Patents

Literature

37results about How to "Suitable for automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

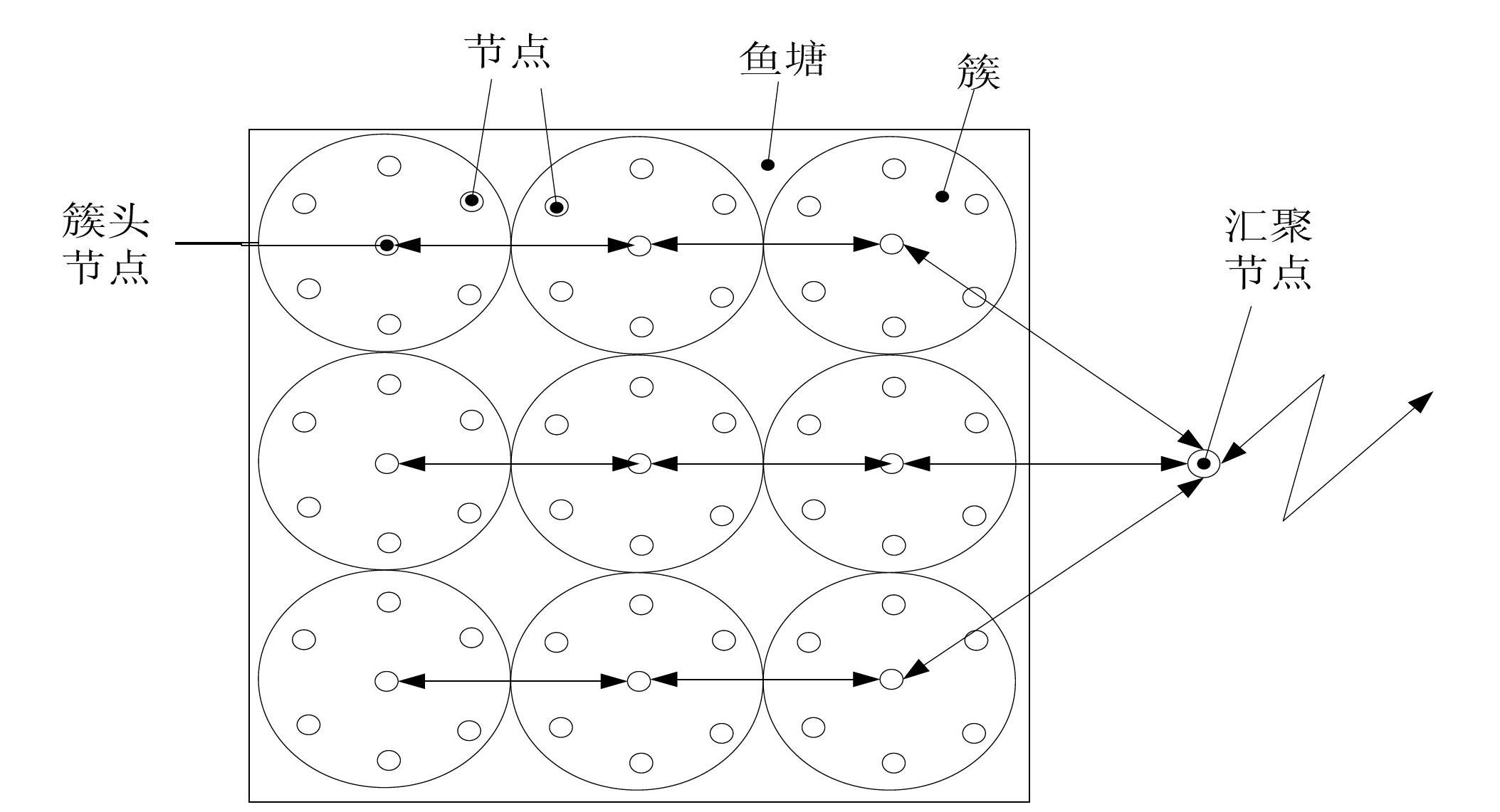

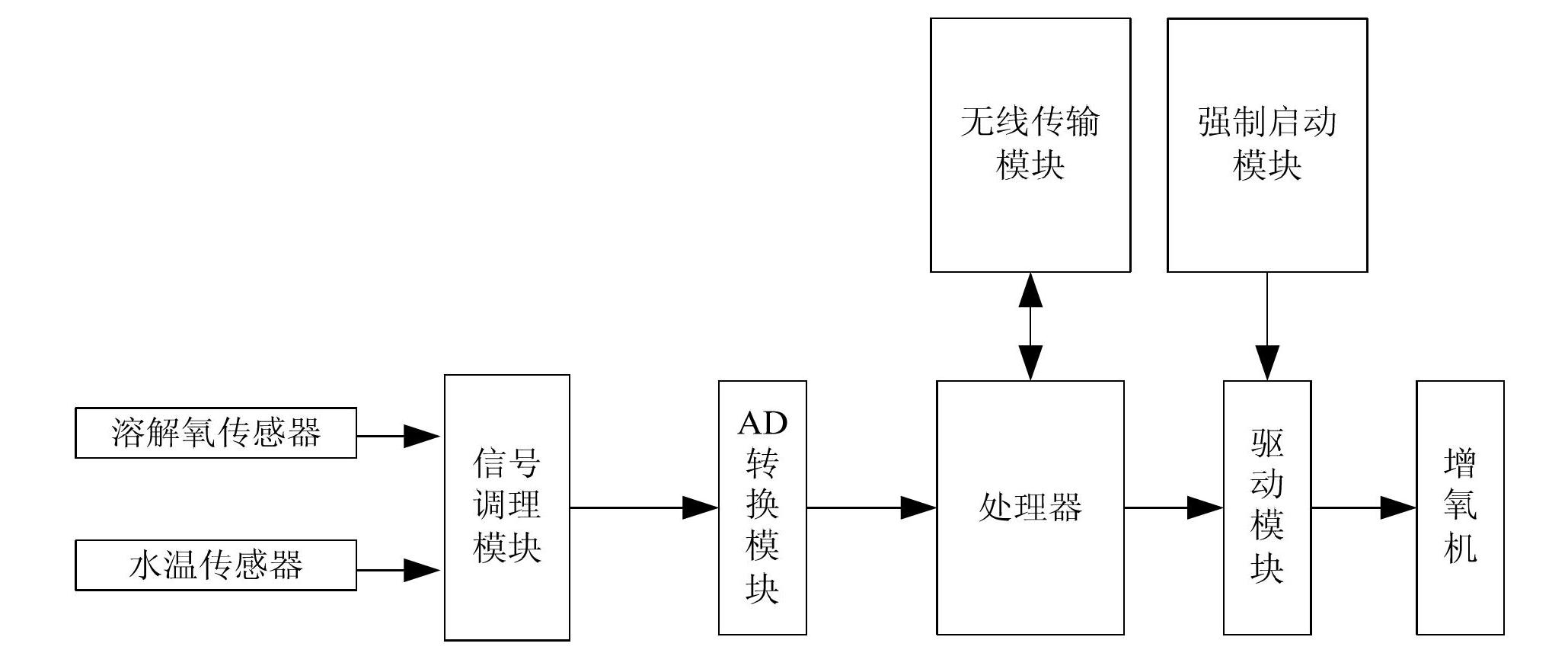

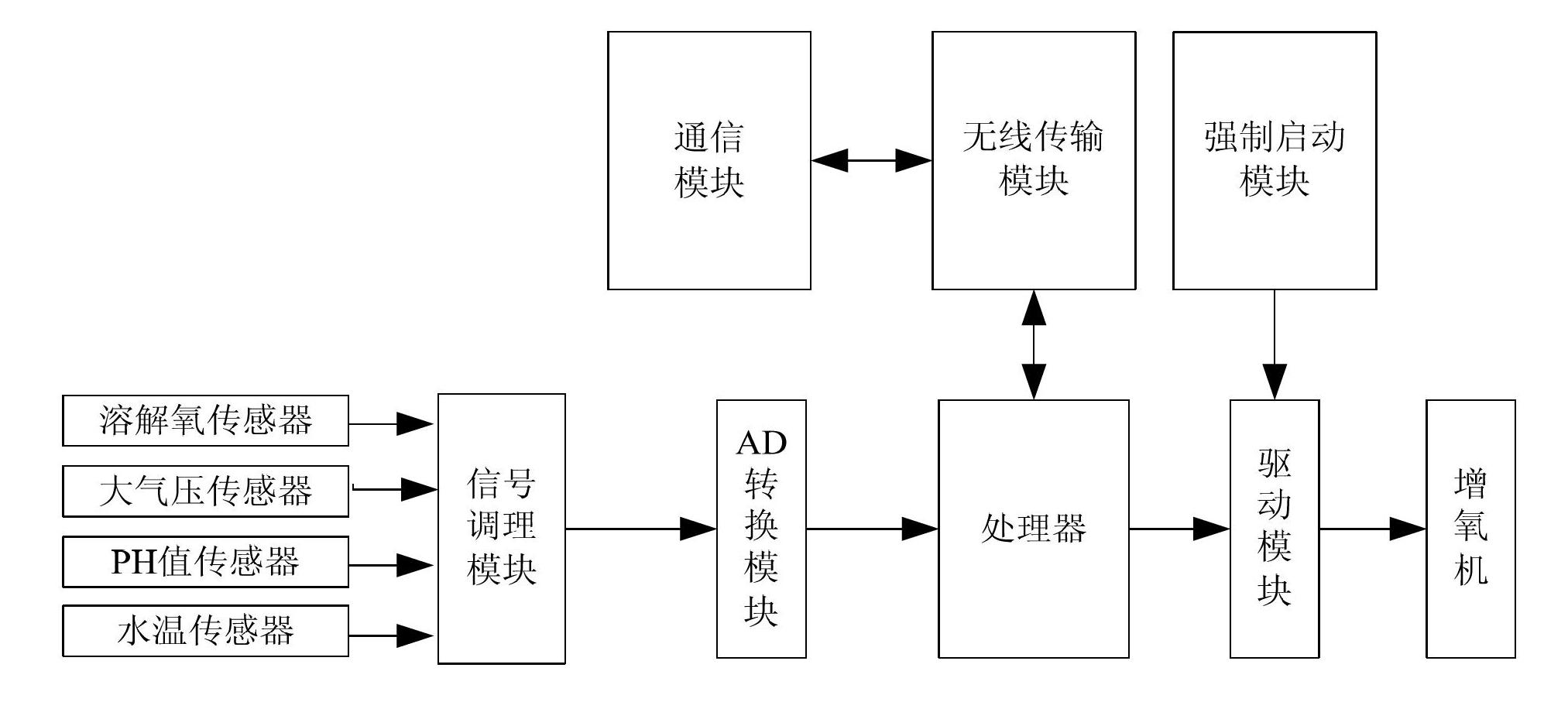

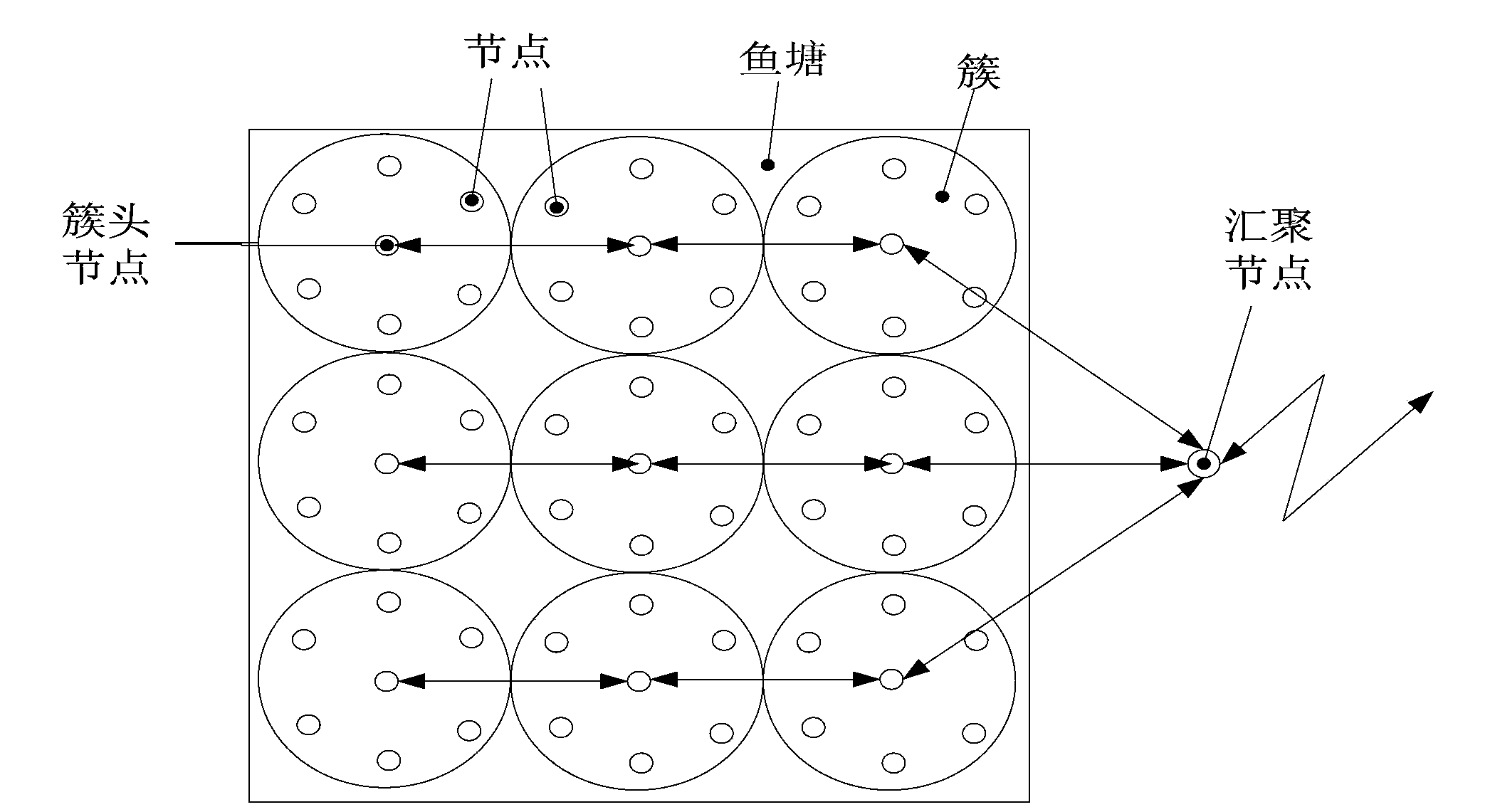

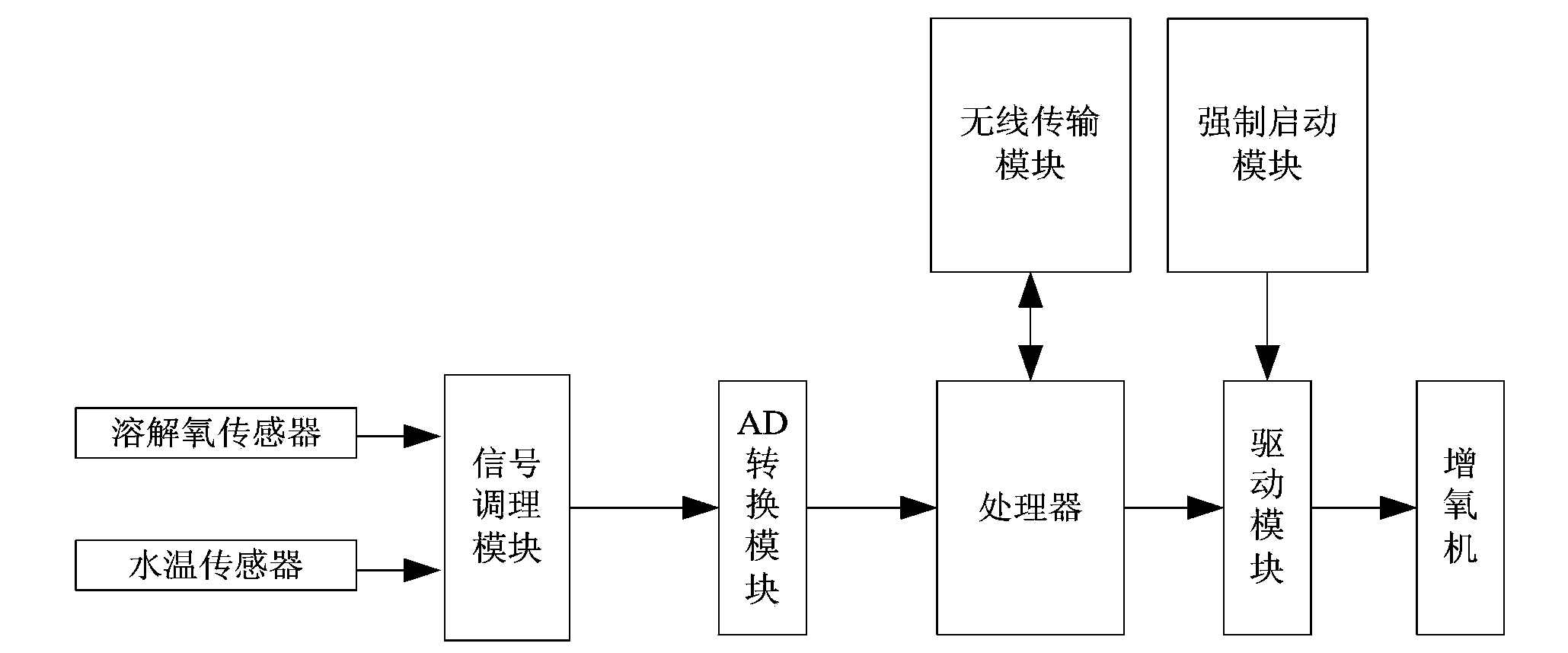

Monitoring system for aquaculture environment of fresh-water fish on basis of wireless sensor network

InactiveCN102645927AOptimize layoutFlexible layoutClimate change adaptationPisciculture and aquariaAutomatic controlWireless mesh network

The invention relates to a monitoring technology for the aquaculture environment of fresh-water fish and discloses a monitoring system for the aquaculture environment of the fresh-water fish on the basis of a wireless sensor network. The monitoring system comprises cluster head nodes connected with i nodes, wherein k cluster head nodes are connected with collecting nodes; m collecting nodes are connected with a monitoring center; and all i, k and m are natural numbers. The monitoring system is characterized in that the nodes, the cluster head nodes and the collecting nodes are configured with a water temperature sensor, a dissolved oxygen sensor, an aerator, a node processing module and a wireless transmission module. The collecting nodes also comprise an atmospheric pressure sensor, a PH value sensor and a communication module; the atmospheric pressure sensor, the PH value sensor and the node processing module are connected; and the communication module is connected with the wireless transmission module and is used for transmitting data to the monitoring center and receiving an instruction. The monitoring system disclosed by the invention can realize large-range wireless monitoring network layout, and is very suitable for automatic control of large-scale fresh-water aquaculture.

Owner:SICHUAN TIANXING LIGHTING ENG DESIGN

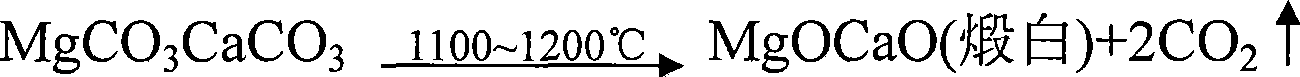

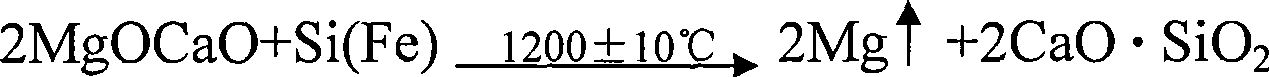

Process for smelting magnesium by microwave heating Pidgeon process

The invention discloses a magnesium reduction process through a micro-wave heating silicothermic method; the process comprises the following steps: 1. dolomite calcinations: the dolomite is heated to 1100 DEG C to 1200 DEG C and becomes calcined dolomite; 2. the calcined dolomite, silicon nitride powder and fluorite powder are weighed, mixed, milled and then pressed into a ball which meets technological requirements; 3. the ball is put into a closed non-metal reduction tank of a micro-wave heating oven to be heated under 1000 DEG C to 1200 DEG C, so that the magnesium compound in the ball reacts with the silicon nitride powder; 4. the vacuum degree of the closed non-metal reduction tank is kept to be 13.3Pa or higher for 4h to 6h; magnesium vapor is condensed in a condenser and becomes crude magnesium; 5. the crude magnesium is heated, melted and refined by solvent, to obtain refined magnesium; 6. acid washing and the like. The method evenly and quickly heats in the principle of micro-wave heating with high heating efficiency, is easy to be controlled, saves production cost, is safe, environment protective and harmless.

Owner:重庆科健冶金材料有限公司

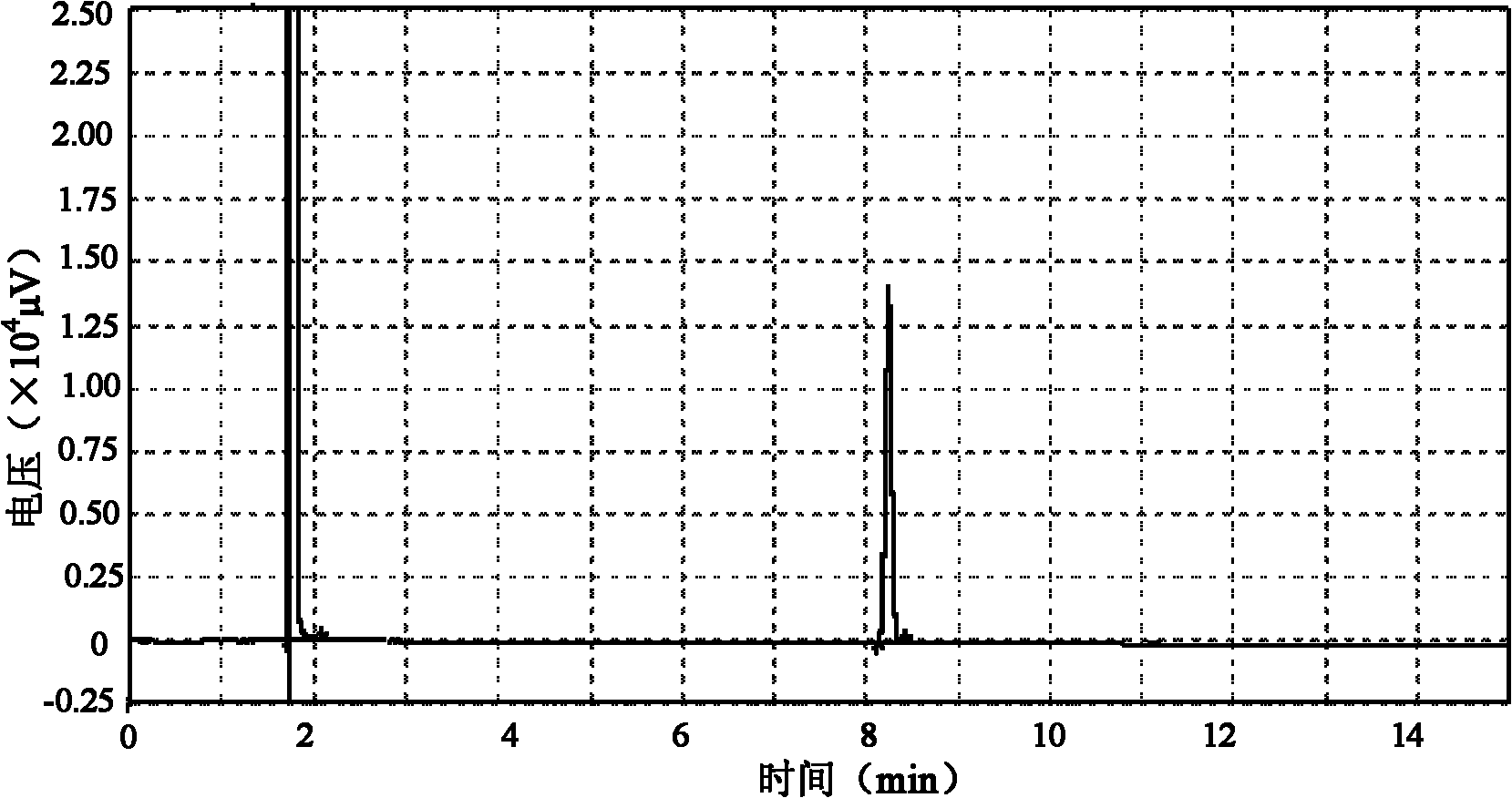

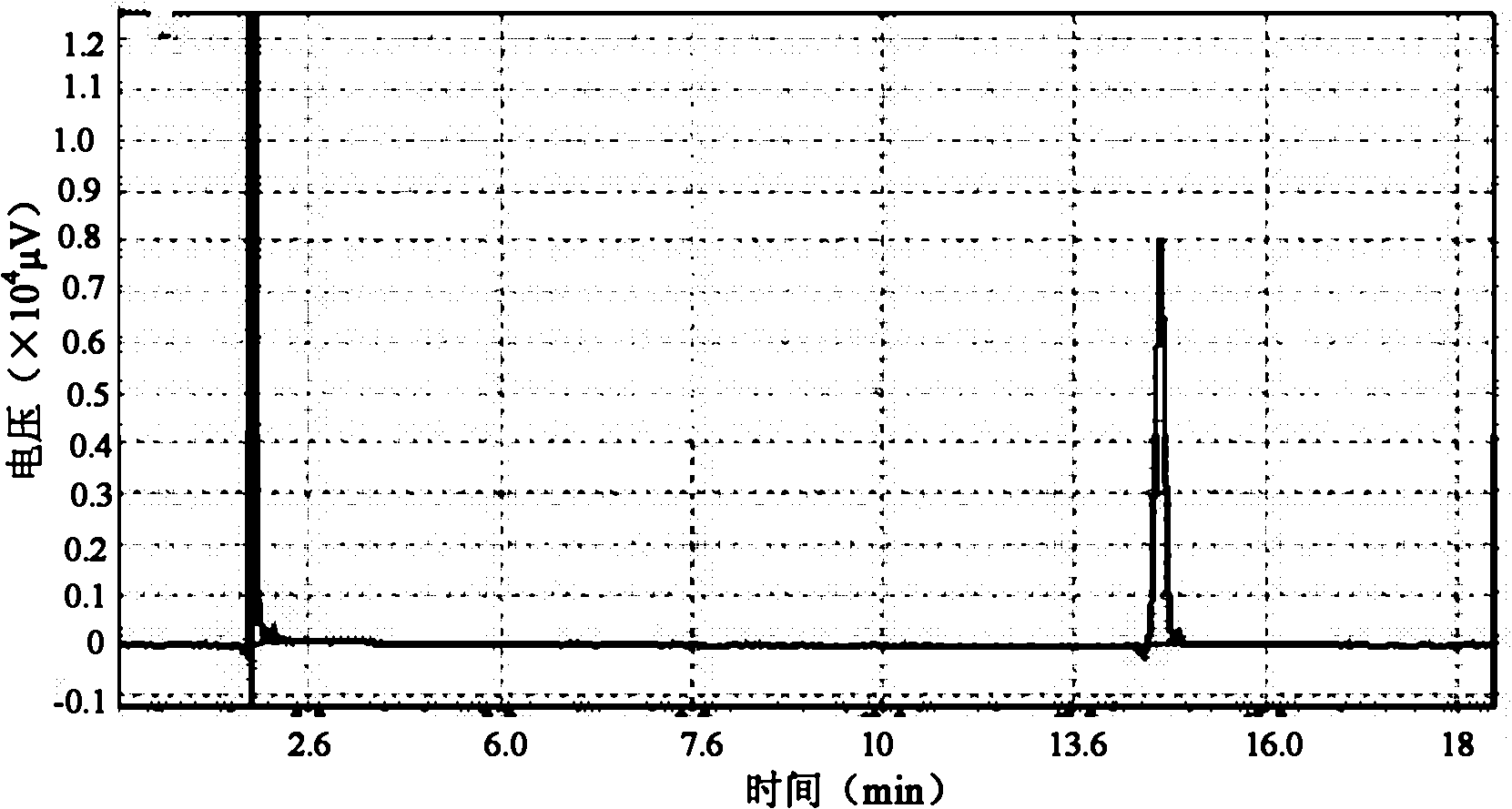

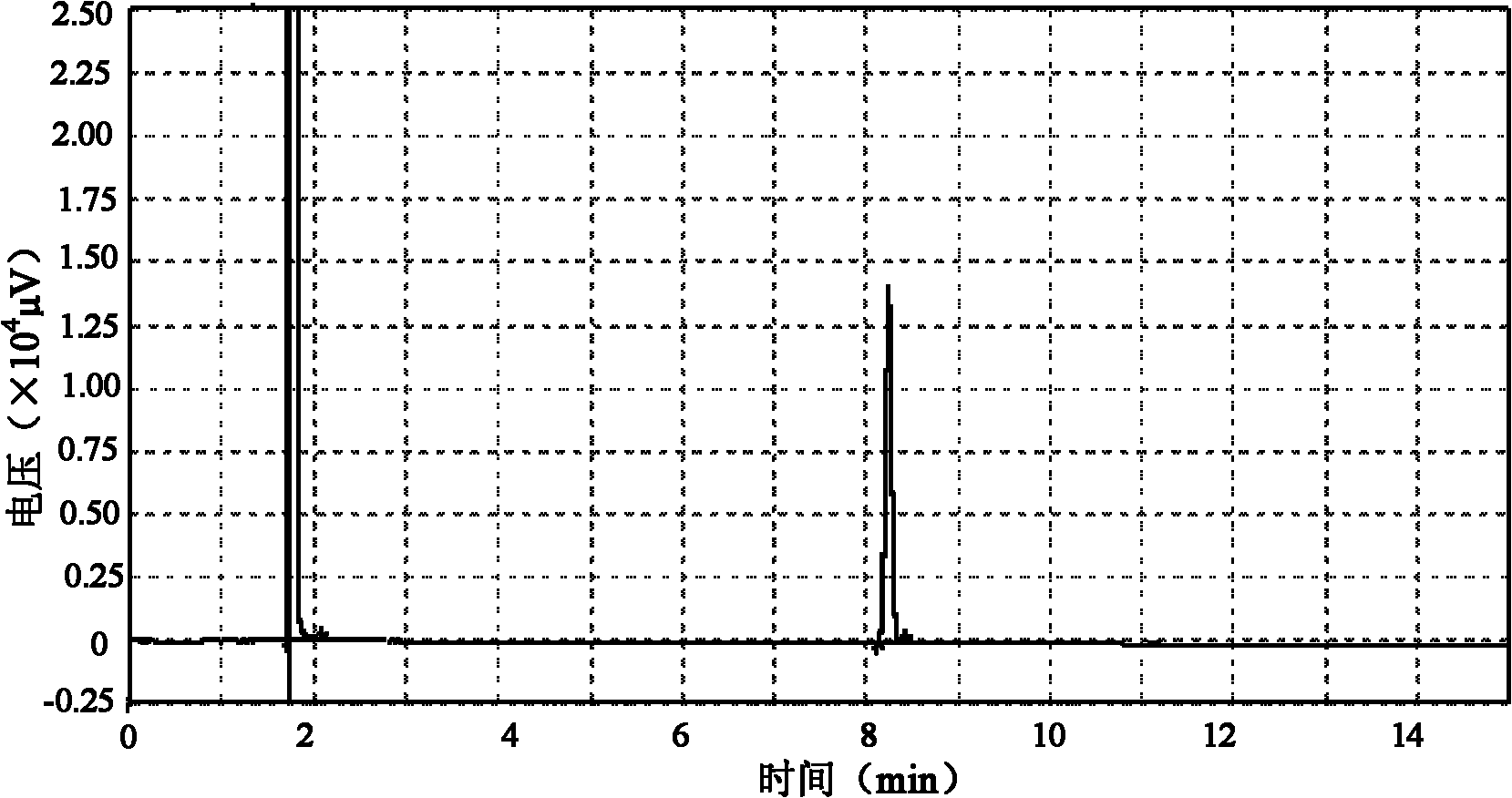

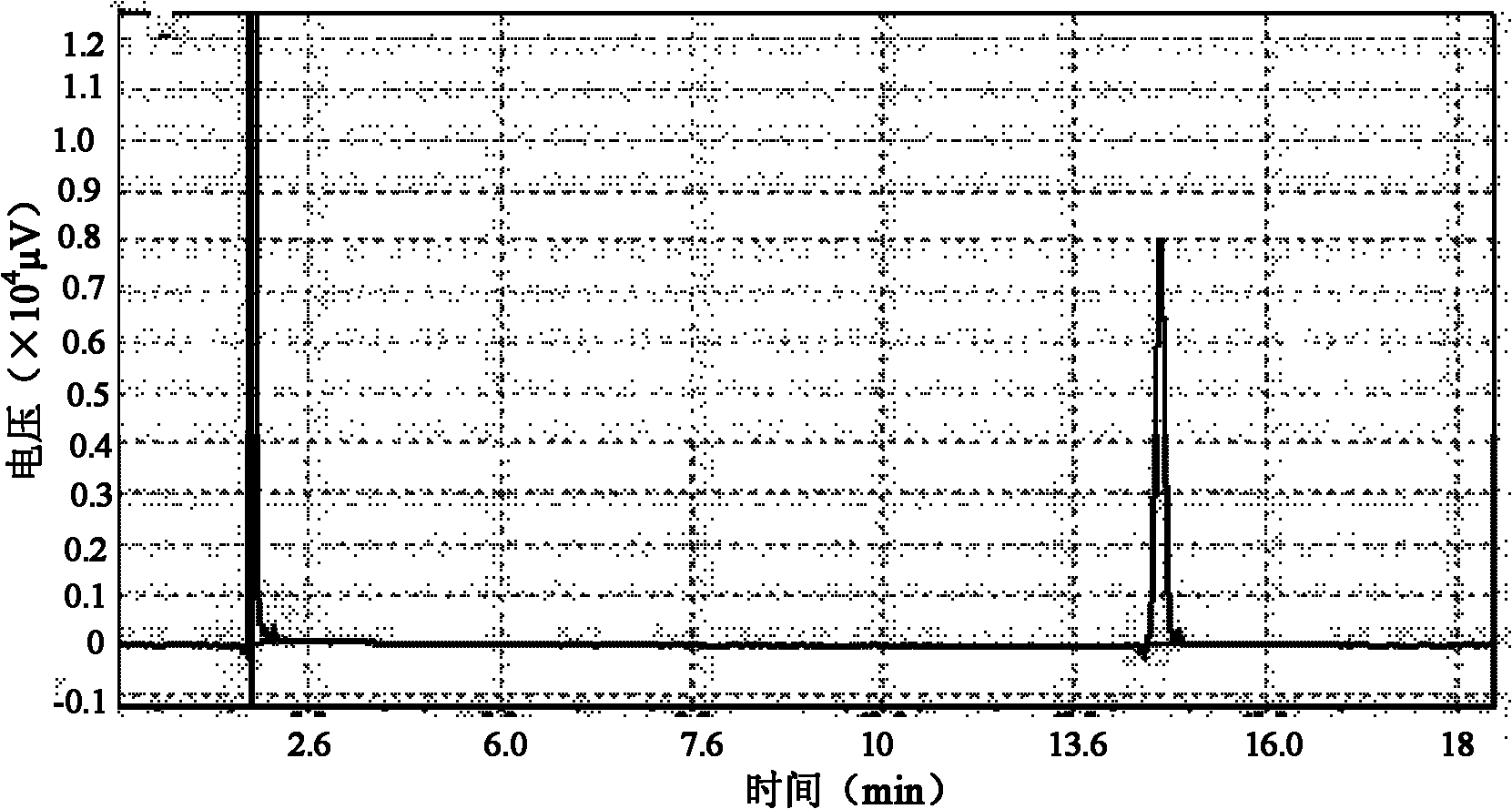

The preparation method of epa ethyl ester and dha ethyl ester

ActiveCN102285880AHigh yieldSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationFraction CollectorAutomatic control

The invention discloses a method for preparing ethyl eicosapentaenate (EPA) and ethyl docosahexaenoate (DHA) and relates omega-3 long-chain polyunsaturated fatty acids. The method comprises: preparing prepared solution to be separated by using a fish oil coarse raw material, which contains ethyl EPA and ethyl DHA, and using an organic solvent as a solvent; transferring the prepared solution to be separated into a material storage tube of a semi-prepared / prepared high-efficiency liquid chromatography-mass spectrum combined apparatus system, starting the semi-prepared / prepared high-efficiency liquid chromatography-mass spectrum combined apparatus system of which a mobile phase is aqueous solution of methanol or ethanol, balancing a chromatographic column, sampling automatically, separating and purifying ethyl EPA and ethyl DHA, and trigging a distillate collector by a mass spectrum online detection signal to collect pure ethyl EPA liquid and ethyl DHA liquid separately and automatically; and subjecting the pure ethyl EPA and ethyl DHA to reduced pressure concentration, extraction and reduced-pressure concentration respectively and thus obtaining ethyl EPA and ethyl DHA, of which the purities are both over 99 percent. The method is characterized by simple and convenient operation and high yield and is suitable for automatic control and synchronous separation.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

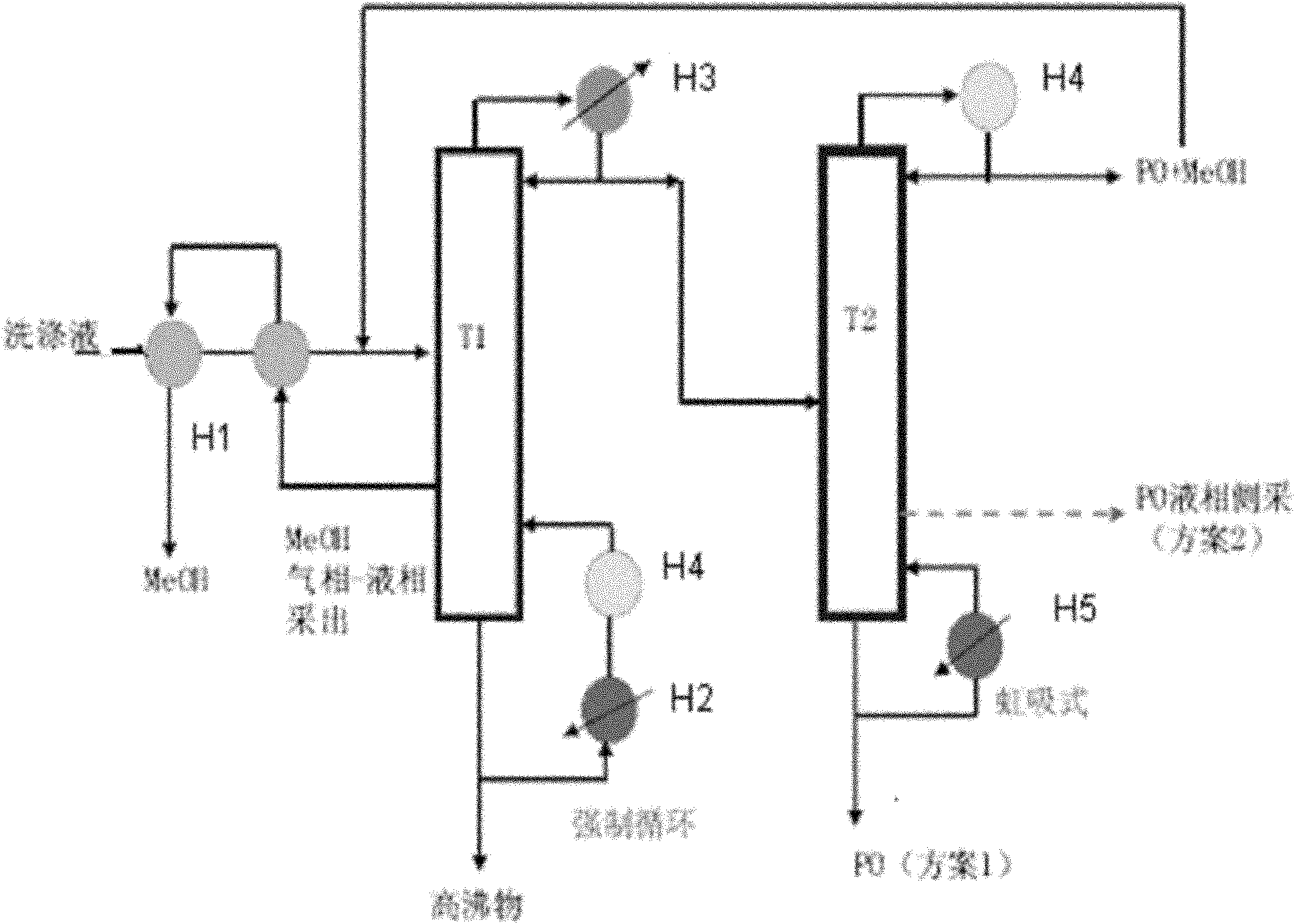

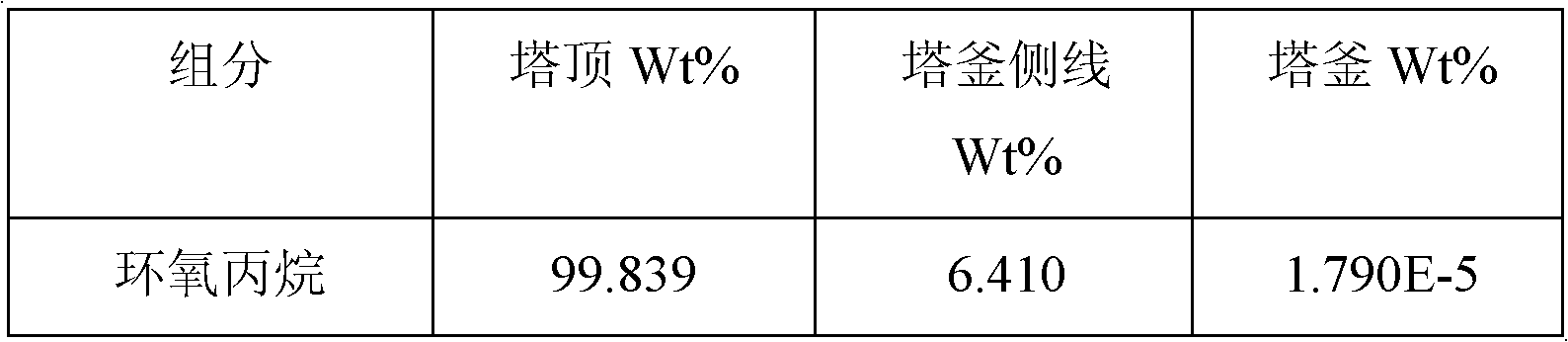

Method for separating out and purifying epoxypropane and methyl alcohol

ActiveCN102093316AReduce the temperatureReduce generationOrganic compound preparationHydroxy compound preparationAlcoholHigh pressure

The invention discloses a method for separating out and purifying epoxypropane and methyl alcohol. The method comprises the following steps: 1) rectifying washing mother liquor which contains the epoxypropane and methyl alcohol and is used for producing aliphatic polycarbonate in a first rectifying tower so as to obtain tower top material containing crude epoxypropane from the tower top of the first rectifying tower and obtain the methyl alcohol from a tower plate at the tower kettle side line of the first rectifying tower; and 2) rectifying the tower top material containing the crude epoxypropane in a second rectifying tower so as to obtain the epoxypropane from the tower plate of the tower kettle or tower kettle side line of the second rectifying tower. In the invention, a double-tower efficient rectification mode is adopted, namely, vacuum or normal pressure rectification is used in the first tower, and high pressure rectification is used in the second tower, thereby extremely effectively separating out two target substances epoxypropane and methyl alcohol, obtaining high-purity epoxypropane and methyl alcohol materials, reducing by-products and fully utilizing material energy,and the industrial process reaches the requirement of green chemistry.

Owner:CHINA NAT OFFSHORE OIL CORP +2

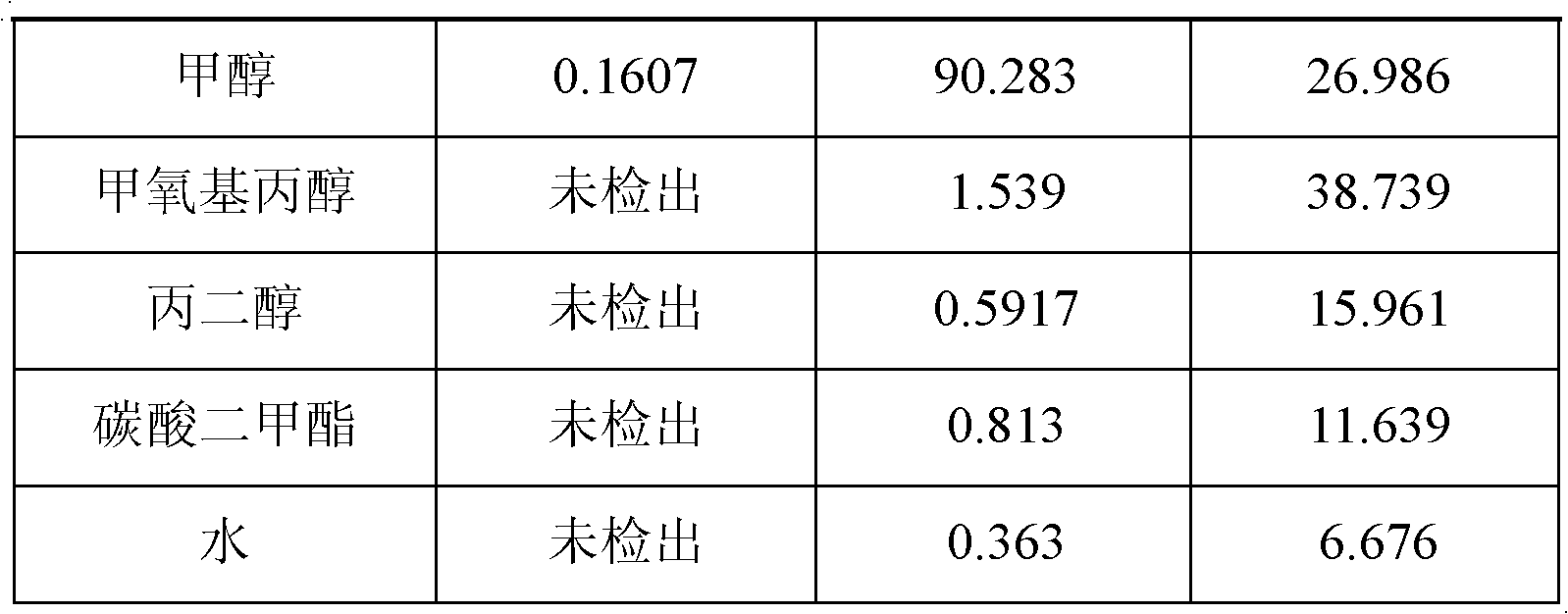

Two-section dry-type magnetic separation purification process before combustion of pulverized coal

InactiveCN101531938ASuitable for automatic controlSolid fuelsMagnetic separationEngineeringBall mill

The invention discloses a two-section dry-type magnetic separation purification process before the combustion of pulverized coal; the process comprises the step that after sampling is carried out by a ball mill, coal used for power generation firstly enters a coarse separator firstly and the process is characterized by also comprising the steps as follows: granule pulverized coal meeting the requirements of combustion granularity by the coarse separator directly enters a fine powder separator while the coarse powder burning coal is delivered to a microwave mixer, and treated simultaneously by adding a magnetic seed and a catalyst, and then conveyed to a first-section magnetic separator to carry out desulfurization and ash removal after treatment, later, cleaned coal after magnetic separation is returned to the ball mill again, and then tail coal is separated out; micro-powder fine coal which is separated out by the fine powder separator is directly conveyed to a burner while qualified pulverized coal which is separated out enters another microwave mixer, and also treated simultaneously by adding the magnetic seed and the catalyst, and then conveyed to a second-section magnetic separator to carry out desulfurization and ash removal after treatment, later, cleaned coal after magnetic separation is delivered to the burner for combustion, and then tail coal is separated out; and the process has the advantages of high efficiency, quick effect, energy conservation and electricity conservation, cleanness and safety, and good desulfurization effect.

Owner:HENAN POLYTECHNIC UNIV

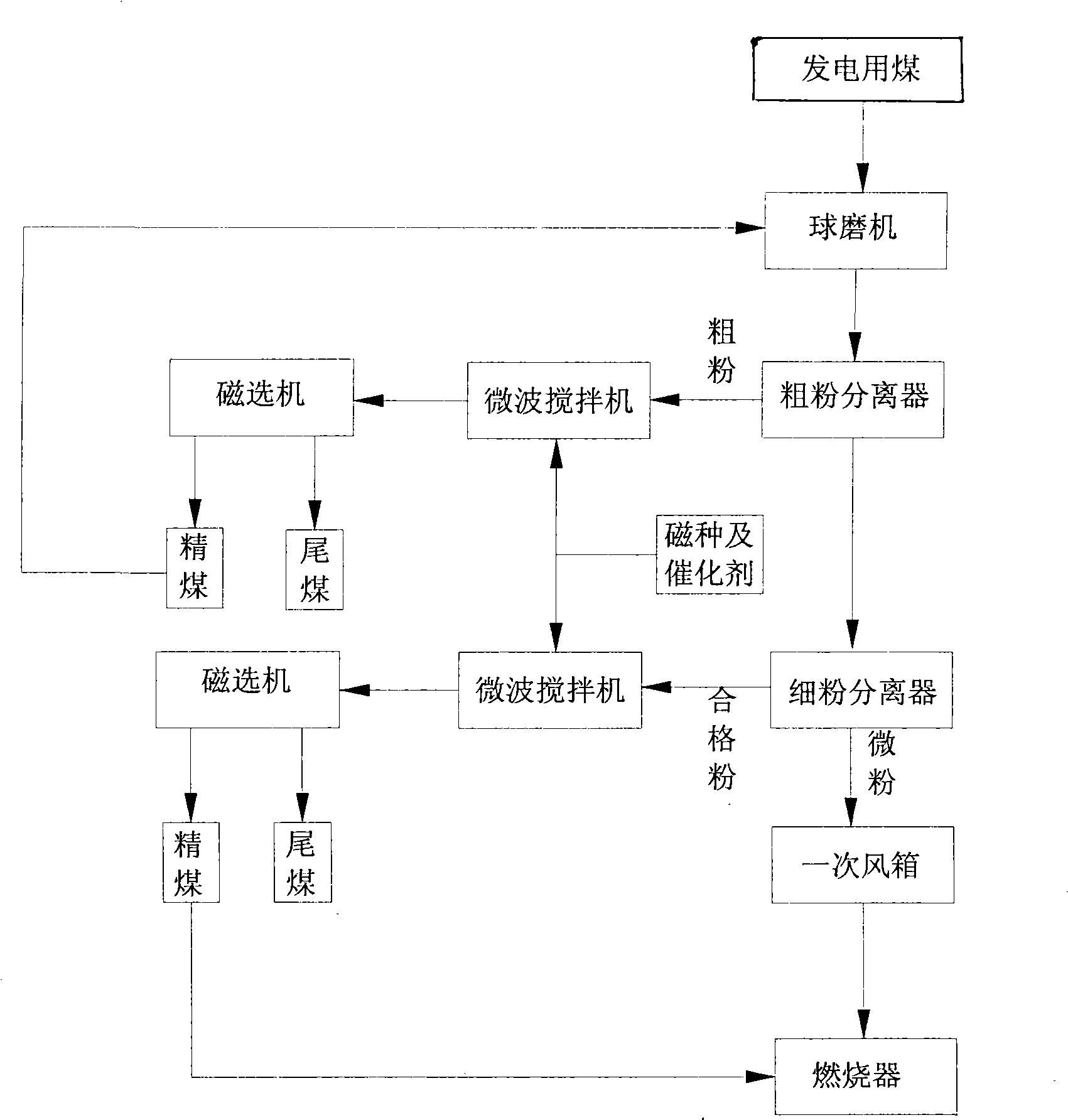

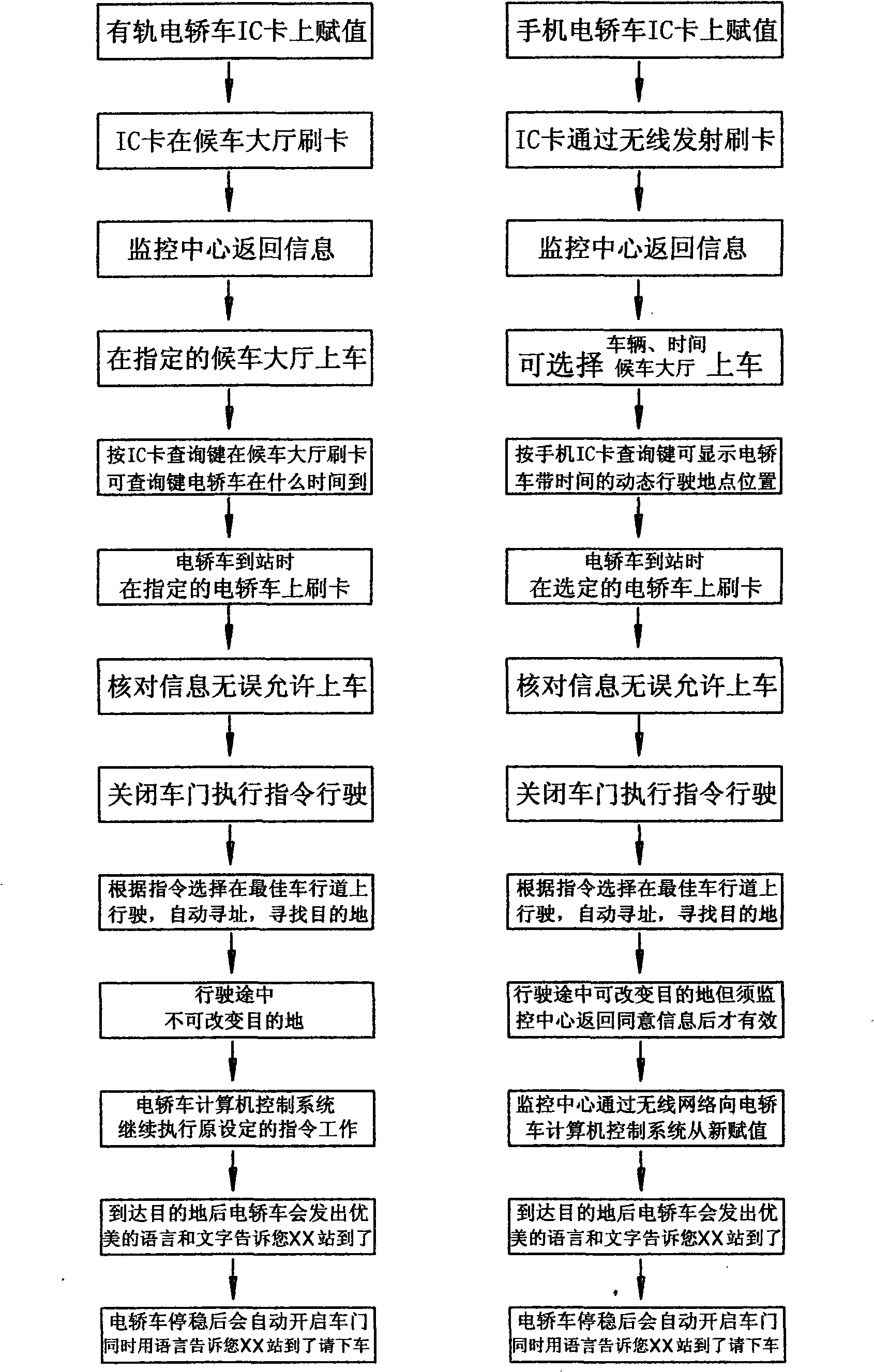

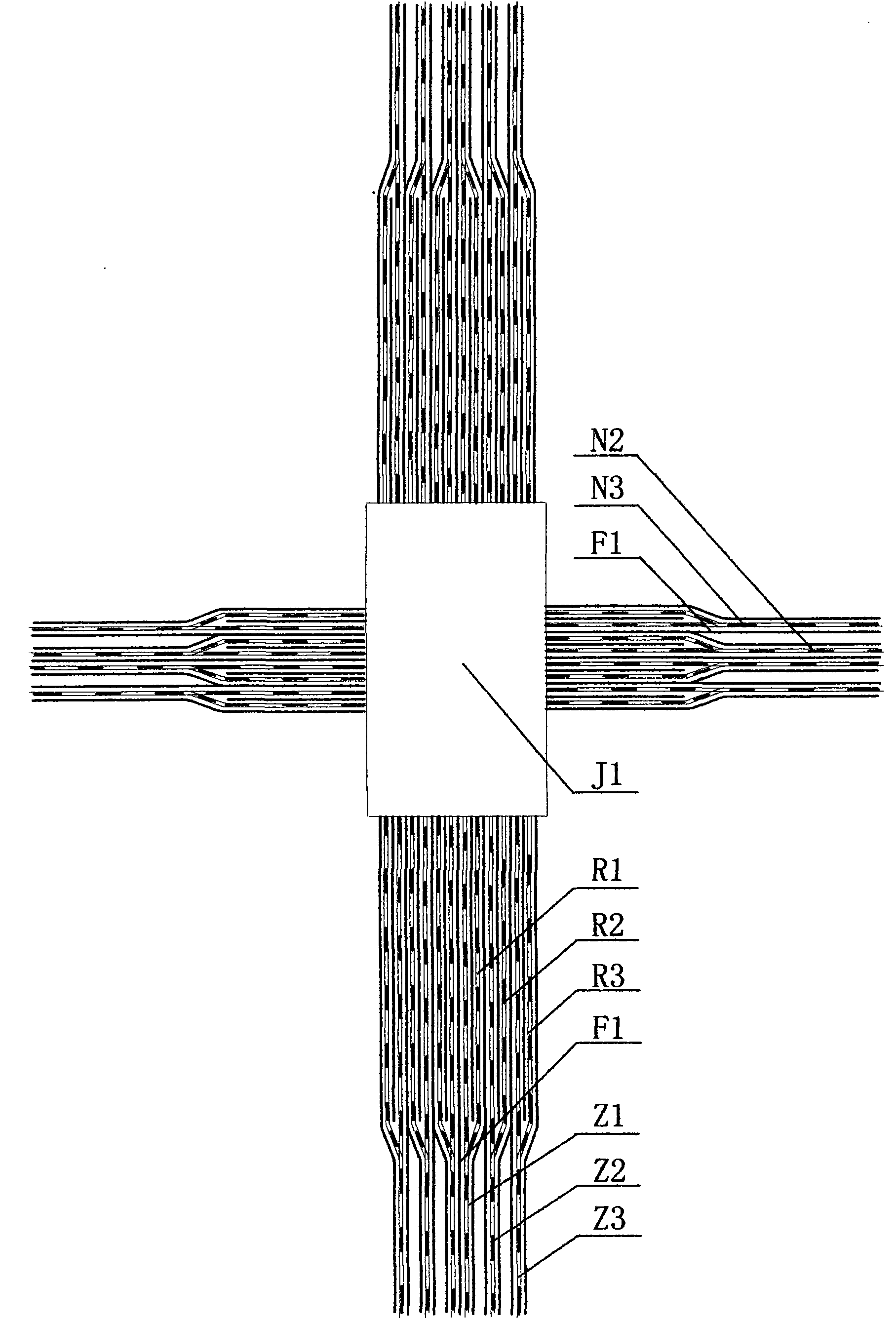

Unmanned rail electric vehicle and sky-train system

InactiveCN102107662ATravel convenienceConvenient carAutomatic systemsElectric locomotivesSteering wheelSky

The invention relates to an unmanned rail electric vehicle and a sky-train system. Regarding the rail electric vehicle, a lane is laid by turnout-free light rails and an anti-impact vertical guide pavement closed and laminate lane, and the vehicle runs on the railway, thus being named as sky-train; the rail electric vehicle adopts unmanned driving, and a destination is found through addressing codes by a vehicular computer system and through road infrared remote control information; a rail electric vehicle monitor center, an automatic indoor parking lot, a high-rise high-capacity indoor parking lot, an indoor platform and a waiting room are arranged; a bus-type rail electric vehicle ticket can be booked by a method which sends a short message via an internet mobile phone, and a taxi-type rail electric vehicle or a household rail electric vehicle can be reserved for pickup on time at a right station; a steering mechanism does not have a steering wheel, the vehicle steering can be completed by a main steering wheel and an auxiliary steering wheel through guiding pavement; and the rail electric vehicle can be a bus type, a taxi type, a household type and an online goods delivery and receiving type.

Owner:张兔生

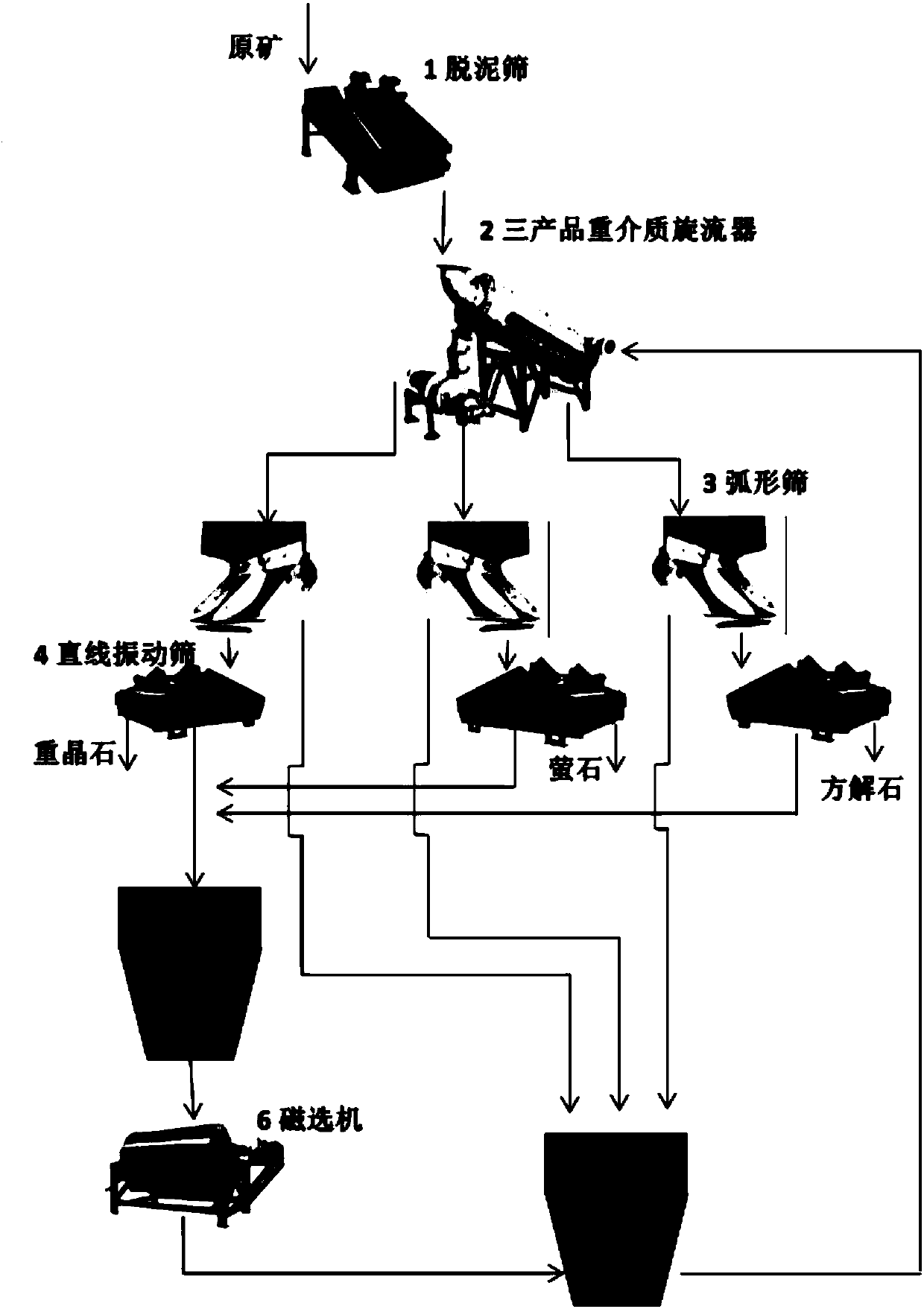

Dense medium beneficiation method for barites

InactiveCN107774438AGuaranteed recyclingIncrease total reservesSievingVortex flow apparatusAutomatic controlLower grade

The invention discloses a dense medium beneficiation method for barites. According to the dense medium beneficiation method, dense medium suspension liquid with proper density is prepared according todifferent densities of minerals and is utilized for separating usable minerals and gangue minerals, and two minerals with the density difference equal to or more than 0.2g / cm<3> can be effectively separated. The dense medium beneficiation method has the beneficial effects that low-grade resources can be processed, and the total reserves of the minerals can be increased; and universal and standardauxiliary equipment is adopted in the whole separation process, is low in investment, small in occupied area, easy to operate, low in operation cost and applicable to complete automatic control, so that the economic benefit of mines can be greatly increased.

Owner:HUAIBEI HUAXING GONGMAO

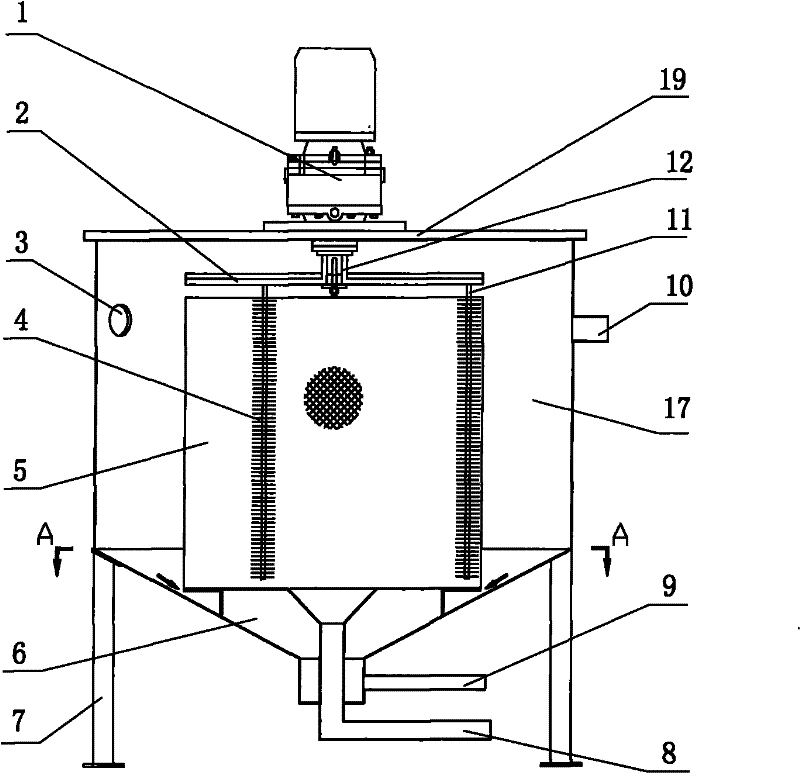

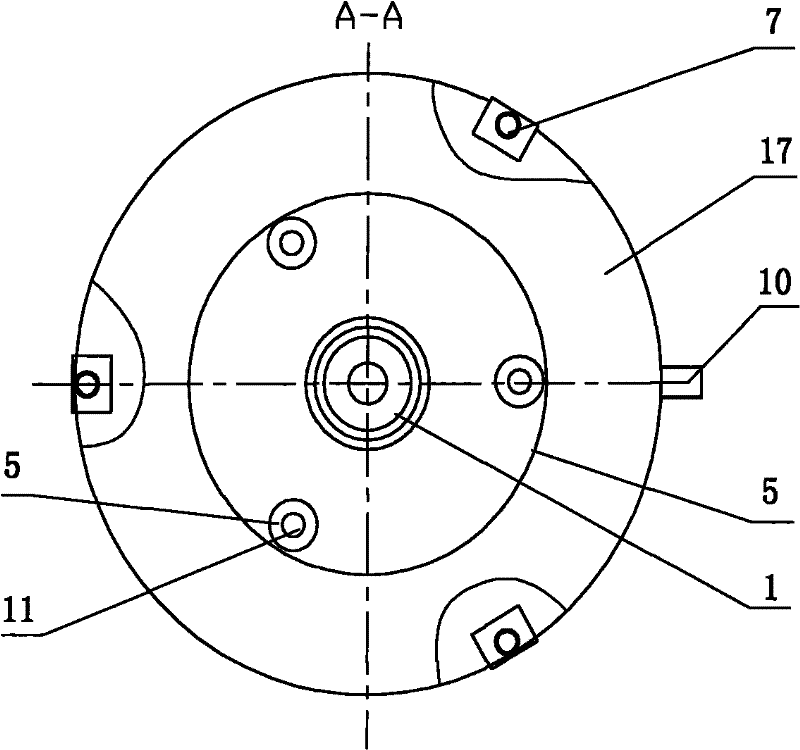

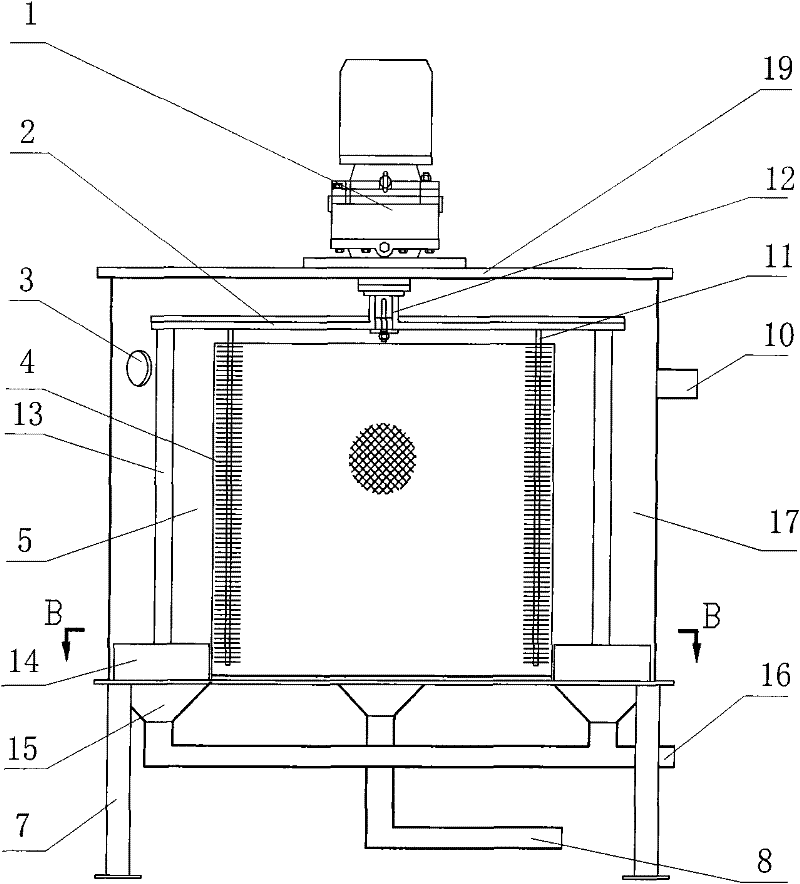

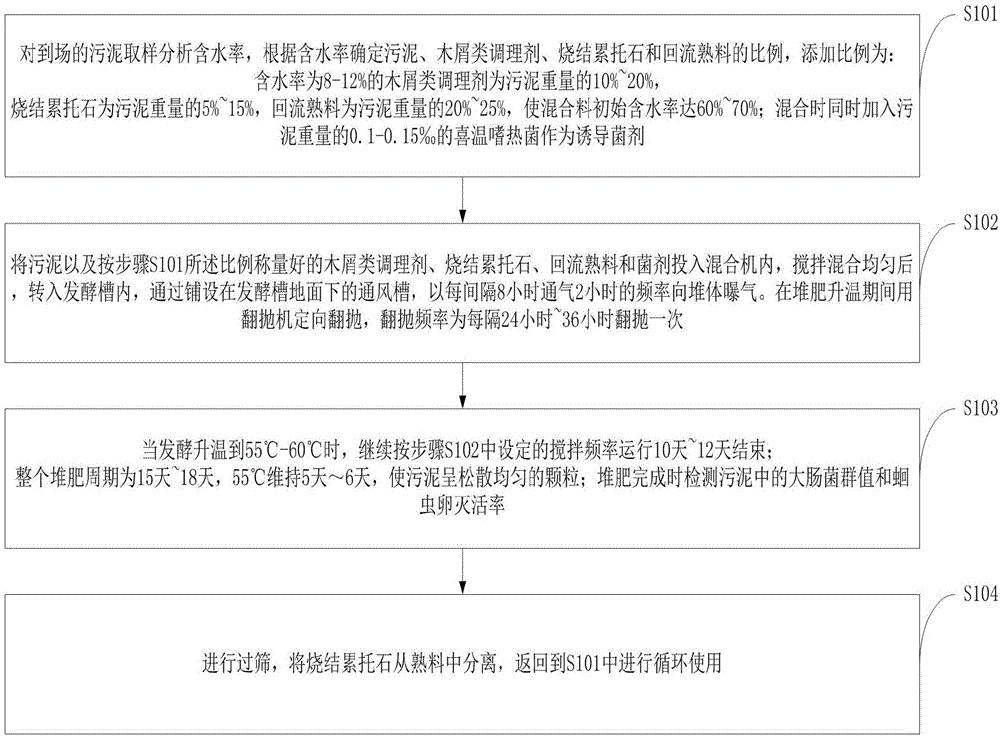

Method for sludge composting using new regulator

InactiveCN1587213AEasy to separateLarge specific surface areaBio-organic fraction processingClimate change adaptationSludge compostOxygen

The present invention relates to new technological process of aerobically composting sludge with suspended biological carrier normally used in sewage treatment as the amendment. The sludge material is added with wood dust in 5-15 wt% of sludge and suspending biological carrier stuffing in 5-10 wt% of sludge as the amendment to make the stirred material possess water content of 60-70 %. The aerobic fermentation apparatus is dynamically controlled I ventilation and stirring frequency for fast composing treatment. Finally, the suspending biological carrier stuffing is sieved out for reuse. The new amendment of the present invention has good attaching performance, no loss and reuse, and the present invention has high composing efficiency.

Owner:TONGJI UNIV

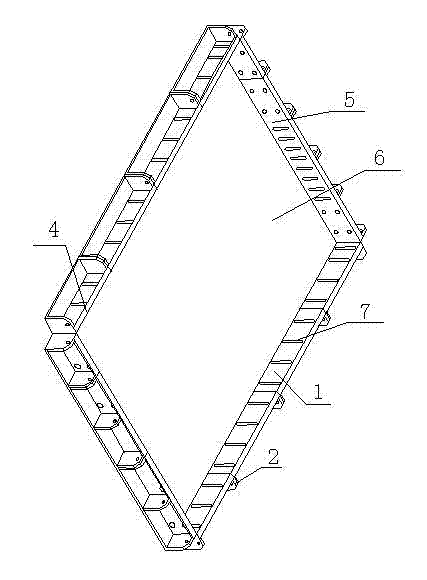

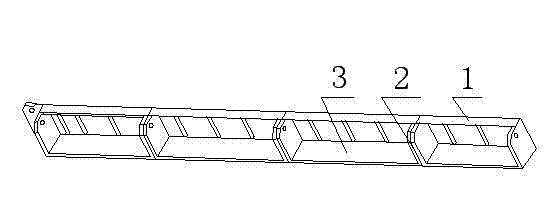

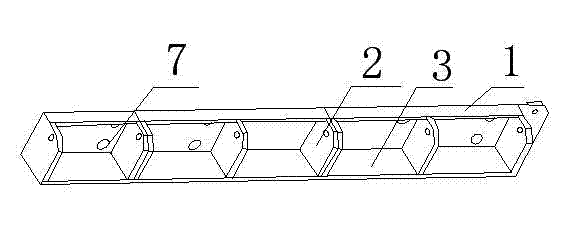

Mold and processing method for free-combination and suction-type building component processing

InactiveCN102285000AVarious formsLow costMould separation apparatusMouldsConstruction engineeringStructural engineering

The mold and processing method used in the processing of free-combination and suction-type building components. Nowadays, there are many kinds of molds for the processing of concrete prefabricated components, and the disassembly and assembly remain unchanged. Every time the mold is installed, holes must be drilled on the bottom formwork to connect the fixed mold frame, which makes the processing speed of concrete prefabricated components slow, and the labor intensity of workers increases. The low efficiency is not suitable for industrial production and processing of concrete prefabricated components, and the quality requirements of concrete prefabricated components cannot be guaranteed, so that the processing cost of concrete prefabricated components remains high. The composition of the present invention includes: a unit mold (1), a magnetic frame (2), the unit mold attracts the side of the magnetic frame to form a magnetic mold unit (3), and a group of magnetic mold units attract each other to form a strong magnetic force The one-side moulds (4), the strong magnetic one-side moulds are attracted to each other to form an upper mould (5), and the upper moulds are attracted to a bottom formwork (6) to form a building component processing mould. The invention is used for the production of concrete prefabricated elements.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL +1

Method and device for producing nano calcium carbonate by microwave drying

ActiveCN104229850AFast heatingAchieve heating effectCalcium/strontium/barium carbonatesMaterial nanotechnologyHeating timeMicrowave

The invention discloses a method for producing nano calcium carbonate by microwave drying. The method is carried out according to the following steps: (1) preparing Ca(OH)2 raw refined slurry; (2) preparing boiled calcium carbonate slurry; (3) preparing an activated calcium carbonate filter cake; (4) pelletizing; (5) carrying out microwave drying; and (6) crushing and sieving to prepare a nano calcium carbonate product. A device for producing nano calcium carbonate by microwave drying comprises a pelletizer, a feeding hopper, a conveyor belt, a transmission mechanism, a tunnel type microwave drying box, a microwave generator, a discharge hopper and a moisture removal mechanism. The method and the device are adopted to produce nano calcium carbonate, so that time of drying operation in a production process of the nano calcium carbonate can be greatly shortened, the energy consumption is lowered, the agglomeration of the nano calcium carbonate is weakened and the dispersion is improved, and thus, the quality of the nano calcium carbonate is improved; the prepared nano calcium carbonate has the advantages of small grain size, low agglomeration strength, a great specific surface area, small hardness and good dispersion; and moreover, the heating time is short, so that the whiteness of the nano calcium carbonate can be improved.

Owner:FUJIAN HONGFENG NANO TECH

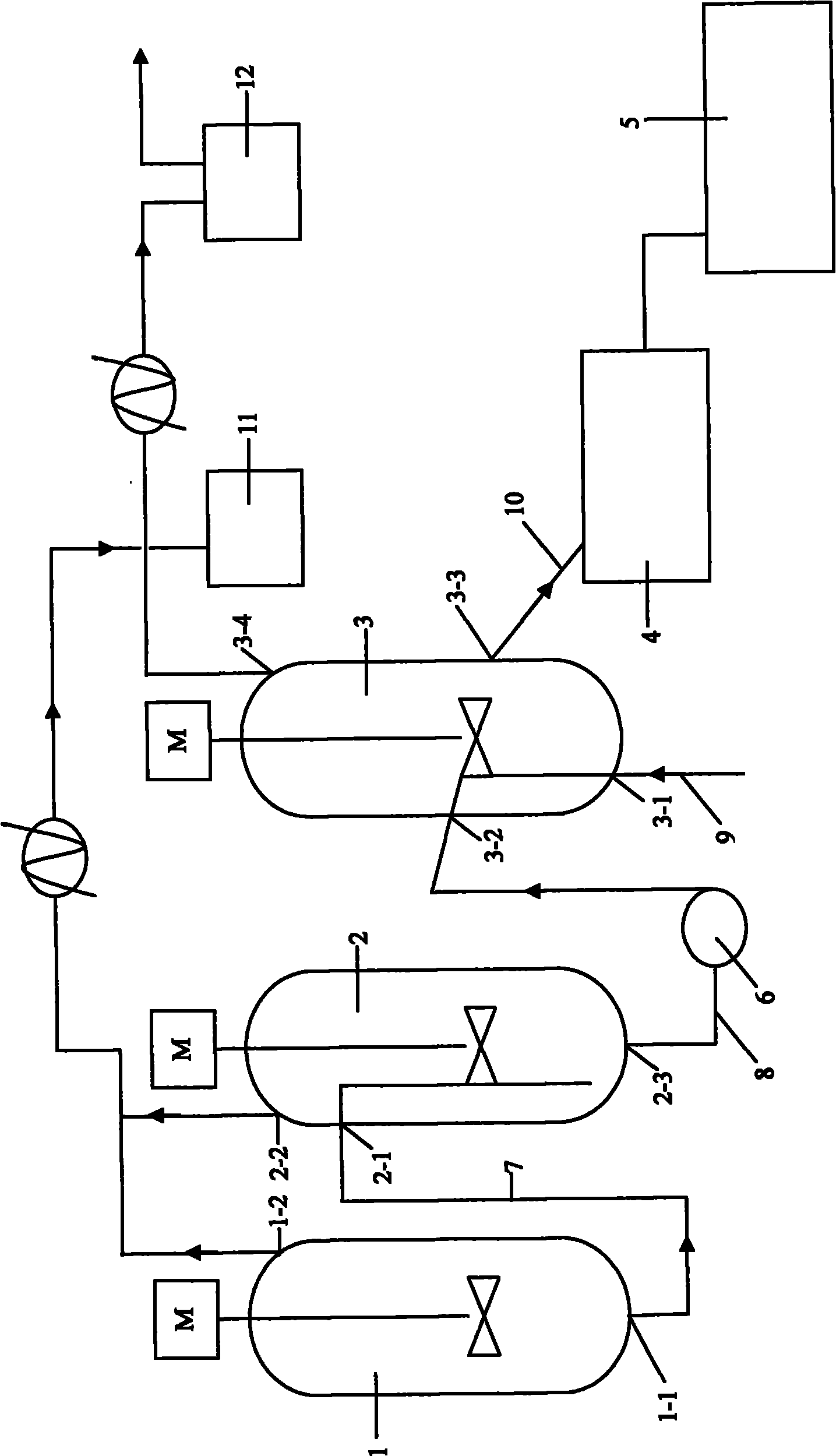

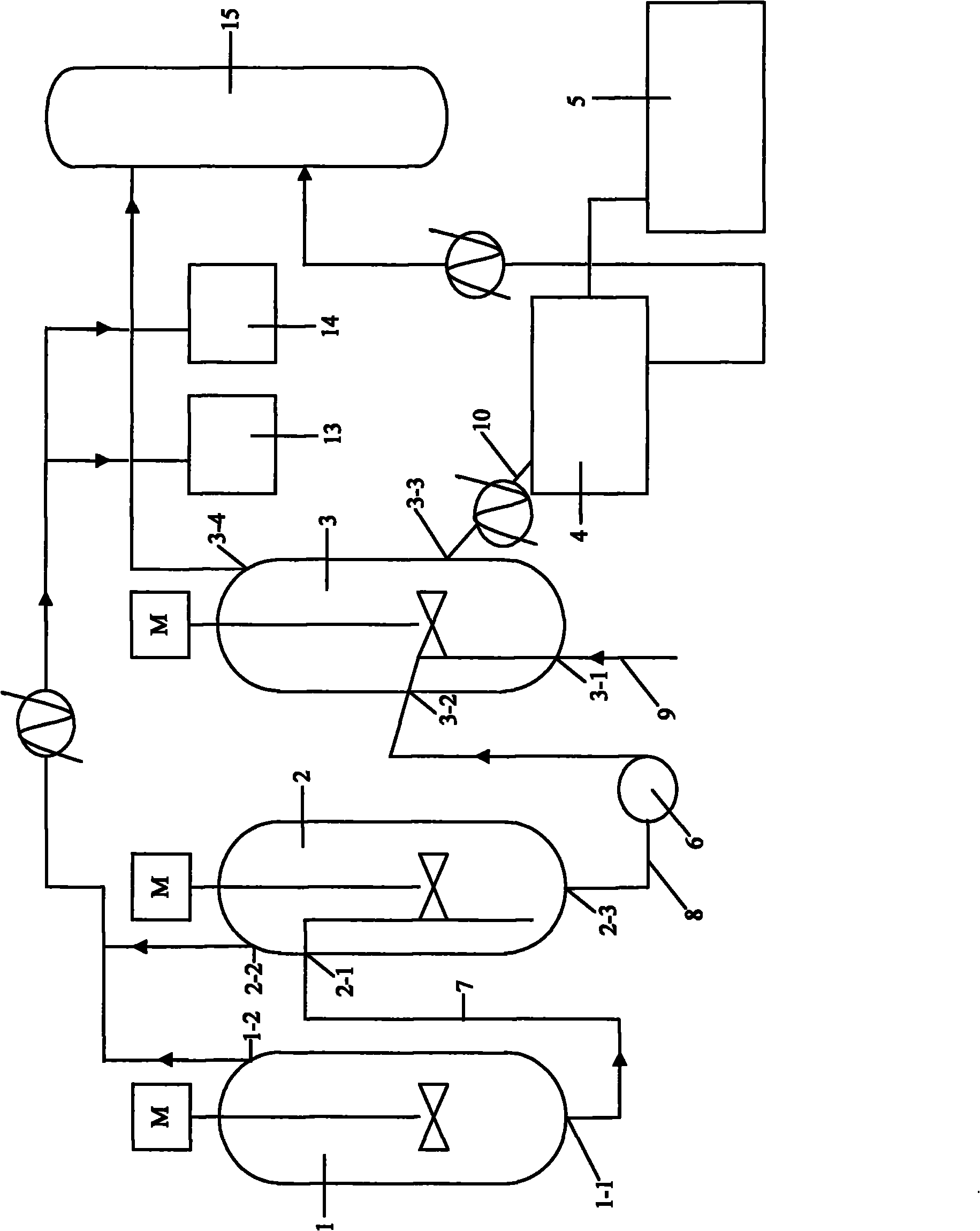

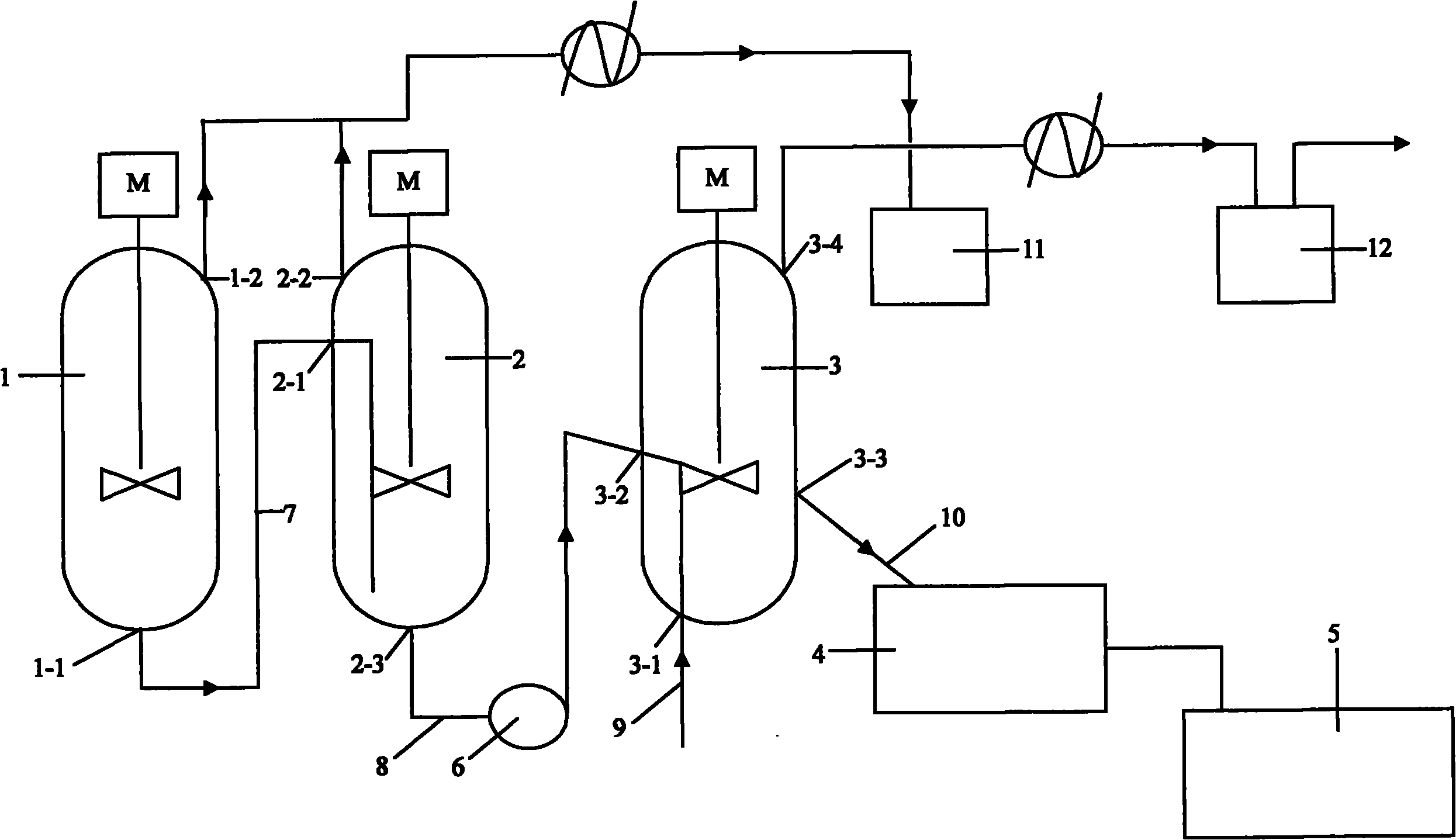

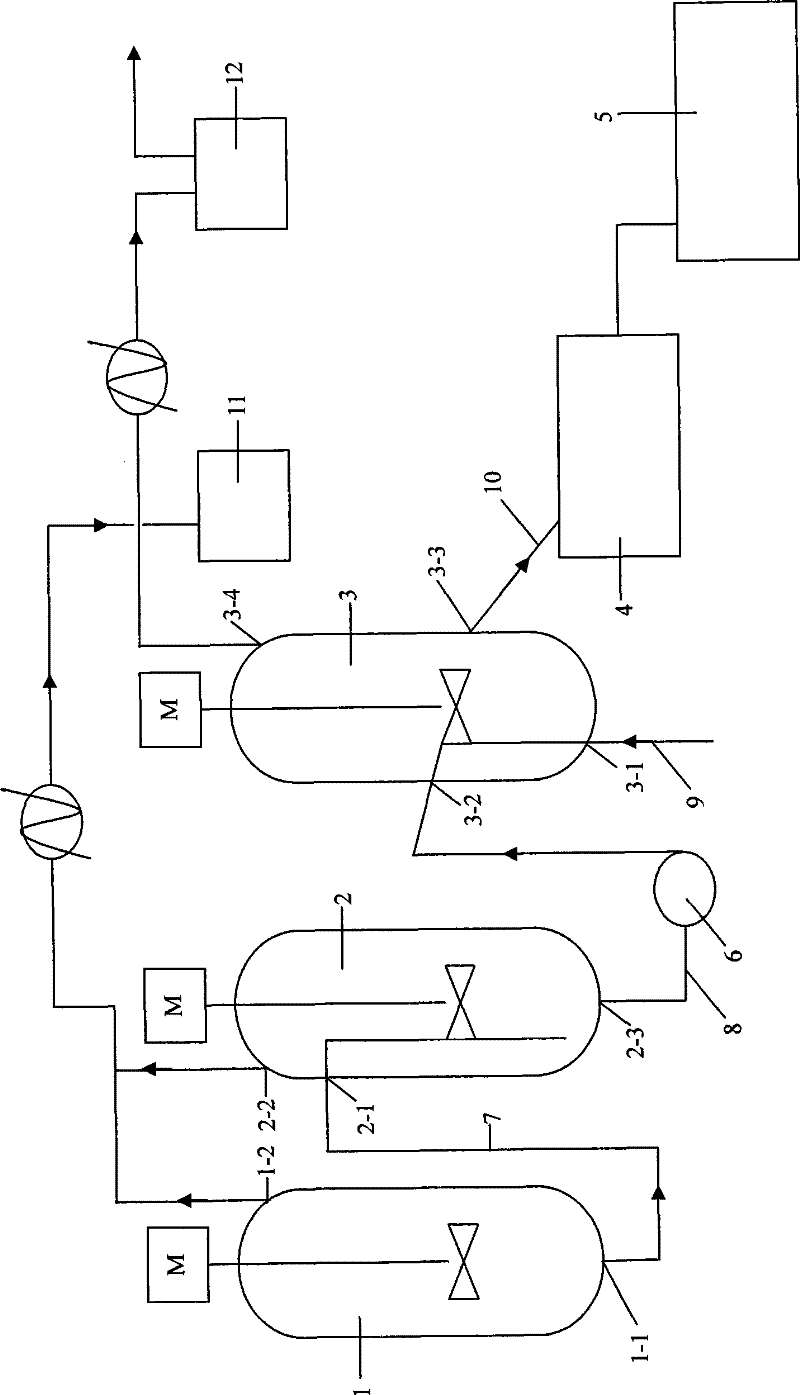

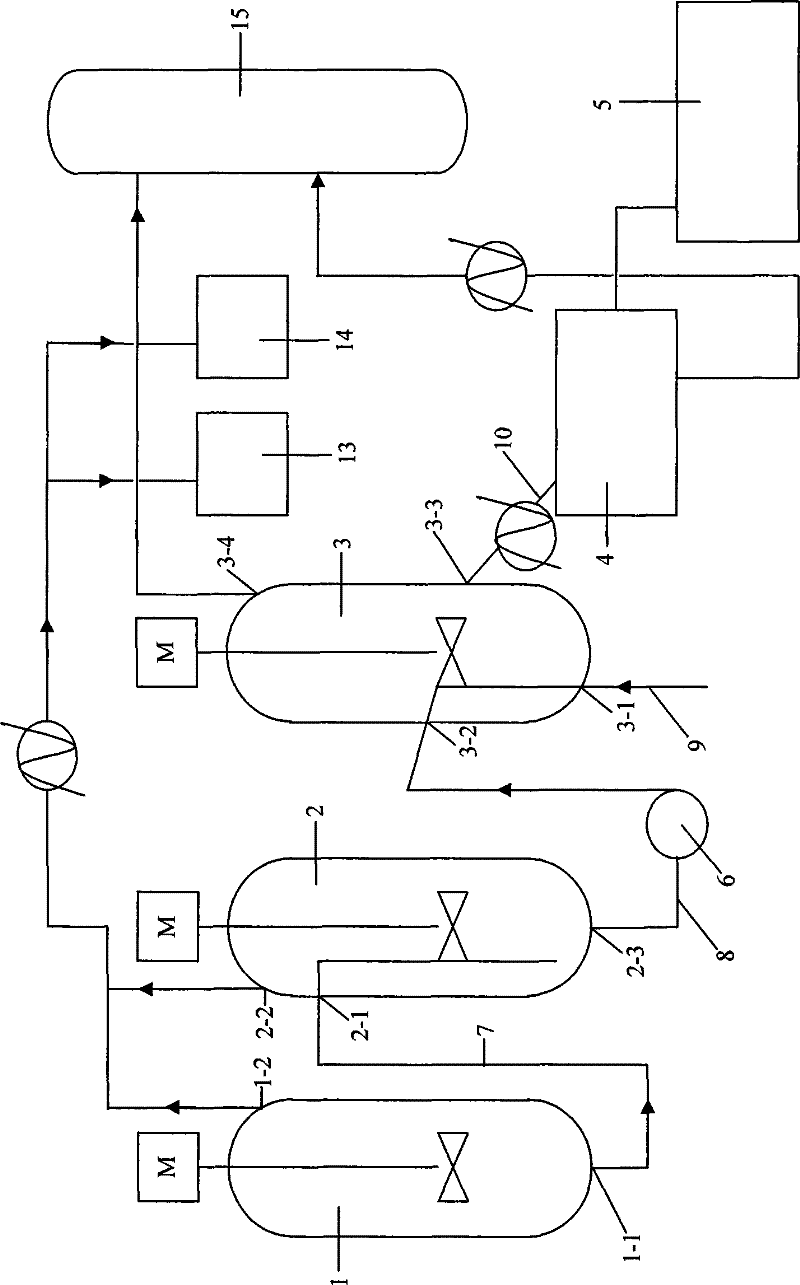

Aliphatic polycarbonate washing coagulation devolatilization method and specific device thereof

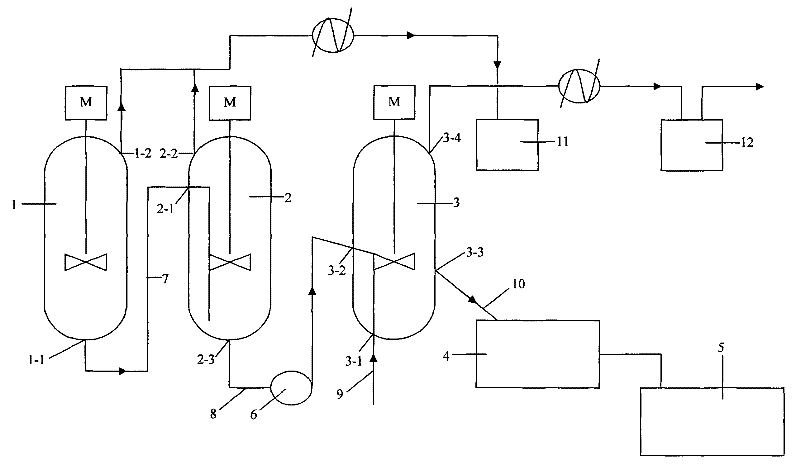

The invention discloses an aliphatic polycarbonate washing coagulation devolatilization method and a specific device thereof. The device according to the invention comprises: a polymerization kettle (1), a flash glue solution vessel, a coagulation system composed of more than one washing coagulation kettles (3), a solid-liquid separation system (4), a polymer drying system (5), a gear pump (6) and a connecting pipeline, wherein the polymerization kettle is provided with a product outlet at the lower part thereof and a gas outlet at the upper part thereof; the flash glue solution vessel is provided with an inlet and a gas outlet at the upper part thereof and a liquid outlet at the lower part thereof; and the washing coagulation kettle is provided with a washing coagulant inlet at the lower part thereof, a liquid inlet and a liquid outlet at the middle part thereof and a gas outlet at the upper part thereof. The method according to the invention has the advantages of: simple production technology, good suitability for automated control, continuous washing coagulation devolatilization; sufficient use of materials and energies, no gas-phase emptying in the process owing to the use of a closed vessel with pressure, very few solid-liquid wastes, complete ash removal and devolatilization of products, meeting the use demands in related fields, low industrial production cost and green chemistry standard-reaching industrialization process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A kind of vermiculite oxygen shoveling agent and its rapid composting fermentation method for treating sludge

InactiveCN102276318AImprove permeabilityImprove loosenessBio-organic fraction processingOrganic fertiliser preparationMicroorganismSludge compost

A vermiculite oxygen scavenger and a rapid composting fermentation method for treating sludge by using the same. The sludge composting fermentation oxygen scavenger is a mixture of plant particles and vermiculite, and its weight ratio is 1:1-1.3. Its advantages are: increase the permeability and looseness of the compost; make the compost fermentation process uniform; after composting, the obtained clinker is loose, the vermiculite and the material are easy to separate, and the dominant microorganisms attached to the micropores on the surface can be separated with time. They are used together as recycled materials; due to the low loss of vermiculite particles during use, they can be recycled and reused, and the loss rate of each compost is less than 5%; the operating cost is low, and the crushing process of sawdust or straw is reduced, greatly reducing Labor intensity and obvious economic benefits; the early heating speed of composting is fast, and the dehydration and cooling of the compost body are more rapid at the end of composting; the time required for composting to decompose can be shortened by 5-7 days, which is about 1 / 2 shorter than the composting cycle of similar industrial composting technologies at home and abroad 3. It improves the composting efficiency and is more suitable for the automatic control of the composting process.

Owner:武汉正清和环保科技开发有限公司

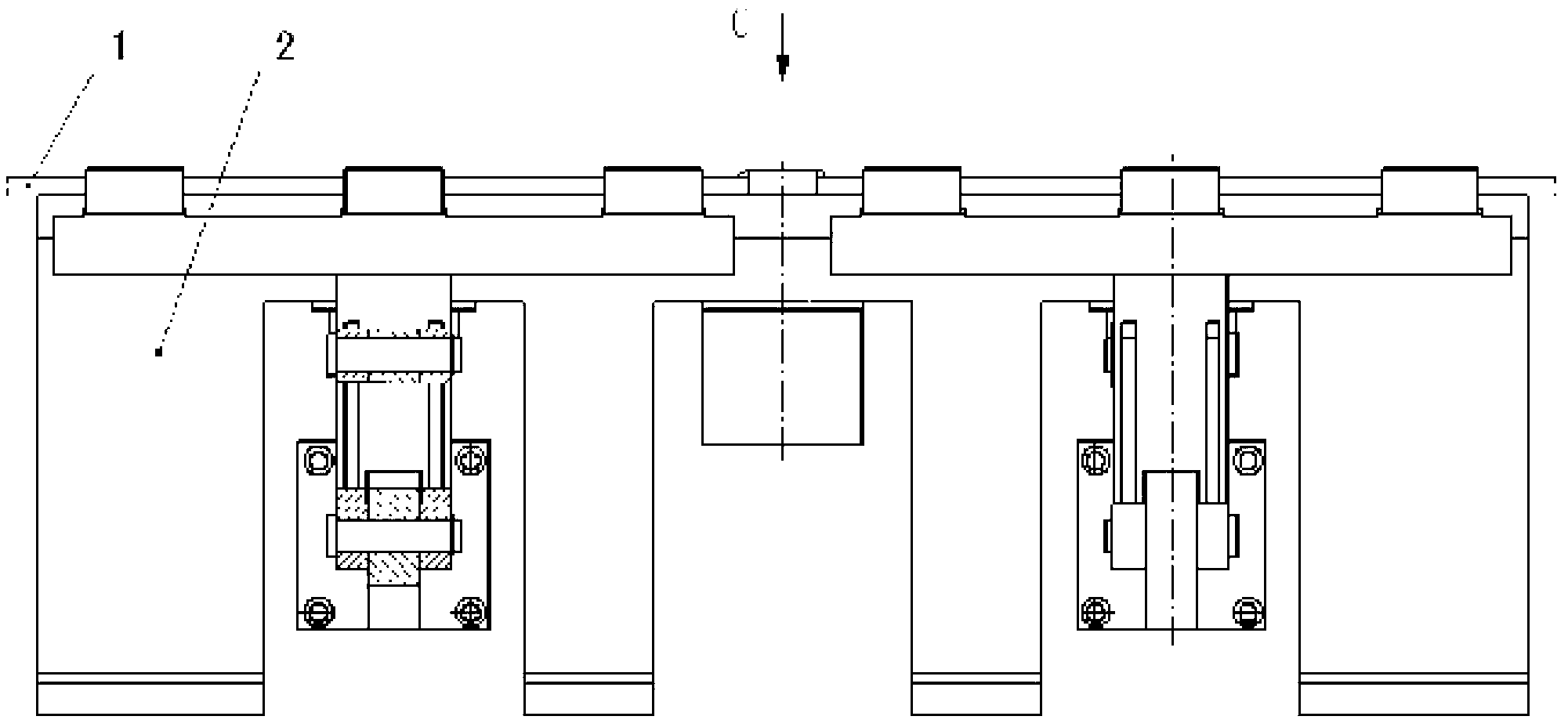

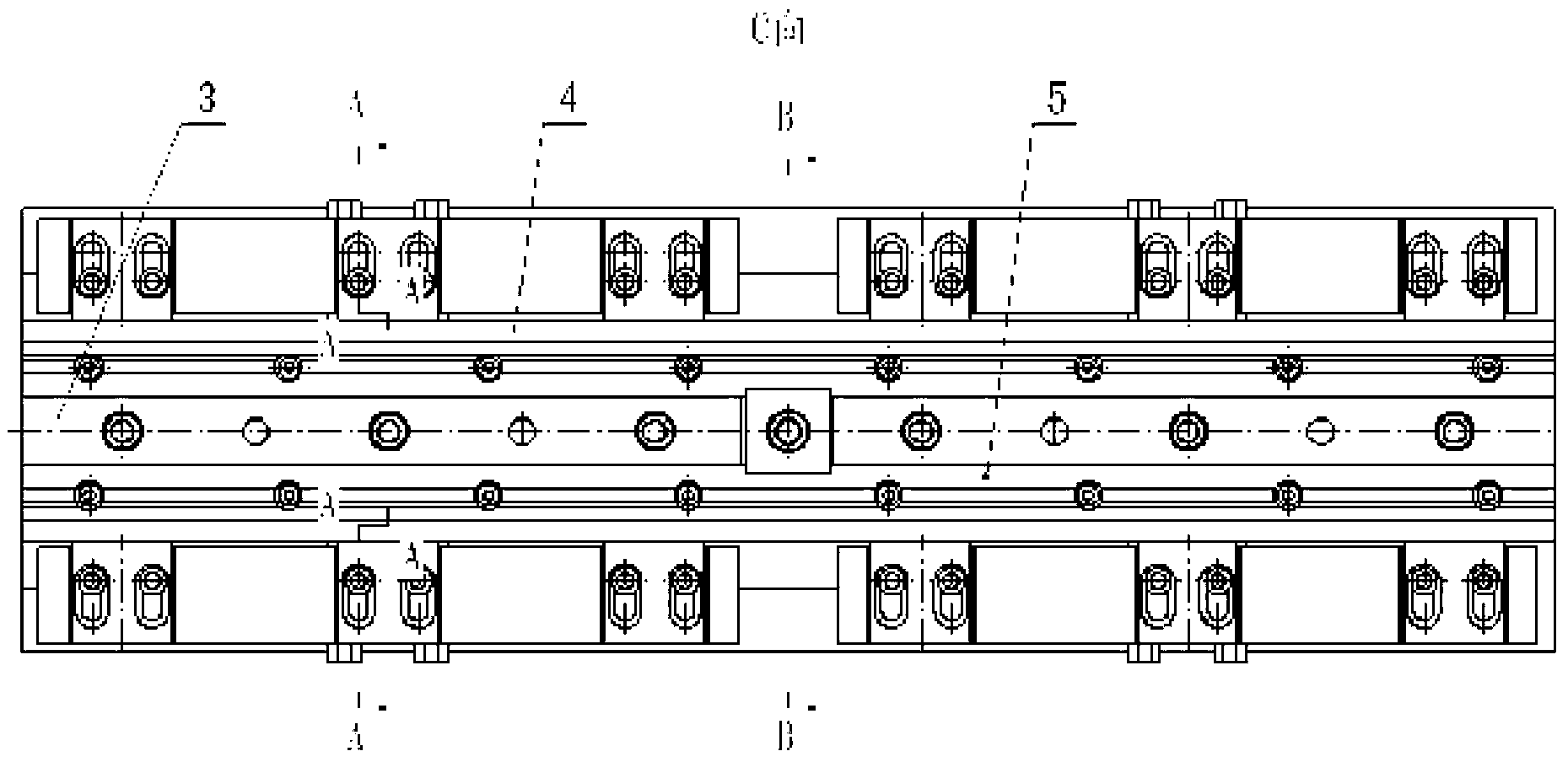

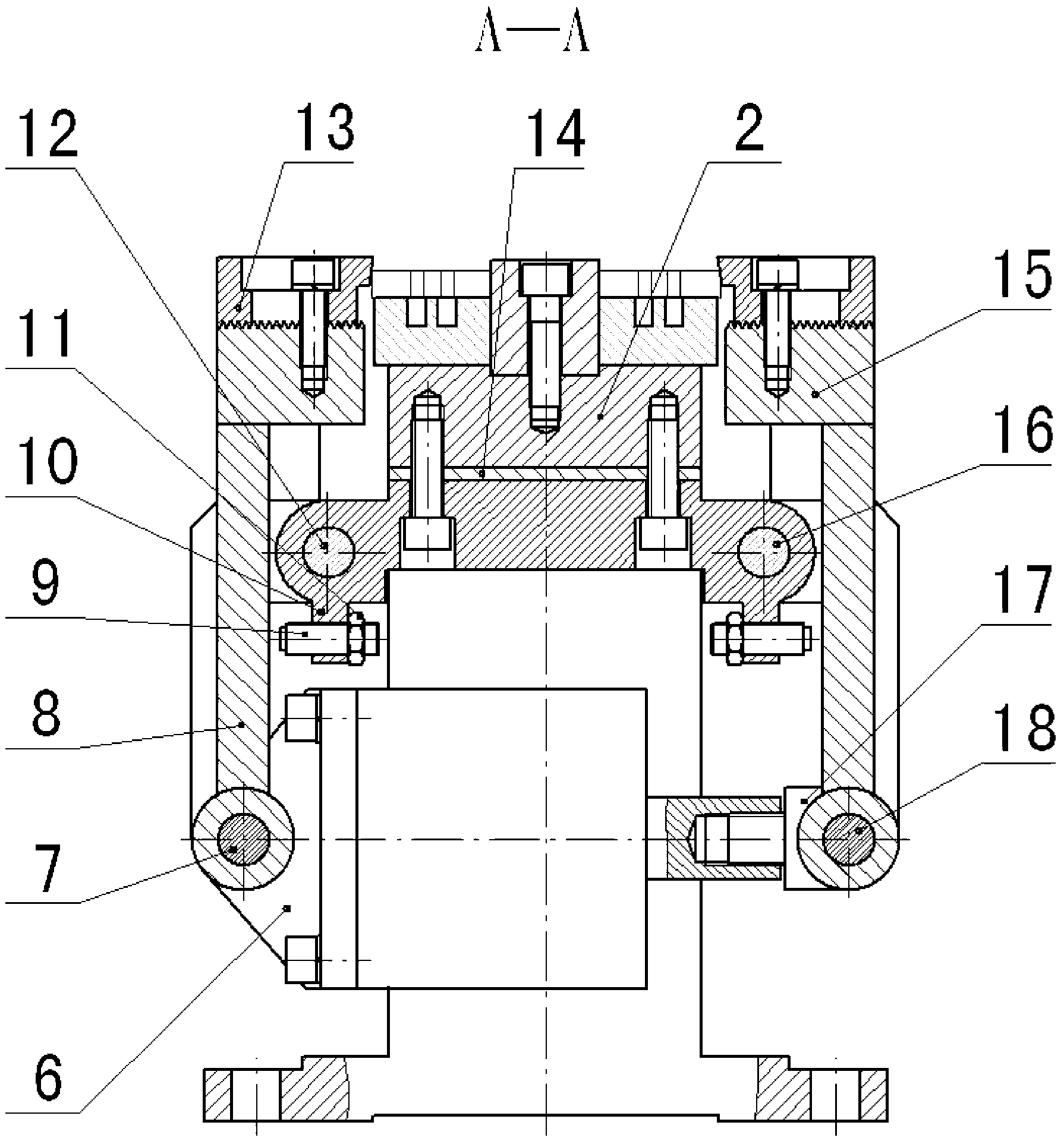

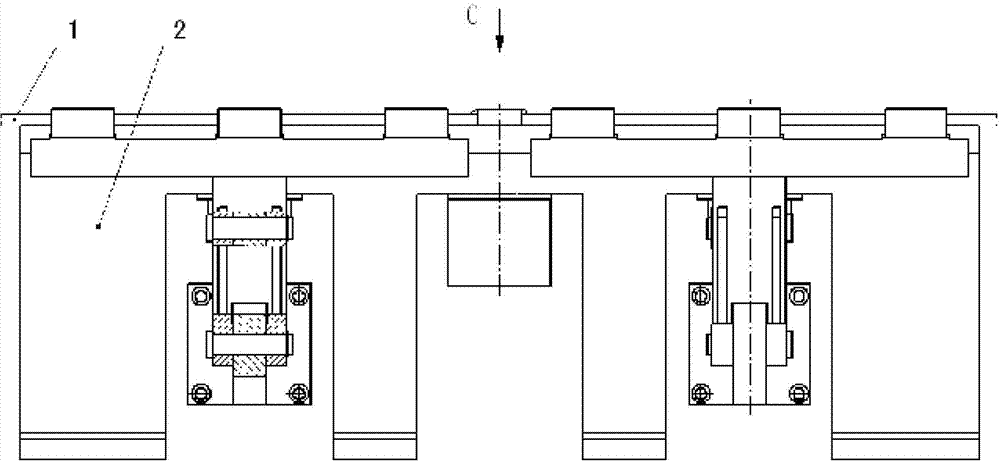

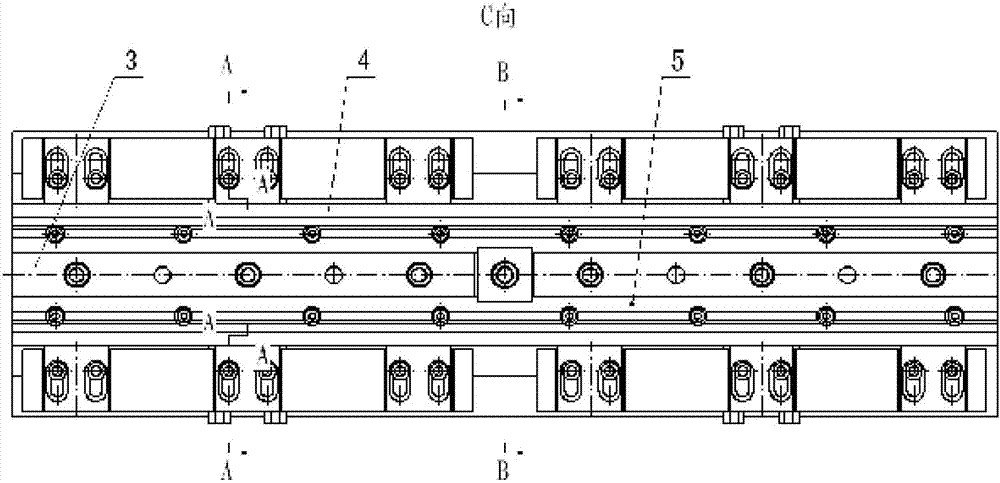

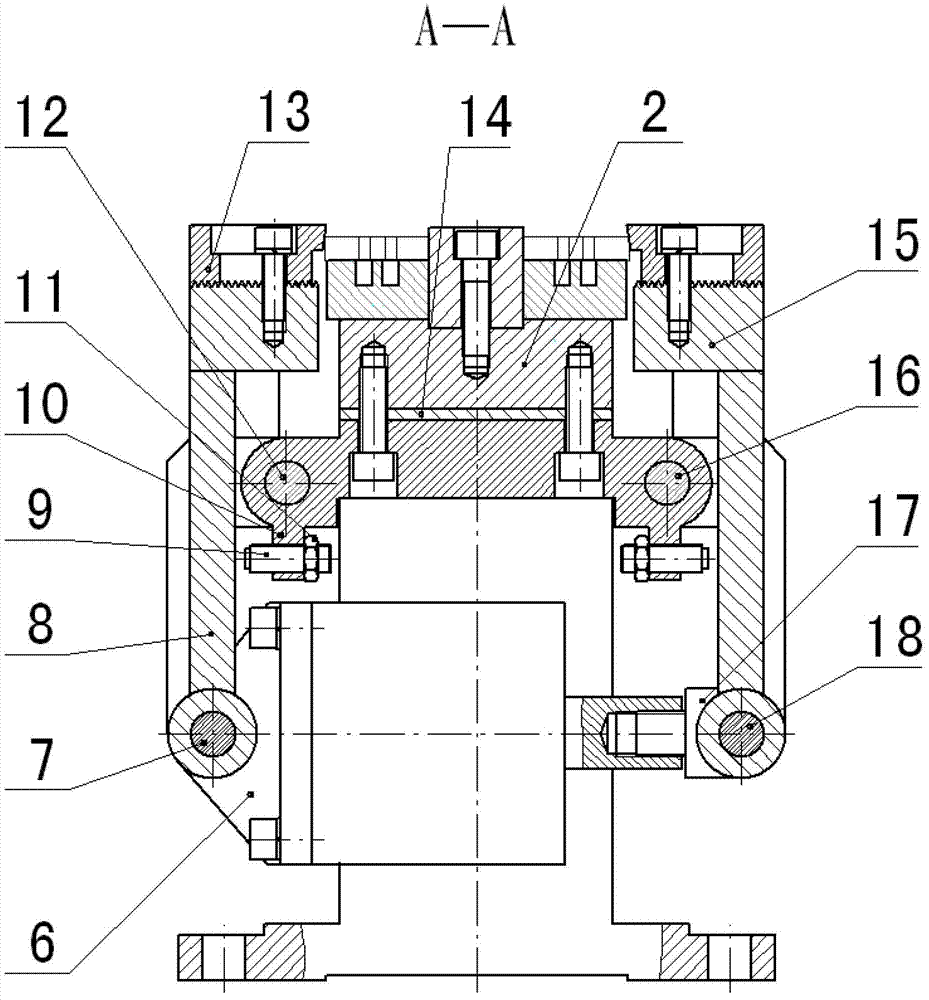

Fixture for steam turbine generator rotor coil vent hole machining

ActiveCN103286585AIncrease productivityAchieving lateral compressionPositioning apparatusMetal-working holdersReciprocating motionEngineering

The invention discloses a fixture for steam turbine generator rotor coil vent hole machining. Two rotor coils are placed flat on a left die holder and a right die holder respectively, and are separated and positioned by a positioning check block. A lateral pressing air cylinder piston rod stretches out and draws back to drive a movable fulcrum pin shaft of a left oscillating bar and a movable fulcrum pin shaft of a right oscillating bar to motion, so that the left oscillating bar is driven to swing around a fixed fulcrum pin shaft of the left oscillating bar, and the right oscillating bar is driven to swing around a fixed fulcrum pin shaft of the right oscillating bar. A limiting block on the left side and a limiting block on the right side limit an opening of the left oscillating bar and an opening of the right oscillating bar to be consistent in size. The left rotor coil and the right rotor coil are tightly pressed or loosened at the same time through a lateral pressing head. An upward pressing air cylinder piston rod stretches out and draws back to drive an upward pressing head to move in a reciprocating mode along a positioning check block guide hole, so that the left rotor coil and the right rotor coil are loosened or tightly pressed in the vertical direction. The fixture for the steam turbine generator rotor coil vent hole machining is high in automation degree, high in work efficiency, strong in universality, simple in structure, reliable in operation, long in service life, and capable of greatly mitigating the labor intensity for an operator.

Owner:HARBIN ELECTRIC MASCH CO LTD

Quick composting technique

InactiveCN101265133ALarge specific surface areaStrong bioadhesionBio-organic fraction processingOrganic fertiliser preparationOperational costsEconomic benefits

The invention relates to a method for composting organic wastes by blending renewable materials with matrixes, which relates to a novel process for aerobic compost treatment of organic wastes. The invention utilizes a dedicated modified zeolite for aerobic rapid compost treatment. The method comprises the following steps: modifying zeolite, mixing the modified zeolite with organic wastes as matrixes, allowing fermentation, sieving, and separating the dedicated modified zeolite from the treated organic wastes for cycle use. The dedicated modified zeolite has good adhesivity and can be used repeatedly without loss. The compost product has remarkable reduction effect. The utilization efficiency of compost equipment is high. The materials are loose and easy to be separated. The compost period is shortened by 1 / 3. The operational cost is reduced with high economic benefit. The inventive method is widely used for the aerobic compost treatment of various organic wastes.

Owner:SHANGHAI ANSHI BIO TECH

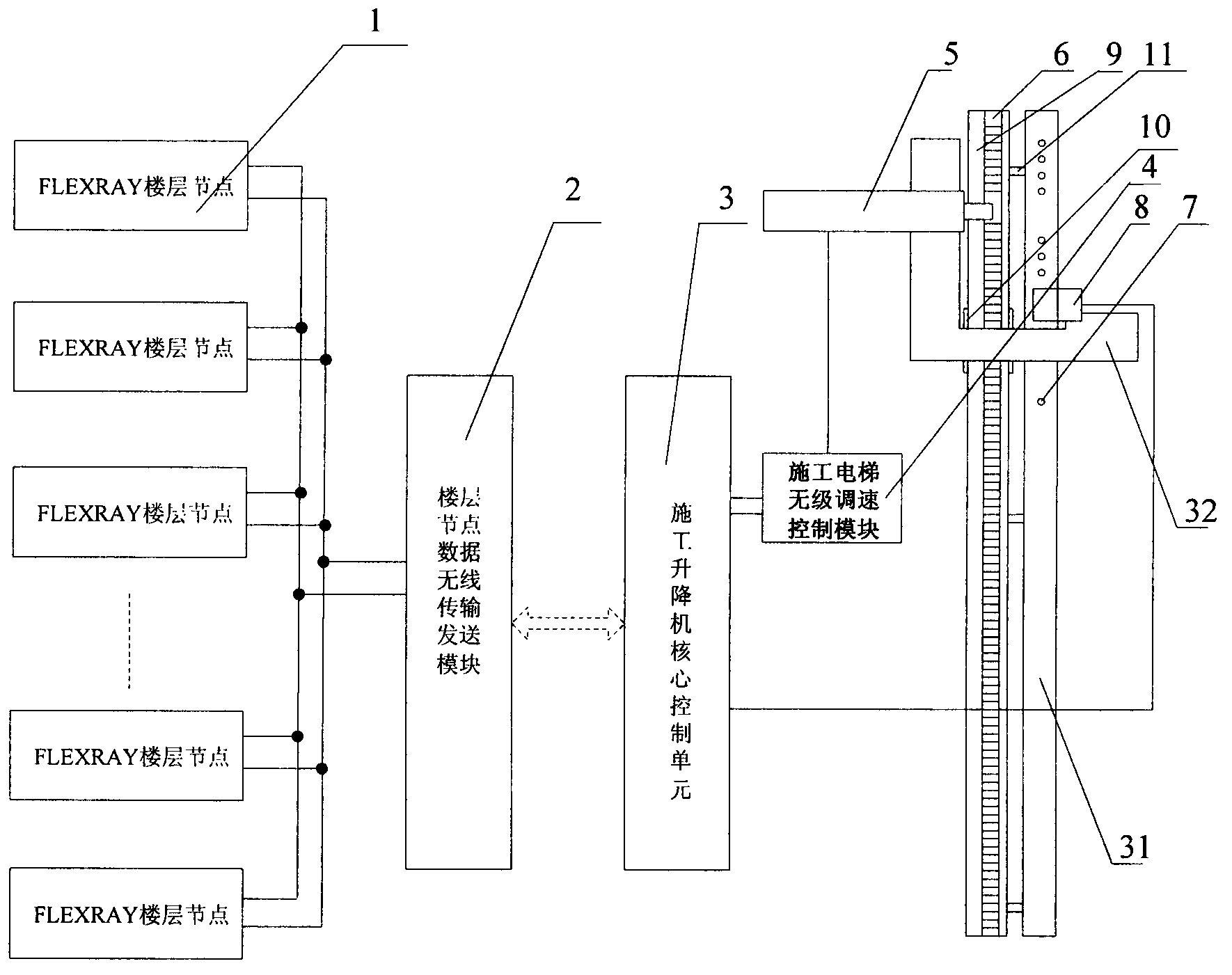

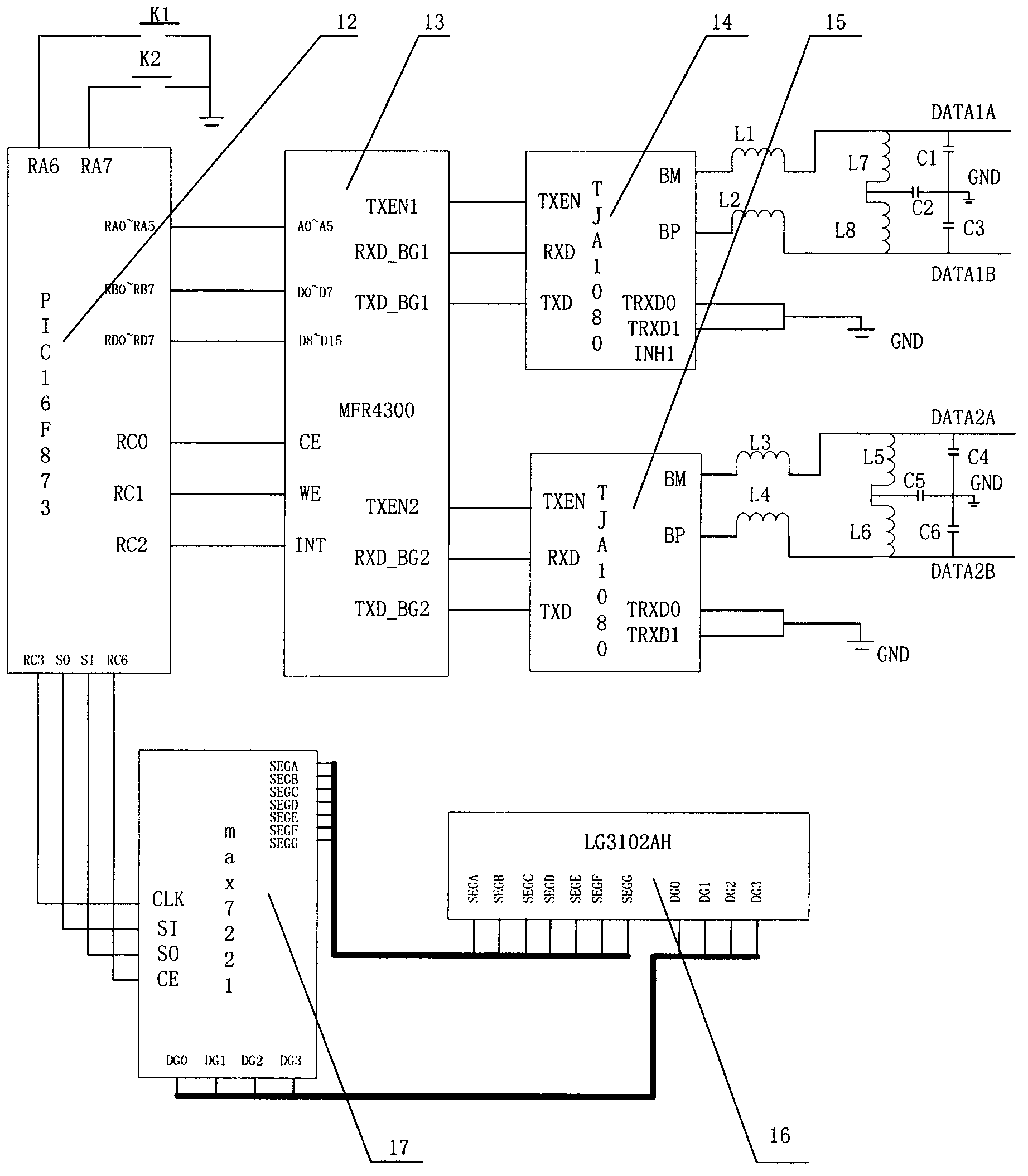

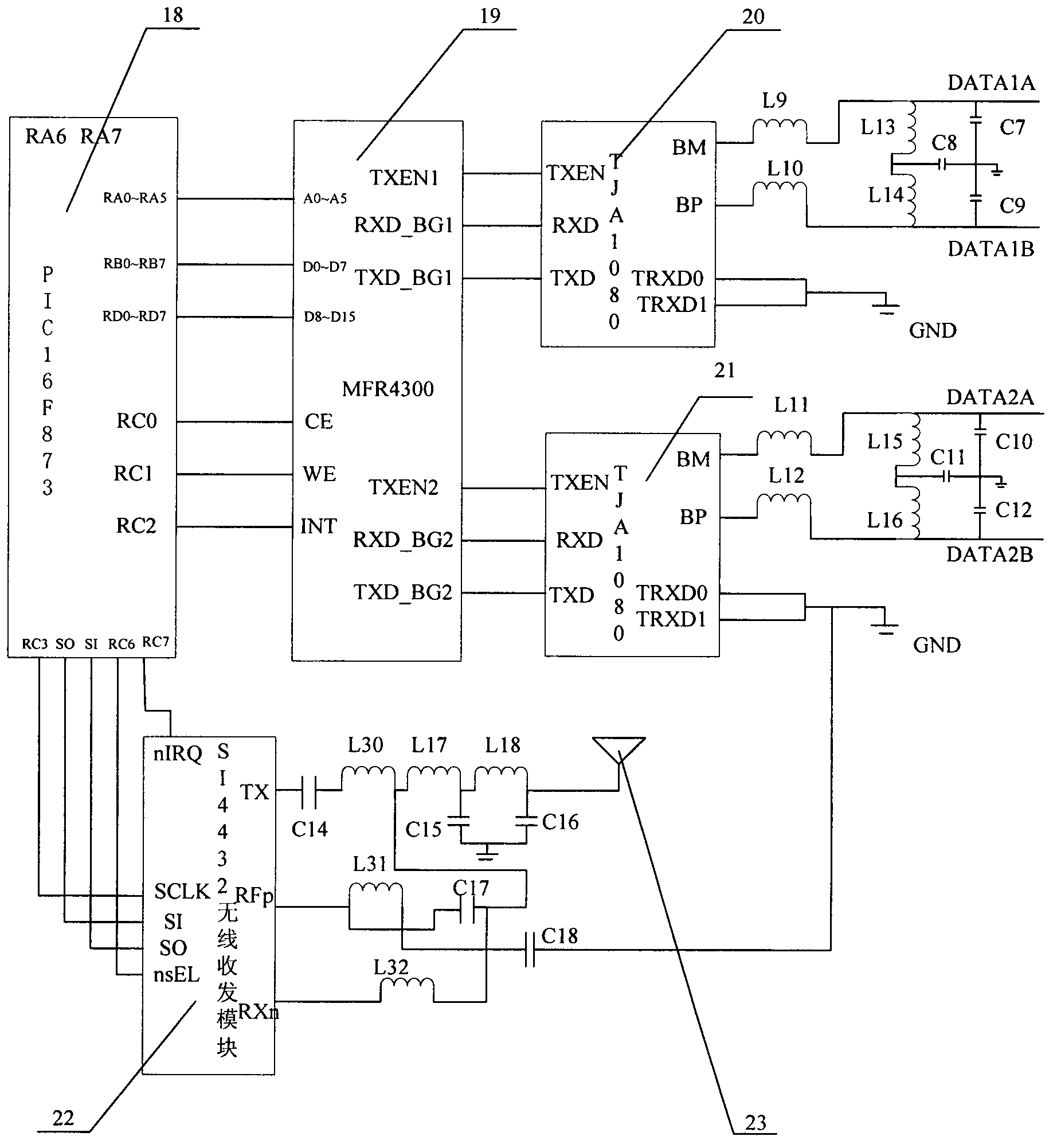

Automatic construction elevator control system

InactiveCN103193117ALong transmission distanceImprove reliabilityElevatorsData transmissionAutomatic control

The invention relates to the technical field of construction elevator equipment, in particular to an automatic construction elevator control system. The automatic construction elevator control system comprises an elevator support, a cab is arranged on the elevator support, a rack and a sensor bar are arranged on the elevator support, a motor corresponding to the rack and a photoelectric sensor corresponding to the sensor bar are arranged on the cab, the photoelectric sensor is connected with a construction elevator core control unit, the motor is connected with the construction elevator core control unit through a construction elevator stepless speed regulating control module, and the construction elevator core control unit is connected with a wireless floor node data transmission module which is connected with FLEXRAY floor nodes. Automatic floor selecting and leveling of a construction elevator can be achieved, current floor number is displayed on each node, and the automatic construction elevator control system is stable, reliable, convenient to expand and particularly suitable for automatic control of construction elevators.

Owner:廊坊市和美文化艺术有限公司

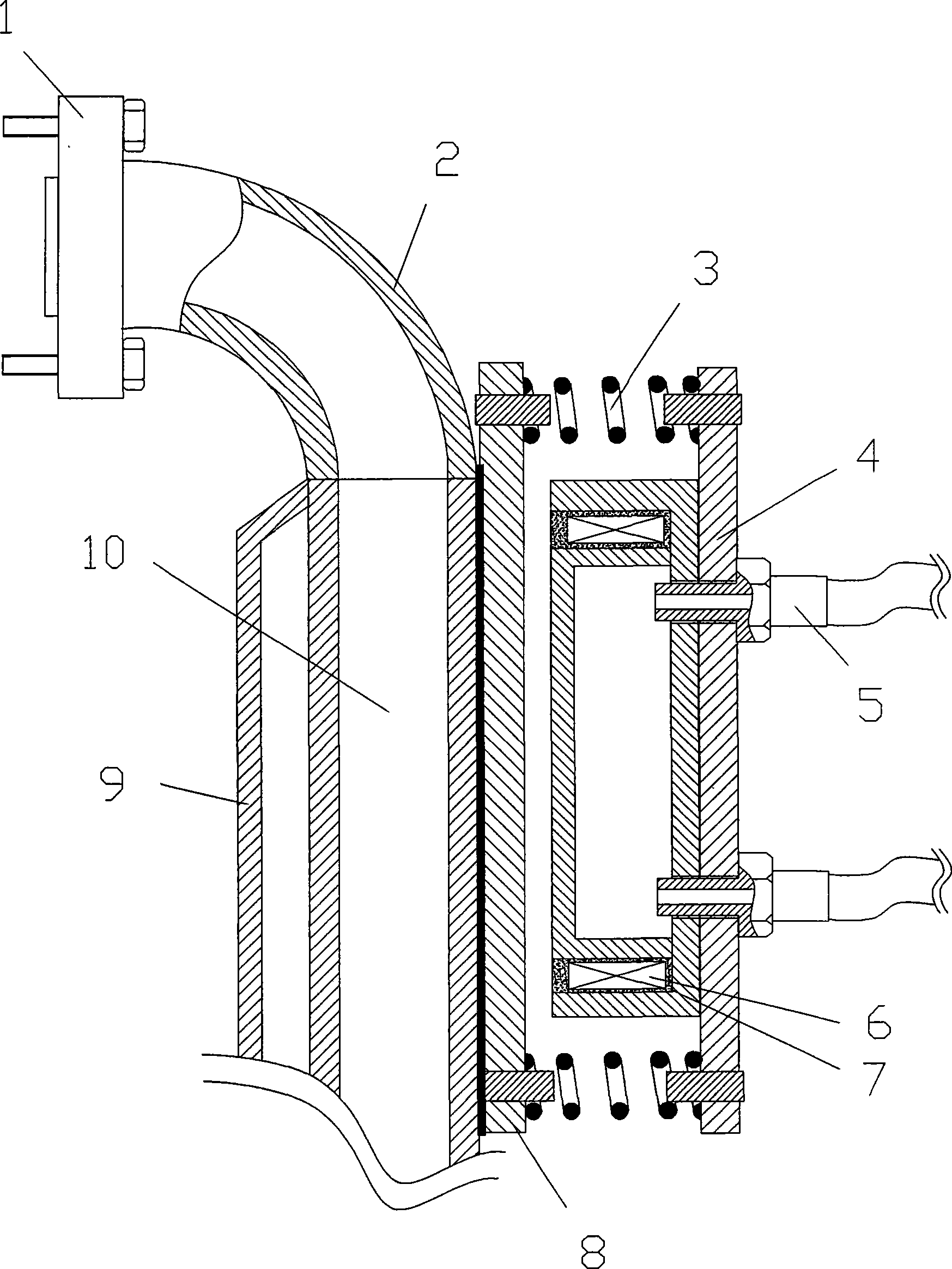

Heat recovery device of controllable vehicle exhaust

InactiveCN101451484AImprove controllabilitySuitable for automatic controlInternal combustion piston enginesExhaust apparatusAutomatic controlEngineering

The present invention discloses a controllable automobile tail gas heat recovery device which comprises the following structure: connect a waste heat box in series on the foreside of a exhausting pipe that closes to its mouth; one ectotheca side of the waste heat box is flat iron plate; support and suspend a water tank by spring on the flat iron plate wherein the water tank is made of iron and in parallel with the flat iron plate; a groove is set on the border of the water tank and the notch of the groove facing the flat iron plate; a coil is embedded inside the groove; the side of the water tank that facing the flat iron plate is flat; and a water in-out joint is provided on the back side of the water tank. Connect the water tank of the device to the cooling water road of the engine in series, when the coil energized, the water tank attracts the flat iron plate of the waste heat box, and heat of the waste heat box passes to the water tank to heat water inside; when no heating needed, cut off power supply of the coil, then the water tank takes off the waste heat box and stops absorbing heat. The controllability of the present device is good and can be applied on automatic control.

Owner:卢能晓

Method for preparing ethyl eicosapentaenate (EPA) and ethyl docosahexaenoate (DHA)

ActiveCN102285880BHigh yieldSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationFraction CollectorAutomatic control

The invention discloses a method for preparing ethyl eicosapentaenate (EPA) and ethyl docosahexaenoate (DHA) and relates omega-3 long-chain polyunsaturated fatty acids. The method comprises: preparing prepared solution to be separated by using a fish oil coarse raw material, which contains ethyl EPA and ethyl DHA, and using an organic solvent as a solvent; transferring the prepared solution to be separated into a material storage tube of a semi-prepared / prepared high-efficiency liquid chromatography-mass spectrum combined apparatus system, starting the semi-prepared / prepared high-efficiency liquid chromatography-mass spectrum combined apparatus system of which a mobile phase is aqueous solution of methanol or ethanol, balancing a chromatographic column, sampling automatically, separating and purifying ethyl EPA and ethyl DHA, and trigging a distillate collector by a mass spectrum online detection signal to collect pure ethyl EPA liquid and ethyl DHA liquid separately and automatically; and subjecting the pure ethyl EPA and ethyl DHA to reduced pressure concentration, extraction and reduced-pressure concentration respectively and thus obtaining ethyl EPA and ethyl DHA, of which the purities are both over 99 percent. The method is characterized by simple and convenient operation and high yield and is suitable for automatic control and synchronous separation.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

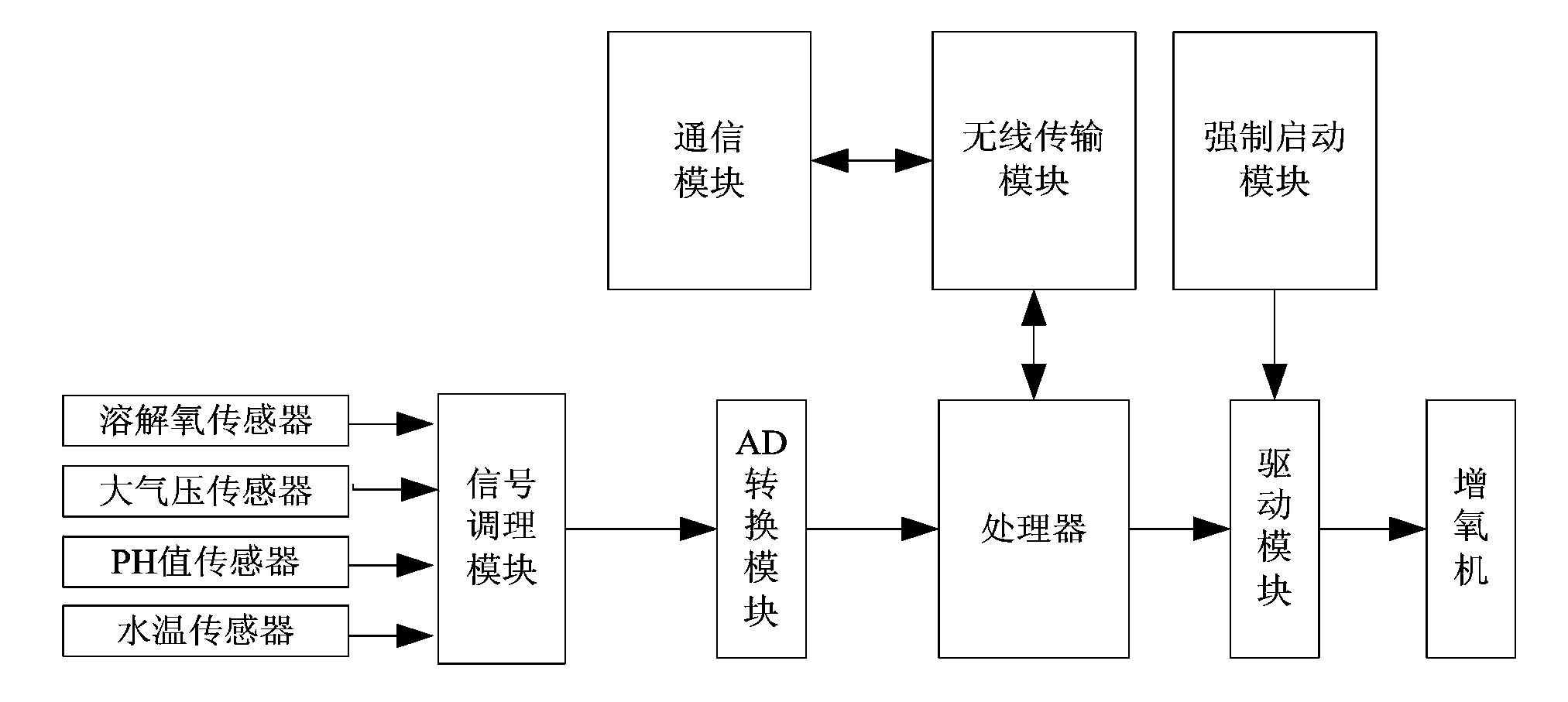

Monitoring system for aquaculture environment of fresh-water fish on basis of wireless sensor network

InactiveCN102645927BOptimize layoutFlexible layoutClimate change adaptationPisciculture and aquariaAutomatic controlLarge range

The invention relates to a monitoring technology for the aquaculture environment of fresh-water fish and discloses a monitoring system for the aquaculture environment of the fresh-water fish on the basis of a wireless sensor network. The monitoring system comprises cluster head nodes connected with i nodes, wherein k cluster head nodes are connected with collecting nodes; m collecting nodes are connected with a monitoring center; and all i, k and m are natural numbers. The monitoring system is characterized in that the nodes, the cluster head nodes and the collecting nodes are configured with a water temperature sensor, a dissolved oxygen sensor, an aerator, a node processing module and a wireless transmission module. The collecting nodes also comprise an atmospheric pressure sensor, a PH value sensor and a communication module; the atmospheric pressure sensor, the PH value sensor and the node processing module are connected; and the communication module is connected with the wireless transmission module and is used for transmitting data to the monitoring center and receiving an instruction. The monitoring system disclosed by the invention can realize large-range wireless monitoring network layout, and is very suitable for automatic control of large-scale fresh-water aquaculture.

Owner:SICHUAN TIANXING LIGHTING ENG DESIGN

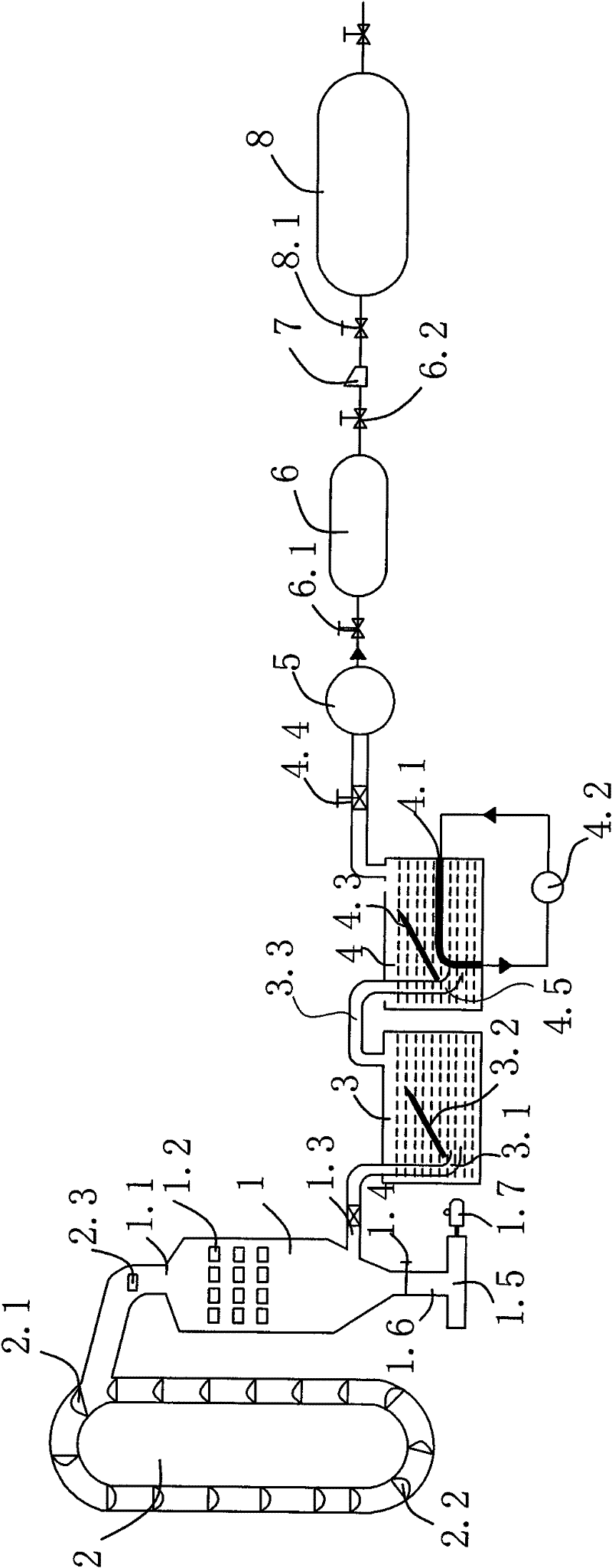

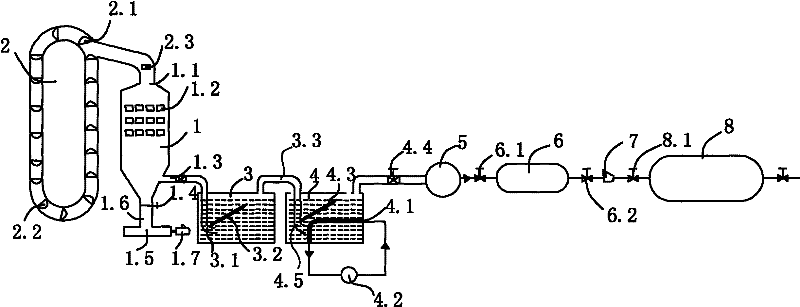

Method for preparing flammable gas by cracking of agriculture and forestry wastes, and special apparatus thereof

InactiveCN102399596AHigh calorific valueHigh purityGranular/pulverulent flues gasificationMicrowaveTar

The present invention relates to a method for preparing flammable gas by cracking of agriculture and forestry wastes, and a special apparatus thereof. The method is characterized in that: agriculture and forestry wastes are crushed and pelletized, and then are added to a cracking furnace; with adopting a microwave ignition manner, the crushed agriculture and forestry wastes and a small amount of air are subjected to a thermal cracking reaction under an incomplete combustion condition to produce the flammable gas. The special apparatus comprises a furnace body, a material inlet arranged on the top of the furnace body, a waste material outlet arranged on the bottom of the furnace body, and a flammable gas outlet. The special apparatus is characterized in that: microwave heating sources are arranged in a line-row type manner on the upper part of the furnace body; the material inlet is communicated with a material feeder by a pipe; the flammable gas outlet is arranged on the lower part of the furnace body, and is sequentially connected with a tar purifier and a cooler by pipes. According to the present invention, based on the characteristic of the microwave heating technology, with combination of the incomplete combustion reaction generated by the sucked air and the material, the efficiency of the production of the flammable gas is high, and the production capacity is improved, wherein the air is sucked by the negative pressure generated by suction of the flammable gas with the vacuum pump.

Owner:SHENZHEN ZHONGGUAN BIOLOGICAL ENERGY TECH

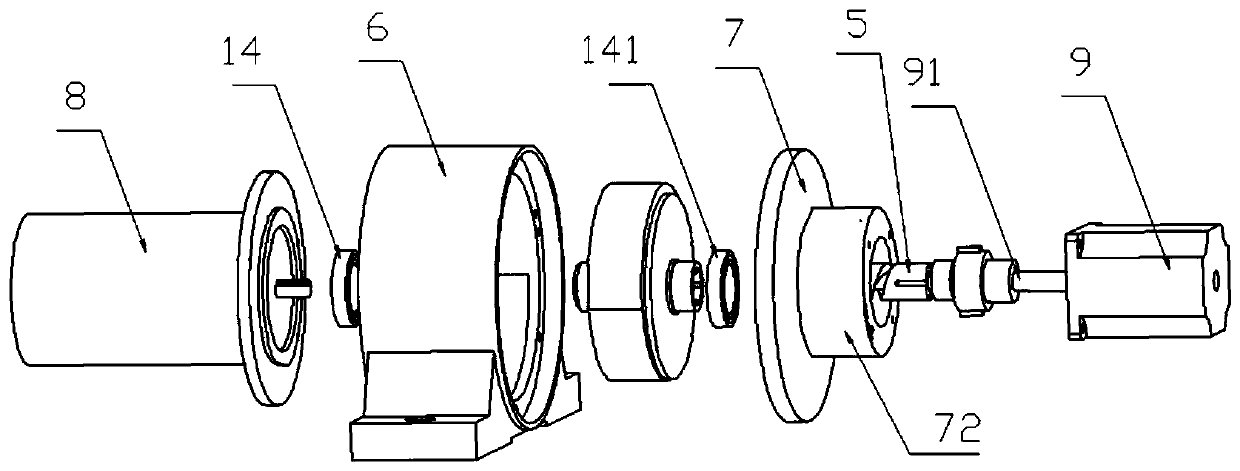

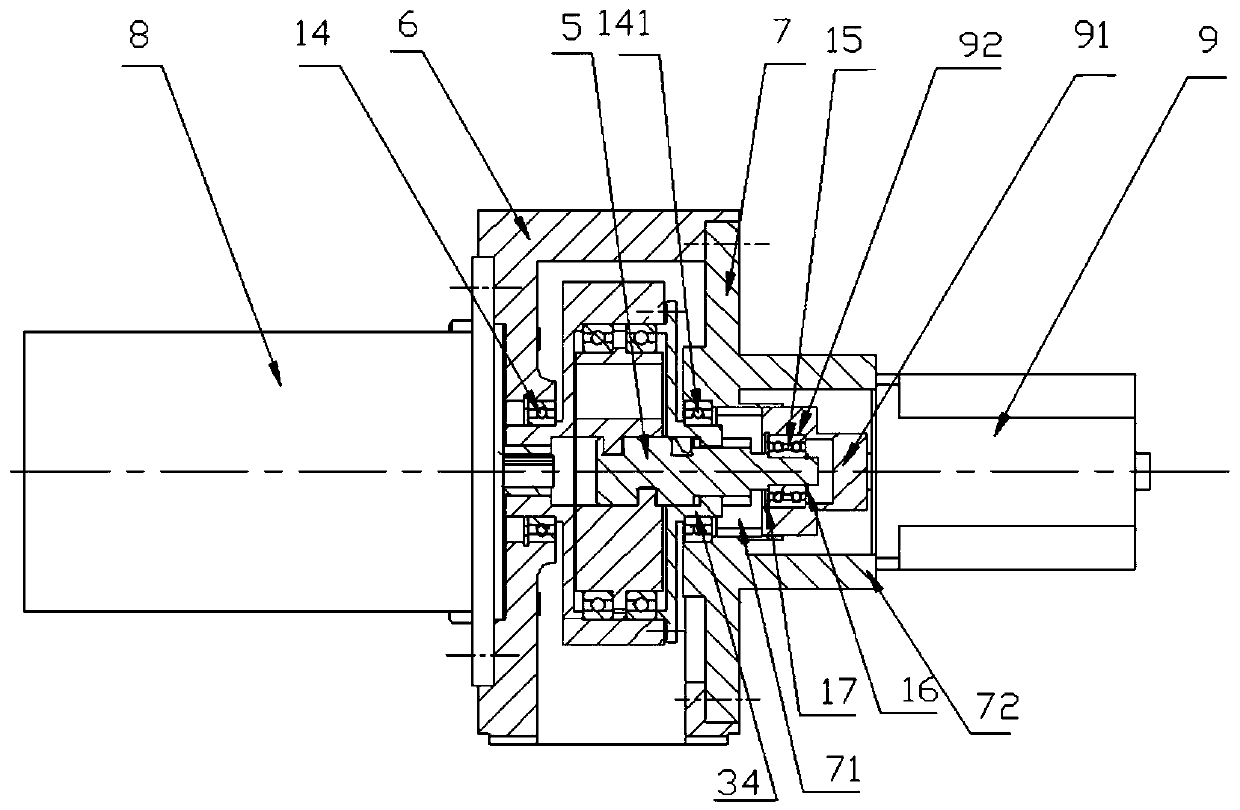

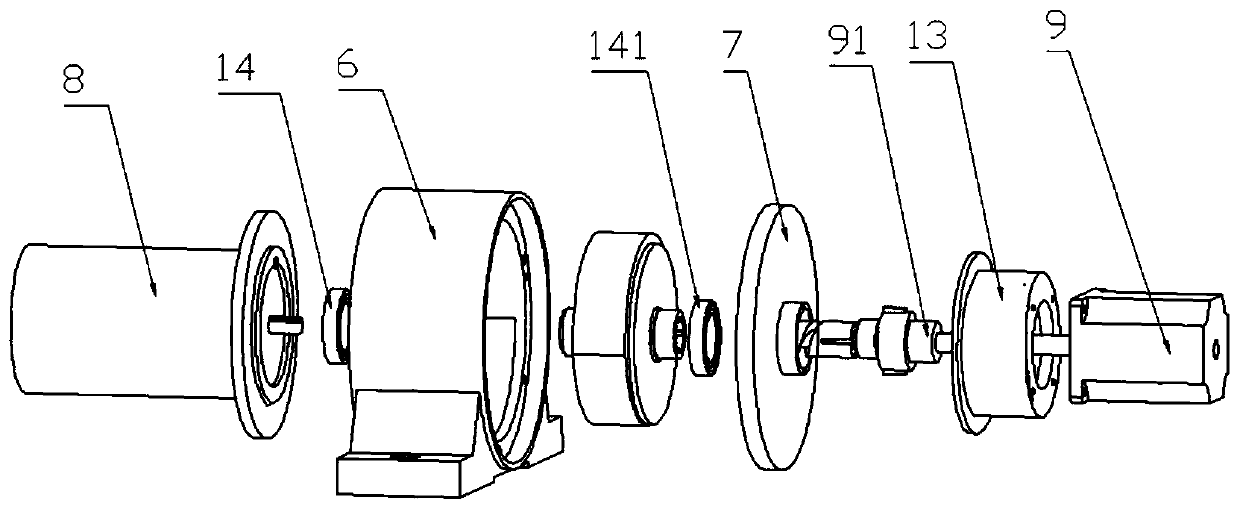

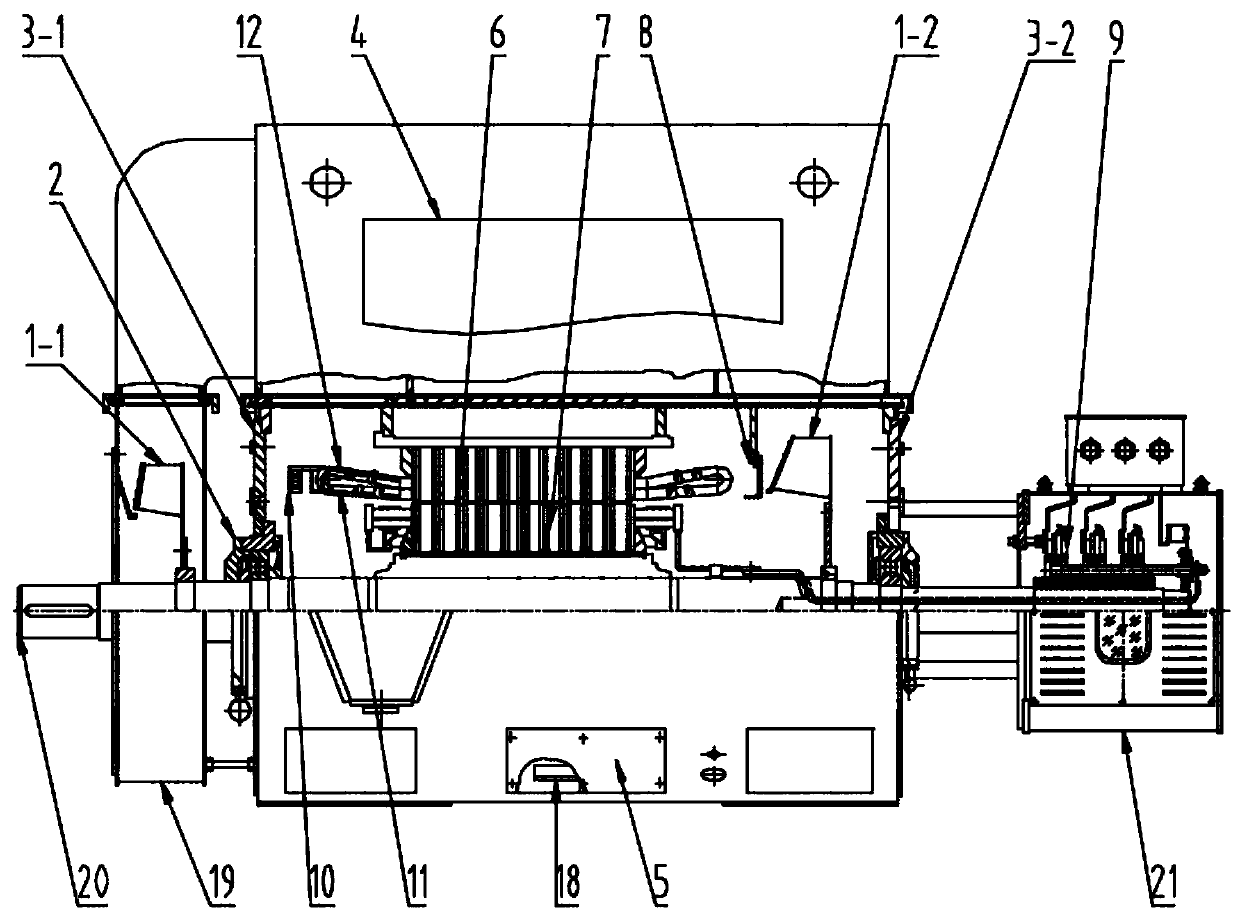

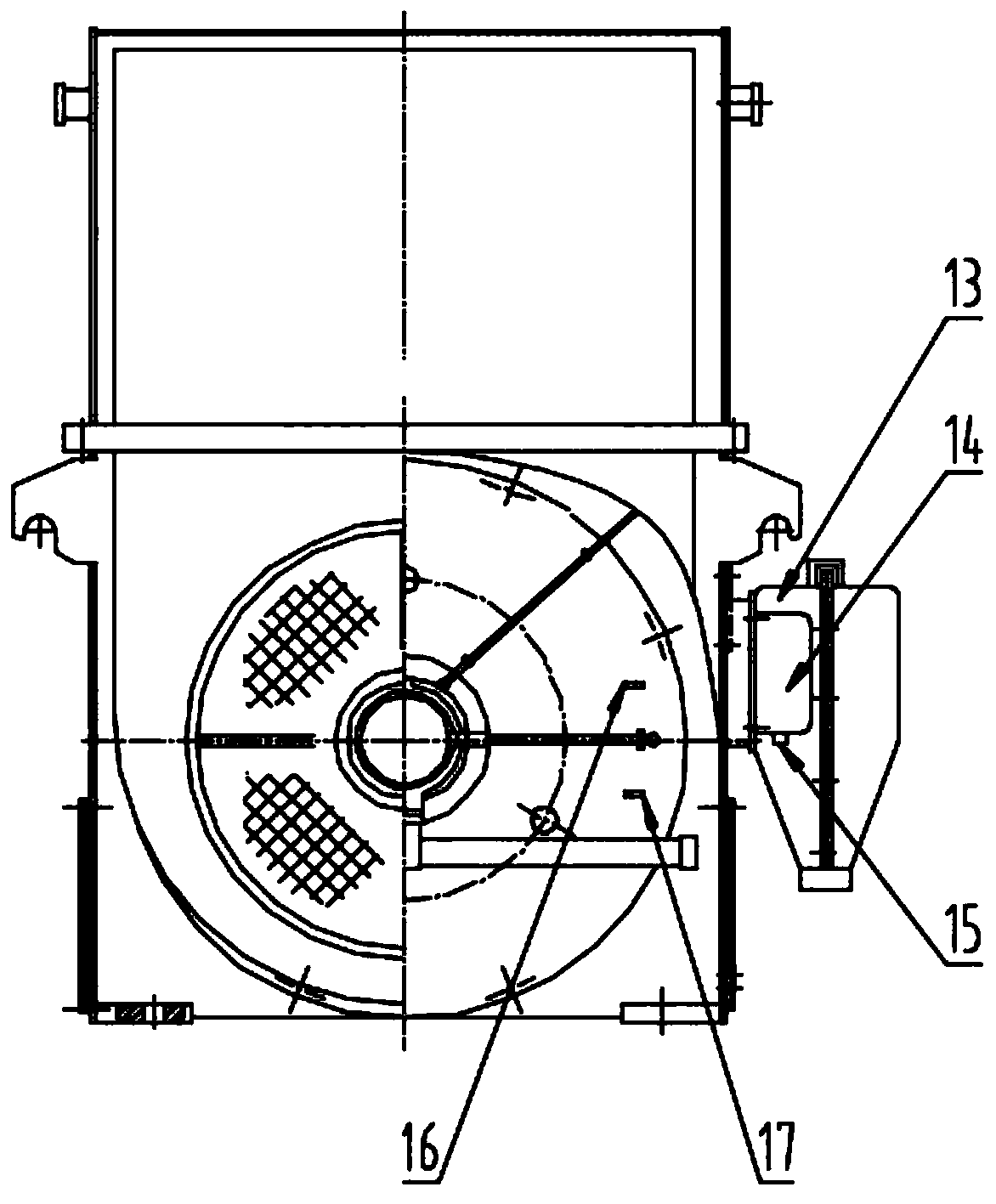

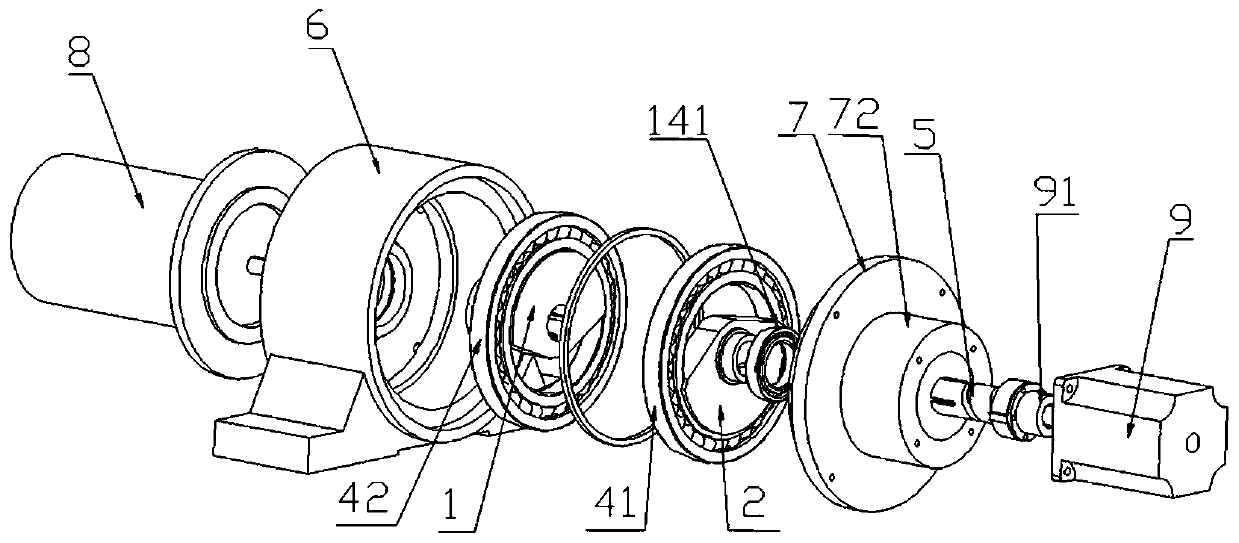

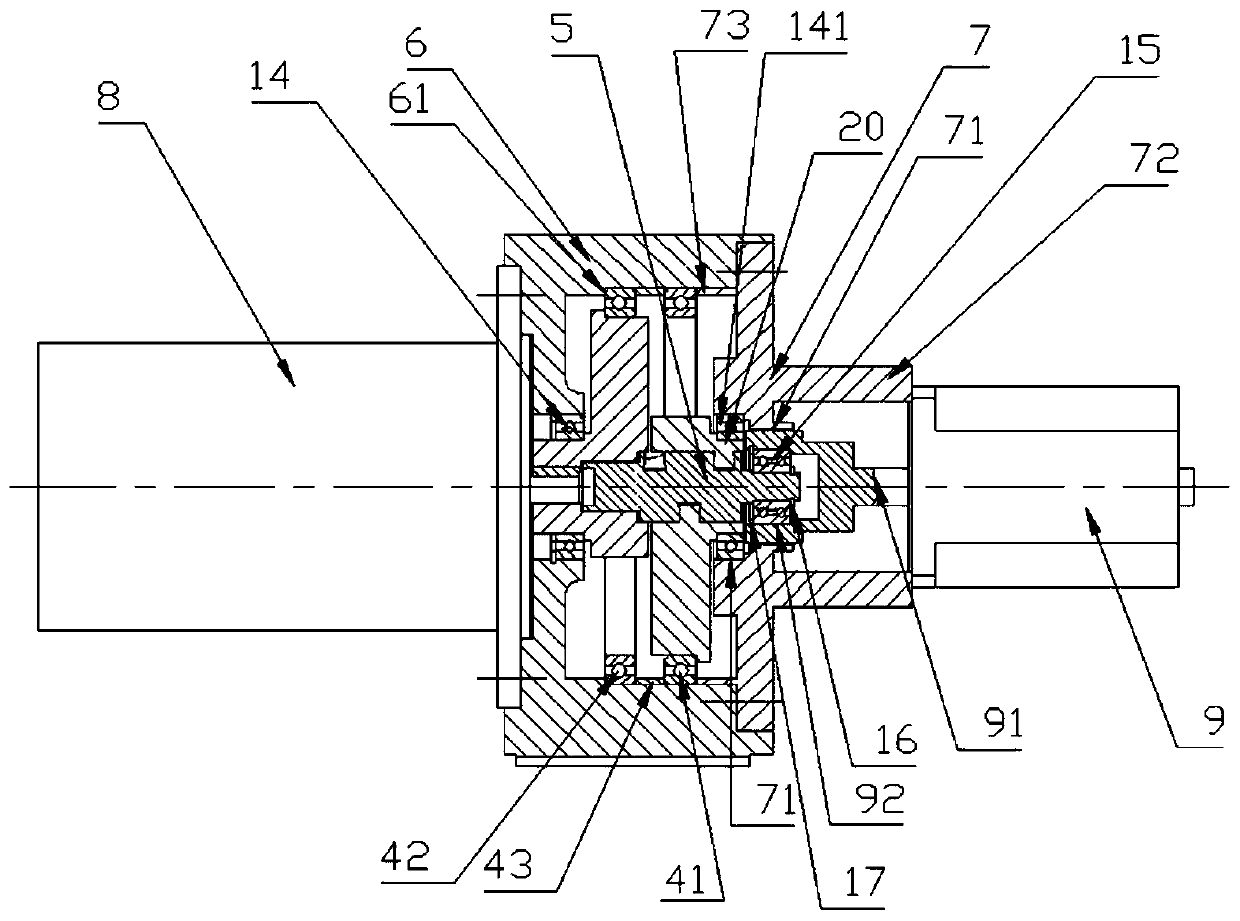

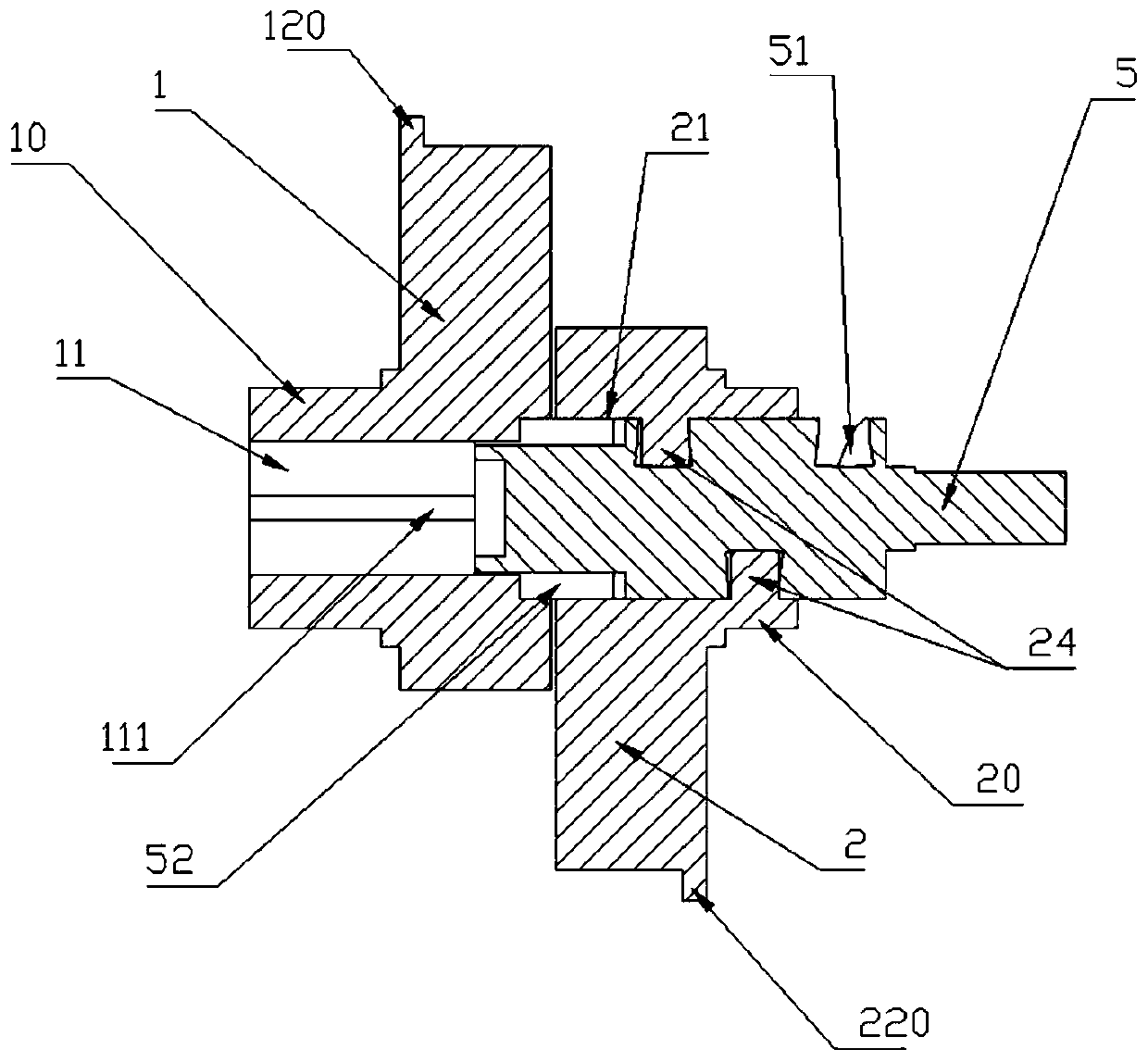

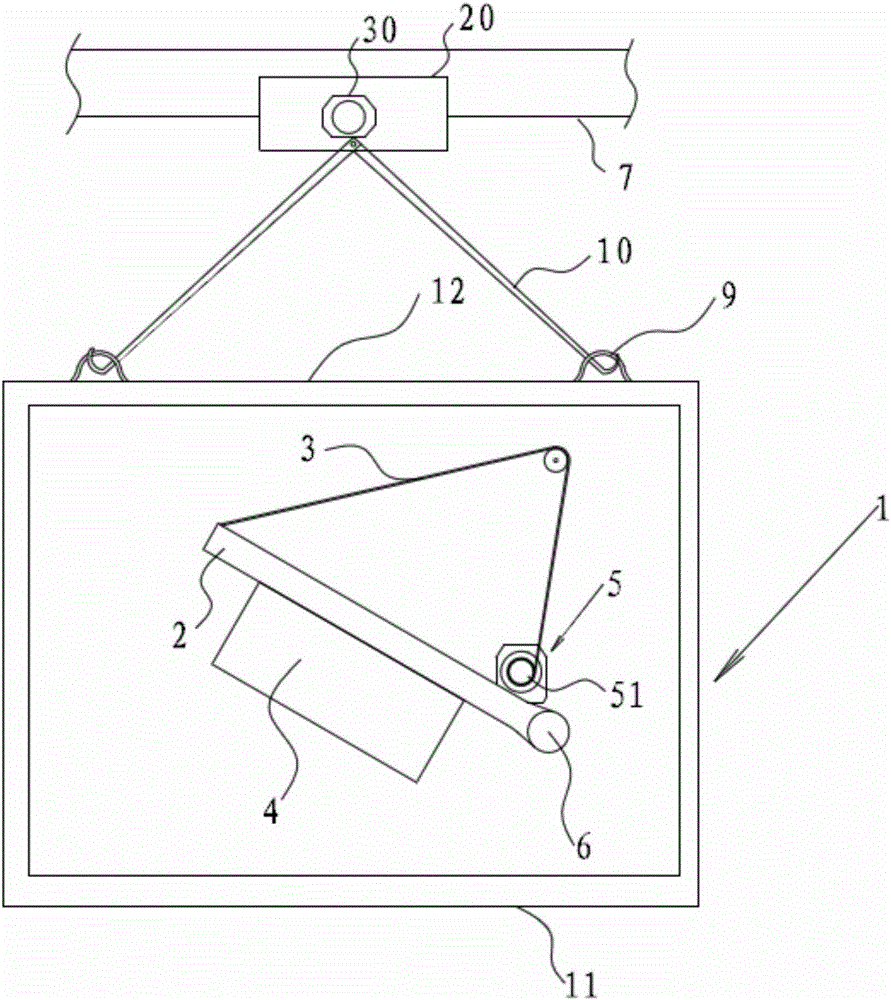

Vibration exciter

PendingCN111229579AAvoid damageAccurate control parametersMechanical vibrations separationLinear motionElectric machinery

The invention discloses a vibration exciter, and belongs to the technical field of vibration machinery. The vibration exciter comprises an eccentric vibrator, a vibration excitation box (6) for accommodating the eccentric vibrator, a vibration excitation motor (8) for driving the eccentric vibrator to rotate, and further comprises a servo linear motion system (9) for adjusting the eccentricity ofthe eccentric vibrator, the eccentric vibrator comprises an outer eccentric body (1), an inner eccentric body (2) and a connecting shaft (5), the inner eccentric body (2) is connected with the connecting shaft (5) through a spiral groove and a boss structure matched with the spiral groove; the outer eccentric body (1) is connected with the connecting shaft (5) through a linear groove and a boss structure matched with the linear groove; and the servo linear motion system (9) is fixedly connected with the connecting shaft (5) in the axial direction, and the servo linear motion system (9) is rotatably connected with the connecting shaft in the peripheral direction of the surface. The vibration exciter can adjust the magnitude of exciting force at a static state or any rotating speed.

Owner:JINAN HAOTE INNOVATION MANAGEMENT & CONSULTING PARTNERSHIP LLP

Novel explosion-proof motor

InactiveCN110676968AFast coolingEnsure production safetyStructural associationCooling/ventillation arrangementPlatinumElectric machine

The invention discloses a novel explosion-proof motor, which comprises an outer fan, a bearing, an end cover, a cooler, a cover plate, a stator, a rotor, a wind shield, a slip ring, a platinum thermistor, a temperature measurement connecting wire, a galvanized metal hose, a main junction box, a temperature measurement junction box, a heater junction box, an oil injection hole, an oil discharge hole, a heater, a fan cover, a motor main shaft and a monitoring box, wherein the cooler is arranged on the top of an explosion-proof motor main body; the cooler is of a double-fan structure and is fastened at the top of the explosion-proof motor main body through a bolt; a wire core of the temperature measurement connecting wire is made of platinum rhodium alloy and is used for connecting a platinumthermistor and the stator; and the galvanized metal hose wraps the temperature measurement connecting wire. According to the novel explosion-proof motor, design optimization is performed on the outerfan, an explosion-proof motor junction box housing and a sealing part; and the improvement of the outer fan makes the cooling speed of the explosion-proof motor improved; and the redesign and improvement of the junction box reduce spark probability in the operation process of the explosion-proof motor.

Owner:JIANGSU XINPENG ENERGY TECH

Vibration exciter

PendingCN111250377AAvoid damageAccurate control parametersMechanical vibrations separationLinear motionElectric machinery

The invention discloses a vibration exciter, and belongs to the technical field of vibration machinery. The vibration exciter comprises an eccentric vibrator, a vibration excitation box (6) for accommodating the eccentric vibrator, a vibration excitation motor (8) for driving the eccentric vibrator to rotate and further a servo linear motion system (9) for adjusting eccentricity of the eccentric vibrator; and the eccentric vibrator at least comprises a first eccentric body (1), a second eccentric body (2) and a connecting shaft (5), wherein at least one of the first eccentric body (1) and thesecond eccentric body (2) is connected with the connecting shaft (5) through a spiral groove and a boss structure matched with the spiral groove, and the servo linear motion system (9) is connected with the connecting shaft (5). The vibration exciter can adjust the magnitude of exciting force at a static state or any rotating speed.

Owner:JINAN HAOTE INNOVATION MANAGEMENT & CONSULTING PARTNERSHIP LLP

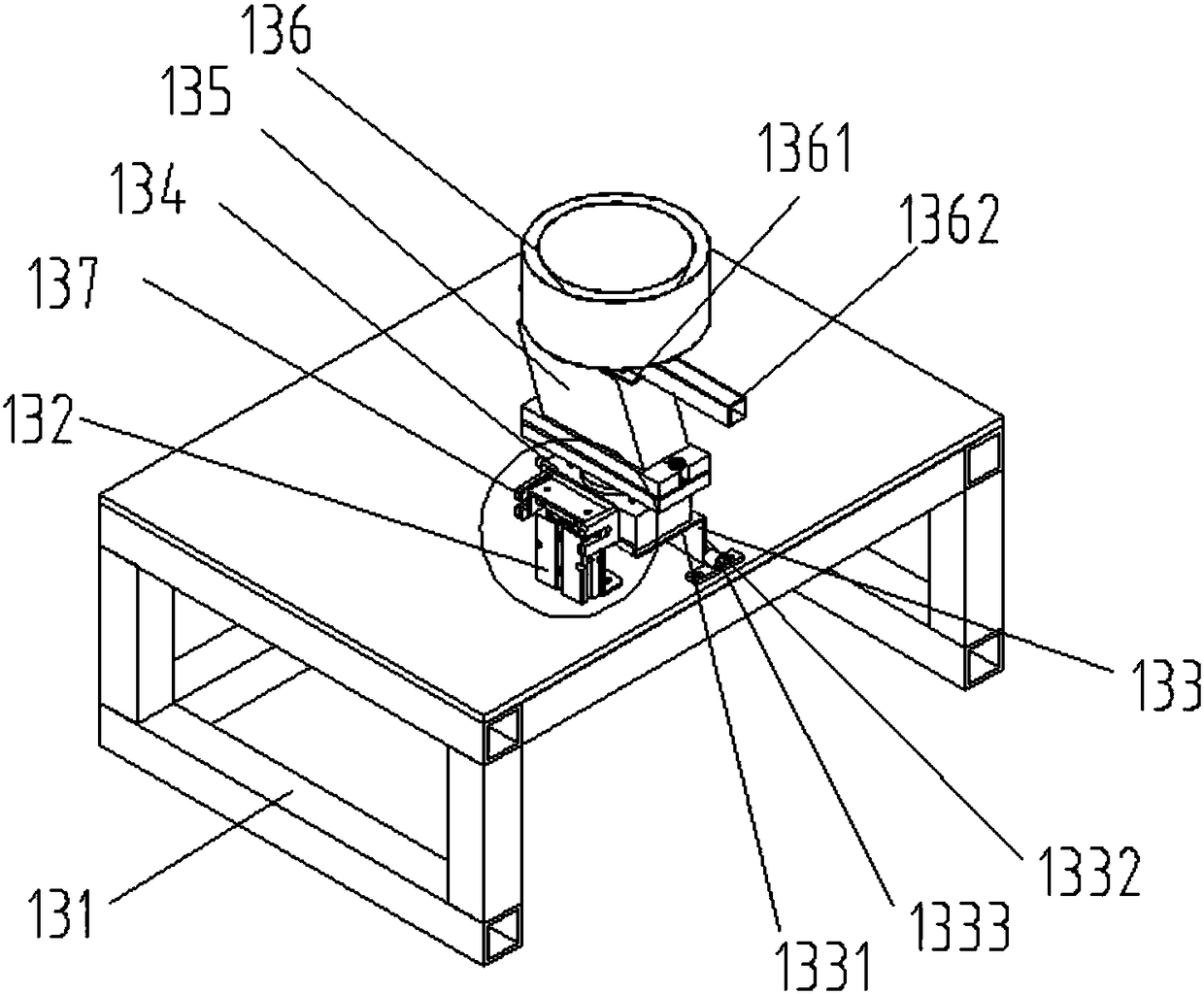

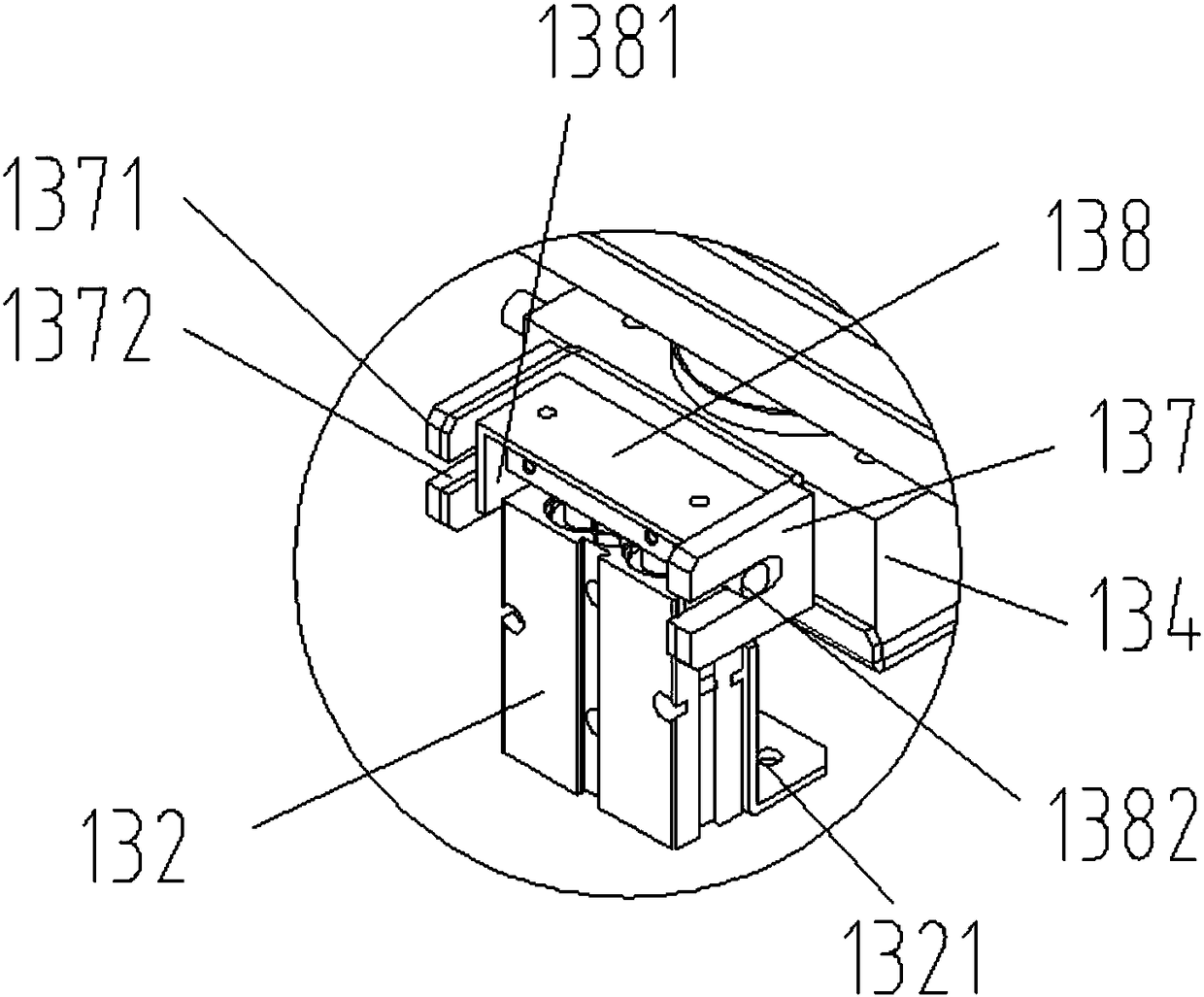

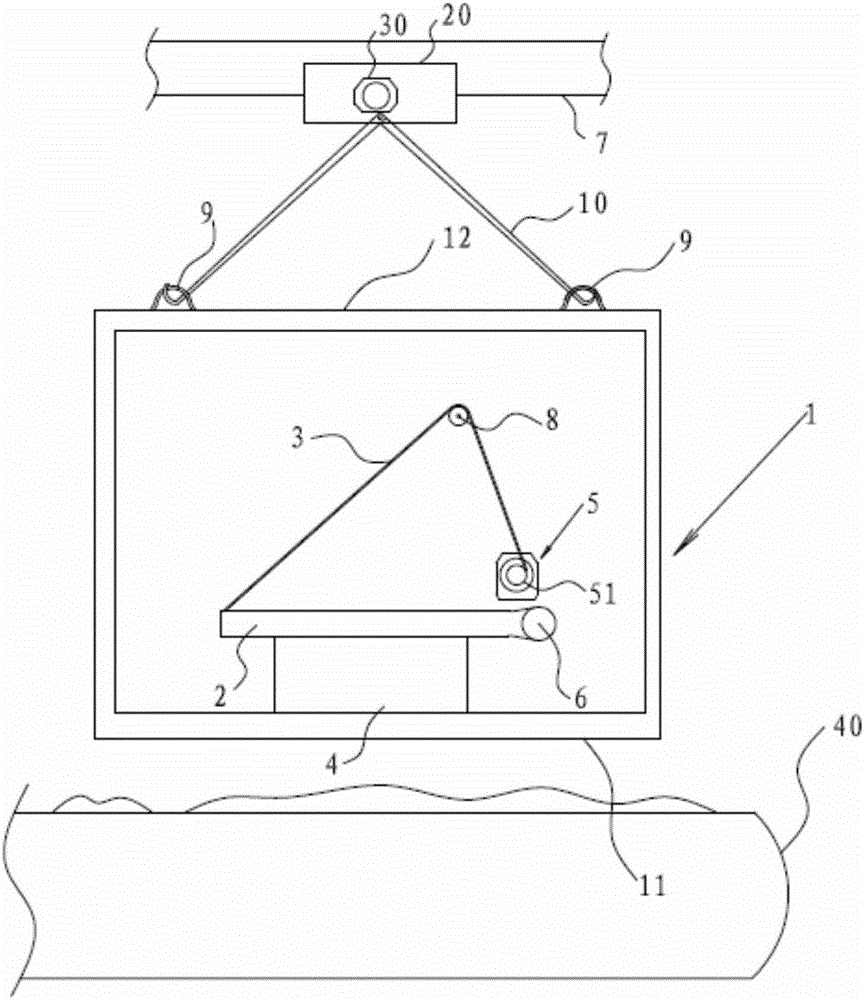

Vibration feeding device

The invention relates to a vibration feeding device. The vibration feeding device comprises a receiving hopper, a vibrator, and a tilt conveying mechanism; the receiving hopper is arranged at the upper end, used for loading samples, and provided with a receiving hopper nozzle for discharging; the vibrator is connected with the receiving hopper and used for driving the receiving hopper to vibrate and driving the samples in the receiving hopper to vibrate and to be output from the receiving hopper nozzle ; and the tilt conveying mechanism is arranged on the lower portion of the vibrator and usedfor tilting the receiving hopper and pouring the samples. According to the vibration feeding device, the conveying flow can be continuously and accurately controlled according to the preset standardweight, conveying is conducted in a vibrating mode, the purpose of slow conveying is achieved, and control is convenient.

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

Aliphatic polycarbonate washing coagulation devolatilization method and specific device thereof

Owner:CHINA NAT OFFSHORE OIL CORP +2

Special fixture for processing steam turbine generator rotor coil ventilation hole

ActiveCN103286585BAchieving lateral compressionSimple structurePositioning apparatusMetal-working holdersReciprocating motionEngineering

The invention discloses a fixture for steam turbine generator rotor coil vent hole machining. Two rotor coils are placed flat on a left die holder and a right die holder respectively, and are separated and positioned by a positioning check block. A lateral pressing air cylinder piston rod stretches out and draws back to drive a movable fulcrum pin shaft of a left oscillating bar and a movable fulcrum pin shaft of a right oscillating bar to motion, so that the left oscillating bar is driven to swing around a fixed fulcrum pin shaft of the left oscillating bar, and the right oscillating bar is driven to swing around a fixed fulcrum pin shaft of the right oscillating bar. A limiting block on the left side and a limiting block on the right side limit an opening of the left oscillating bar and an opening of the right oscillating bar to be consistent in size. The left rotor coil and the right rotor coil are tightly pressed or loosened at the same time through a lateral pressing head. An upward pressing air cylinder piston rod stretches out and draws back to drive an upward pressing head to move in a reciprocating mode along a positioning check block guide hole, so that the left rotor coil and the right rotor coil are loosened or tightly pressed in the vertical direction. The fixture for the steam turbine generator rotor coil vent hole machining is high in automation degree, high in work efficiency, strong in universality, simple in structure, reliable in operation, long in service life, and capable of greatly mitigating the labor intensity for an operator.

Owner:HARBIN ELECTRIC MASCH CO LTD

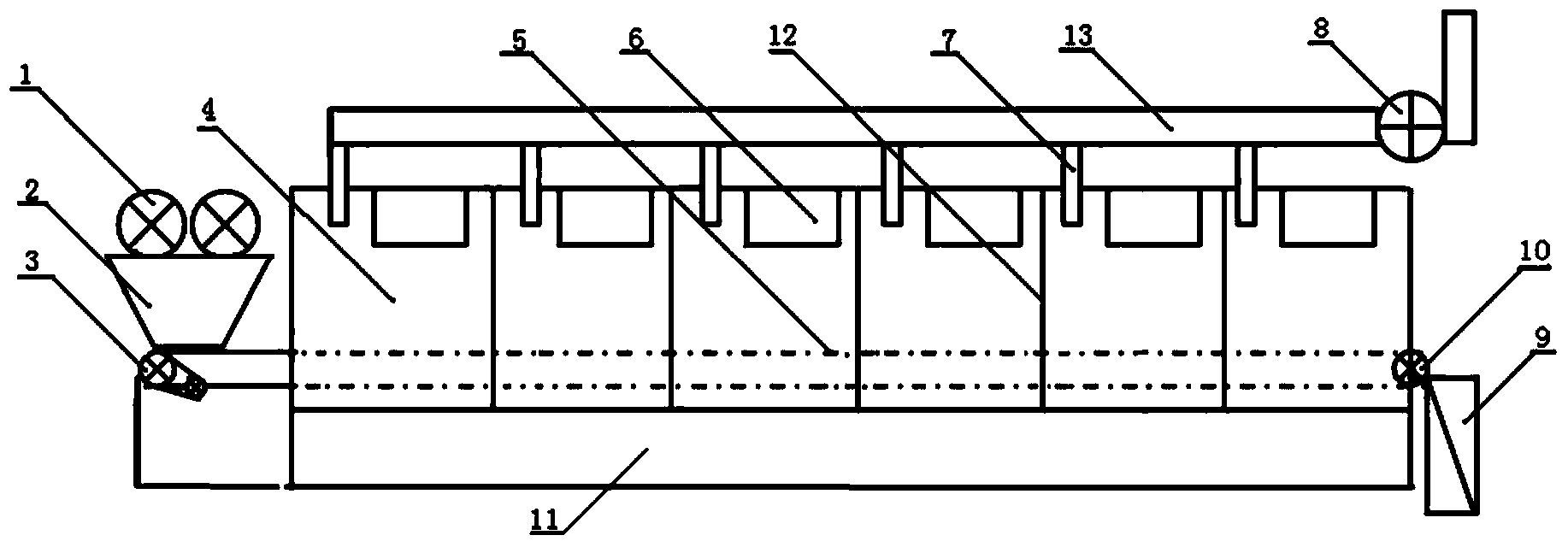

Underwater particulate matter clearing device of aquaculture system

InactiveCN101700006BSimple structureImprove filtering effectPisciculture and aquariaParticulatesUnderwater

The invention relates to the aquaculture water treatment field, in particular to an underwater particulate matter clearing device of an aquaculture system; a screen cylinder (5) formed by a filtering screen is arranged in a vertical-type cylindrical sedimentation pool (17) and is axially arranged with the sedimentation pool (17); a tangential water inlet (3) and an overflow port (10) are arrangedon the pool wall at the upper part of the sedimentation pool (17), and a drain pipe (8) is arranged at the bottom part of the sedimentation pool (17), a rotating rack (2) is arranged on an output shaft (12) of a reduction box (1) above the sedimentation pool (17), a plurality of lower extension rods (11) which are provided with screen clearers are arranged on the rotating rack (2), and the screenclearer is a hairbrush (4) or a spray head (18), and a sewage drainage mechanism is arranged below the sedimentation pool (17). The underwater particulate matter clearing device of the aquaculture system in the invention has simple structure, convenient operation, good filtering effect, low power and water consumption, low vibration and low nose, and can remove micro particles easily, thereby being suitable for automation control of a computer and prolonging the service life of the whole device.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Composting method using rectorite as accessory material

InactiveCN106518190AIncrease permeability and loosenessPromote air circulationBio-organic fraction processingSewage/sludge fertilisersAeration rateIon exchange

The invention discloses a composting method using rectorite as an accessory material. The composting method comprises the following steps: adding 10 to 20% of wood chip and straw and 5 to 15% of sintered rectorite in the process of composting and pretreatment of sludge and allowing the water content of the initial materials mixed under stirring to be 60%; controlling turning frequency and aeration rate of composting; and after completion of composting, carrying out screening to form a composting product-organic matrix with uniform particle sizes and separating rectorite from soil for cyclic usage. The sintered rectorite applied to composting has the advantages of adsorptivity, ion exchange performance, air permeability, low loss and repeated usability; the composting product obtained in the invention is high in decrement rate; the utilization efficiency of composting cabins is high; the composting product is loose and is easy to separate; a composting period is shortened by 1 / 4; operation cost is reduced; economic benefits are increased; and the method is extensively applicable to aerobic composting of a variety of sludges.

Owner:武汉正清和环保科技开发有限公司

Permanent Magnetic Separator

InactiveCN103623921BAutomatic disengagementReduce lossMagnetic separationAutomatic controlEngineering

Owner:WUXI ZHIYUDE TECH

Quick two-way stop valve

ActiveCN105972226BOpen fastShorten the opening and closing timeSpindle sealingsLift valveAxial pressureEngineering

The invention discloses a rapid double-direction stop valve. The rapid double-direction stop valve comprises a valve body, an end cover and a valve rod. The end cover is fixed to the upper portion of the valve body, a seal lip stretching into the valve body is arranged on the end cover, a valve plug for dividing the interior of the valve body into an upper gas chamber and a lower gas chamber is movably arranged in the valve body, a gas hole communicating the upper gas chamber with the lower gas chamber is formed in the valve plug, and the valve rod stretches into the valve body from the lower portion of the valve body to be fixedly connected with the valve plug; a first gas opening communicated with the upper gas chamber is formed in the valve body, and a second gas opening communicated with the upper gas chamber is formed in the end cover; and the valve plug and the seal lip are matched to control the first gas opening and the second gas opening to be on and off. When the stop valve is opened and closed, axial pressure borne by the valve plug is reduced, opening and closing of the stop valve can be rapidly achieved through small driving force, and the service life of the valve plug is prolonged.

Owner:SICHUAN LIDI VEHICLE CHASSIS TECH CO LTD

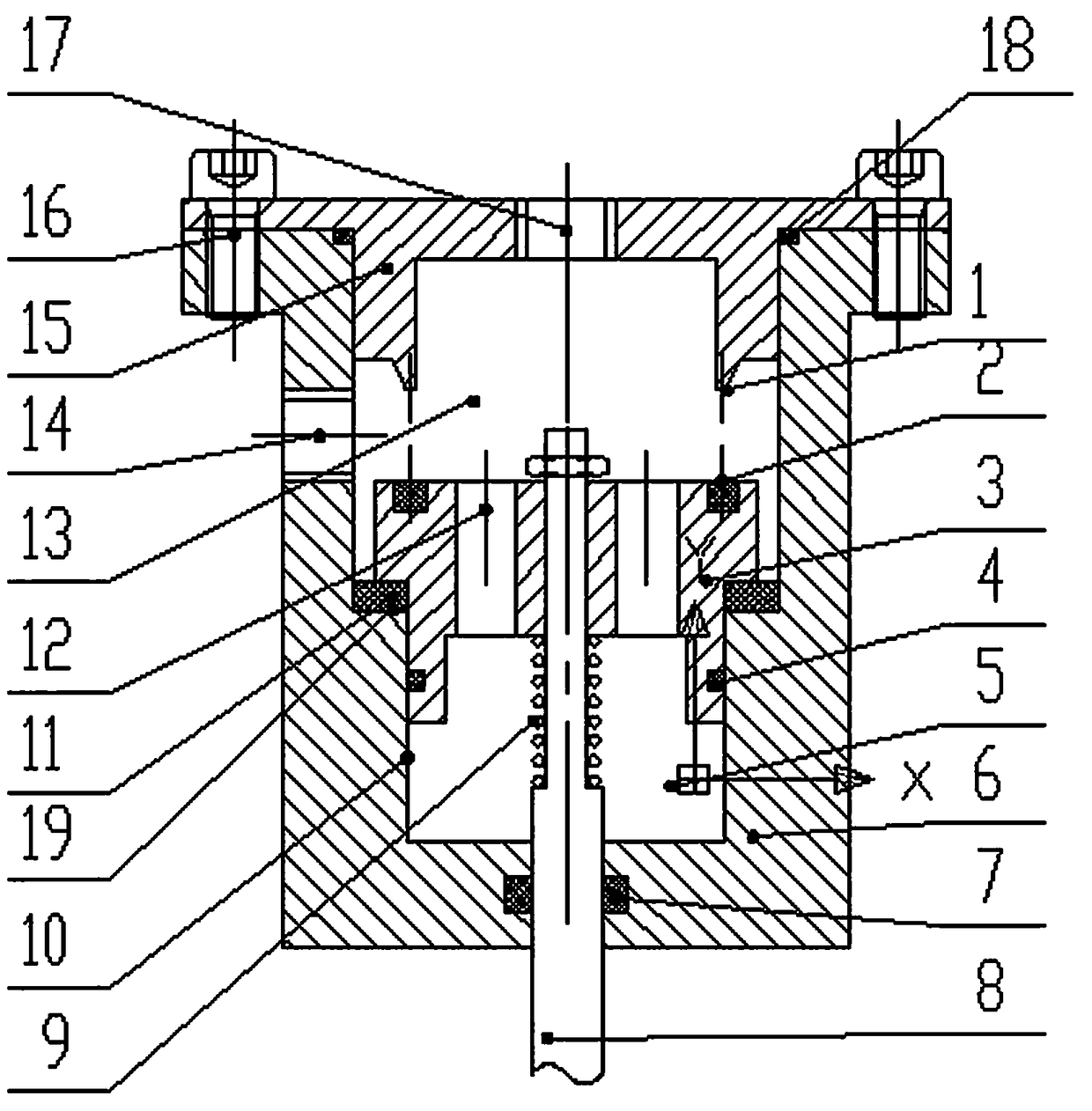

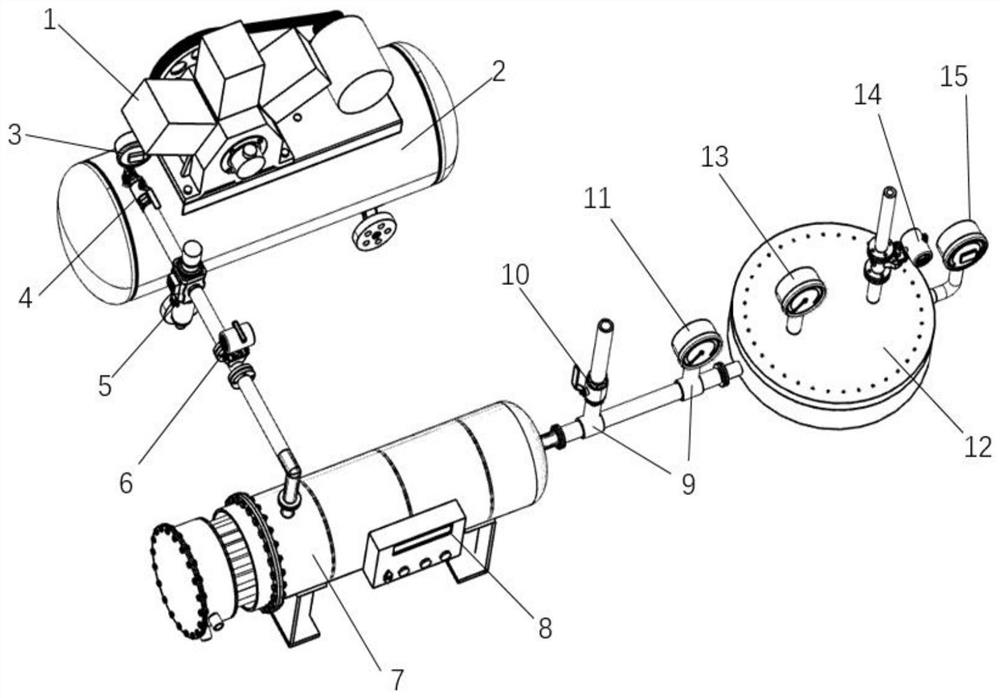

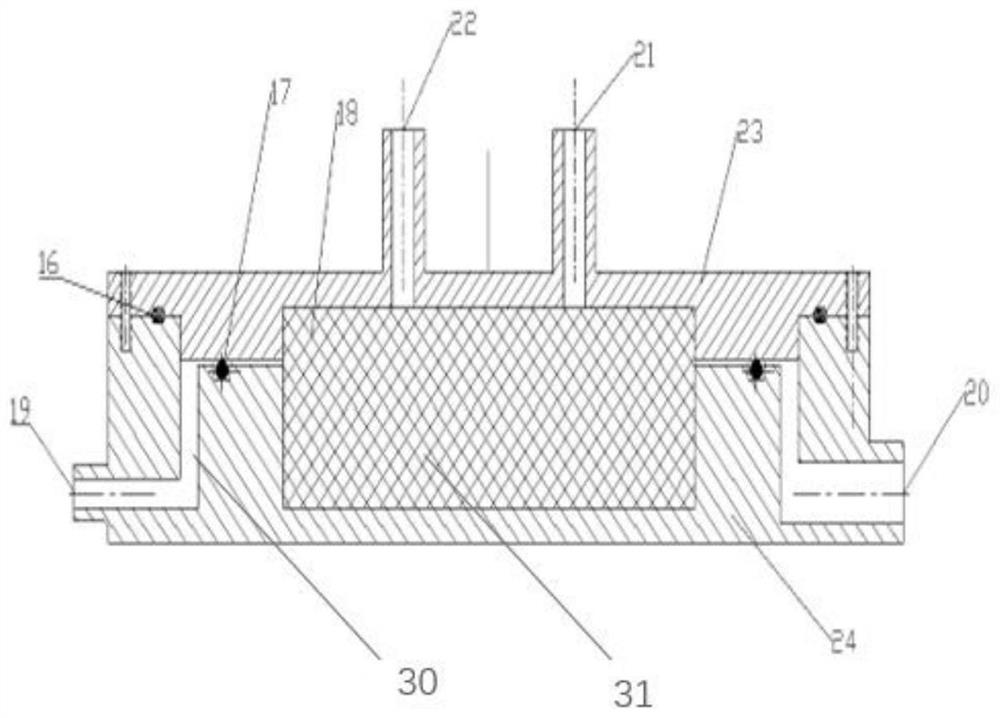

Wind tunnel device for continuous high temperature sealing performance test

ActiveCN108254130BRealization of high temperature sealing performance testUnlimited testing timeAerodynamic testingFluid-tightness measurement using fluid/vacuumGas cylinderEngineering

The invention discloses a wind tunnel device for continuous high-temperature sealing performance testing. The wind tunnel device is composed of an air compressor, a gas cylinder, a normal-temperaturepressure gauge, a stop valve a, a reducing valve, an air flow meter a, a pipeline type air heater, a stop valve b, a high-temperature thermometer a, high-temperature pressure gauge, a test section, anair flow meter b, and a high-temperature thermometer b. The air compressor pressurizes air and stores the processed air in the gas cylinder; the reducing valve adjusts the pressure; heating is carried out by using the pipeline type air heater; with the test section, a testing piece is fixed in a specific trench of the test section, the distance between an upper cover plate of the test section anda pedestal is changed by replacing adjusting gaskets with different dimensions so as to change the compression amount of the testing piece; and with the high-temperature thermometer a, the high-temperature pressure gauge, the air flow meter b, and the high-temperature thermometer b arranged in front of and in rear of a sealing device, sealing and heat insulating parameters of the testing piece onthe conditions of different compression amounts, different pressure differences, and different temperatures are obtained.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com