Automatic accurate assembling assembly for oil pump

An oil pump and precise technology, which is applied in the field of automatic and precise assembly of oil pumps, can solve problems such as low assembly efficiency, insufficient compression, and assembly failure, and achieve the effects of high work efficiency, ingenious conception, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

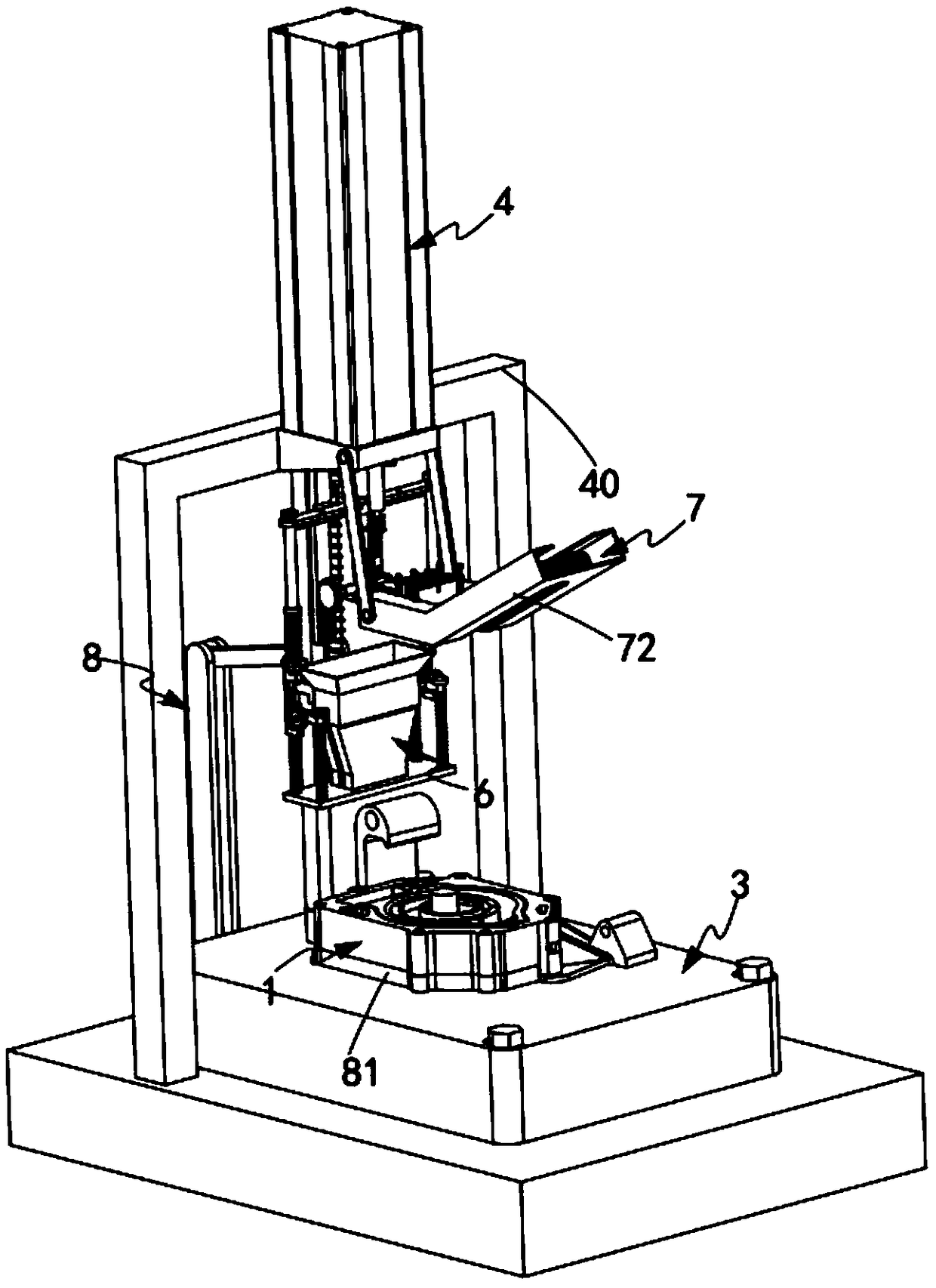

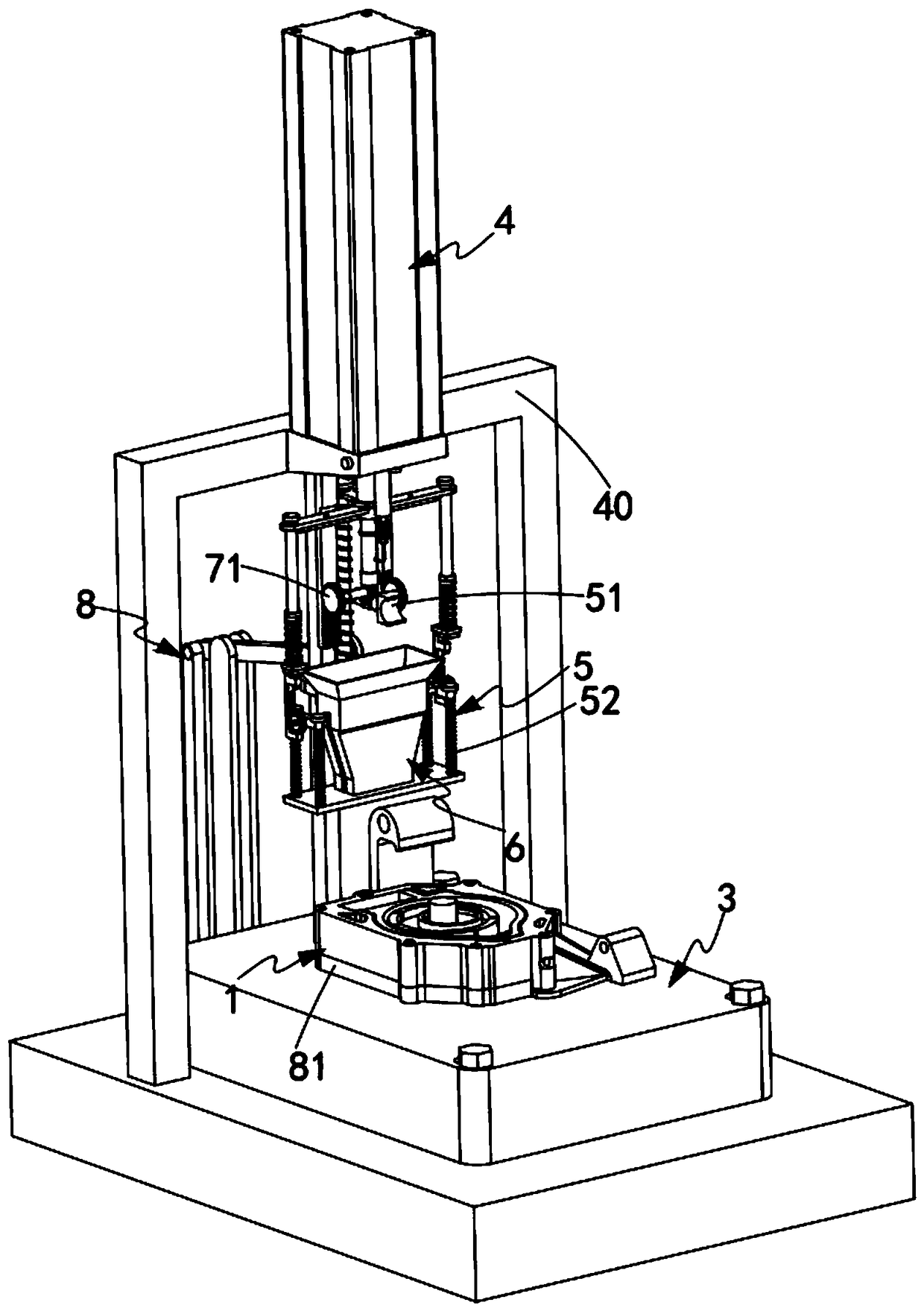

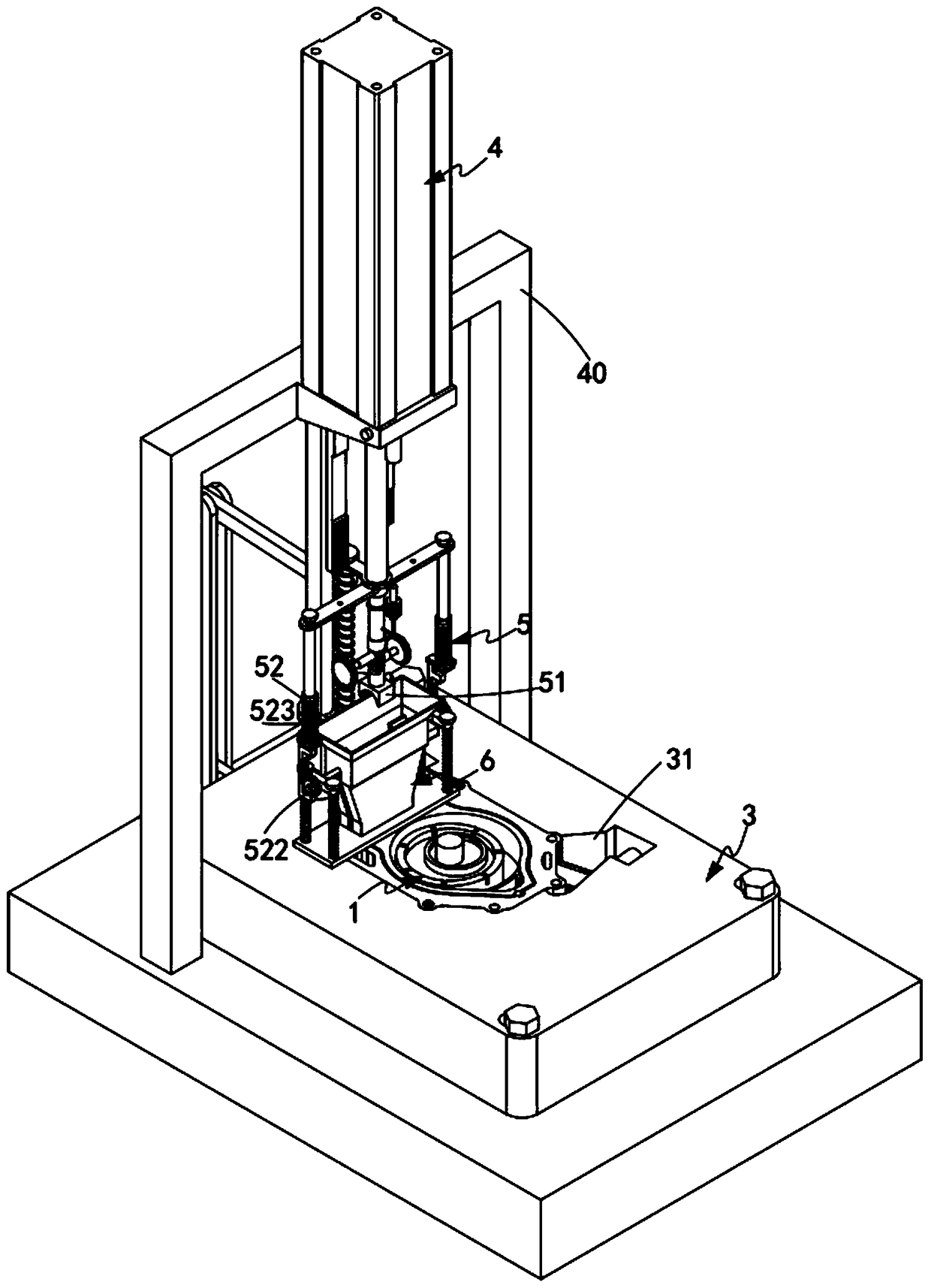

[0086] like figure 1 , figure 2 , image 3 and Figure 4 As shown, an oil pump automatic and precise assembly assembly is used for assembling the oil pump housing 1 and the oil pump spring 2. The oil pump housing 1 is provided with a mounting groove 11, and the mounting groove 11 is used for installing the oil pump spring 2. Also includes:

[0087] Base 3, the base 3 is provided with a positioning groove 31 matching the shape of the oil pump housing 1, the oil pump housing 1 is placed in the positioning groove 31, and the oil pump housing 1 is provided with a mounting The end face of the groove 11 is exposed;

[0088] Assembling the cylinder 4, the assembly cylinder 4 is installed above the base 3 through the mounting bracket 40, and the pushing end 41 of the assembly cylinder 4 is perpendicular to the installation groove 11 and vertically reciprocates downwards;

[0089] Extrusion mechanism 5, said extrusion mechanism 5 is arranged on the pushing end 41 of said assembly...

Embodiment 2

[0137] Figure 21 It is a structural schematic diagram of an oil pump automatic and precise assembly assembly of the present invention; Figure 21 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0138] like Figure 21 , Figure 22 and Figure 23 As shown, an oil pump automatic and precise assembly assembly also includes an automatic lifting mechanism 8 arranged on the base 3, and the automatic lifting mechanism 8 drives the oil pump casing 1 in the positioning groove 31 to move vertically. lift settings.

[0139] Further, the automatic lifting mechanism 8 includes:

[0140] Lifting seat 81, the lifting seat 81 is slidably arranged in the positioning groove 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com