Hot rolling reeling scroll defect control method

A control method and technology of hot-rolled coils, applied in the field of hot-rolled rolling, can solve problems such as extremely high precision requirements for pinch mixed installation, unstable quality indicators, and large elastic coefficient of pinch roll bearing seats, so as to reduce manual participation Steps, reduce labor costs, improve production efficiency and the effect of corporate profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

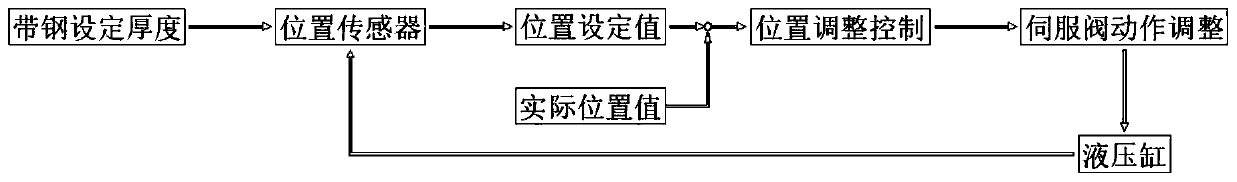

Method used

Image

Examples

Embodiment 1

[0025] As a preferred embodiment of the present invention: the thickness of the steel strip is h, the roll gap of the pinch roll is S, when h≤4.0mm, S0=0.15mm, when 4.0≤h≤10mm, S0=0.5mm, when 10≤h≤20m S0=0.8mm, S=h-S0; the width of the pinch roller gap is slightly smaller than the thickness of the strip steel, when the pinch roller drives the strip steel to wind up, the pinch roller can exert sufficient pressure on the strip steel, When the rollers are intact, the pinch rollers can effectively prevent the strip from shifting or wandering, and the h value is directly equal to the direct thickness of the rolled strip, and the setting of the S0 value is based on the thickness of the strip to withstand The pressure value is set, the greater the thickness of the strip, the probability of its deviation or wandering also increases, the value of the roll gap S changes with the value of the strip thickness h and S0 is used as a reference value, It is a predetermined value determined by...

Embodiment 2

[0027] As a preferred embodiment of the present invention: the hydraulic cylinders pressed on both sides in step 4 are respectively OS and DS, and the sensor values in step 4 are OS:h1DS:h2; the hydraulic cylinders pressed on both sides are respectively marked as OS side and On the DS side, it is convenient to make the hydraulic cylinders on both sides corresponding to the servo valves on the OS side and DS side one by one, and two sensors are respectively located inside the hydraulic cylinders on the OS side and DS side, and the hydraulic cylinders on the OS side are pressed down. When the hydraulic cylinder and the DS side pressure cylinder shrink, the sensor inside can quickly detect the depression distance of the OS side depression hydraulic cylinder or the DS side depression hydraulic cylinder, and convert the depression distance signal into an electrical signal It is sent to the OS side servo valve or DS side servo valve, and the OS side servo valve or DS side servo val...

Embodiment 3

[0029] As a preferred embodiment of the present invention: the actual deviation of pressing both sides in step 4 is h0, h0=h1-h2; by calculating the value of h0, the OS side presses down the hydraulic cylinder or the DS side presses down the hydraulic cylinder to lift up , so that the pressure exerted by the pinch roller and the strip steel is always kept within the predetermined value, no matter if the surface of the strip steel is horizontally depressed or the surface of the pinch roller is worn, the pinch roller can always be closely attached to the strip steel, and will not A gap occurs between the surface of the pinch roll and the surface of the strip, so that the strip moves more smoothly and the strip moves smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com