Special fixture for processing steam turbine generator rotor coil ventilation hole

A technology of steam turbine generator and rotor coil, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. The effect of pollution, high production efficiency and fast clamping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

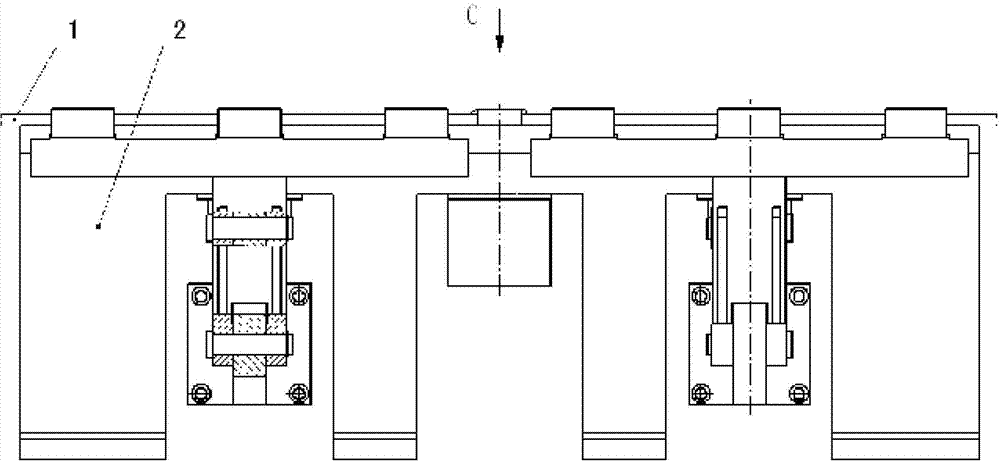

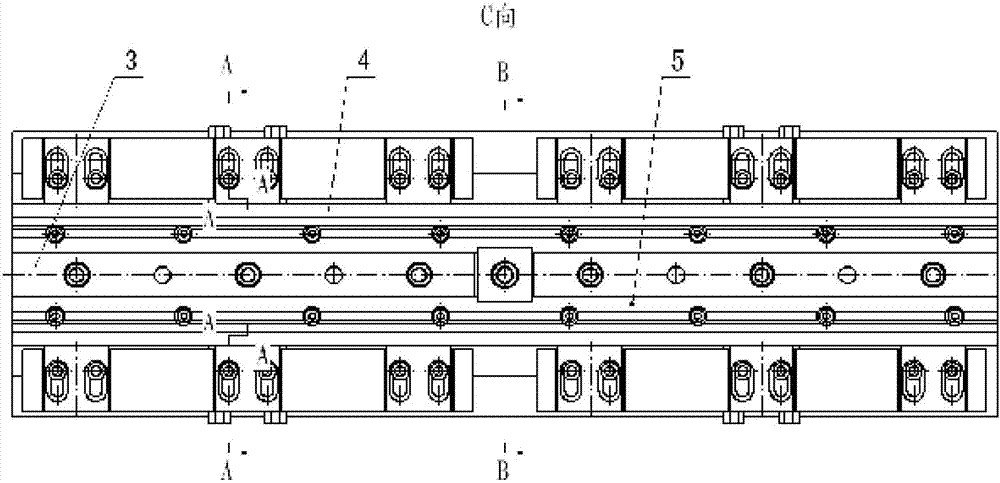

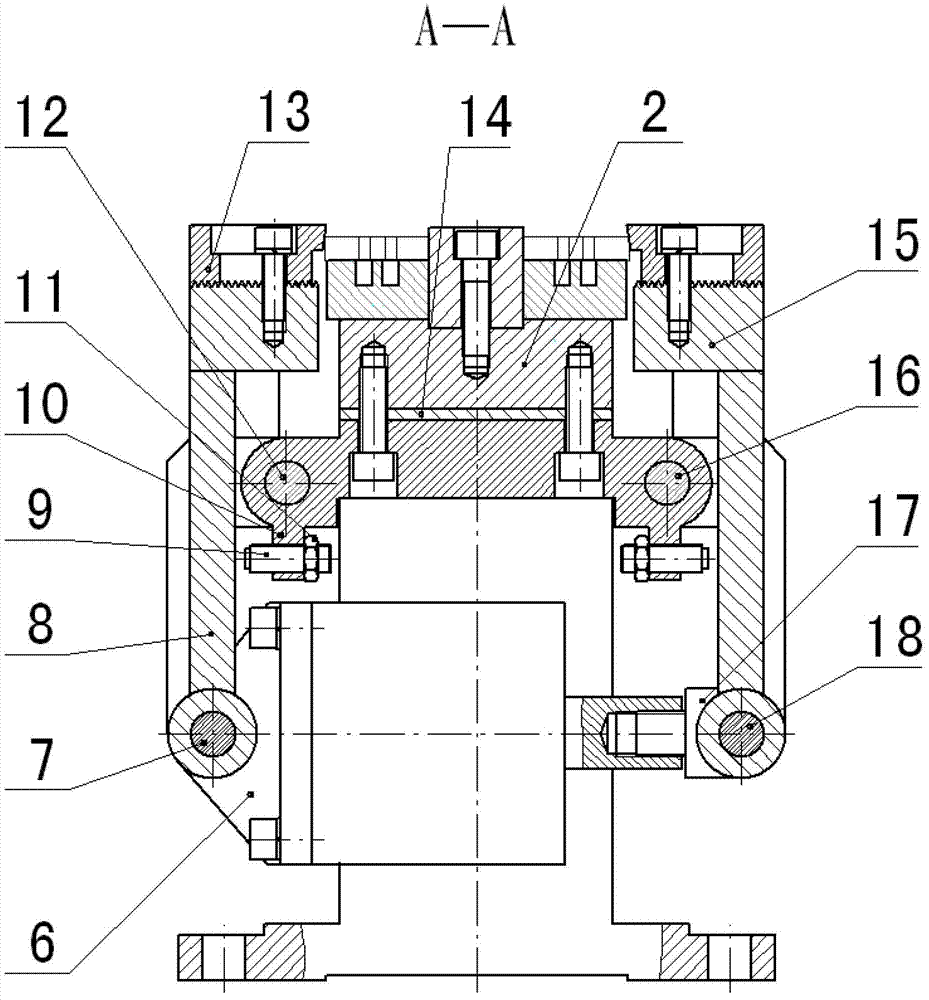

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a special jig for machining ventilation holes of the rotor coil of a turbogenerator is composed of a rotor coil 1, a base 2, a positioning block 3, a first mold base 4, a second mold base 5, a side pressure cylinder 6, and a pin I7. , left swing rod 8, limit block 9, support seat 10, lock nut 11, pin shaft II 12, side pressure head 13, adjustment pad I 14, right swing rod 15, pin shaft III 16, joint 17, pin shaft IV 18, upper Press head 19, bolt 20, adjustment pad II 21, upper pressure cylinder 22 and other main components. like figure 1 , figure 2 As shown, the two rotor coils 1 are placed on the first mold base 4 and the second mold base 5 respectively, separated and positioned by the positioning block 3, the first mold base 4, the second mold base 5 and the positioning block 3 are respectively installed on the base 2, two left swing rods 8 and two right swing rods 15 are respectively installed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com