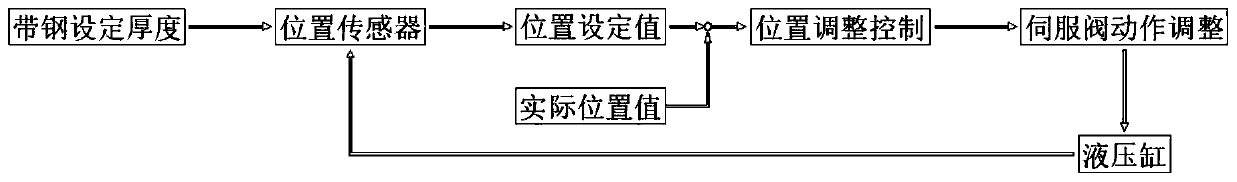

Hot rolling reeling scroll defect control method

InactiveCN110216148AReduce manual stepsReduce labor costsRoll mill control devicesMetal rolling arrangementsEngineeringPosition sensor

The invention discloses a hot rolling reeling scroll defect control method, and relates to the field of hot rolling. The thickness of strip steel is set, the roll gap of a pinch roll is set, the stripsteel enters a reeling machine, the strip steel enters the roll gap between a reeling assisting roll and a core bar in the reeling machine till the core bar is expanded, and tension is established between the core bar and a finish rolling rack F6. The values of position sensors of pressing hydraulic cylinders on the two sides are adopted for reference, the two-side pressing actual deviation is calculated, a computer automatically gives the OS servo valve signals according to the actual deviation value, the hydraulic cylinders are elevated or the computer automatically gives DS servo valve signals, and the hydraulic cylinders are elevated. Through control over gaps of the pinch roll, actually, the actual deviation on the two sides is accurately obtained under the pressure control situation; through the deviation feedback value, the deviation is automatically or manually adjusted for ensuring the relative horizontal closed-loop control process of the pinch roll, the reeling machine is more automatic and stable in the running process, the artificial participation steps are reduced, and the labor cost is reduced.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Jelly extracting machine

The invention relates to a jelly extracting machine, which comprises a machine frame, wherein the machine frame is provided with a pushing mechanism, a feeding mechanism and an extracting device, wherein a royal jelly queen cup strip can move in the feeding mechanism, the pushing mechanism and the extracting device are sequentially arranged on the moving route of the royal jelly queen cup strip, the pushing mechanism is used for pushing the royal jelly queen cup strip to move along the feeding mechanism, and the extracting device is used for gathering larva and extracting jelly from the royaljelly queen cup strip, so that the automation of jelly extracting is achieved, and the working efficiency is improved.

Owner:杭州余杭飞瑞五金制品有限公司

Automatic polishing equipment

InactiveCN106994630AImprove work efficiencySave human effortAutomatic grinding controlGrinding feedersSurface mountingEngineering

The invention discloses an automatic grinding device, which comprises a workbench, and a grinding mechanism and a conveying mechanism are installed on the upper wall of the workbench. The beneficial effect of the present invention is that the automatic grinding process can automatically rotate and change the surface when one surface is polished, and the two sides can be polished at the same time. Human error free, easy to use.

Owner:东莞市鹏翼自动化科技有限公司

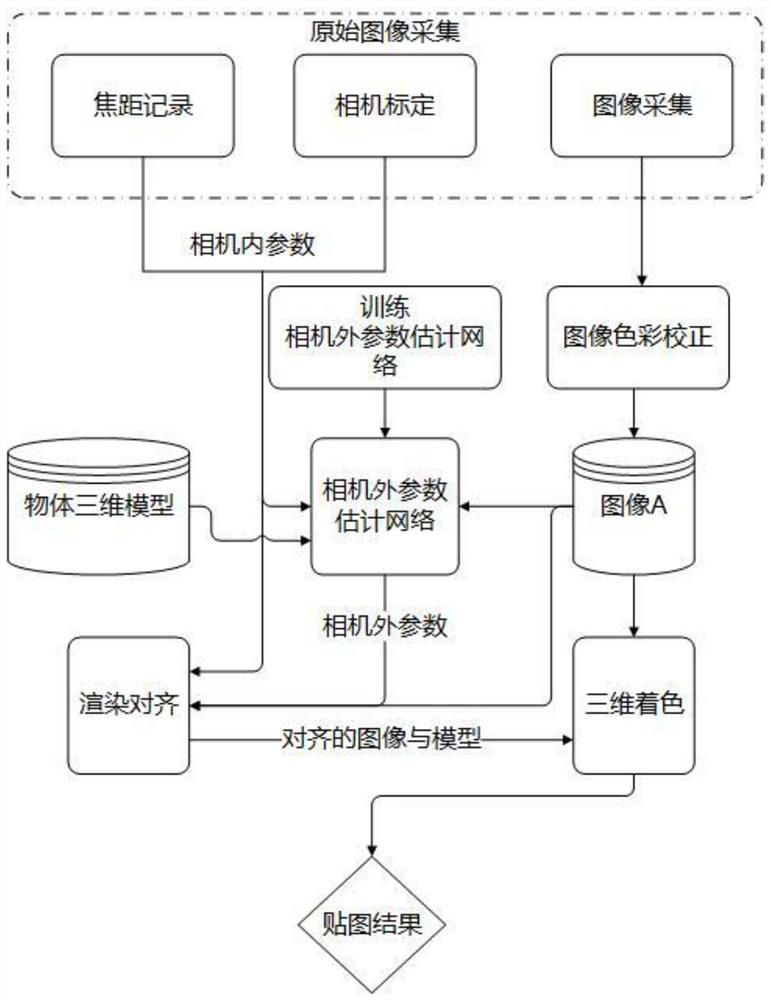

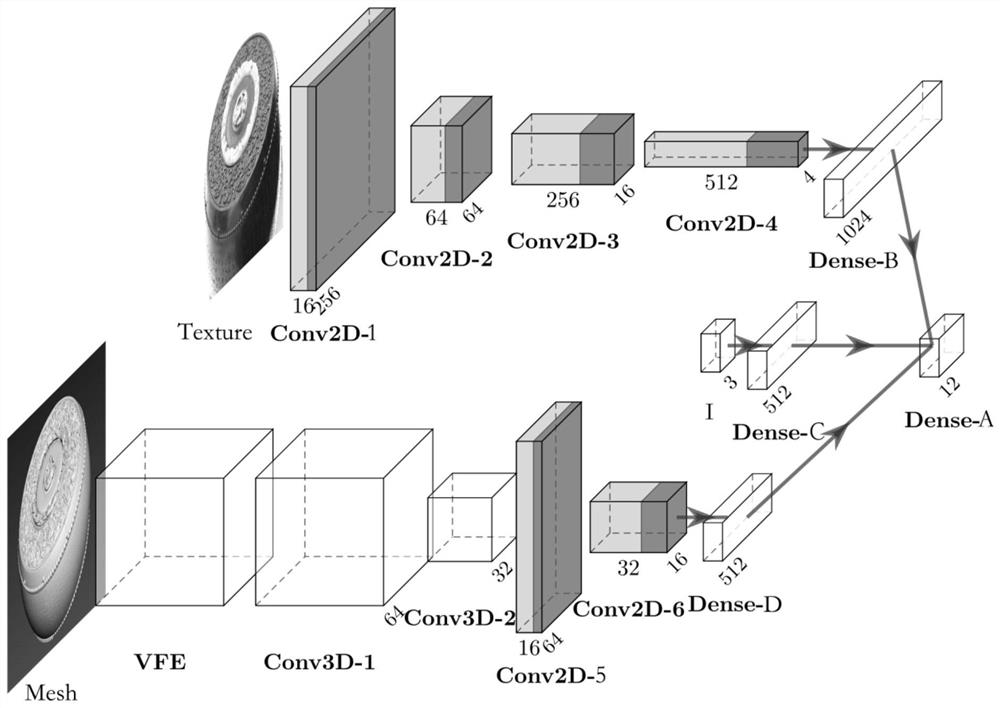

Non-contact automatic mapping method based on deep learning

PendingCN111768452AReduce manual stepsPromote resultsImage analysisNeural architecturesComputer visionThree dimensional model

The invention discloses a non-contact automatic mapping method based on deep learning. The method comprises the following steps: calibrating a camera by using a color test card through a Zhang Zhengyou calibration method to obtain camera internal parameters; collecting a plurality of original images of the object and recording focal length parameters; correcting the color of the original image byusing the color test card picture to obtain an image A; and establishing and training a camera external parameter estimation network; inputting the image A, the camera internal parameters and the object three-dimensional model into a trained camera external parameter estimation network to obtain camera external parameters; inputting the external and internal parameters of the camera, the three-dimensional model of the object and the image A into a rendering pipeline for processing to obtain a rendering result, and performing rendering alignment; and enabling the rendering pipeline to store thecolor value of the image of the area determined to be used in the image A in a texture mapping file according to the UV coordinates. According to the invention, the automatic mapping process is realized, a large number of manual steps are reduced, parameters transmitted by a user can be received for fine adjustment, and the high-quality mapping speed is accelerated.

Owner:TIANJIN UNIV

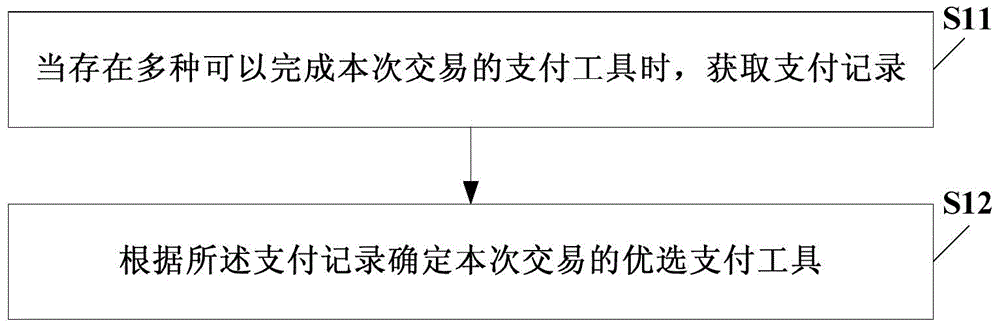

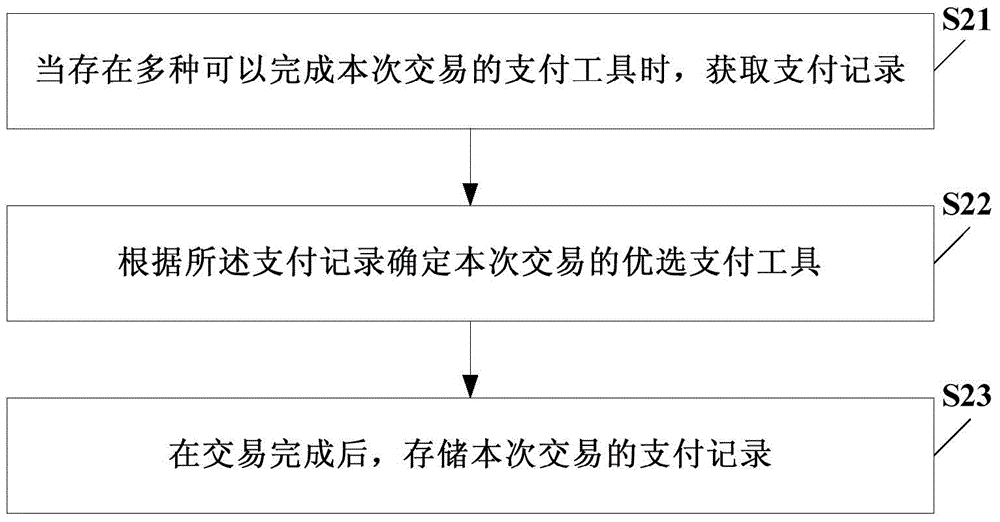

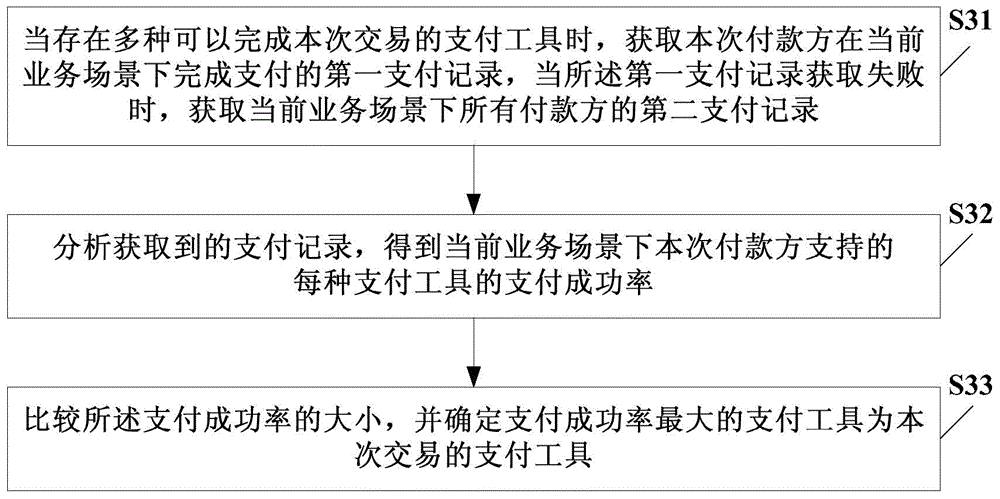

Network payment control method and apparatus

InactiveCN105335850AReduce manual stepsSimplify the payment processPayment protocolsCommercePayment orderOperating system

Embodiments of the application disclose a network payment control method and apparatus. The method comprises: when payment tools need to be selected, obtaining a payment record, and determining a preferred payment tool of a current transaction according to the payment record, wherein the payment success rate of each payment tool supported by a current payer in a current business scene is obtained by analyzing the payment record, and the payment tool with the highest payment success rate is taken as the preferred payment tool of the current transaction. According to the embodiments of the application, the payment tools can be automatically selected, the manual operation steps of the payer are reduced, the payment process is simplified, and the payment and transaction efficiency are improved. In addition, the payment tool with the highest payment success rate is taken as the preferred payment tool of the current transaction, so that the probability of one-time payment success can be increased, the re-selection of the payment tools is avoided, and the payment and transaction efficiency can be improved.

Owner:ALIBABA GRP HLDG LTD

Municipal road sewer pipeline construction equipment and method

ActiveCN113006240AReduce manual stepsSave human effortClimate change adaptationSewer pipelinesBrush deviceSewerage

The invention relates to the technical field of municipal sewer engineering, in particular to municipal road sewer pipeline construction equipment and a method. The municipal road sewer pipeline construction equipment comprises moving rails, wherein the moving rails are laid on both sides of a groove, driving assemblies which are used for moving on the moving rails are installed on the moving rails, a mounting frame is arranged above the driving assemblies, a pipeline moving mechanism which is used for movably placing a tongue-and-groove pipe is arranged above the mounting frame, and a pipeline fixing mechanism which is used for fixing the placing position of the tongue-and-groove pipe is further installed on the mounting frame. The municipal road sewer pipeline construction equipment is characterized by further comprising an oil brushing device; and the oil brushing device is used for automatically brushing oil on a rubber ring on the inserting opening end of the tongue-and-groove pipe. According to the municipal road sewer pipeline construction equipment of the technical scheme, the purpose of automatically brushing a non-corrosive lubricant on the rubber ring at the inserting opening when the tongue-and-groove pipe is placed into the groove is achieved, and the technical problem that the tongue-and-groove pipe can be directly installed after entering the groove is solved.

Owner:广东裕仁生态建设有限公司

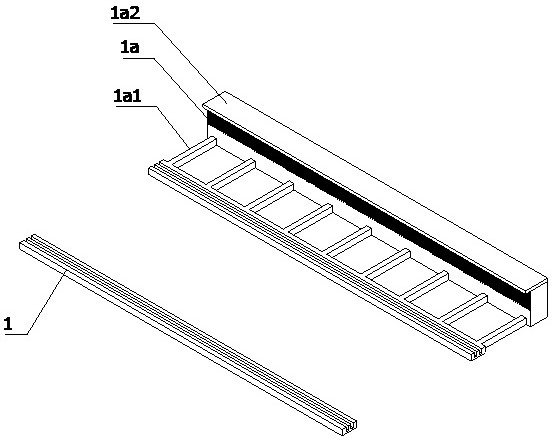

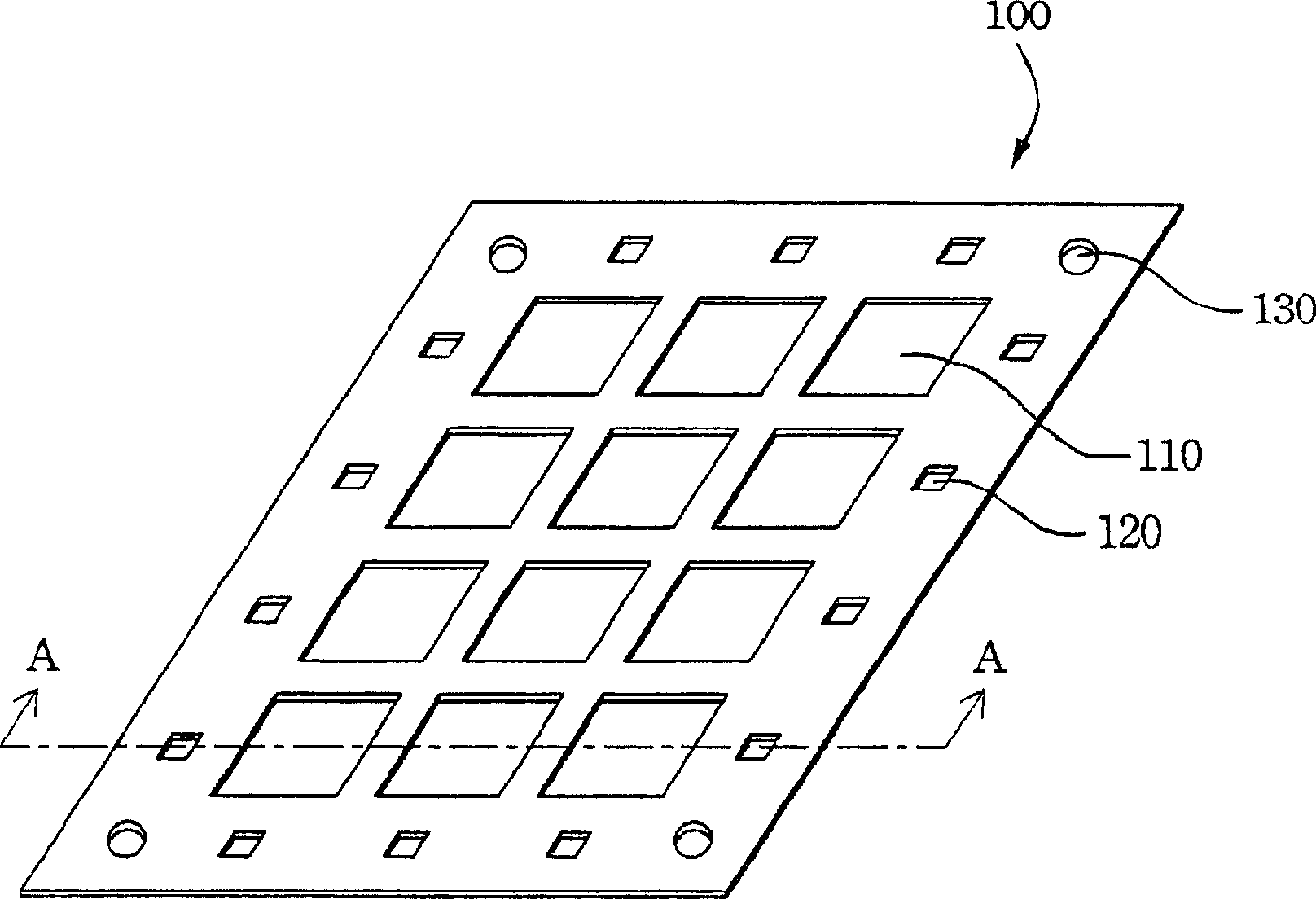

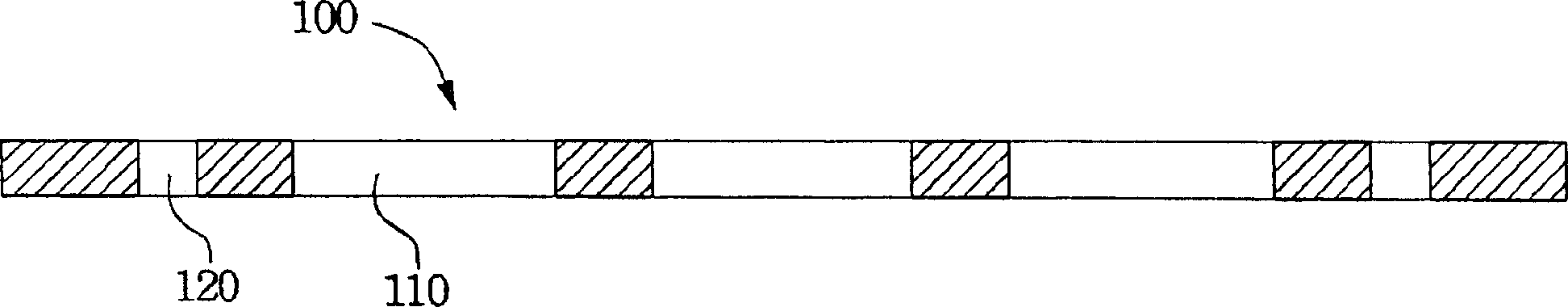

Method for making key module

InactiveCN1825513AShorten production hoursReduce manual stepsElectric switchesMan-hourPulp and paper industry

The invention is a method for manufacturing a key module, for shortening producing man-hour and reducing unqualified rate caused by artificial mistake, firstly manufacturing a module substrate comprising plural key holes, soft glue location parts and module location parts, forming soft glue parts on the module substrate, successively manufacturing a key substrate comprising plural keys and cut parts, then bonding the key substrate with the soft glue parts, and finally cutting the cut parts with laser to form keys so as to form the key module.

Owner:QUANTA COMPUTER INC

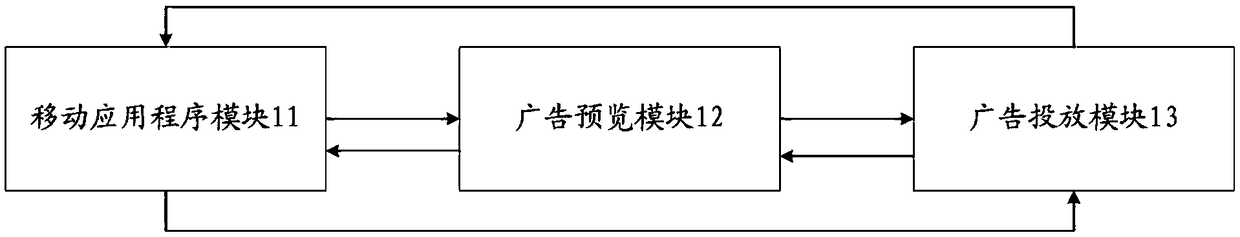

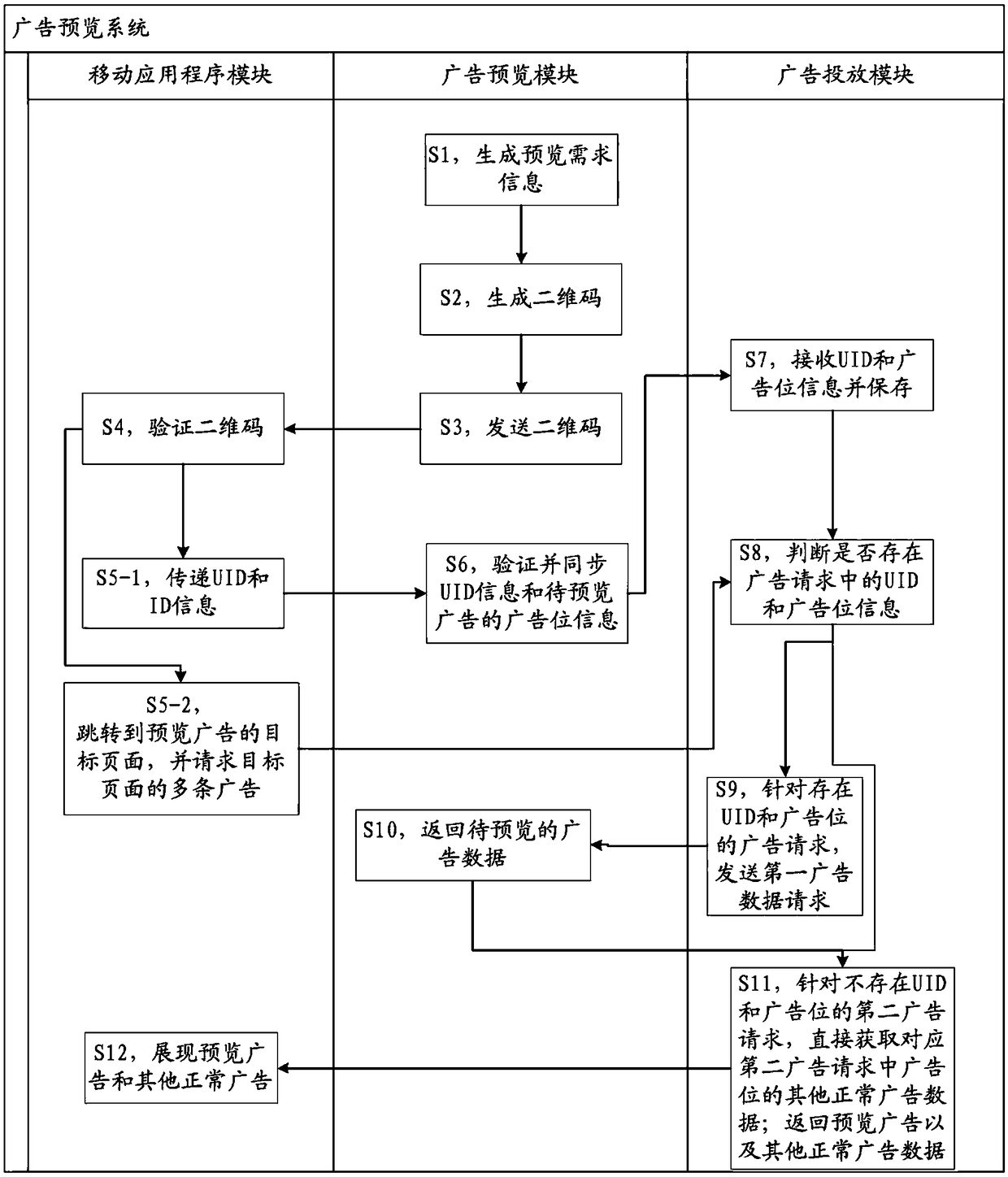

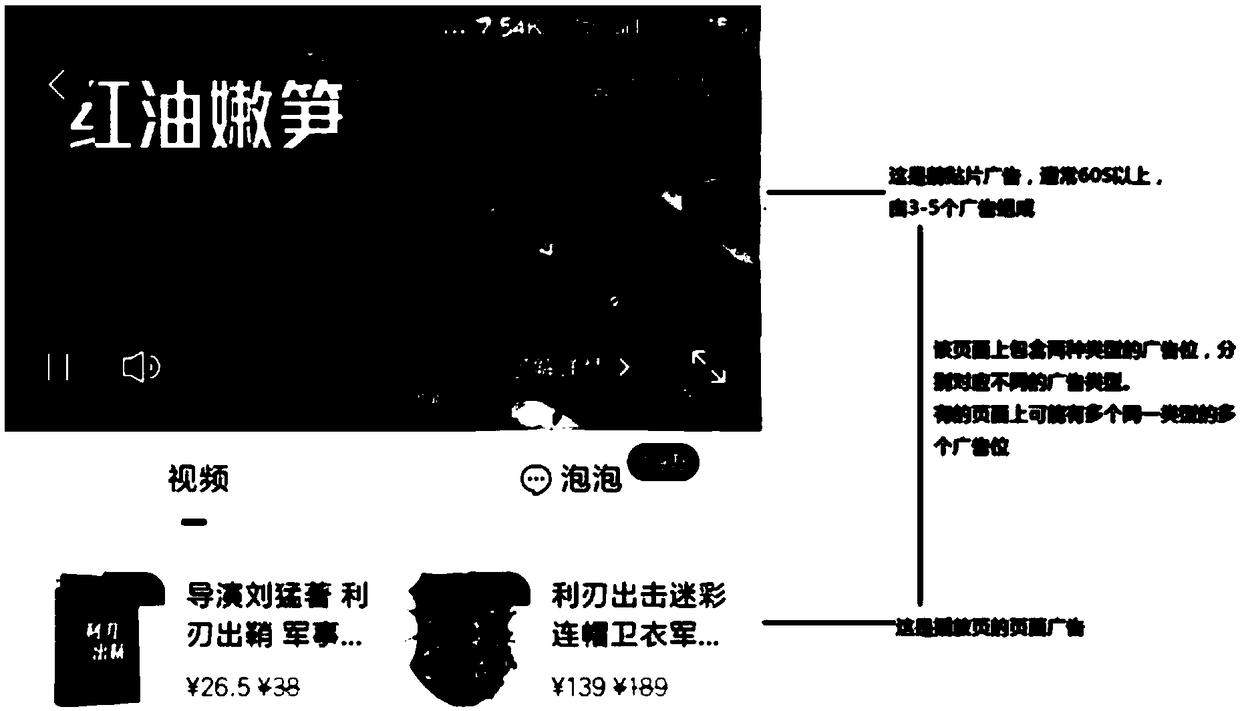

Advertisement previewing system and method

ActiveCN108665302AReduce manual stepsRealize automatic transmissionMarketingComputer terminalApplication software

The invention provides an advertisement previewing system and method. The method comprises the steps that an advertisement previewing module sends an advertisement previewing notice to a mobile application program module; the mobile application program module sends an equipment number of a mobile terminal to the advertisement previewing module; the advertisement previewing module stores the equipment number and advertisement data corresponding to the advertisement previewing notice in a binding mode and sends the equipment number to an advertisement serving module; the advertisement serving module receives and saves the equipment number; the mobile application program module skips to a target page for advertisement playing according to advertisement playing page data and sends an advertisement request of the target page to the advertisement serving module; the advertisement serving module finds the equipment number from at least one equipment number saved locally and sends the advertisement data request to the advertisement previewing module; and the advertisement previewing module receives the advertisement data request, finds target advertisement data stored with the equipment number in a binding mode from advertisement data stored locally and sends the target advertisement data to the mobile application program module through the advertisement serving module.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

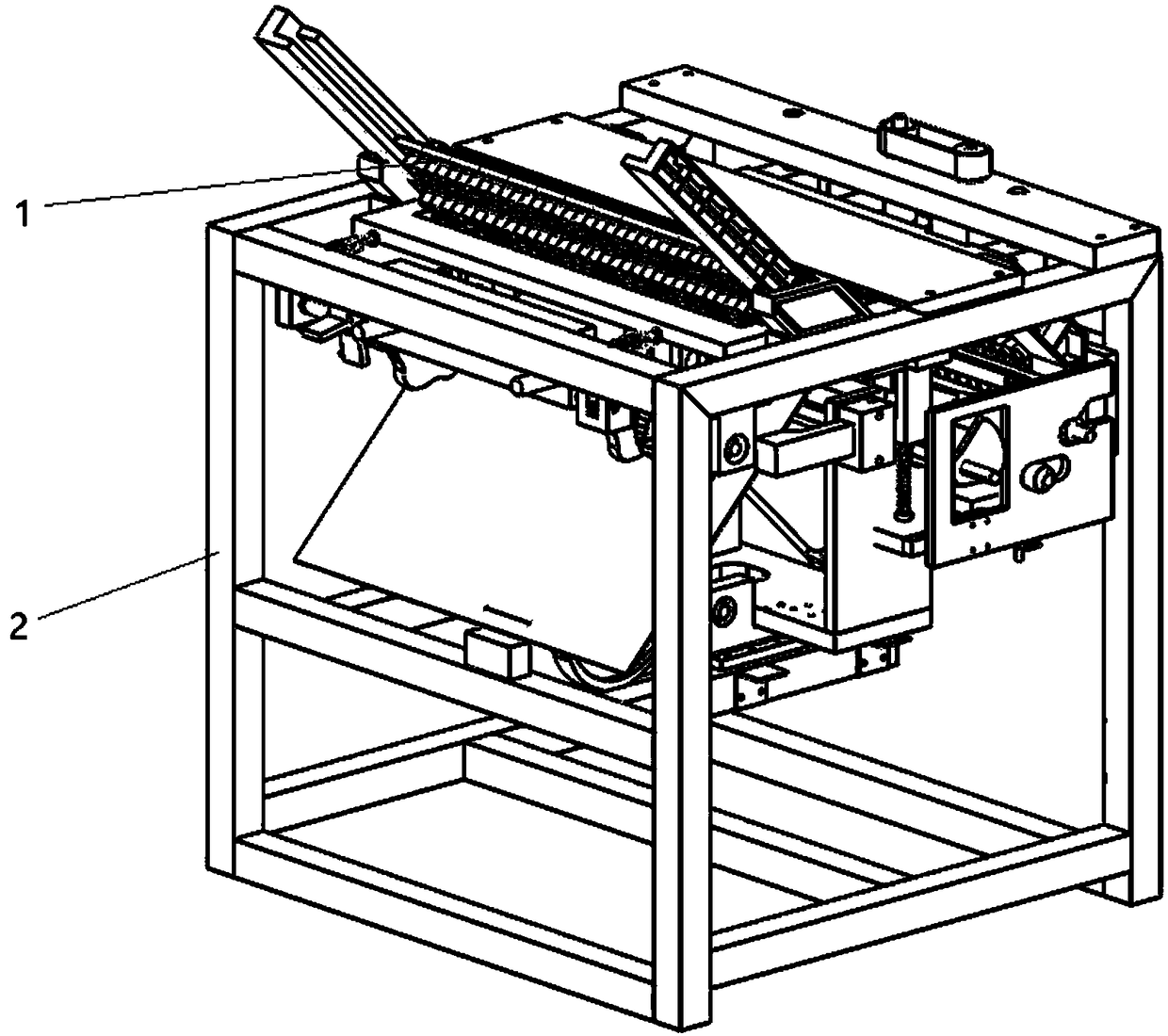

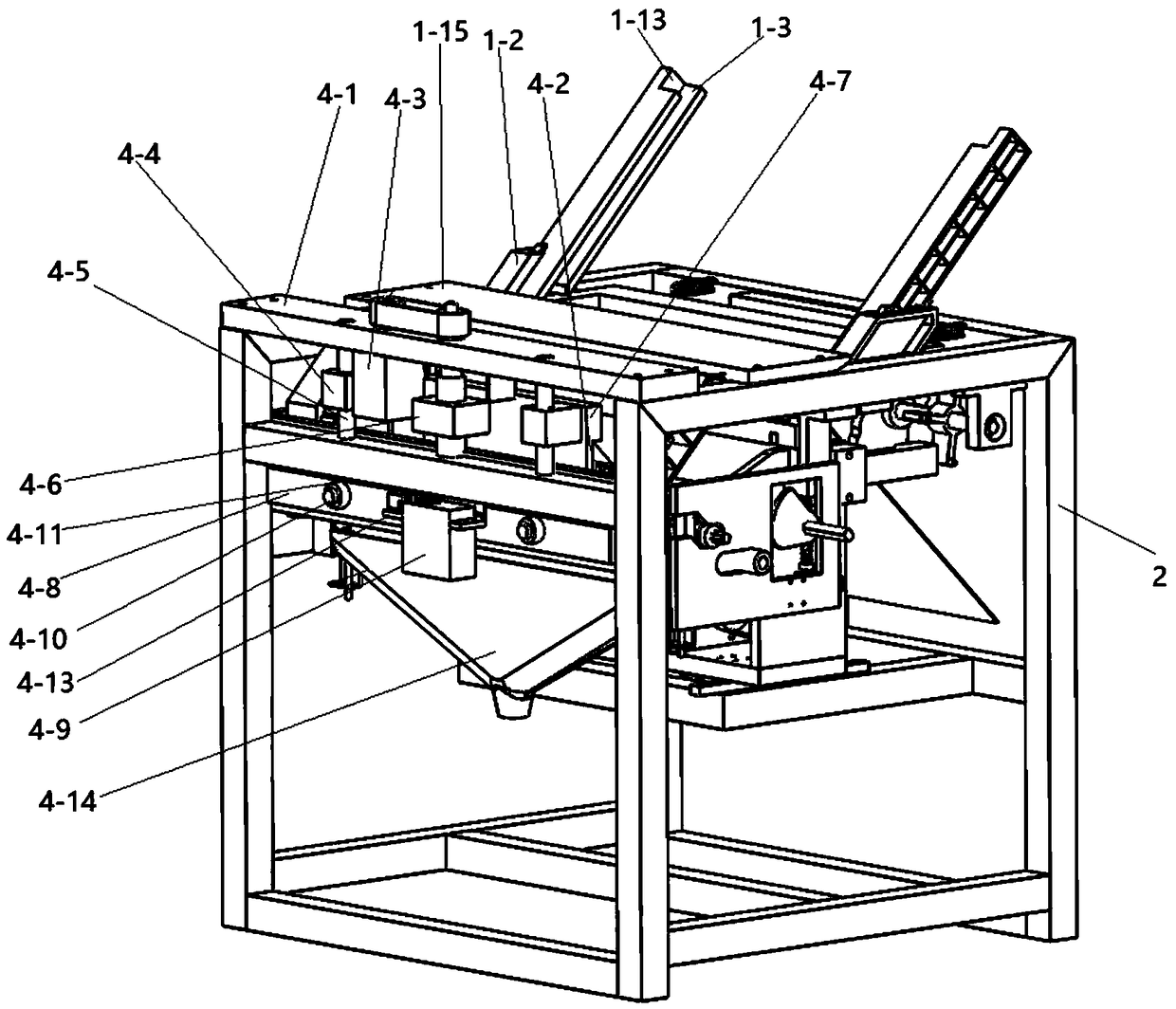

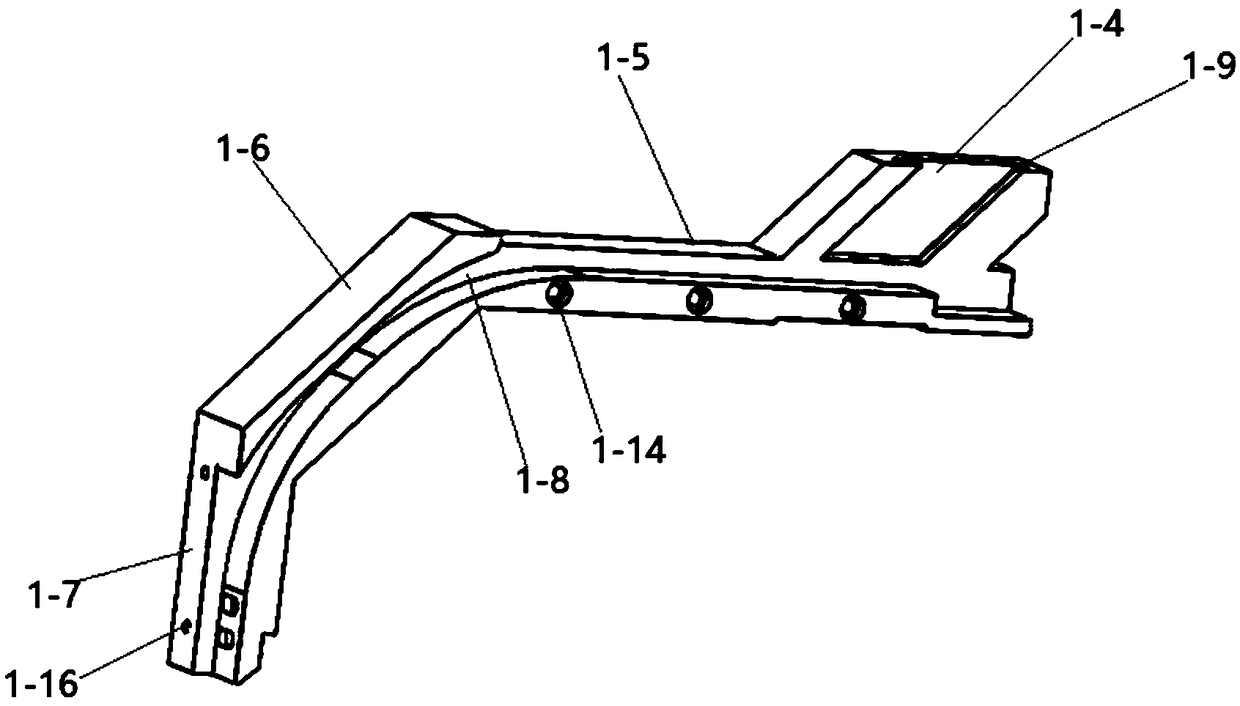

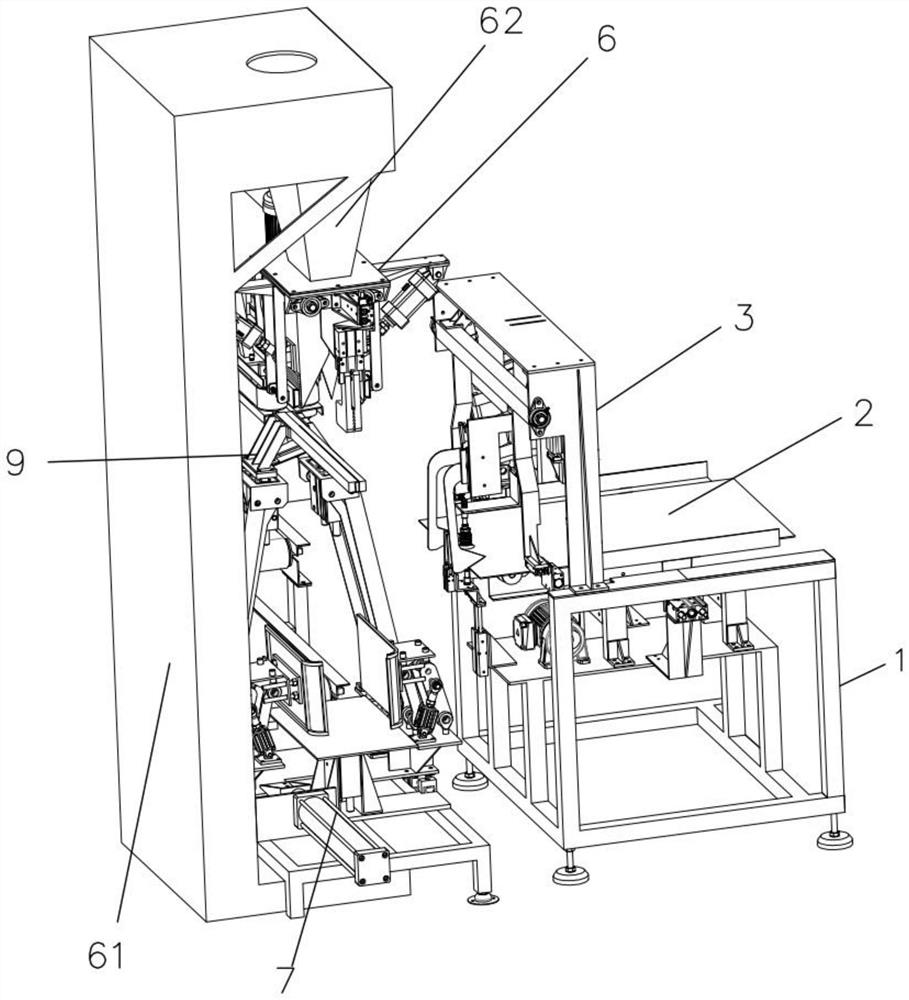

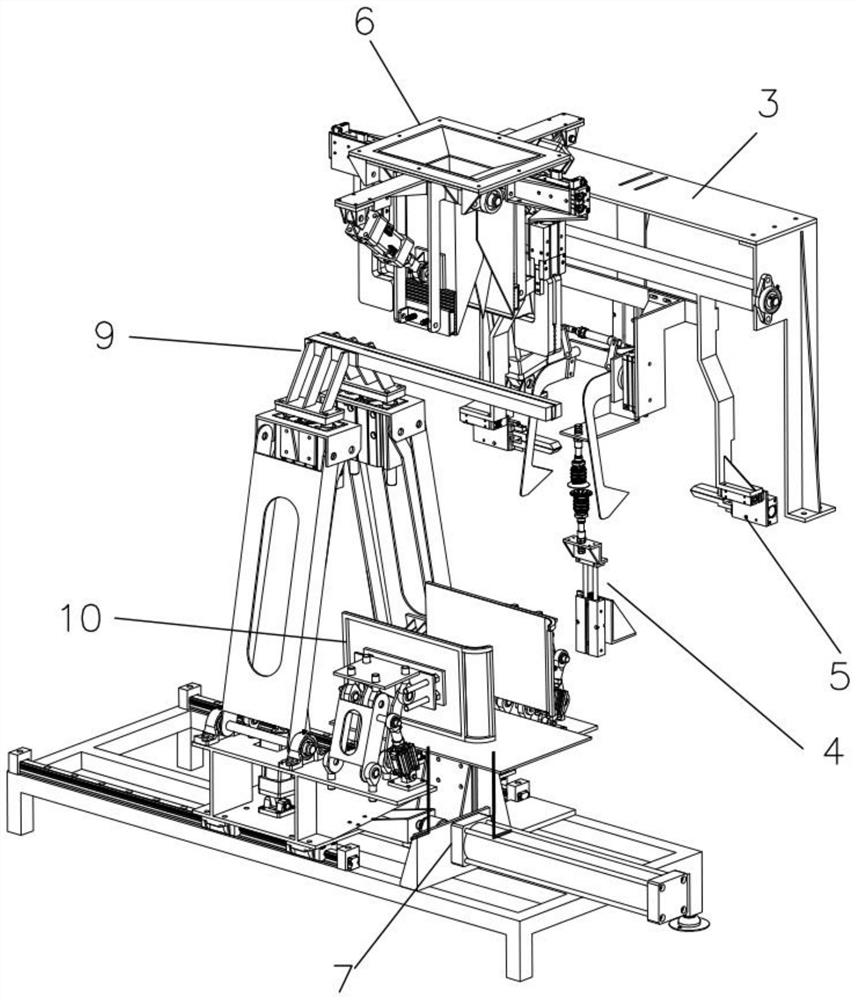

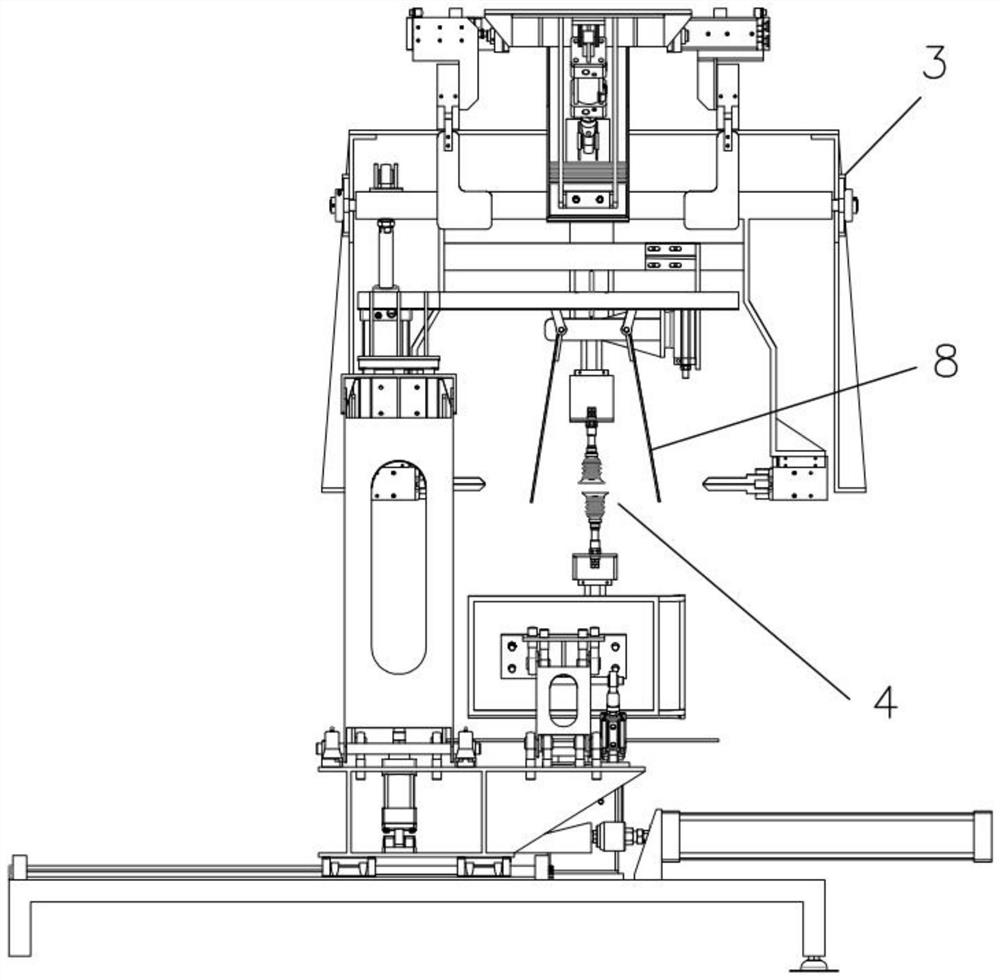

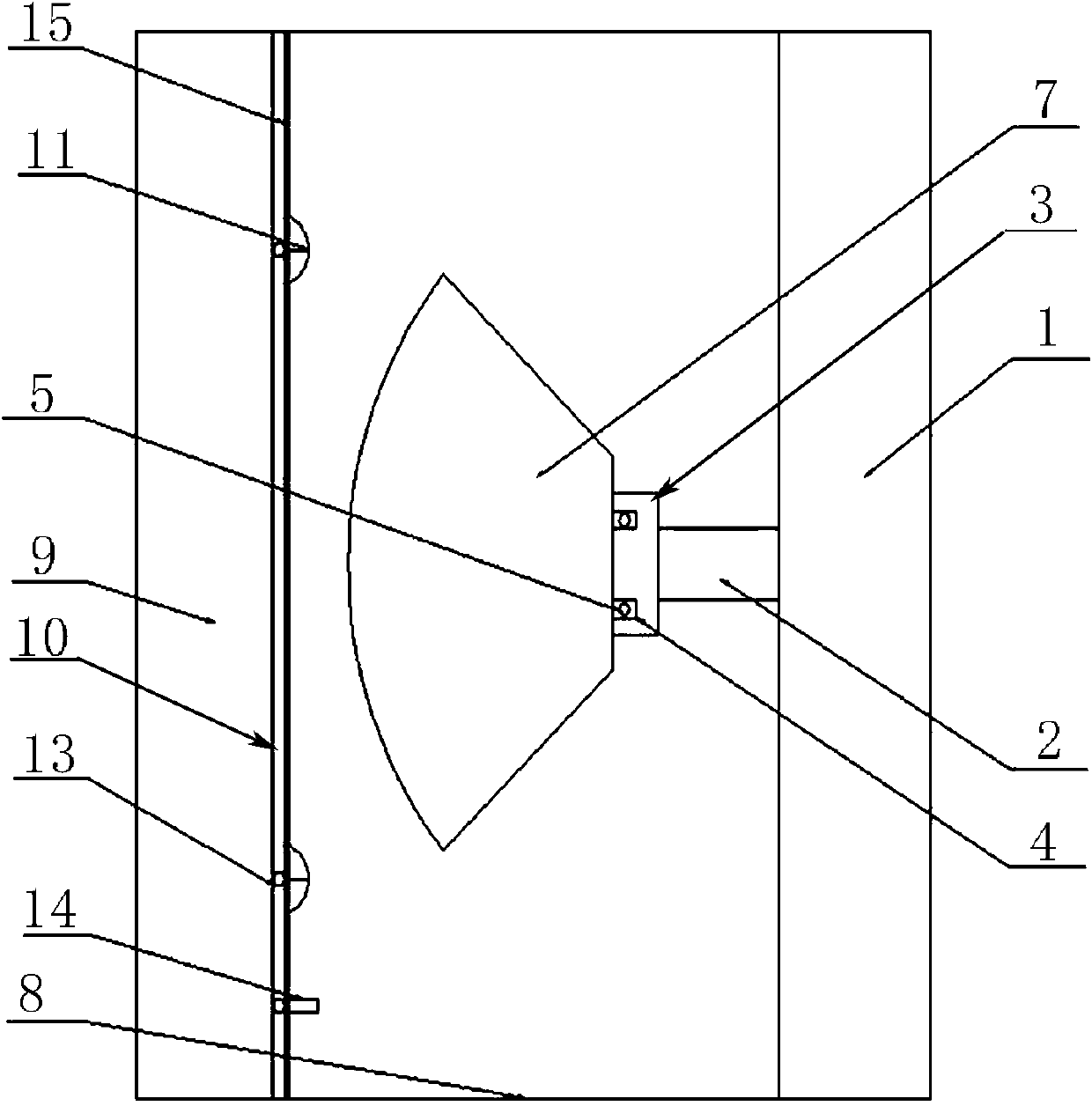

Bagging and packaging equipment for automatic production line

PendingCN112078884AImprove location accuracyReduce manual stepsWrapper twisting/gatheringPackaging automatic controlManufacturing lineManufacturing engineering

The invention discloses bagging and packaging equipment for an automatic production line. According to the technical scheme, the bagging and packaging equipment comprises a rack, a PLC, a conveying device, a rotating device, an auxiliary bag opening suction opening device, a bag clamping device, a discharging and bag clamping device and a bag holding and transplanting device; the rotating device and the auxiliary bag opening suction opening device are correspondingly installed on the upper side of the rack and located above the conveying device; the bag holding and transplanting device is located below the discharging and bag clamping device; the conveying device is used for conveying a bag; the bag clamping device is installed at the bottom of the rotating device; the auxiliary bag opening suction opening device sucks the upper side of the bag and controls the bag clamping device to clamp the two sides of the bag; the bag is rotated by 90 degrees through the rotating device; the two sides of the bag are clamped through the discharging and bag clamping device for receiving; and transfer is performed through the bag holding and transplanting device after receiving. The bagging and packaging equipment has the advantages that bagging is convenient and labor-saving, the labor cost can be reduced, the production efficiency can be improved, the automation degree is high, a bag opening is prevented from being deformed through clamping of the bag opening after discharging, fixed-point movement can be realized, and stable movement can be realized.

Owner:杭州三泰自动化设备有限公司

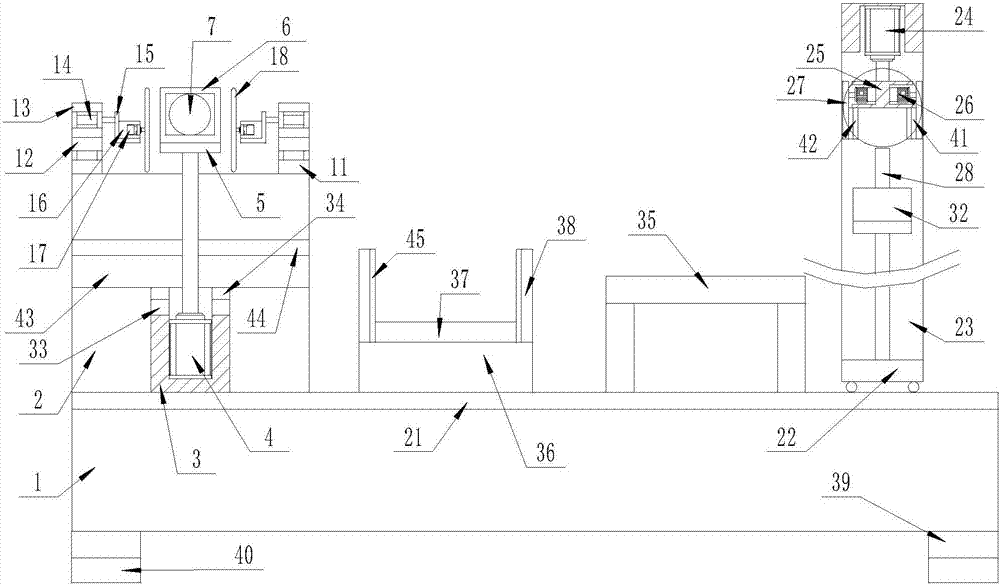

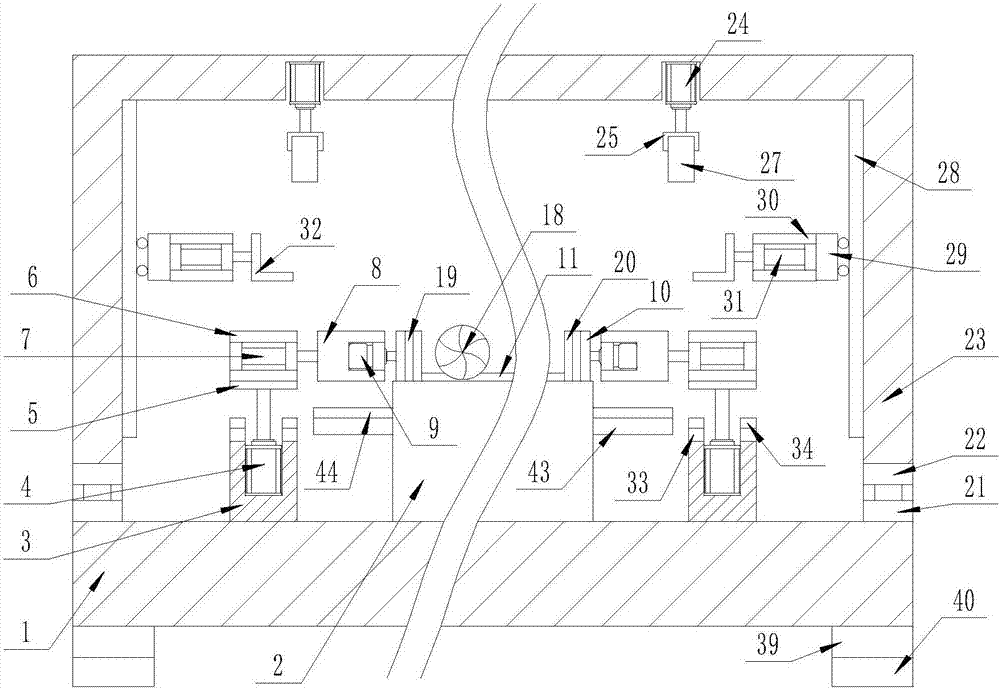

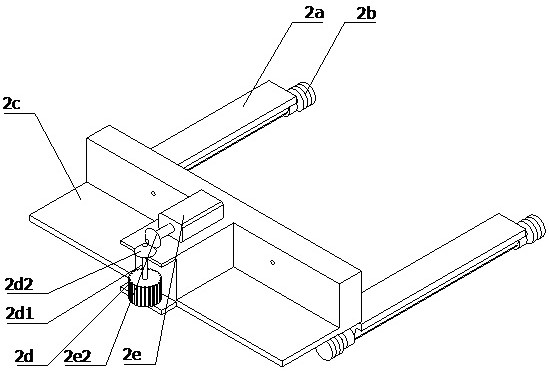

Vertical metal corrugated pipe bending test device

PendingCN111044387AReduce manual stepsReduce human errorDetection of fluid at leakage pointMaterial strength using steady bending forcesClassical mechanicsEngineering

The invention discloses a vertical metal corrugated pipe bending device for an anti-leakage test after a metal corrugated pipe is bent. The device comprises an oil pressure system and an output movingrod extending out of the oil pressure system, and a connector at a top end of the output moving rod is provided with two slots with fastening screw holes and is used for being connected with an arc-shaped pressing plate; the device also comprises a sample containing tank, through slideways for supporting rollers and supporting base plates to freely move up and down are arranged in edges of two sides of an opening of the tank, and a 3m steel ruler is bonded to an end portion of a side surface of each tank and used for span adjustment; and the sample containing tank is connected with the oil pressure system through a connecting frame. The invention provides a test span of the device and a set of arc-shaped pressing plate matched with the device so that a radian of the bent metal corrugatedpipe is uniform, accuracy of a test result is ensured, a personal error of the test is greatly reduced, and the device has an extremely high popularization prospect.

Owner:中铁十七局集团第一工程有限公司

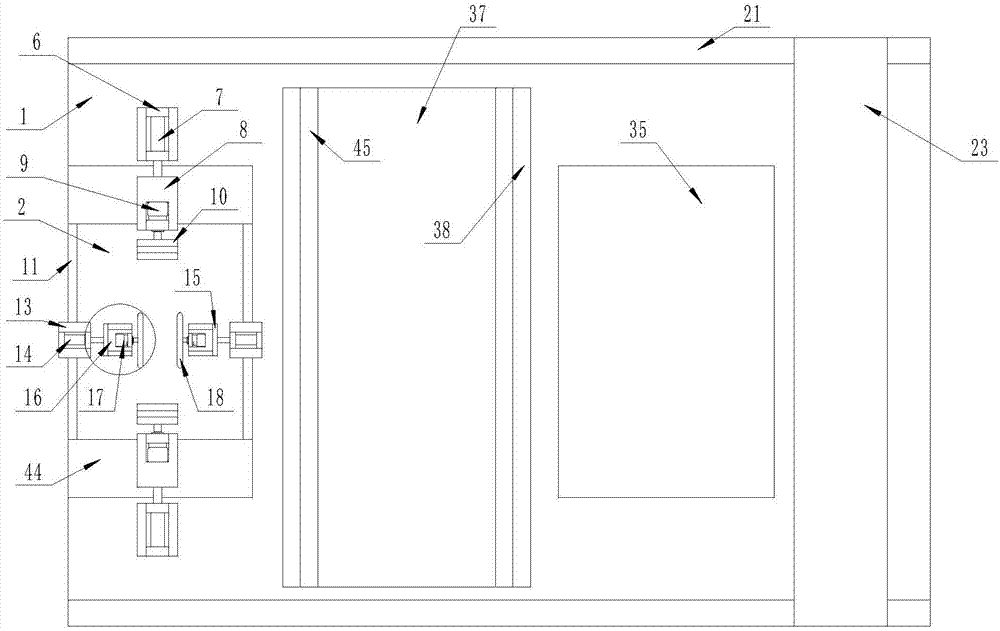

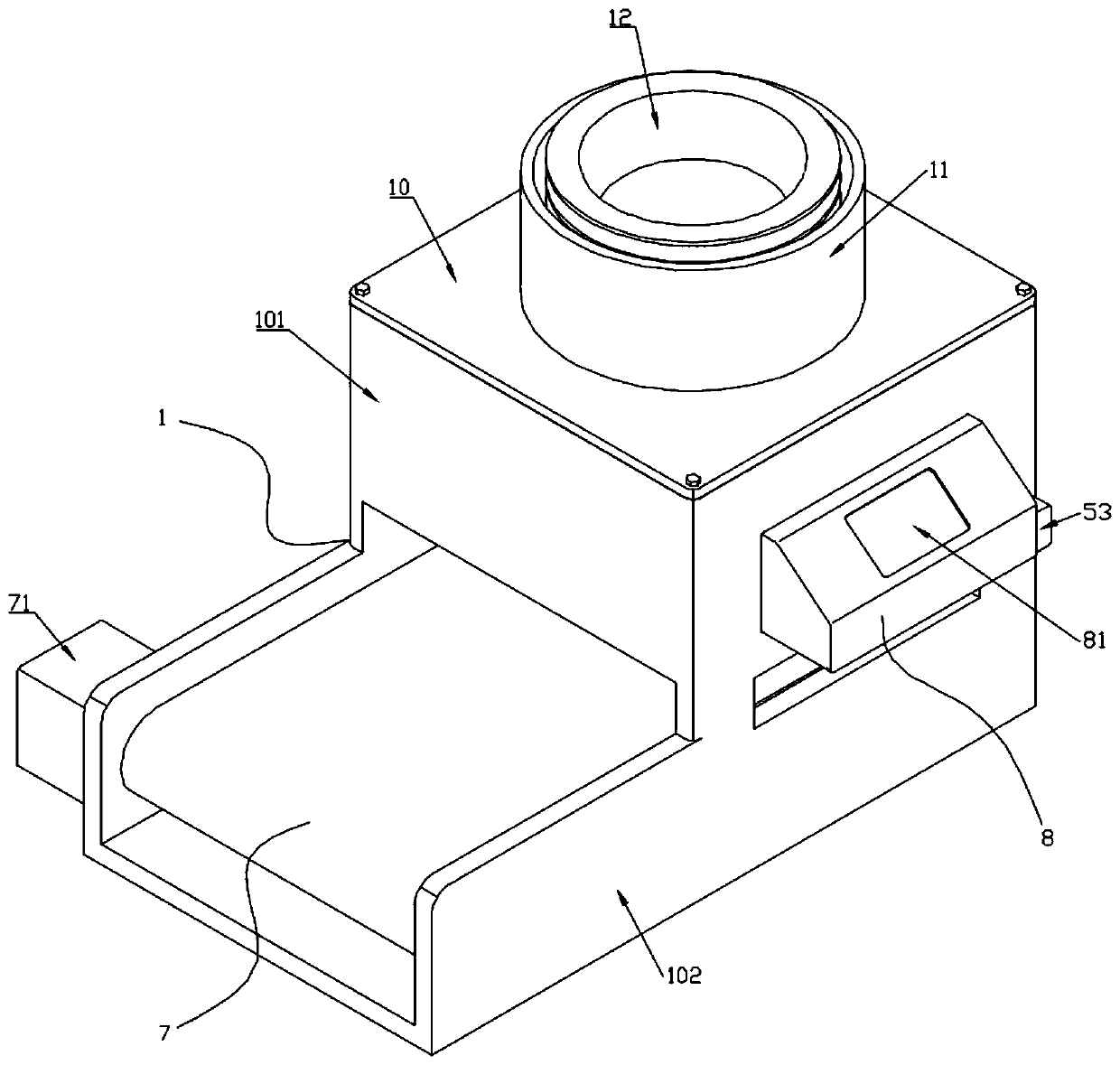

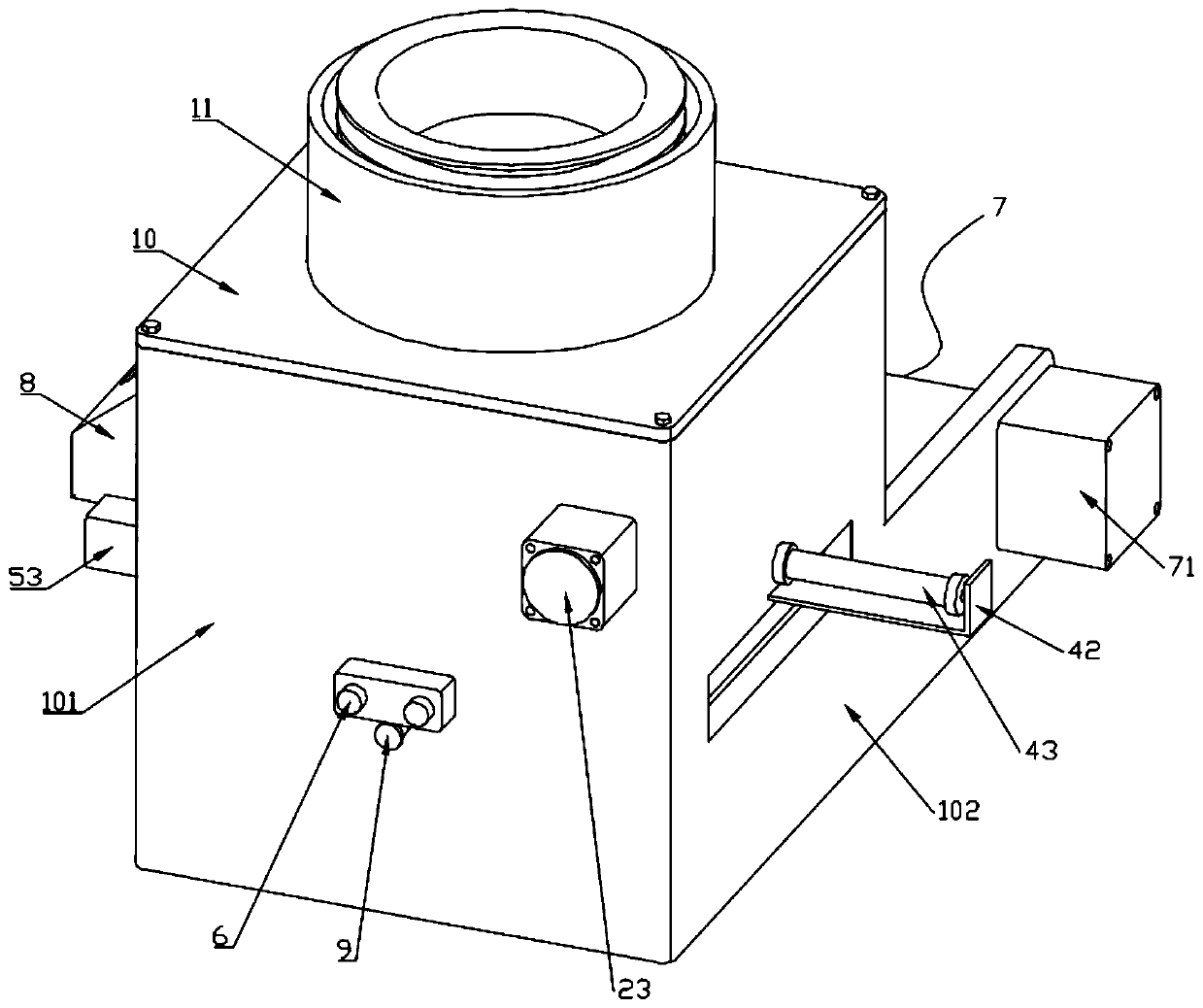

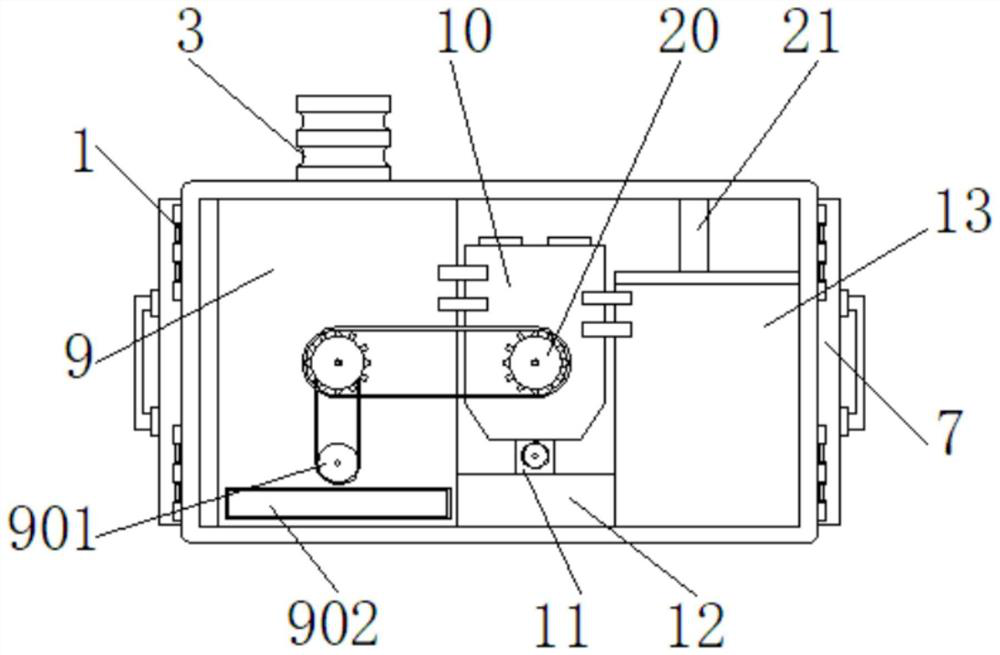

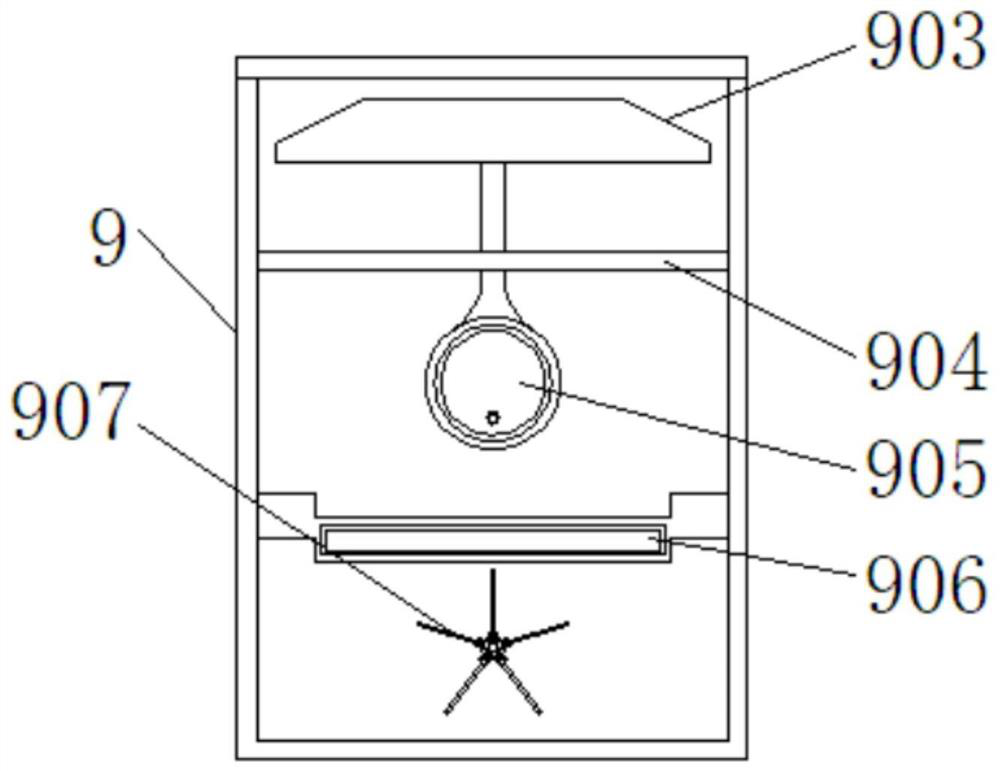

Automatic taking and using device and method for urine cup in urine testing process

ActiveCN110550416AReduce the probability of contaminationEliminate manual labeling processDe-stacking articlesConveyor partsEngineeringAutomatic testing

The invention discloses an automatic taking and using device and method for a urine cup in the urine testing process, and relates to the technical field of urine detection. The automatic taking and using device comprises a shell, a clamping mechanism, a supporting mechanism, a centering mechanism, a laser coder, a conveying mechanism and a card swiping device; and the shell includes a vertical shell and a horizontal shell which are integrally formed, the clamping mechanism, the supporting mechanism and the centering mechanism are all installed in the vertical shell, the card swiping device isinstalled outside the vertical shell, and the conveying mechanism is installed inside the horizontal shell. By means of the automatic taking and using device and method, bar code or two-dimensional code information matched with identity information of a patient is printed on the urine cup before the urine cup is taken and used, the process of manual labeling by testing staff is omitted, the condition that one cup is provided for one person is ensured, and the accuracy of detection information is ensured. In addition, whole-process automation and intelligentization of the taking and using process of the urine cup are achieved, the step of manual intervention is reduced, and the probability of pollution to the urine cup is reduced.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

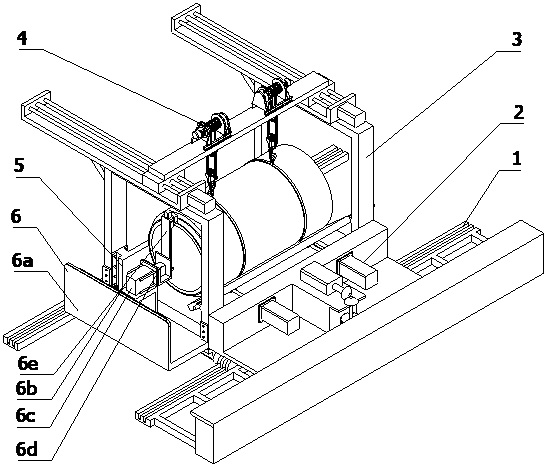

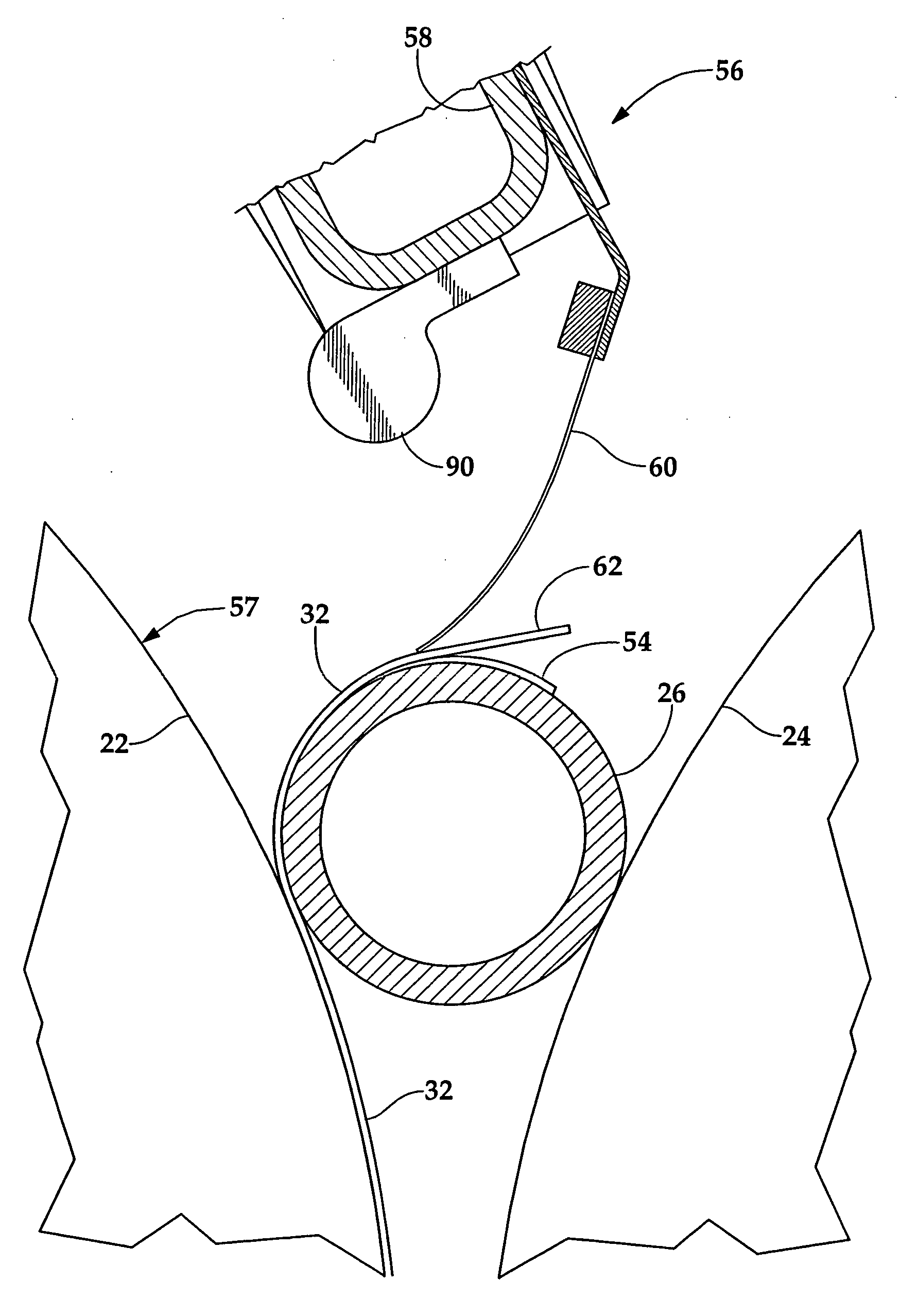

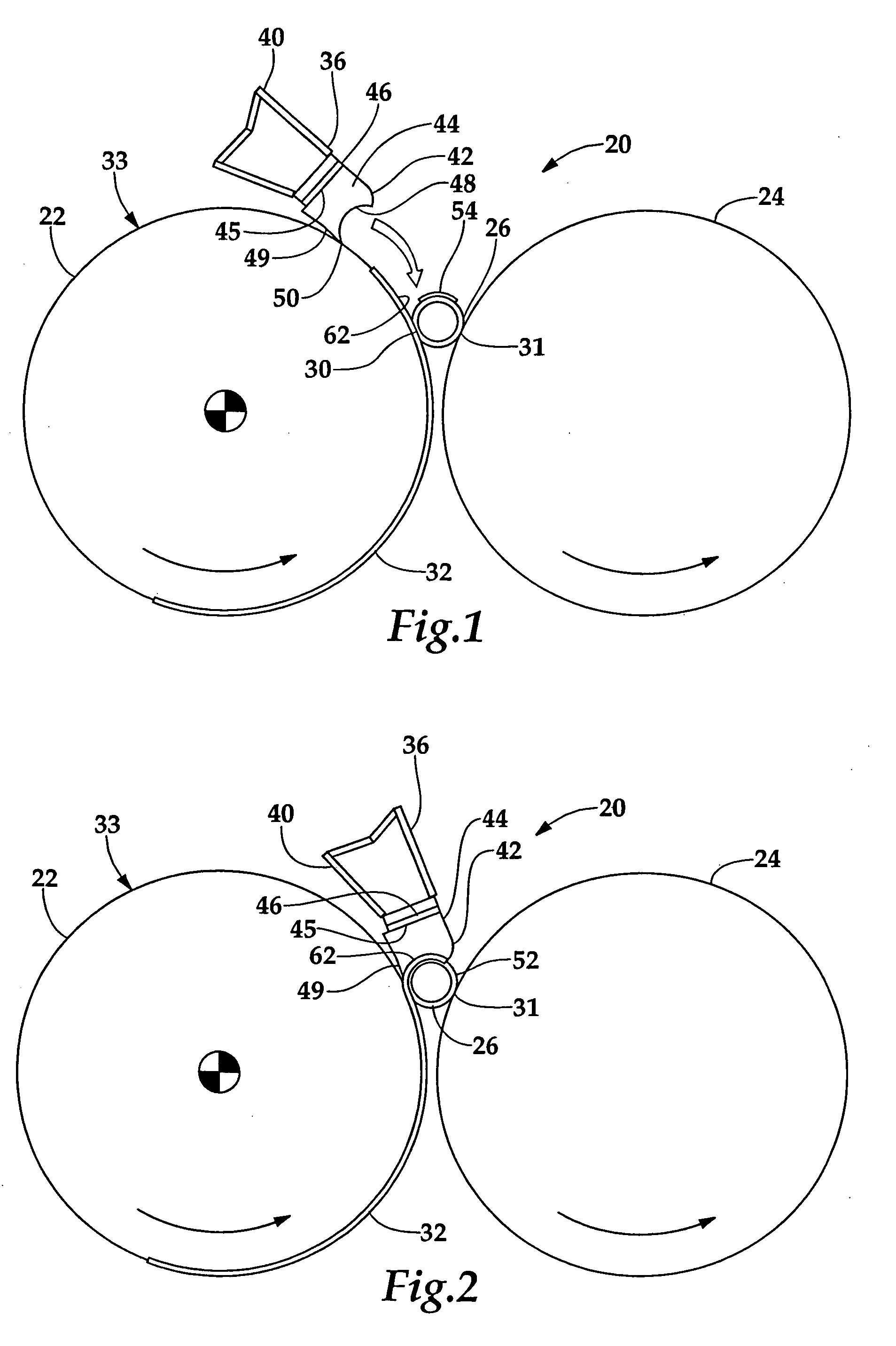

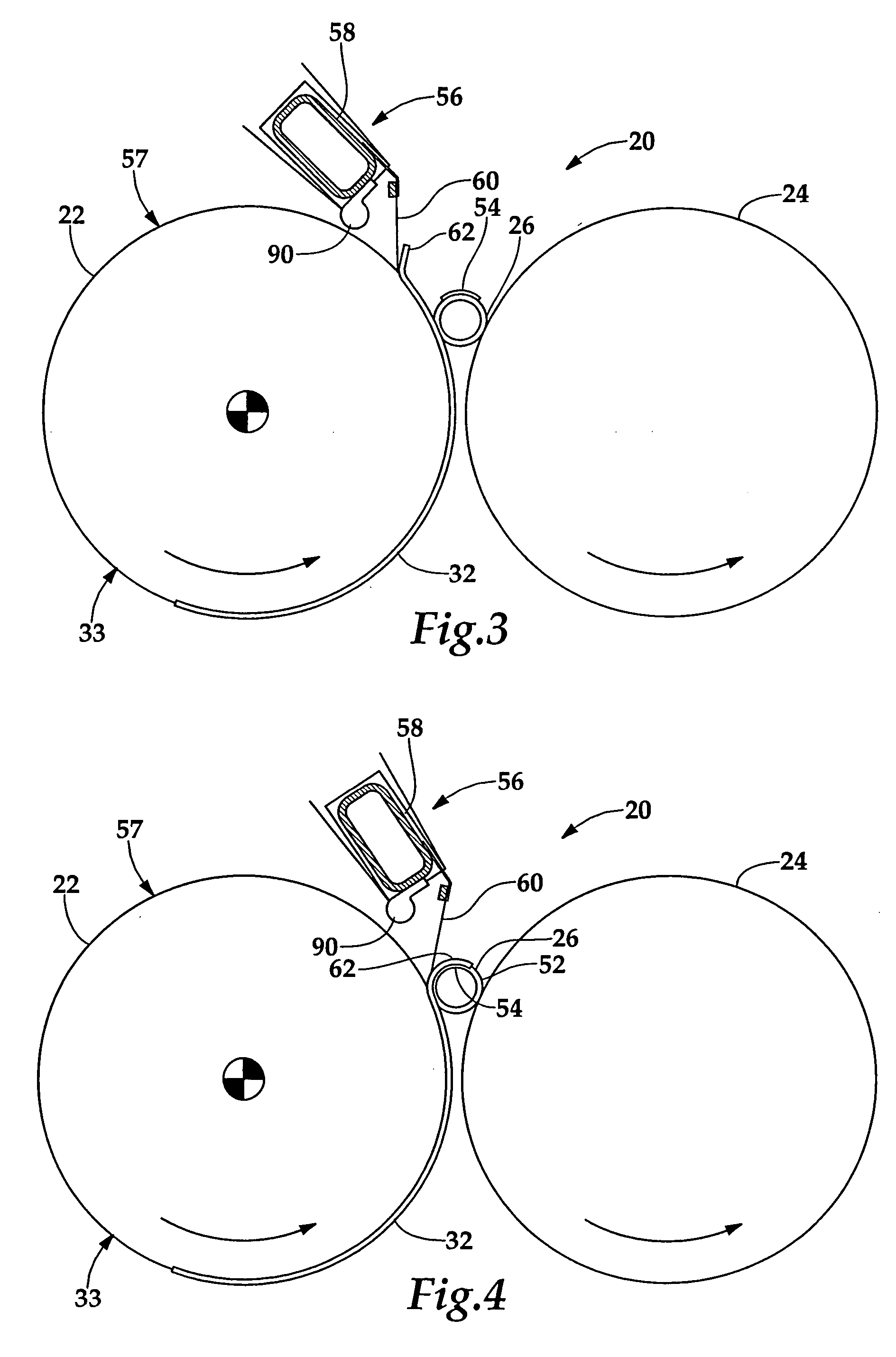

Winder roll starting apparatus for thick webs

ActiveUS20060266871A1Improve productivityShorten the timeWebs handlingEngineeringMechanical engineering

A winder has a scraper mounted about the axis of a winder drum for circumferential movement. The scraper has a semi-cylindrical concave surface which extends in the cross machine direction, the concave surface meets a second surface to form a scraping edge. The scraping edge engages the winder drum, scraping a web from the surface of the winder drum and pressing the web into engagement with double-sided sticky tape on a winder core with the concave surface. An alternative embodiment scraper has a flexible blade which extends in the cross machine direction and which functions similar to a spatula to scrape the pulp web off the surface of the winder drum and wipe the pulp web onto the double-sided sticky tape on the winding core.

Owner:VALMET TECHNOLOGIES INC

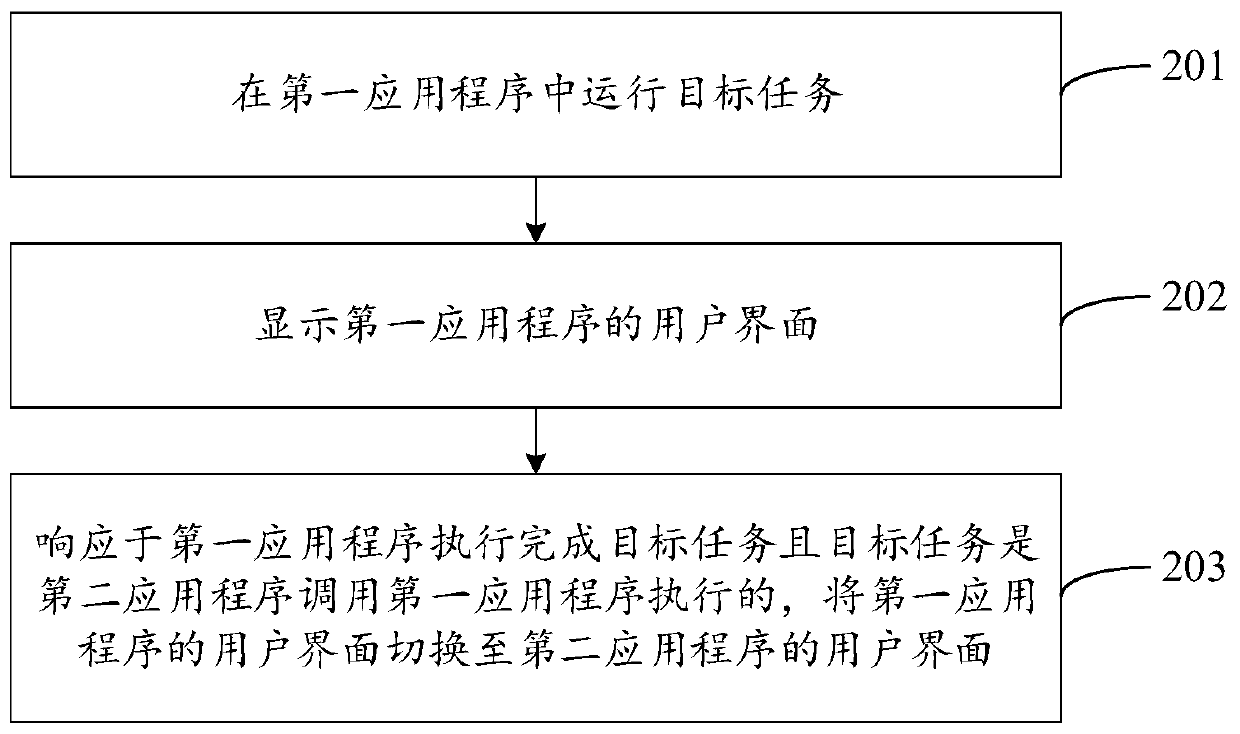

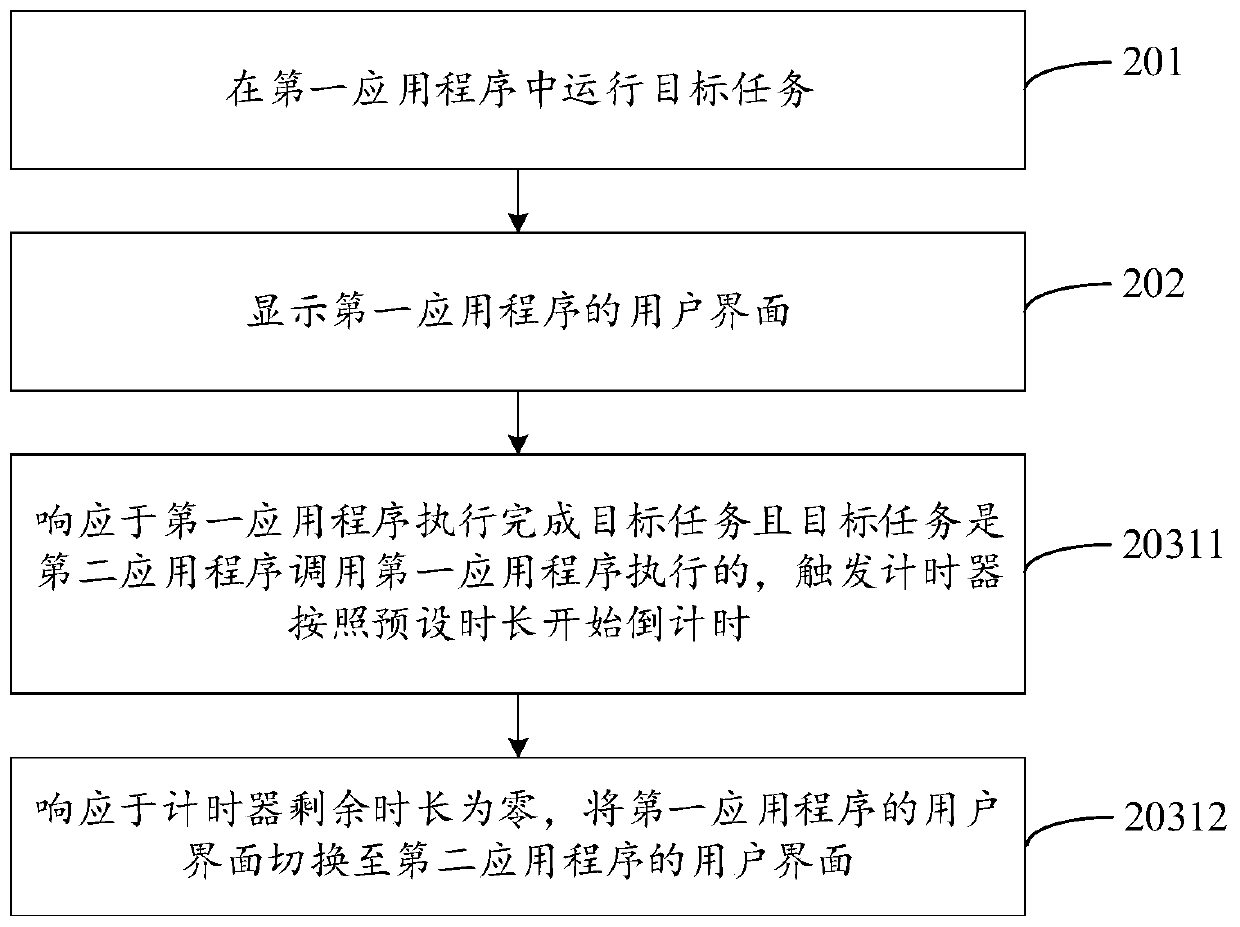

Application program switching method and device, equipment and storage medium

PendingCN111338772AImprove efficiencyReduce manual stepsProgram initiation/switchingVideo gamesSoftware engineeringUser interface

The invention discloses an application program switching method, device and equipment and a storage medium, and relates to the technical field of application programs. The method comprises the following steps: running a target task in a first application program; displaying a user interface of the first application program; and in response to the fact that the first application program executes the target task and the target task is executed by the second application program by calling the first application program, switching the user interface of the first application program to the user interface of the second application program. According to the method, when the first application program is called and executed by the second application program to complete the target task, the second application program is automatically switched back from the first application program, a user does not need to manually operate, even if the first application program exits and enters the second application program again, and the efficiency of returning to the second application program from the first application program is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Preparation method of artemisia apiacea essential oil for pet skin health care and device thereof

PendingCN112940845AEasy to addEasy to mix and filterFatty-oils/fats refiningPharmaceutical delivery mechanismThreaded pipeDrive motor

The invention discloses a preparation method of an artemisia apiacea essential oil for pet skin health care and a device thereof, the device comprises a device box body, a supporting force arm, an inner threaded pipe, an instrument box body, a threaded rod, a bevel gear and a driving water pump, an equipment cover plate is fixed to the outer side of the device box body through bolts, and a feeding pipeline is welded and fixed to the position over the device box body; a driving motor is connected to the outer side of the device box body in a nested mode, the instrument box body is welded and fixed to the outer side of the device box body, an equipment box door is hinged and fixed to the outer side of the device box body, a squeezing box body and a liquid mixing tank body are installed in the device box body at the same time, and a control valve is welded and fixed to the lower portion of the liquid mixing tank body. According to the preparation method of the artemisia apiacea essential oil for pet skin health care and the device, an eccentric wheel and a belt pulley are arranged; and the eccentric wheel is arranged and drives a point pressing mechanism to vertically lift and roll, so that the cleaned artemisia apiacea raw material can be manually and continuously added, and the artemisia apiacea raw material can be automatically rolled and filtered.

Owner:HENAN HEIMA ANIMAL PHARM CO LTD

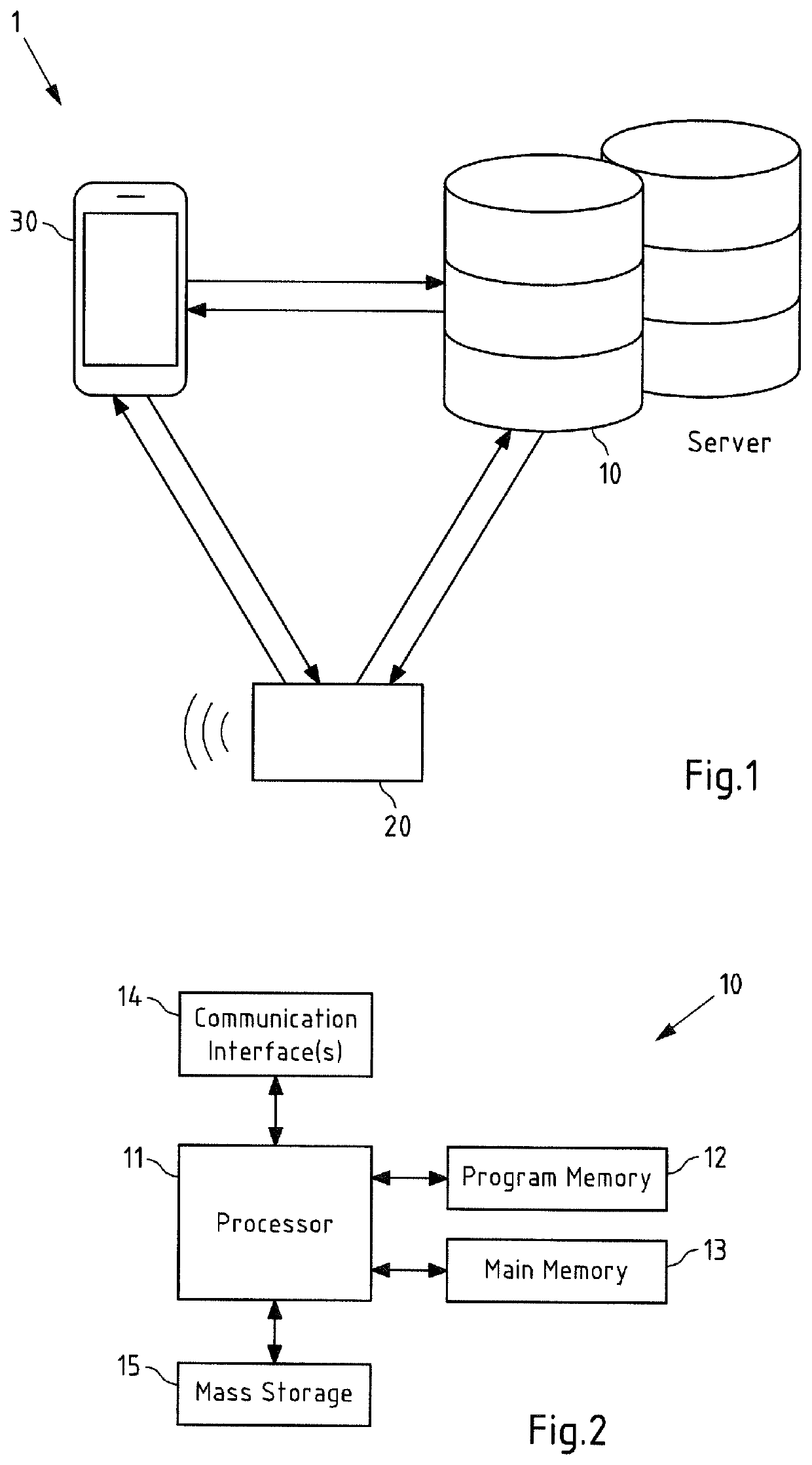

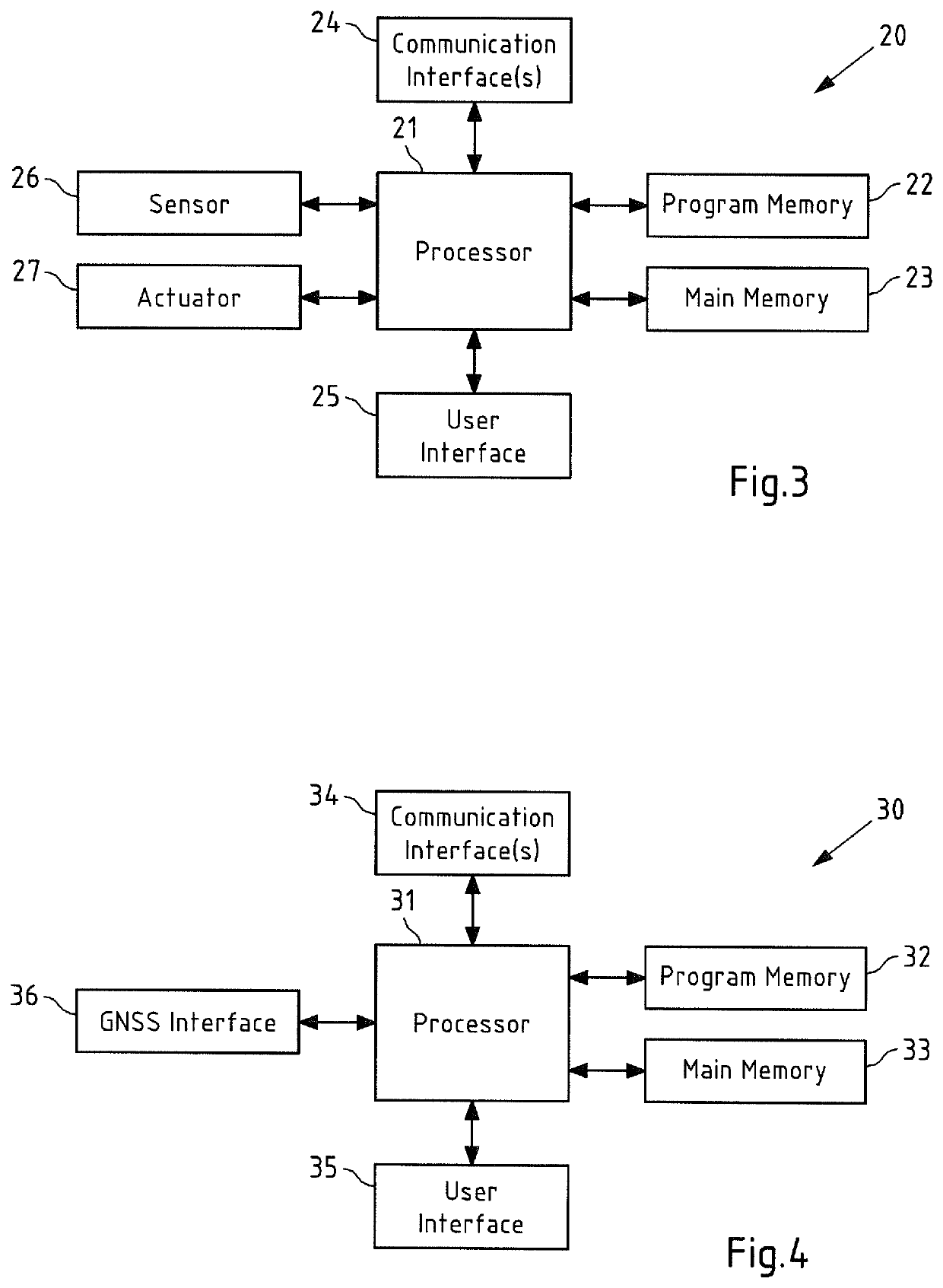

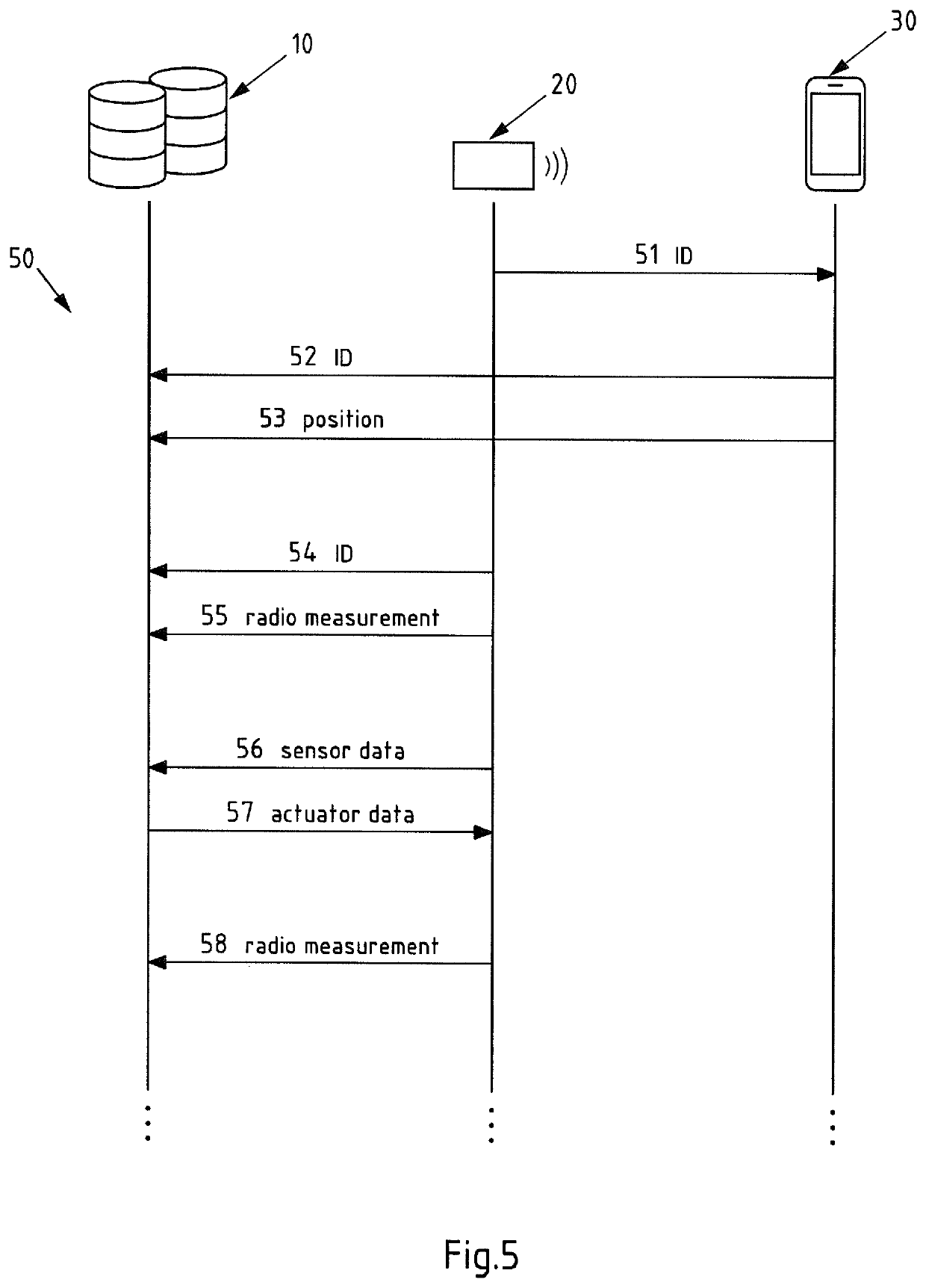

Managing sensor and/or actuator devices

PendingUS20210204095A1Precise positioningReduce manual stepsPosition fixationLocation information based serviceComputer hardwareEngineering

A method is disclosed, performed by at least a first apparatus, for managing at least a second apparatus, the second apparatus being a sensor and / or actuator device or a part thereof, the method comprising: obtaining identifier information of the second apparatus and obtaining positioning information associated with the identifier information and indicative of a position of the second apparatus; determining updated positioning information of the second apparatus at least based on an obtained radio measurement taken by the second apparatus; and at least based on the updated positioning information of the second apparatus, determining whether the second apparatus has been relocated and / or updating the positioning information associated with the identifier information of the second apparatus.

Owner:HERE GLOBAL BV

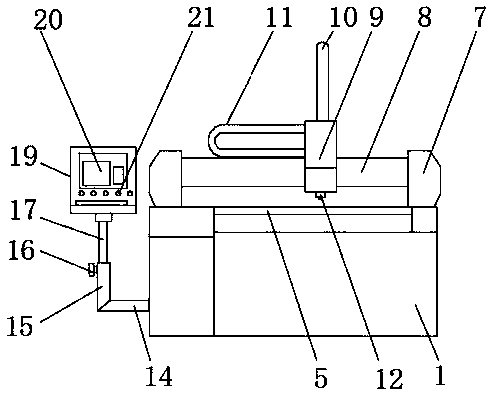

Laser cutting machine tool for machining plates

InactiveCN108890149AReduce manual stepsHigh degree of automationLaser beam welding apparatusEngineeringMachine tool

The invention discloses a laser cutting machine tool for machining plates. The laser cutting machine tool comprises a base, a support is fixedly mounted on the outer surface of the front end of the base, a conveying belt is arranged on the outer surface of the upper end of the support, supporting legs are fixedly mounted on the outer surface of the lower end of the support, guide rods are fixedlymounted on the outer surfaces of two sides of the base, two groups of connecting seats are arranged at the upper end of the base and positioned on the outer surfaces of the guide rods, a beam is fixedly mounted between two groups of connecting seats, a sliding seat is movably mounted on the outer surface of the upper end of the beam, a lifting track is arranged on the outer surface of the upper end of the sliding seat, a horizontal movable track is arranged on the outer surface of one side of the sliding seat and positioned above the beam, and a fixed rod is fixedly mounted on the outer surface of the base and positioned in the front of a maintenance door. According to the laser cutting machine tool, manual operation steps can be decreased, automation degree is improved, and the machine tool can be conveniently used and has practicability.

Owner:SUZHOU DANENG LASER TECH CO LTD

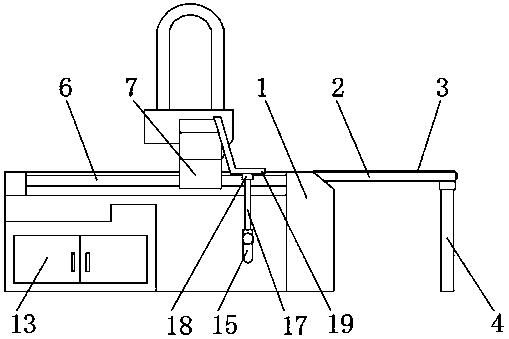

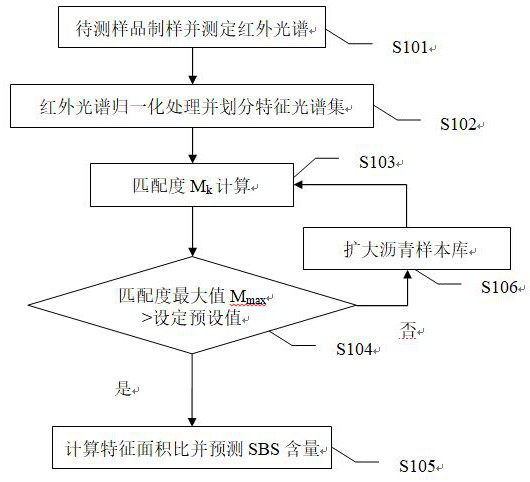

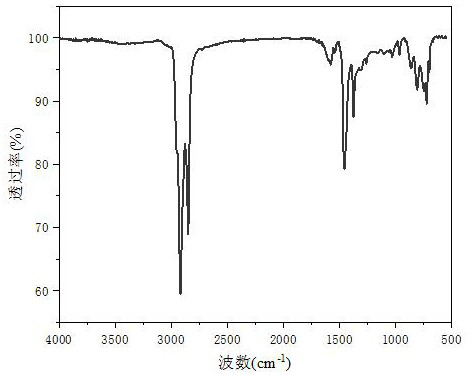

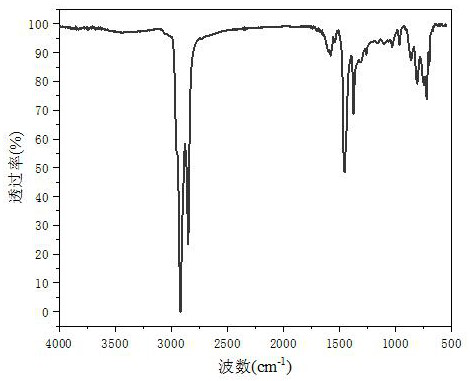

Rapid SBS content detection method based on modified asphalt sample library

PendingCN114739941AEasy pretreatmentImprove matchMaterial analysis by optical meansCheminformatics data warehousingFt ir spectraAsphalt

The invention discloses a rapid SBS content detection method based on a modified asphalt sample library. The method comprises the following steps: preparing a sample to be detected and measuring an infrared spectrum; dividing the normalized infrared spectrum into a characteristic spectrum set according to a characteristic wave band; calculating the matching degree between the characteristic spectrum set of the to-be-detected sample and the characteristic spectrum sets of all standard samples in the modified asphalt sample library; according to the comparison condition of the maximum value of the matching degree obtained through calculation and a preset value, the characteristic area ratio is calculated, and the SBS content is predicted or the modified asphalt sample library continues to be expanded. The testing method is simple, convenient and rapid, the influence of raw material asphalt on SBS content prediction is considered, the modified asphalt sample library can be automatically updated and expanded, and the SBS content detection efficiency is improved.

Owner:SOUTHEAST UNIV

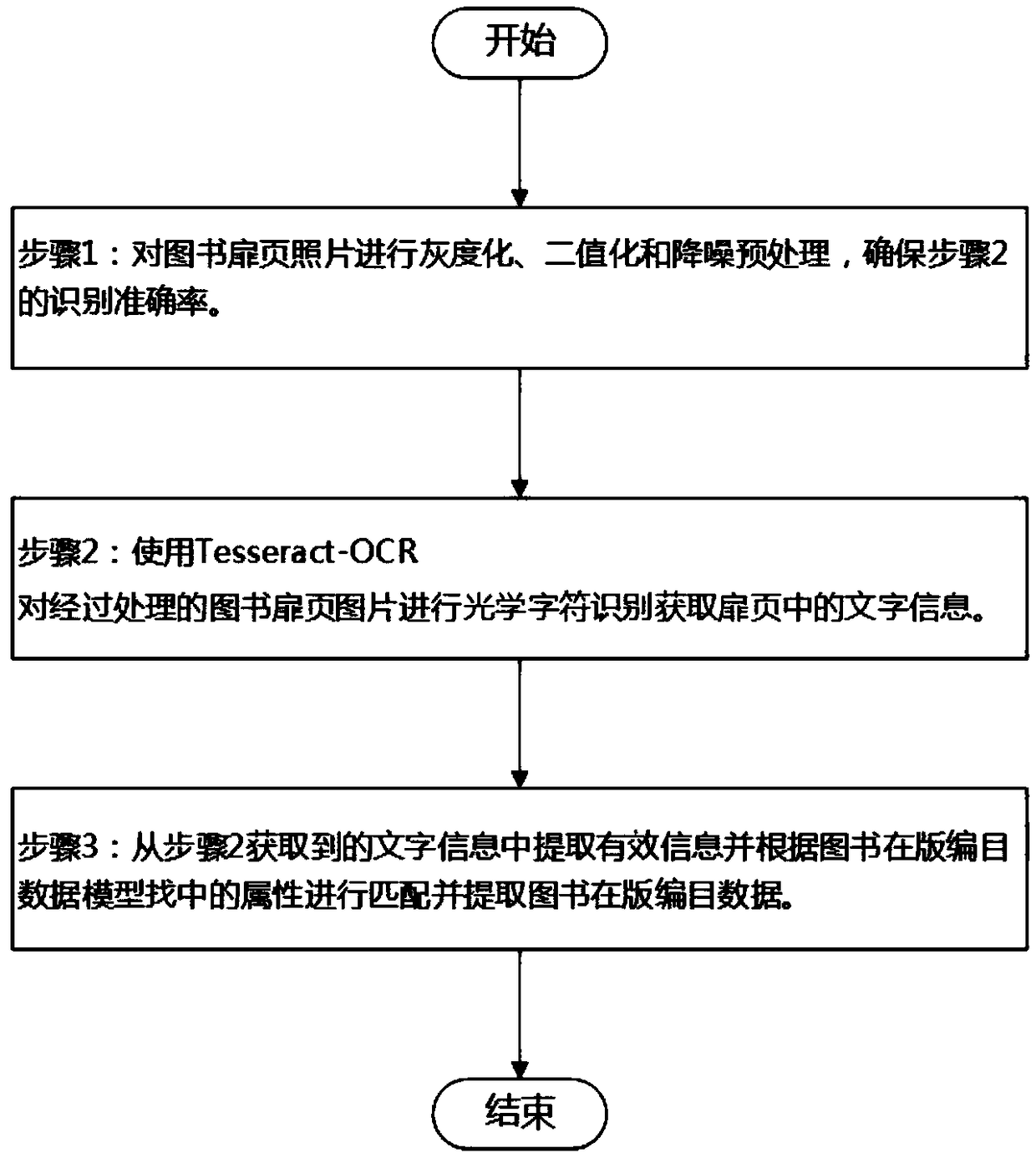

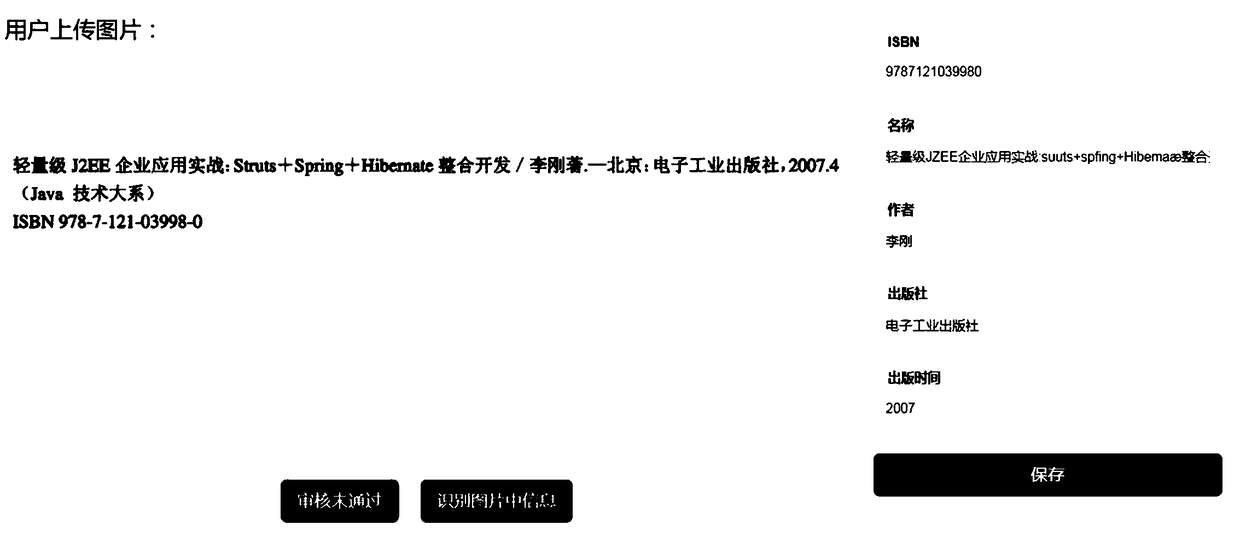

Method for obtaining book cataloguing data offline in a shared book system

InactiveCN109344297AReduce manual stepsReduce labor costsOther databases indexingOptical character recognitionCataloging

The invention provides a method for obtaining book in-print cataloging data (CIP) offline in a shared book system. Firstly, the title page picture is preprocessed to separate the pixel points of the text from the background pixel points and remove the noise of the interference recognition so as to improve the accuracy of data acquisition. Then optical character recognition is performed on the processed title page picture of the book to obtain the text information in the picture. Finally, the title, author, publisher, year of publication and ISBN number of the book are analyzed from the text information according to the format characteristics of the in-print cataloguing data. the book in-print cataloguing data can be directly obtained through the physical book title page photograph or the electronic book title page photograph when the shared book system is in an offline state without connecting to the Internet.

Owner:BEIJING UNIV OF TECH

Hole drilling clamping device

InactiveCN108000213AAvoid safety hazardsReduce manual stepsWork clamping meansLarge fixed membersElectric machineryDrill hole

The invention relates to a hole drilling clamping device. The hole drilling clamping device comprises a supporting table, a clamping mechanism, a hole drilling mechanism and a conveying mechanism, wherein the supporting table comprises a table top and supporting columns, and a first supporting seat and a second supporting seat are disposed on the table top; the clamping mechanism comprises an aircylinder and an abutting block, the air cylinder is hinged to the first supporting seat, a hinge shaft is hinged to the second supporting seat and connected with a piston rod, the abutting block is slideably connected to the table top, and a pull rod is hinged between the abutting block and the hinge shaft; the hole drilling mechanism comprises hole drilling support, a hole drilling table and a rotating disc, a driving gear is mounted inside the hole drilling table and comprises an active gear body and a passive gear body which are engaged with each other, the active gear body is a sector gearand is connected with a motor, a shaft hole is formed in the center of the passive gear body, the rotating disc is mounted at the upper end of the hole drilling table and comprises a disc body, a rotating shaft, clamping grooves and a chassis, and the rotating shaft is disposed in the shaft hole of the passive gear body in a penetrating mode; and the conveying mechanism is a conveying belt. By means of the hole drilling clamping device, the problems that the hole drilling efficiency is low, and the potential safety hazards exist when workpieces are taken away manually after hole drilling in the hole drilling process are solved.

Owner:重庆市合川区云天机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com