Patents

Literature

34results about How to "Achieve horizontal placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

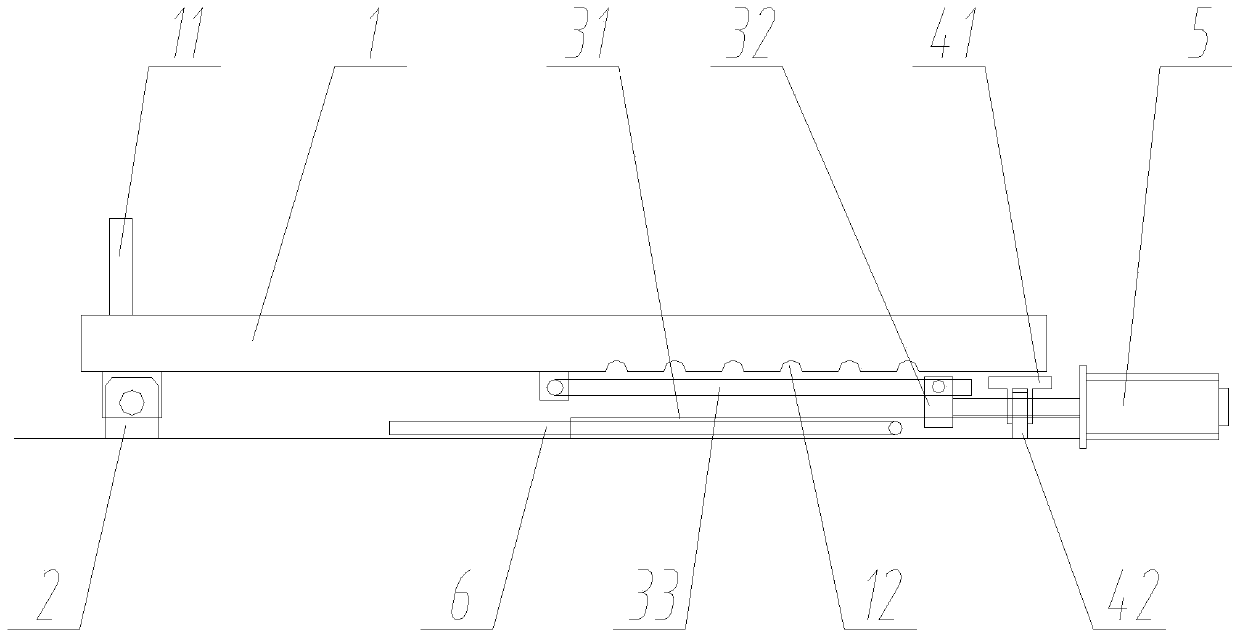

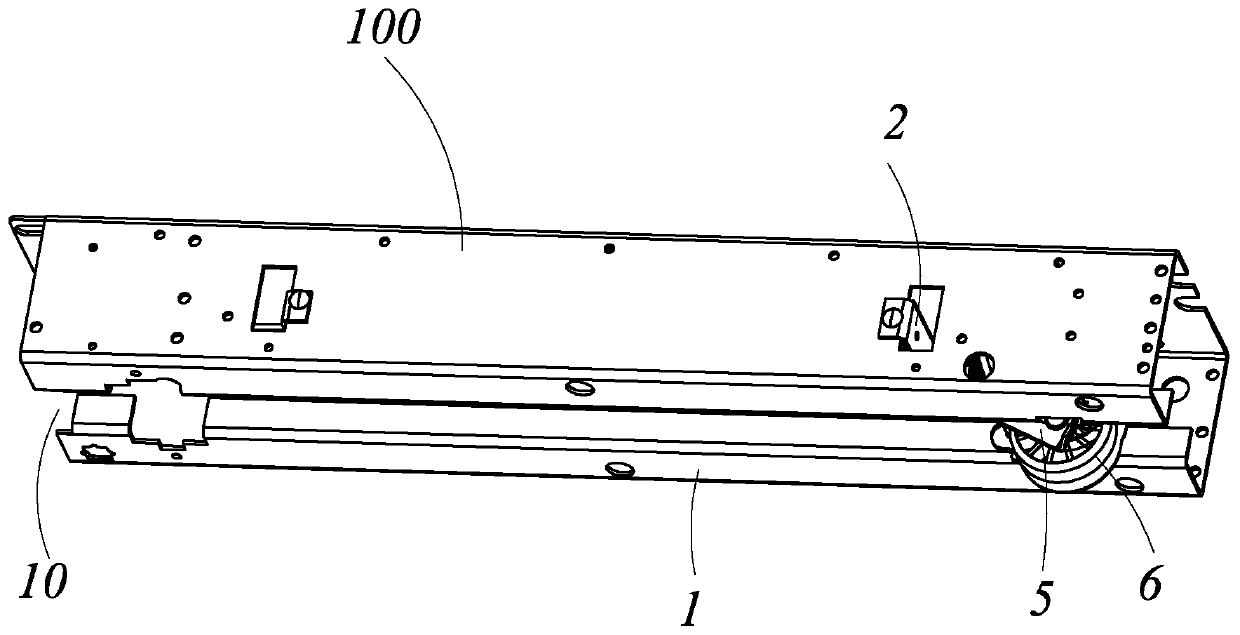

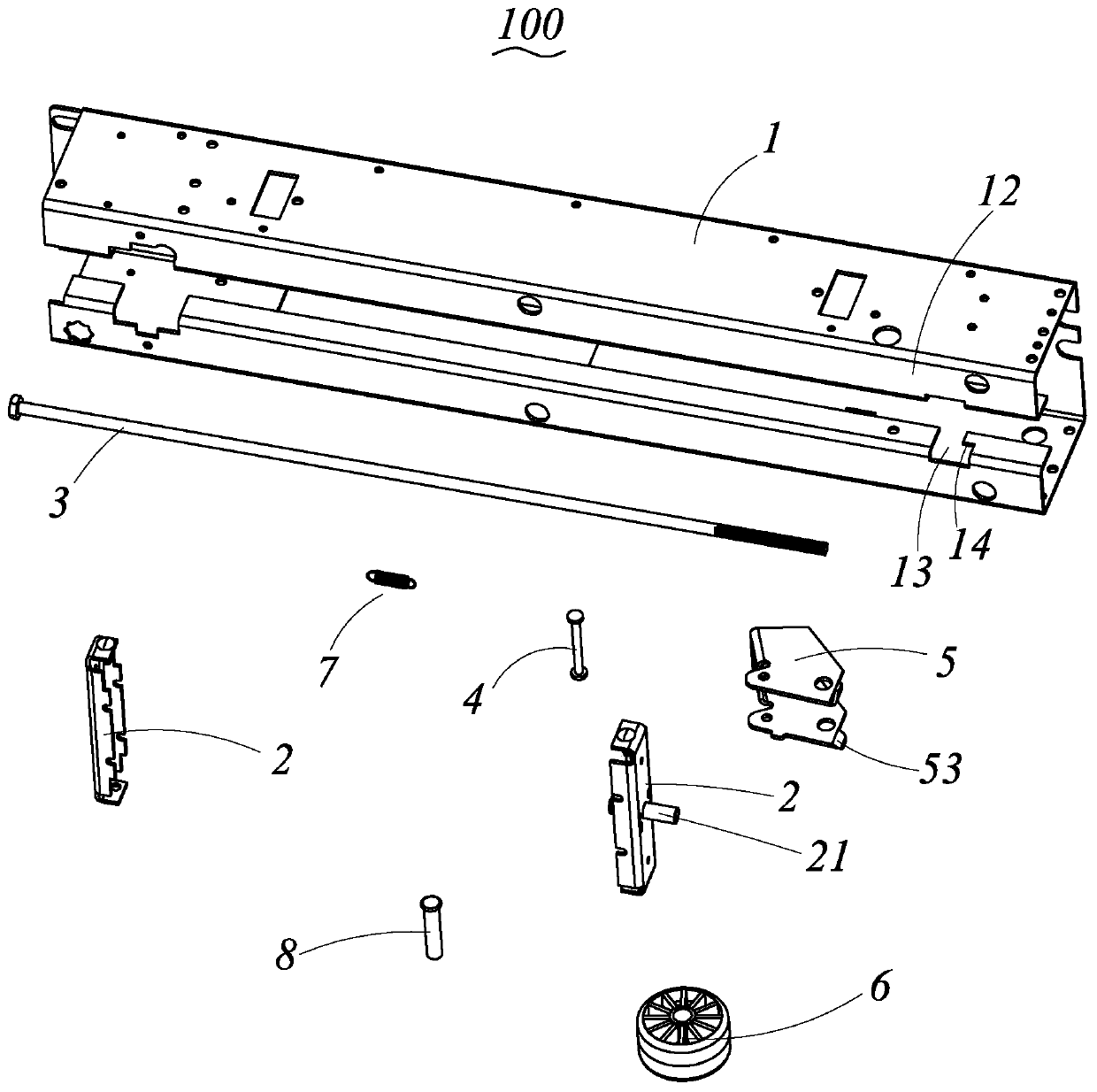

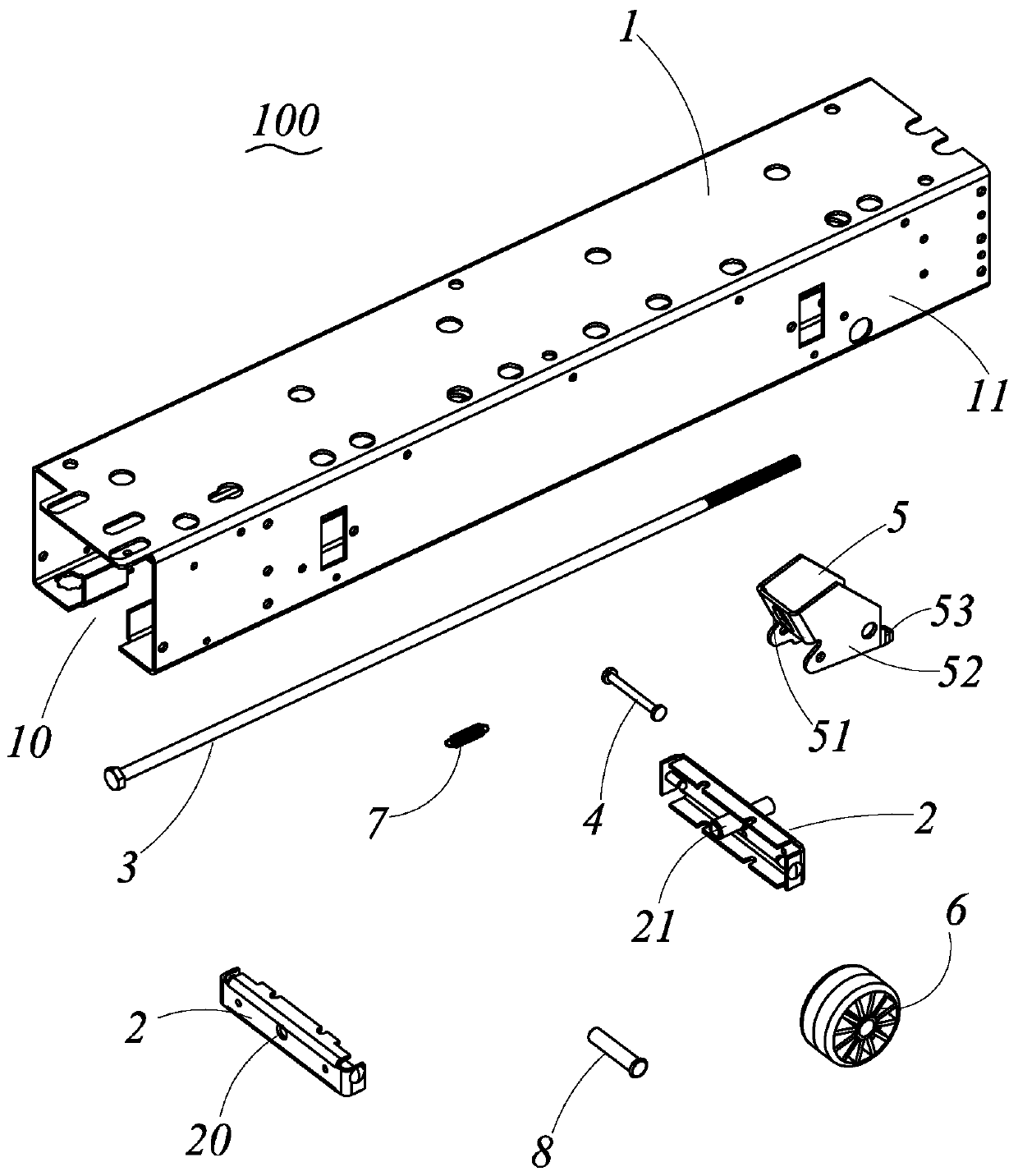

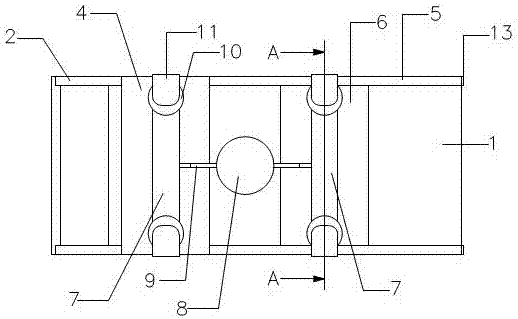

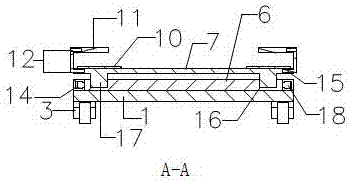

Threaded pipe assembly device

ActiveCN103659246AImprove tightening qualityGuarantee personal safetyMetal working apparatusThreaded pipeEngineering

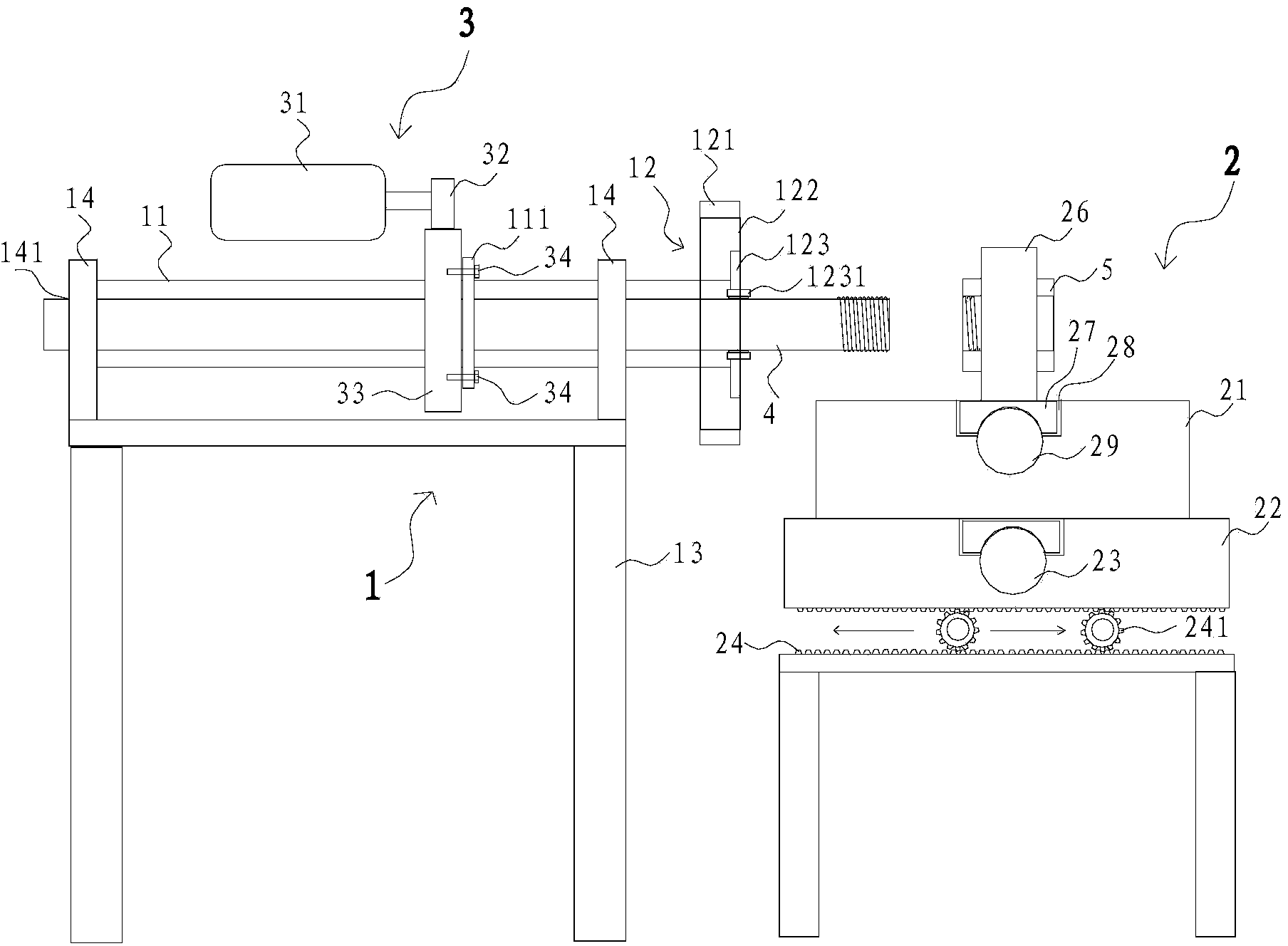

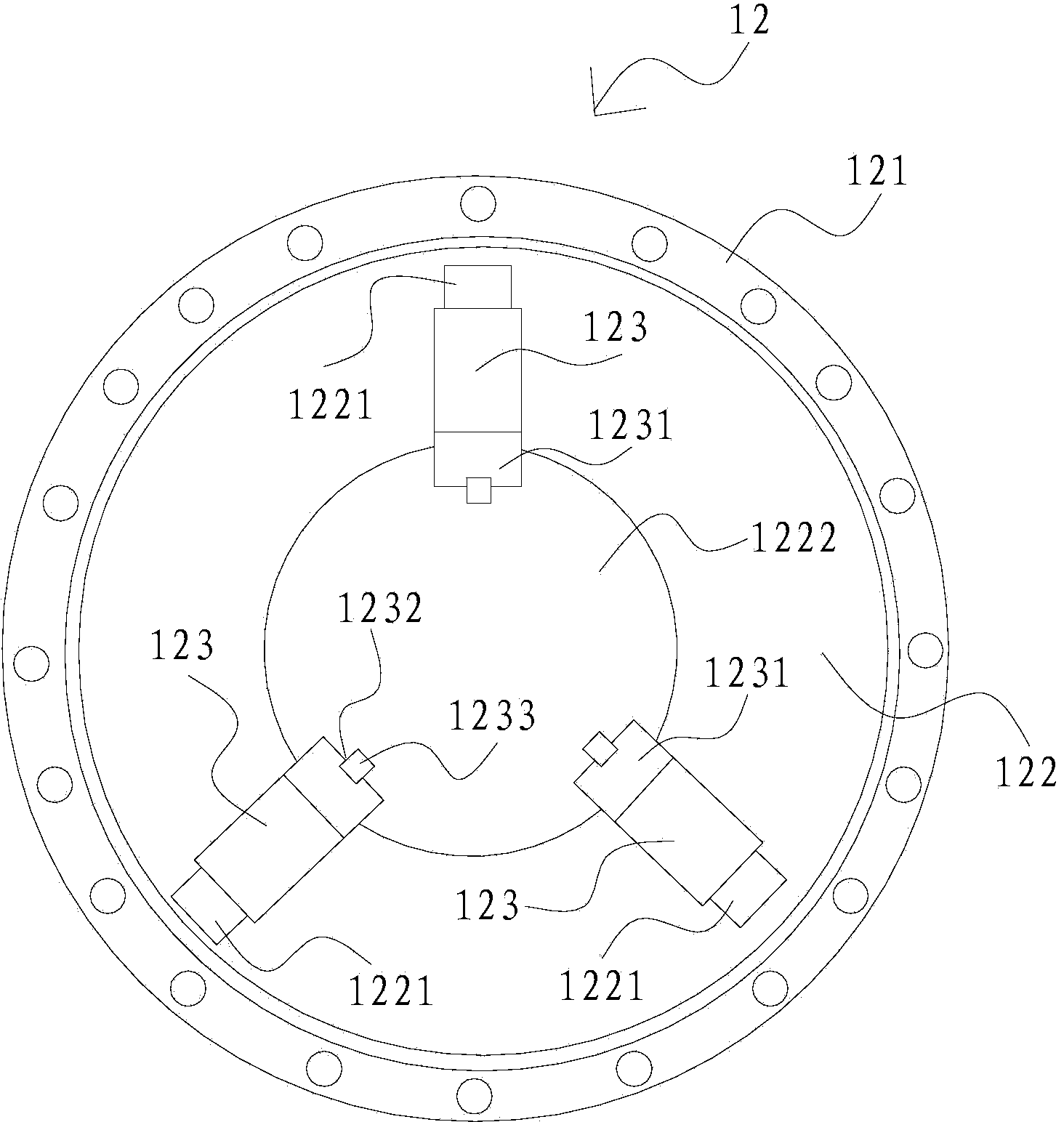

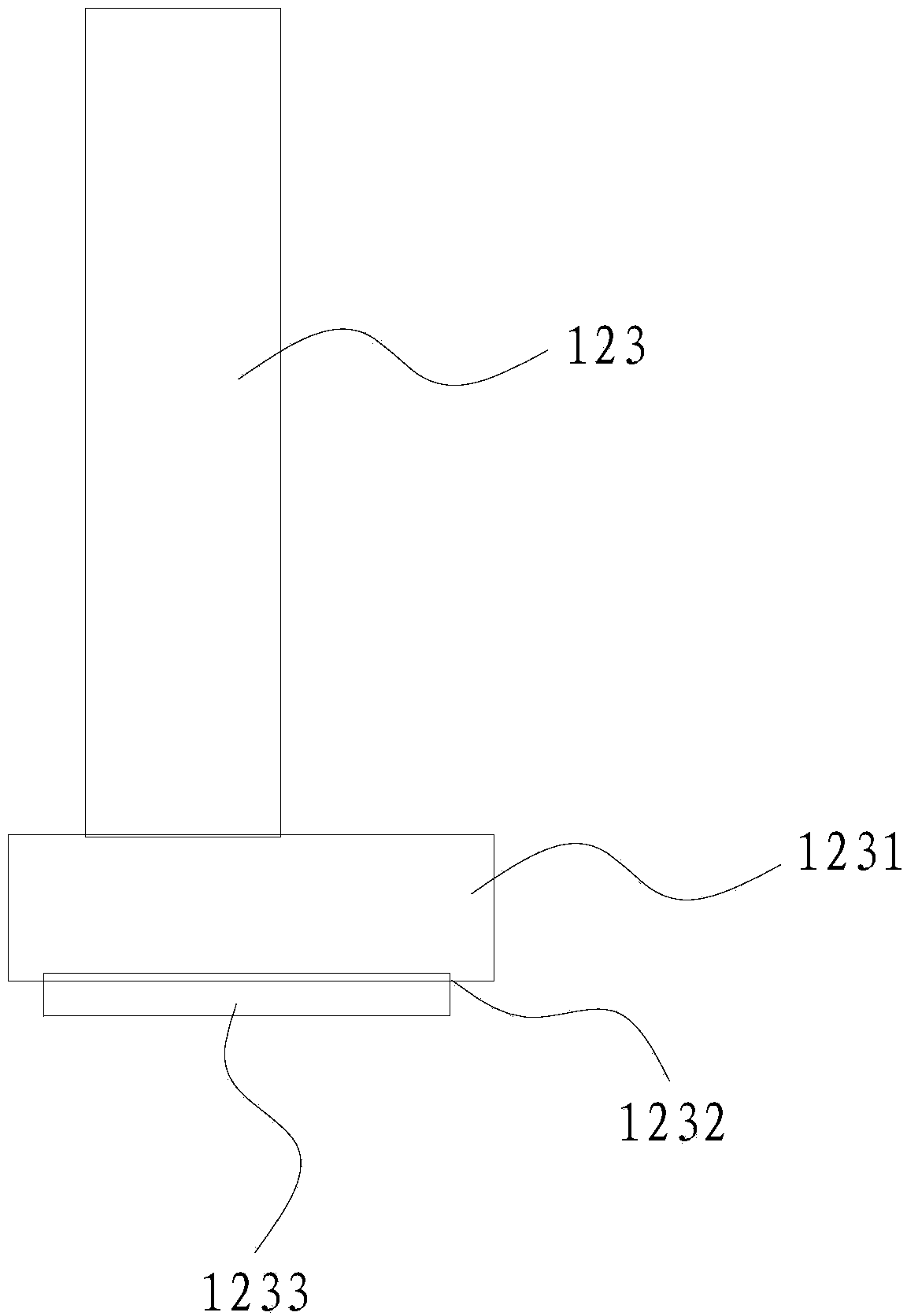

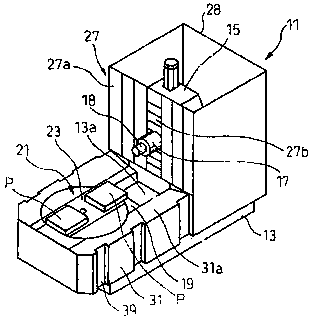

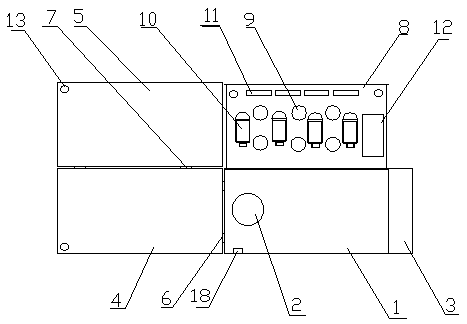

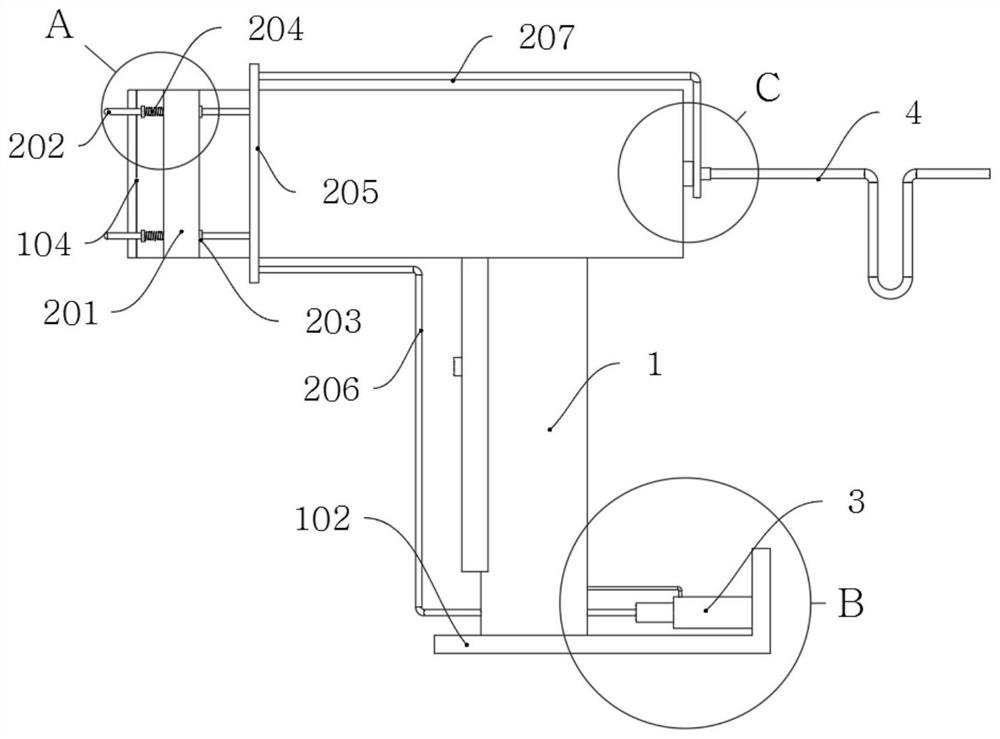

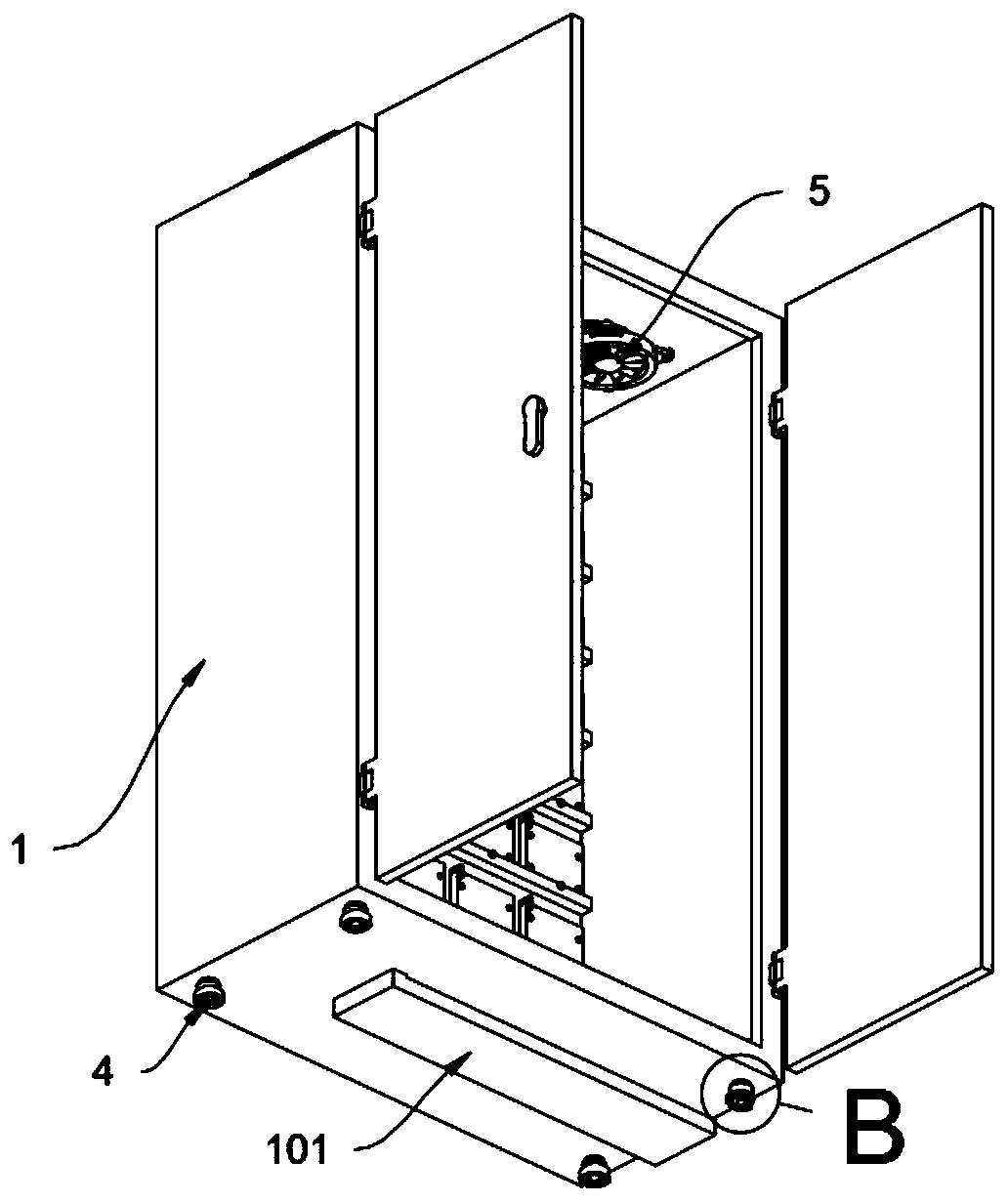

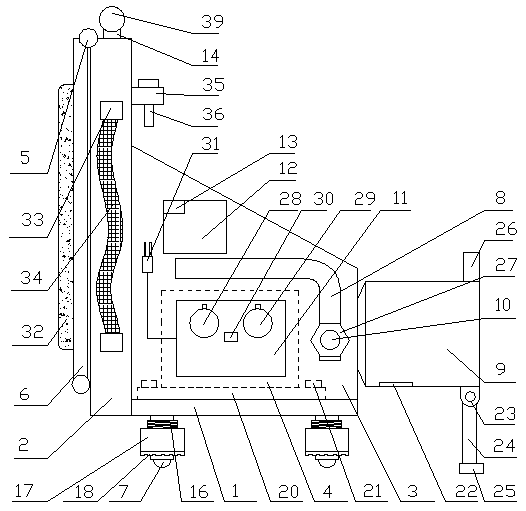

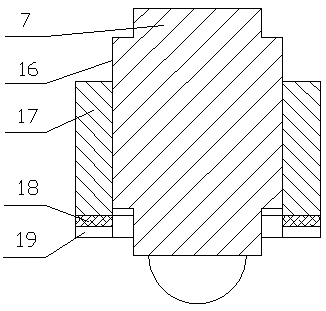

The invention discloses a threaded pipe assembly device comprising a first fixing unit, a second fixing unit and a driving unit. The first fixing unit is used for fixing a pipe to be assembled. The second fixing unit is used for clamping a pipe joint to be assembled and capable of sliding along the horizontal direction. The driving unit is used for driving the pipe to rotate. The pipe and the pipe joint are oppositely arranged at the same horizontal height, the pipe is fixed through the first fixing unit, and when the driving unit drives the pipe to rotate, the second fixing unit clamps the pipe joint to get close to the pipe, and the pipe is matched with the pipe joint. The threaded pipe assembly device has the advantages that a traditional pure manual assembly mode is converted into the one with the driving unit providing force, so that labor force is saved; the driving unit can provide force in electric, pneumatic modes and the like, the force provided by the driving unit is stronger as compared with that of human beings, tightening quality between the pipe joint and the pipe is higher, bayonet pliers used by workers are omitted, skid danger is avoided, and personal safety of the workers can be greatly guaranteed.

Owner:商丘市天路工程机械有限公司

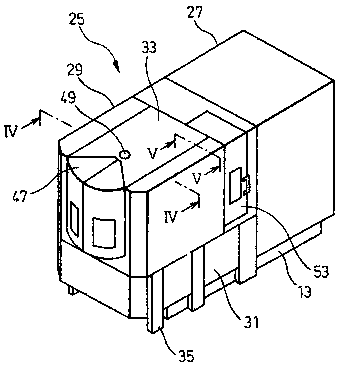

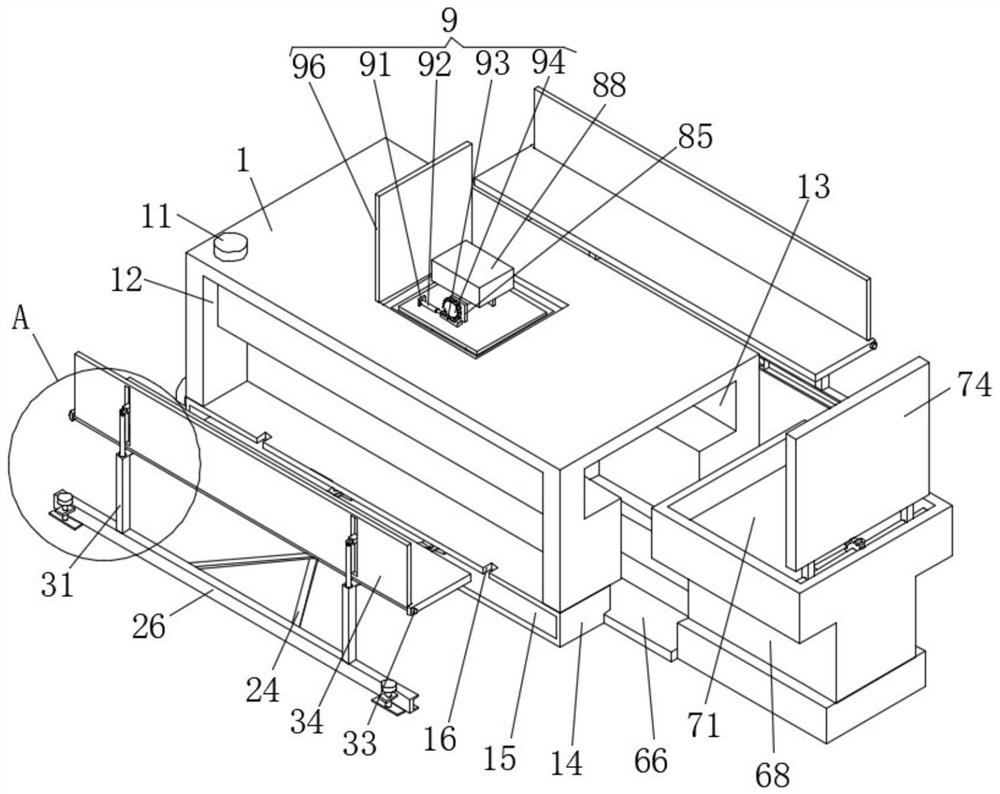

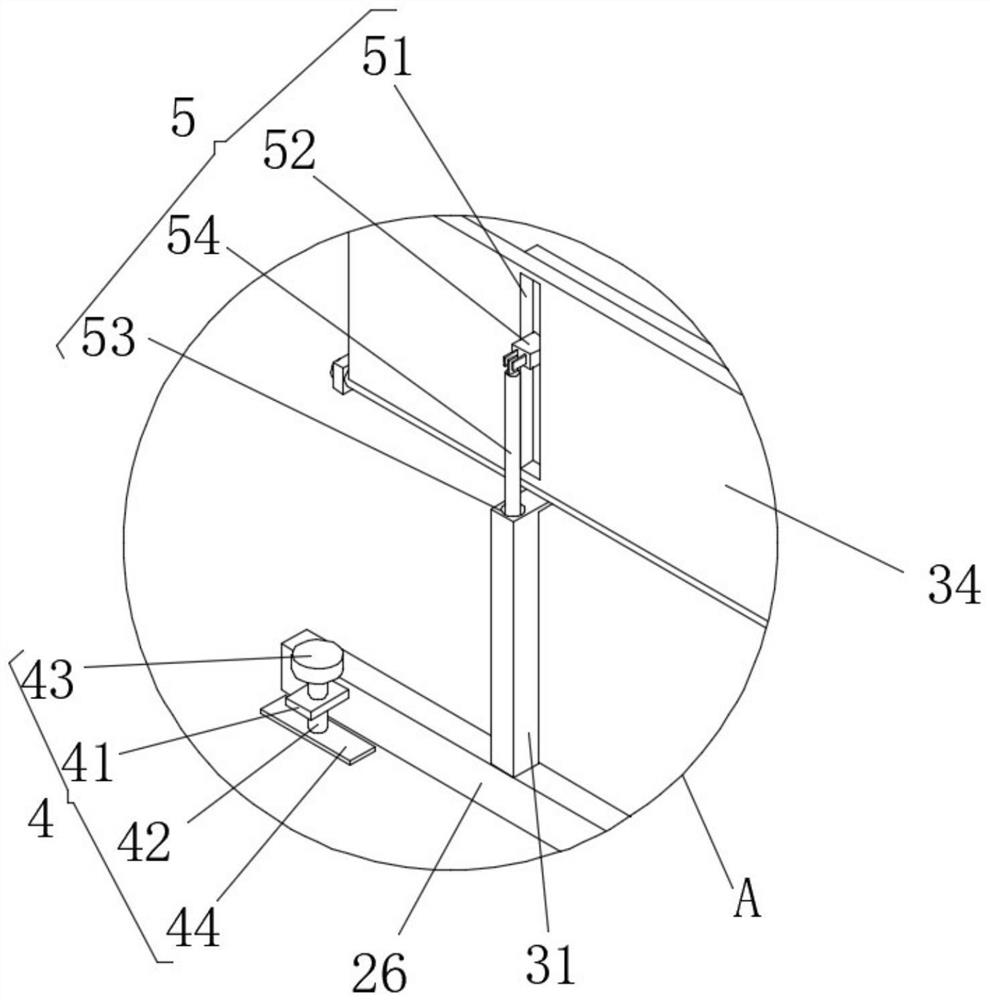

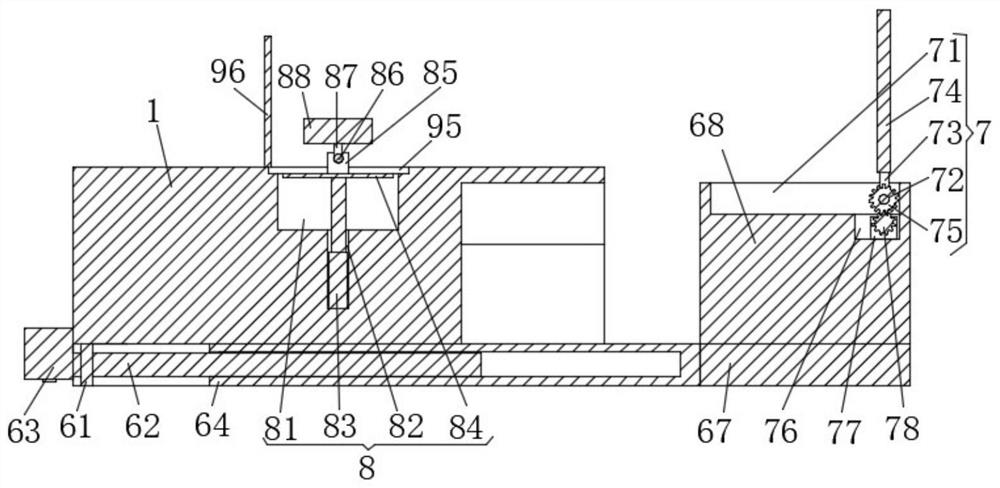

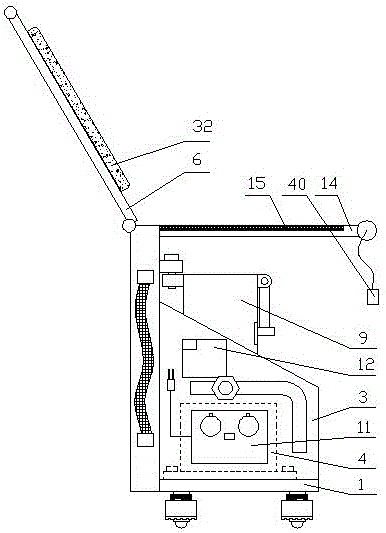

Machine tool protective cover with precision maintaining function

InactiveCN108326628AWeaken influenceMachining accuracy changesMaintainance and safety accessoriesFront coverEngineering

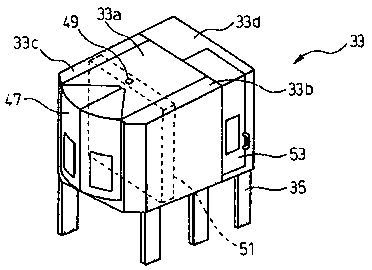

The invention relates to a machine tool protective cover with a precision maintaining function. The machine tool protective cover mainly comprises a front cover shell and a rear cover shell. The frontcover shell comprises lower coaming plates and an upper coaming plate disposed above the lower coaming plates, wherein a plurality of grooves are formed in the outer sides of the lower coaming plates, and supporting bosses are arranged on the inner sides of the lower coaming plates. Adjustable supports embedded in the grooves are arranged at the lower end of the upper coaming plate, and sealing pressing plates are arranged at the lower end of the upper coaming plate. By arranging elastic sealing elements on the supporting bosses, the upper coaming plate is embedded inside the lower coaming plates. The rear cover shell mainly comprises first guide rail protective covers which move in the horizontal direction in a telescopic mode and second guide rail protective covers which move in the vertical direction in a telescopic mode, a spindle head of a machine tool moves, and the first guide rail protective covers and the second guide rail protective covers act as sealing partition plates between a machine tool processing area and a machine tool stand column. The machine tool protective cover with the precision maintaining function reduces the deformation affecting the machine tool without increasing the installation space of the machine tool, allows the machine tool to maintain own inherent machining precision, and does not need to repeatedly perform machine tool debugging.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

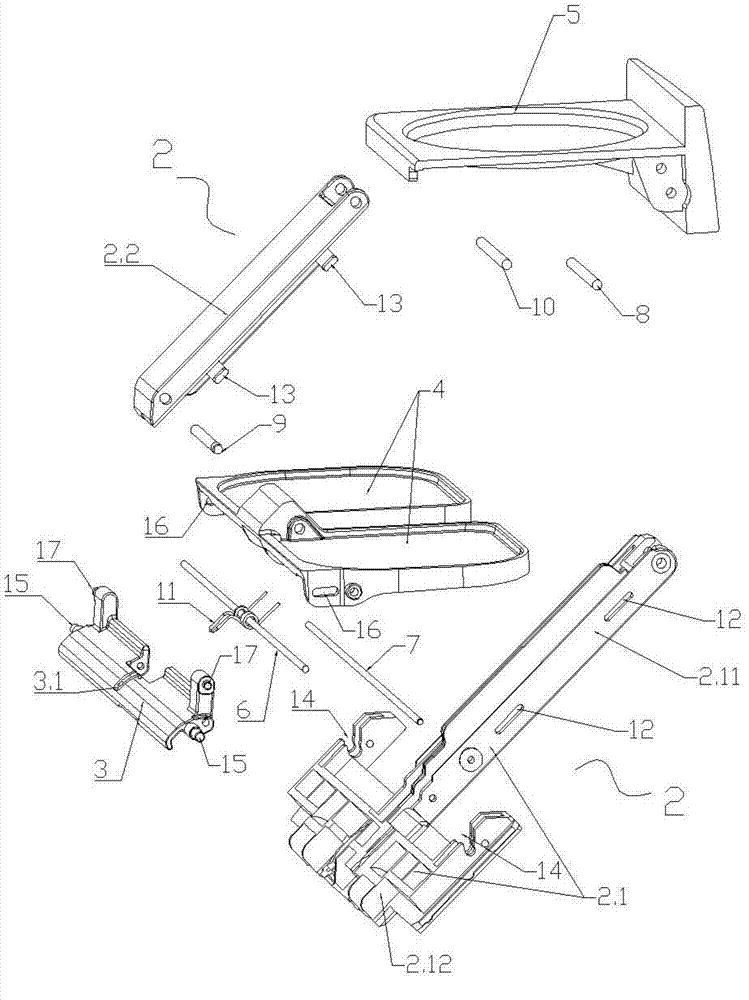

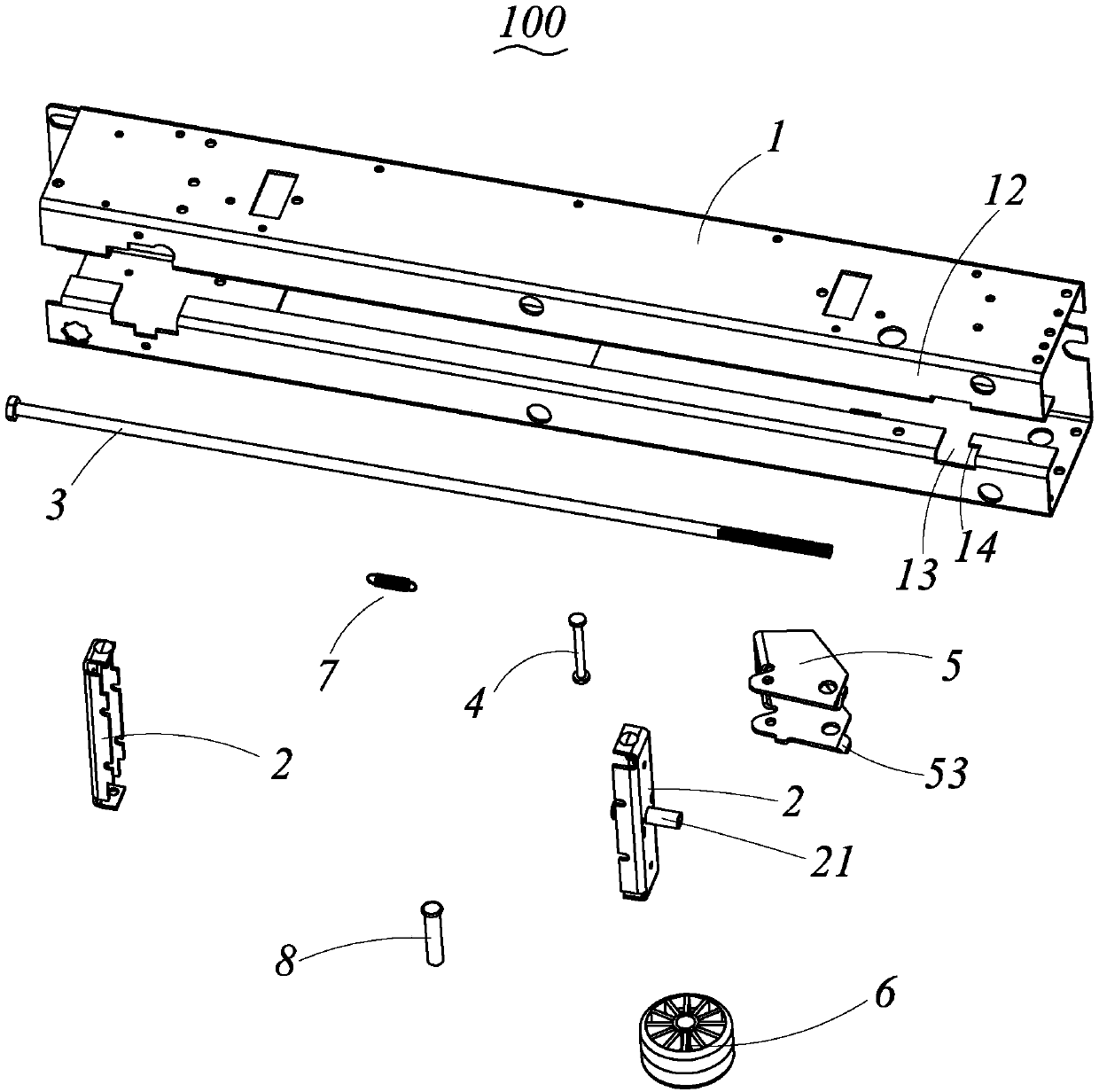

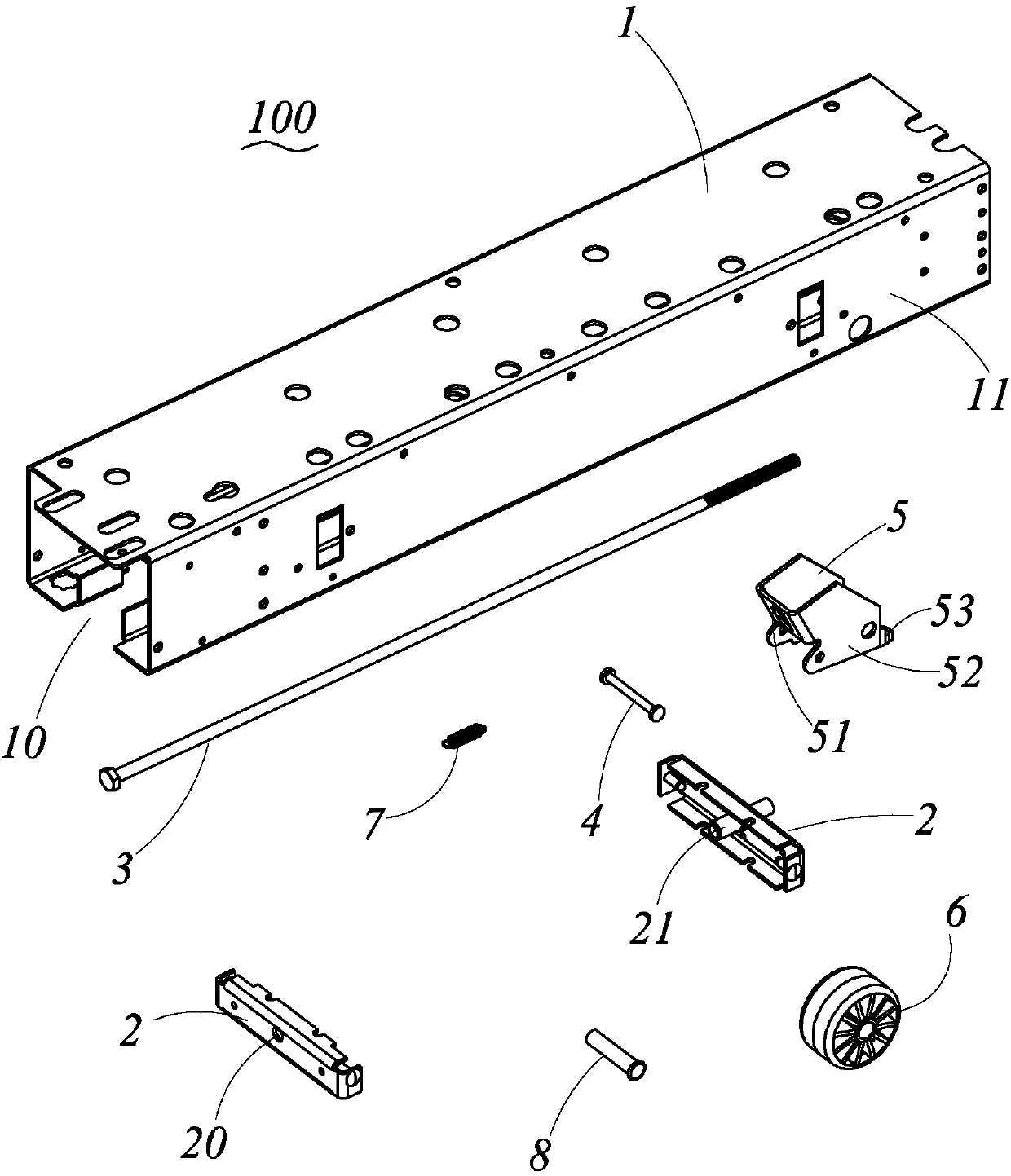

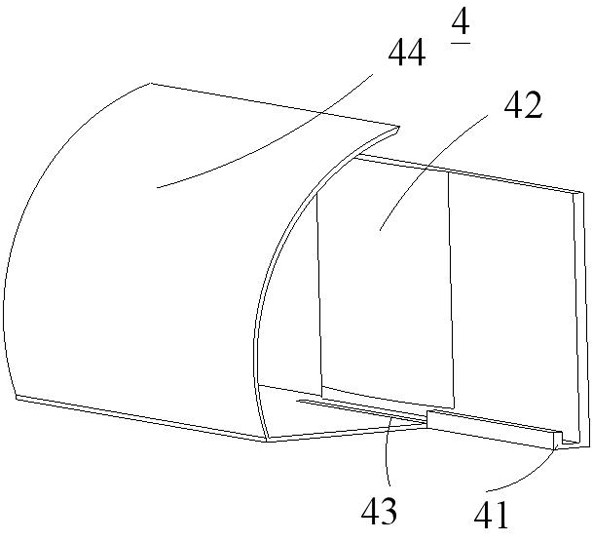

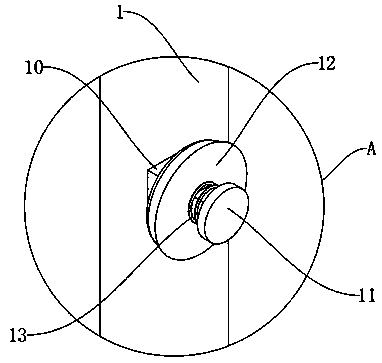

Saucer for vehicle

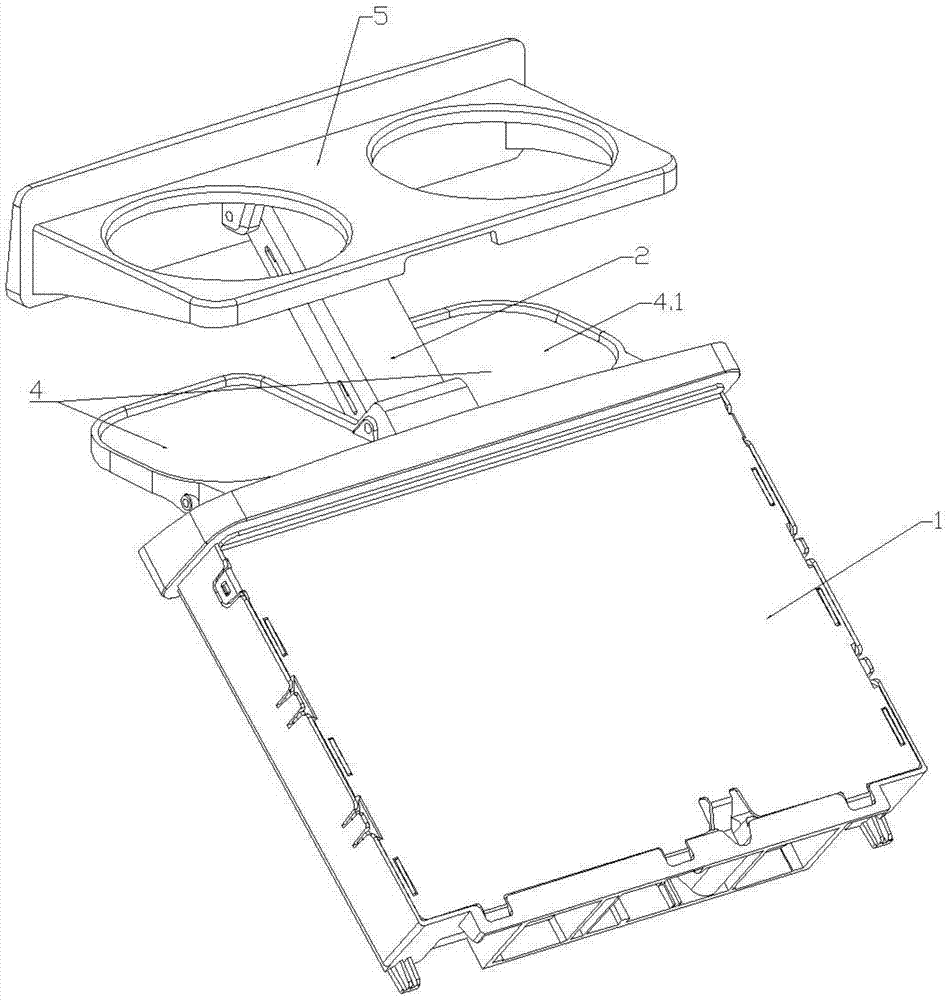

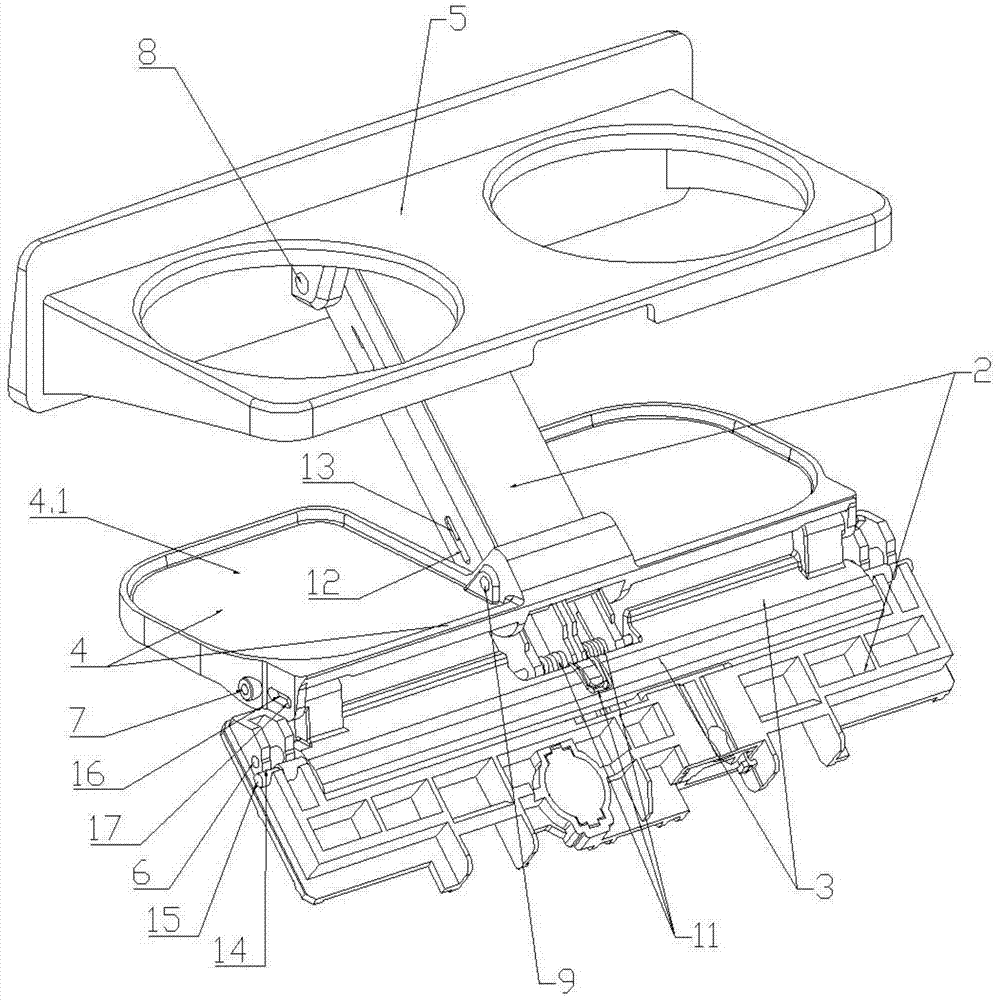

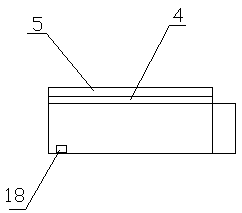

ActiveCN103786621AReduced horizontal installation distanceAchieve horizontal placementVehicle arrangementsEngineeringSaucer

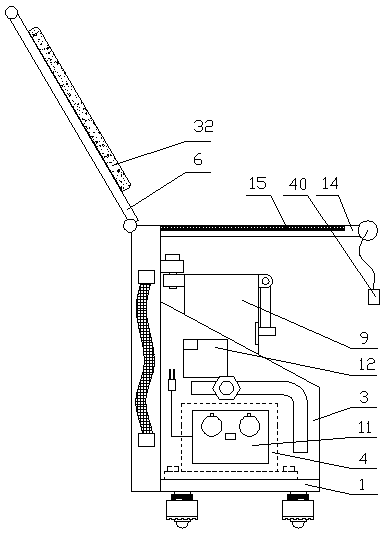

A saucer for a vehicle comprises a shell (1) and a bracket mechanism. The bracket mechanism comprises a saucer support (2), a hinge (3), a tray body (4) and a cup ring support (5). The saucer support (2) is composed of a lower sliding rod (2.1) and an upper moving rod (2.2). The hinge (3), the tray body (4) and the cup ring support (5) are rotationally installed on a longitudinal girder (2.11) of the lower sliding rod (2.1) through a first long shaft (6), a second long shaft (7) and a first short shaft (8). The tray body (4) and the cup ring support (5) are rotationally connected with the upper moving rod (2.2). The hinge (3) is in pivoted connection with a beam (2.12) of the lower sliding rod (2.1) and the tray body (4) through a first pivoting displacement structure and a second pivoting displacement structure. The first long shaft (6) is provided with a spring (11). The saucer for the vehicle can be installed obliquely so that the requirement for the installation position lacking in horizontal installation space can be met.

Owner:NINGBO SHUAITELONG GRP CO LTD

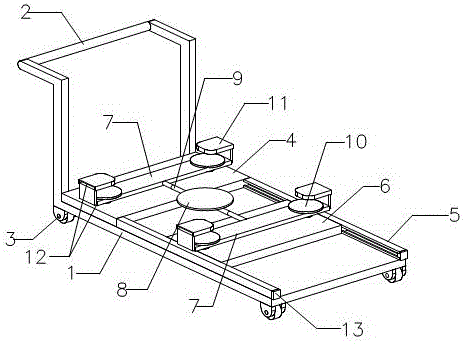

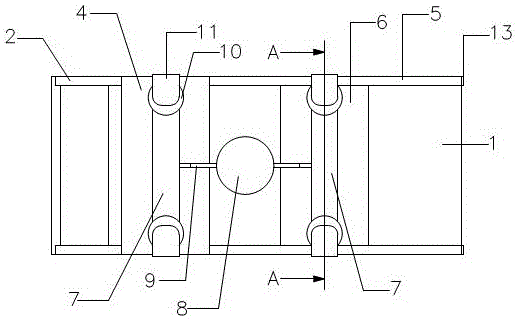

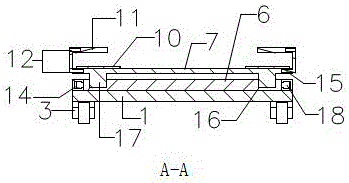

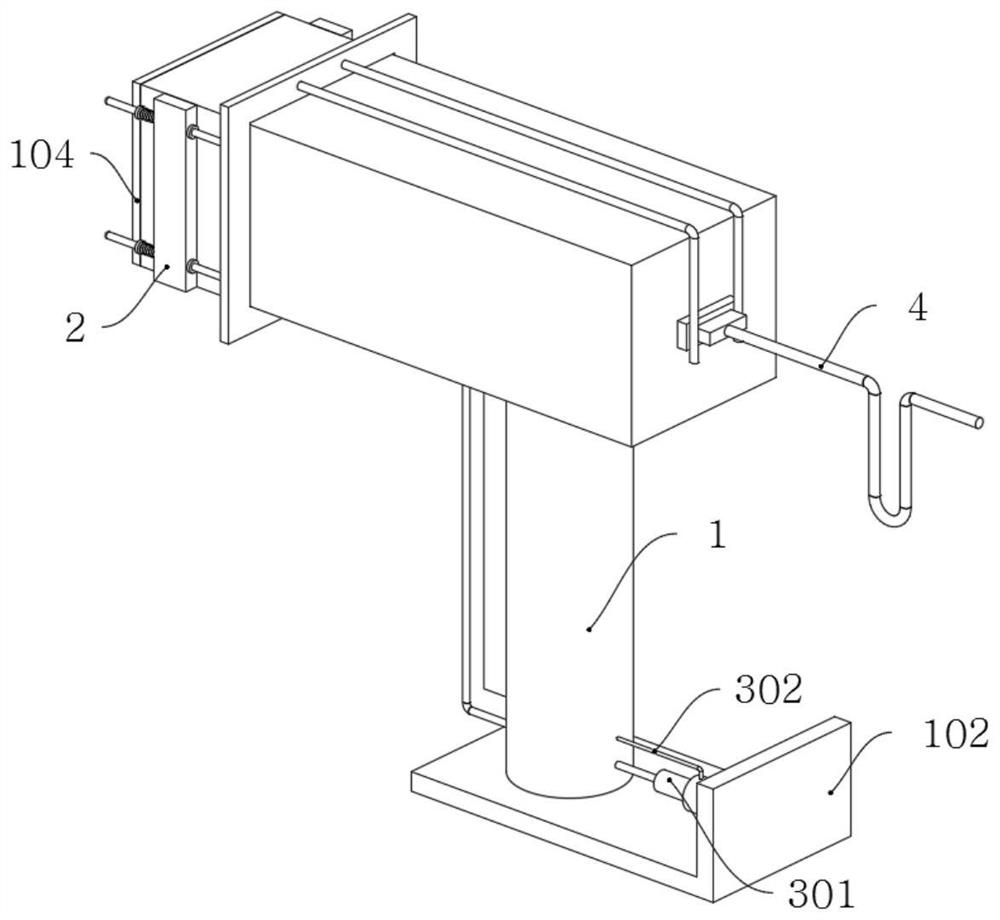

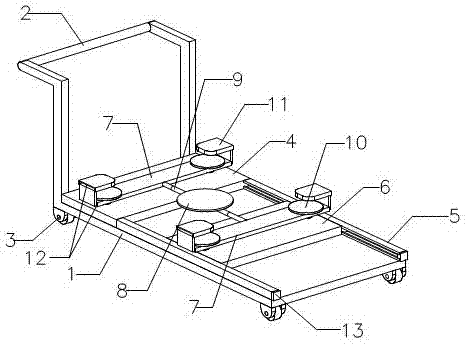

Glass curtain wall conveying trolley

ActiveCN105857365AAchieve horizontal placementRealize multi-layer overlaySledgesBuilding material handlingVehicle frameMultiple layer

The invention discloses a glass curtain wall conveying trolley which is provided with a plate type frame. A hand-push rod is arranged on the left side of the plate type frame, rollers are arranged at the bottom of the plate type frame, a main positioning base plate is arranged on the side, which is close to the hand-push rod, of the plate type frame, two symmetrical guide rails are arranged on the right side of the main positioning base plate, guide grooves are formed in symmetrical side surfaces of the guide rails, an auxiliary positioning base plate is arranged between the two guide rails, and guide sliders which are in slide fit with the guide grooves are arranged on the auxiliary positioning base plate; two supporting plates are respectively arranged on the main positioning base plate and the auxiliary positioning base plate and are connected with each other by a telescopic connecting rod, and symmetrical expansion brackets are arranged at the front end and the rear end of each supporting plate. The glass curtain wall conveying trolley has the advantages that the areas of the bottom supporting plates can be changed, and accordingly glass curtain walls with different sizes and areas can be horizontally arranged on the glass curtain wall conveying trolley; the glass curtain walls can be separated from one another by the expansion brackets, accordingly, multiple layers of glass curtain walls can be overlaid on one another, and the conveying efficiency can be improved.

Owner:常熟东南高新技术创业服务有限公司

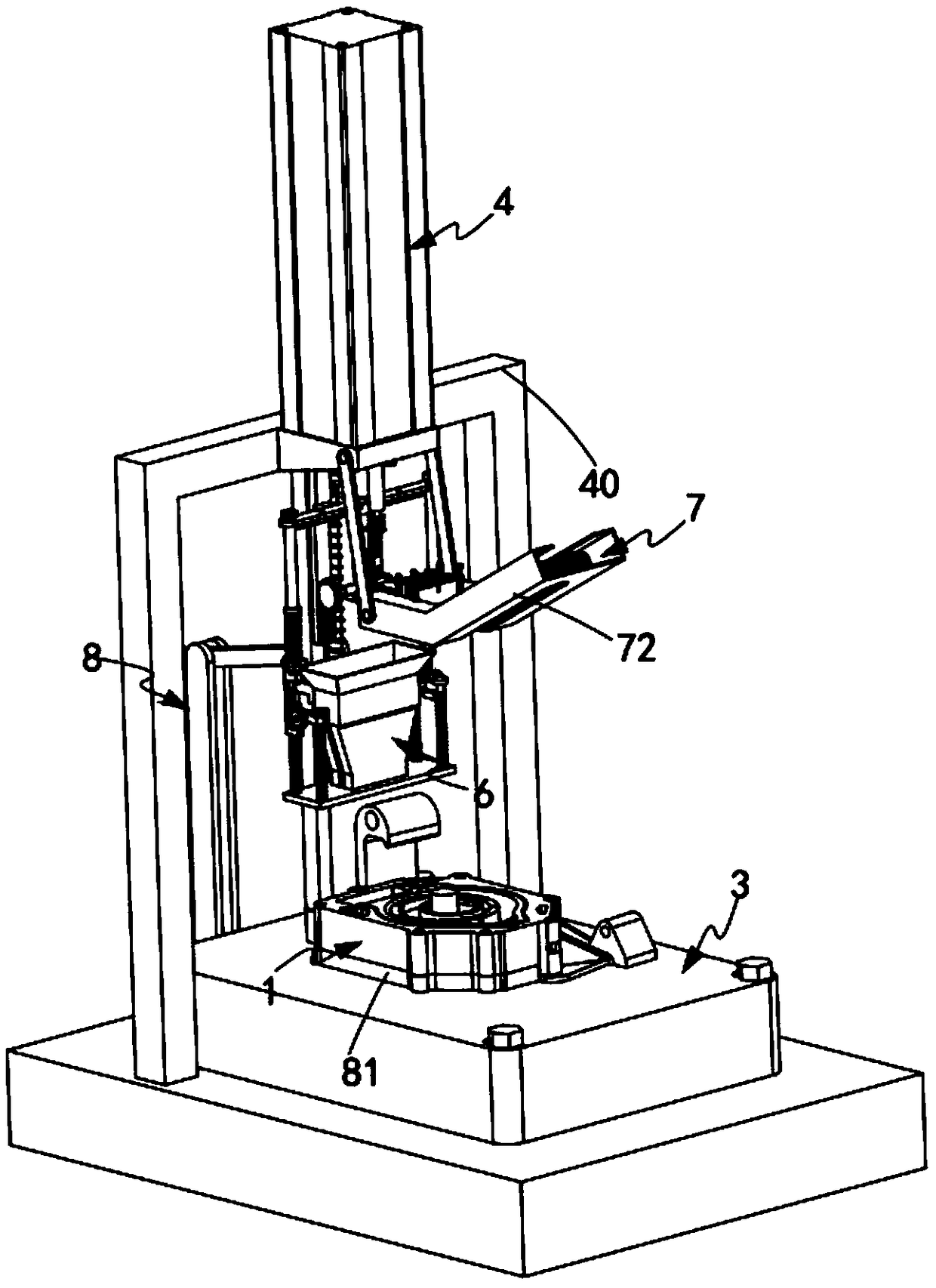

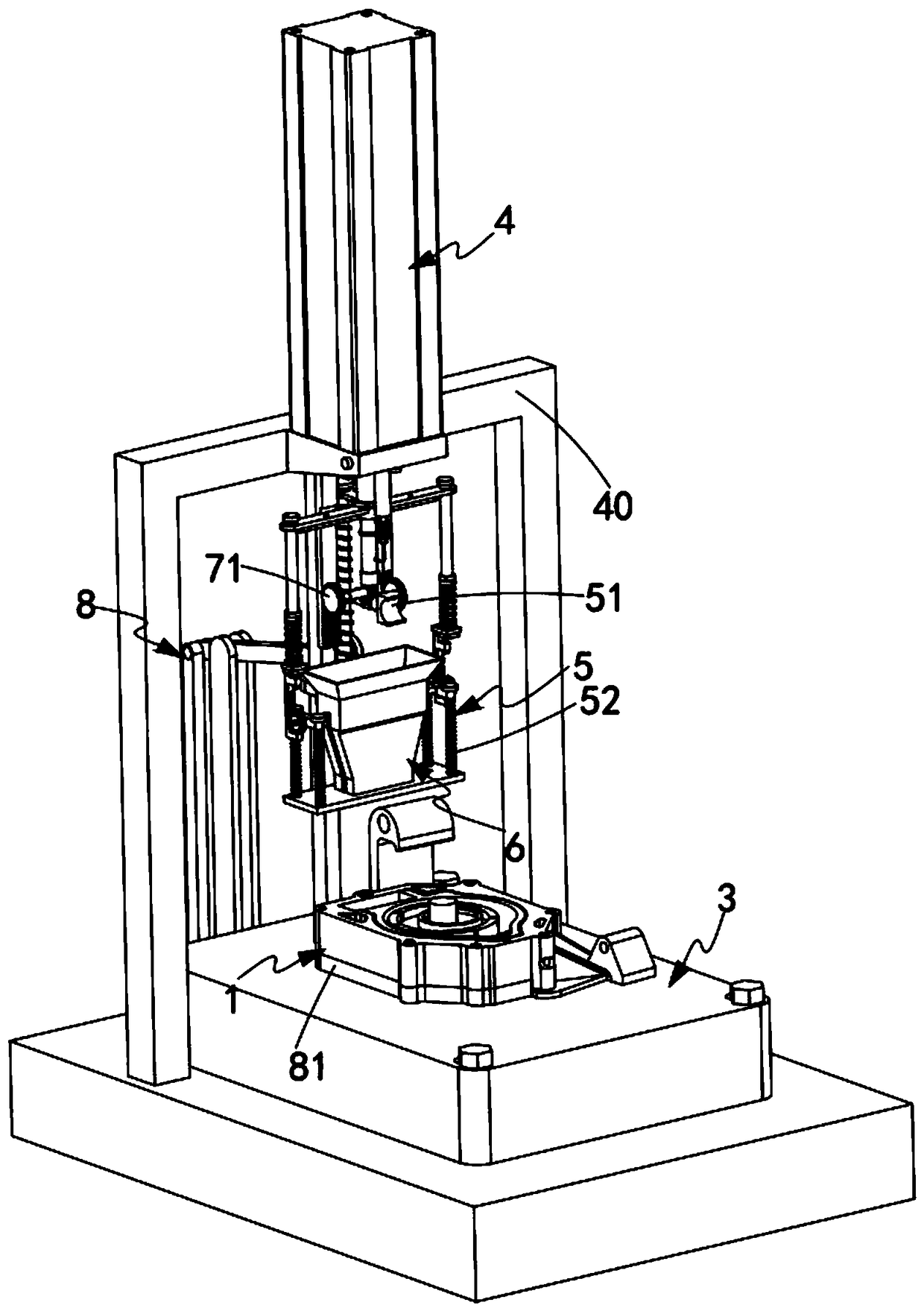

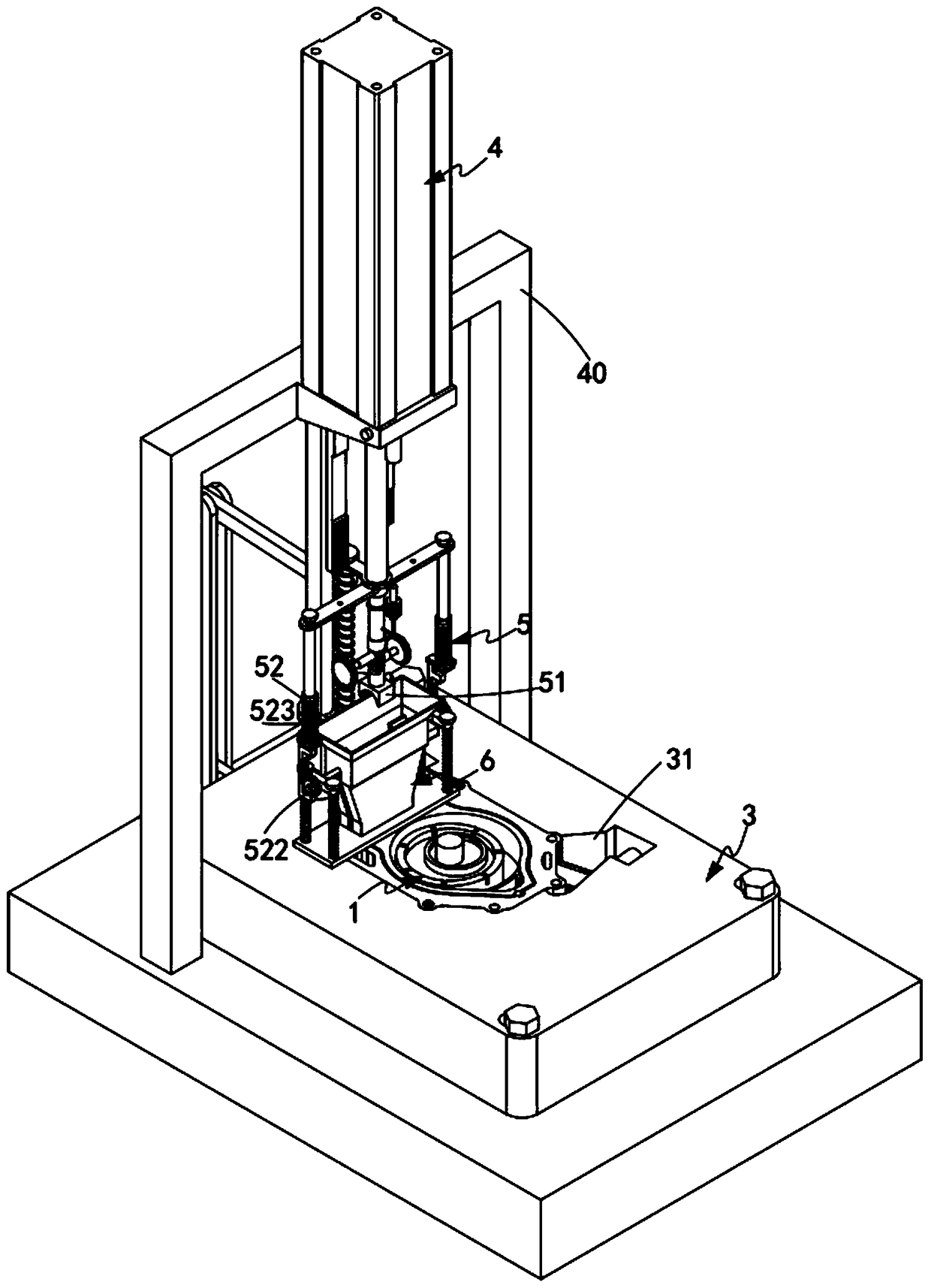

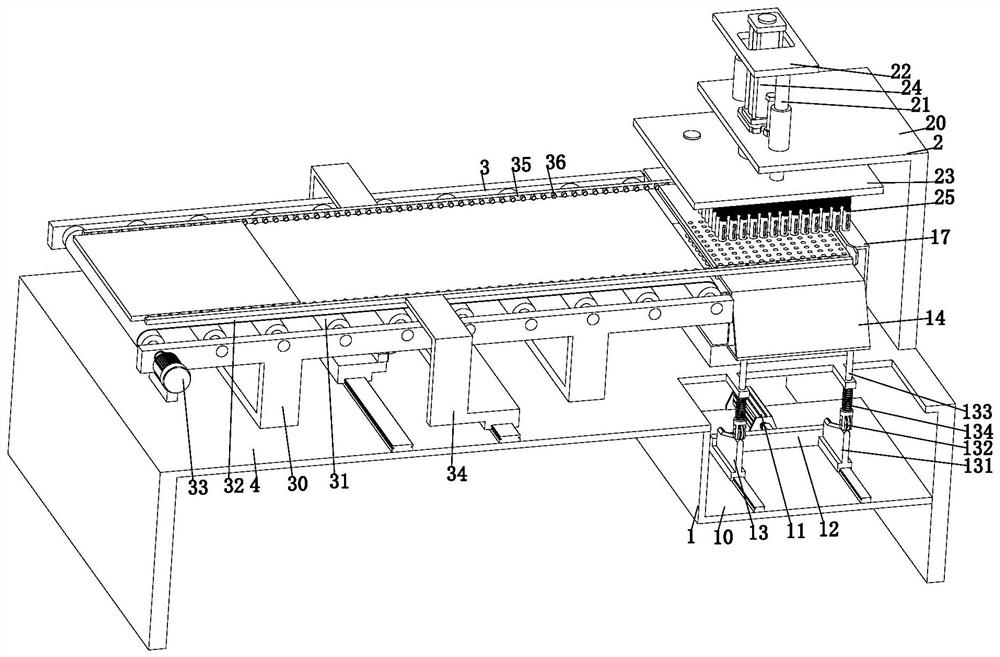

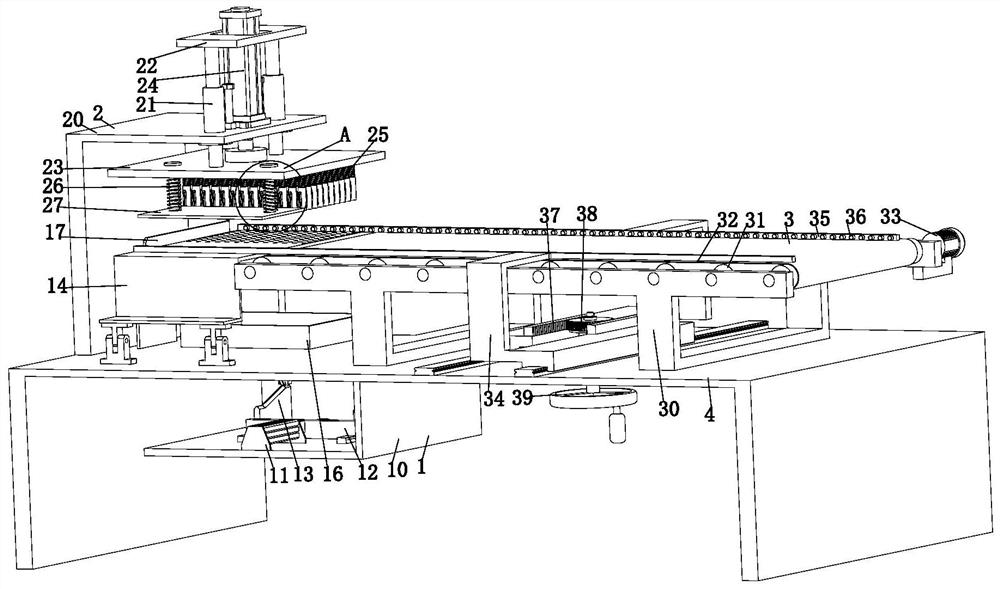

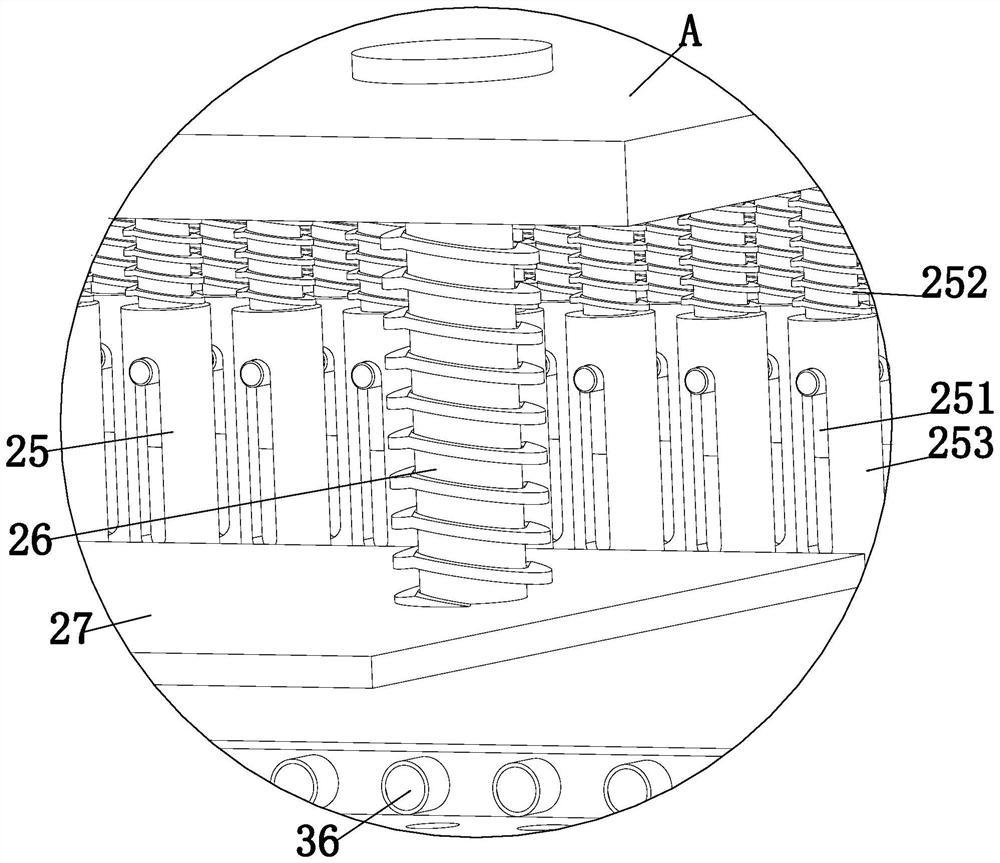

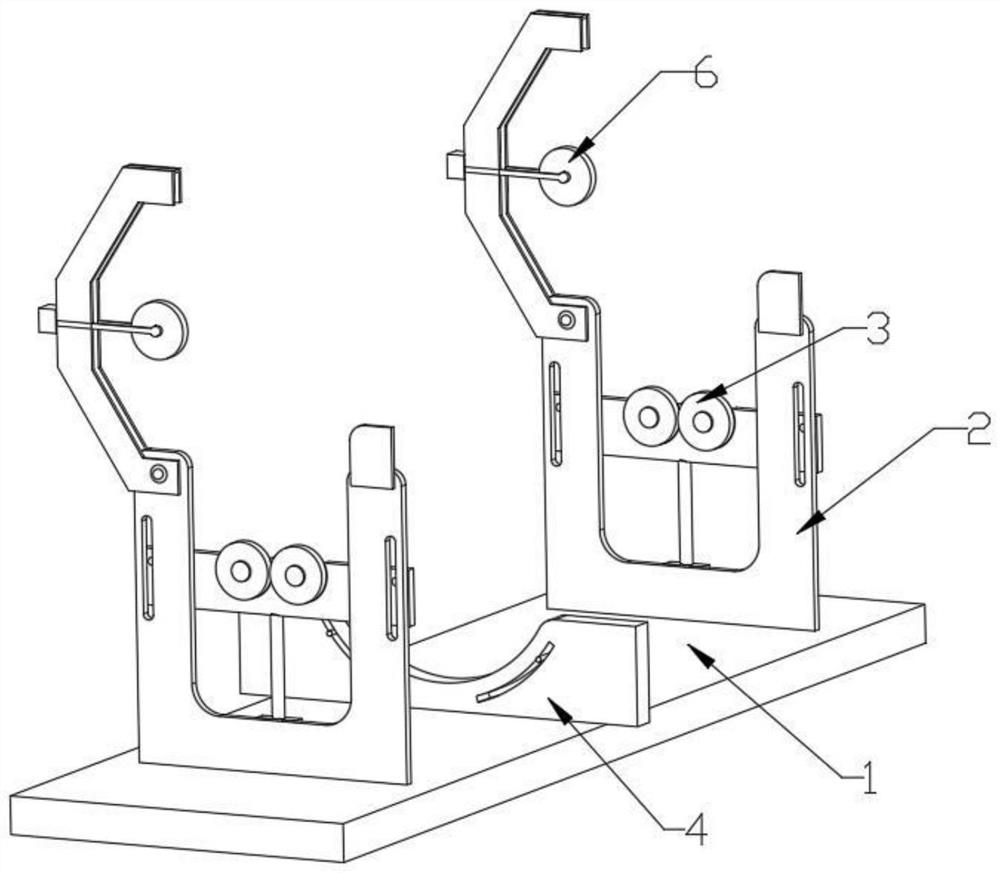

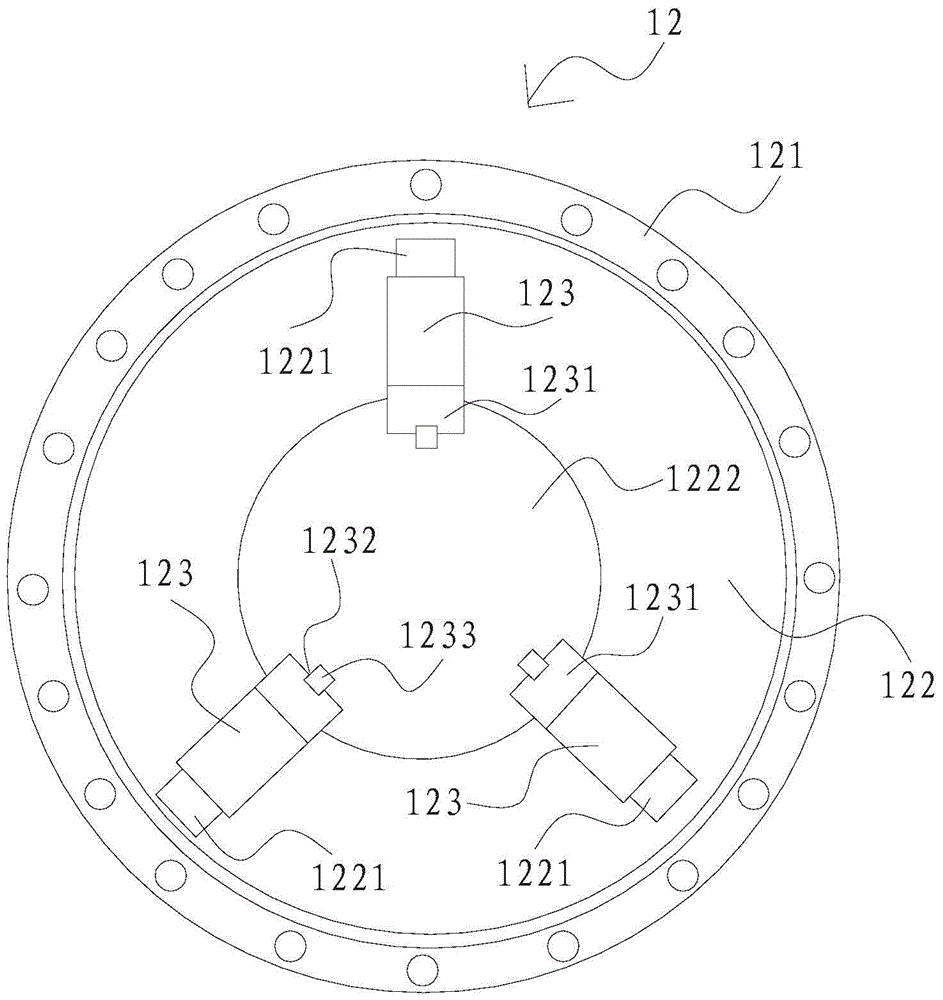

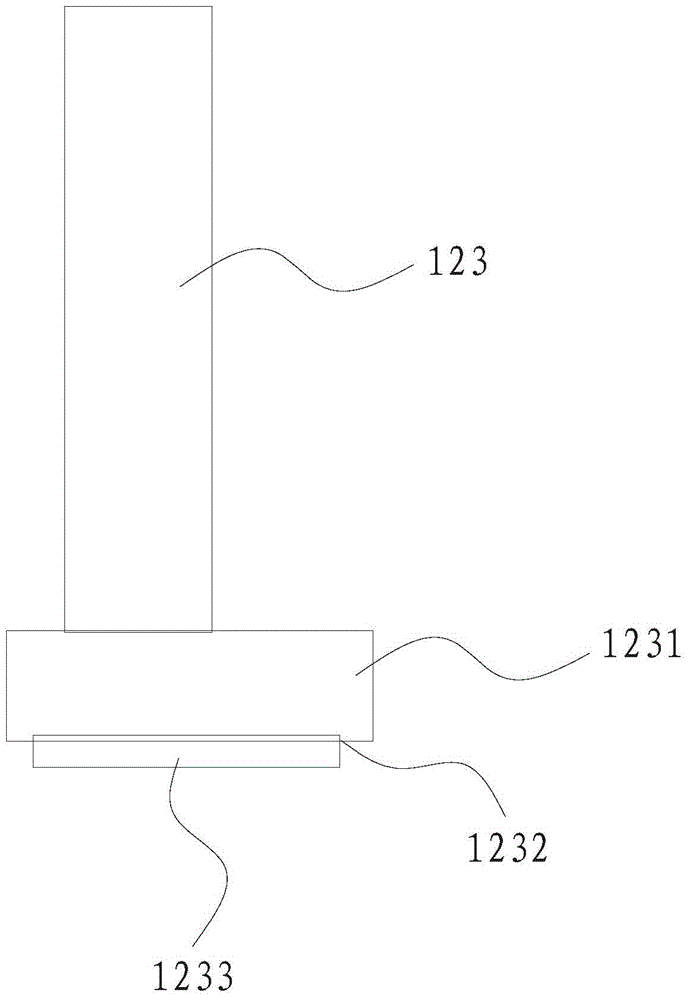

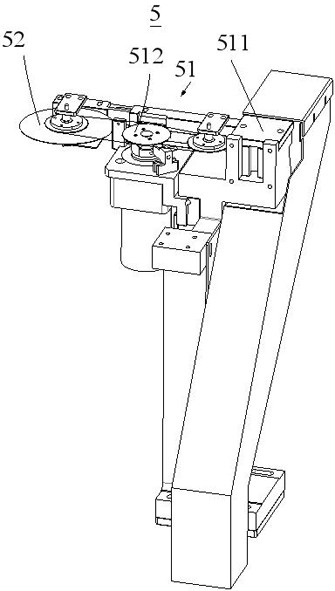

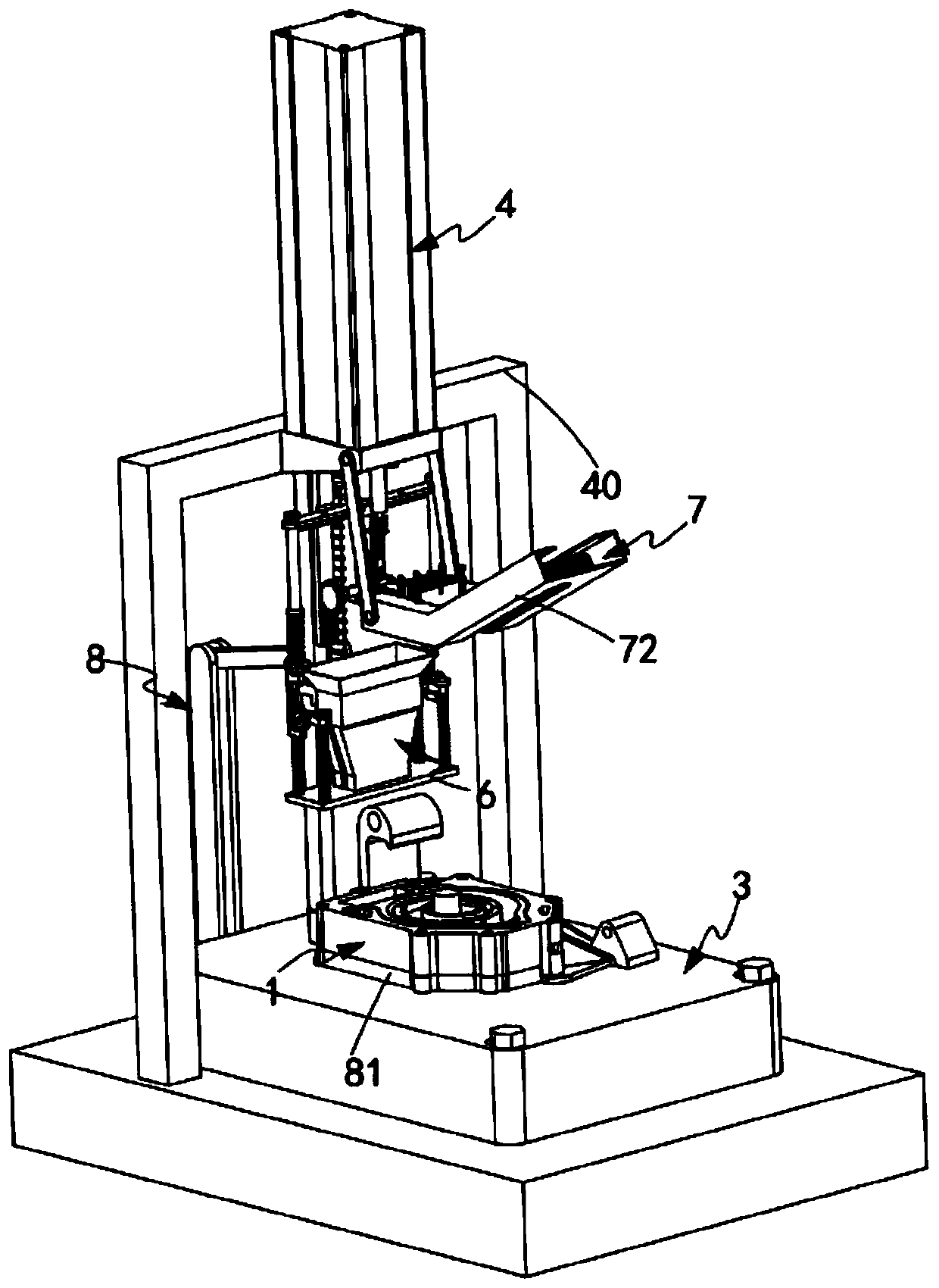

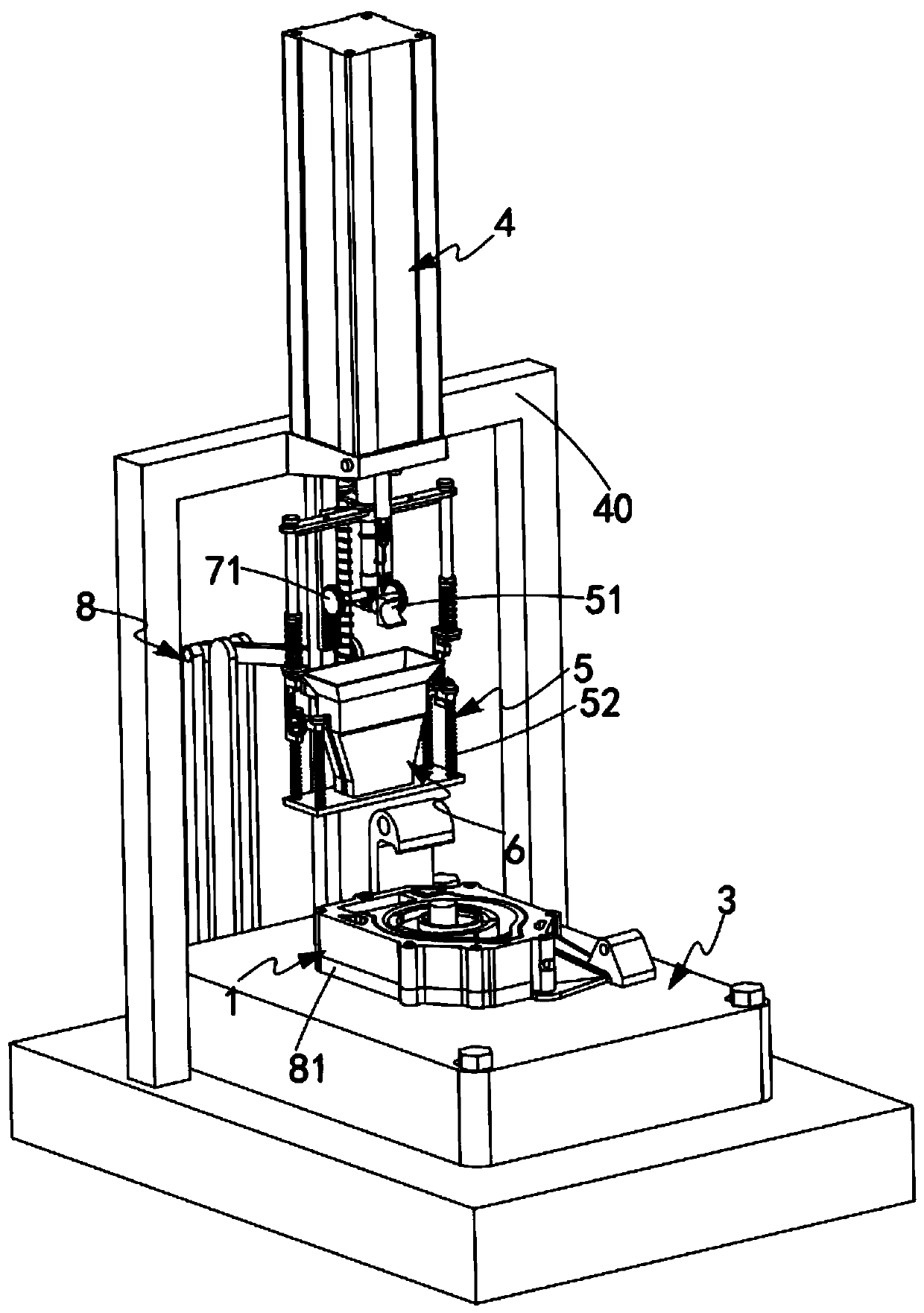

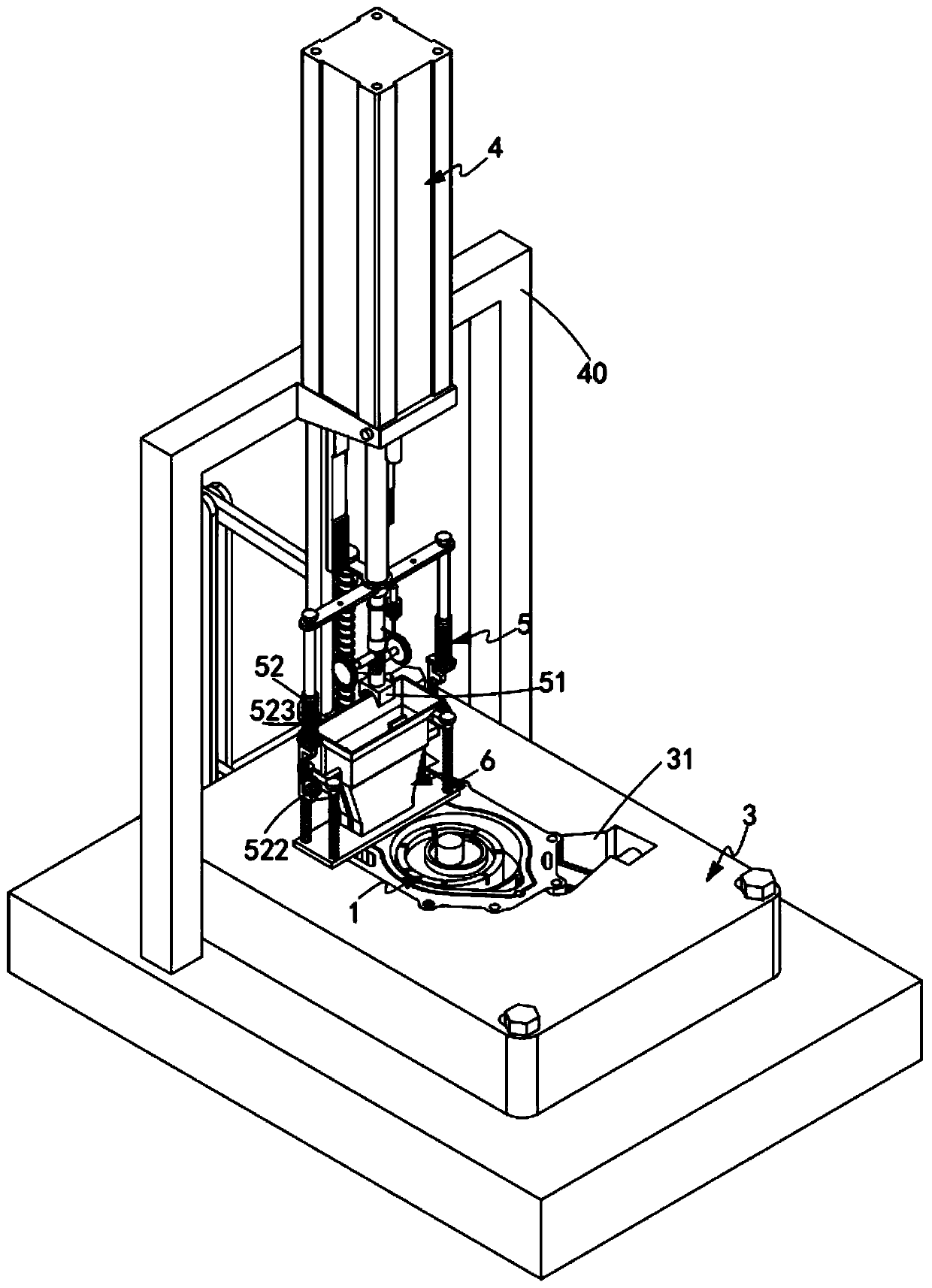

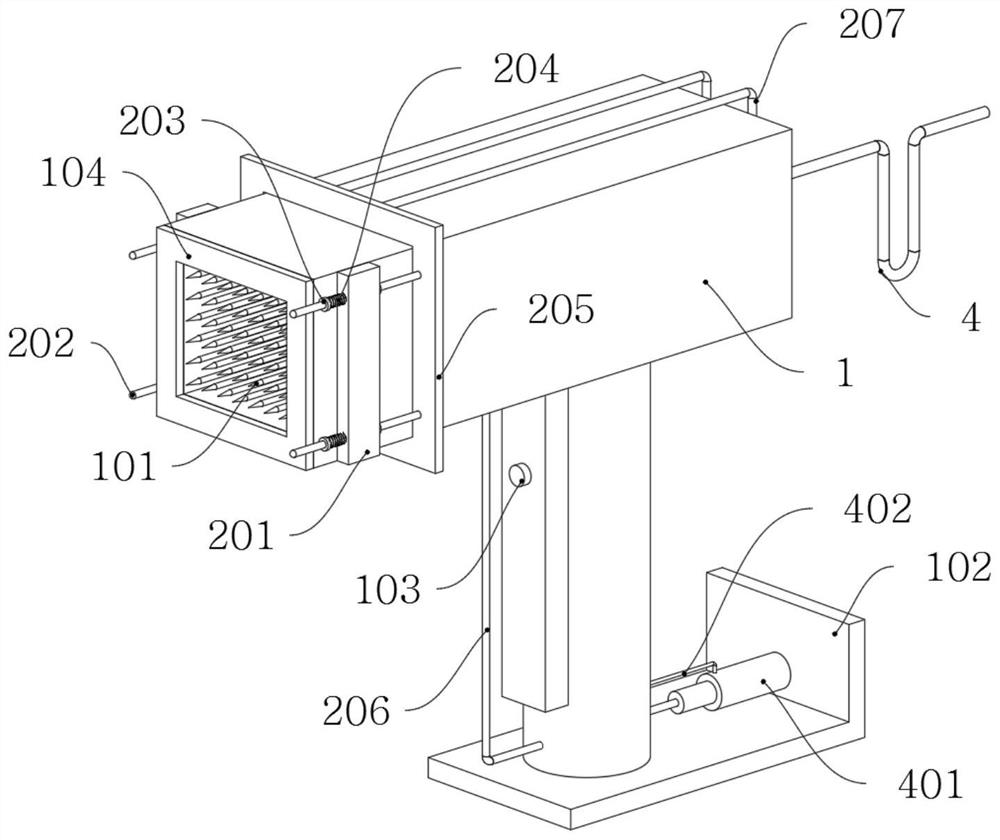

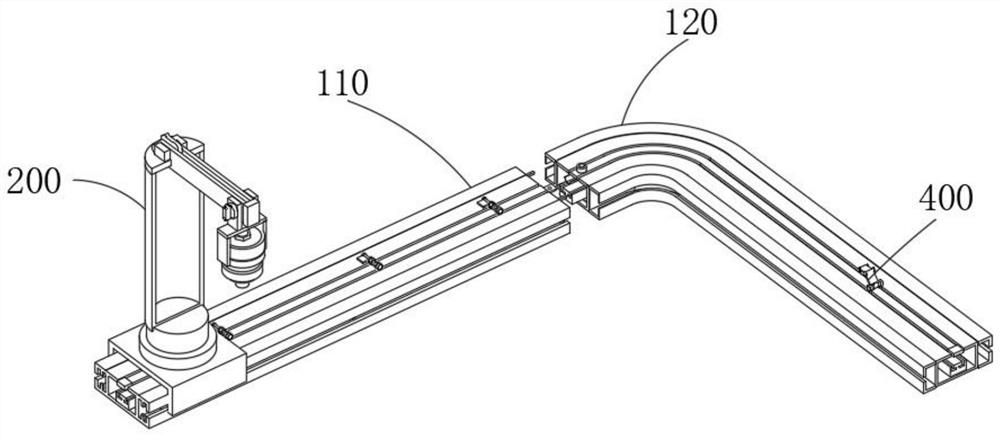

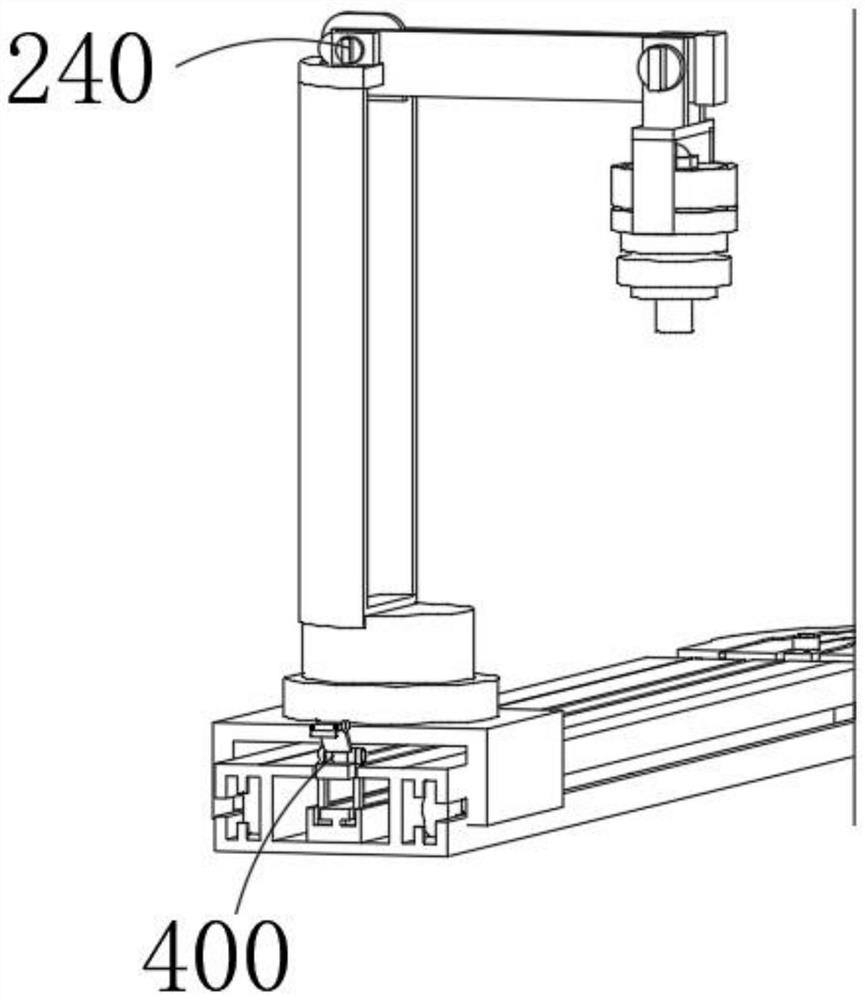

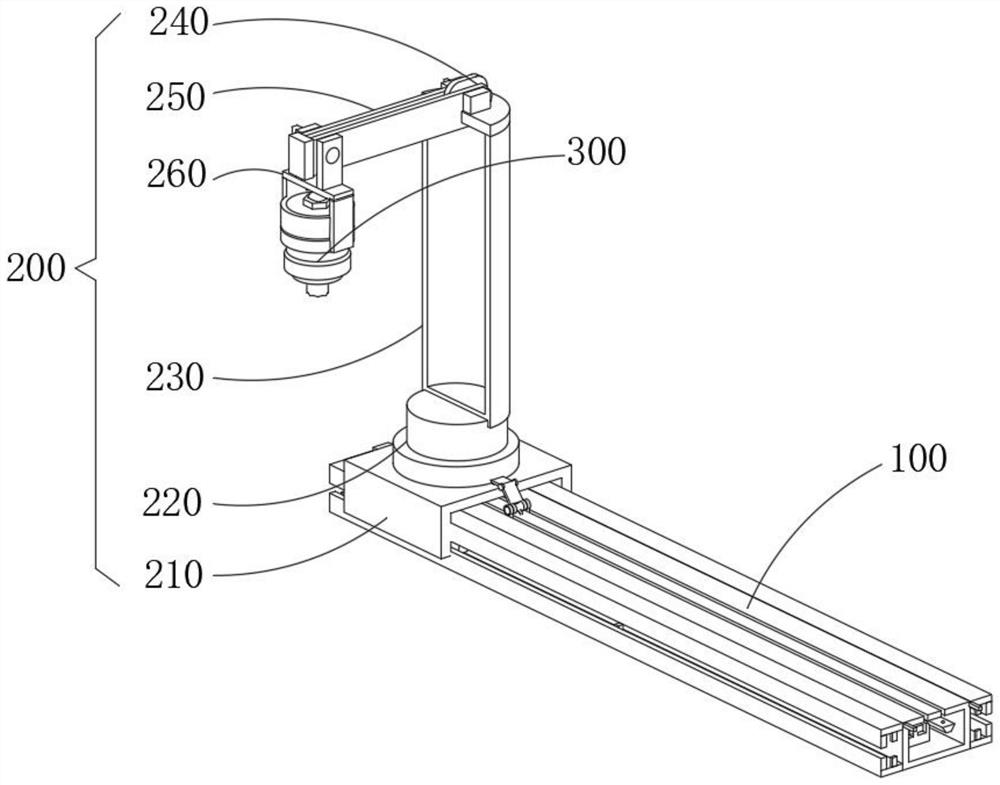

Automatic accurate assembling assembly for oil pump

ActiveCN109366141AAchieve horizontal placementImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic accurate assembling assembly for an oil pump. The automatic accurate assembling assembly for the oil pump comprises a base, an assembling cylinder, an extrusion mechanism, a compression groove and a rotary suction mechanism. The extrusion mechanism comprises an extrusion block and an overturning assembly. The rotary suction mechanism comprises a rotary assemblyand a discharging assembly. According to the automatic accurate assembling assembly for the oil pump, the extrusion block is rotatably connected to a pushing end of the assembling cylinder, and the extrusion block can rotate to be horizontal. After one-time assembling of oil pump springs and an oil pump shell, an oil pump cylinder retracts, and the extrusion block is driven to be horizontal by theoil pump cylinder; and besides, the extrusion block is magnetized through an electromagnet, and the oil pump springs output by the discharging assembly is sucked by the extrusion block. When the assembling cylinder pushes, the extrusion block is vertically arranged and loses magnesium; the oil pump springs fall onto a bearing base accurately; the technical problem of accurate feeding of the oil pump springs is solved; horizontal placement of the oil pump springs is achieved; moreover, the oil pump springs are fed automatically; and working efficiency is higher.

Owner:CHANGXING BEST MASCH CO LTD

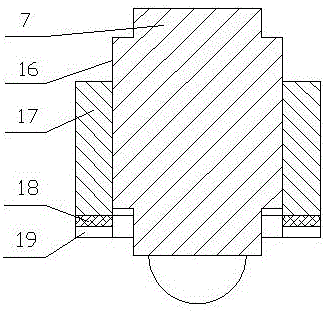

Height-adjustable corner supporting assembly, household appliance and adjusting method of supporting foot

ActiveCN107859815AThe adjustment method is simple and reliableAvoid leaningMachine framesDomestic cooling apparatusMechanical engineeringMethod of support

The invention provides a height-adjustable corner supporting assembly, a household appliance and an adjusting method of a supporting foot. The corner supporting assembly comprises the supporting foot,a fixed seat, an adjusting part rotationally fixed to the fixed seat and an adjusting rod cooperating with the adjusting part. The supporting foot is fixed to the adjusting part. The adjusting rod isarranged on the front side of the adjusting part in a manner of extending in the front-and-back direction and can achieve adjustment movement in the front-and-back direction. When the adjusting rod is subjected to backward adjustment movement, the adjusting rod can push the adjusting part to rotate, and then the supporting foot is driven to move downwards. By means of the arrangement, the heightof the rear end of the household appliance can be adjusted under the condition that the household appliance is not moved out, and therefore the problem that the household appliance is inclined due toground flatness is avoided, horizontal placement is achieved, safety and reliability are achieved, and accuracy is high.

Owner:HAIER SMART HOME CO LTD

Air purifier shell filtering hole forming machining device

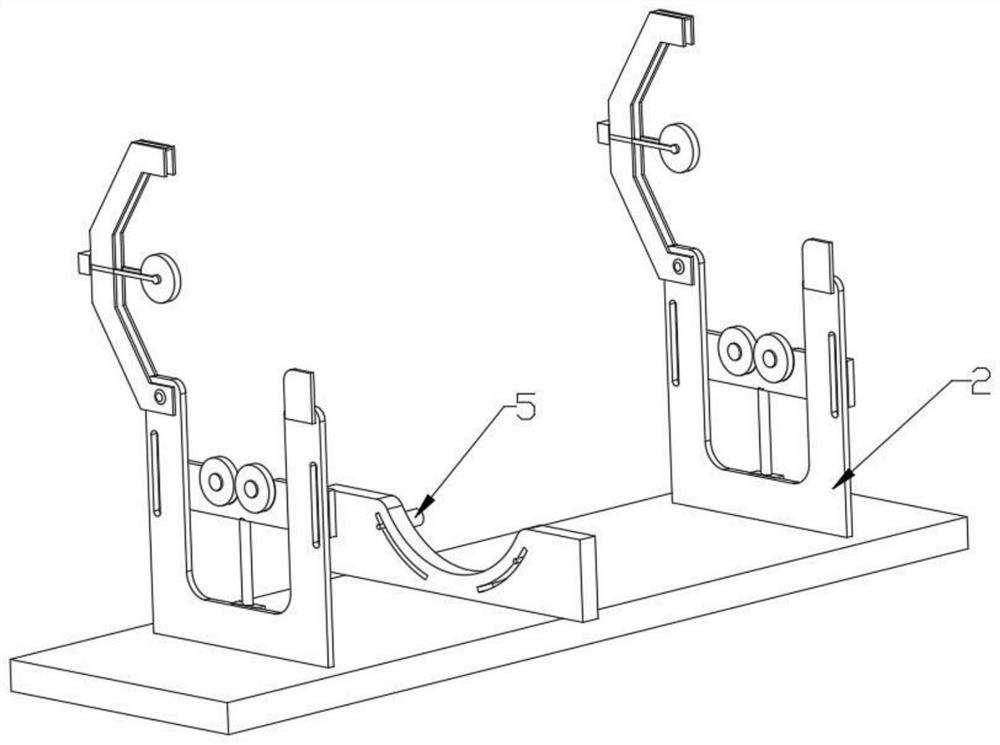

InactiveCN113001662AAchieving Synchronized Pitch ShiftingReduce frictional resistanceMetal working apparatusAir purifiersEngineering

The invention provides an air purifier shell filtering hole forming machining device which comprises a discharging mechanism, a stamping mechanism, a conveying mechanism and a main beam support, the conveying mechanism and the stamping mechanism are installed on the main beam support, the discharging mechanism is arranged between the conveying mechanism and the stamping mechanism, and the discharging mechanism is mounted on the main beam support. The air purifier shell filtering hole forming machining device solves the problems that the filter holes in the shell of the air purifier are formed in a blanking manner at present, and are not well fixed in advance and then punched in the forming process, so that the filter holes of the shell are formed in a non-circumferential manner, the hole pattern size is deviated, more burrs are caused, in addition, the shell is prone to being damaged due to too large pressing force in the pressing and fixing process, the production cost is increased, the punched shell needs to be manually collected and taken, and the shell filtering hole forming efficiency is low.

Owner:王晓寅

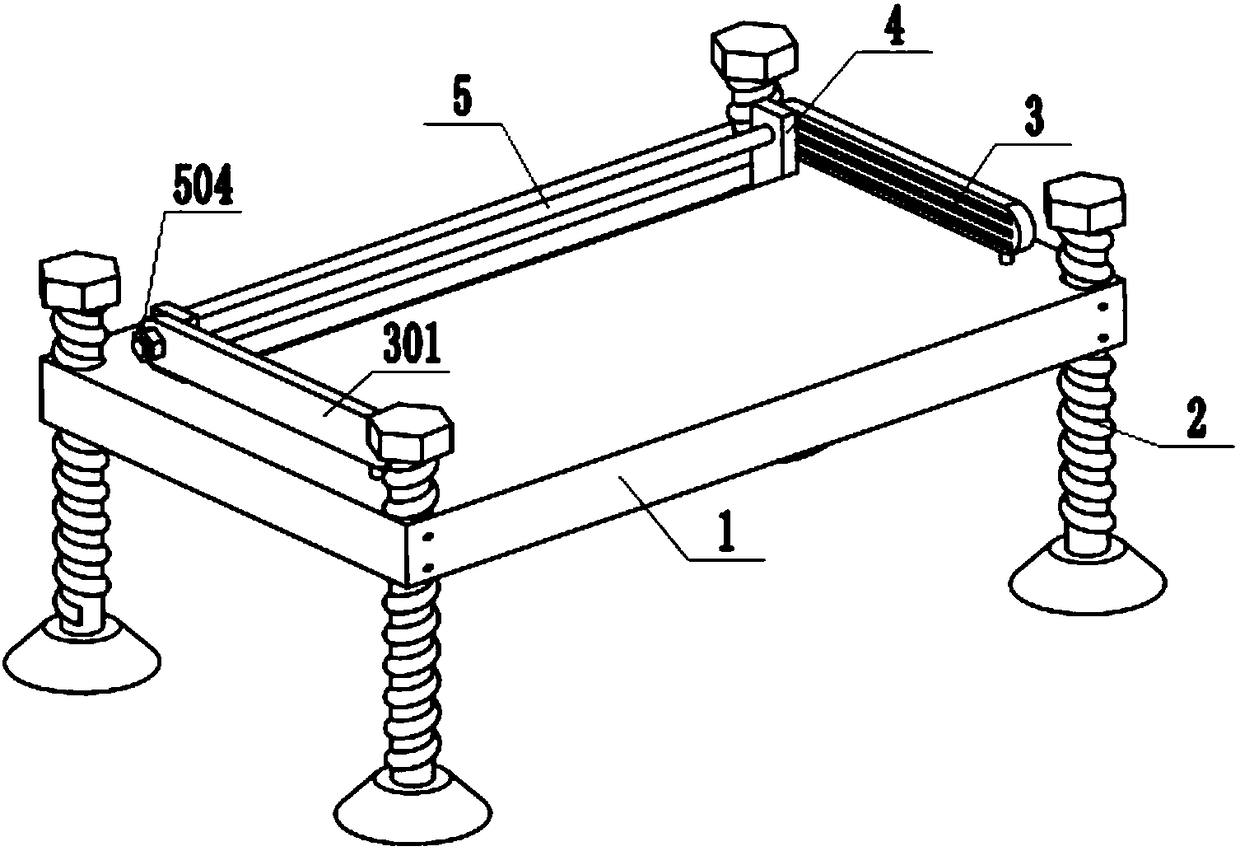

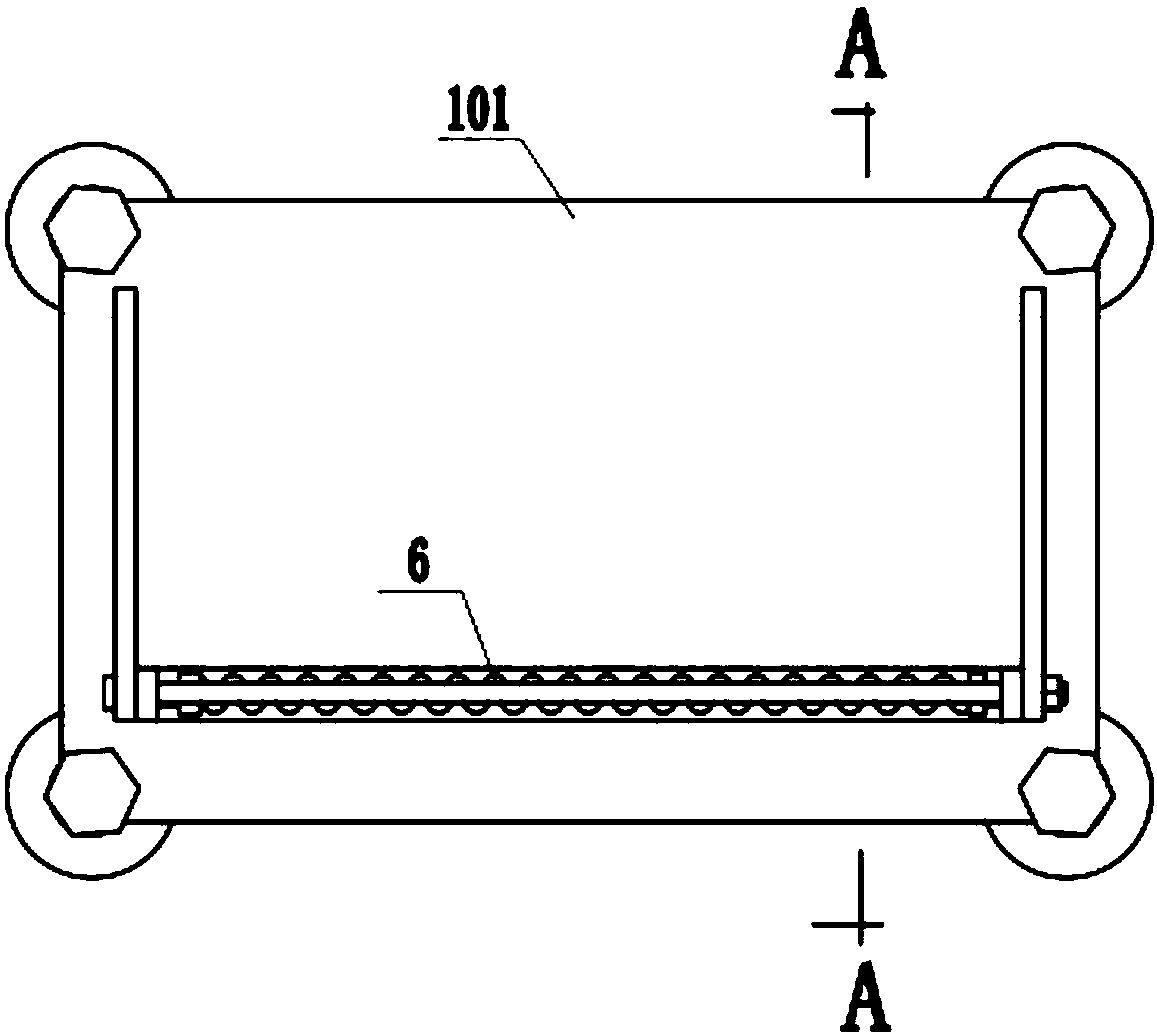

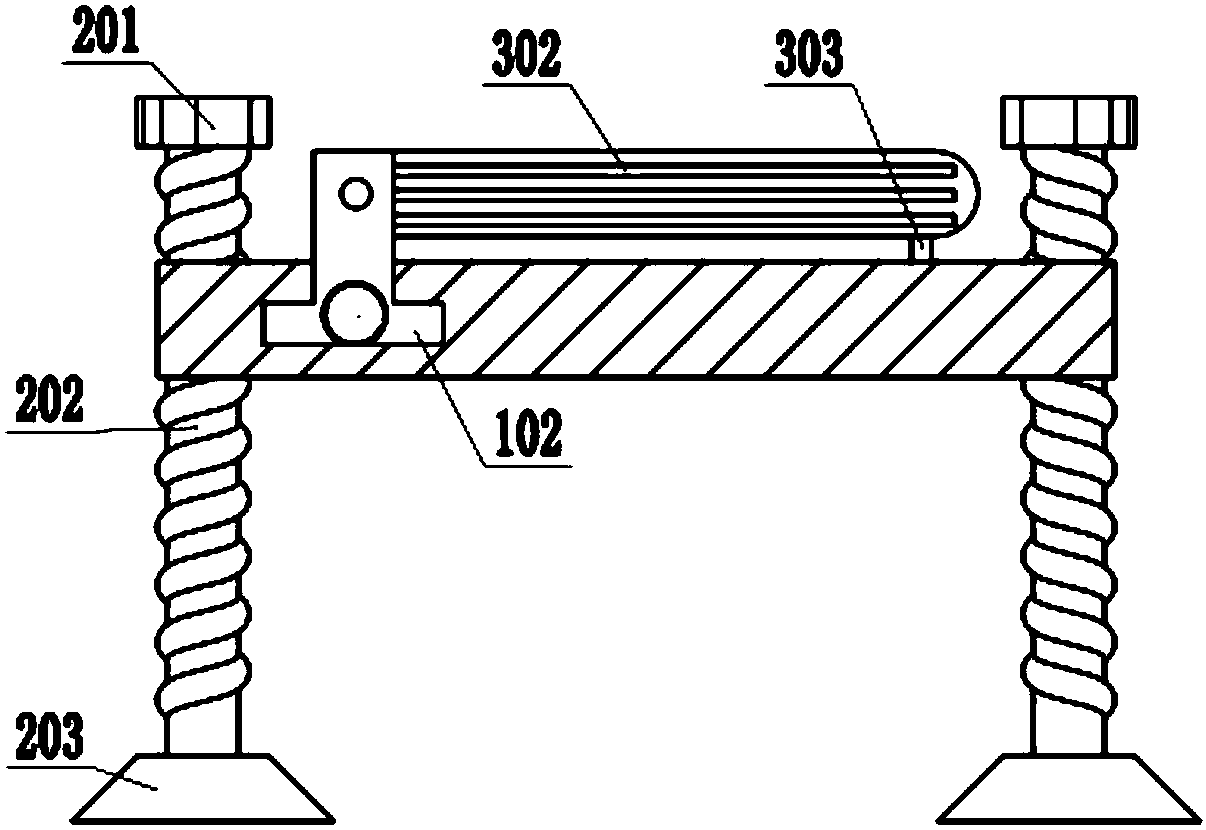

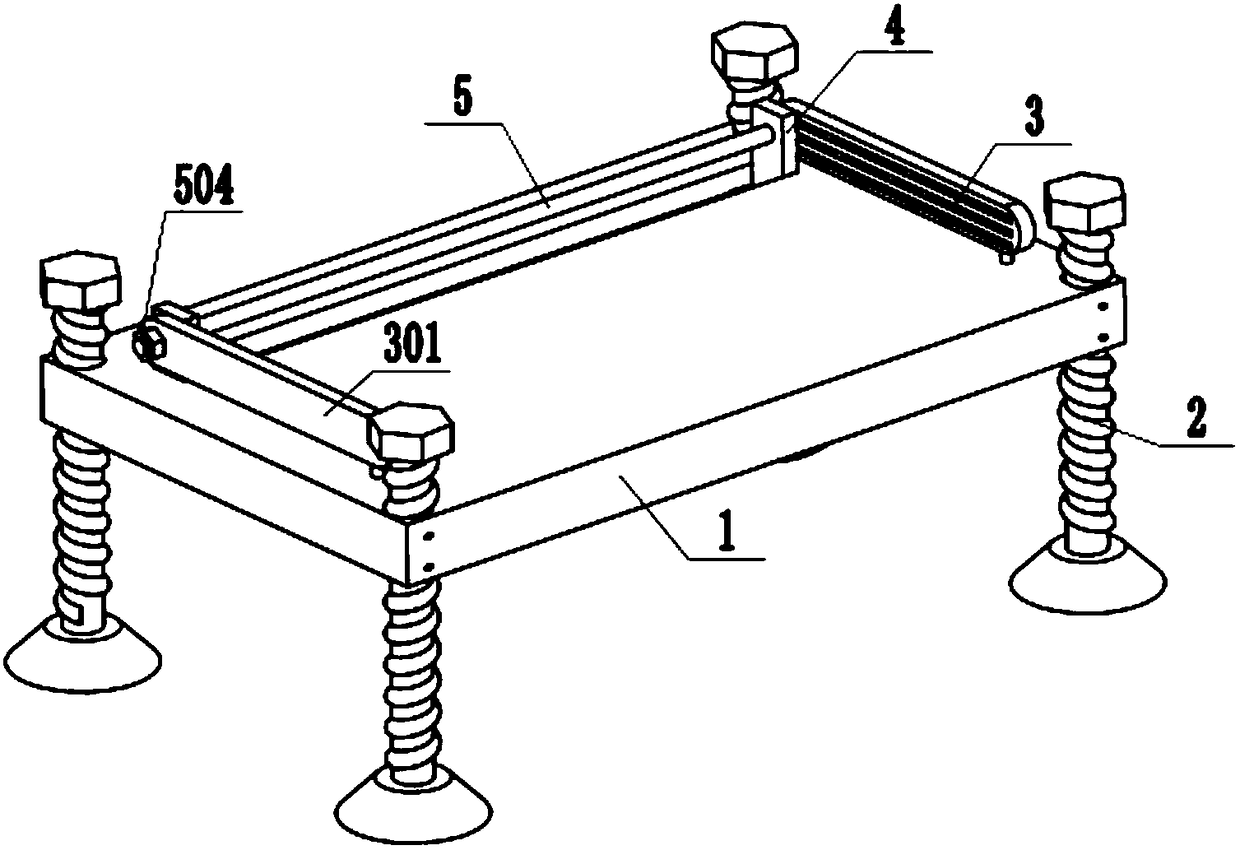

Installation method and application method of electronic component assembly support

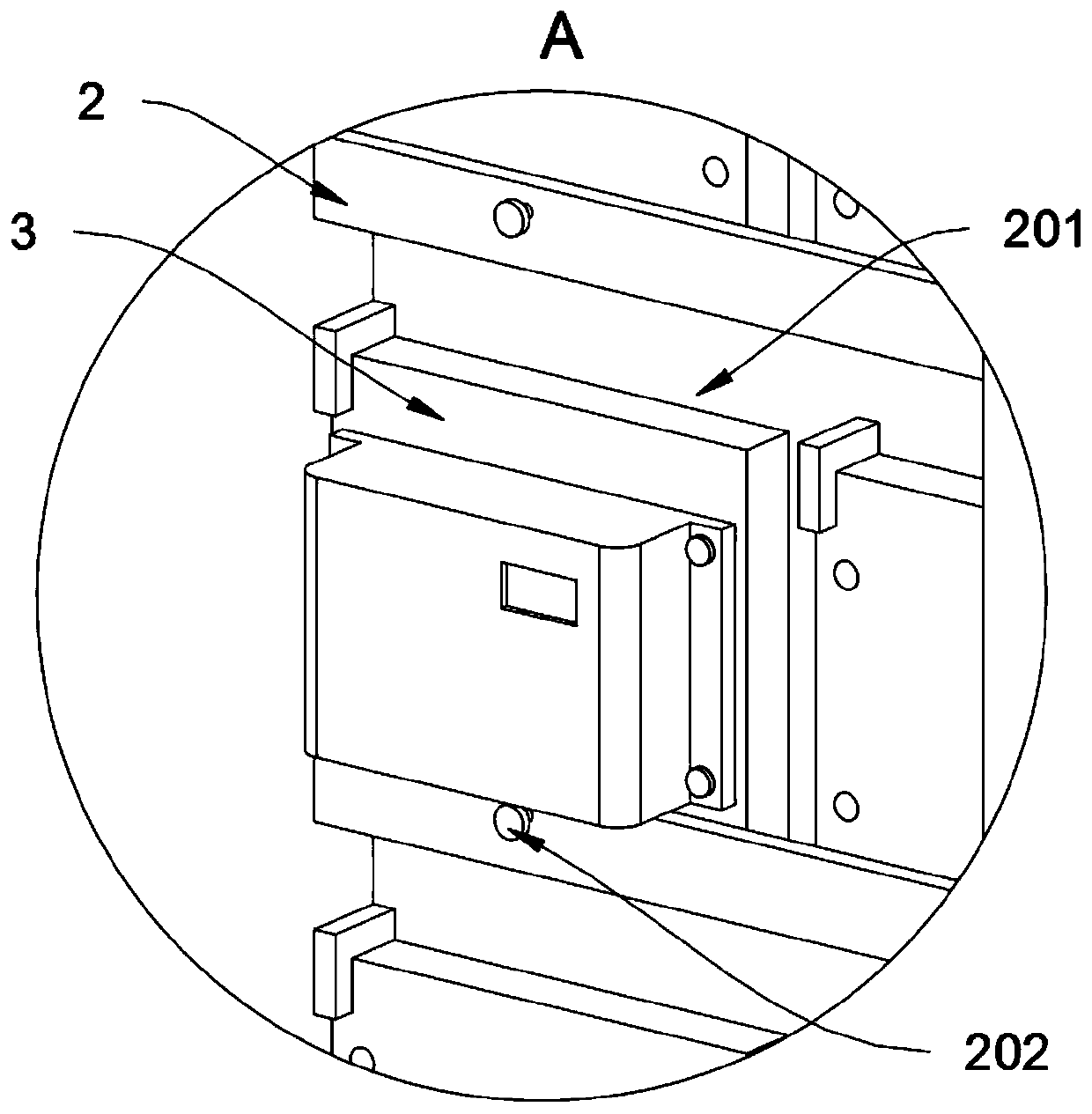

InactiveCN108495480AEasy to installAchieve clampingPrinted circuit assemblingElectrical componentsEngineeringElectronic component

The invention discloses an installation method of an electronic component assembly support. The installation method comprises the steps of S1, clamping a circuit board by a clamping plate 3; S2, rotating an angle of the circuit board, and fixing the circuit board by a nut 504; and S3, adjusting a height of each support leg 2 according to the height and the working demand, and fixing a base 1 by asuction disc 203.

Owner:冯水军

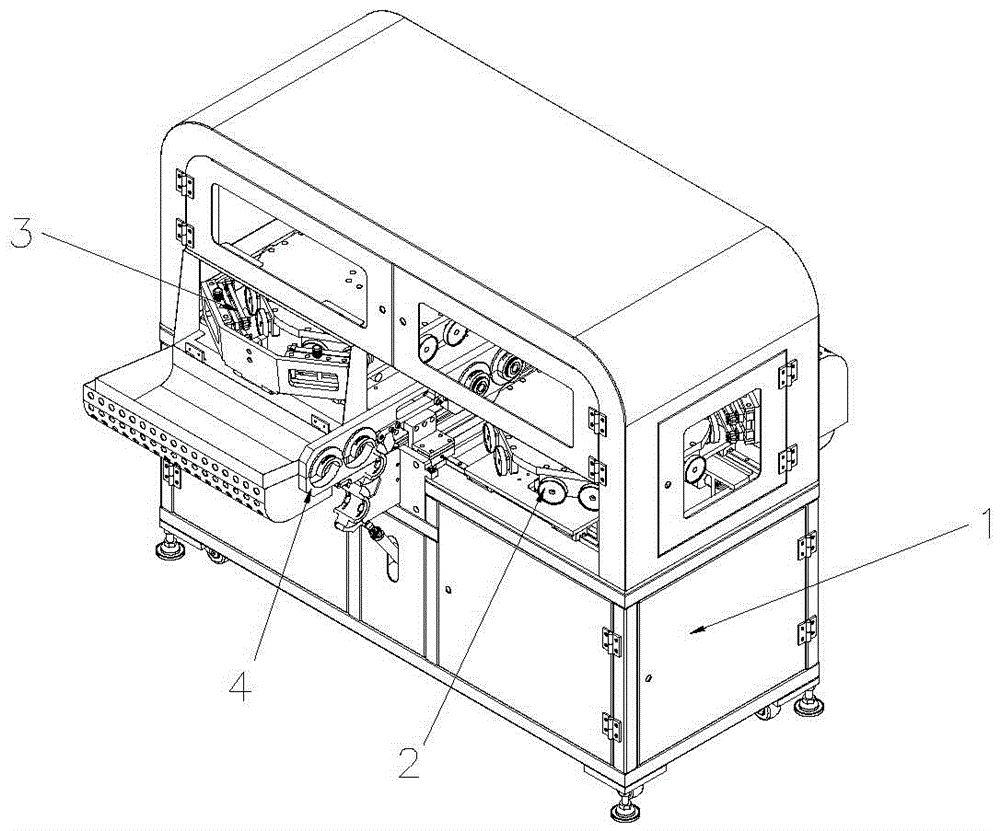

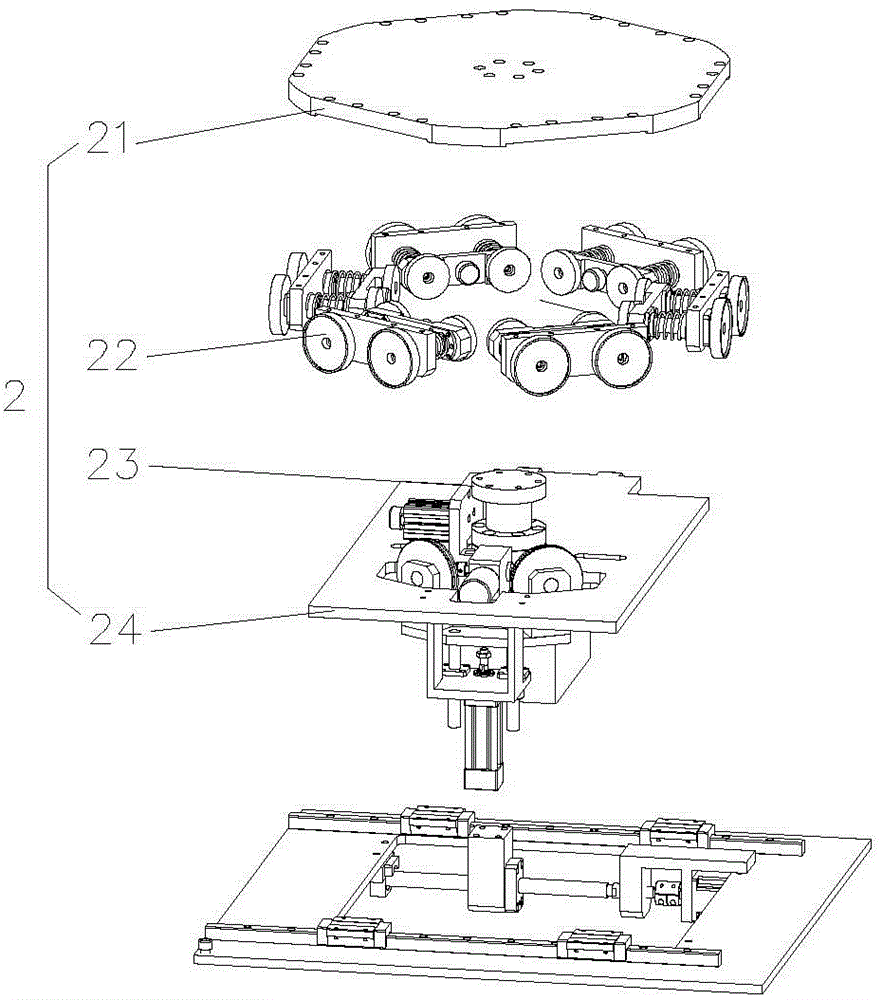

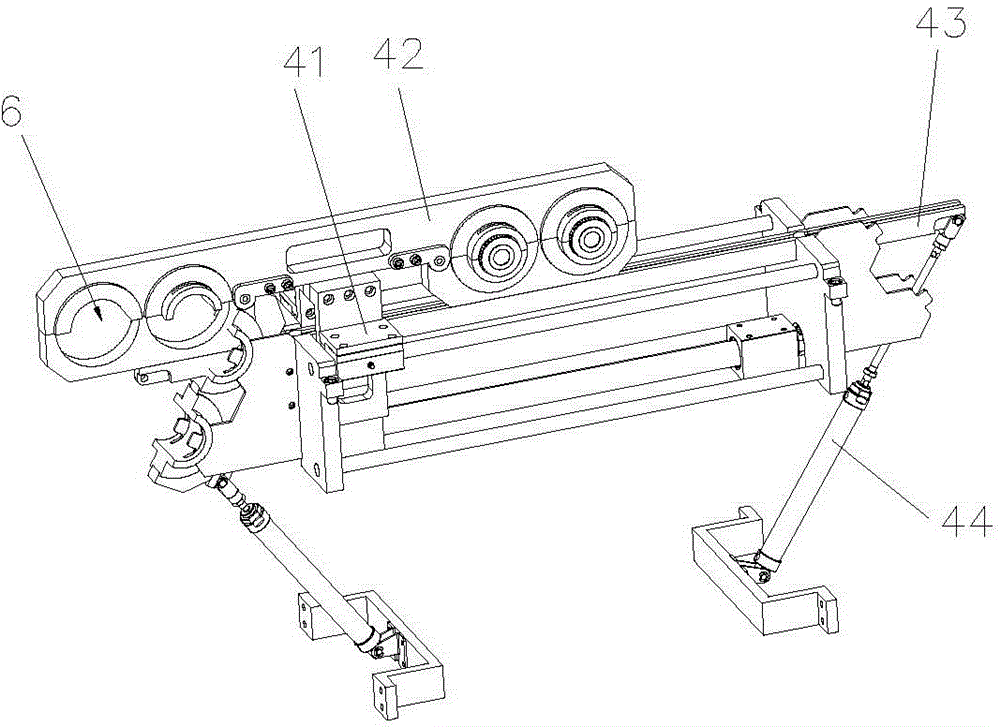

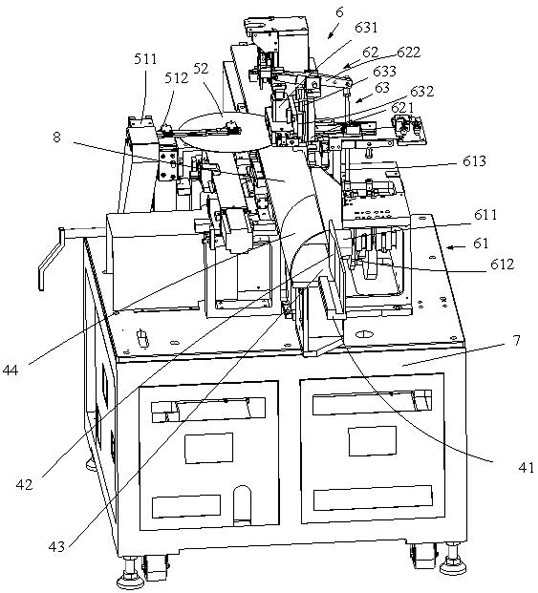

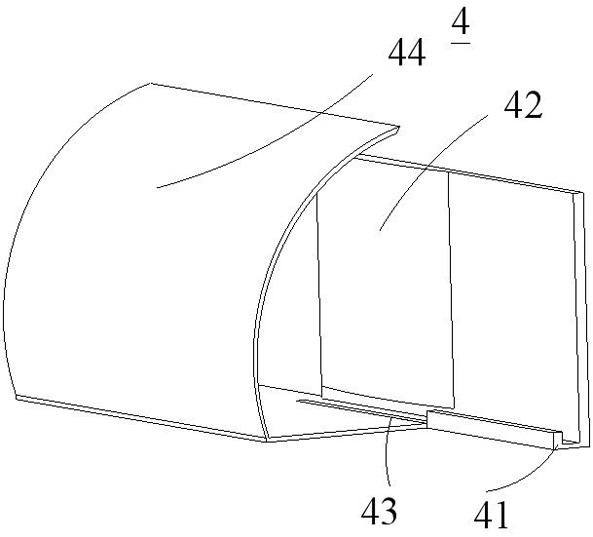

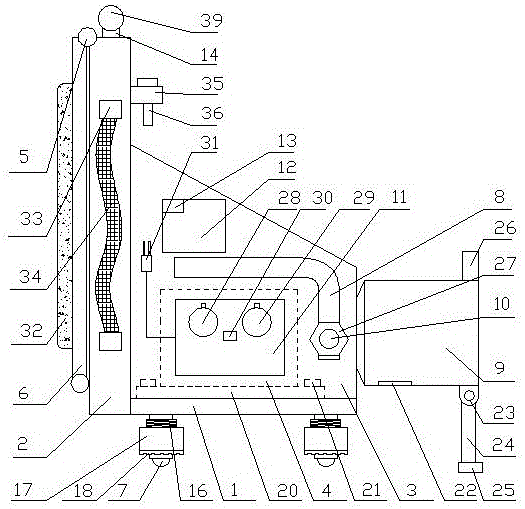

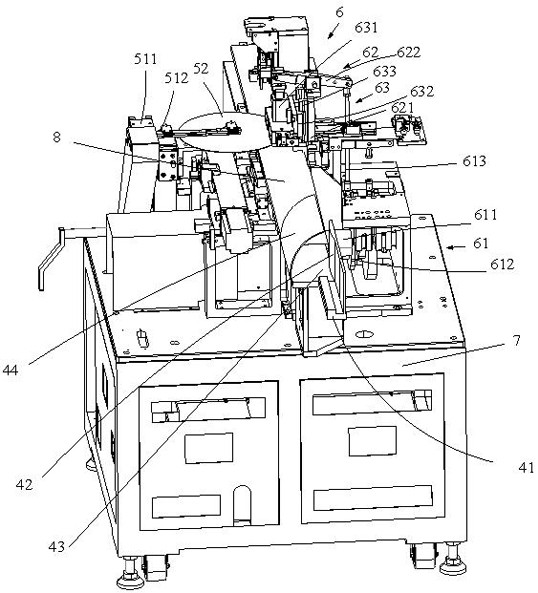

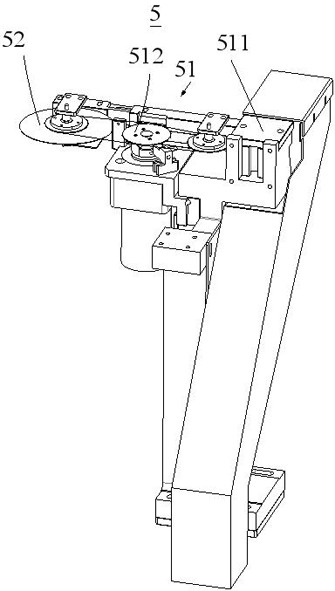

Multi-station welding equipment

ActiveCN106583998AAvoid falling phenomenonAchieve horizontal placementWelding/cutting auxillary devicesAuxillary welding devicesFilter elementWelding

The invention relate to the production technical field of filter elements in filters, in particular to multi-station welding equipment. The multi-station welding equipment comprises a rack, a rotary table jig used for fixing an upper end cover, a heating device used for heating the end cover, a clamping moving mechanism used for a filter element cartridge and a material pushing mechanism used for pushing the end cover to the filter element cartridge to assemble; the rotating table jig comprises a rotating table, at least one group of jig devices and a first drive device used for driving the rotating table to rotate; and the clamping moving mechanism comprises a horizontal moving base which is in sliding connection to the rack, and a clamping assembly which is arranged on the horizontal moving base. The multi-station welding equipment has the beneficial effects that: the filter element cartridge is horizontally arranged through the multi-station welding equipment, so that a dropping phenomenon of a central shaft in the filter element cartridge in a production process is completely avoided, product coaxiality is improved and a product qualification rate is increased; and meanwhile, the rotating table jig is equipped with a plurality of clamping devices which are used for clamping the end cover matched with the filter element cartridge, so that a continuous working process is realized, and therefore, a current situation that shutdown is needed for loading and unloading is solved, production efficiency is improved and production cost is reduced.

Owner:DONGGUAN YERUN AUTOMATION EQUIP CO LTD

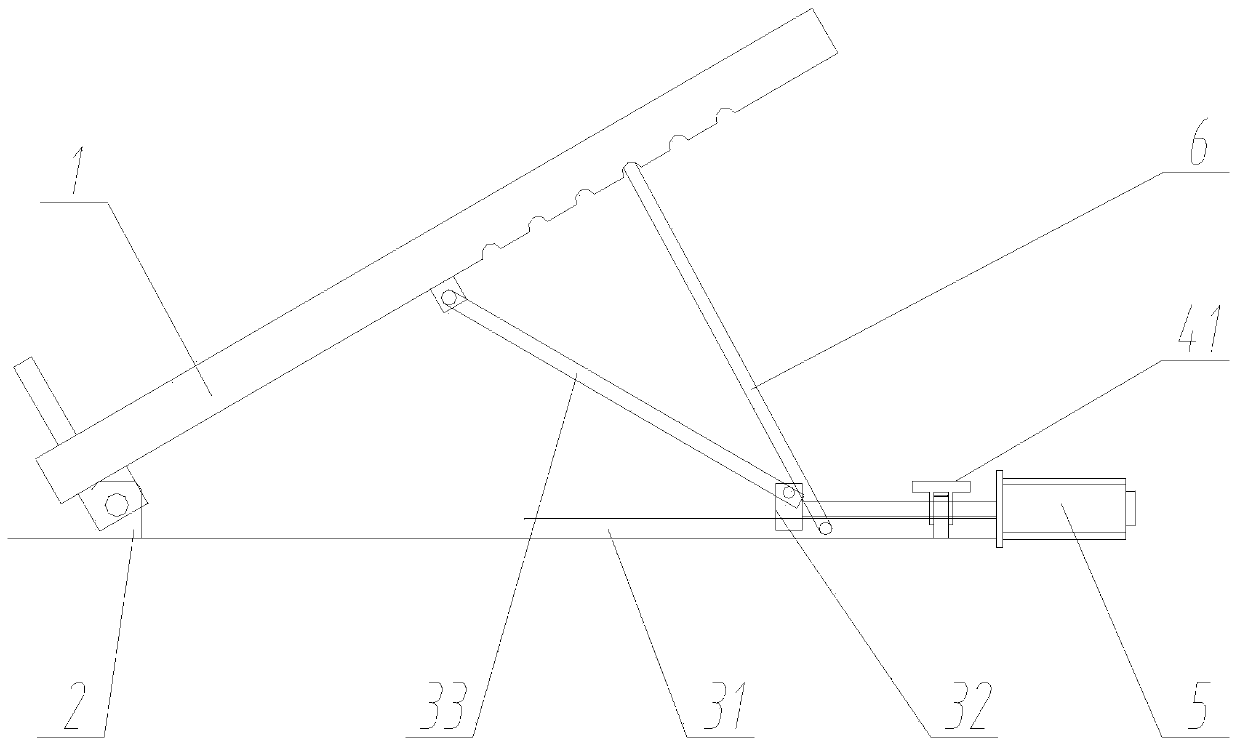

Wallboard supporting die table

The invention discloses a wallboard supporting die table. The wallboard supporting die table comprises a die table, a pushing assembly and a moving assembly. The lower end of the die table is rotationally mounted on a base fixedly arranged on a bottom plate, and a connecting rod is rotationally mounted at the lower end of the middle of the die table. The moving assembly comprises a supporting plate, a fixing block and a connecting rod. The supporting plate is horizontally arranged and located below the right end of the die table, the fixing block is arranged on the supporting plate in a left-and-right sliding manner, and the other end of the connecting rod is rotationally mounted on the fixing block. The pushing assembly comprises a hydraulic cylinder, the hydraulic cylinder is located onthe right side of the supporting plate, and the piston end of the hydraulic cylinder is fixedly connected with the fixing block. A groove set is arranged below the right portion of the die table. Thegroove set comprises multiple evenly-formed positioning grooves. A positioning rod is arranged on the supporting plate, one end of the positioning rod is rotationally mounted on the supporting plate,and the other end of the positioning rod is arranged in the positioning grooves in an embedded manner. The wallboard supporting die table is simple in structure and convenient to hoist and carry, andwallboard supporting and automatic inclination adjusting are achieved.

Owner:徐州华裕建筑科技有限公司

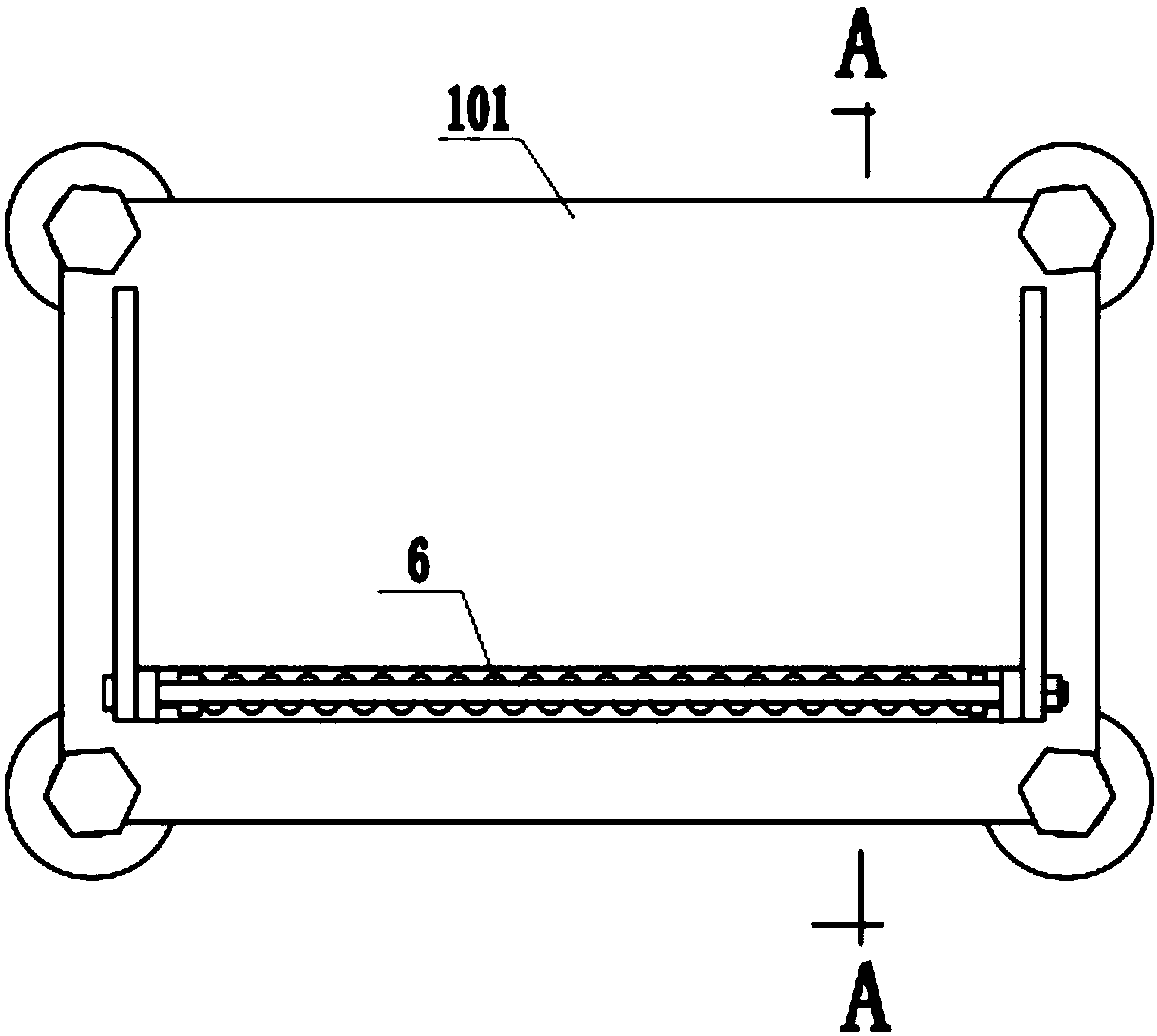

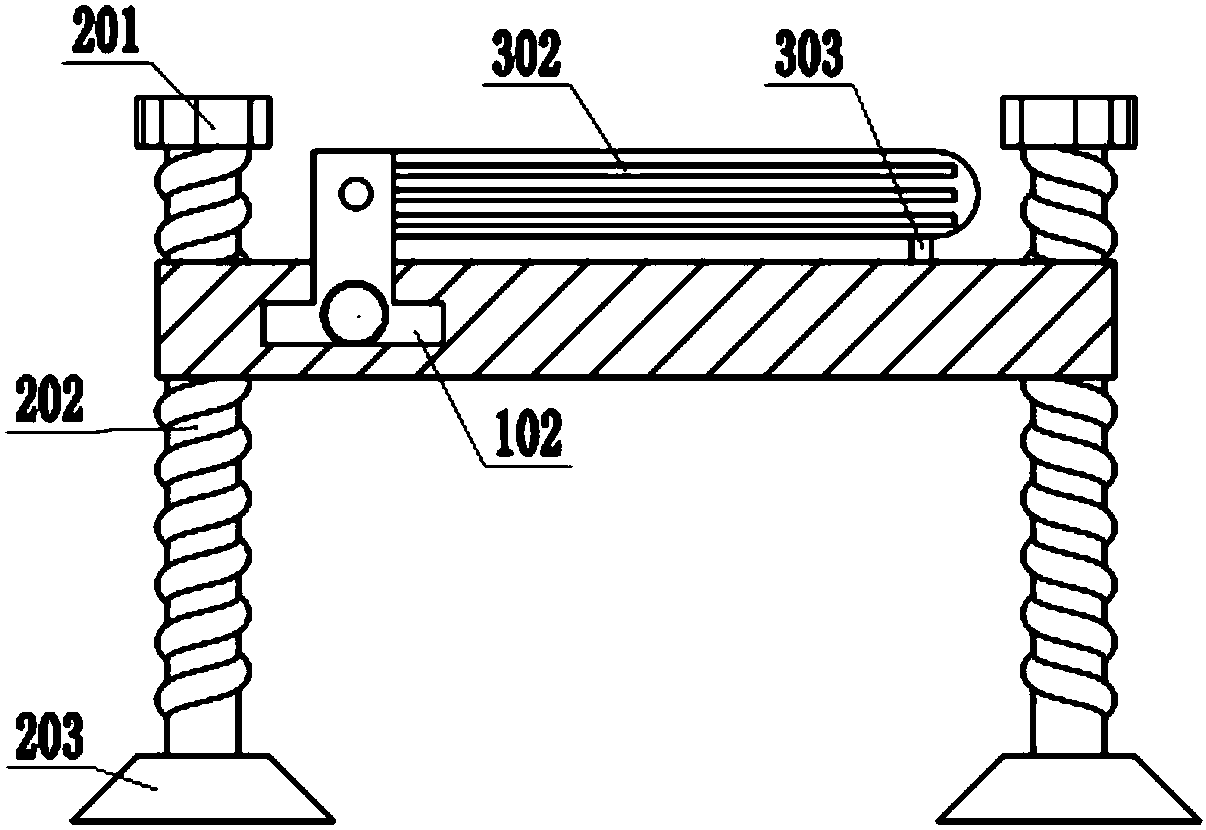

Electronic component assembly support and application method thereof

InactiveCN108495481AEasy to installPrevent slidingPrinted circuit assemblingElectrical componentsEngineeringSlide plate

The invention discloses an electronic component assembly support, and relates to the technical field of an electronic device support. The electronic component assembly support is characterized by comprising a base, support legs, clamping plates, sliding blocks, a rotation shaft and a spring, wherein the base comprises a seat plate, a sliding groove is formed in one side of the seat plate, the twosliding blocks are arranged, two ends of the spring are connected with the two sliding blocks, the spring is arranged in the sliding groove, the two sliding plates are respectively matched with the two sliding blocks by the rotation shaft, and the four support legs are respectively arranged at four corners of the seat plate. By the support, the circuit board can be clamped, installation of an electronic component is facilitated, the electronic component is prevented from sliding, the installation accuracy is improved, and the quality of an electronic product is ensured.

Owner:冯水军

Solar energy traveling tea set

PendingCN108523587AAchieve horizontal placementSimple structureBatteries circuit arrangementsServing trayElectricityEngineering

The invention provides a solar energy traveling tea set. The set comprises a tea tray, a heating plate is arranged on the surface of the tea tray, a teapot box is arranged at the left side of the teatray, a solar panel I and a solar panel II are successively arranged on the upper side of the tea tray, the solar panel I is connected with the tea tray through a hinge I, the solar panel II is connected with the solar panel I through a hinge II, a drawer type storage cabinet is arranged inside the tea tray, and a plurality of teacup seats, a plurality of supporting leg grooves, a tea ceremony auxiliary tool groove and a tea caddy groove are arranged inside the drawer type storage cabinet. The tea set is simplified in structure and convenient to carry, when the tea set is used in the nature and other places without electricity, the solar energy is utilized for supplying power to boil water, when the tea set is used in hotels and other places with the electricity, normal electricity is utilized to boil water, and when the tea set is used in an uneven place, the supporting legs can be adjusted to make the tea tray placed horizontally. During the travel process, tea-tasting pleasure can be achieved at any time, and the tea set is economical and practical.

Owner:王颢颐

Five-point positioning-based shaft-sticking type motor installation test device

PendingCN114035048AFast adjustmentAchieve horizontal placementMeasurement instrument housingDynamo-electric machine testingElectric machineryEngineering

Owner:ZHENJIANG ZHONGCHUAN XIANDAI GENERATING EQUIP CO LTD

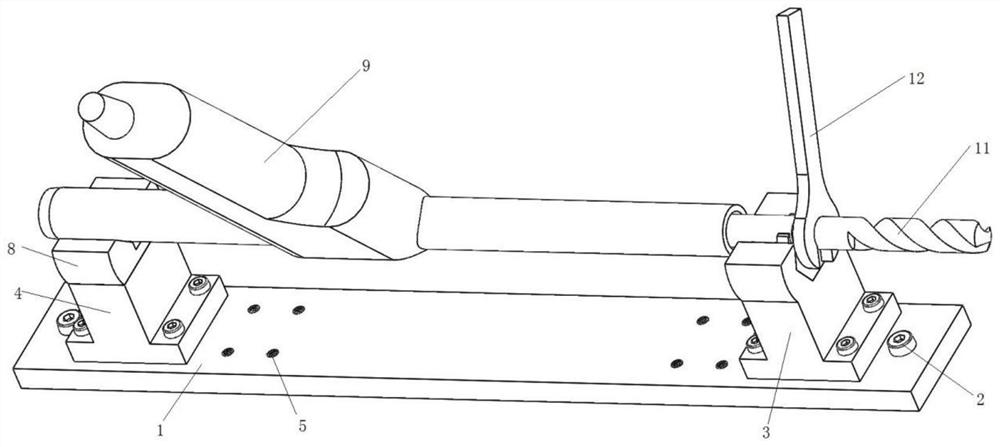

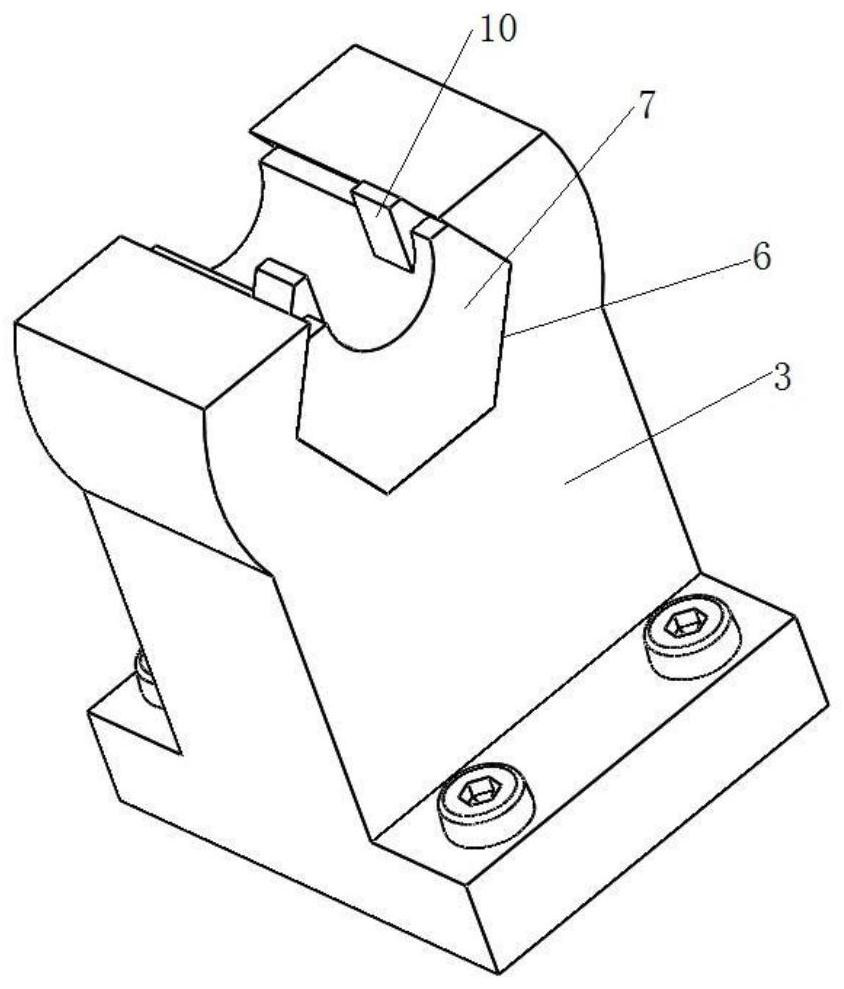

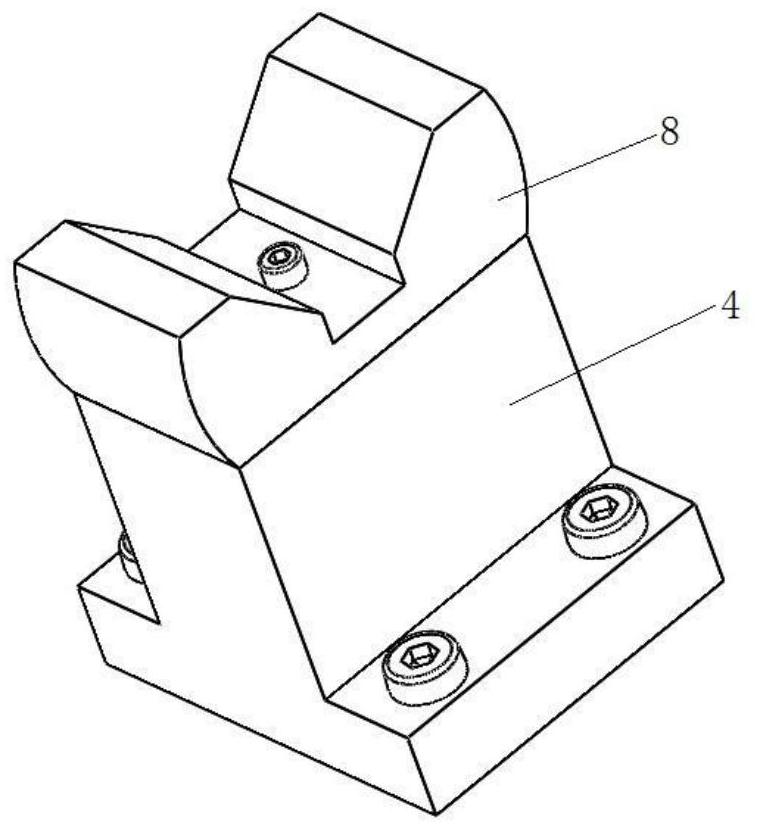

Quick tool changing device for automatic feeding drill

PendingCN112222480AImprove consistencyAutomatic convenienceMetal-working hand toolsBoring/drilling componentsRotational axisWorkbench

The invention discloses a quick tool changing device for an automatic feeding drill. The quick tool changing device comprises a bottom plate, the bottom plate is fixedly installed on a workbench through locking bolts, the two ends of the bottom plate are fixedly connected with a tool locking base and a supporting seat through bolts correspondingly, a notch is formed in the middle of the top end ofthe tool locking base, and a tool locking opening is formed in the notch in an inserted mode; and two sets of symmetrically-arranged clamping heads are arranged at the top end of the tool locking opening, a supporting seat supporting opening is fixedly connected to the top end of the supporting seat through bolts, a horizontally-arranged automatic feeding drill is installed between the supportingseat supporting opening and the tool locking opening, and a rotating shaft clamping opening of the automatic feeding drill is matched with the clamping heads of the tool locking opening. According tothe quick tool changing device, the problem that the automatic feeding drill and a tool are difficult to disassemble is solved, assembly type adjustment can be carried out so as to adapt to tool changing operation of automatic feeding drills of different types and different sizes by operators, and the consistency of the tool changing process is improved.

Owner:南京航浦机械科技有限公司 +1

Combined multi-style leisure furniture

ActiveCN112220245ARealize linear movementRealize automatic extensionBenchesConvertible chairsElectric machineryStructural engineering

The invention discloses combined multi-style leisure furniture. The furniture comprises a table body, a transmission assembly and a rotating assembly; Side matching grooves are symmetrically formed inthe two sides of the table body, an end matching groove is formed in one end of the table body, supports are symmetrically arranged on the two sides of the bottom face of the table body respectively,guide grooves are formed in the side faces of the supports, limiting grooves are symmetrically formed in the two sides of the upper surfaces of the guide grooves, a stretching assembly is arranged onthe limiting grooves and provided with an arm-chair assembly, the arm-chair assembly is provided with a supporting assembly, a flattening assembly is arranged on the supporting assembly, a lifting assembly is arranged in the middle of the surface of the table body, and an adjusting assembly is arranged on the lifting assembly; the transmission assembly comprises a bottom plate, a lead screw, a first motor, a square rod, a bottom groove, a limiting plate, a base and a pedestal, the bottom plate is fixedly connected to one end of the middle of the bottom face of the table body, and one end of the lead screw is rotationally connected to the bottom plate. The combined multi-style leisure furniture can achieve combination of multiple styles, can achieve multiple functions through combination and is diversified in function and high in practicability.

Owner:北京国林系统家具有限公司

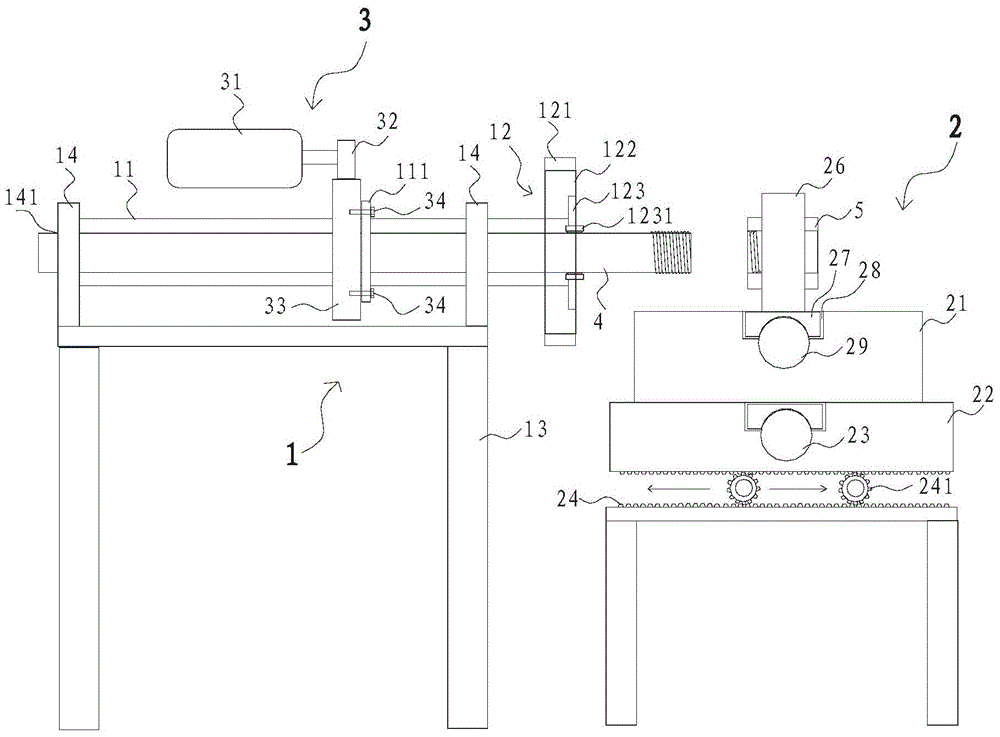

Thread pipe assembly device

ActiveCN103659246BImprove tightening qualityGuarantee personal safetyMetal working apparatusThreaded pipeEngineering

The invention discloses a threaded pipe assembly device comprising a first fixing unit, a second fixing unit and a driving unit. The first fixing unit is used for fixing a pipe to be assembled. The second fixing unit is used for clamping a pipe joint to be assembled and capable of sliding along the horizontal direction. The driving unit is used for driving the pipe to rotate. The pipe and the pipe joint are oppositely arranged at the same horizontal height, the pipe is fixed through the first fixing unit, and when the driving unit drives the pipe to rotate, the second fixing unit clamps the pipe joint to get close to the pipe, and the pipe is matched with the pipe joint. The threaded pipe assembly device has the advantages that a traditional pure manual assembly mode is converted into the one with the driving unit providing force, so that labor force is saved; the driving unit can provide force in electric, pneumatic modes and the like, the force provided by the driving unit is stronger as compared with that of human beings, tightening quality between the pipe joint and the pipe is higher, bayonet pliers used by workers are omitted, skid danger is avoided, and personal safety of the workers can be greatly guaranteed.

Owner:商丘市天路工程机械有限公司

IoT-based electronic equipment production system

ActiveCN113543497BAchieve horizontal placementIncrease productivityPrinted circuit assemblingConveyor partsThe InternetConveyor belt

The invention belongs to the technical field of electronic equipment, and specifically relates to an electronic equipment production system based on the Internet of Things, which includes: an overturning device, which is suitable for overturning a plate in a vertical state into a plate in a horizontal state; an element device, the The component device is suitable for storing components; the installation device is arranged above the component device, and when the conveyor belt transports the horizontal plate to the installation device, the installation device is suitable for installing the components on the component device in a horizontal The original vertical plate is placed horizontally on the plate in the state, which improves the production efficiency of electronic equipment and reduces the cost.

Owner:江苏鑫埭信息科技有限公司

An automatic and precise assembly of an oil pump

ActiveCN109366141BAchieve horizontal placementImprove work efficiencyMetal working apparatusEngineeringOil pump

The invention provides an automatic accurate assembling assembly for an oil pump. The automatic accurate assembling assembly for the oil pump comprises a base, an assembling cylinder, an extrusion mechanism, a compression groove and a rotary suction mechanism. The extrusion mechanism comprises an extrusion block and an overturning assembly. The rotary suction mechanism comprises a rotary assemblyand a discharging assembly. According to the automatic accurate assembling assembly for the oil pump, the extrusion block is rotatably connected to a pushing end of the assembling cylinder, and the extrusion block can rotate to be horizontal. After one-time assembling of oil pump springs and an oil pump shell, an oil pump cylinder retracts, and the extrusion block is driven to be horizontal by theoil pump cylinder; and besides, the extrusion block is magnetized through an electromagnet, and the oil pump springs output by the discharging assembly is sucked by the extrusion block. When the assembling cylinder pushes, the extrusion block is vertically arranged and loses magnesium; the oil pump springs fall onto a bearing base accurately; the technical problem of accurate feeding of the oil pump springs is solved; horizontal placement of the oil pump springs is achieved; moreover, the oil pump springs are fed automatically; and working efficiency is higher.

Owner:CHANGXING BEST MASCH CO LTD

Height-adjustable corner support assembly, household appliance and adjustment method for support feet

ActiveCN107859815BThe adjustment method is simple and reliableAvoid leaningMachine framesDomestic cooling apparatusEngineeringMechanical engineering

Owner:HAIER SMART HOME CO LTD

Electric power converter and method for operating same

ActiveCN106452018AStable supportAchieve fixationElectric powerBattery overcharge protectionFrequency changerTransformer

The invention discloses an electric power converter and a method for operating the same. The electric power converter comprises a device base. A rear plate is arranged at an end of the device base, side plates are arranged on two sides of the device base, a transformer bank is arranged on the device base, a side of the upper end of the rear plate is hinged to a pulling plate by hinges, a set of universal wheels is arranged on the lower portion of the device base, corner slide grooves are formed in the side plates, each corner slide groove is matched with a connecting screw at an end of a frequency converter set, a controller and a storage battery are arranged on the side plate on a side of the device base, a charge interface is arranged on the storage battery, a frame is slidably arranged in the rear plate, and a solar cell panel is laid on the frame. The electric power converter and the method have the advantages that the electric power converter can move conveniently in a labor-saving manner, can be carried on the backs when inconvenient to pull and is easy to operate and convenient to use; the shape of the electric power converter can be changed, and accordingly the electric power converter can be used in narrow spaces and is wide in applicability; the electric power converter has solar energy utilization functions, accordingly, users can conveniently charge other mobile equipment, energy can be saved, and environments can be protected.

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

Microneedle type multifunctional slimming and fat dissolving filling instrument

PendingCN113244523AAchieve shrinkageDoes not affect the use of punctureCoupling device detailsMicroneedlesMedicineEngineering

The invention provides a microneedle type multifunctional slimming and fat dissolving filling instrument, relates to the technical field of beauty instruments, and solves the problems that a plug head and a beauty instrument are easy to loosen, and the plug head cannot be automatically prevented from loosening in the process of beautifying by pressing a button; and finally, the problem that the existing device cannot realize the organic combination of the protection structure and the pressing of the beauty button through the structural improvement is solved. A microneedle type multifunctional slimming and fat dissolving filling instrument comprises a gun body. The gun body is of a beautifying gun structure. The number of the auxiliary rods B is two, and the two auxiliary rods B are symmetrically welded to the seat body. The two auxiliary rods B are both of an L-shaped rod structure, and the two auxiliary rods B jointly form a hanging structure of the gun body. The two auxiliary rods B are in elastic contact with the plug, and when the auxiliary rod A is repeatedly pressed, the auxiliary rods B and the plug are in a continuous impact shape, so that the plug is prevented from loosening.

Owner:张玉坤

High-dynamic DC voltage controller of photovoltaic inverter

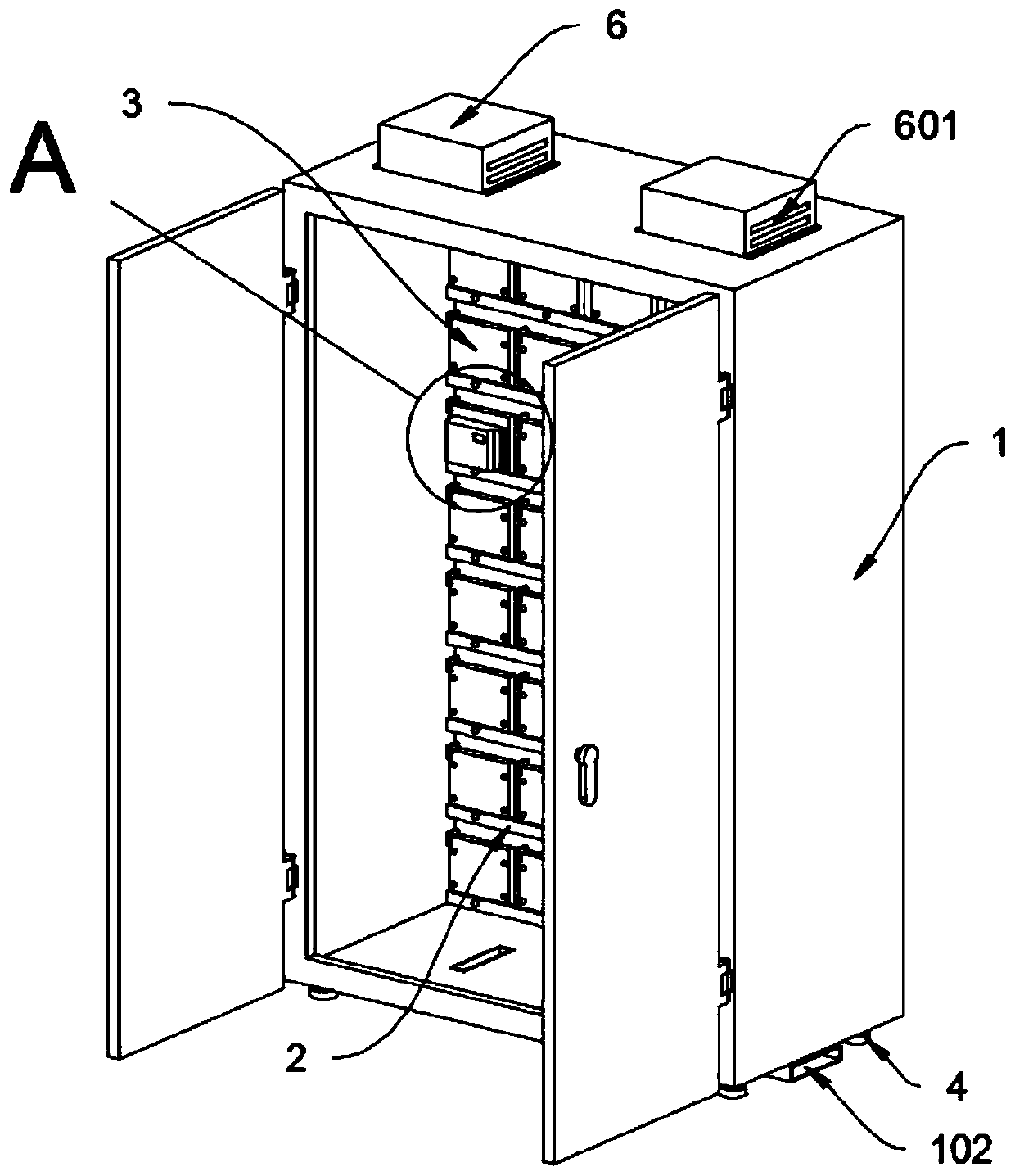

PendingCN111431479AAchieve horizontal placementAvoid wear and tearPhotovoltaicsPhotovoltaic energy generationControl theoryMechanical engineering

The invention provides a high-dynamic DC voltage controller of a photovoltaic inverter. The high-dynamic DC voltage controller comprises a box body, nine groups of mounting seats are fixedly connectedin the box body in a rectangular array shape through bolts, electric appliance element mounting seats are fixedly connected on the mounting seats, and electric appliance elements are fixedly connected on the electric appliance element mounting seats through bolts. When the supporting pipe is in contact with the ground, friction between the supporting pipe and the ground can be replaced by rotation between the adjusting seat and the supporting pipe, the frictional resistance during adjustment is reduced, and the bottom plate can be prevented from being abraded by the supporting pipe; comparedwith the existing device, the device can realize horizontal placement of the box body; and the adjusting structure is reasonable and practical, and the problems that time is wasted during dismounting,moving is not convenient enough, and rapid horizontal adjustment cannot be achieved when the controller is placed on the uneven ground due to the fact that the number of electrical components in thecontroller cabinet body is large, the space is narrow, and a plurality of fixing bolts need to be dismounted are solved.

Owner:ZHEJIANG EIFESUN ENERGY TECH

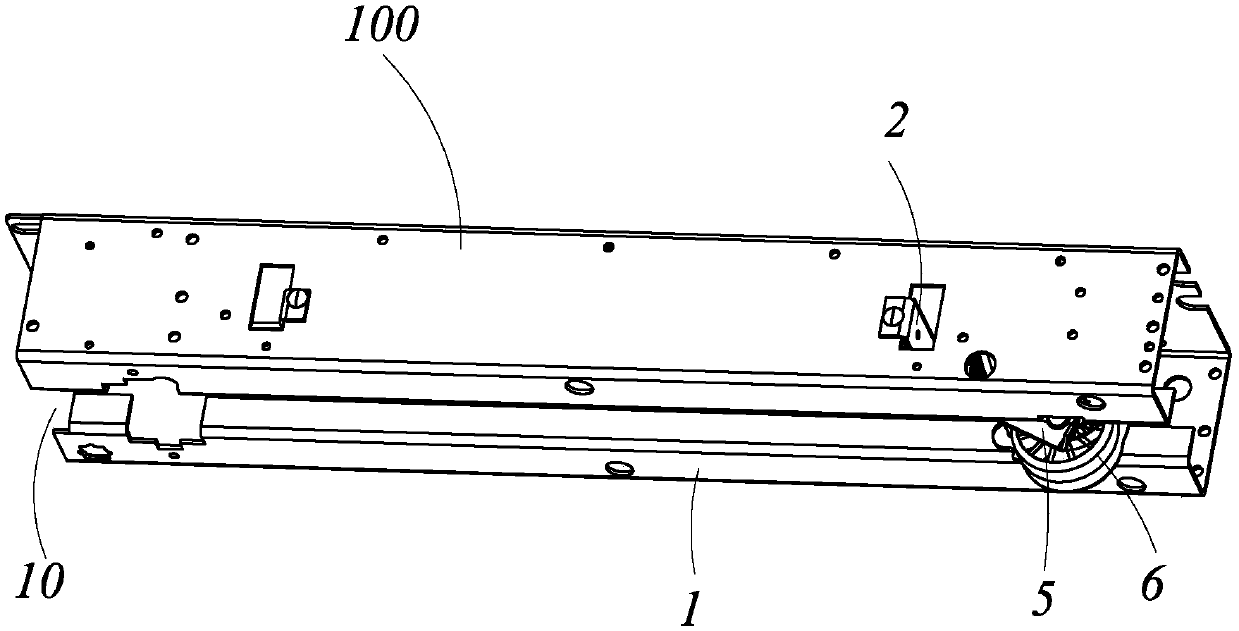

Expressway subgrade and pavement damage detection device

PendingCN113281404AAchieve horizontal placementGuaranteed to be placed horizontallyAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerRoad surface

The invention belongs to the technical field of highway detection, and particularly relates to an expressway subgrade and pavement damage detection device which comprises a fixed sliding rail, a transmitter supporting frame and a transmitting transducer, wherein the fixed sliding rail is loaded on a pavement to be detected, the transmitter supporting frame is suitable for sliding relative to the fixed sliding rail and is assembled on the fixed sliding rail, the transmitting transducer is installed on the transmitter supporting frame and moves along with the transmitter supporting frame, and the fixed sliding rail comprises a first guide rail, a second guide rail and a splicing structure used for splicing the first guide rail and the second guide rail. According to the expressway subgrade and pavement damage detection device, the fixed sliding rail and the transmitter supporting frame are arranged, the transmitter supporting frame is used for clamping the transmitting transducer, then the transmitter supporting frame is installed on the fixed sliding rail, the receiver is placed above the fixed sliding rail, and horizontal placement of the transmitter and the receiver is achieved.

Owner:米建朝

Electronic equipment production system based on Internet of Things

ActiveCN113543497AAchieve horizontal placementIncrease productivityPrinted circuit assemblingConveyor partsThe InternetMechanical engineering

The invention belongs to the technical field of electronic equipment, and particularly relates to an electronic equipment production system based on the Internet of Things. The system comprises: a turnover device, wherein the turnover device is suitable for turning a plate in a vertical state into a plate in a horizontal state; an element device suitable for storing elements; and a mounting device arranged above the element device, wherein when a conveying belt conveys the plate in the horizontal state to the mounting device, and the mounting device is suitable for mounting the elements on the element device on the plate in the horizontal state, so that the plate which is originally vertical is horizontally placed. According to the invention, the production efficiency of the electronic equipment is improved, and the cost is reduced.

Owner:江苏鑫埭信息科技有限公司

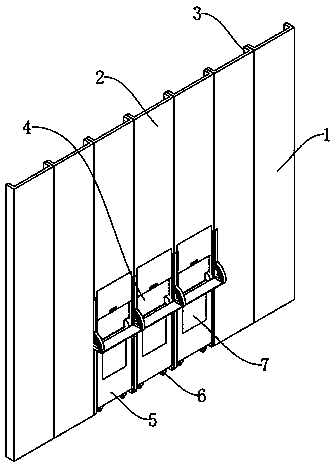

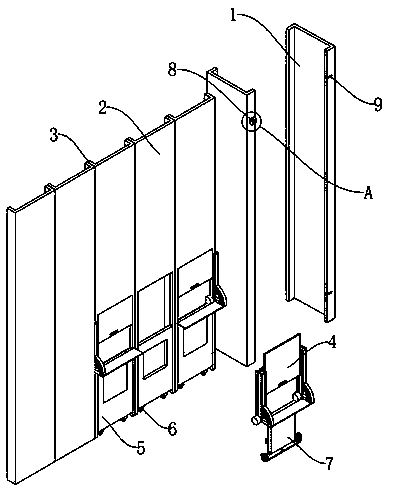

Composite wallboard used for building assembling

PendingCN110409728AFix unstable installationAchieve horizontal placementCovering/liningsSuspended tablesWall plateEngineering management

Owner:ANHUI FUHUANG STEEL STRUCTURE

A glass curtain wall transport trolley

ActiveCN105857365BAchieve horizontal placementRealize multi-layer overlaySledgesBuilding material handlingVehicle frameMultiple layer

The invention discloses a glass curtain wall conveying trolley which is provided with a plate type frame. A hand-push rod is arranged on the left side of the plate type frame, rollers are arranged at the bottom of the plate type frame, a main positioning base plate is arranged on the side, which is close to the hand-push rod, of the plate type frame, two symmetrical guide rails are arranged on the right side of the main positioning base plate, guide grooves are formed in symmetrical side surfaces of the guide rails, an auxiliary positioning base plate is arranged between the two guide rails, and guide sliders which are in slide fit with the guide grooves are arranged on the auxiliary positioning base plate; two supporting plates are respectively arranged on the main positioning base plate and the auxiliary positioning base plate and are connected with each other by a telescopic connecting rod, and symmetrical expansion brackets are arranged at the front end and the rear end of each supporting plate. The glass curtain wall conveying trolley has the advantages that the areas of the bottom supporting plates can be changed, and accordingly glass curtain walls with different sizes and areas can be horizontally arranged on the glass curtain wall conveying trolley; the glass curtain walls can be separated from one another by the expansion brackets, accordingly, multiple layers of glass curtain walls can be overlaid on one another, and the conveying efficiency can be improved.

Owner:常熟东南高新技术创业服务有限公司

A power converter and method of operating the same

ActiveCN106452018BStable supportAchieve fixationElectric powerBattery overcharge protectionFrequency changerTransformer

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

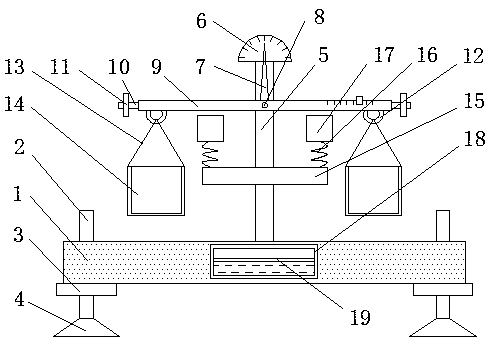

Balance used for physical teaching

InactiveCN107749217AReasonable structureInnovative designWeighing apparatus using counterbalanceEducational modelsStop timeThreaded rod

The invention discloses a balance used for physical teaching. The balance comprises a base plate, a support column, an external thread, a rotation plate, an internal thread, a pedestal, a fixing rod,a sector ruler, a pointer, a fixing shaft, a crossbeam, a threaded rod, an adjusting nut, a hanging ring, a hanging rope, a tray, a fixing plate, an elastic spring, a rubber block, a water storage shell and a glass strip. The structure of the balance used for physical teaching is reasonable and the design is novel. Through mutual cooperation of the support column, the rotation plate, the pedestal,the base plate, the water storage shell and the glass strip, the base plate can be placed horizontally so that the balance can be stably used, balance measurement precision is guaranteed and usage isconvenient. Through interaction of the rubber block, the elastic spring and the fixing rod, a fluctuated angle of the crossbeam is reduced, crossbeam stop time is shortened, an operator can read conveniently, a practical value is high and popularization and usage are convenient.

Owner:刘轩

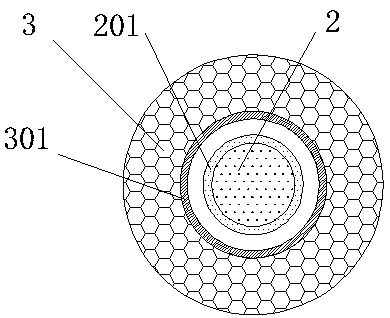

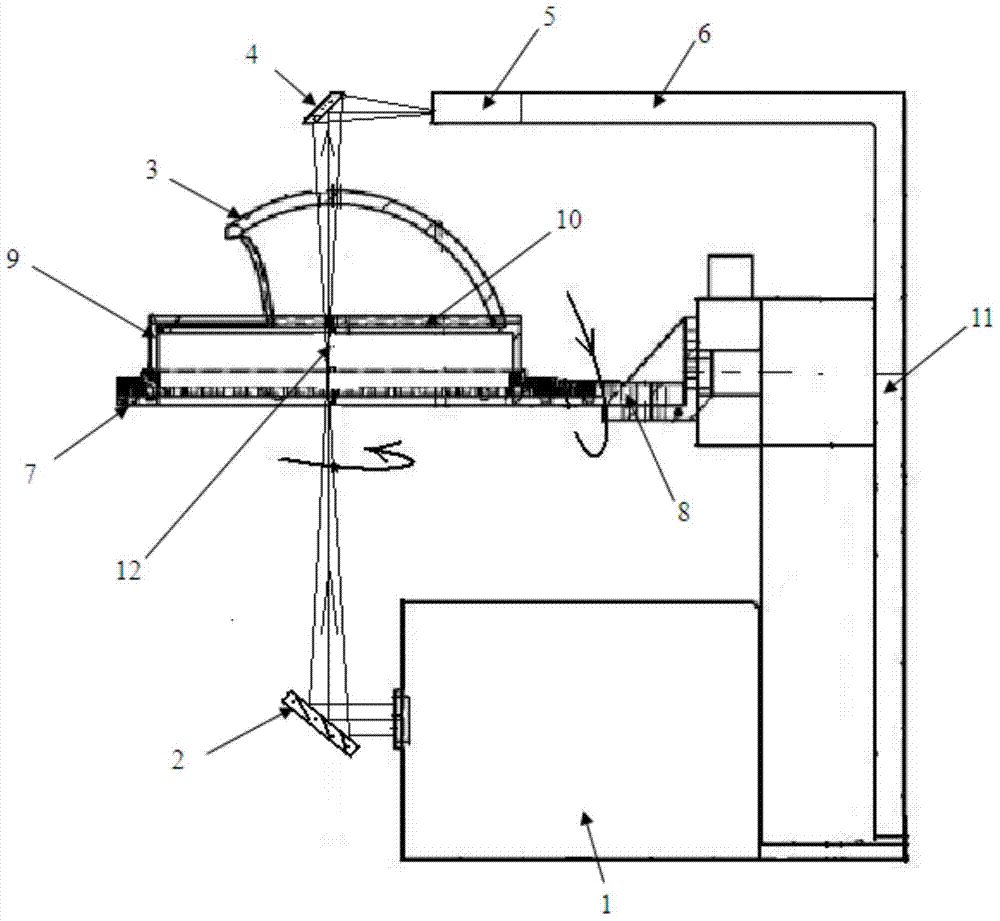

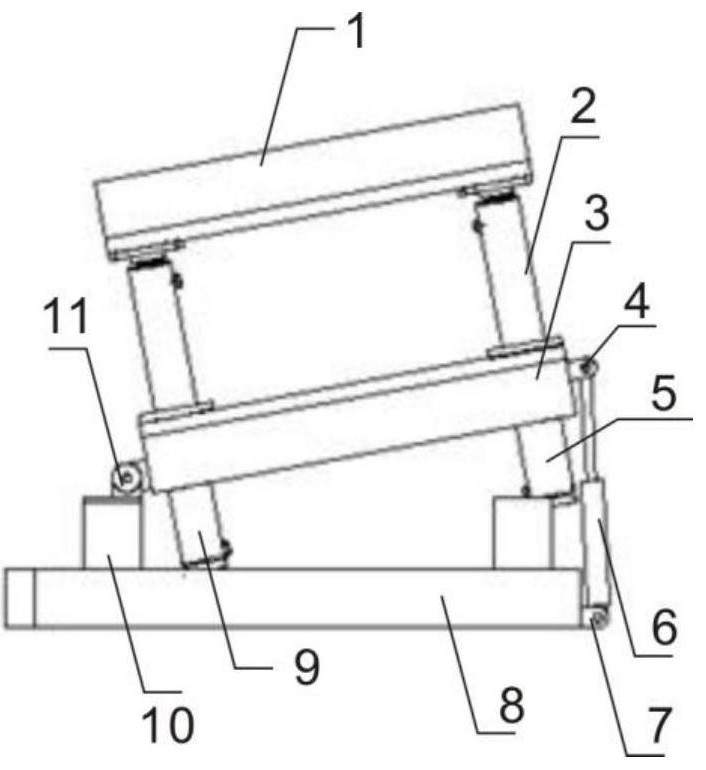

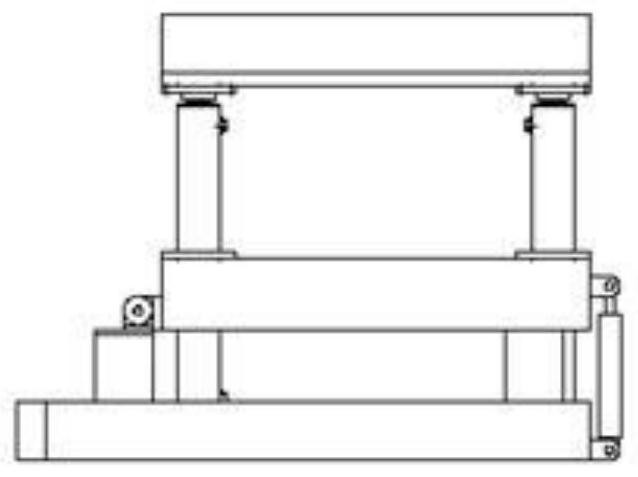

A detection device for testing the transmittance of an optical dome film layer

ActiveCN104330356BAchieve horizontal placementAvoid cumbersome clampingMaterial analysis by optical meansOptical transmittanceSpectrometer

The invention relates to a detection device for testing the transmittance of the film layer of an optical dome. The test light is converted into converging light in the vertical direction through the concave reflector. The converging light converges at the spherical center of the fairing and passes through the tested fairing in a normal way, and converges to the detector through another concave reflector to detect the rectification. The transmittance of the cover film layer, and then rotate the biaxial measurement platform to detect the transmittance of the entire fairing film layer. The technical solution of the invention can solve the problem that the measurement space of the current spectrometer is limited, the transmittance of the entire film layer of the dome cannot be fully detected and the measurement is inaccurate.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

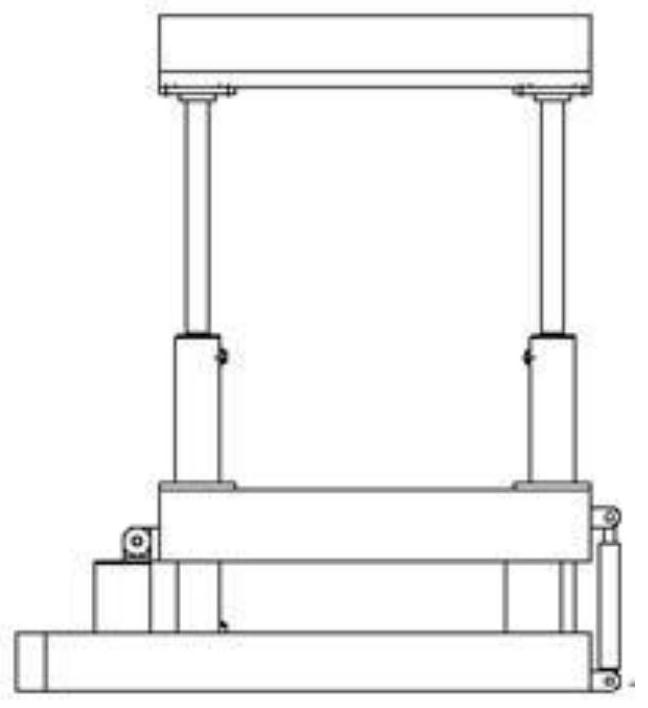

Special horizontal inclined hydraulic mould frame for PDCPD (Polydicyclopentadiene) material

The invention provides a special horizontal inclined hydraulic mould frame for a PDCPD (Polydicyclopentadiene) material. The special horizontal inclined hydraulic mould frame comprises a base, an upper mould plate and a lower mould plate, wherein the upper mould plate and the lower mould plate are arranged above the base and are parallel to each other; a lifting oil cylinder is arranged on the upper end face of the lower mould plate, the output end of the top of the lifting oil cylinder is connected with the bottom end face of the upper mould plate, and the bottom of the lower mould plate is connected with a rear supporting rod and a front supporting rod; a lower forming block is arranged at the top of the base, and the edge of the top of the lower forming block is connected with the left end face of the lower mould plate through a third rotating shaft; the right end face of the base is connected with a reverse oil cylinder through a second rotating shaft; and the output end of the top of the reverse oil cylinder is connected with the right end face of the lower mould plate through a first rotating shaft. According to the special horizontal inclined hydraulic mould frame, a mould can be horizontally placed and can be inclined at the same time, and thus the technological conditions needed when a pdcpd product is formed can be met; and the smooth face of the product is placed on a lower mould, so that generation of bubbles on the smooth face is reduced to the maximum extent, and the product with the high front face smoothness is obtained.

Owner:CHENGDU SHENGDAQIANG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com