Jelly extracting machine

A pulp machine and rack technology, applied in the field of dredging machines, can solve the problems of labor-intensive, destroying the natural block of royal jelly, time-consuming, etc., and achieve the effects of improving work efficiency, reducing pre-processing, and reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

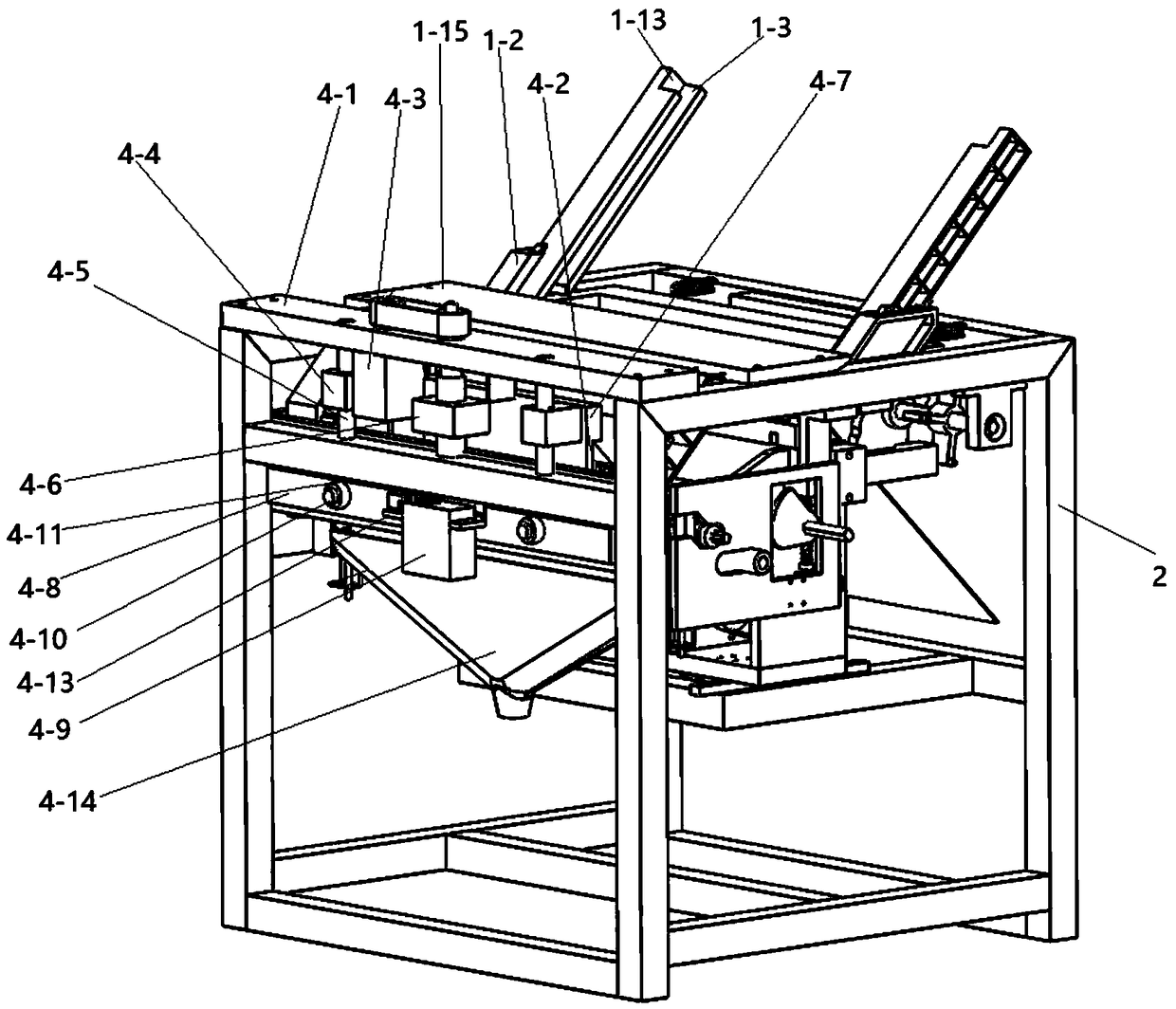

[0038] The present invention will be further described below in conjunction with the drawings.

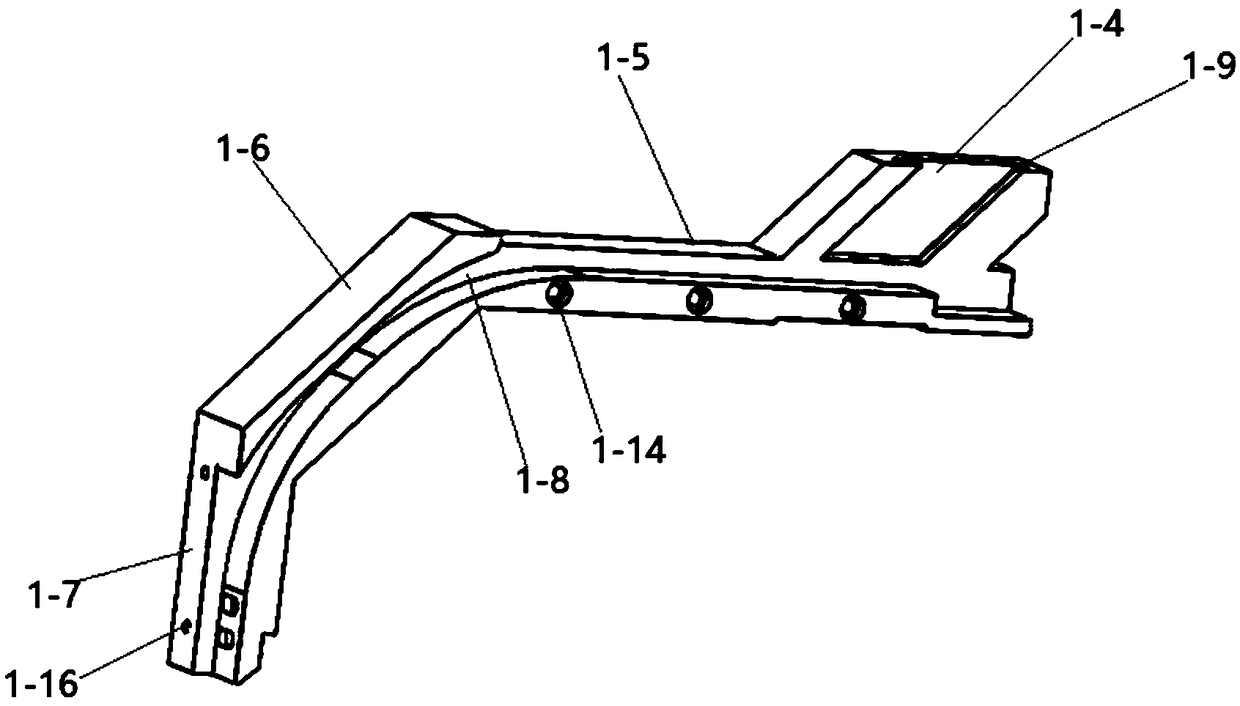

[0039] The pulp digging machine of the present invention is specially used to extract insects and dig pulp from the royal jelly table base strip. In the prior art, the pre-treatment process of extracting insects and digging pulp and digging pulp is often performed manually, even if The few excavators in the prior art also cannot realize the automation of the entire process from the removal of the platform base bar to the completion of the removal of insects and slurry. For this reason, the present invention designs such an automatic excavator.

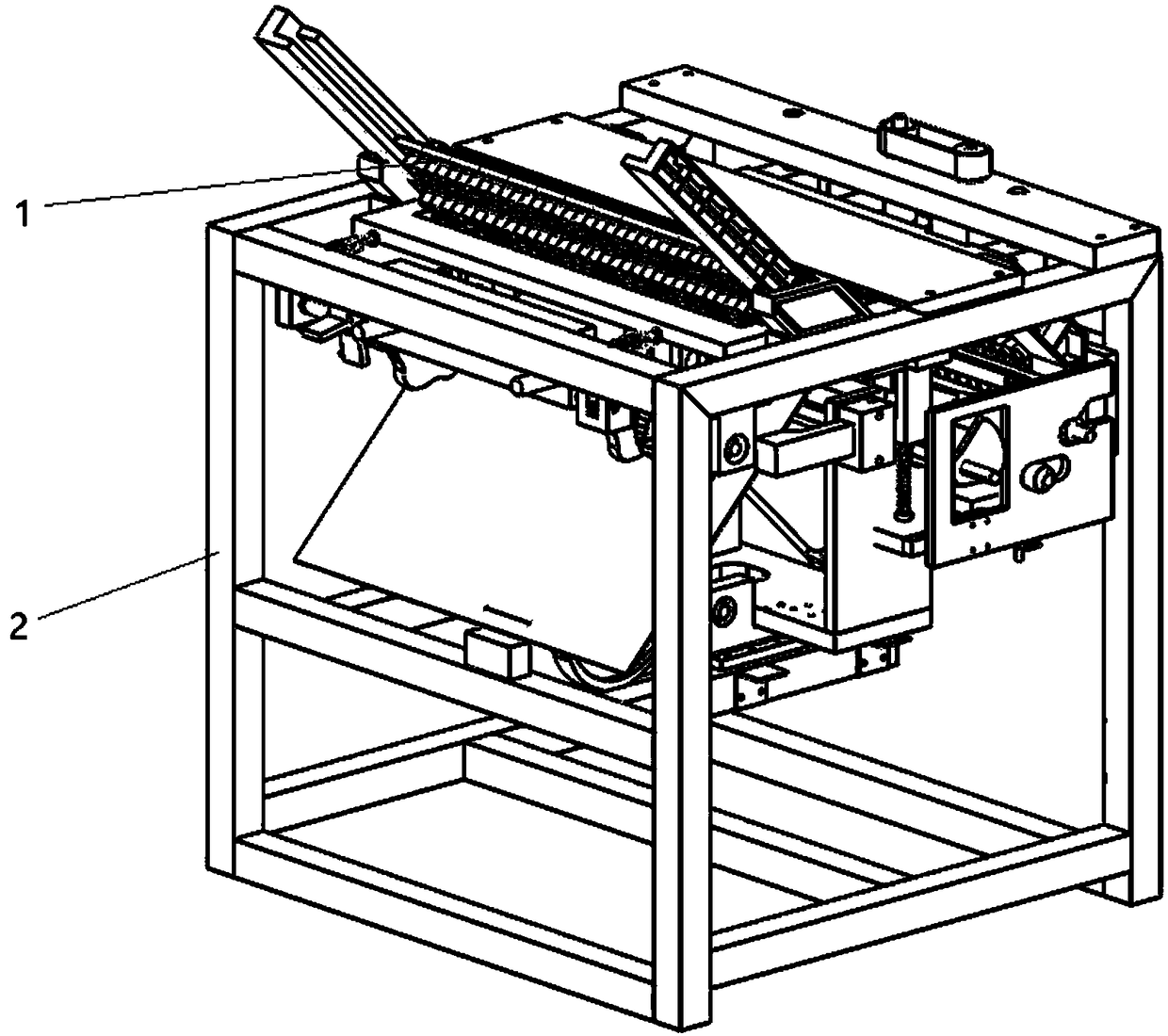

[0040] The fully automatic digging machine includes a frame 2. The frame 2 is equipped with a pushing mechanism, a feeding mechanism and a digging device. The royal jelly table base bar 1 can move in the feeding mechanism. The pushing mechanism and the digging device are arranged in the royal jelly in turn. In the moving stroke of the base bar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com