Sleeve for automatically installing loose joint in pipe connector

A technology for automatic installation and pipe joints, applied in hand-held tools, manufacturing tools, etc., which can solve the problems of high labor intensity of operators, difficult to guarantee the quality of fastening, and depending on the tightening torque, so as to reduce labor intensity and improve connection. Efficiency and effect of improving tightening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

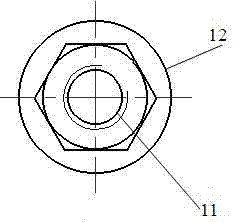

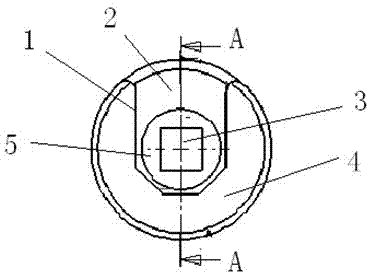

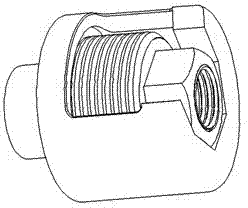

[0013] A sleeve used for automatic installation of joints in pipe fittings according to the present invention, see figure 2 and image 3 , the sleeve includes a body 4, on the body 4 is provided with an end opening 1 compatible with the internal thread part of the union, a middle slot 2 compatible with the external thread part of the union, and a driving device The matching interface 3; the end opening 1 is set at one end of the body 4, and the end opening 1 communicates with the middle slot 2; the interface 3 is set at the other end of the body 4.

[0014] The opening at the end is the opening of the internal thread part of the fixed joint, that is, the octagonal (or hexagonal) opening, and the size matches the octagonal (or hexagonal) size, which is a clearance fit. The size of the slot in the middle matches the width of the union, which is a clearance fit. The size of the centering structure matches the diameter of the union, which is a clearance fit. F is a cavity cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com