Threaded pipe assembly device

A technology for assembling devices and pipelines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high labor costs, slow installation speed, and affecting the personal safety of installation workers, so as to achieve personal safety and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

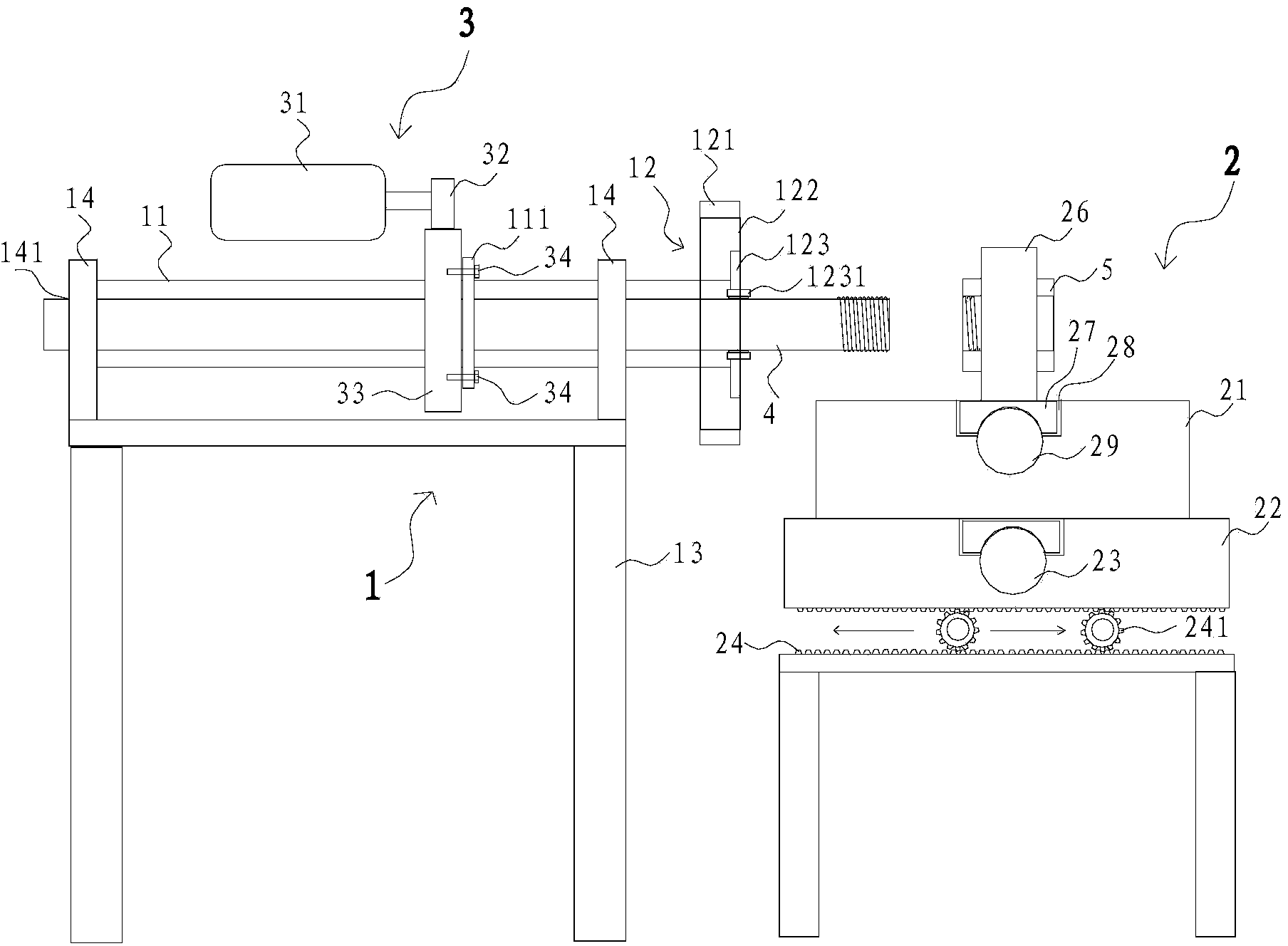

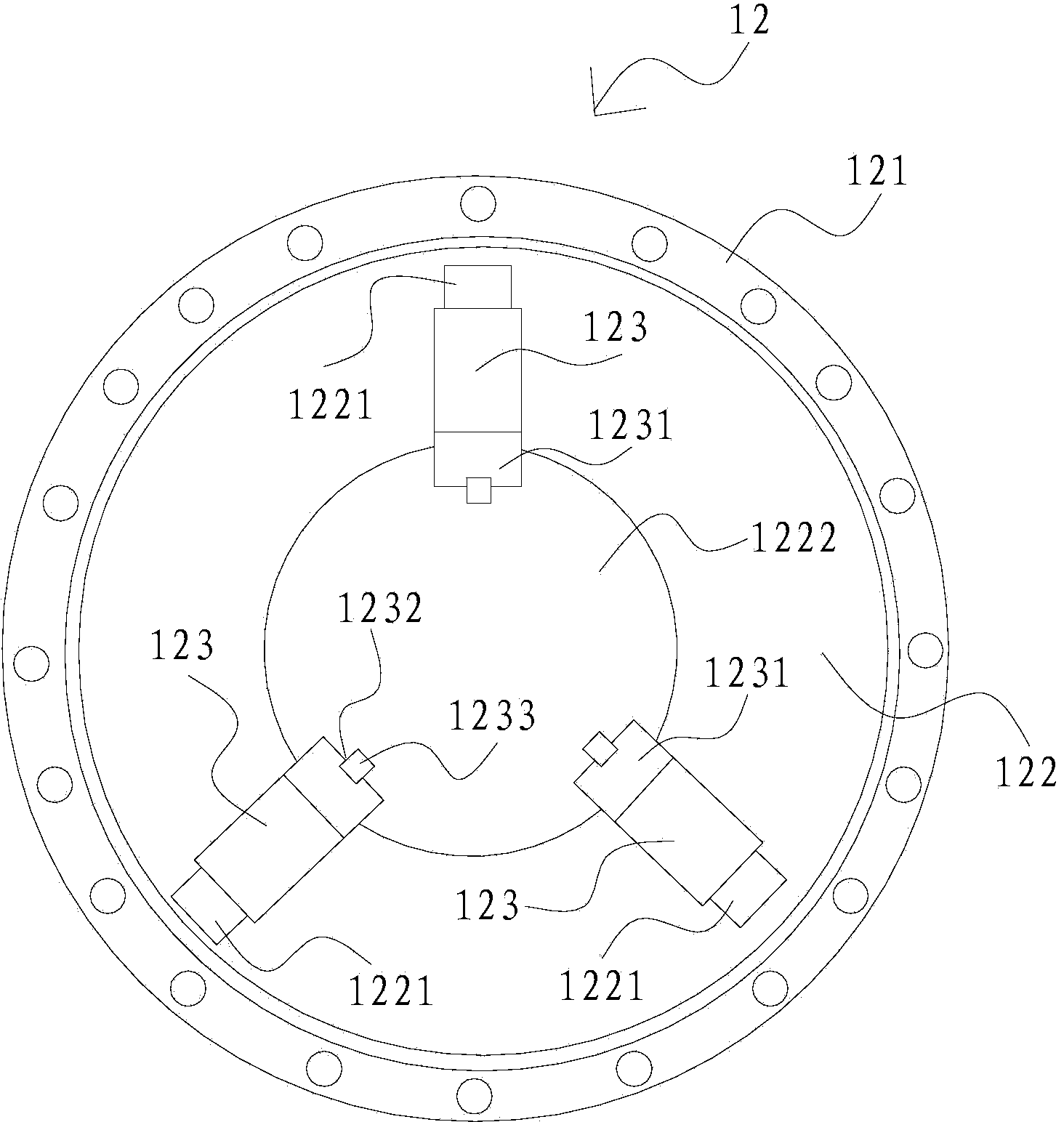

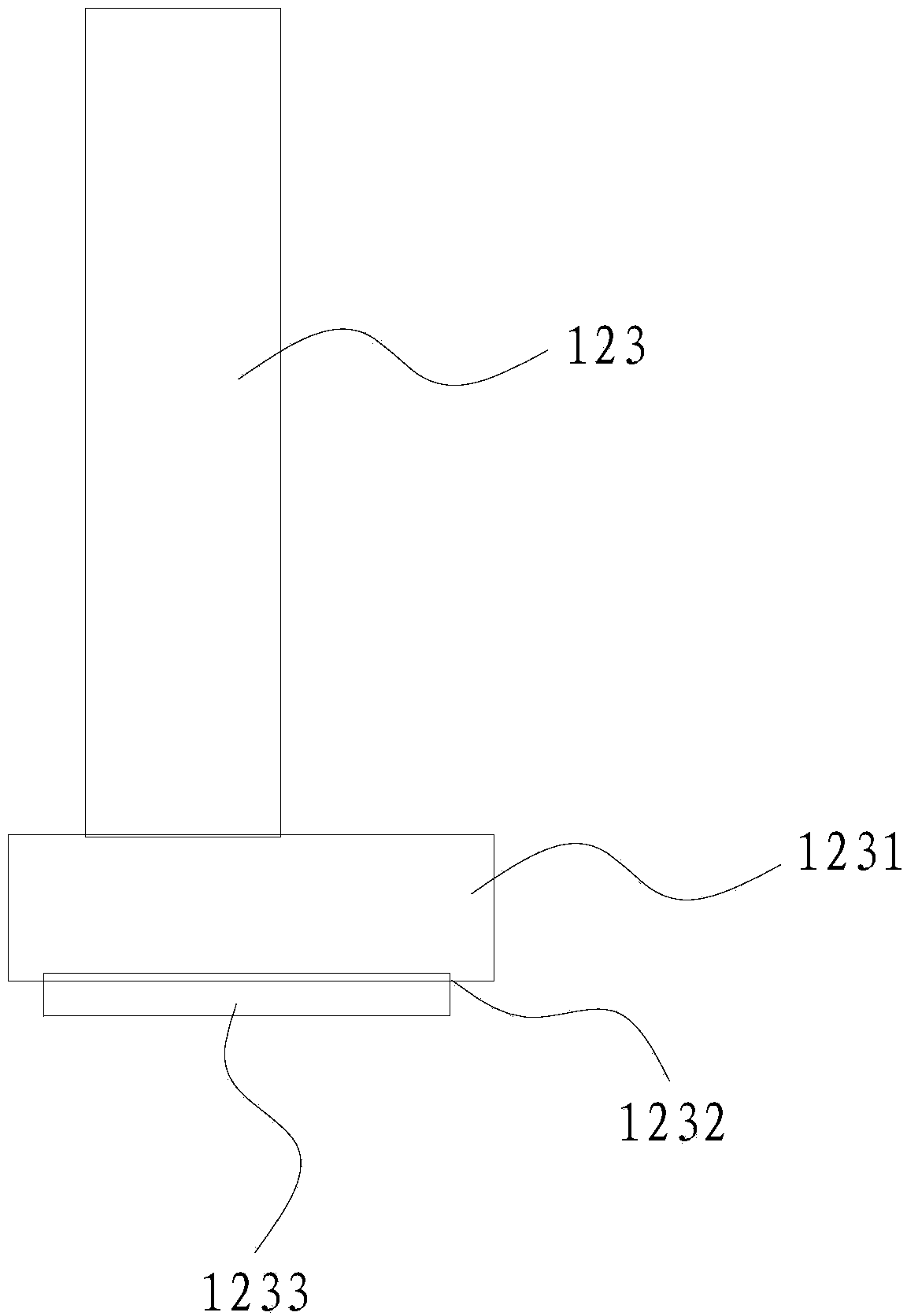

[0027] Attached below Figure 1 to Figure 7 The present invention is described in further detail.

[0028] figure 1 Schematically shows a threaded pipe assembly device according to an embodiment of the present invention, such as Figure 1 to Figure 5 As shown, the threaded pipe assembly device includes a first fixing unit 1 , a second fixing unit 2 and a driving unit 3 . Wherein, the first fixing unit 1 is used to fix the pipe body 4 to be assembled; the second fixing unit 2 is used to clamp the pipe joint 5 to be assembled, and the second fixing unit 2 can slide in the horizontal direction; the driving unit 3 is used to Drive pipe body 4 to rotate.

[0029] The pipe body 4 and the pipe joint 5 are respectively arranged at the same level by the first fixing unit 1 and the second fixing unit 2, and the pipe body 4 is driven to rotate by the driving unit 3. At the same time, the second fixing unit 2 clamps the pipe joint 5 close to The first fixing unit 1 finally realizes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com