Automatic polishing equipment

A technology of equipment and grinding mechanism, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding automatic control device, etc., can solve the problems of many steps, slow work efficiency, error-prone, etc., to avoid human error and reduce labor Steps, work efficiency and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

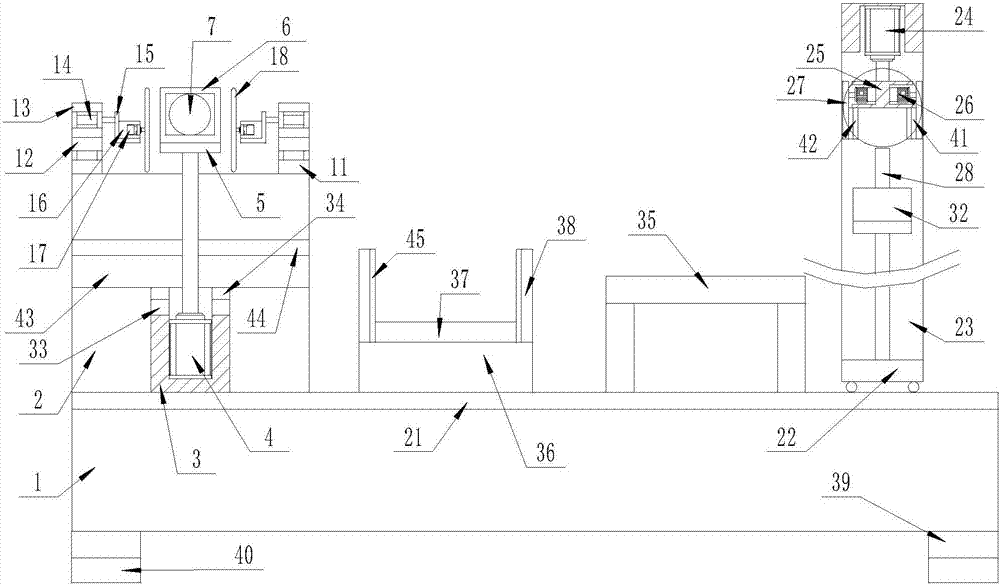

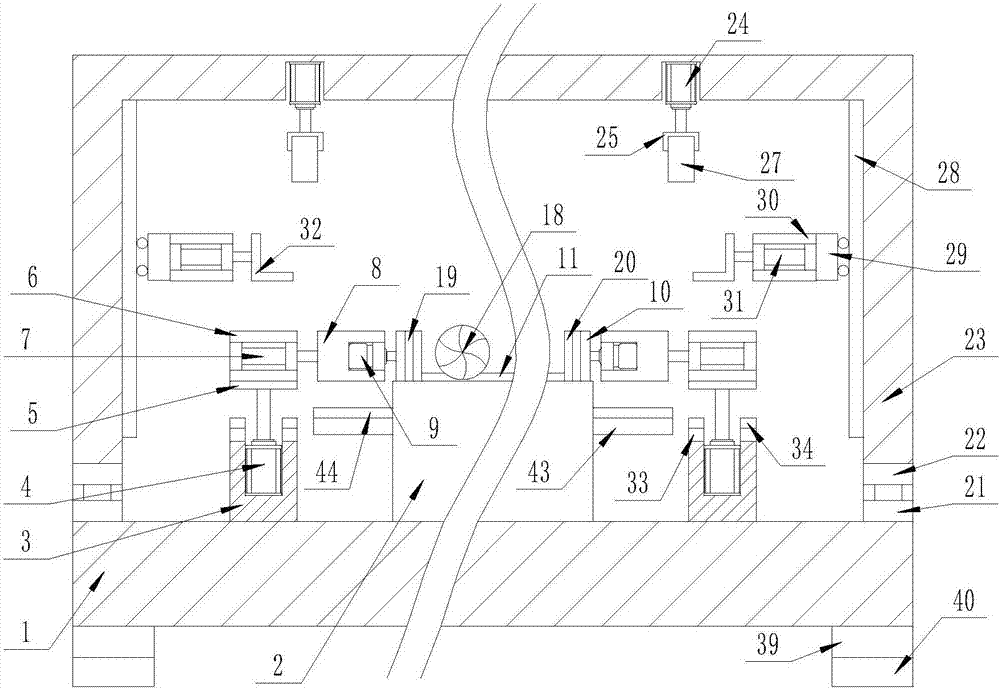

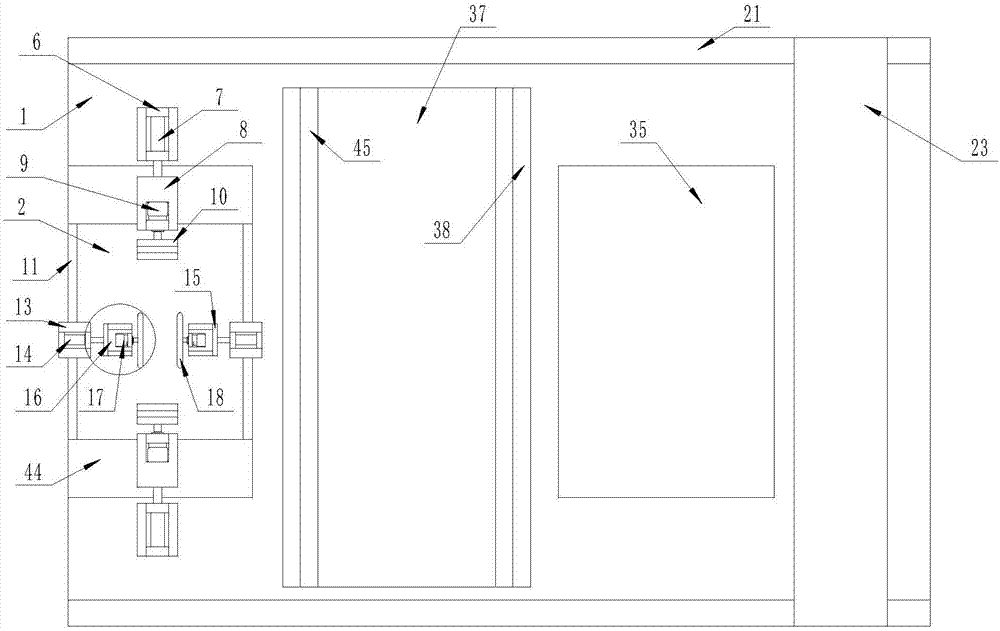

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a kind of automatic polishing equipment comprises workbench 1, and described workbench 1 upper wall is equipped with grinding mechanism and conveying mechanism, and described grinding mechanism is fixed on workbench 1 by operation platform 2 that is fixed on workbench 1 upper wall surface. A pair of support rods 3 on the upper wall and located on both sides of the console 2, the first cylinder installation groove opened on the upper end surface of the support rod 3, the first hydraulic cylinder 4 fixed in the first cylinder installation groove and the telescopic end upwards, fixed The first supporting plate 5 on the telescopic end of the first hydraulic cylinder 4, the first push rod mounting seat 6 installed on the upper wall of the first supporting plate 5, is installed in the first pushing rod mounting seat 6 and the telescopic end is horizontal Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com