Quick tool changing device for automatic feeding drill

A technology of automatic feed drilling and tool changing device, which is applied in the direction of boring machine/drilling machine parts, drilling/drilling equipment, metal processing equipment, etc., which can solve the problems of automatic feed drilling and tool disassembly difficulties, and achieve consistent improvement sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

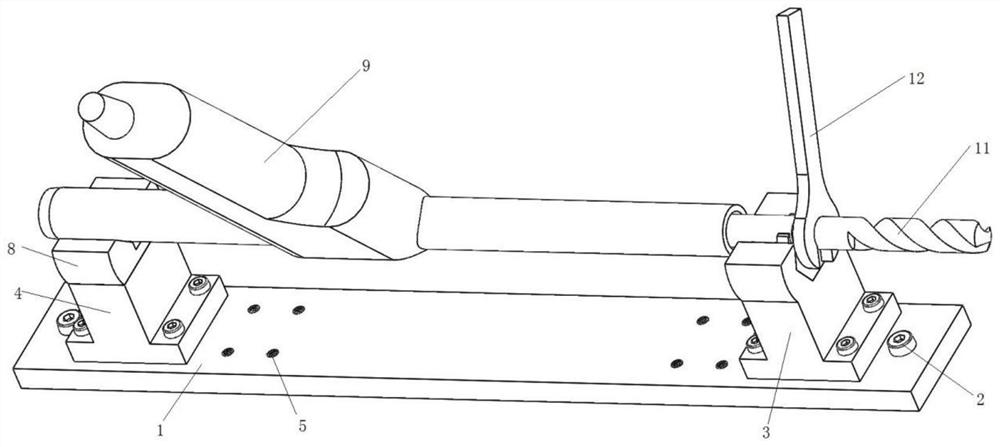

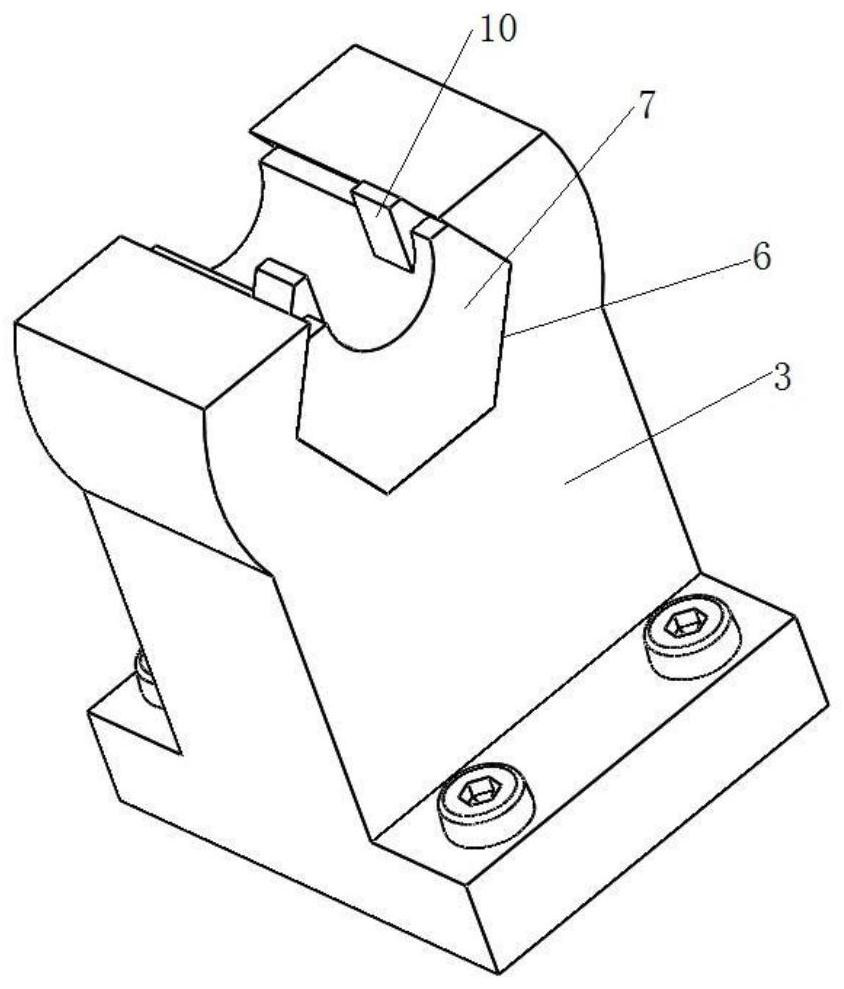

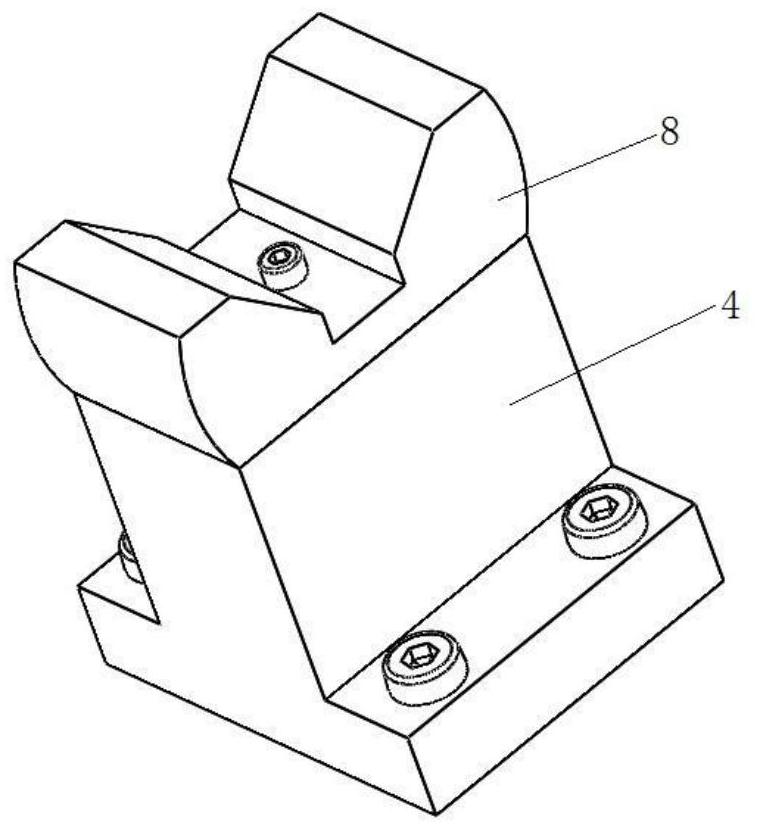

[0023] Such as Figure 1 to Figure 4 As shown, the present invention is a quick tool change device for automatic feed drill, including a bottom plate 1, the bottom plate 1 is fixed and installed on the workbench through locking bolts 2, and the workbench needs to have a certain self-weight or through anchor screws and The ground is fixed to ensure the stability of the bottom plate 1 during use; the two ends of the bottom plate 1 are respectively fixedly connected with the lock seat 3 and the support seat 4 by bolts, and the bottom plate 1 is provided with multiple sets of threaded holes 5 at equal intervals, and the threaded holes 5 It is connected with bolts to fix the lock tool seat 3 and the support seat 4, and the position of the lock tool seat 3 and the support seat 4 can be adjusted according to the size of the automatic feed drill 9 to meet the quick c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com