Vertical metal corrugated pipe bending test device

A metal bellows, bending test technology, applied to the measuring device, using a stable bending force to test the strength of the material, and detecting the appearance of fluid at the leak point, etc., can solve the problem that the corresponding test device is not given and the test result is uncertain In order to achieve good practical application and promotion value, reasonable design and few uncontrollable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

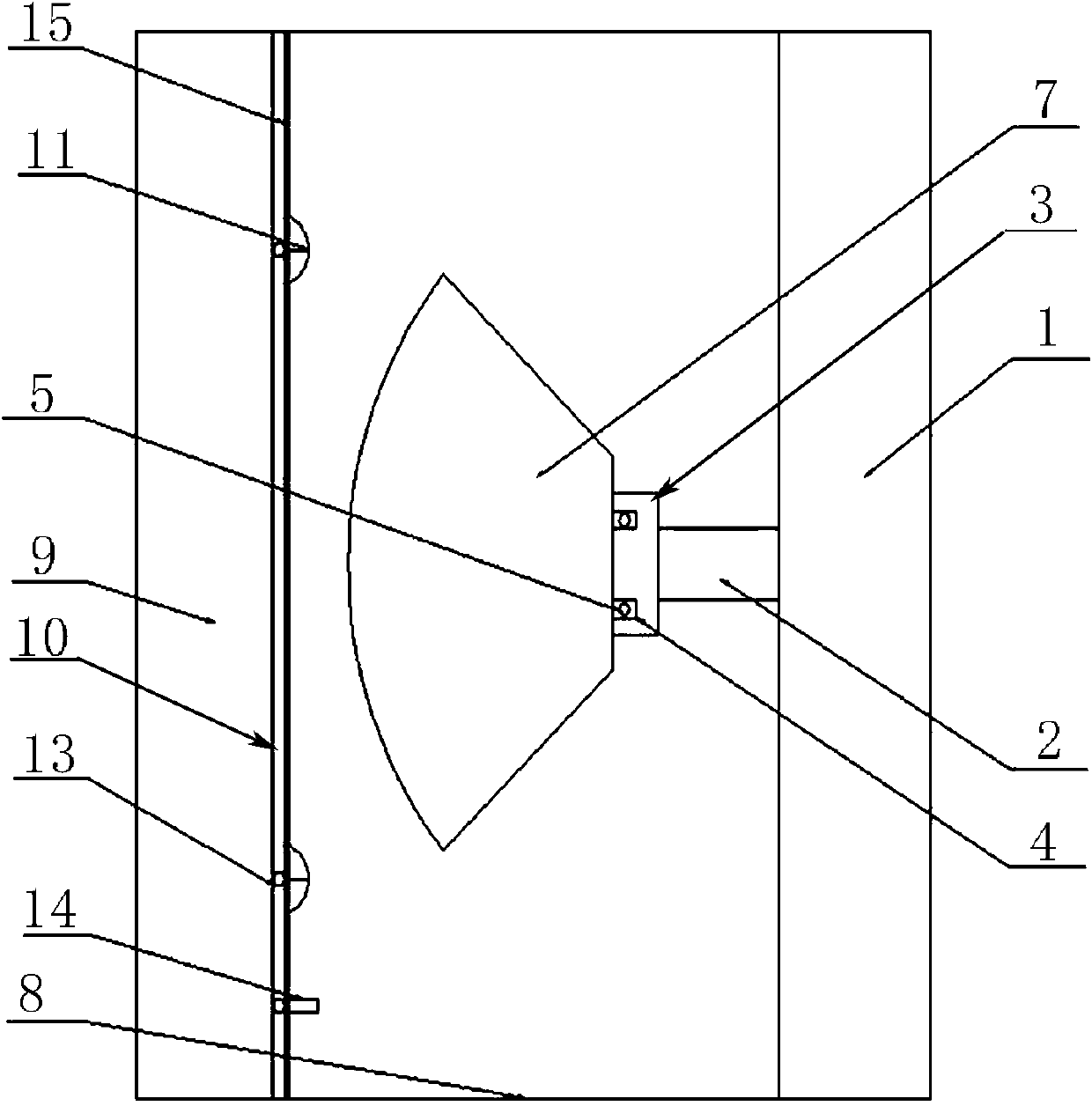

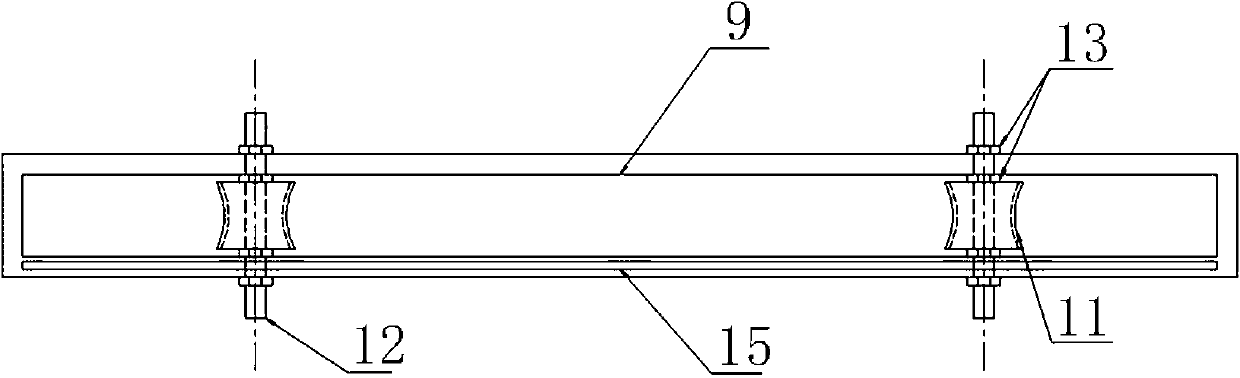

[0029] A vertical metal bellows bending device for anti-leakage test after bending of metal bellows mainly includes two parts, mainly a vertical hydraulic cylinder 1 and a vertically placed sample tank 9.

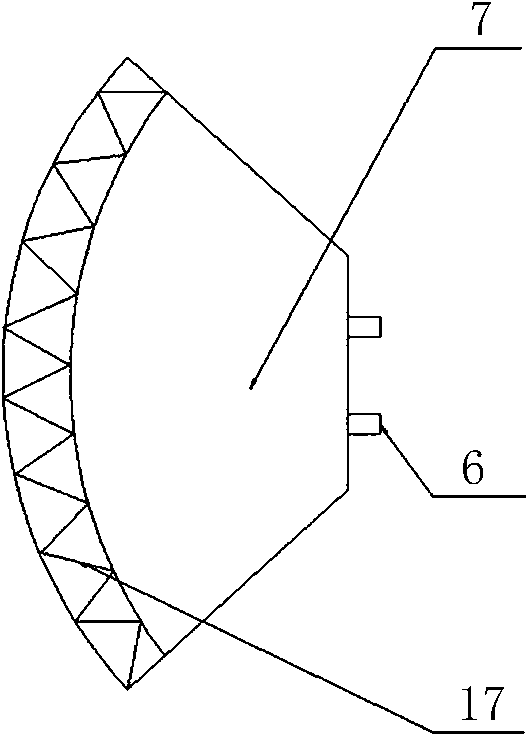

[0030] Such as figure 1 As shown, the middle part of the hydraulic cylinder 1 is provided with an output movement rod 2, and the end of the output movement rod 2 is provided with a connector 3, and an arc-shaped pressure plate 7 is installed on the connector 3. Specifically, the end surface of the connector 3 is provided with two belt fastening The slot 4 of the screw hole, the arc pressure plate 7 passes through the two insertion rods 6 on its back (such as image 3 shown) is inserted into the slot 4 on the end face of the connector 3 and locked by the fastening bolt 5.

[0031] Such as figure 1 As shown, the arc surface of the arc-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com