Composite wallboard used for building assembling

A wall panel and duplex technology, applied in the direction of architecture, building structure, application, etc., can solve the problems of weak installation, simple design structure, troublesome installation, etc., and achieve the effect of solving the trouble of fixed installation and solving the weak installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

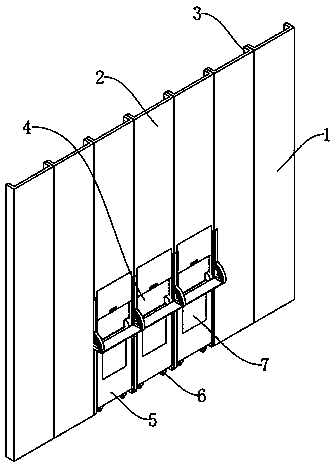

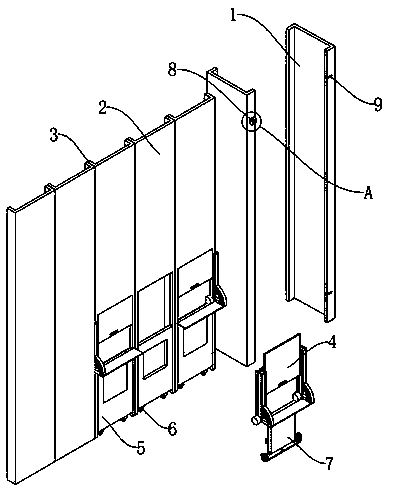

[0027] see Figure 1-4 , a compound wall panel for building assembly, including a fixed panel body 1 and an installation panel body 2, the backs of the fixed panel body 1 and the installation panel body 2 are fixedly connected with a protruding panel 3, and a connecting panel is installed on one side of the protruding panel 3 Mechanism 8, the other side of the protruding plate 3 is provided with a connecting groove 9, the connecting groove 9 matches the connecting mechanism 8 on the adjacent protruding plate 3, and the adjacent fixed plate body 1 or mounting plate body 2 passes through the connecting mechanism 8 It is connected with the connection groove 9; the installation plate body 2 is provided with an installation opening, and the table plate turning mechanism 4 is fixedly installed inside the installation opening, and a movable storage mechanism is also provided under the installation plate body 2, and the movable storage mechanism includes a movable plate 5 , the bottom...

Embodiment 2

[0031] see Figure 5-6 , based on Embodiment 1, the difference is that;

[0032] The table top folding mechanism 4 includes a mounting frame 15 and a connecting plate 18, the mounting frame 15 is fixedly connected with the mounting plate body 2, the mounting frame 15 is provided with a chute 16, and the mounting frame 15 is fixedly connected with a baffle plate 17, which is connected The plate 18 is fixedly connected in the installation opening of the mounting plate body 2 , the connecting plate 18 is fixedly connected with a first rotating shaft connecting block 19 , and the first rotating shaft connecting block 19 is rotatably connected with a first rotating shaft.

[0033] Table top folding mechanism 4 also includes connecting frame 20, the bottom end of connecting frame 20 is fixedly connected on the first rotating shaft, and connecting frame 20 is provided with through groove 21, and through groove 21 matches with chute 16, and connecting frame 20 Limiting grooves 22 are...

Embodiment 3

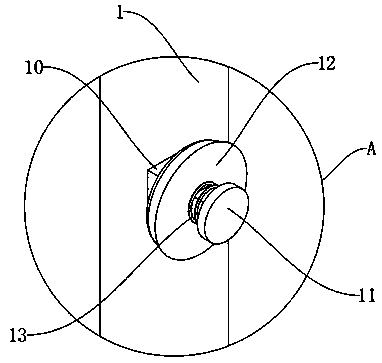

[0037] refer to Figure 7 ; Based on Embodiment 1 or 2, the difference is that;

[0038] The storage board 7 includes a storage board body 27, the bottom end of the storage board body 27 is fixedly connected with a second rotating shaft 28, the storage board body 27 is rotationally connected with the movable plate 5 through the second rotating shaft 28, and the two ends of the second rotating shaft 28 are fixedly connected There is a first connecting rod 29, the first connecting rod 29 is fixedly connected with a first belt pulley 30, the first rotating shaft connection block 19 is internally connected with a second belt pulley, the second belt pulley is fixedly connected on the first rotating shaft, and the transmission The belt 14 is connected around the first belt pulley 30 and the second belt pulley; the end of the first connecting rod 29 away from the second rotating shaft 28 is fixedly connected to the first bevel gear 31, and the first bevel gear 31 is engaged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com