Main bending side pressing buckling mechanism for front cover buckling mold

A technology of a mold and a front cover is applied in the field of the main bending side pressing and fastening mechanism, which can solve the problems of poor fastening and pressing quality, and achieve the effect of improving the fastening quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

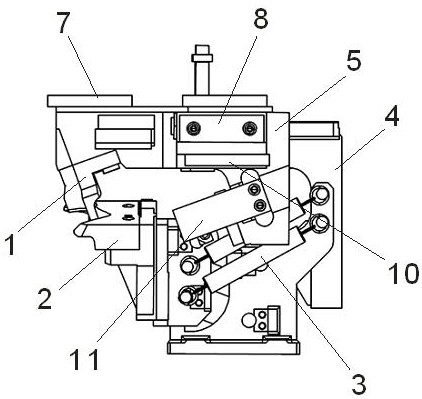

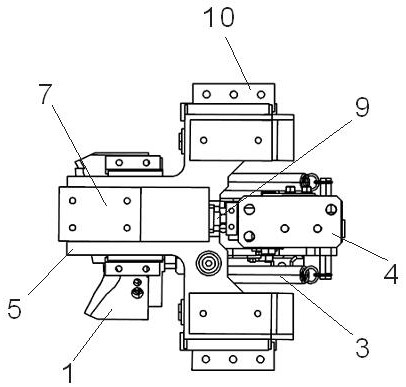

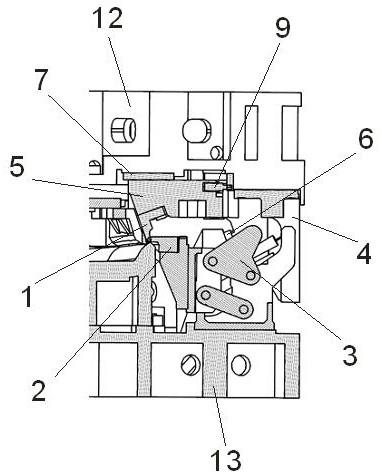

[0019] Example: see Figure 1 to Figure 3 , a main bending side pressing and fastening mechanism for the fastening mold of the front cover, including an upper mold base 12, a lower mold base 13, a main scimitar 1, a pre-scimitar 2, a rocker mechanism 3 and a driver 4. The rocker mechanism 3 is installed on the lower mold base 13, the pre-scimitar 2 is connected with the rocker mechanism 3, the driver 4 is installed on the upper mold base 12, and corresponds to the position of the rocker mechanism 3, and the driver 4 follows the During the downward movement of the mold base 12, the pre-bending knife 2 can be driven by the rocker mechanism 3 to carry out the pre-bending work.

[0020] A sliding block 5 is also arranged on the upper die base 12, and the sliding block 5 is connected with the upper die base 12 in a sliding fit and can slide in a horizontal plane. During the installation process, the upper mold base 12 is provided with a leading slider and a side guiding slider, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com