Patents

Literature

30results about How to "Realize automatic adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

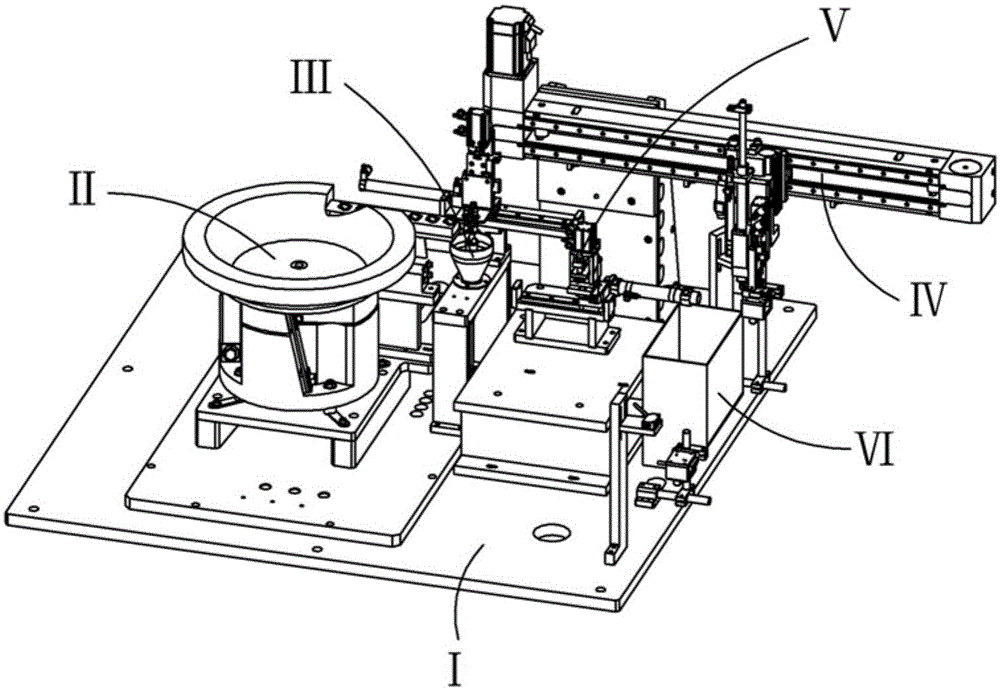

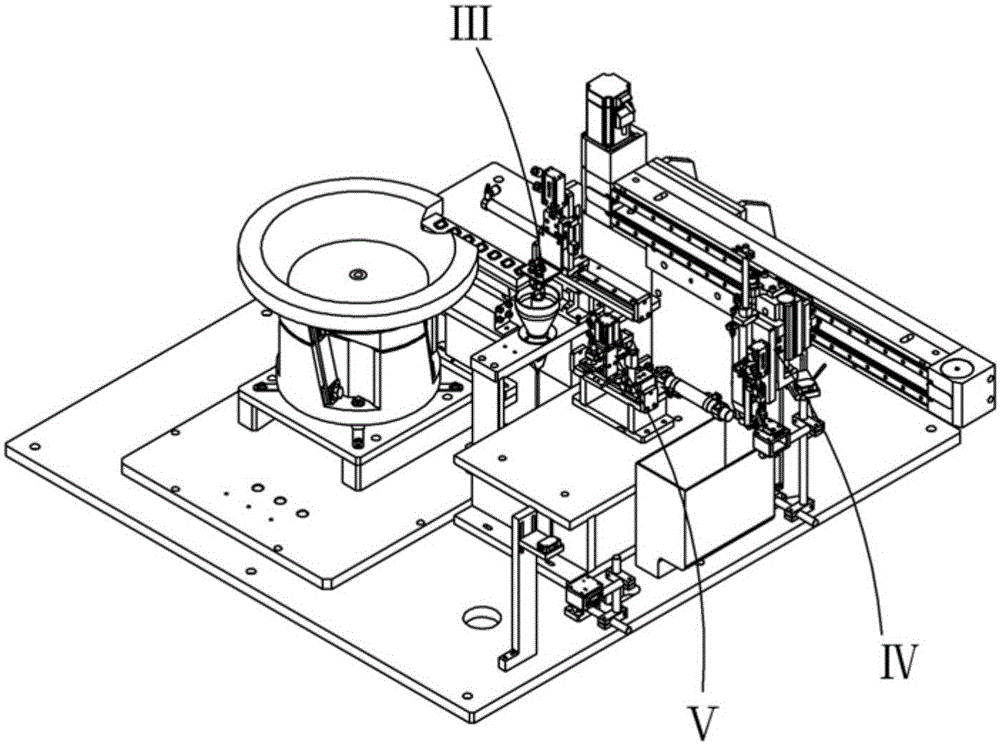

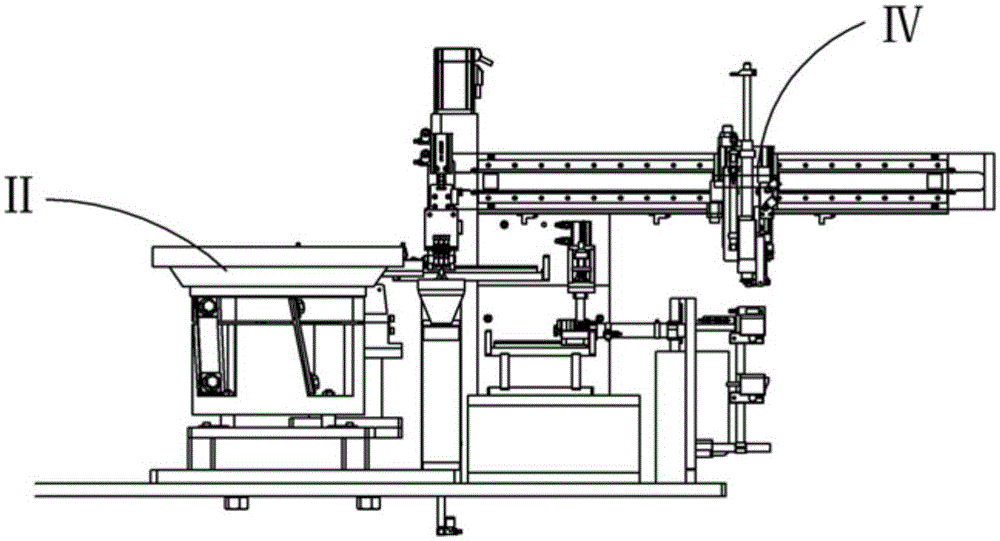

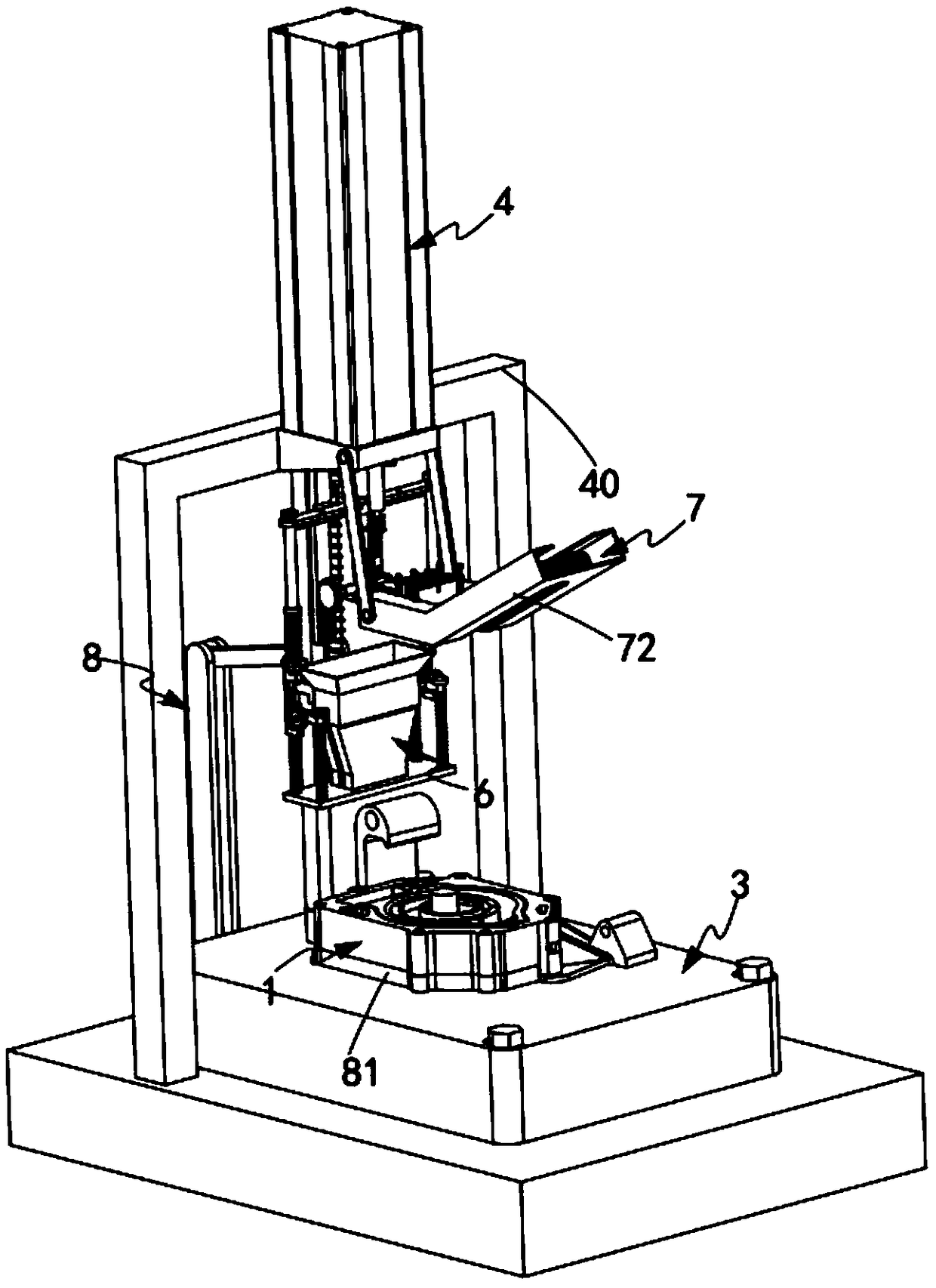

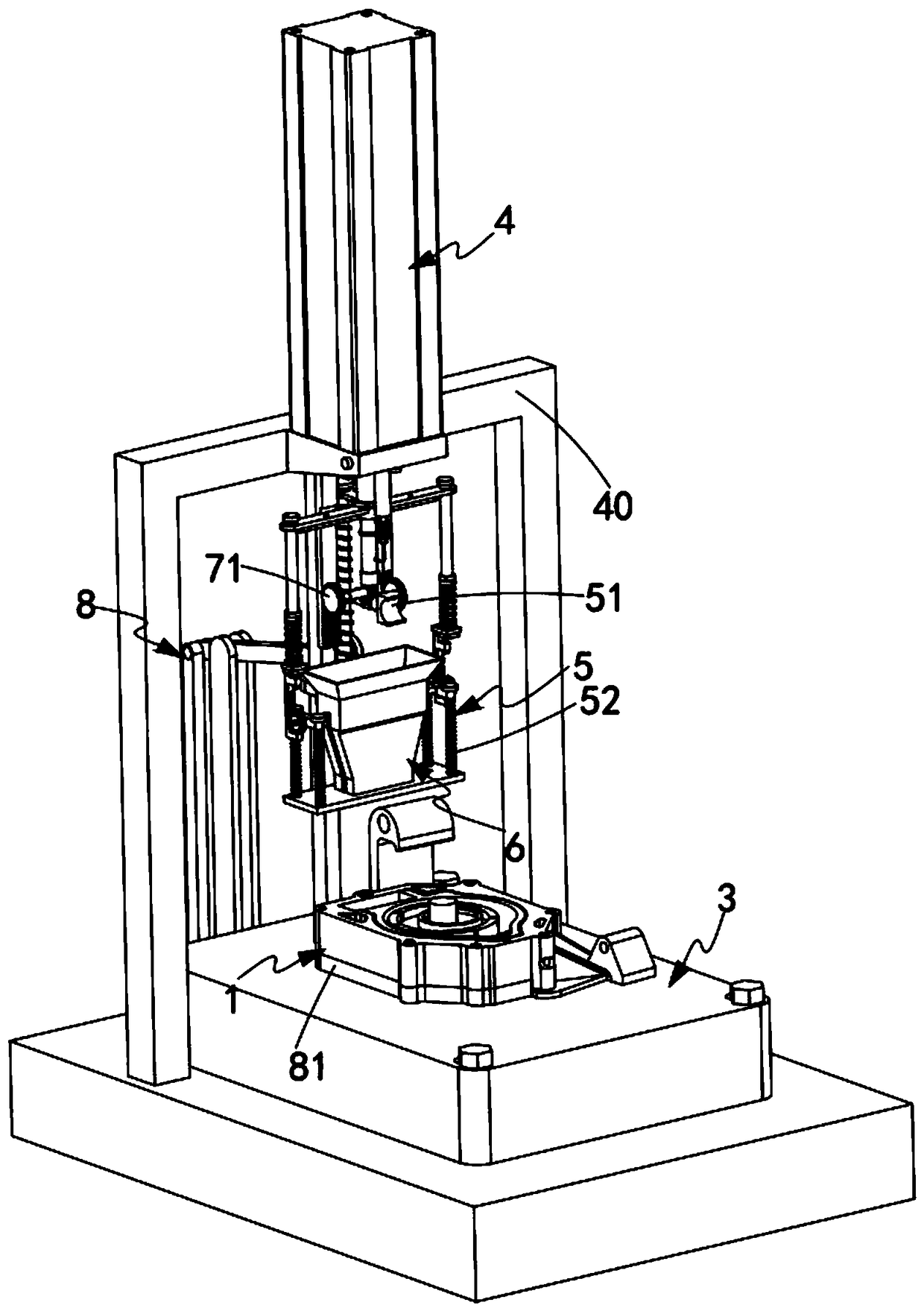

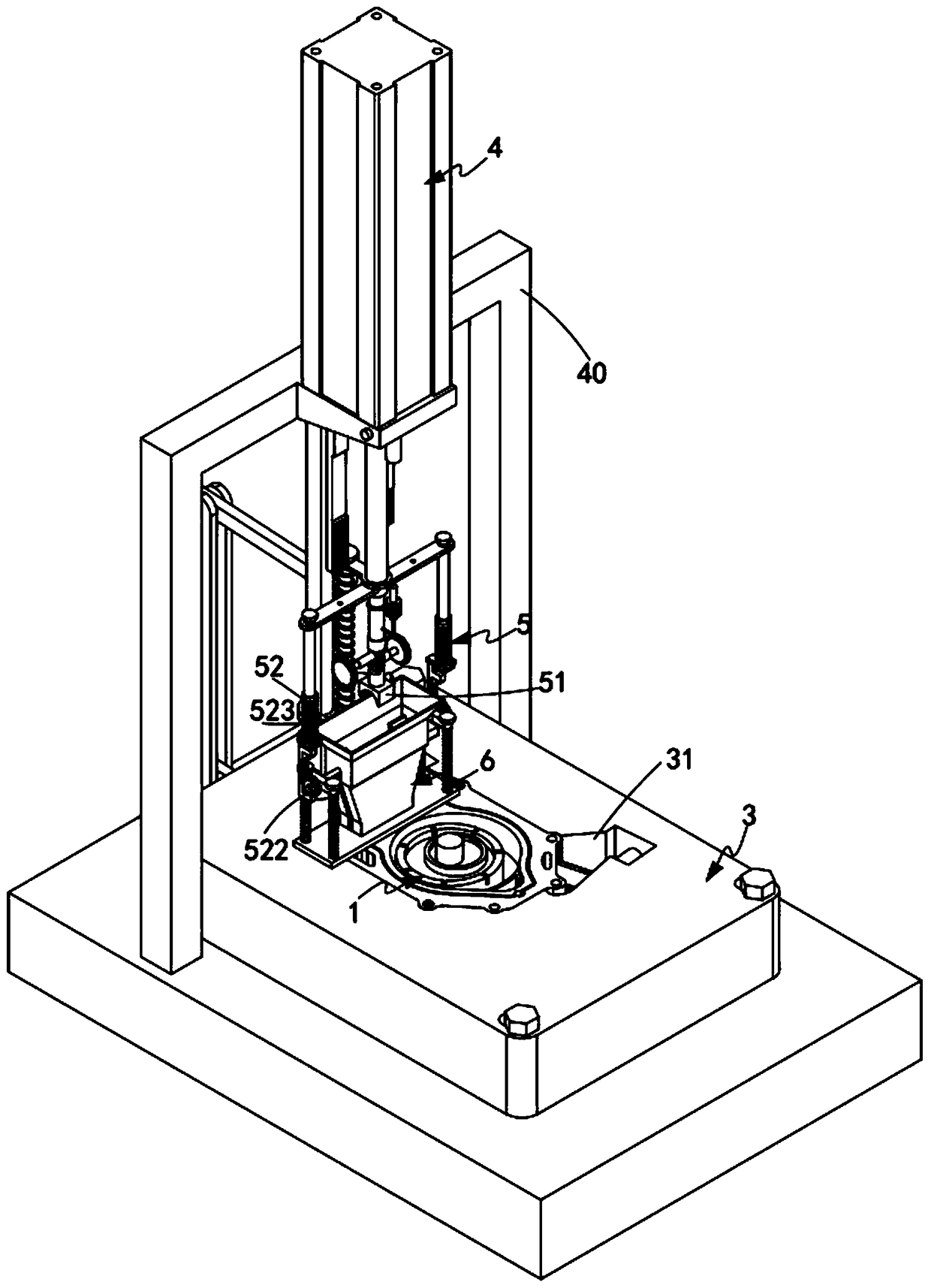

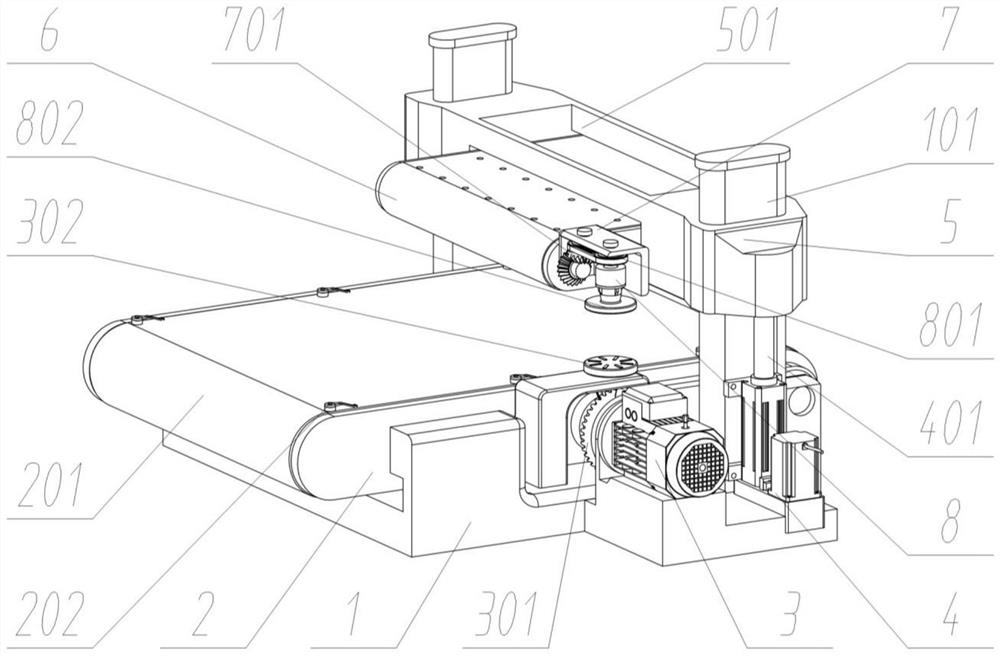

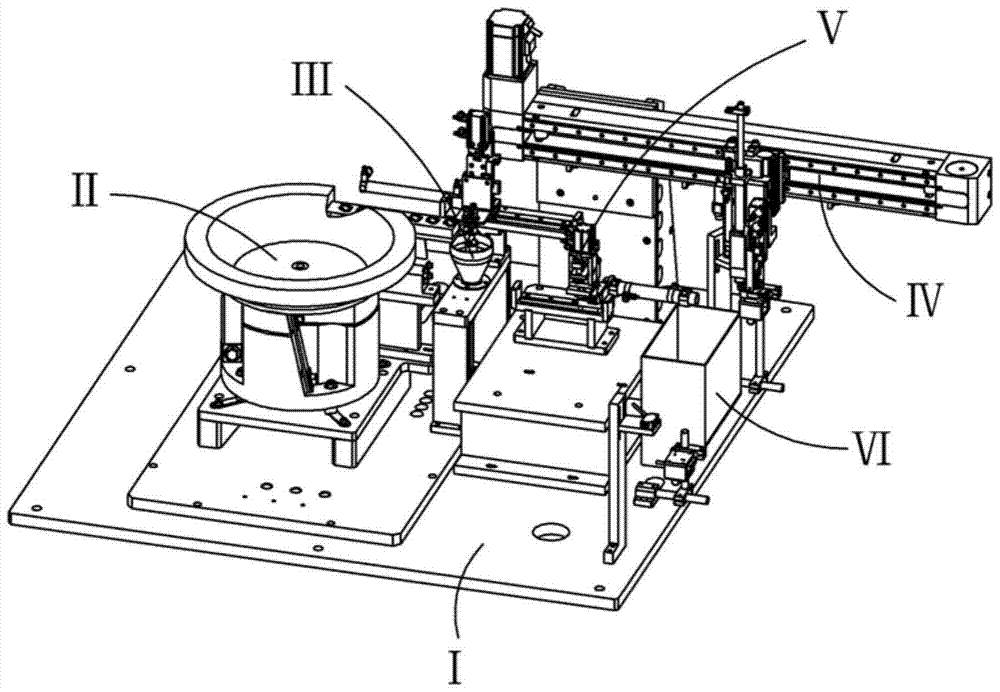

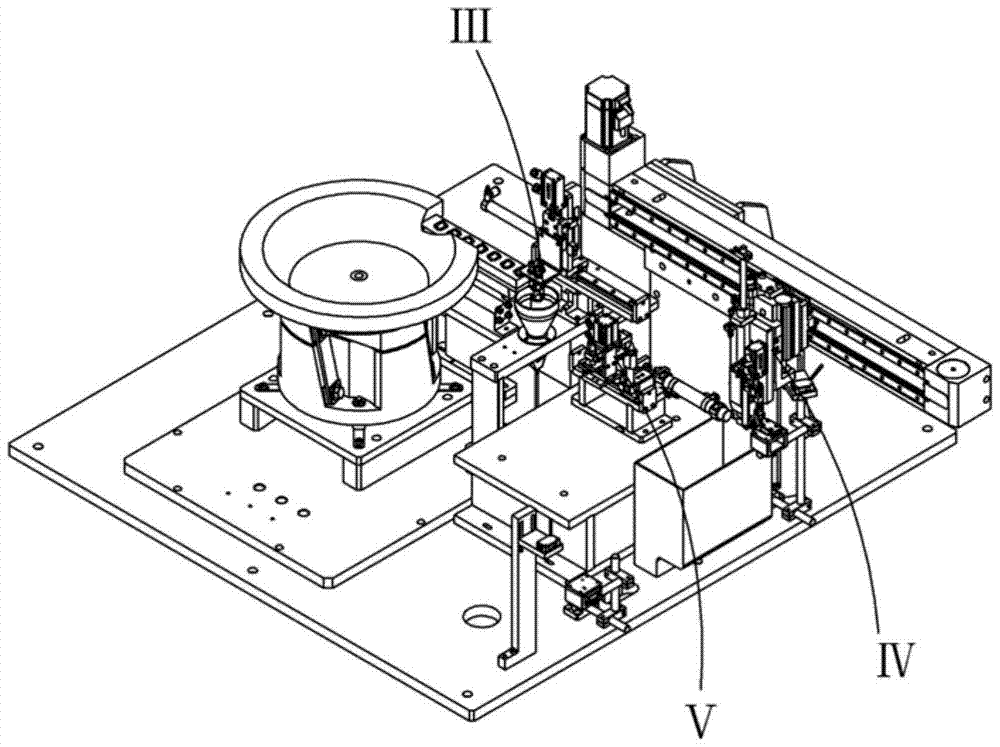

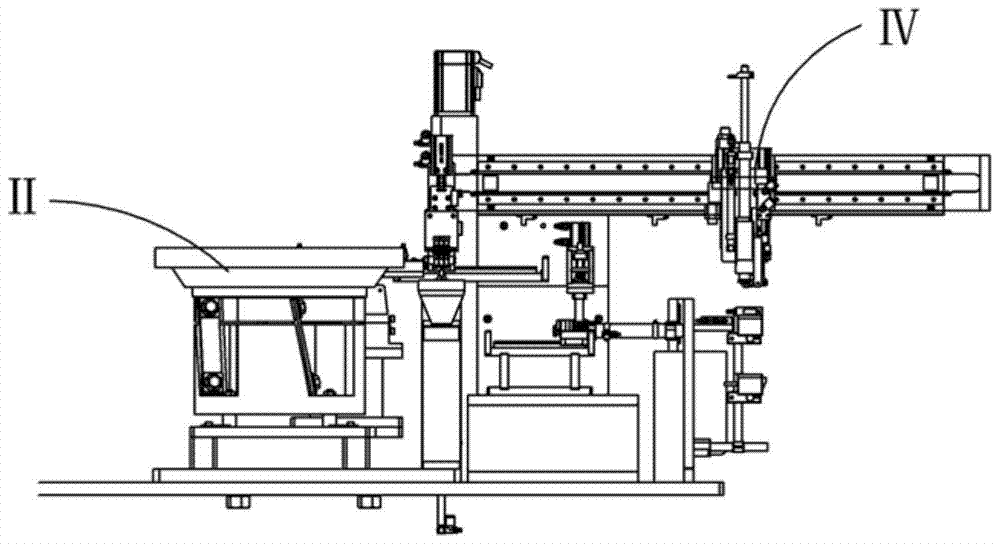

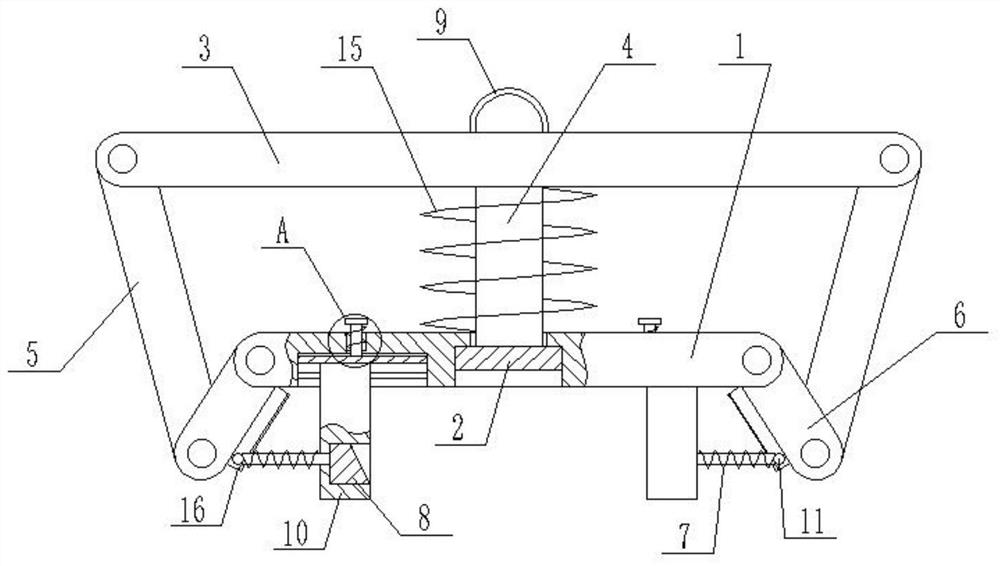

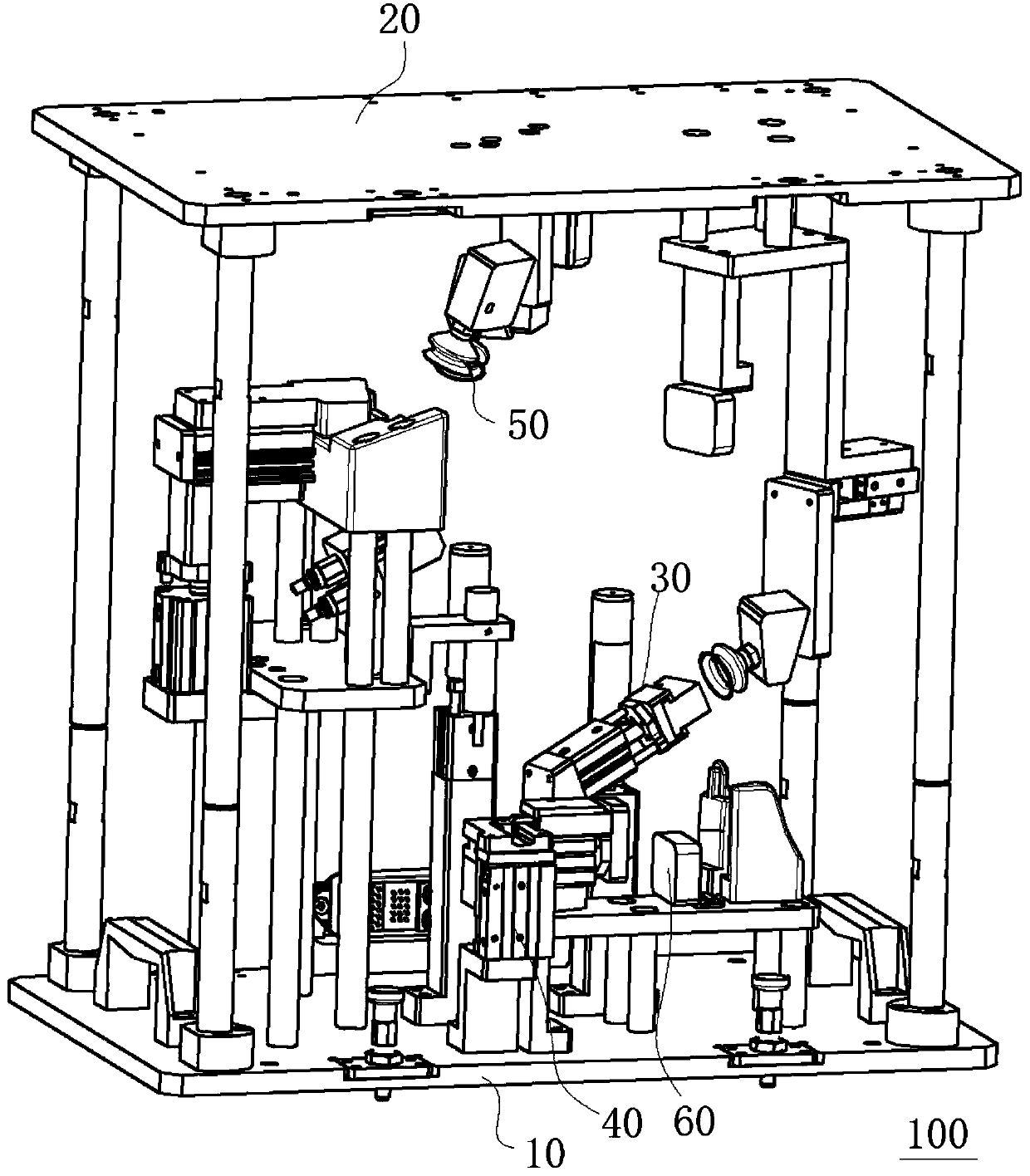

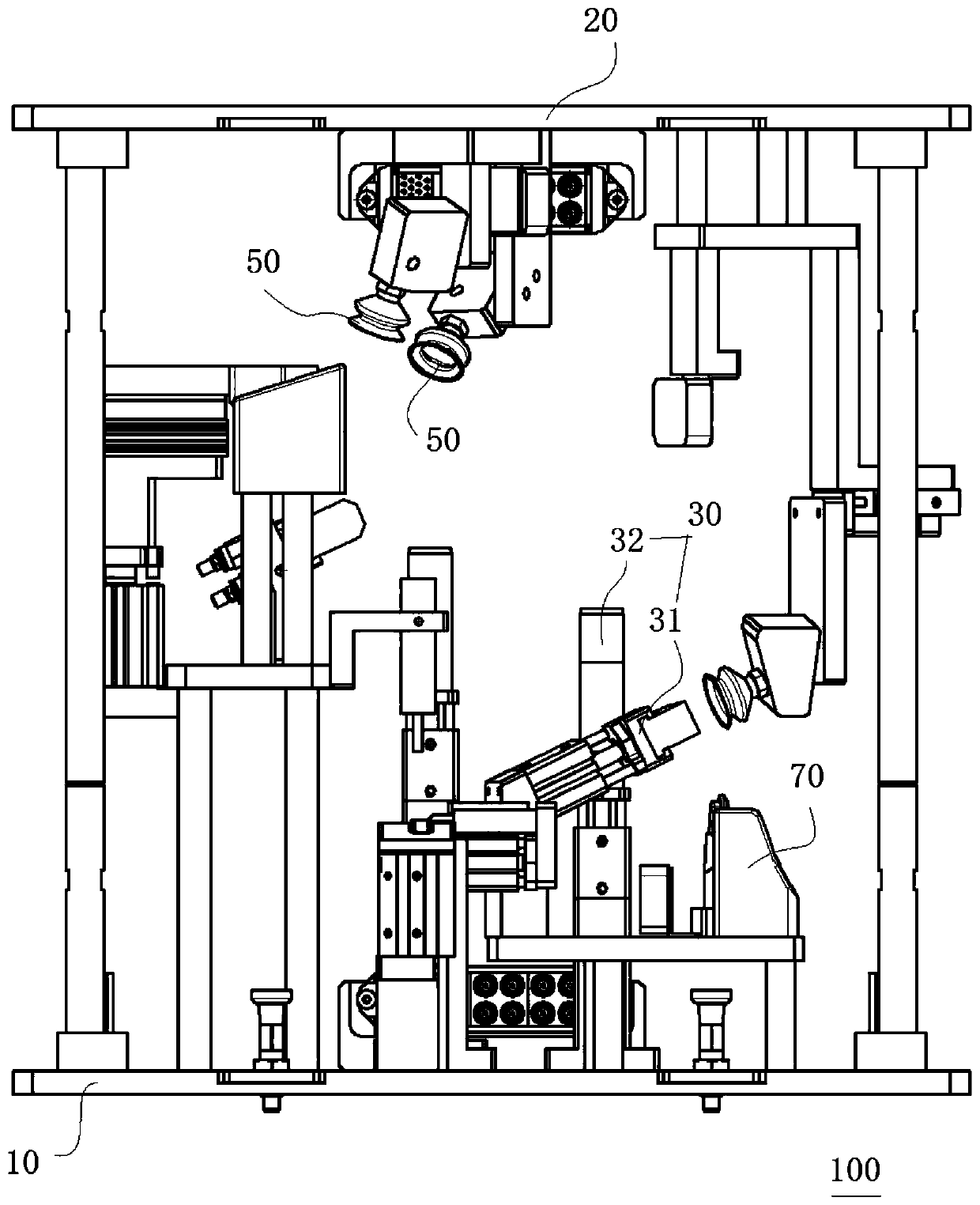

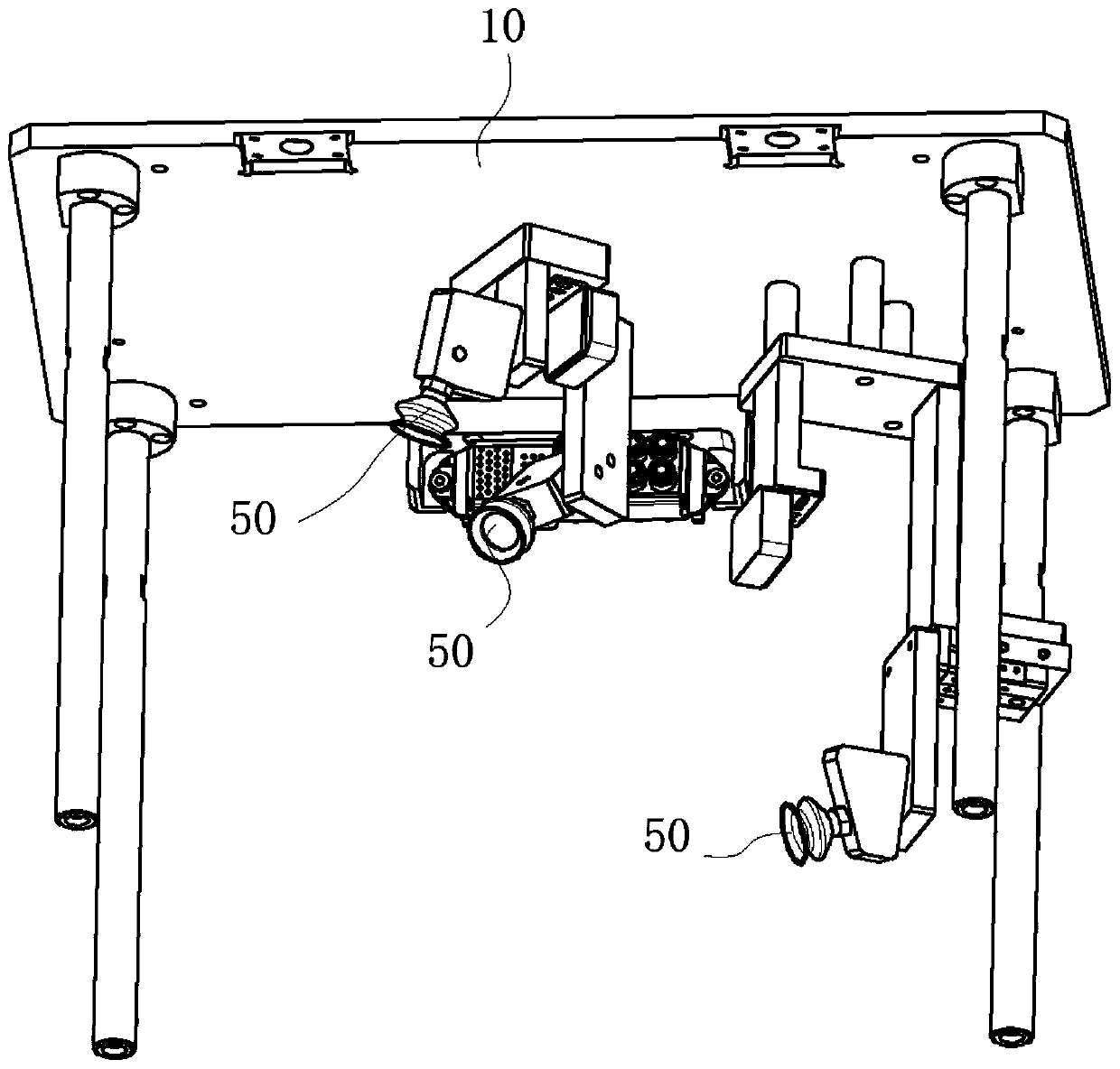

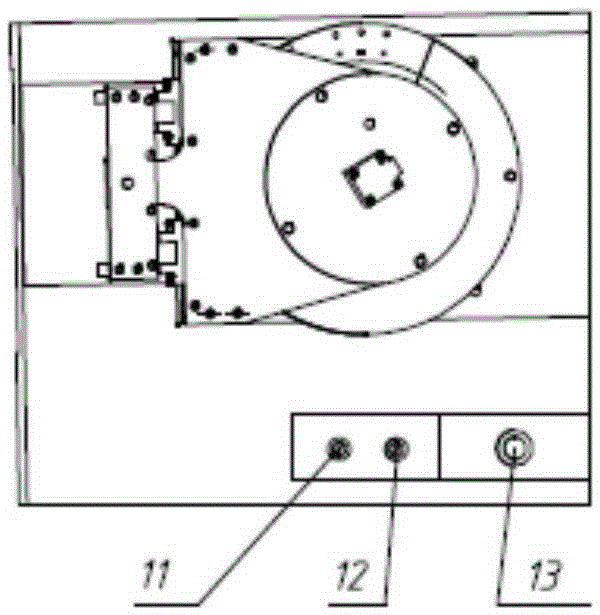

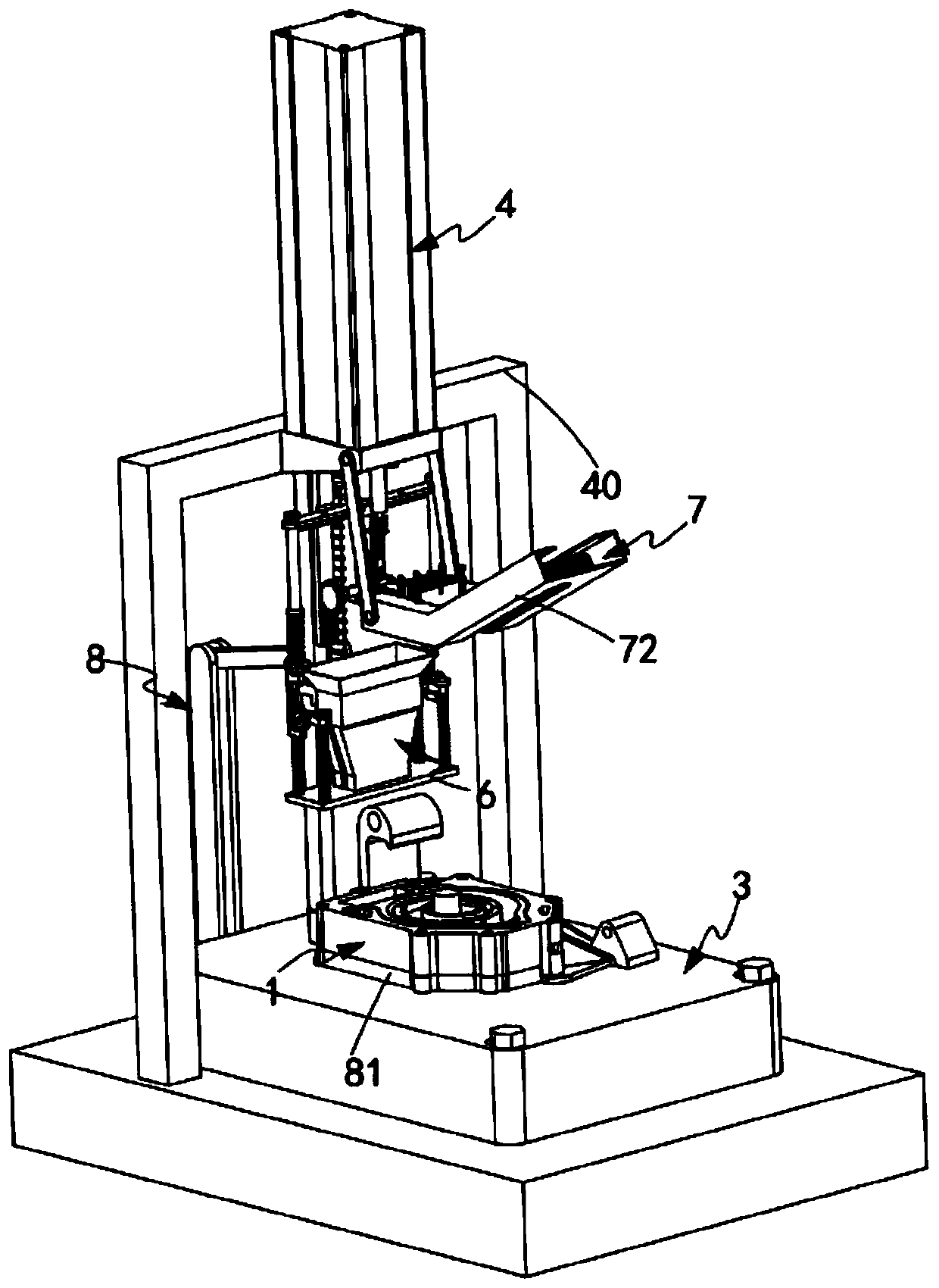

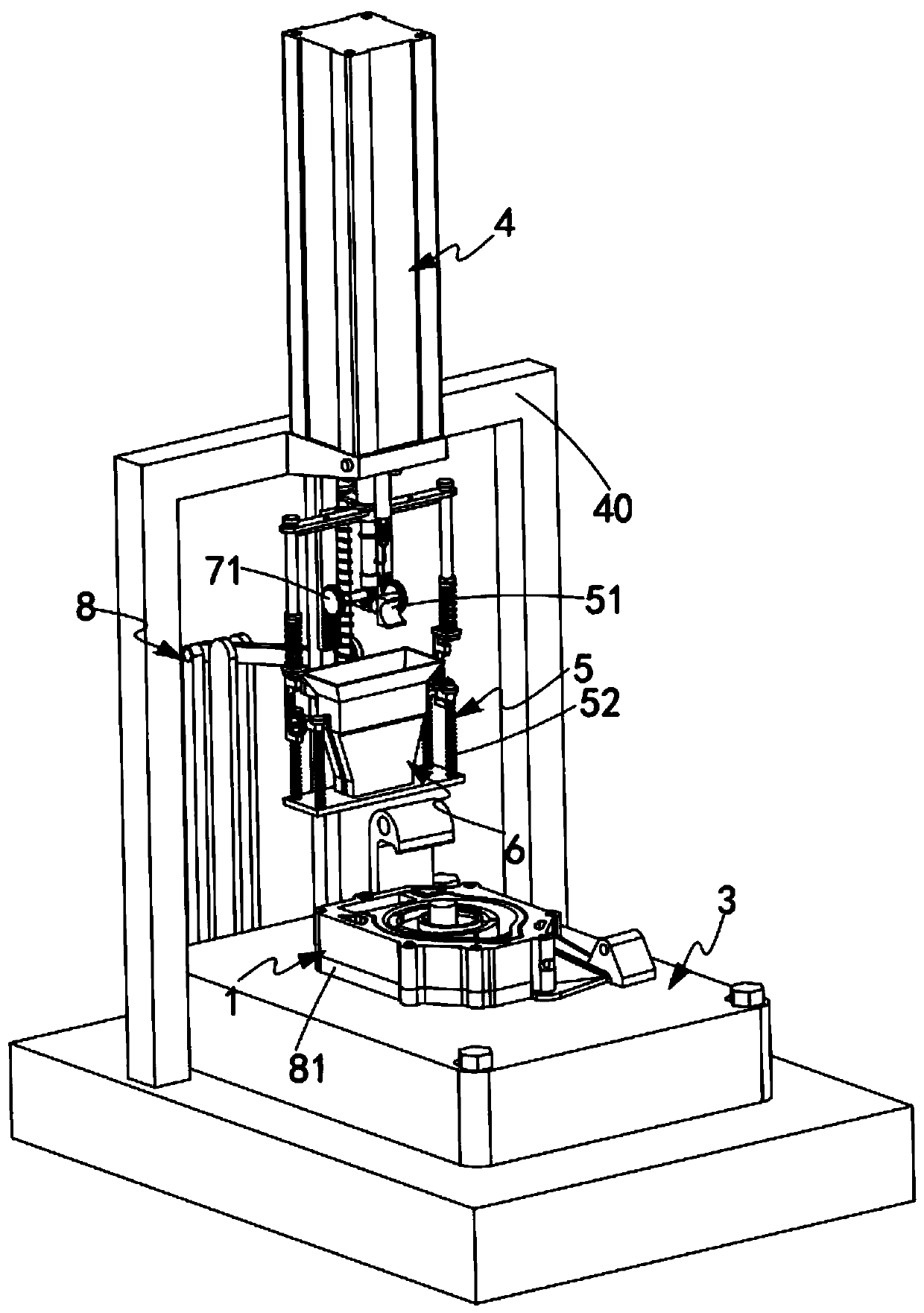

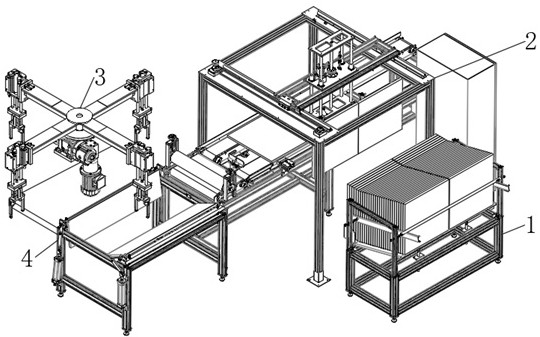

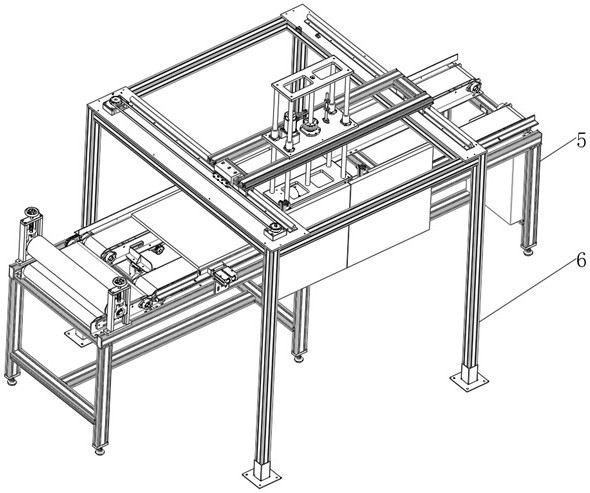

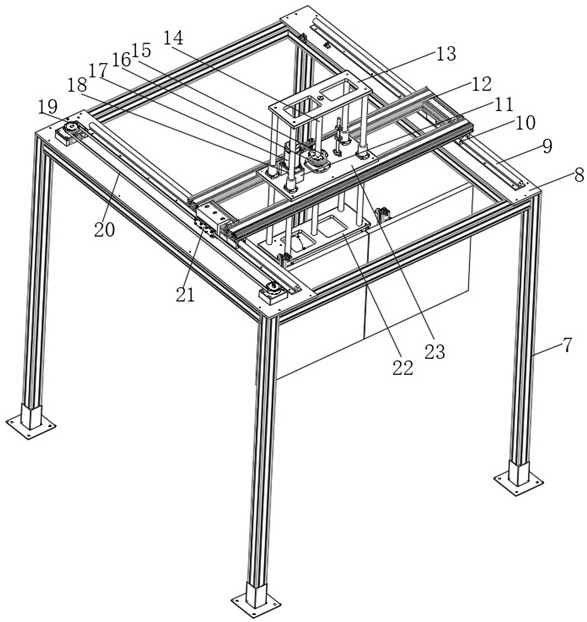

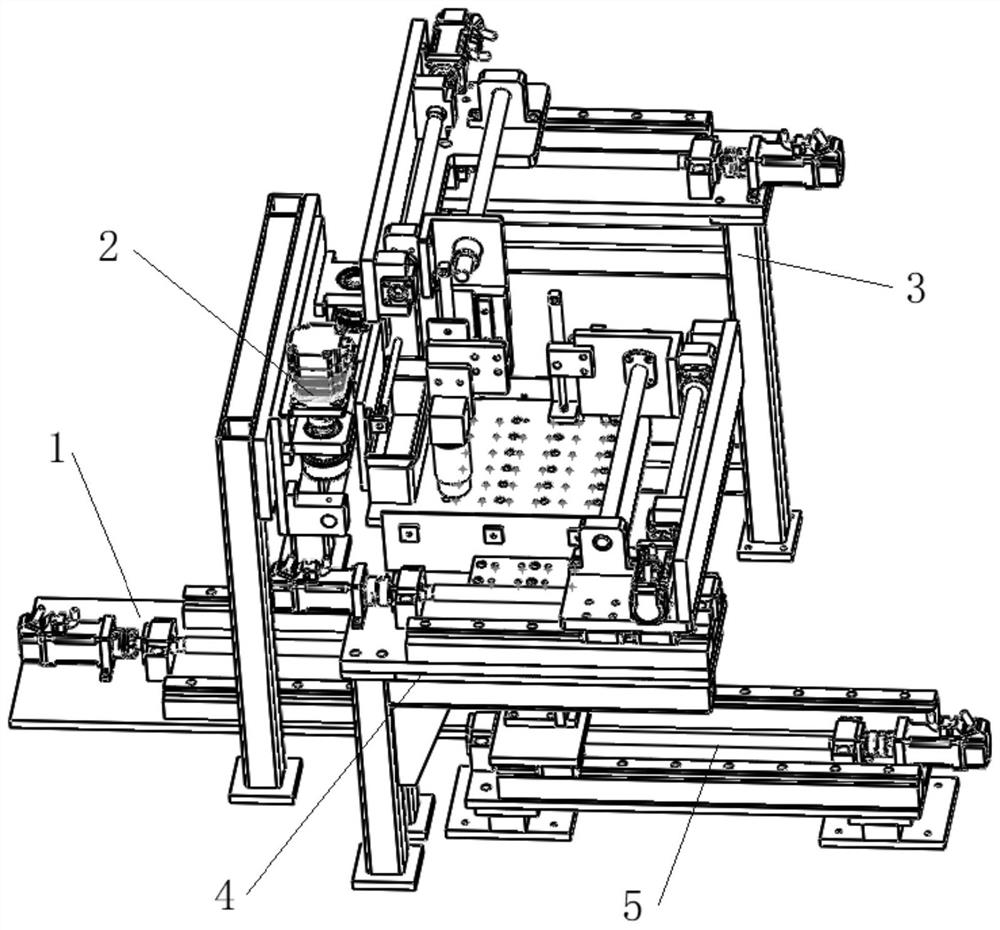

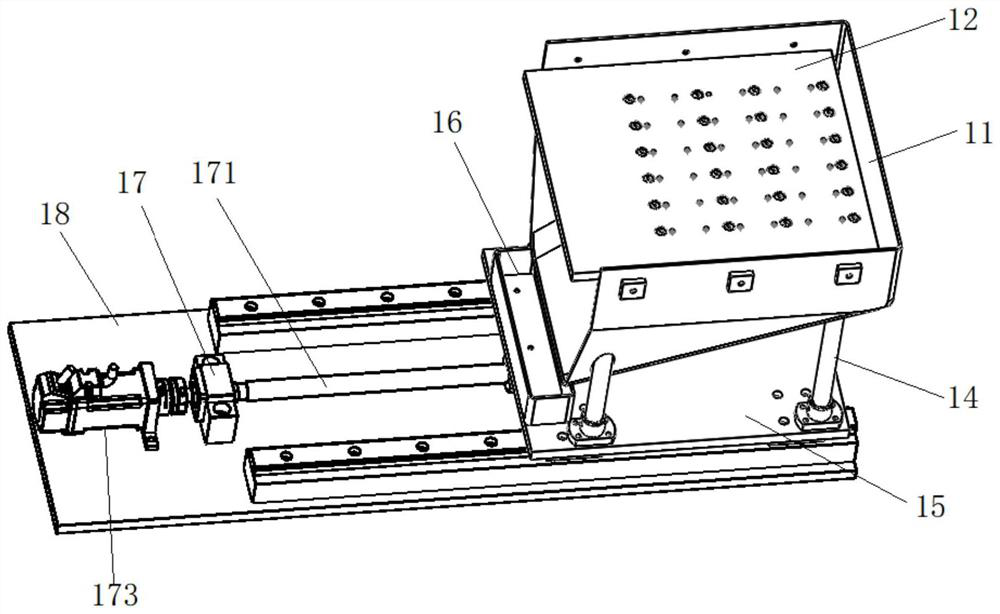

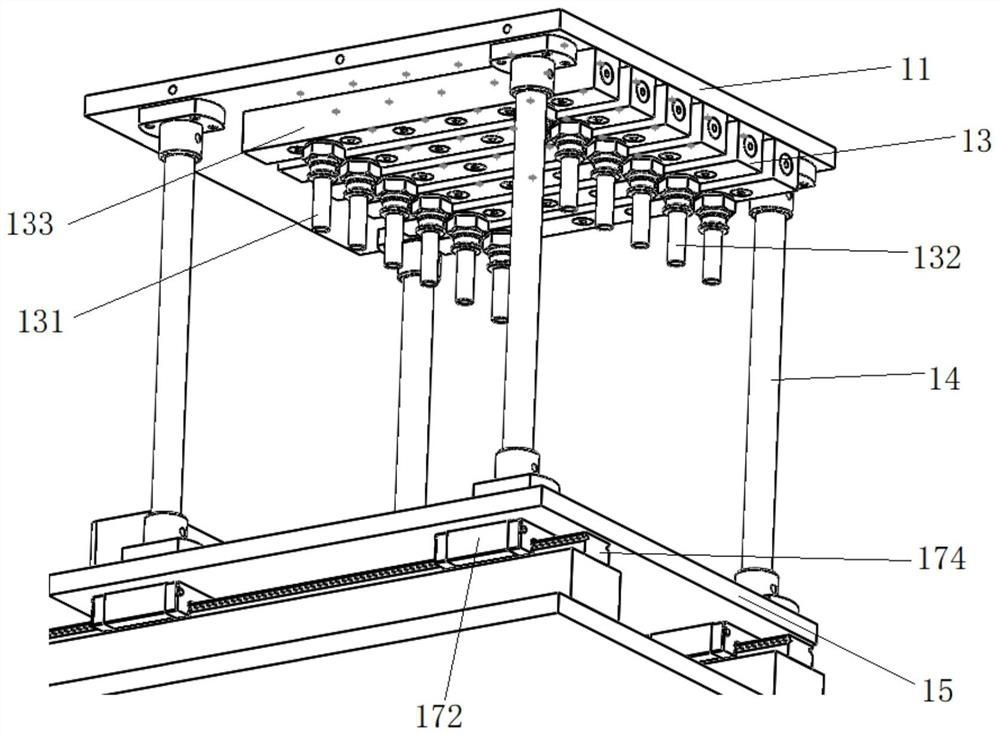

Automatic installing mechanism of wave washer

ActiveCN105033631AEasy to operateImprove installation efficiencyMetal working apparatusEngineeringUltimate tensile strength

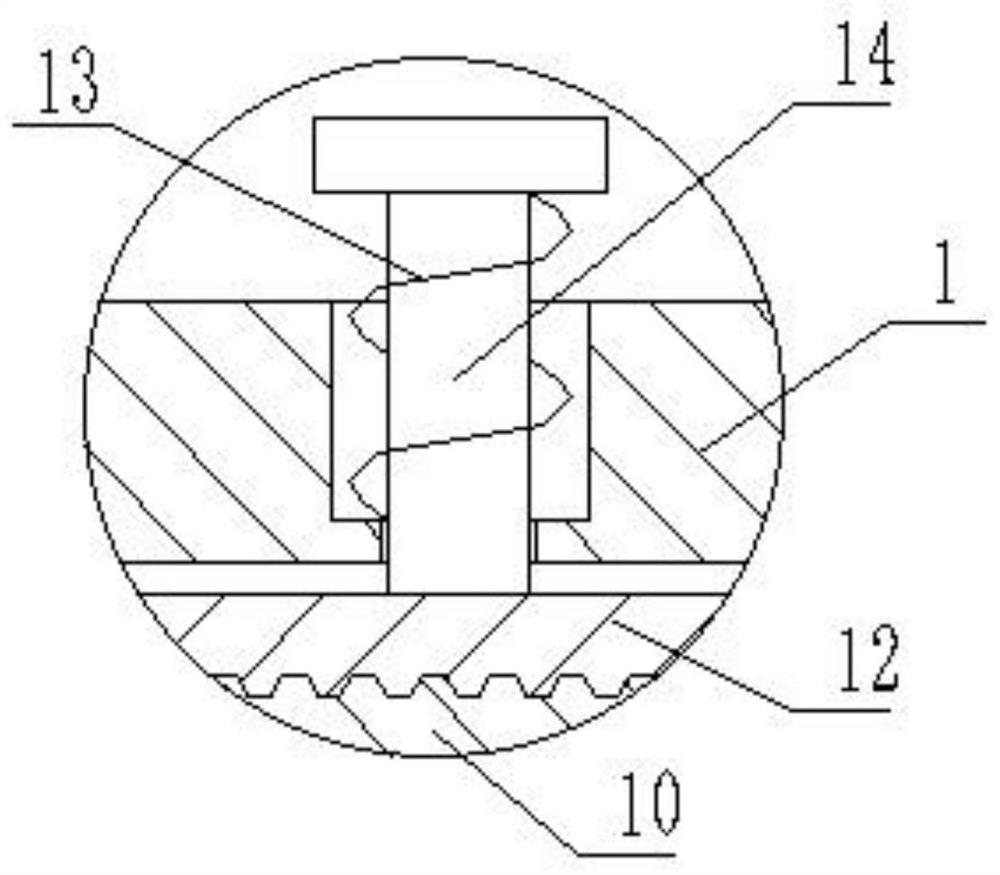

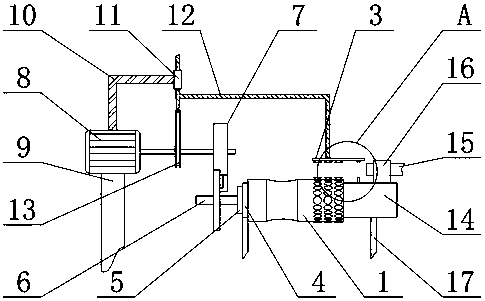

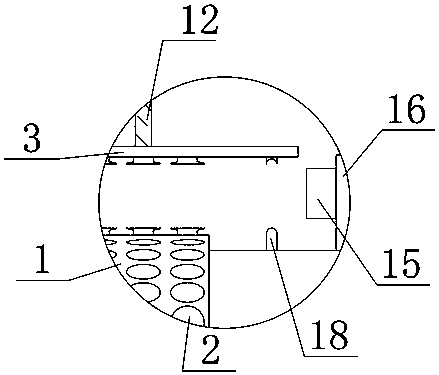

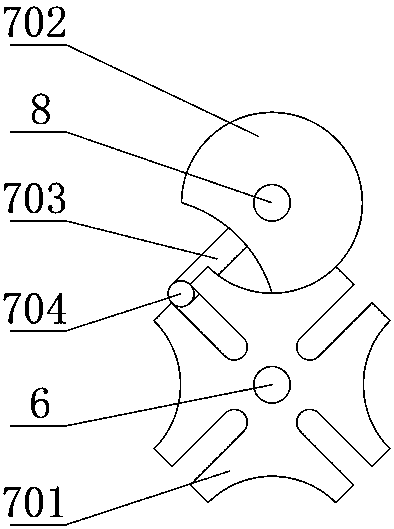

The invention relates to an automatic installing mechanism of a wave washer. A bottom plate is provided with a vibrator feeding mechanism. The vibrator feeding mechanism conveys the wave washer to a vibration disc end. A material taking mechanism is arranged at the position, located on the right rear portion of the vibrator feeding mechanism, of the bottom plate. The material taking mechanism can suck the wave washer out of the vibration disc end and place the wave washer in a hopper, and positioning and ejecting of the wave washer are facilitated. A conveying mechanism is arranged above the right rear portion of the bottom plate. The conveying mechanism can convey the positioned and ejected wave washer to a detecting mechanism or an installing position. The detecting mechanism is arranged at the position, located on the right side of the material taking mechanism, of the bottom plate, and can detect whether the thickness of the wave washer is qualified or not. A waste box is arranged at the position, located on the right side of the detecting mechanism, of the bottom plate and contains waste. By means of the mechanism, automatic adsorbing, conveying and installing of the wave washer can be achieved; and the installing efficiency is improved, the installing quality is guaranteed, the labor intensity of workers is relieved, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

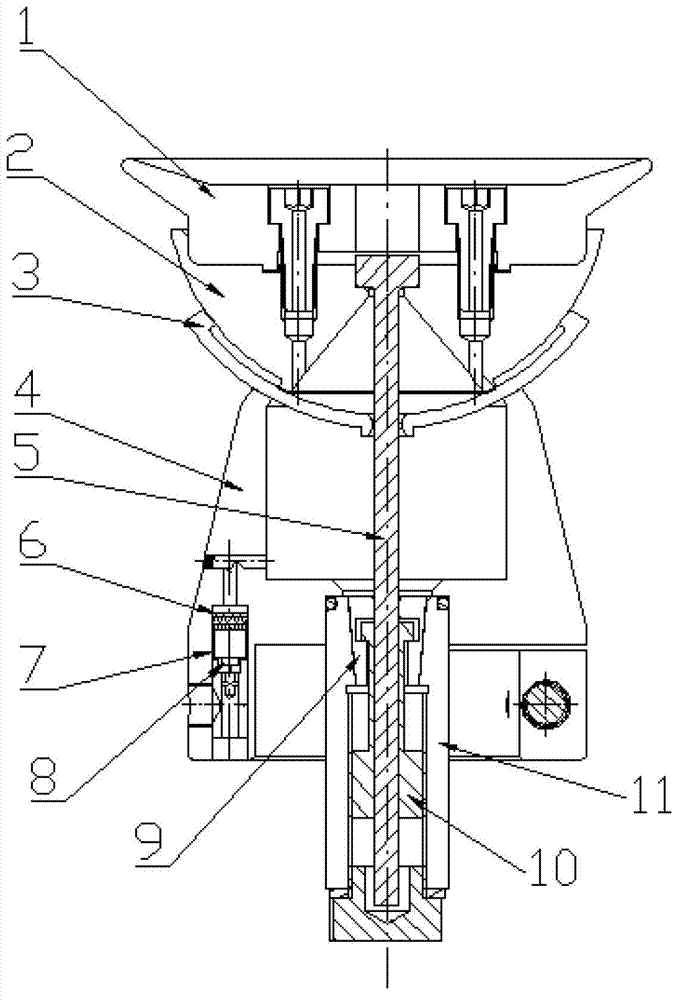

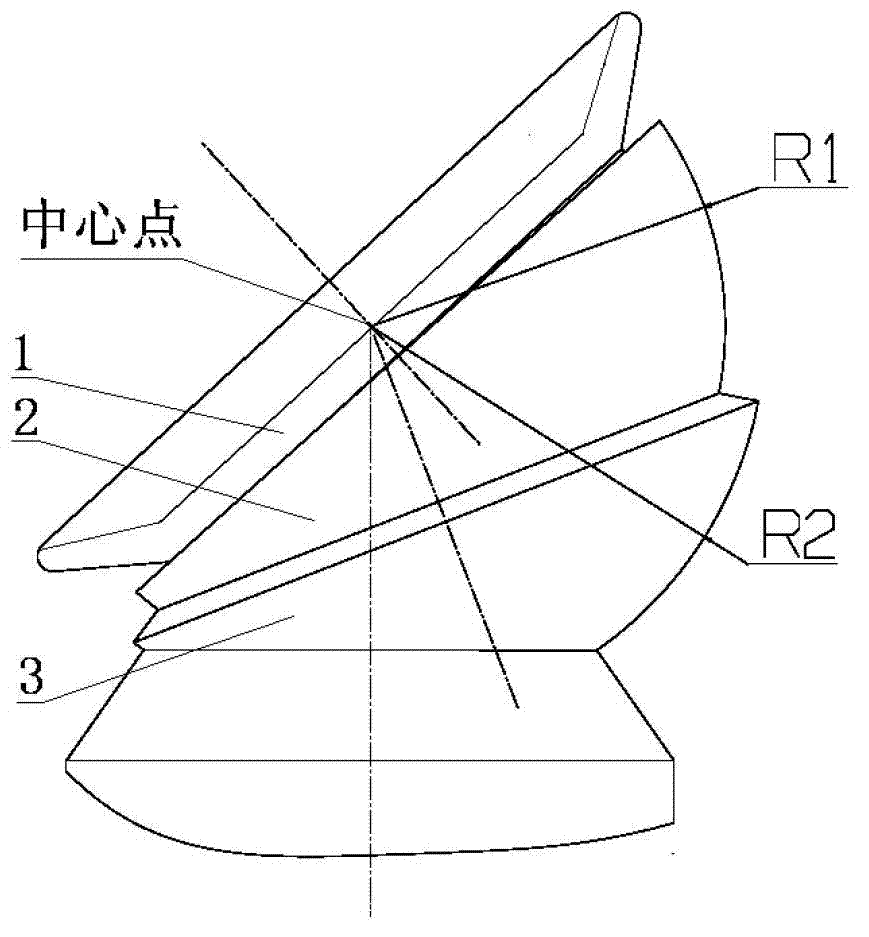

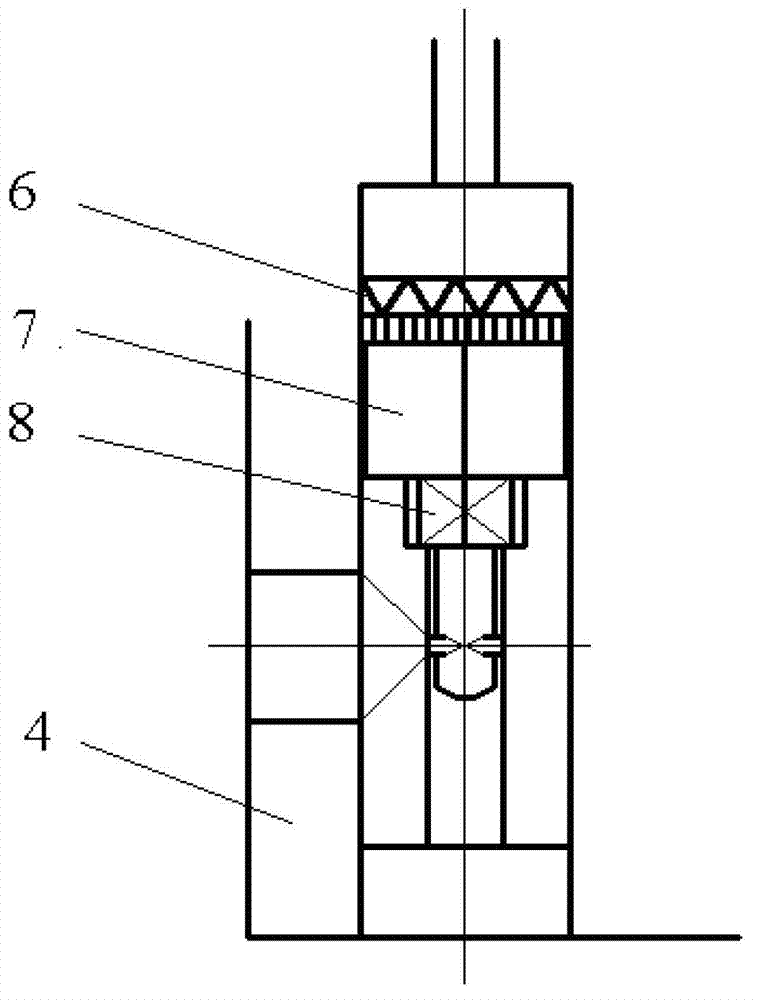

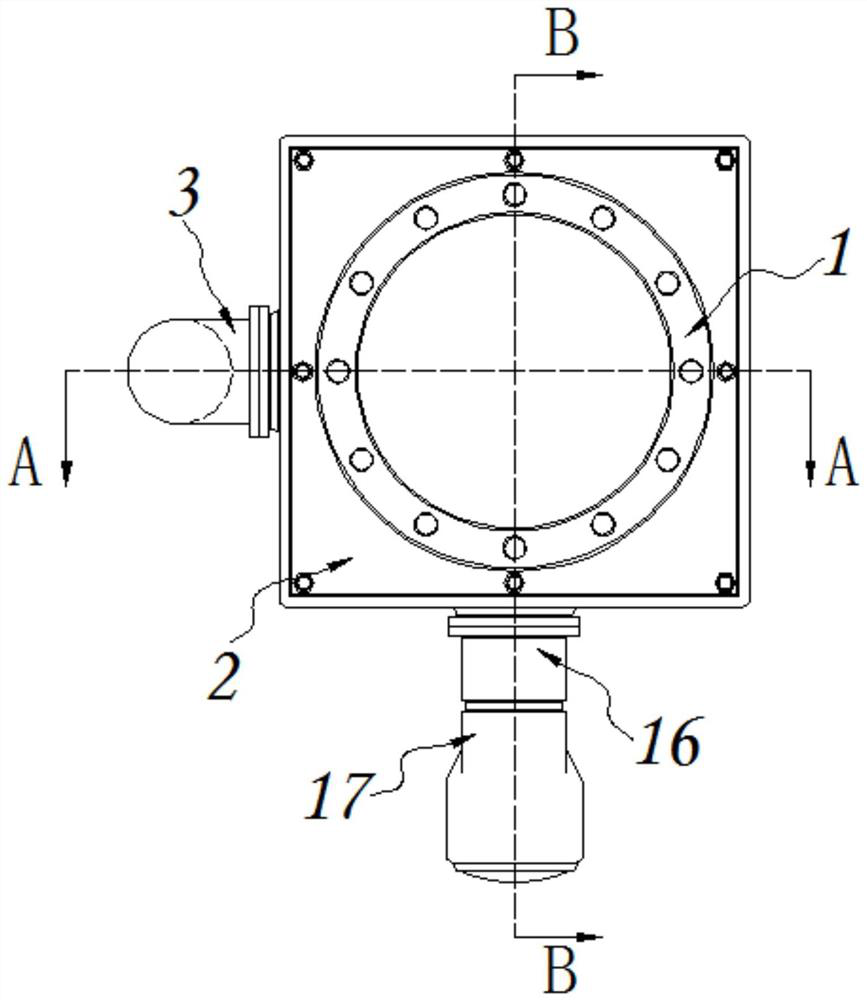

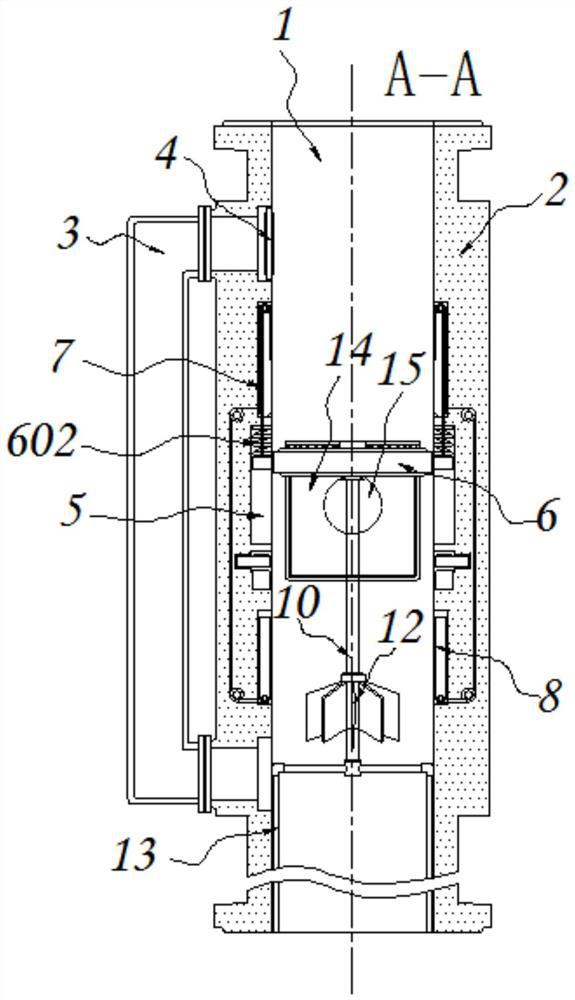

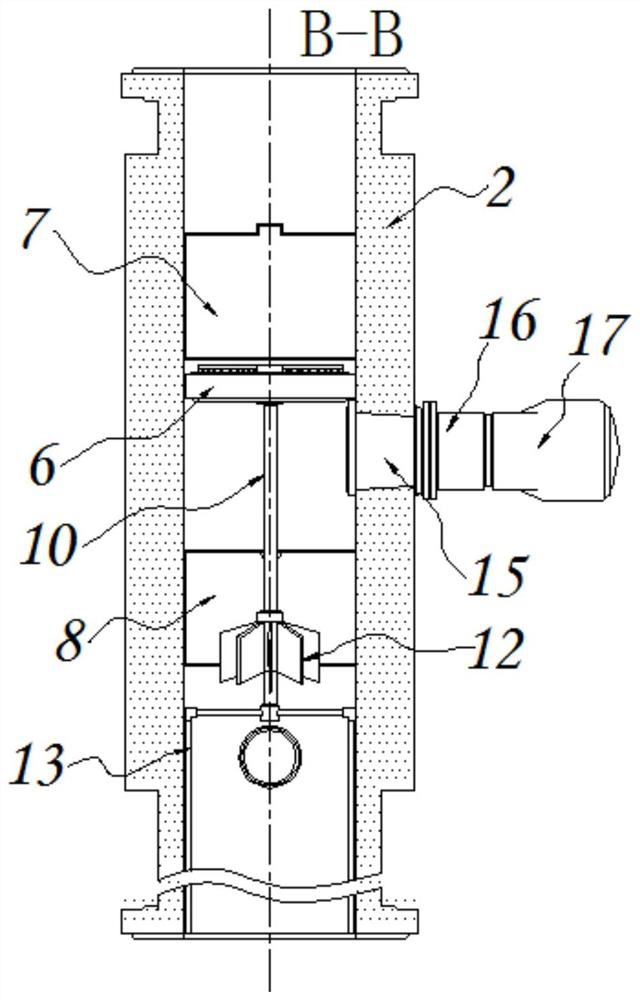

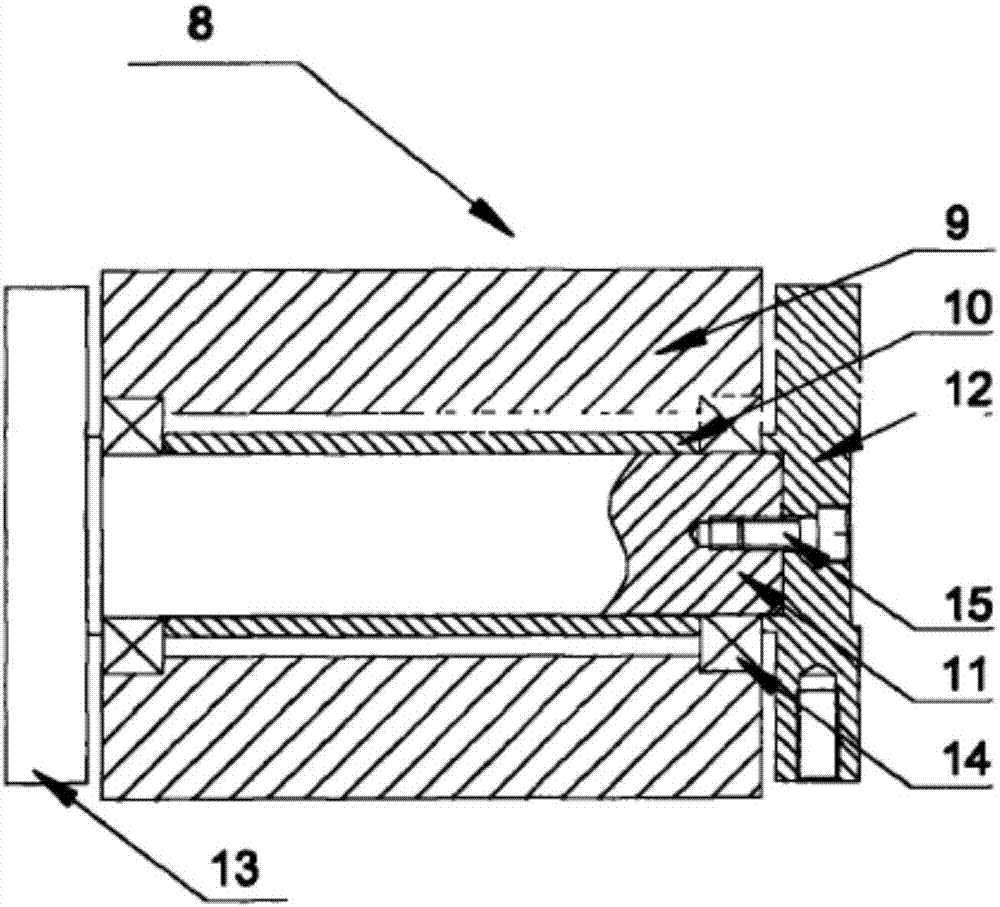

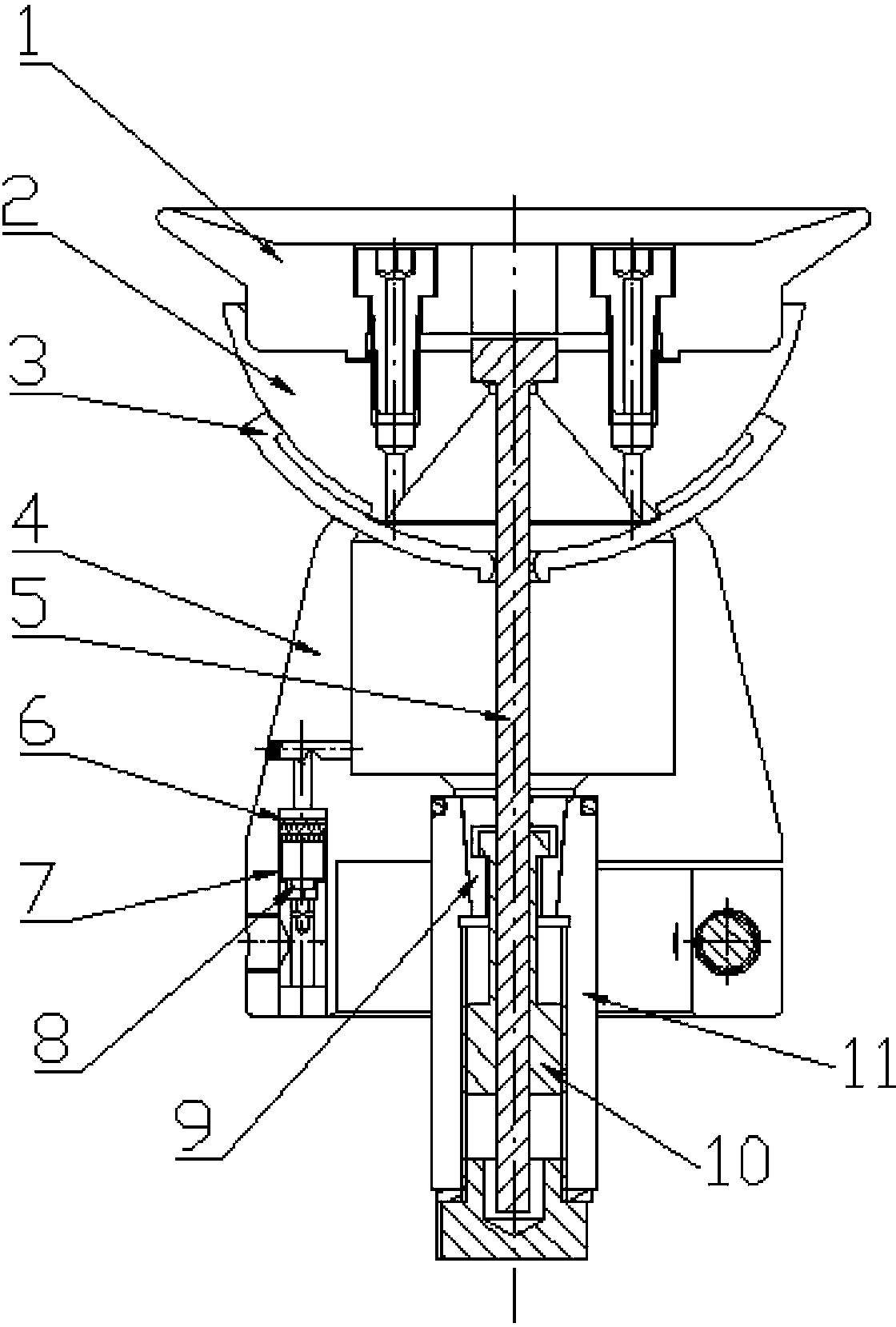

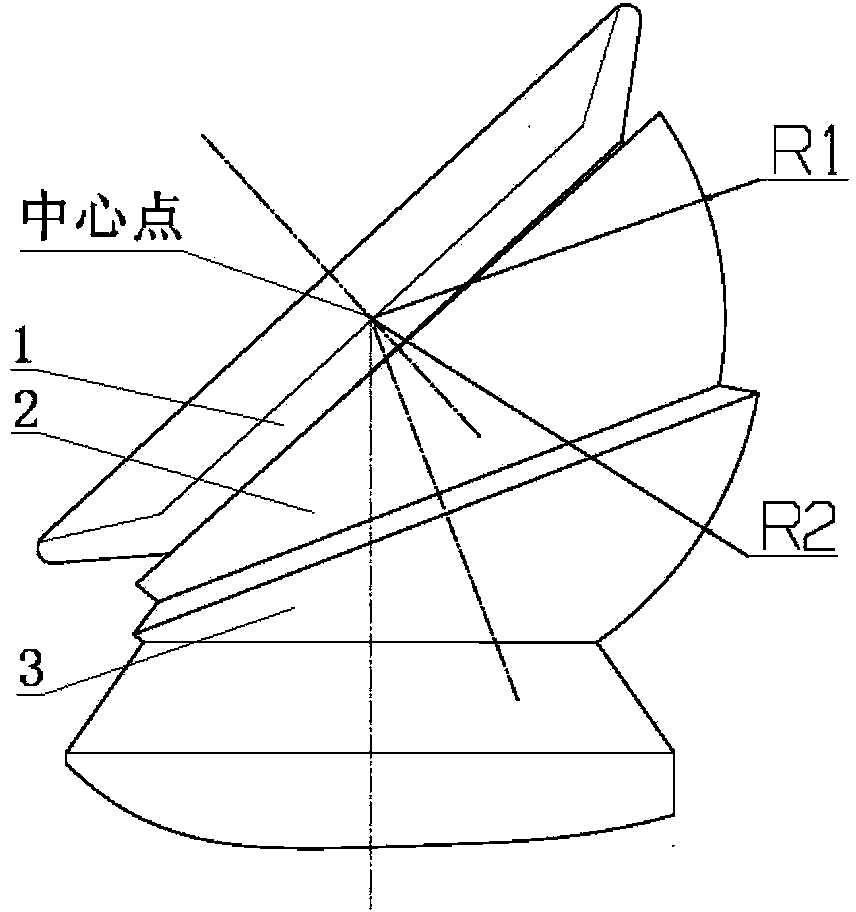

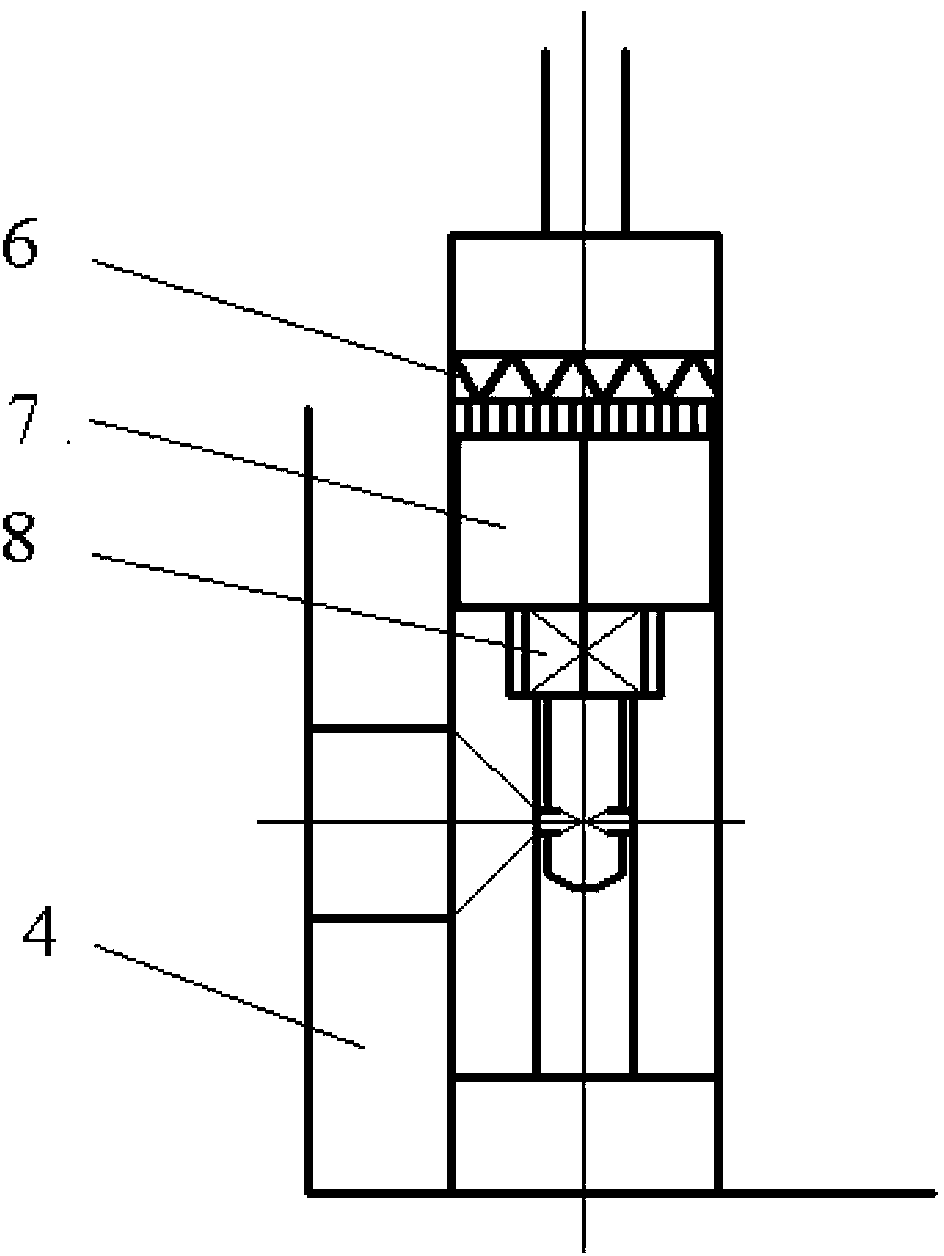

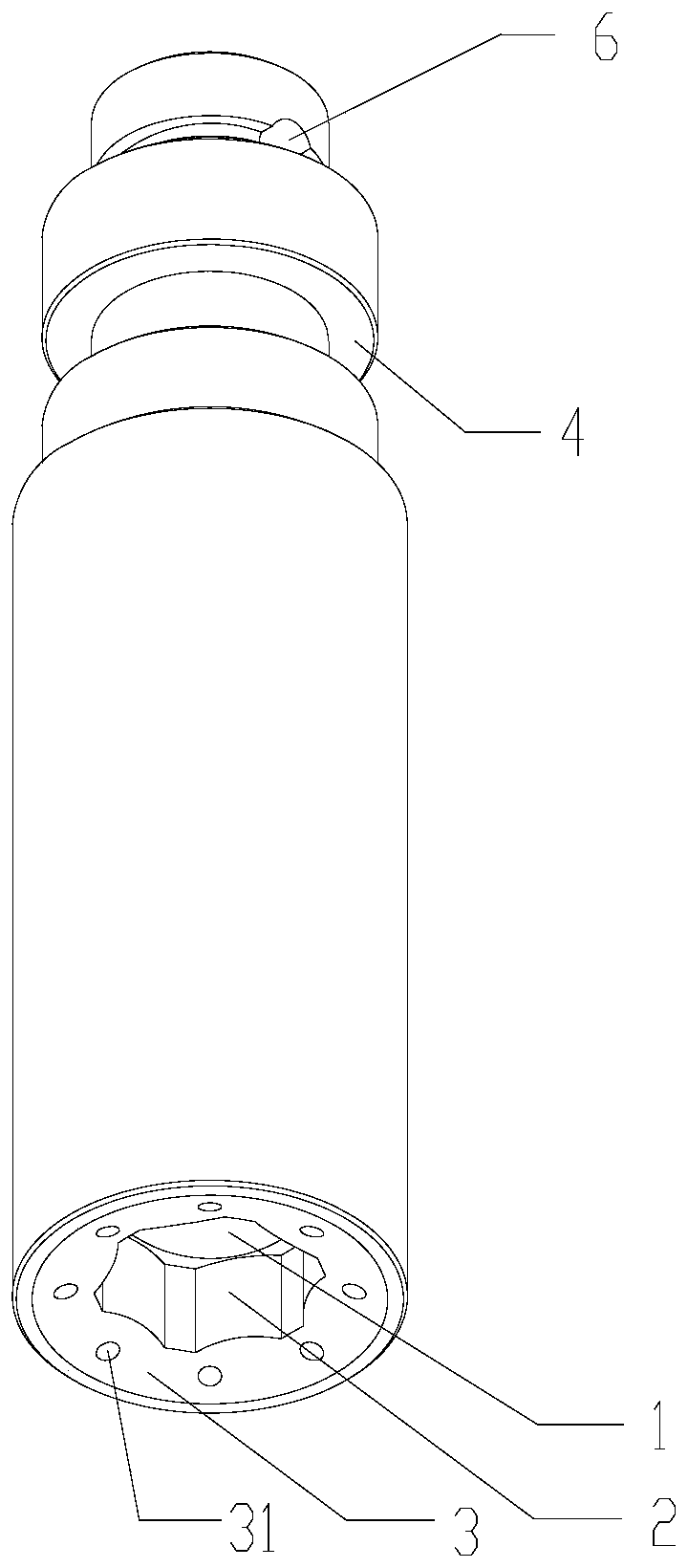

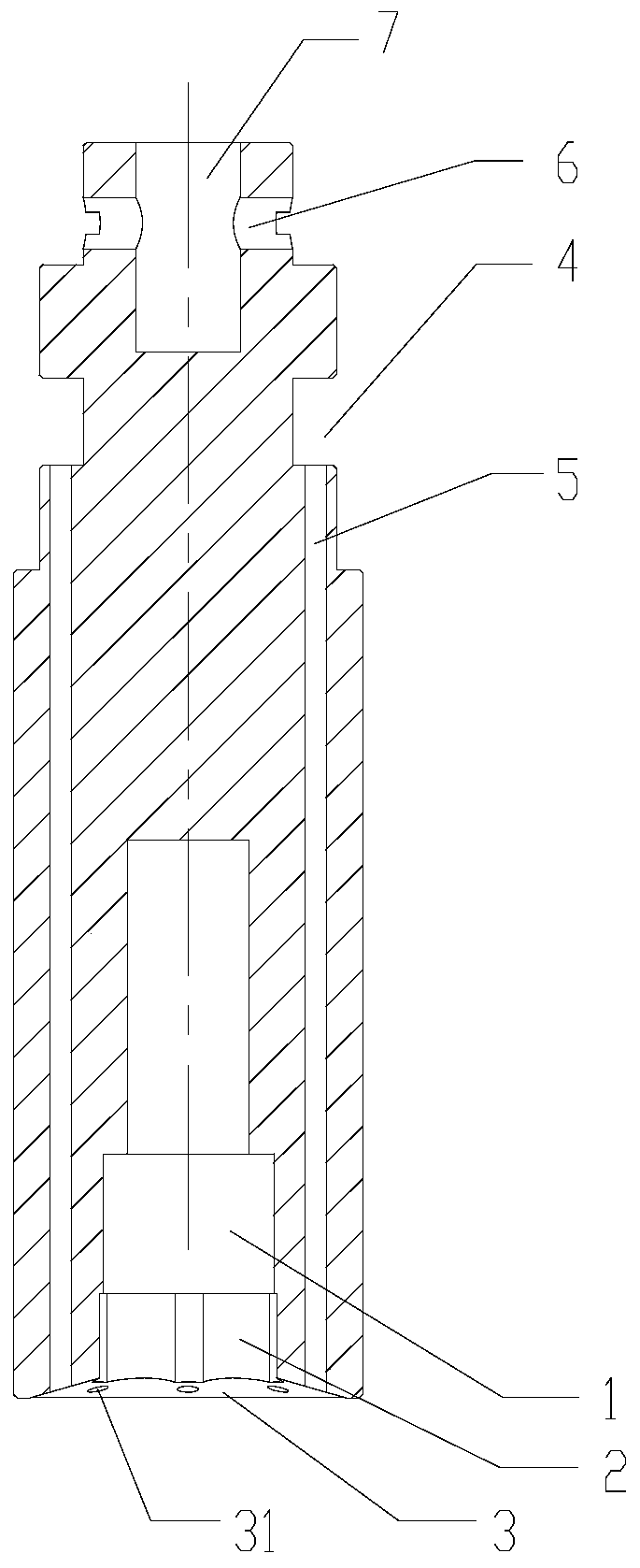

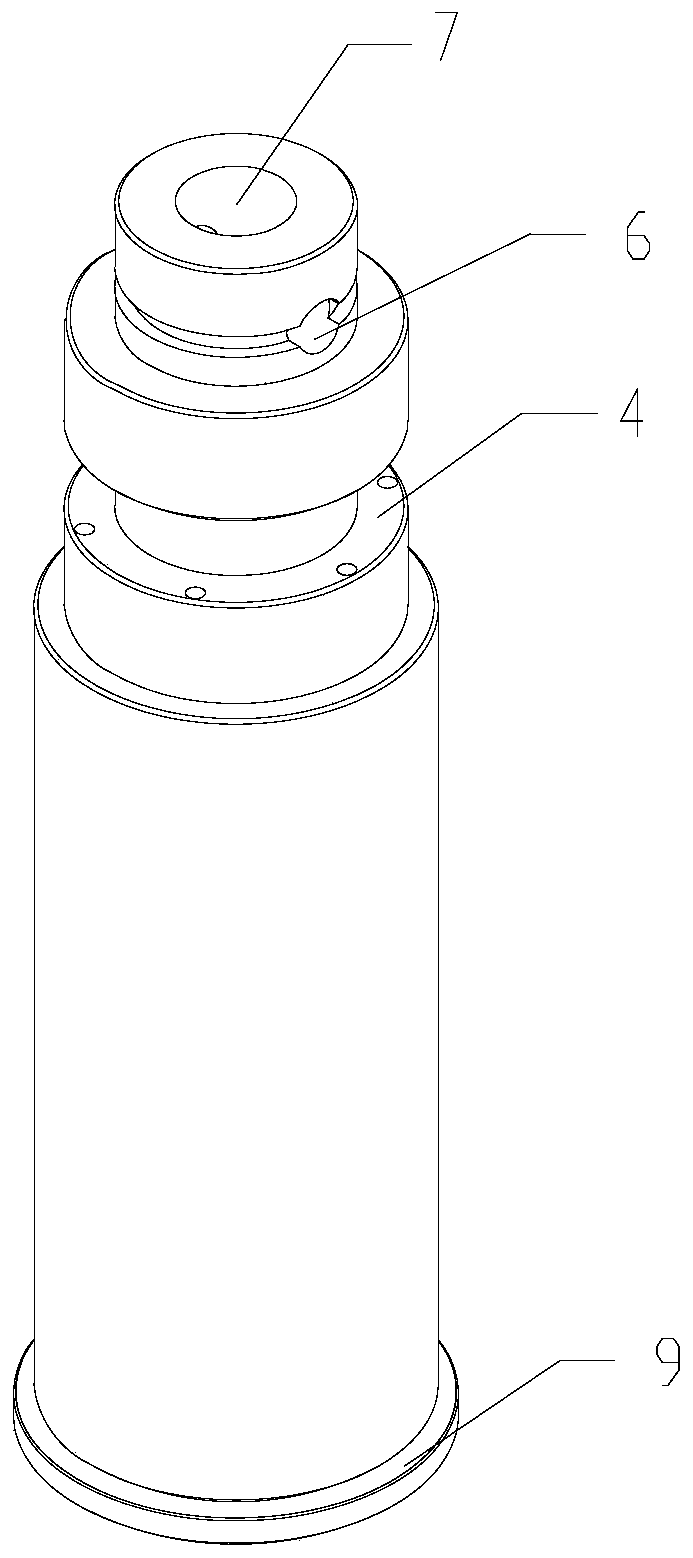

Universal vacuum chuck with automatic closing function

The invention discloses a universal vacuum chuck with an automatic closing function, which is a device for adsorption fixation of large three-dimensional surface parts. The device mainly comprises a seal lip suction disc (1), a first layer of rotary spherical bowl (2), a second layer of rotary spherical bowl (3) and a spherical bowl supporting seat (4). The structure of the two layers of rotary spherical bowls guarantees that the chuck can swing in the angle range of 45 DEG to adapt to the requirements of adsorption fixation of different three-dimensional surface parts; and meanwhile, a vacuum automatic feedback adjustment device comprising a sliding block with a pin hole on the side wall of the supporting seat, a spring and a dustproof net guarantees that a vacuum air channel is automatically connected for adsorbing the parts when the parts are on the chuck, and after the parts are taken down, only a pin hole air channel on a moving block is connected to achieve the purpose of almost closing the chuck. According to the universal vacuum chuck, the vacuum chuck is integrated with the vacuum feedback adjustment device, so that the vacuum pumping flow quantity in the working and intermittent states can be automatically adjusted, and the function of automatically adsorbing the parts in the presence of the parts and automatically closing the chuck in the absence of the parts is achieved.

Owner:JILIN UNIV

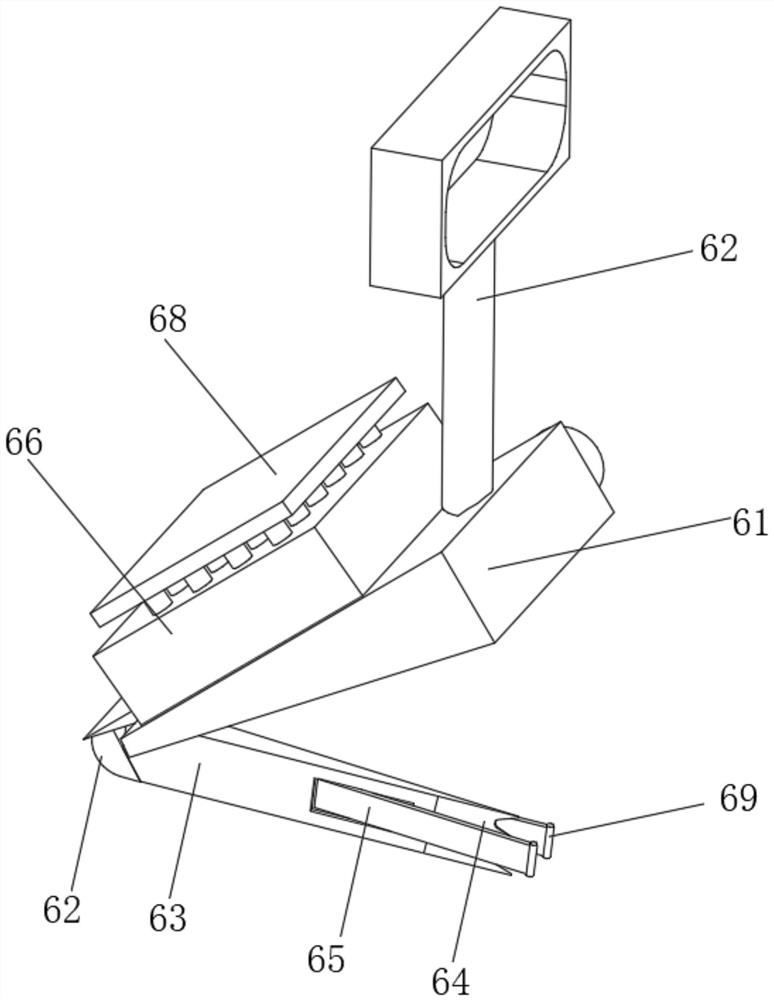

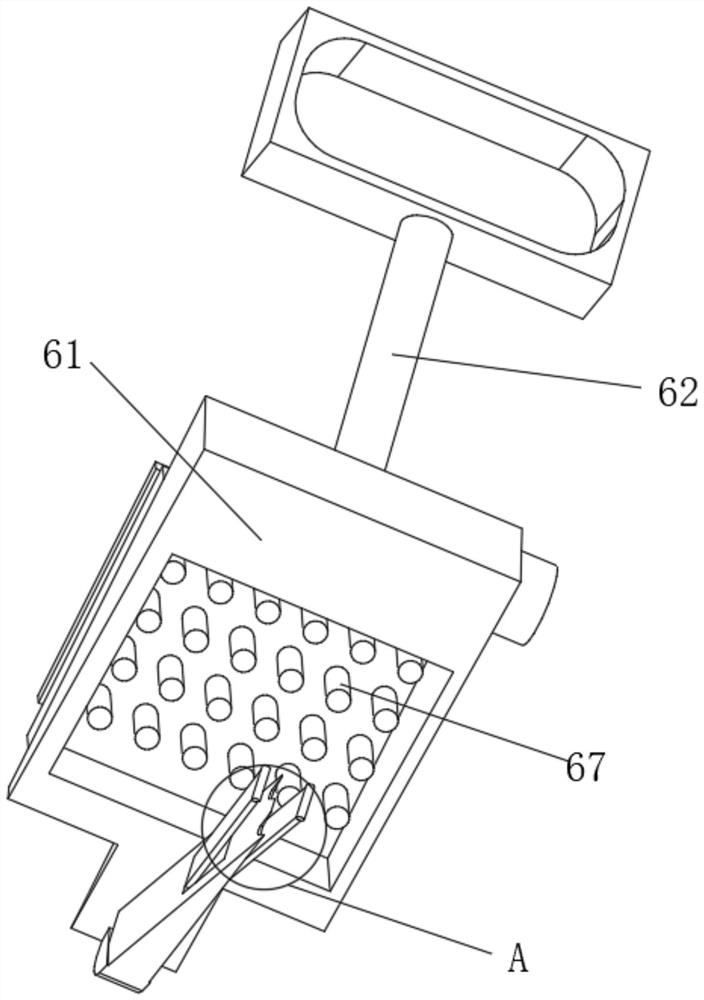

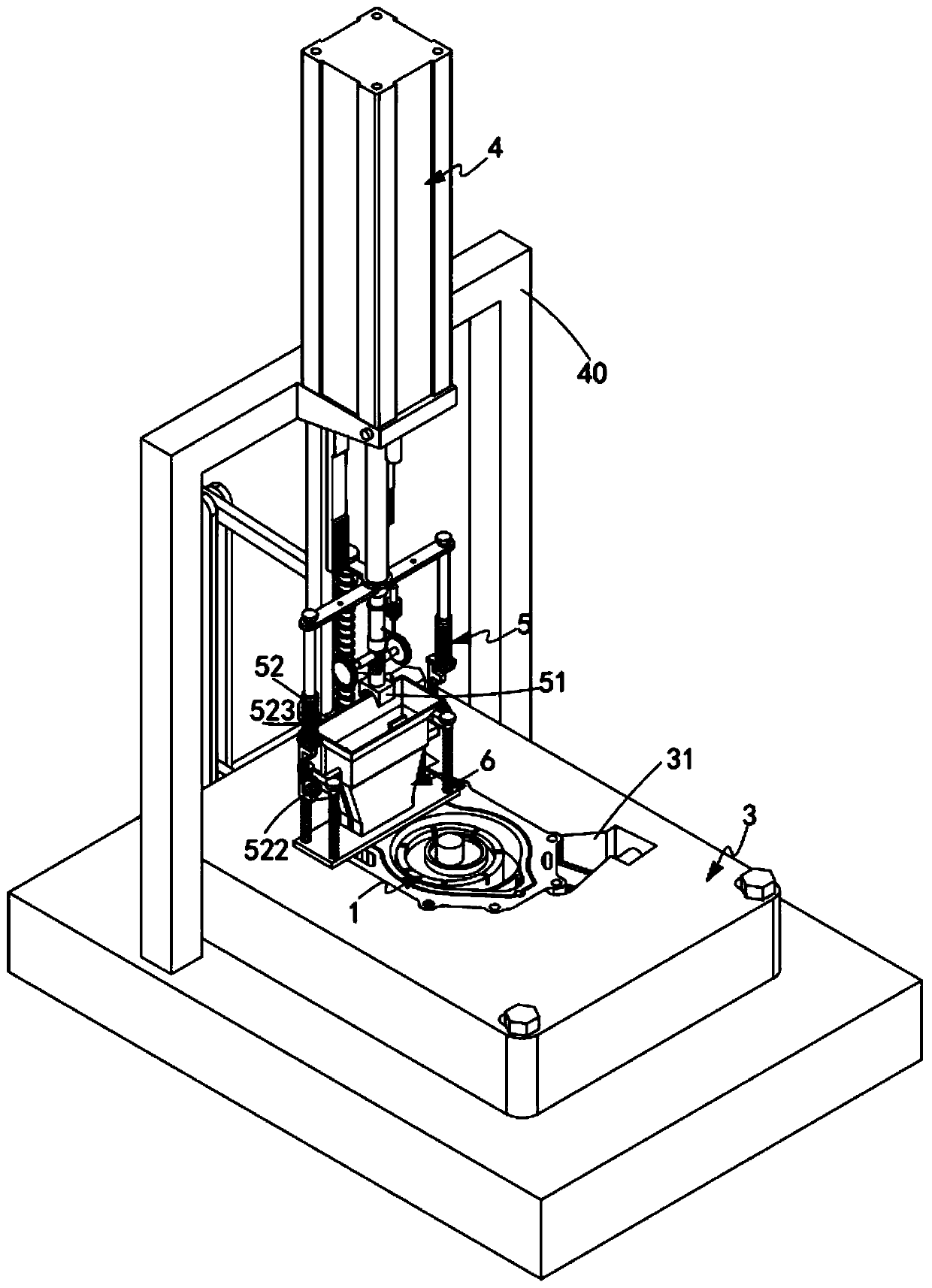

Automatic accurate assembling assembly for oil pump

ActiveCN109366141AAchieve horizontal placementImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic accurate assembling assembly for an oil pump. The automatic accurate assembling assembly for the oil pump comprises a base, an assembling cylinder, an extrusion mechanism, a compression groove and a rotary suction mechanism. The extrusion mechanism comprises an extrusion block and an overturning assembly. The rotary suction mechanism comprises a rotary assemblyand a discharging assembly. According to the automatic accurate assembling assembly for the oil pump, the extrusion block is rotatably connected to a pushing end of the assembling cylinder, and the extrusion block can rotate to be horizontal. After one-time assembling of oil pump springs and an oil pump shell, an oil pump cylinder retracts, and the extrusion block is driven to be horizontal by theoil pump cylinder; and besides, the extrusion block is magnetized through an electromagnet, and the oil pump springs output by the discharging assembly is sucked by the extrusion block. When the assembling cylinder pushes, the extrusion block is vertically arranged and loses magnesium; the oil pump springs fall onto a bearing base accurately; the technical problem of accurate feeding of the oil pump springs is solved; horizontal placement of the oil pump springs is achieved; moreover, the oil pump springs are fed automatically; and working efficiency is higher.

Owner:CHANGXING BEST MASCH CO LTD

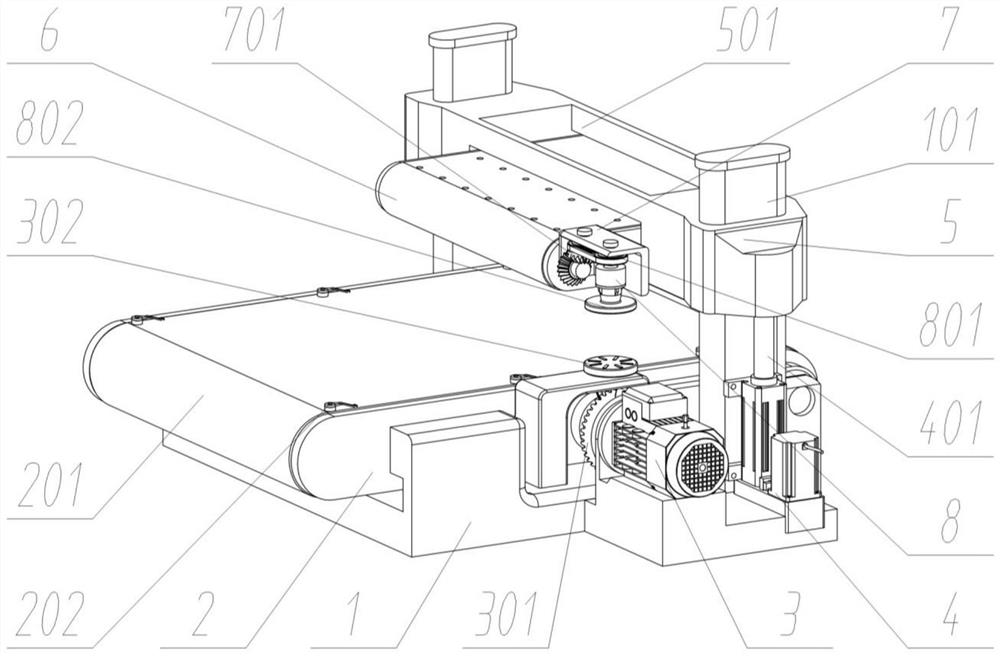

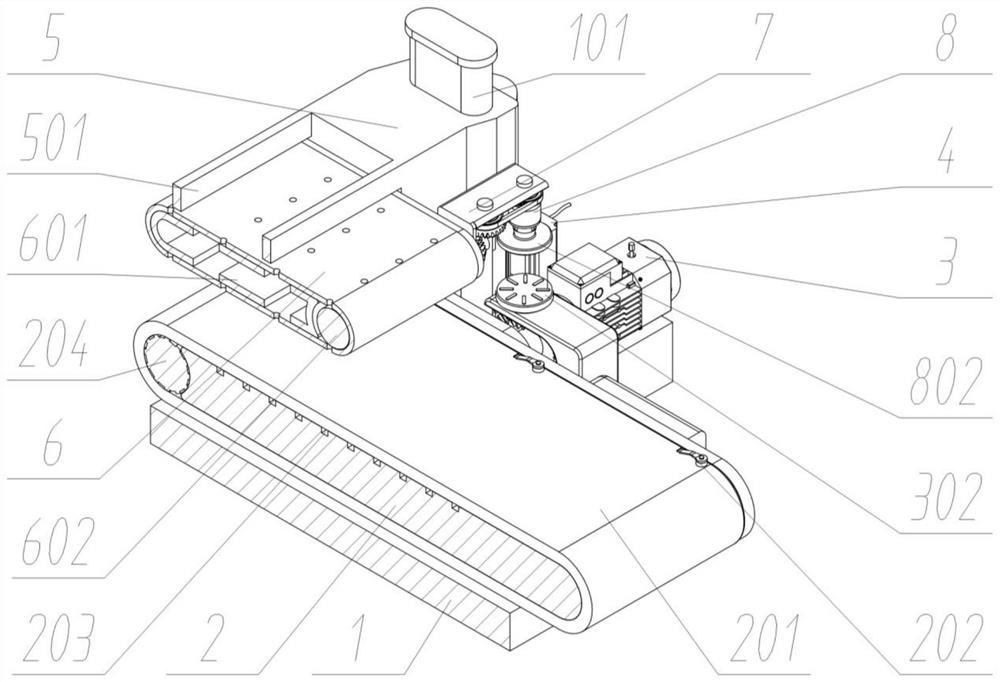

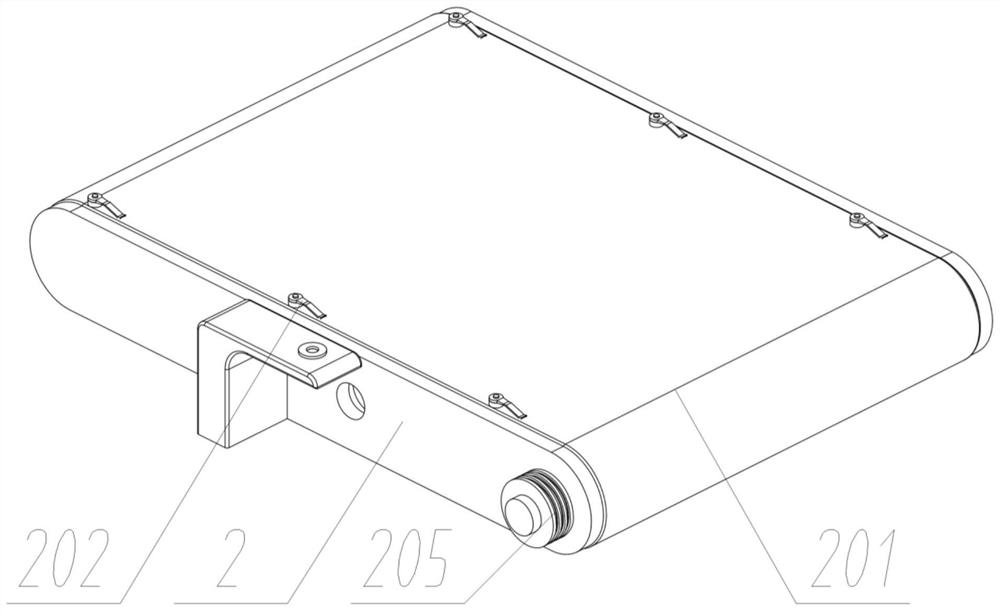

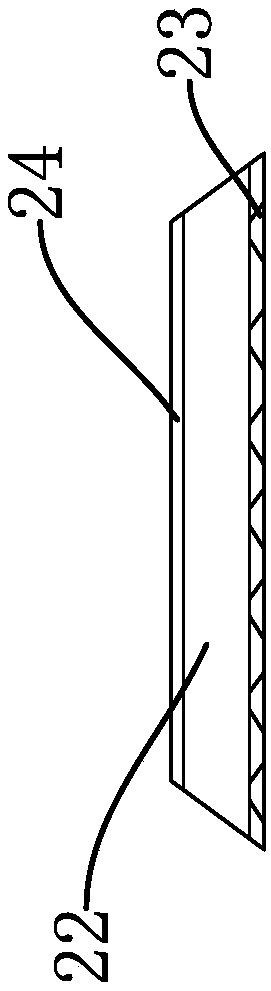

Graphene printing breathable layer preparation device

ActiveCN111959119ALabor-saving manual operationLabor-saving operationRotary pressesPrinting press partsTextile printerElectric machinery

The invention discloses a graphene printing breathable layer preparation device, and relates to the technical field of textile printing. The purpose is to solve the problems that in existing graphenepreparation, the installation and handling printing effects are poor, the equipment resource utilization rate is relatively low, integration is relatively poor, and manpower resources are wasted. Thedevice comprises a printing support frame, wherein a set of cloth roller support frames are fixedly connected to the top of the printing support frame; a set of drive motors are fixedly connected to the right side of the printing support frame; a set of graphene roller support frames are slidably connected to the top of the rear side of the printing support frame; the bottoms of the graphene roller support frames are fixedly connected with a set of conveyor belt negative pressure bins; the right sides of the conveyor belt negative pressure bins are fixedly connected with a set of transmissionconnecting frames, and the bottoms of the transmission connecting frames are rotatably connected with a set of cushioning clutch connectors. Labors are replaced by machines, which is easier and more labor-saving; the drive motors drive a through-hole conveyor belt and a cloth conveyor belt to rotate, so that the resource utilization rate is higher; and by generating negative pressure, the through-hole conveyor belt automatically adsorbs graphene, and the operation is convenient and simple.

Owner:CHANGZHOU JIASHIJIA DECORATIVE NEW MATERIAL

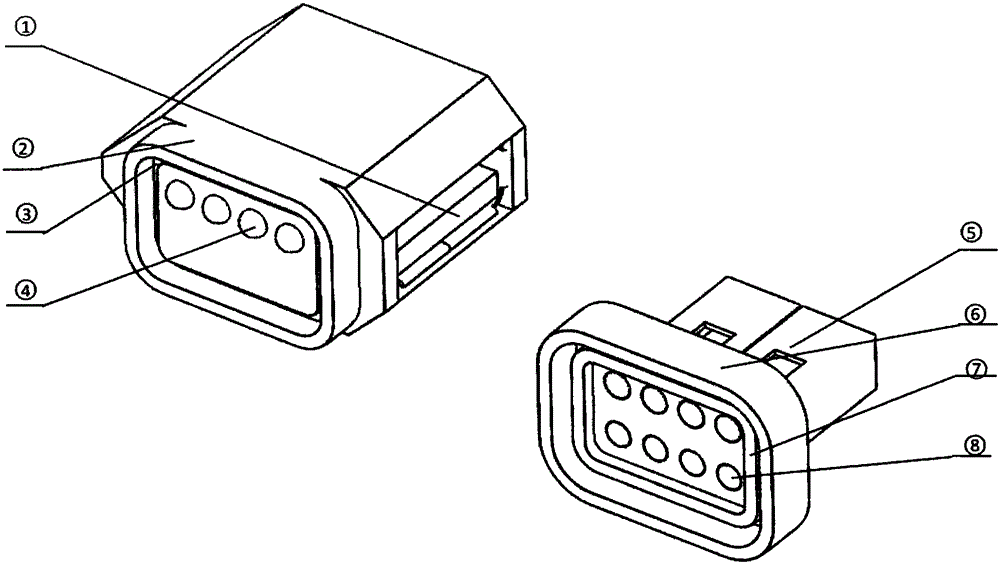

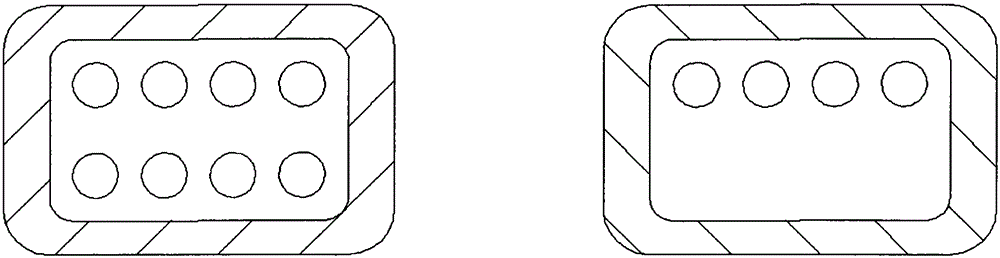

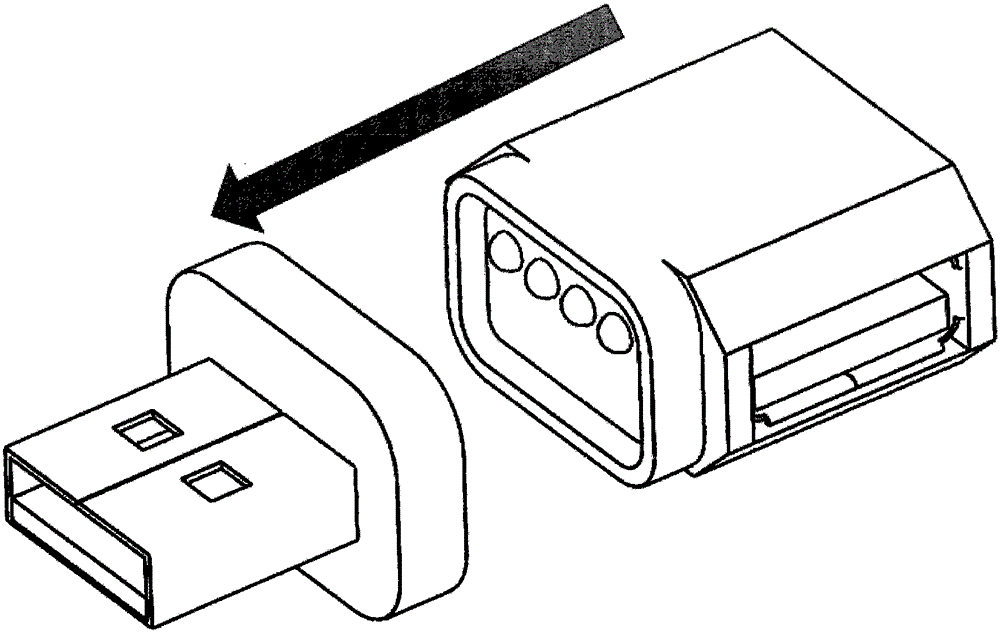

Magnetic transfer device for USB interface

InactiveCN106207608AImprove usabilityIncrease the odds of successEngagement/disengagement of coupling partsMobile endUSB

The invention relates to a magnetic transfer device for a USB interface, which is characterized in that the magnetic transfer device comprises a USB interface female seat (1), a mobile end shell (2), a mobile end magnet (3), mobile end contacts (4), a USB interface male terminal (5), a fixed end shell (6), a fixed end magnet (7) and fixed end contacts (8), wherein the mobile end magnet (3) and the fixed end magnet (7) are mutually attracted in the case of work to fix the mobile end shell (2) and the fixed end shell (6); and the mobile end contacts (4) and the fixed end contacts (8) are connected for transmitting data. Due to special arrangement of the contacts, when the two parts are attracted, being forward or inverse of the mobile end interface does not influence normal connection. The device is applicable to all machines and peripheral devices adopting the USB interface.

Owner:张宇星

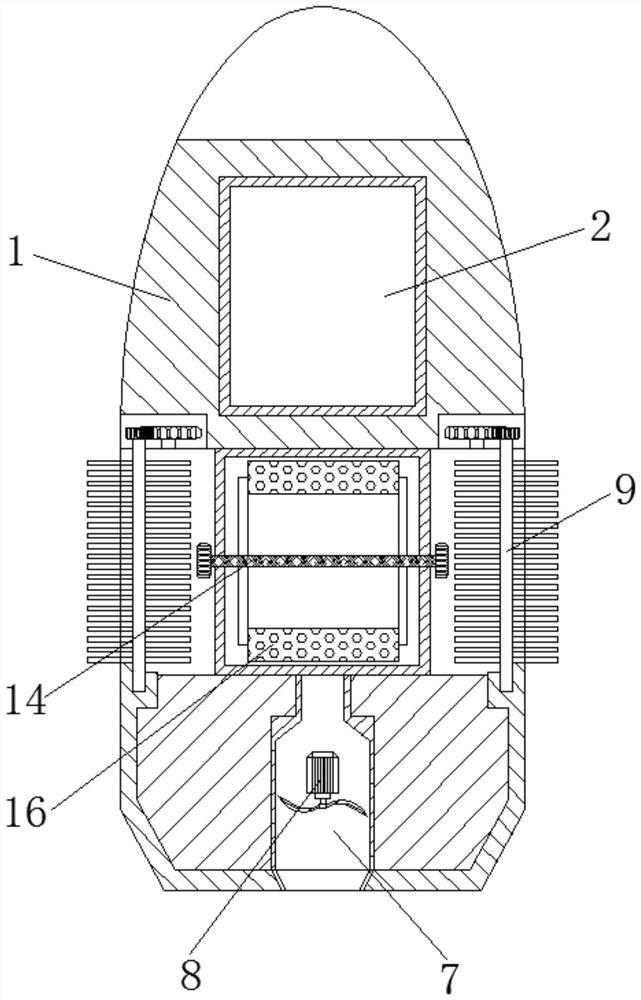

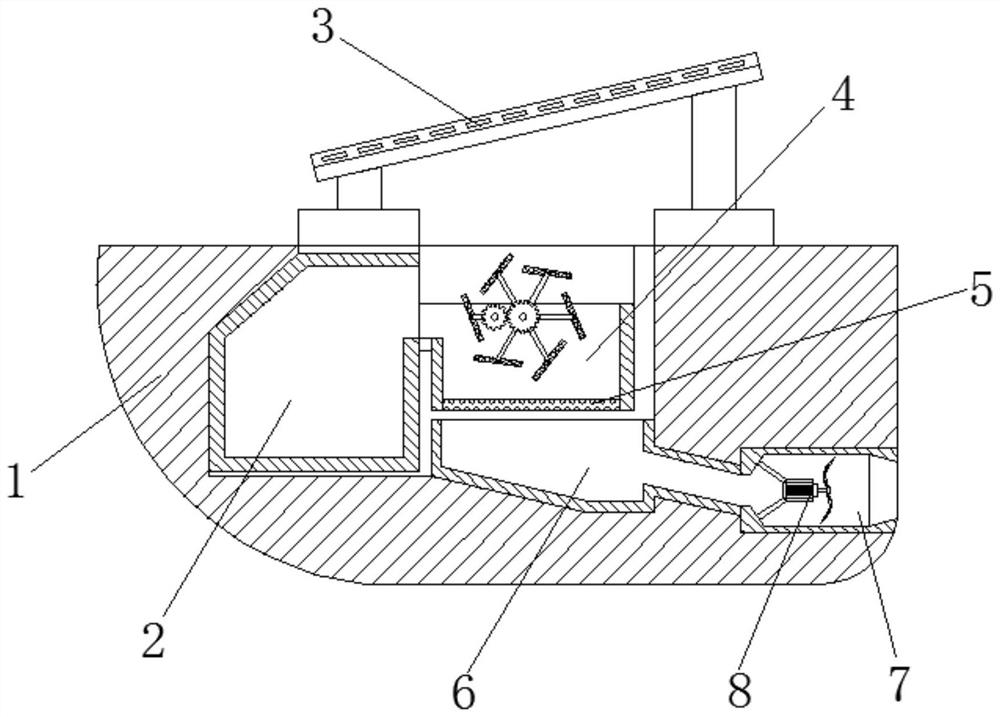

Drainage type energy-saving garbage salvage ship

InactiveCN111976905ARealize automatic adsorptionWater cleaningWaterborne vesselsRefuse collectionWater filter

The invention relates to the technical field of environmental protection, and discloses a drainage type energy-saving garbage salvage ship. The drainage type energy-saving garbage salvage ship comprises a ship body, a garbage storage cabin is arranged on the front portion of the ship body, a solar panel is arranged on a deck of the ship body, a cleaning cabin is arranged on the upper portion of the middle of the ship body, a screen is arranged at the bottom of the cleaning cabin, and a water filtering cabin is arranged below the cleaning cabin; and a jet cabin is arranged at the tail end in the ship body, a jet propeller is arranged in the jet cabin, collecting shafts are arranged at the positions, close to the cleaning cabin, of the two sides of the ship board of the ship body, collectingrods are arranged in the middles of the collecting shafts, and transmission shafts are in gear meshing connection with the ends, close to a prow, of the collecting shafts. According to the drainage type energy-saving garbage salvaging ship, the water level in the cleaning cabin is kept to be continuously lower than the waterline of the ship body, garbage flows into the cleaning cabin along with water flow, floating garbage is automatically adsorbed, meanwhile, the garbage collecting and salvaging speed is synchronously adjusted through a salvaging motor, and more intelligence is achieved; andthe whole energy supply relies on the solar panel erected on the deck, ecological restoration is carried out in a more environment-friendly manner.

Owner:靳卫卫

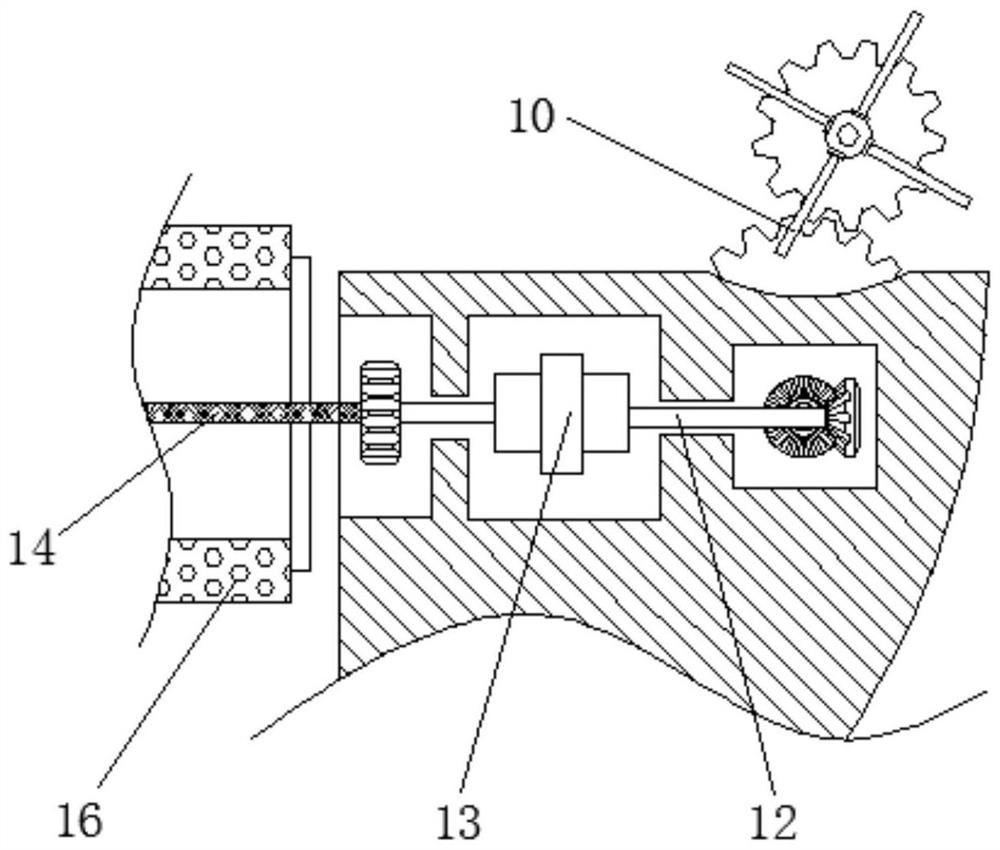

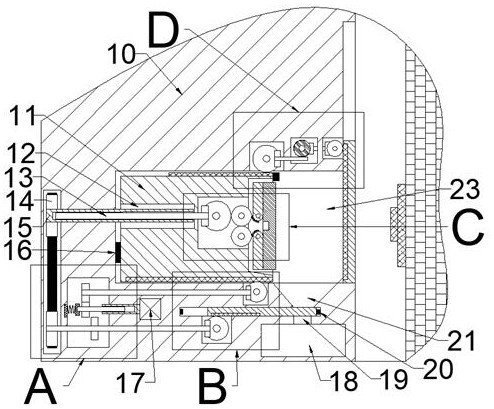

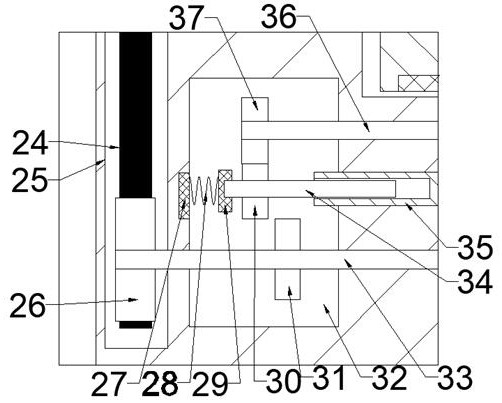

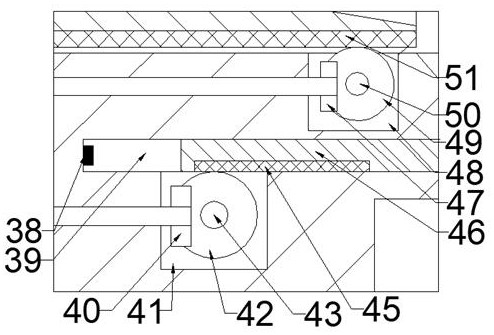

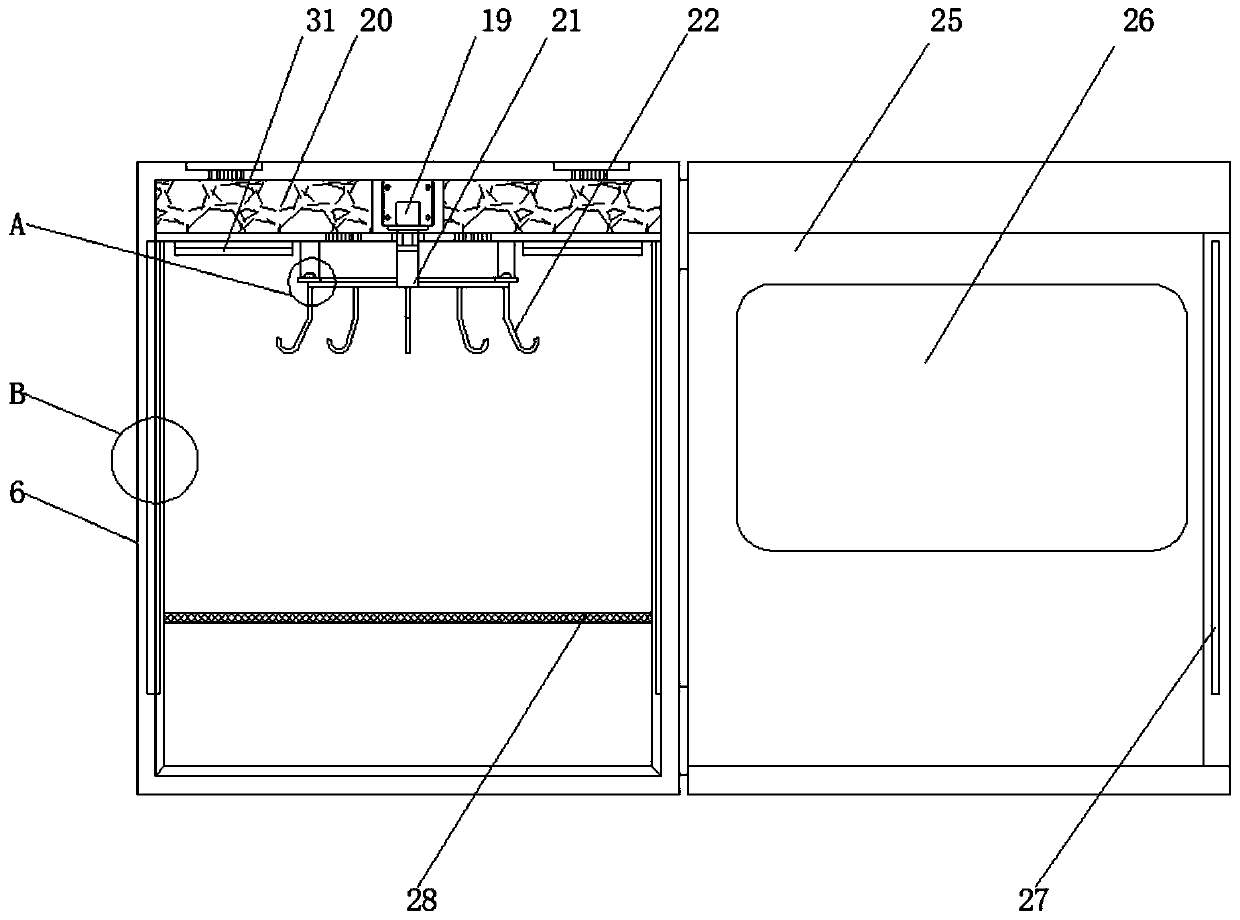

Automatic condensation treatment auxiliary device for water-cooled electronic radiator

InactiveCN112218469ARealize automatic adsorptionRealize discharge workDrying solid materials without heatCasings/cabinets/drawers detailsGear wheelEngineering

The invention relates to the related field of electronic radiators, and discloses an automatic condensation treatment auxiliary device for a water-cooled electronic radiator. The device comprises an equipment box body, a sliding seat cavity is formed in the equipment box body, a sliding seat is connected between the front end wall and the rear end wall of the sliding seat cavity in a sliding fit manner, and the upper end surface of the sliding seat is fixedly connected with a linkage rack; a long shaft sleeve cavity with a leftward opening is formed in the sliding seat. A gear for sliding is fixedly connected into the lower end face of the sliding base, an extrusion belt cavity extending downwards is formed in the left side of the sliding base cavity, and a long shaft sleeve extending rightwards into the long shaft sleeve cavity and extending leftwards into the extrusion belt cavity is connected into the right end wall of the extrusion belt cavity in a running fit mode. The adsorptioncotton can be in full contact with the water-cooled electronic radiator. Condensation is automatically adsorbed, so that a short-circuit fault caused by insulation reduction of equipment due to condensation is prevented as much as possible, half gear rings of upper and lower side pressing plates drive the upper and lower side pressing plates to extrude adsorption cotton, discharging work of the condensation is achieved, and the workload of manual treatment is reduced.

Owner:武义县达香电子有限公司

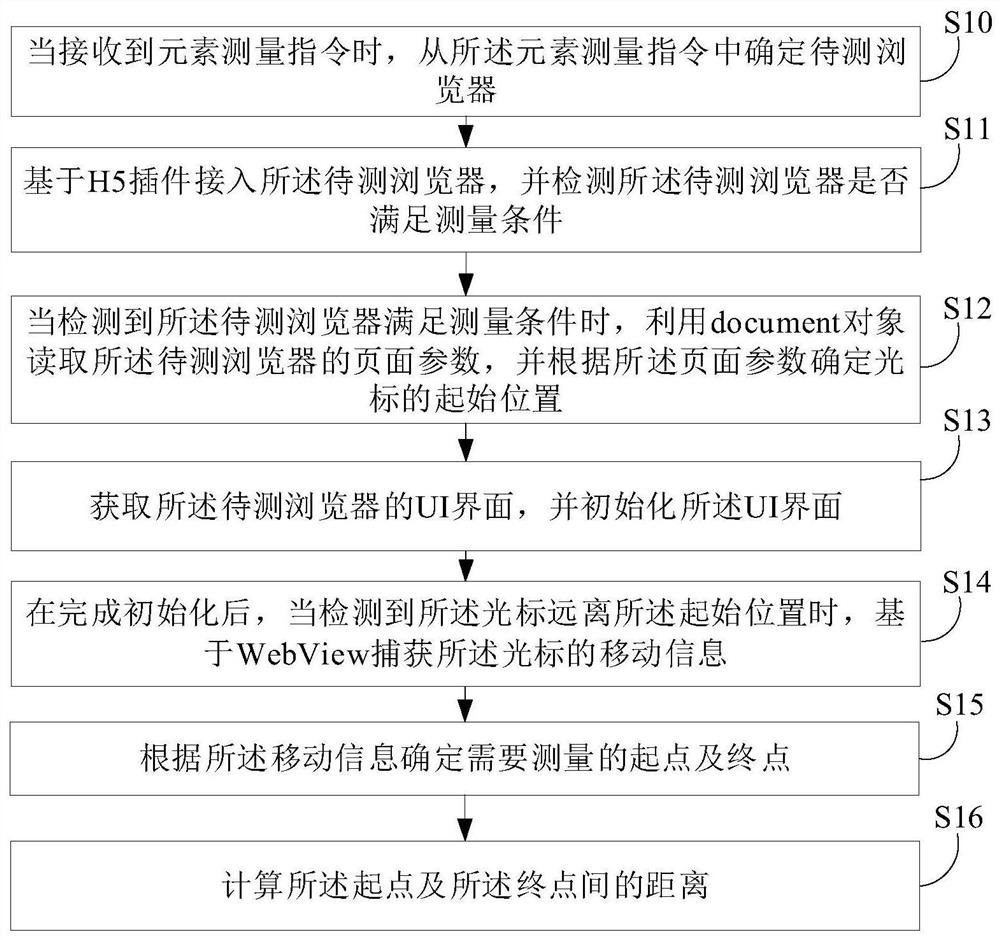

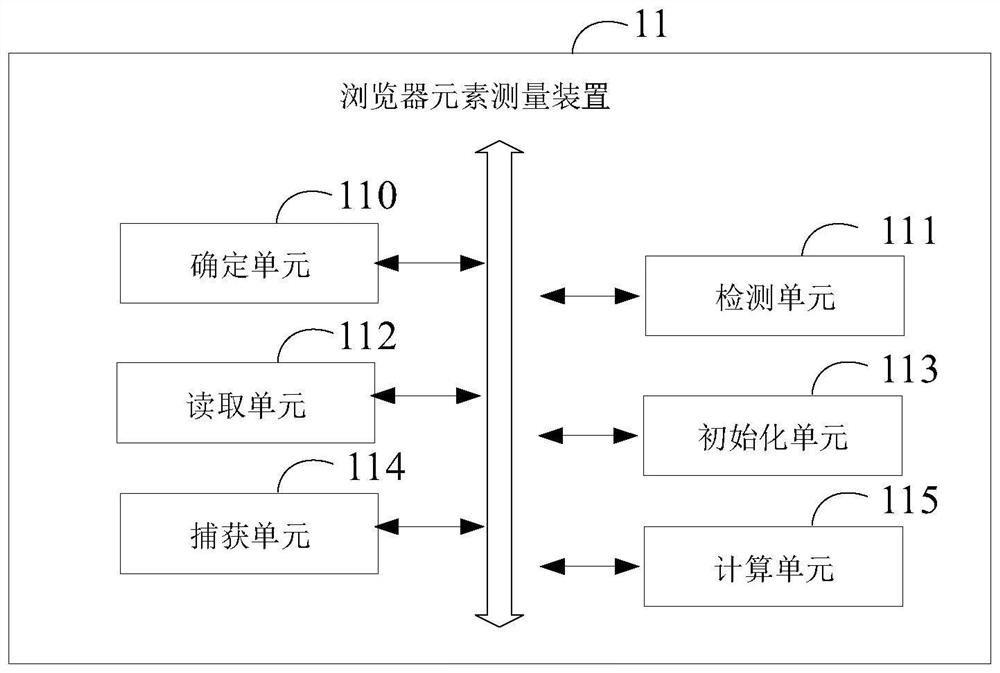

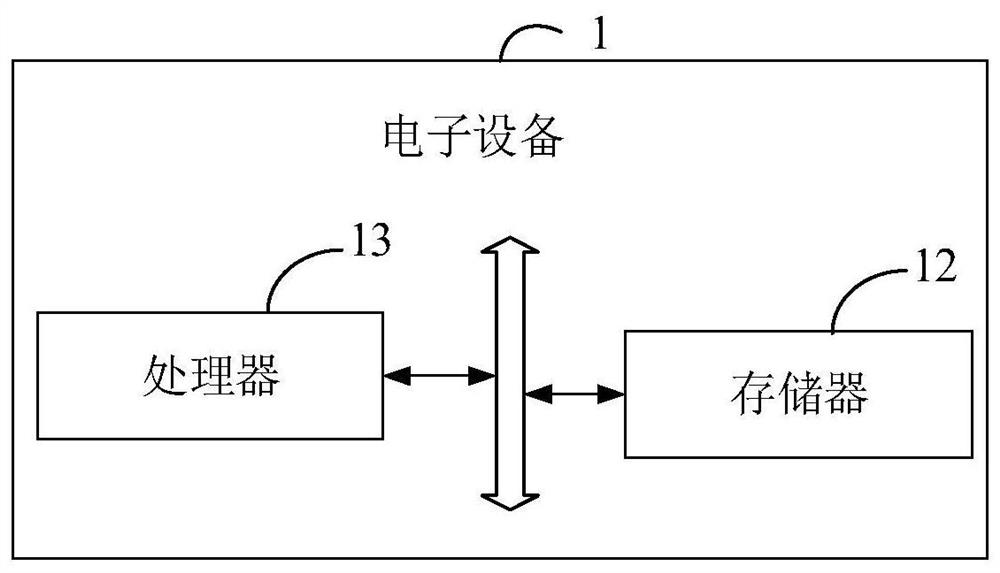

Browser element measurement method and device, electronic equipment and storage medium

PendingCN111680251AEasy to measureConvenient labelingSoftware testing/debuggingWebsite content managementOn-screen displayOperating system

The invention relates to the technical field of artificial intelligence and development, and provides a browser element measurement method and device, electronic equipment and a storage medium. The method comprises the following steps: determining a to-be-tested browser from an element measurement instruction; accessing the to-be-tested browser based on an H5 plug-in, and when the to-be-tested browser meets a measurement condition, reading page parameters of the to-be-tested browser by utilizing the document object so as to determine an initial position of a cursor; obtaining a UI interface ofthe browser to be tested, and initializing the UI interface; after initialization is completed, when it is detected that the cursor is away from the initial position, capturing movement information of the cursor based on WebView; determining a starting point and an ending point which need to be measured according to the movement information; and calculating the distance between the starting pointand the terminal point. The invention also relates to a blockchain technology, and the calculated distance can be stored in the blockchain. By utilizing the method and the device, the browser elements can be automatically and accurately measured, screen display can be used as a measurement basis, and meanwhile, the compatibility problem is solved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

Scrap iron adsorption equipment for contactor installation

PendingCN114192905AConvenient tapping operationRealize automatic pushThread cutting machinesMaintainance and safety accessoriesGear wheelServo

The invention discloses scrap iron adsorption equipment for contactor installation, and relates to the technical field of contactors, the scrap iron adsorption equipment comprises an installation plate, during tapping operation, a tapping rod is driven to work through forward rotation of a servo motor, a rotating gear is driven to rotate through rotation of the tapping rod, and then a transmission gear is driven to rotate through a gear set; a transmission gear rotates to drive a rotating rod to rotate, so that a fan starts to ventilate, through the ventilation operation of the fan, scrap iron generated during tapping operation of a tapping rod enters the bottom of a filter screen through a dust inlet, a conveying pipe and a communicating port, and external air is sucked into a sleeve and is sucked into a connecting pipe through an air conveying pipe; according to the tapping device, the air bag is arranged in the tapping rod, so that external air enters the air bag, the air bag expands to push the servo motor to move downwards, scrap iron generated in the tapping process is automatically adsorbed, meanwhile, the tapping rod is automatically pushed, and tapping operation of the tapping rod is facilitated.

Owner:華能国際電力股ふん有限公司河北清潔能源分公司

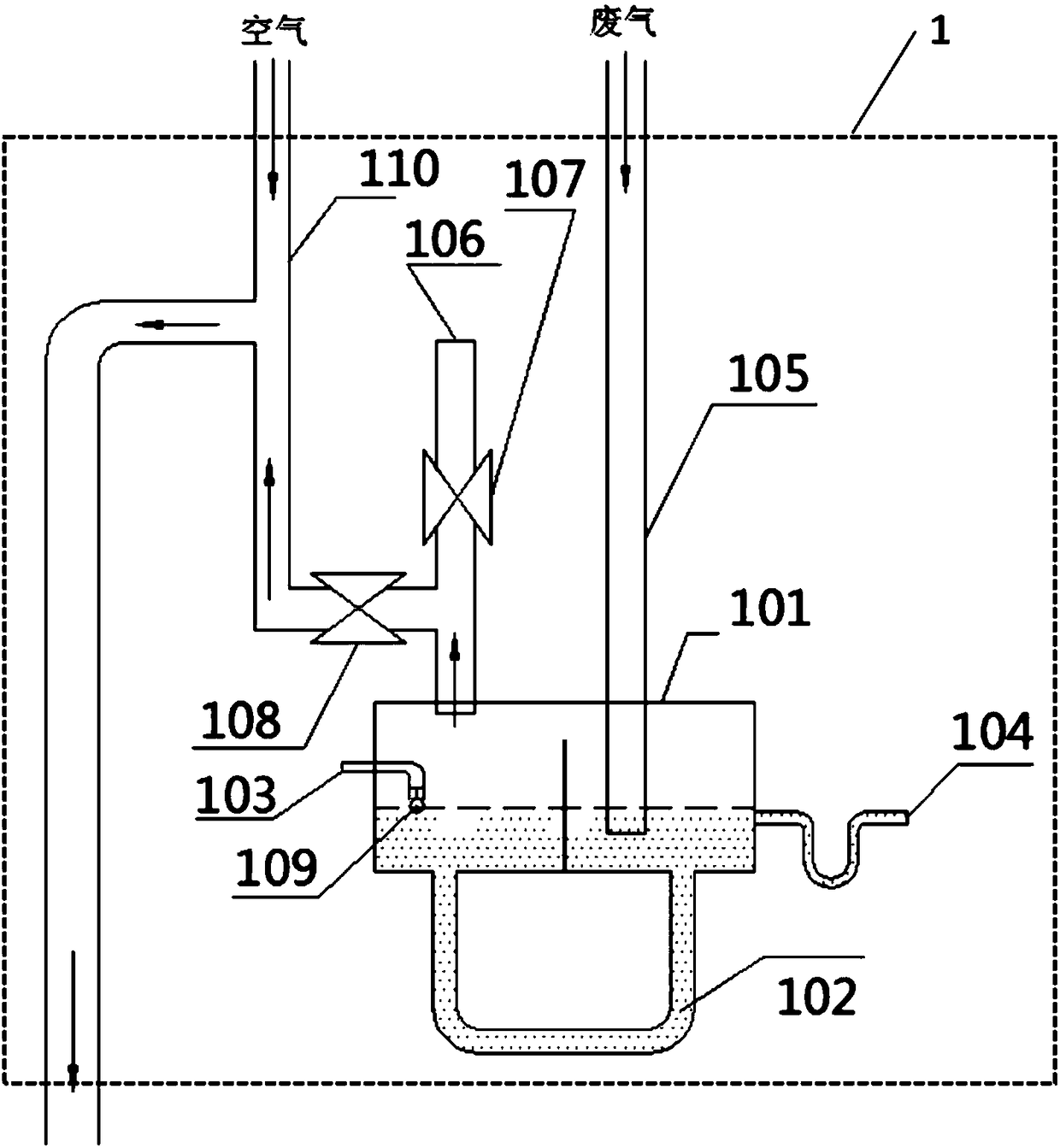

Rubber regenerative exhaust gas treatment device

PendingCN108295587ASmall footprintImprove combustion efficiencyGas treatmentUsing liquid separation agentSmall footprintFlue gas

The invention provides a rubber regenerative exhaust gas treatment device which is characterized by comprising a supply air system, an electric control system, an exhaust gas filtering device, a combustion machine, an incinerator, a flue gas heat absorption cooling tank, a spray absorption tower, a water-gas separator, a dust-removing filter device and a chimney, wherein the exhaust gas filteringdevice, the combustion machine, the incinerator, the flue gas heat absorption cooling tank, the spray absorption tower, the water-gas separator, the dust-removing filter device and the chimney are sequentially connected through a pipe. Exhaust gas passes through the exhaust gas filtering device and then is led into the combustion machine through a pipe, and enters the incinerator for high-temperature incineration; a flue gas pipeline is bent and coiled in the flue gas heat absorption cooling tank, and the flue gas heat absorption cooling tank is provided with a cold water inlet and a hot wateroutlet; and the supply air system is communicated with the incinerator. The rubber regenerative exhaust gas treatment device is small in occupied area and high in combustion efficiency, waste heat energy can be recycled, and the effect of energy saving is achieved. The electric control system comprises a warning device, the warning device is connected with a photosensitive tube detection device in the combustion machine, and once flameout occurs or ignition fails, waste gas and an oil path are automatically cut off to prevent a safety accident.

Owner:NANTONG HUILI RUBBER

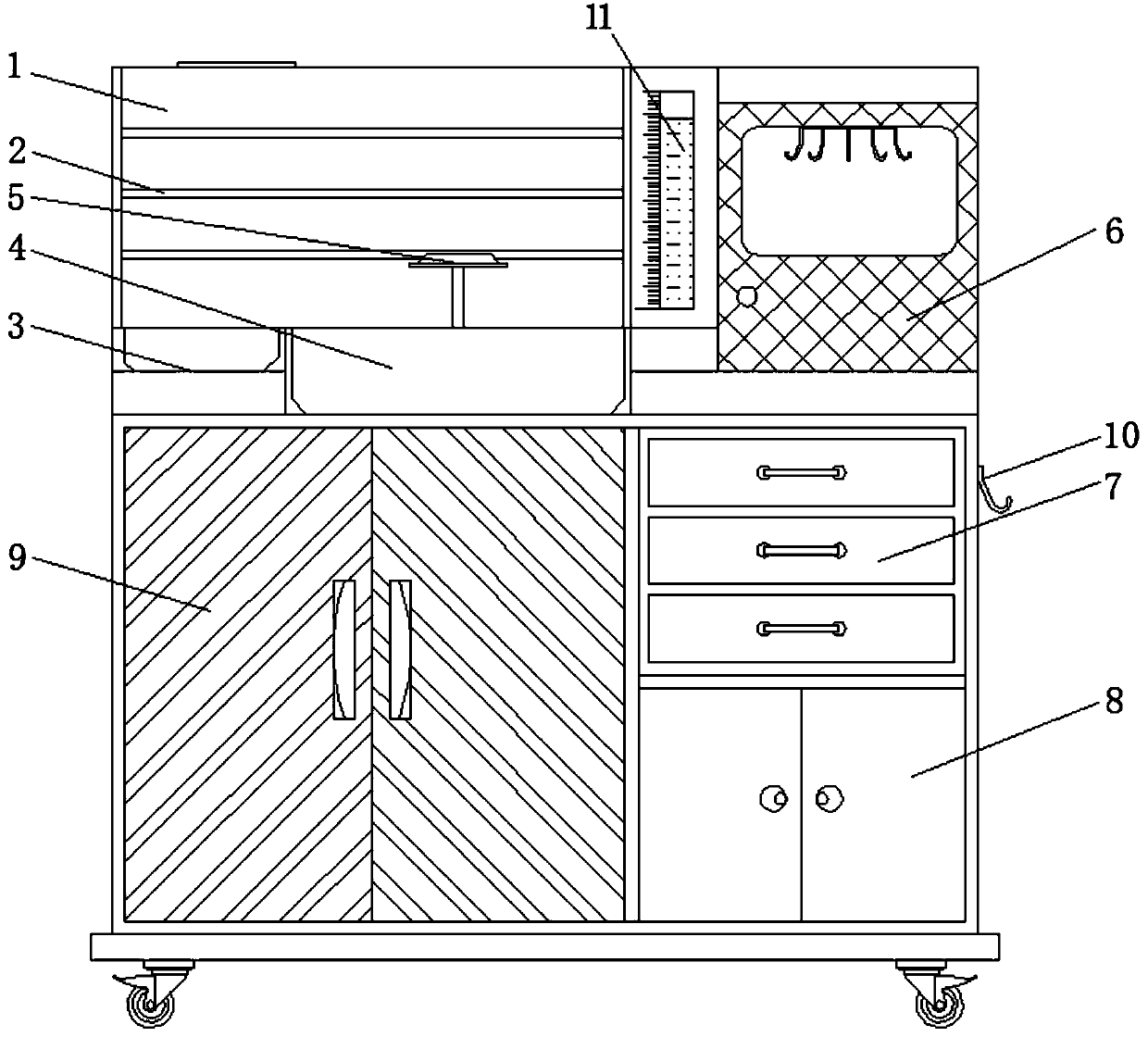

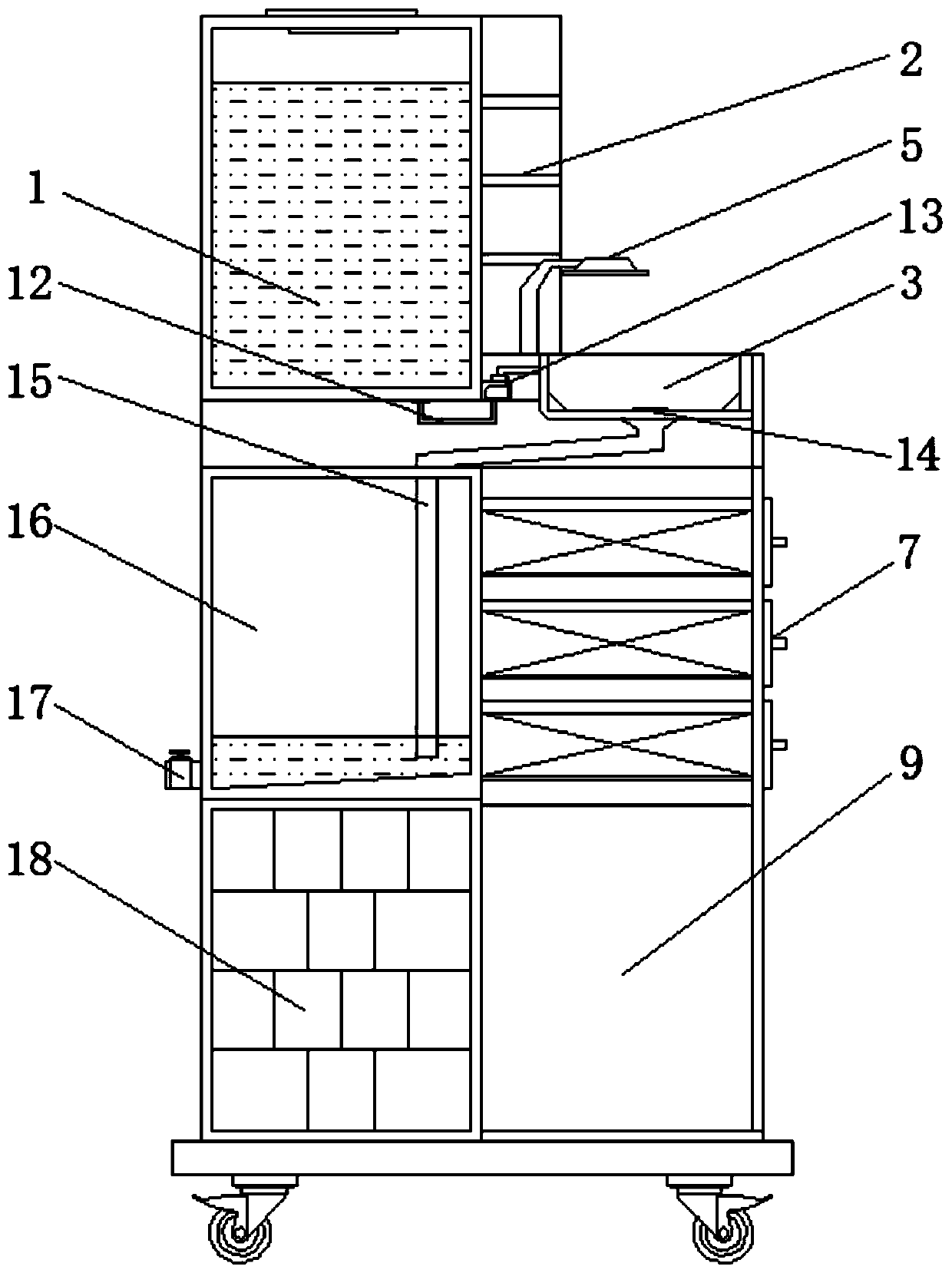

First-aid nursing article disinfection device with drying structure and use method

InactiveCN111001023AEasy to dipSolve the problem of prone to showeringMedical applicatorsChemicalsNursing careEnvironmental engineering

The invention discloses a first-aid nursing article disinfection device with a drying structure and a use method. The device comprises a disinfectant storage box, a drying box, a rotating frame, a boxdoor and an electric heating wire. A storage rack is mounted on the left side of the front surface of the disinfectant storage box. A dipping tank is mounted at the lower left corner of the storage rack. The right side of the dipping tank is connected with a cleaning tank. A spray head is installed above the cleaning tank. The drying box is fixed on the right side of the disinfectant storage box.A storage drawer is arranged below the drying box. A first storage box is installed below the storage drawer. A second storage box is arranged on the left side of the first storage box. A hook is fixed on the right side face of the storage drawer. The whole device is simple in structure and convenient to move. Disinfectant dipping, disinfection and cleaning of first-aid tools and sterilization and drying of the first-aid tools are integrated. Disinfection operation of medical staff in the first-aid nursing process is greatly facilitated, and the whole device is suitable for a first-aid nursing environment.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Water conservancy pipeline with automatic slag removal function for water conservancy project

PendingCN113931275AEasy to useImprove convenienceFatty/oily/floating substances removal devicesSewerage structuresSlagMechanical engineering

The invention discloses a water conservancy pipeline with an automatic slag removal function for a water conservancy project, which comprises a pipeline main body which is connected end to end, erected in a water conservancy construction production place and used for conveying water, and a slag removal pipe is fixedly arranged at the end part of the pipeline main body; the second filter screen serves as a main pipeline filter mechanism and is movably mounted on the inner side of the slag removal pipe; the first water blocking plate and the second water blocking plate are in shaft connection with the inner wall of the slag removal pipe and are used for blocking water flow; the collecting hole is formed in the inner wall of the slag removal pipe and is used for receiving impurities; the slag collecting pipe is fixedly arranged on the outer wall of the slag removing pipe and is used for leading out impurities; and the magnetic blocking sheet is in shaft connection with the side wall of the slag removal pipe and is used for blocking magnetic force. According to the water conservancy pipeline with the automatic slag removal function for the water conservancy project, the pipe wall and the filter screen can be automatically cleaned through the water flow impact effect in the using process, cleaned filter residues can be automatically collected and treated on the premise that conveying is not stopped, and using is convenient and fast.

Owner:广东融盛达物联科技有限公司

A graphene printing breathable layer preparation device

ActiveCN111959119BLabor-saving manual operationLabor-saving operationRotary pressesPrinting press partsTextile printerElectric machinery

The invention discloses a graphene printing breathable layer preparation device, and relates to the technical field of textile printing, so as to solve the problem that the existing graphene preparation has poor installation, handling and printing effects; the utilization rate of equipment resources is relatively low; and the integration is poor and wastes manpower resource issues. Including a group of cloth roller brackets fixedly connected to the top of the printing bracket; a group of drive motors fixedly connected to the right side of the printing bracket; a group of graphene roller brackets slidably connected to the top of the rear side of the printing bracket; the bottom of the graphene roller bracket is fixedly connected There is a set of conveyor belt negative pressure bins; a set of transmission connecting frames are fixedly connected to the right side of the conveyor belt negative pressure bins, and a set of shock-absorbing clutch connectors are rotatably connected at the bottom of the transmission connecting frame. It is easier and labor-saving to replace manual labor by machines; the drive motor drives the through-hole conveyor belt and the cloth conveyor belt to rotate the resource utilization rate more efficiently; the through-hole conveyor belt makes the automatic adsorption operation of graphene convenient and simple by generating negative pressure.

Owner:CHANGZHOU JIASHIJIA DECORATIVE NEW MATERIAL

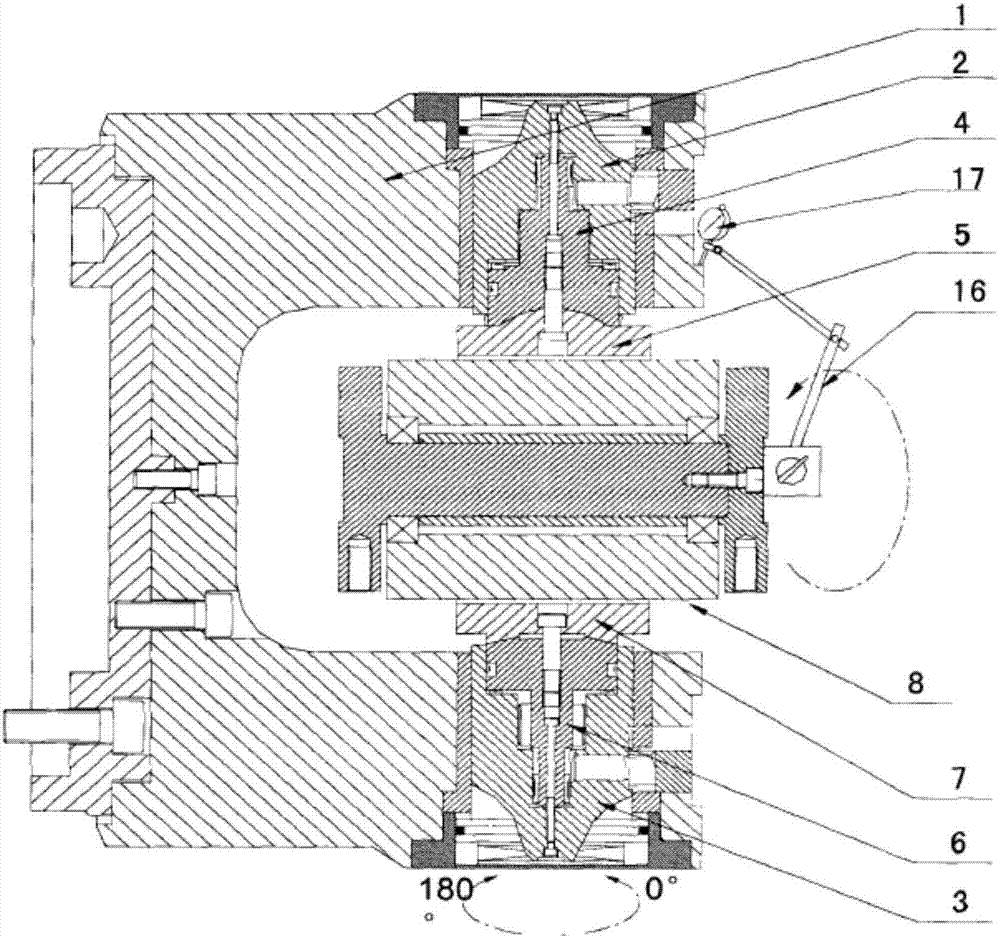

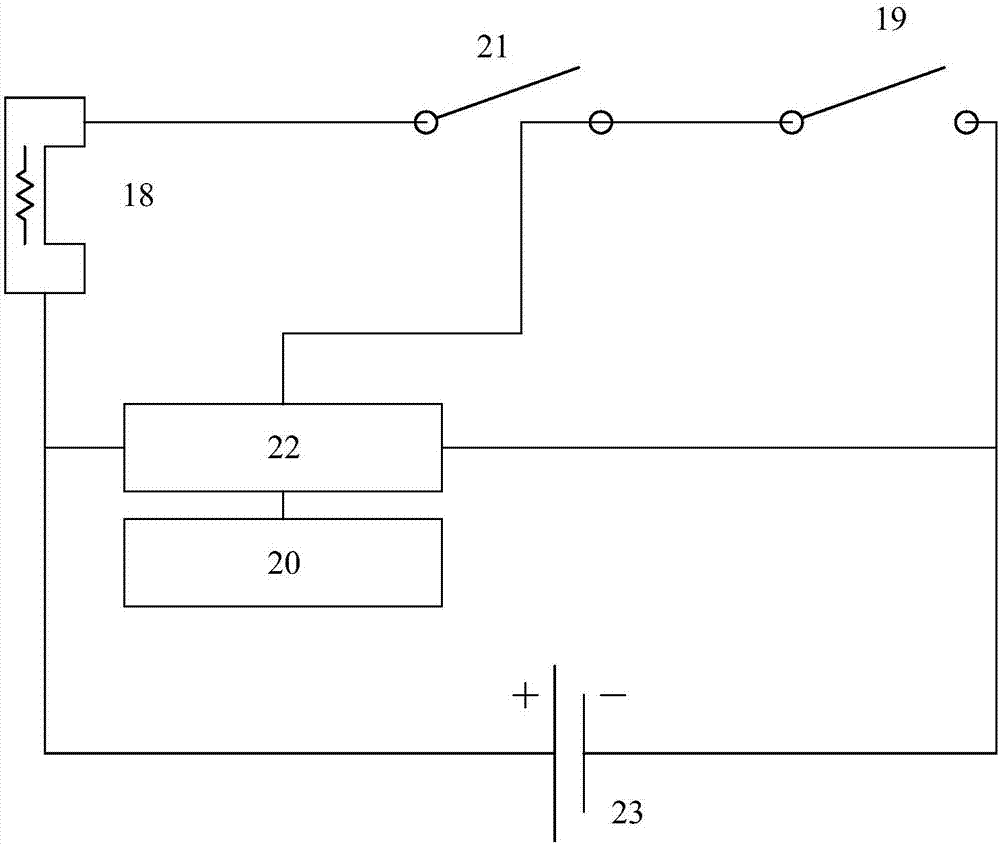

Precision detection equipment for overturn chuck with automatic adsorption function

PendingCN107543467AAvoid high momentumEasy to disassembleMechanical measuring arrangementsMagnetic tension forceMomentum

The invention relates to precision detection equipment for an overturn chuck with an automatic adsorption function, which comprises an overturn chuck, a detection device, a gauge stand bracket and a reading dial gauge for measuring the deviation, and is characterized in that the overturn chuck comprises an upper clamping device and a lower clamping device which are used for clamping the detectiondevice from the upper side and the lower side respectively, the gauge stand bracket comprises a bracket shell, a support rod, an electromagnet and a control switch used for controlling on-off of the electromagnet, the electromagnet is arranged in the bracket shell and is connected with the control switch arranged at the surface of the bracket shell, and two ends of the support rod are connected with the bracket shell and the reading dial gauge used for measuring the deviation respectively. Compared with the prior art, the gauge stand bracket adopts electromagnet type adsorption, thereby beingconvenient for disassembly. Meanwhile, the moment when a magnetic force is generated is controllable, so that the overturn chuck is automatically adsorbed at the instant when the electromagnet is powered on, and great impulsion between the gauge stand bracket and the detection device due to traditional sudden increase in magnetic force is avoided.

Owner:上海瓦姆石油天然气管业有限公司

Permanent Magnetic Separator

InactiveCN103623921BAutomatic disengagementReduce lossMagnetic separationAutomatic controlEngineering

Owner:WUXI ZHIYUDE TECH

An automatic installation mechanism of a wave washer

ActiveCN105033631BEasy to operateImprove installation efficiencyMetal working apparatusEngineeringUltimate tensile strength

The invention relates to an automatic installing mechanism of a wave washer. A bottom plate is provided with a vibrator feeding mechanism. The vibrator feeding mechanism conveys the wave washer to a vibration disc end. A material taking mechanism is arranged at the position, located on the right rear portion of the vibrator feeding mechanism, of the bottom plate. The material taking mechanism can suck the wave washer out of the vibration disc end and place the wave washer in a hopper, and positioning and ejecting of the wave washer are facilitated. A conveying mechanism is arranged above the right rear portion of the bottom plate. The conveying mechanism can convey the positioned and ejected wave washer to a detecting mechanism or an installing position. The detecting mechanism is arranged at the position, located on the right side of the material taking mechanism, of the bottom plate, and can detect whether the thickness of the wave washer is qualified or not. A waste box is arranged at the position, located on the right side of the detecting mechanism, of the bottom plate and contains waste. By means of the mechanism, automatic adsorbing, conveying and installing of the wave washer can be achieved; and the installing efficiency is improved, the installing quality is guaranteed, the labor intensity of workers is relieved, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

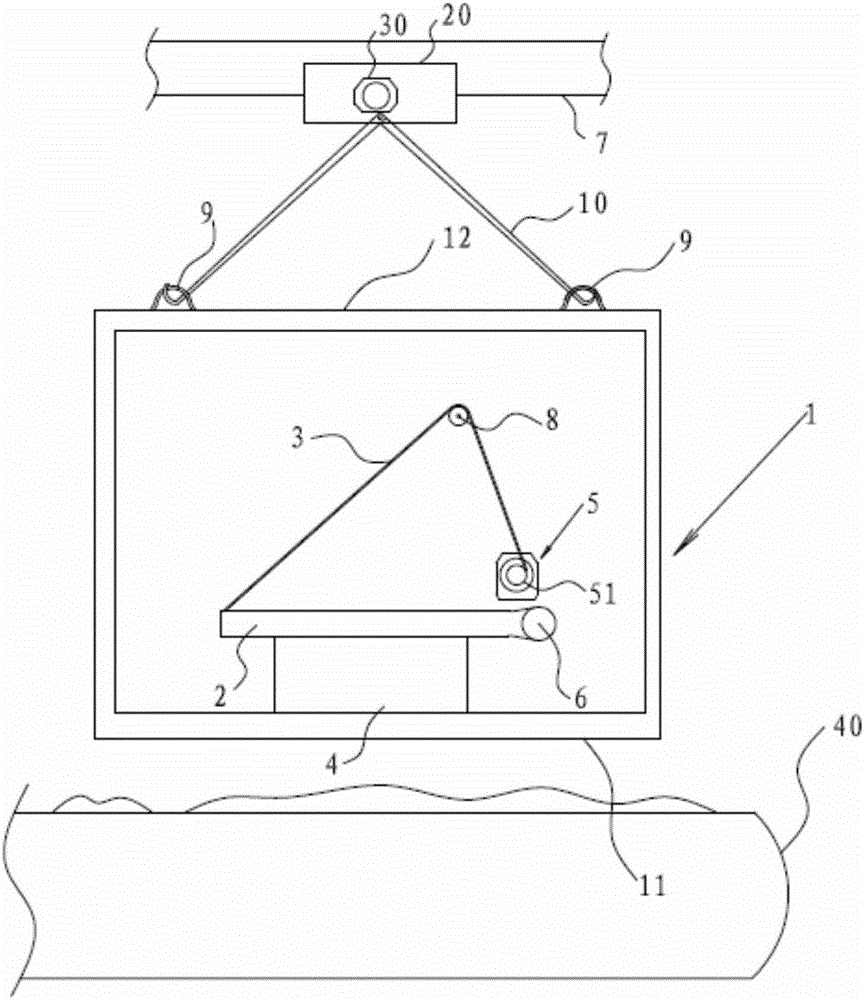

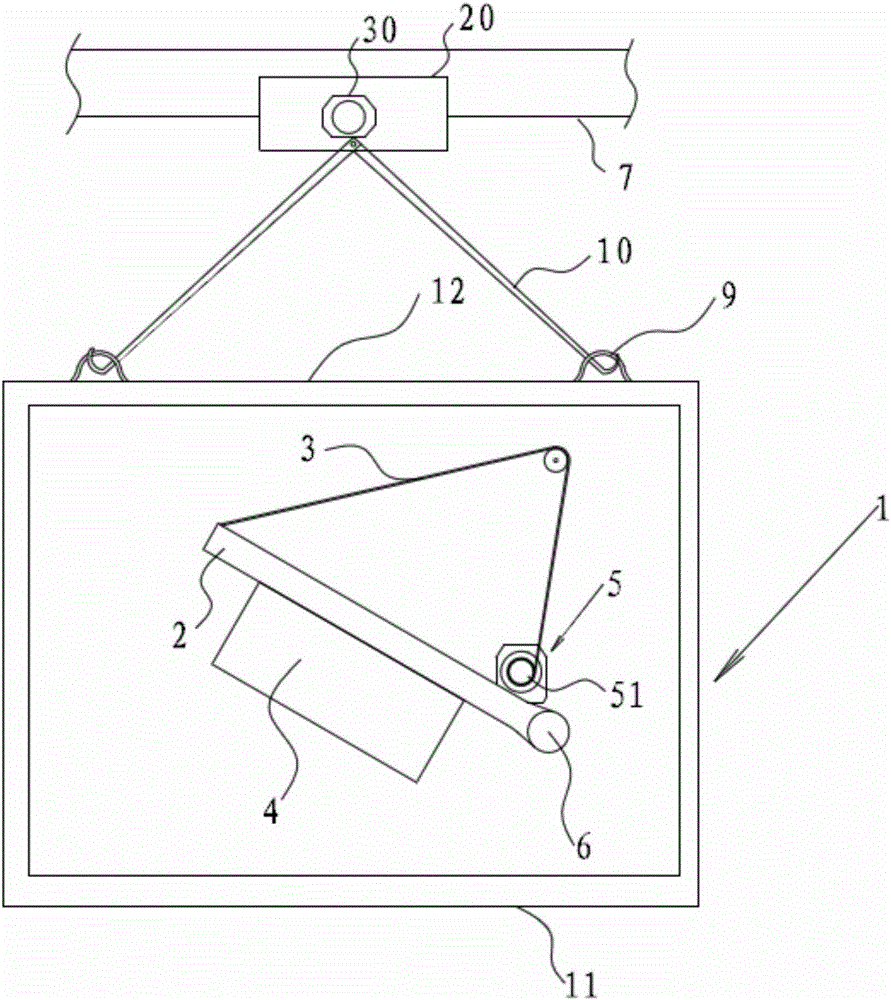

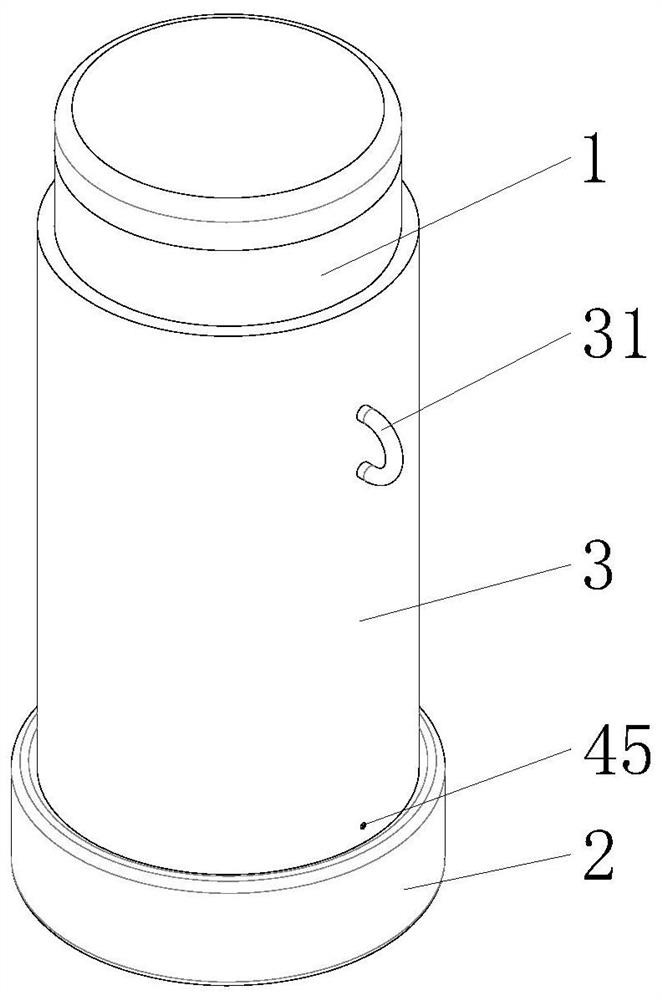

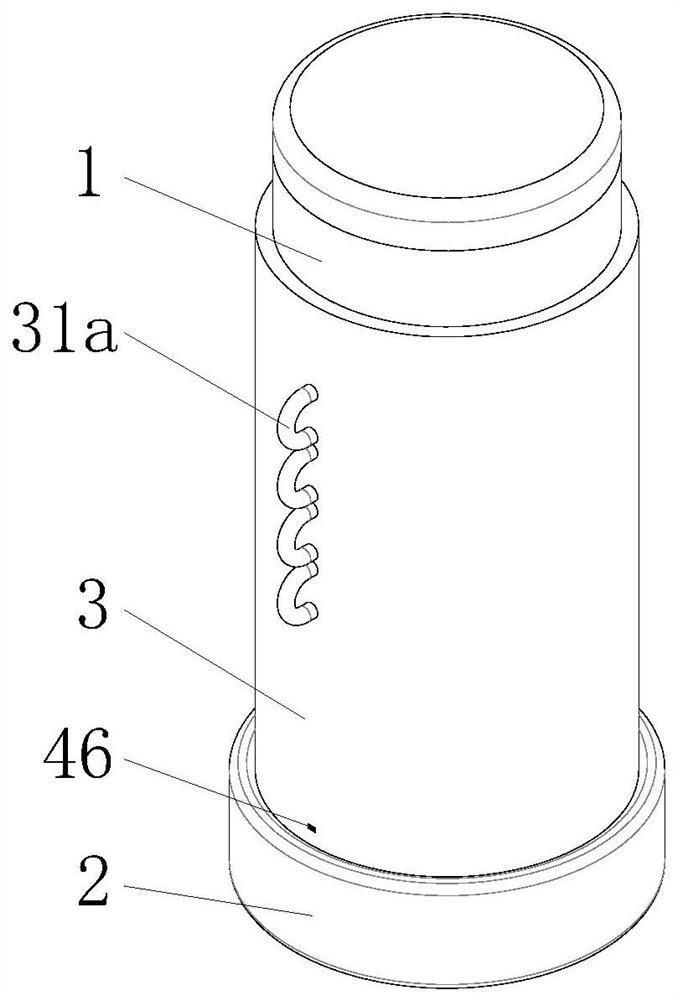

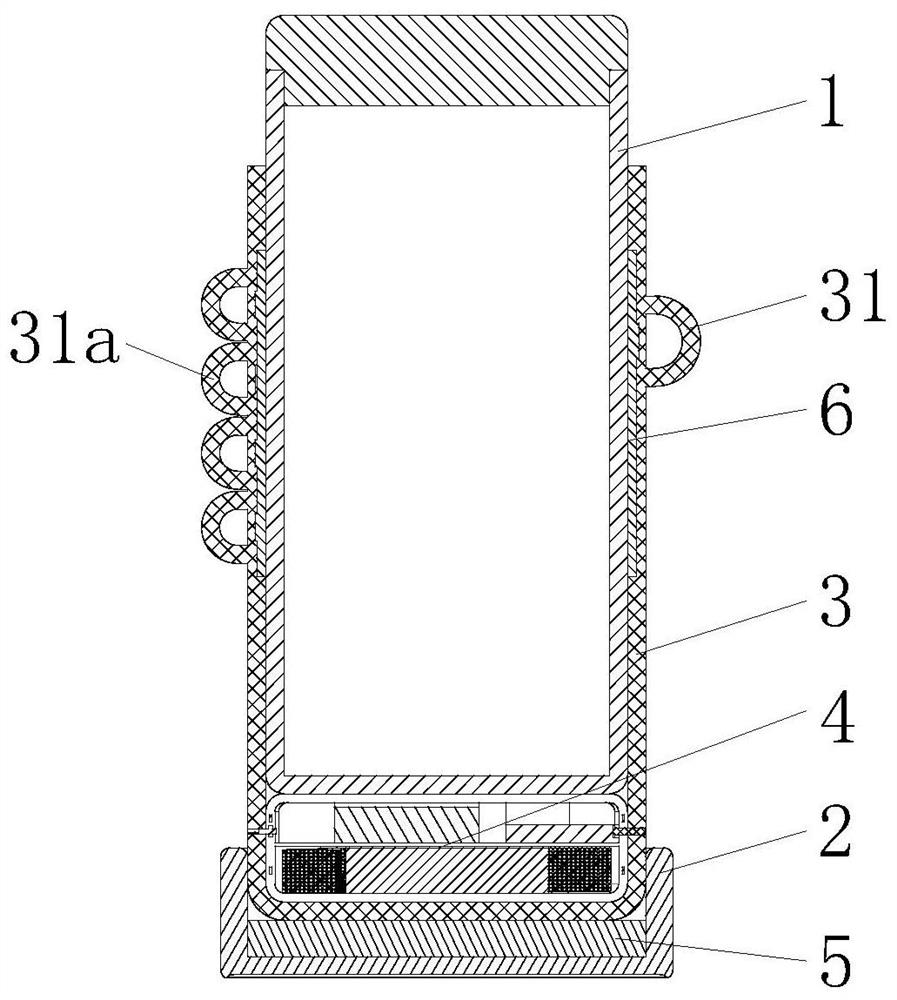

A self-priming positioning and measuring auxiliary device and its use method

ActiveCN111998824BAchieve fixationRealize automatic adsorptionSurveying instrumentsHeight/levelling measurementStructural engineeringAssistive equipment

The invention discloses a self-priming positioning and measuring auxiliary equipment and a use method thereof, which belong to the technical field of building measuring equipment. Including the fixed plate, the fixed plate is connected with a positioning mechanism, and the middle part of the fixed plate is provided with a stepped hole with a small top and a large bottom, and the large mouth of the stepped hole is slidingly connected to the adsorption piece. There is a connecting piece, the end of the connecting piece away from the moving plate extends into the stepped hole and is fixedly connected with the absorbing piece, both ends of the moving plate are rotatably connected with a connecting rod one, and the ends of the two connecting rods one away from the moving plate are both rotatably connected There are two connecting rods, and the two connecting rods are connected to the two ends of the fixed plate in rotation respectively, and the two connecting rods are used to drive the positioning mechanism. It greatly improves the measurement accuracy and work efficiency, and can save manpower to achieve the purpose of reducing construction costs, and can effectively prevent safety accidents in the construction process.

Owner:CHINA MCC17 GRP

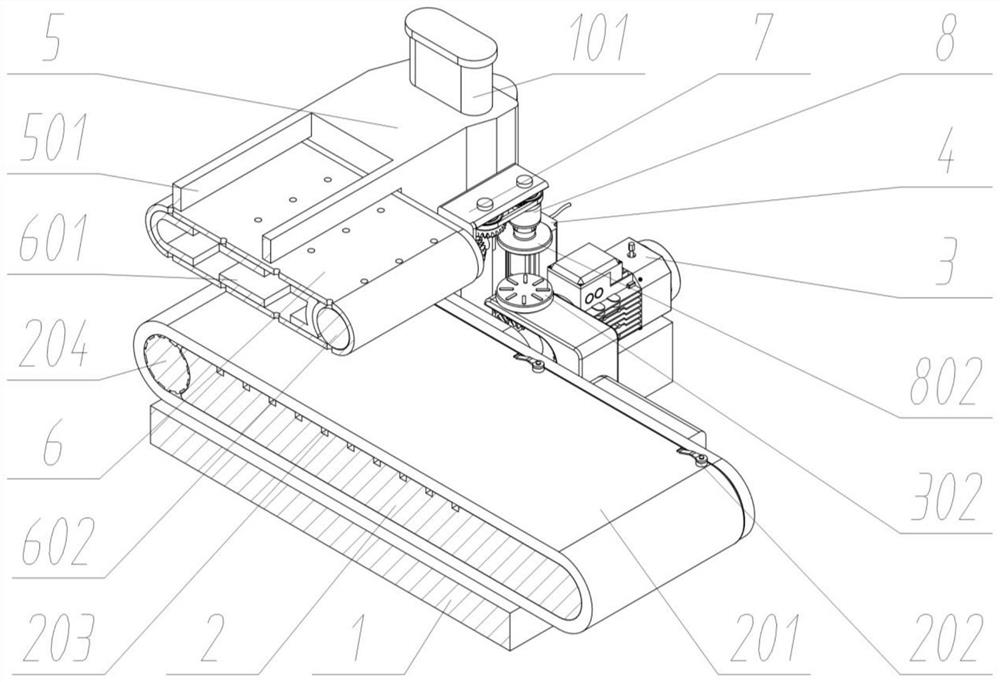

Leisure food damp-proof packaging structure

InactiveCN110065679AAchieve adsorptionRealize the clamping effectPackaging by pressurising/gasifyingWrapper twisting/gatheringTransmission beltEconomic benefits

The invention relates to the technical field of food packaging, in particular to a leisure food damp-proof packaging structure. The packaging structure involves a transmission belt and a motor, the bottom end surface of the motor is fixedly connected with a first supporting leg, the top end surface of the motor is fixedly connected with a fixing rod, a fixing ring is fixedly connected to the rightend of the fixing rod, a pressing rod is slidably connected in the fixing ring, an eccentric wheel is connected to the lower left corner of the pressing rod in a sliding mode, a groove is formed in the eccentric wheel, the eccentric wheel is fixedly connected with a main shaft of the motor, and the right lower end of the pressing rod is fixedly connected with the pressing plate. According to thepackaging structure, the motor, the eccentric wheel and the pressing rod are arranged to be matched with the groove wheel transmission device to carry out conveying and sealing on the leisure food packaging bag, a relatively good moisture-proof effect is realized, the design concept is novel, the design is scientific, huge economic benefits and wide market prospects are achieved, and the packagingstructure is worthy of popularization and application.

Owner:北京快知行科技有限公司

Light fixture detecting device

PendingCN110307939ALightweight structure designRealize automatic adsorptionTesting electric installations on transportLamps testingPositive pressureEngineering

The invention discloses a light fixture detecting device comprising a lower template, an upper template, an airtight detecting member, an electric detecting member, and an absorbing member. The lowertemplate is used for carrying a light fixture product. The upper template is arranged above the lower template; and receiving space is limited between the upper template and the lower template. The airtight detecting member that is disposed at the lower template in the receiving space is capable of carrying out positive pressure airtight detection on a light fixture product. The electric detectingmember that is disposed at the lower template in the receiving space is capable of carrying out electric detection on the light fixture product. The absorbing member is arranged at the upper template; an absorbing surface is formed at the at least one part of the absorbing member and is capable of absorbing or loosening the light fixture product. Therefore, the light fixture product can be absorbed or captured automatically; and gas-electric integrated function detection can be realized.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

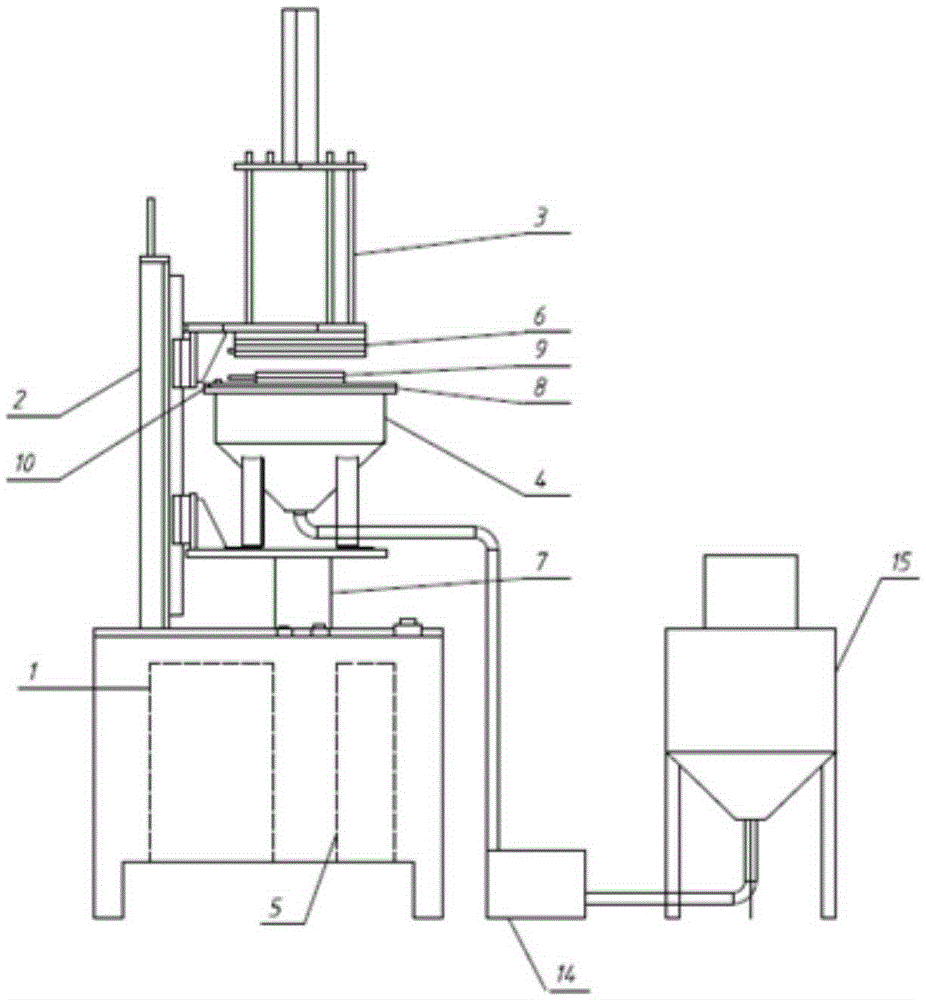

Ceramic carrier catalyst adsorption apparatus

PendingCN106732820ARealize automatic adsorptionMeet the needs of product quality consistencyCatalyst activation/preparationLiquid spraying apparatusAir pumpEngineering

The invention discloses a ceramic carrier catalyst adsorption apparatus including: a console, a support guide rail, a vacuum pump, a slurry pot, a control unit, a telescoping air pump, a control pump, and a stirring barrel. The support guide rail is installed on the console. The vacuum pump is fixed on the support guide rail. The slurry pot and the telescoping air pump are connected to each other so that the slurry pot is driven to slide on the support guide rail by the telescoping air pump. A bolt fixing disk is installed on the slurry pot and is provided with a liquid level controller that is connected to the control unit through a circuit. The control unit is installed under the console. The bottom of the slurry pot is connected to the control pump through a transporting pipe. The control pump is connected to the stirring barrel through the transporting pipe. In the apparatus, a coating method is re-planned so as to achieve auto-adsorption of a ceramic carrier catalyst, thereby saving labor intensity and working hours, increasing productivity, and improving quality consistency of products.

Owner:ANHUI ACT BLUE ENVIRONMENTAL PROTECTION CO LTD

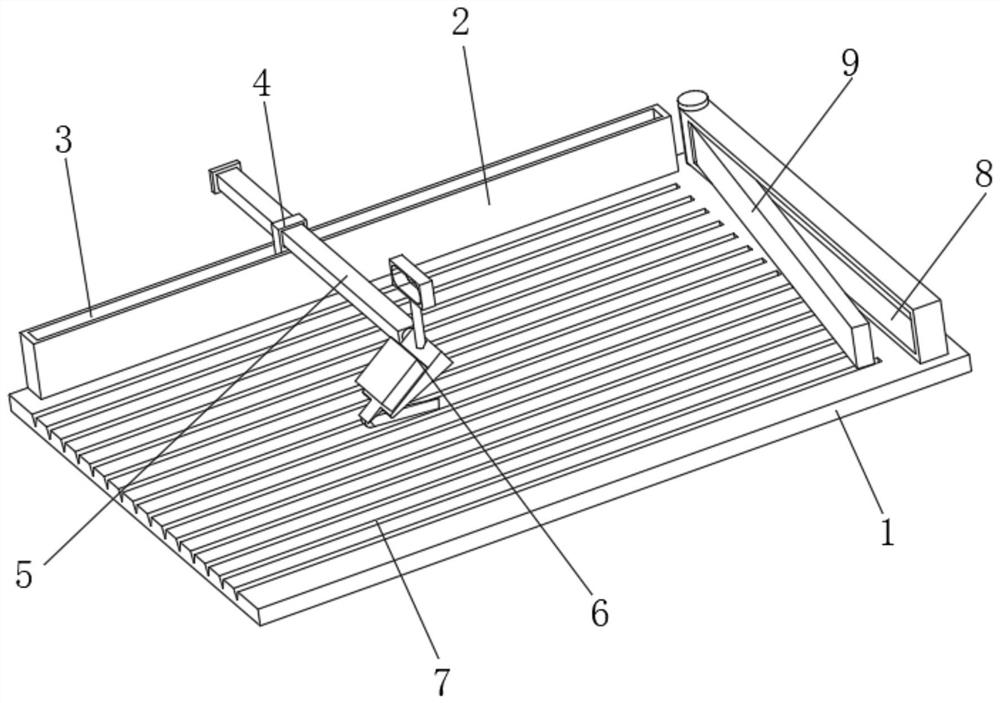

Corrugated paperboard cutting device

PendingCN112936376AImprove stabilityGuaranteed protection performanceMetal working apparatusCorrugated fiberboardEngineering

The invention discloses a corrugated paperboard cutting device which comprises a supporting base plate. A limiting straight plate is fixedly connected to the reverse side of the top of the supporting base plate, a limiting rail is arranged on the top of the limiting straight plate, an adjusting sleeve block is connected with the interior of the limiting rail in a sliding mode, and a supporting insertion rod penetrates through the adjusting sleeve block and is connected with the interior of the adjusting sleeve block in a sliding mode. A cutting mechanism is rotationally connected with the end, located on the obverse side of the adjusting sleeve block, of the supporting insertion rod, limiting grooves are evenly formed in the surface of the top of the supporting base plate at equal intervals, the bottom of the cutting mechanism is arranged in the mode of corresponding to the limiting grooves, a right-angle supporting plate is fixedly connected to the right side of the top of the supporting base plate, the limiting rail is perpendicular to the right-angle supporting plate, and the middle of the end face of the left side of the right-angle supporting plate is rotationally connected with an oblique angle adjusting plate. The invention relates to the technical field of corrugated paperboards. According to the corrugated paperboard cutting device, fixing of non-rectangular corrugated paper is achieved, and the situation that a wavy paper element and the limiting grooves are kept parallel is guaranteed.

Owner:王佳琪

An automatic and precise assembly of an oil pump

ActiveCN109366141BAchieve horizontal placementImprove work efficiencyMetal working apparatusEngineeringOil pump

The invention provides an automatic accurate assembling assembly for an oil pump. The automatic accurate assembling assembly for the oil pump comprises a base, an assembling cylinder, an extrusion mechanism, a compression groove and a rotary suction mechanism. The extrusion mechanism comprises an extrusion block and an overturning assembly. The rotary suction mechanism comprises a rotary assemblyand a discharging assembly. According to the automatic accurate assembling assembly for the oil pump, the extrusion block is rotatably connected to a pushing end of the assembling cylinder, and the extrusion block can rotate to be horizontal. After one-time assembling of oil pump springs and an oil pump shell, an oil pump cylinder retracts, and the extrusion block is driven to be horizontal by theoil pump cylinder; and besides, the extrusion block is magnetized through an electromagnet, and the oil pump springs output by the discharging assembly is sucked by the extrusion block. When the assembling cylinder pushes, the extrusion block is vertically arranged and loses magnesium; the oil pump springs fall onto a bearing base accurately; the technical problem of accurate feeding of the oil pump springs is solved; horizontal placement of the oil pump springs is achieved; moreover, the oil pump springs are fed automatically; and working efficiency is higher.

Owner:CHANGXING BEST MASCH CO LTD

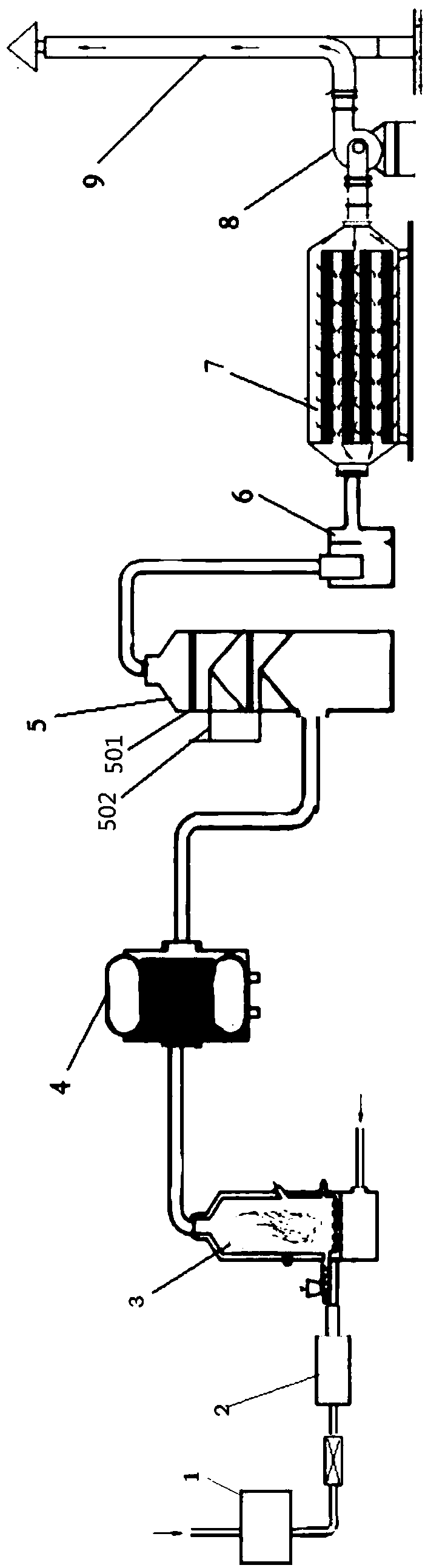

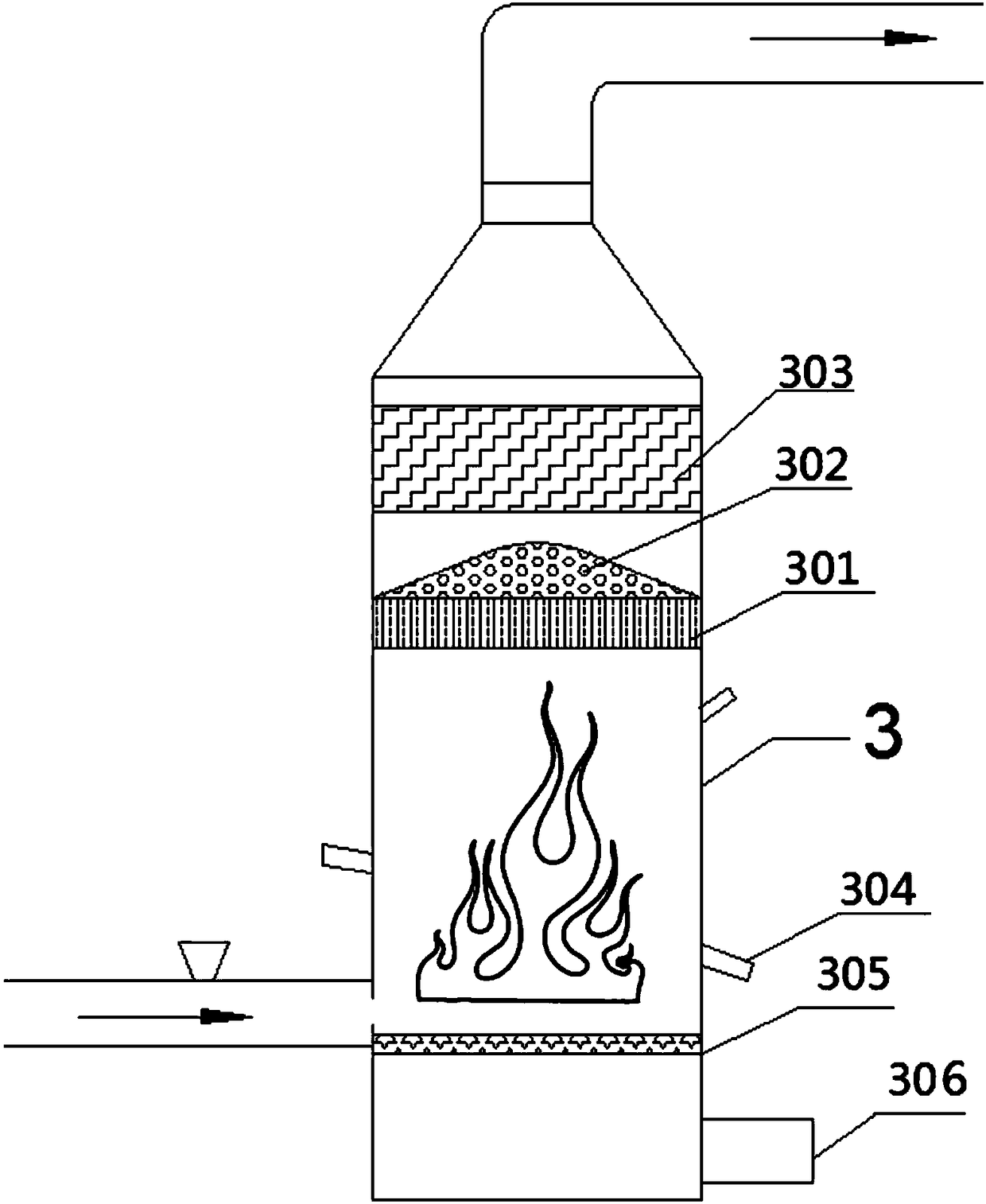

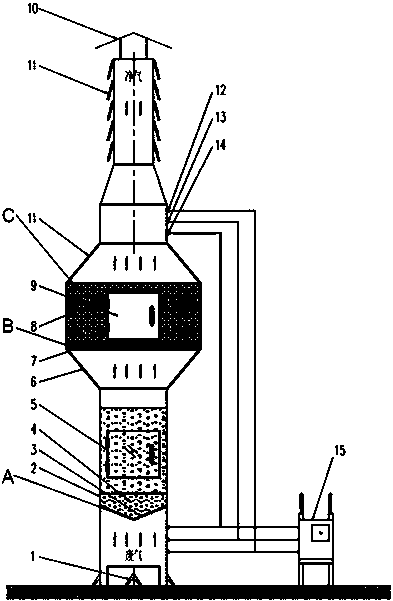

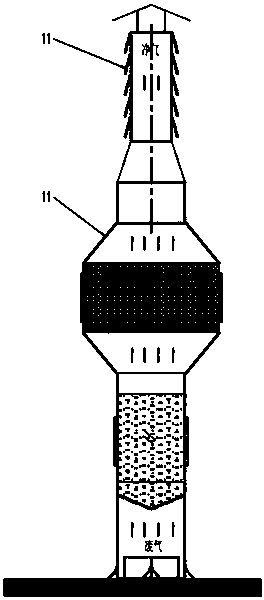

Solar organic waste gas purifying device and implementing method

PendingCN110013737AGuaranteed complianceGuaranteed to lastGas treatmentDispersed particle separationElectric controlSolar cell

The invention relates to a solar organic waste gas purifying device and an implementation method thereof. The solar organic waste gas purifying device comprises a purifying system and an electric control system which are arranged in a frame. The purifying system is provided with a rectangular box body, a mesh tray is arranged in the middle of the rectangular box body, quicklime is placed in the rectangular box body to absorb and release energy, a diffusion type base box body is arranged in the cavity of the upper middle portion of the rectangular box body, a grid-shaped flow guide plate is arranged, the upper portion of the rectangular box body is provided with a convergent opening and gradually extends upwards to converge into a tube, and an air flow guide device is arranged on the top ofthe rectangular box body. The electric control system is provided with a solar cell panel, a temperature sensor, a humidity sensor, a volatile organic matter detection sensor and a radio transmitter,and the radio transmitter transmits information to a control terminal. According to the solar organic waste gas purifying device, intelligent management is realized by utilizing solar energy, traditional power operation is not adopted, an on-line automatic adsorption and process controlled treatment mode is realized, it ensures that the purified waste gas reaches the standard, good management isimplemented, energy consumption is not needed, and the solar organic waste gas purifying device is energy-saving and environment-friendly.

Owner:SHANGHAI SUPERHIGH ENVIRONMENTAL PROTECTION TECH CO LTD

Universal vacuum chuck with automatic closing function

The invention discloses a universal vacuum chuck with an automatic closing function, which is a device for adsorption fixation of large three-dimensional surface parts. The device mainly comprises a seal lip suction disc (1), a first layer of rotary spherical bowl (2), a second layer of rotary spherical bowl (3) and a spherical bowl supporting seat (4). The structure of the two layers of rotary spherical bowls guarantees that the chuck can swing in the angle range of 45 DEG to adapt to the requirements of adsorption fixation of different three-dimensional surface parts; and meanwhile, a vacuum automatic feedback adjustment device comprising a sliding block with a pin hole on the side wall of the supporting seat, a spring and a dustproof net guarantees that a vacuum air channel is automatically connected for adsorbing the parts when the parts are on the chuck, and after the parts are taken down, only a pin hole air channel on a moving block is connected to achieve the purpose of almost closing the chuck. According to the universal vacuum chuck, the vacuum chuck is integrated with the vacuum feedback adjustment device, so that the vacuum pumping flow quantity in the working and intermittent states can be automatically adjusted, and the function of automatically adsorbing the parts in the presence of the parts and automatically closing the chuck in the absence of the parts is achieved.

Owner:JILIN UNIV

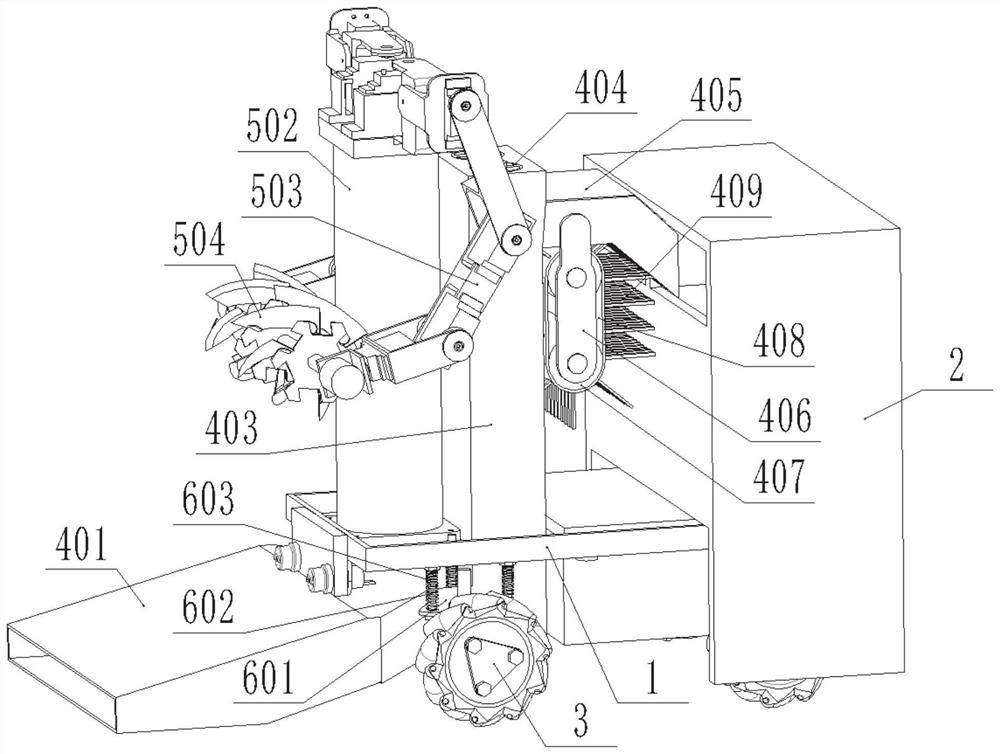

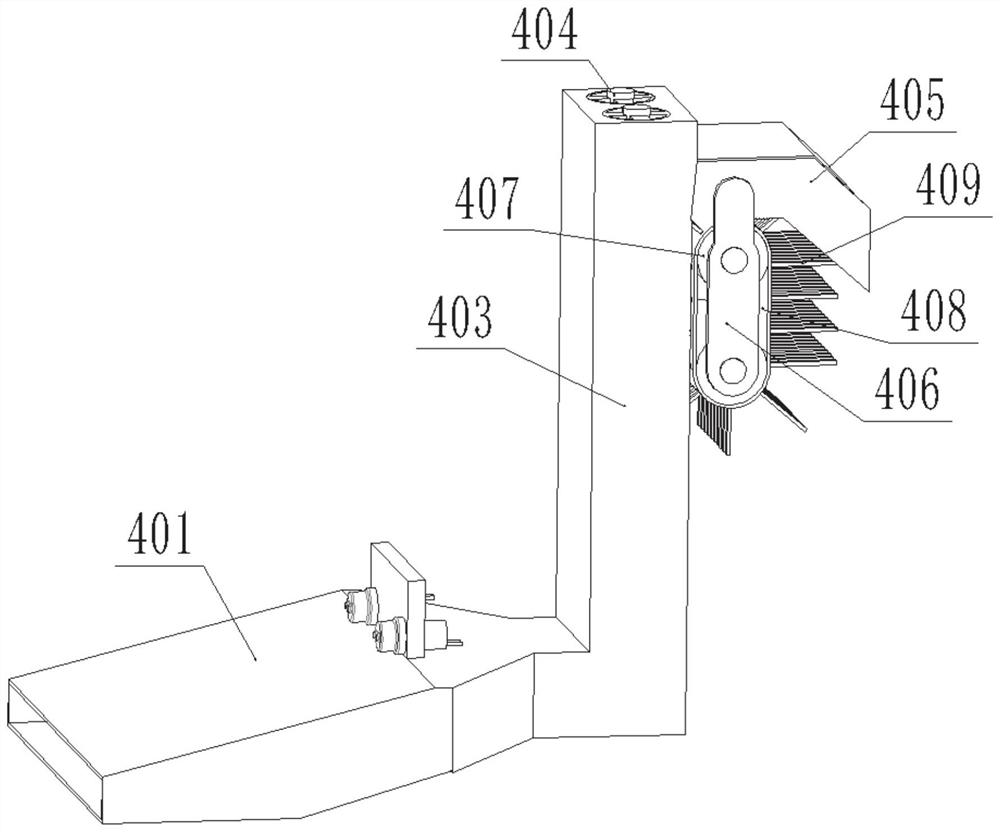

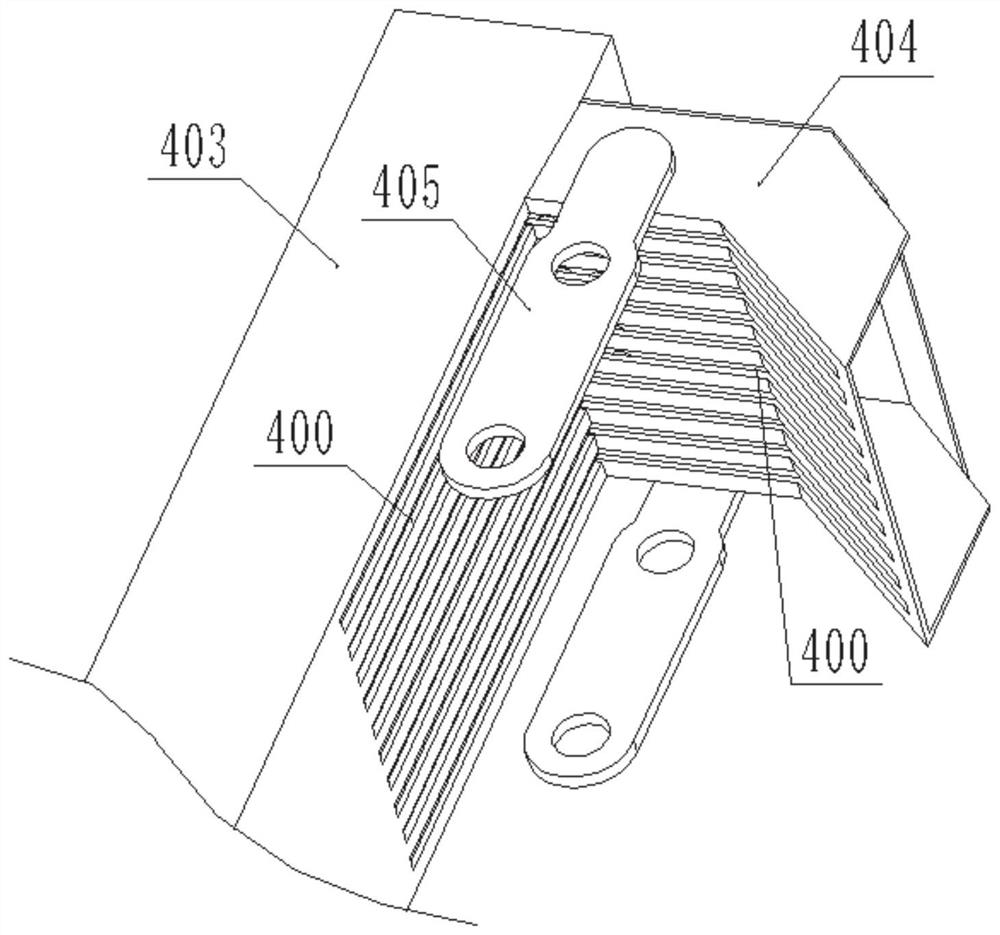

Unmanned environment-friendly vehicle

PendingCN113403992AWalking smoothlySave human effortCuttersCutting implementsProcess engineeringWaste management

Owner:湖南翰坤实业有限公司

Water cup for Alzheimer's disease patients

InactiveCN112618375AInhibit sheddingThe drinking process went wellFeeding-bottlesDomestic articlesRubber CupPhysical medicine and rehabilitation

The invention discloses a water cup for Alzheimer's disease patients. The water cup comprises a cup body and a cup base, wherein a rubber cup sleeve is arranged on the outer side of the cup body in a sleeving manner, the bottom of the rubber cup sleeve is movably embedded into the top of the cup base, and an adsorption device positioned at the bottom of the cup body is embedded into the rubber cup sleeve. A sensing assembly electrically connected with the adsorption device is embedded in the inner wall of the rubber cup sleeve, a plurality of rings located on the outer side of the sensing assembly are integrally arranged on the outer wall of the rubber cup sleeve, and an adsorption block located at the bottom of the rubber cup sleeve is embedded in the cup base. According to the invention, the rubber cup sleeve is arranged outside the cup body, and a hand ring allowing fingers to be inserted is arranged on the outer wall of the rubber cup sleeve, so that the water cup can be effectively prevented from falling off from a hand. By means of magnetic attraction effect, the cup body is automatically adsorbed to the cup base, the cup body can be taken out of the cup base only after the hand is inserted into the hand ring and tightly holds the cup body, and the cup can be effectively prevented from toppling over in the taking and placing process.

Owner:汪泽萍

Rapid carrying device for factory automation based on computer application

ActiveCN112777312AMove quicklyAvoid human involvementTotal factory controlConveyor partsMachinePlant automation

The invention discloses a rapid carrying device for factory automation based on computer application. The rapid carrying device comprises a material frame and a feeding structure, a second discharging structure is arranged at the discharging end of the feeding structure, a first discharging structure is arranged on one side of the second discharging structure, the feeding structure comprises a material conveying structure and a material suction structure, the material suction structure comprises a support, and transverse plates are fixedly installed on the two sides of the top of the support. According to the rapid carrying device for factory automation based on the computer application, mechanical and automatic material taking, overturning, feeding and discharging operation is achieved, the whole process is achieved through a machine, manual participation is avoided, then automatic and rapid plate carrying is achieved, and the carrying speed is increased; and two discharging ends of the first discharging structure and the second discharging structure are arranged, so that bidirectional discharging operation is achieved, materials can be conveyed to different areas according to different requirements, uniform discharging operation can further be achieved, and the use efficiency is high.

Owner:YONGCHENG VOCATIONAL COLLEGE

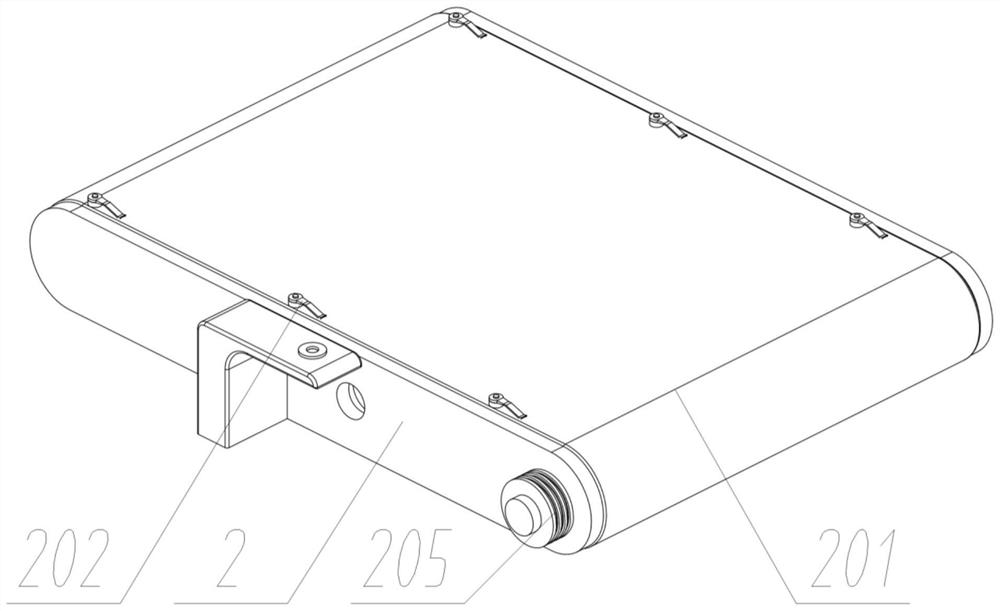

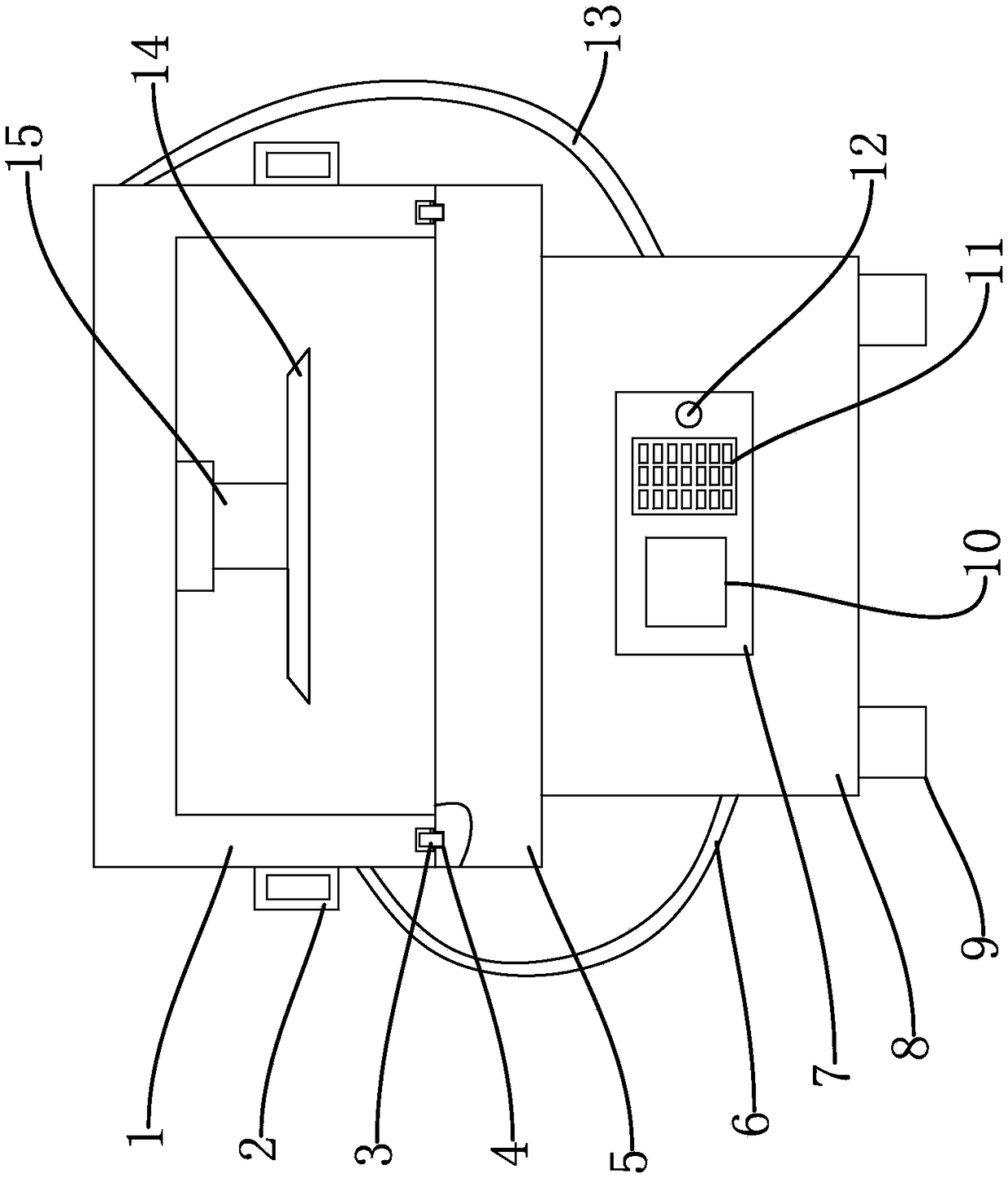

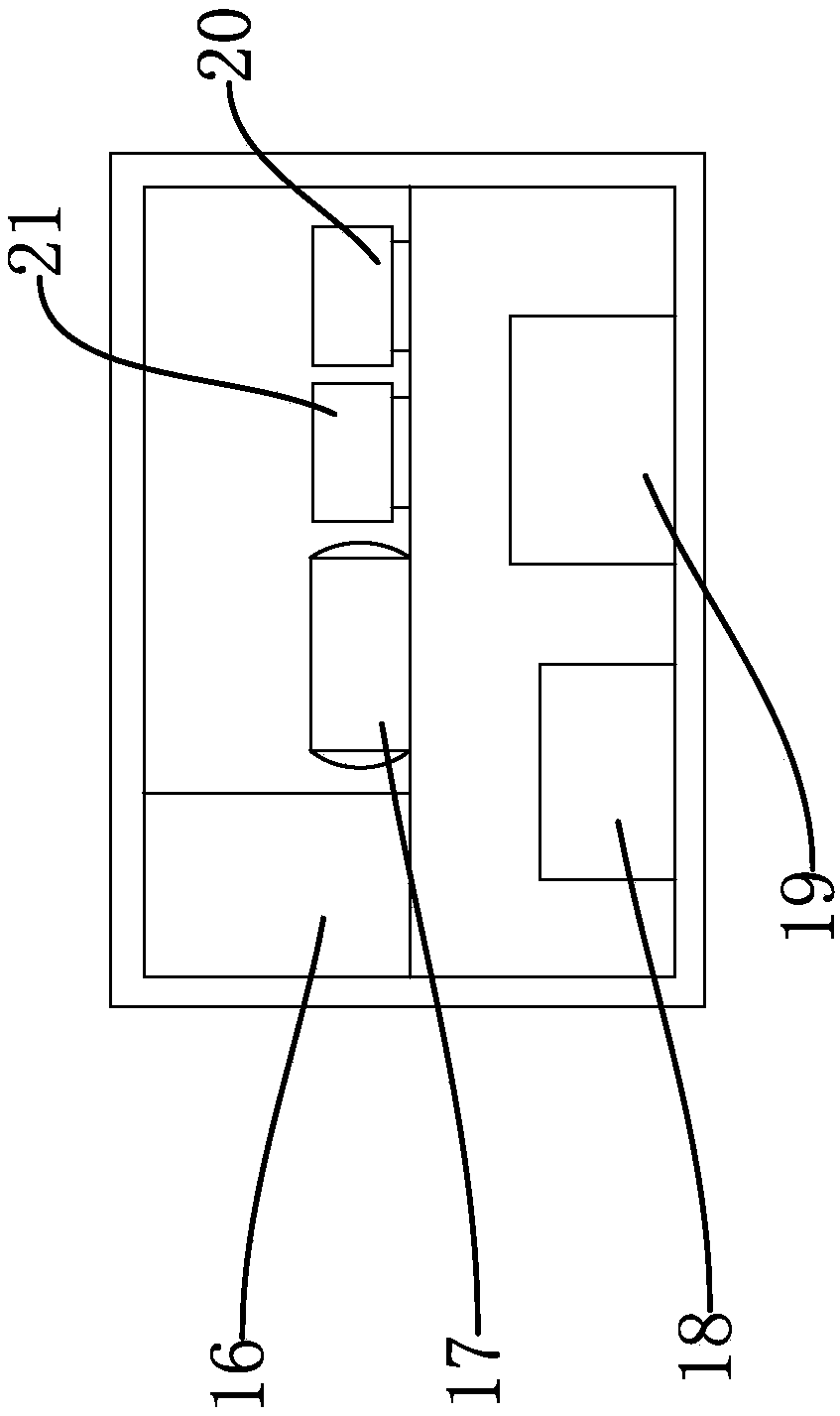

Paper conveying device of paper cup machine

InactiveCN108068399ARealize automatic adsorptionEasy to transportBox making operationsPaper-makingFuel tankEngineering

The invention provides a paper conveying device of a paper cup machine, belongs to the technical field of paper cup machines, and solves the problem of low paper conveying efficiency in the prior art.The paper conveying device of the paper cup machine comprises a cabinet, a conveying table and a bracket; support legs are arranged at four corners of the lower end of the cabinet; an operation plateis arranged on one side wall of the cabinet; the operation plate is provided with a display screen, a keyboard and a switch; an air pipe is arranged at the lower end of the side wall, near the operation plate, of the cabinet; an oil pipe is arranged at the upper end of the side wall, far from the operation plate, of the cabinet; a power supply and a controller are arranged at the bottom end in the cabinet; an oil tank, an oil pump, a driving motor and a fan are arranged at the upper end in the cabinet; the conveying table is arranged at the upper end of the cabinet; slide rails are arranged on the two sides of the upper end of the conveying table; the bracket is arranged in the slide rails; rollers are arranged at the lower end, near the slide rails, of the bracket; push handles are arranged at the middle parts of two side walls, near the rollers, of the bracket; and a lifting column is arranged at the middle part of the upper end of the bracket. The paper conveying device of the paper cup machine has the advantage of high paper conveying efficiency.

Owner:海宁诚达机械有限公司

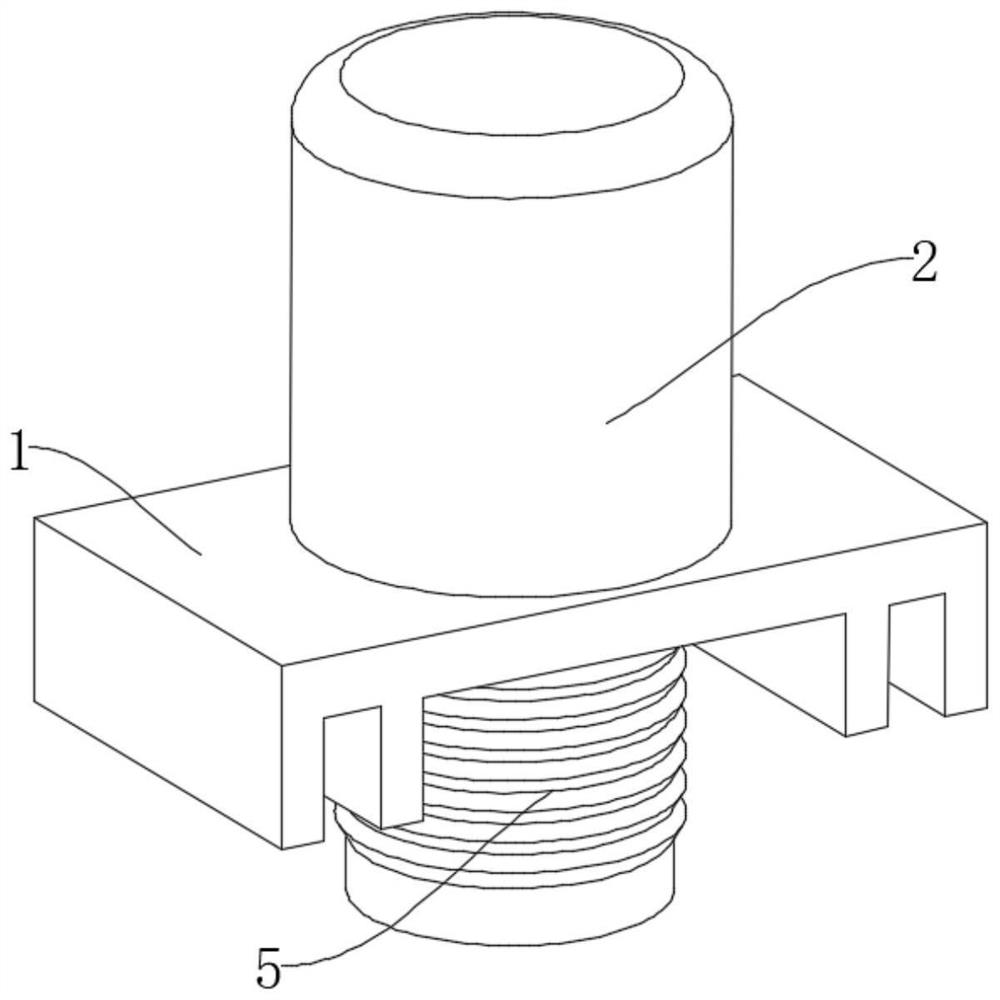

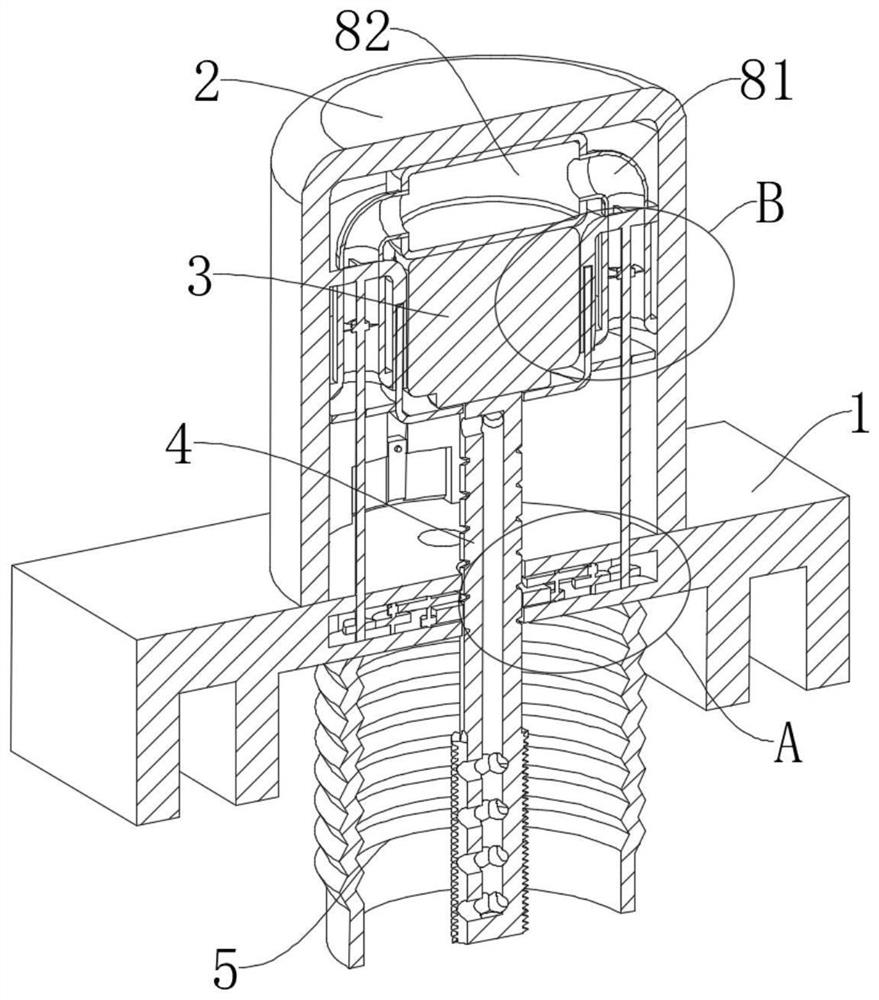

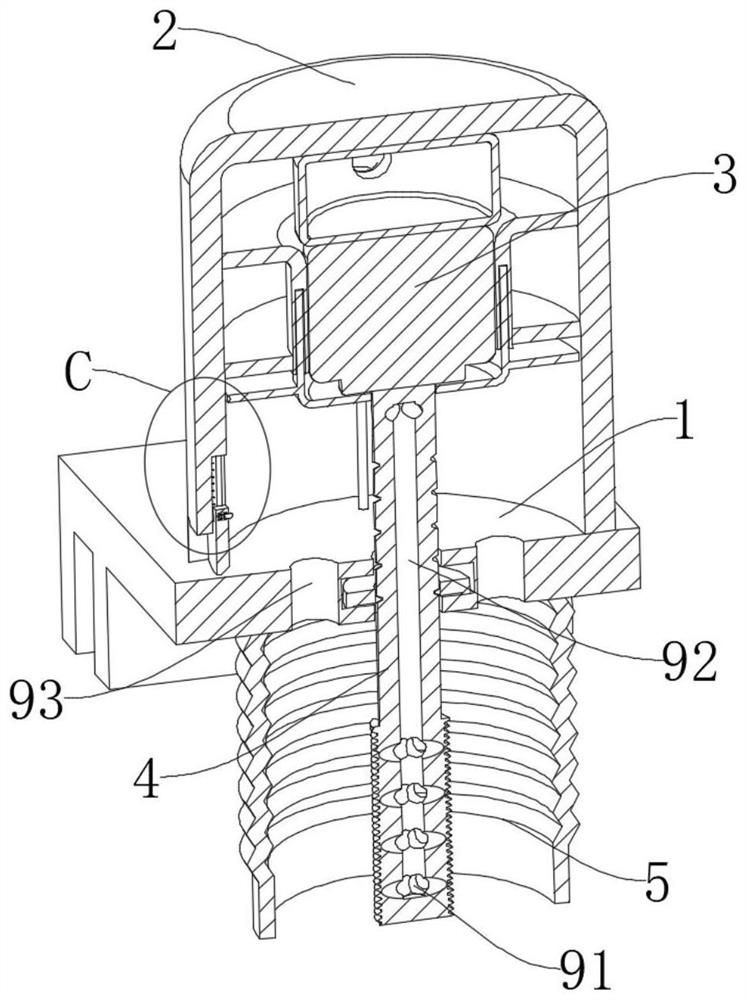

Sleeve, automatic locking device and locking method of nut

PendingCN111230470ARealize automatic adsorptionReduce labor intensityMetal working apparatusProduction lineStructural engineering

The invention discloses a sleeve, an automatic locking device and a locking method of a nut. The sleeve is used for locking the nut; a groove for accommodating the nut is arranged on the end face of the sleeve; and a magnetic piece is arranged at the position, adjacent to the groove, in the sleeve and the magnetic piece is used for adsorbing the nut in the groove. Through the sleeve, the nut can be effectively adsorbed on the magnetic piece, and a gasket is further tightly adsorbed on the bottom end surface of the sleeve through adsorption holes which communicate with a vacuum system. Throughthe automatic locking device and the locking method of the nut, the production bottleneck can be fundamentally broken through, the assembly efficiency of equipment products on a production line is effectively improved, and compared with the existing manual fixing, the locking of the gasket nut is more stable, and meanwhile, the repair caused by manual misoperation is reduced.

Owner:GREE ELECTRICHEFEI +1

Sealing plastic nail temporary storage device for aluminum shell battery liquid injection port

ActiveCN113651099ARealize automatic adsorptionImplement automatic cleanupControl devices for conveyorsCell component detailsMechanical engineeringBattery cell

The invention discloses a sealing plastic nail temporary storage device for an aluminum shell battery liquid injection port. The sealing plastic nail temporary storage device comprises a plastic nail temporary storage mechanism, a plastic nail discharging mechanism used for providing plastic nails for the plastic nail temporary storage mechanism, a plastic nail detecting mechanism used for detecting the plastic nails in the plastic nail temporary storage mechanism, a plastic nail taking mechanism used for taking down the corrected plastic nails from the plastic nail temporary storage mechanism, and a plastic nail correcting and placing mechanism used for temporarily storing the corrected plastic nails sucked by the plastic nail taking mechanism. According to the sealing plastic nail temporary storage device, the probability that the plastic nails are clamped or returned when being discharged through a vibration disc is avoided, and the accuracy during plastic nail temporary storage is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com