Patents

Literature

112results about How to "Uniform torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

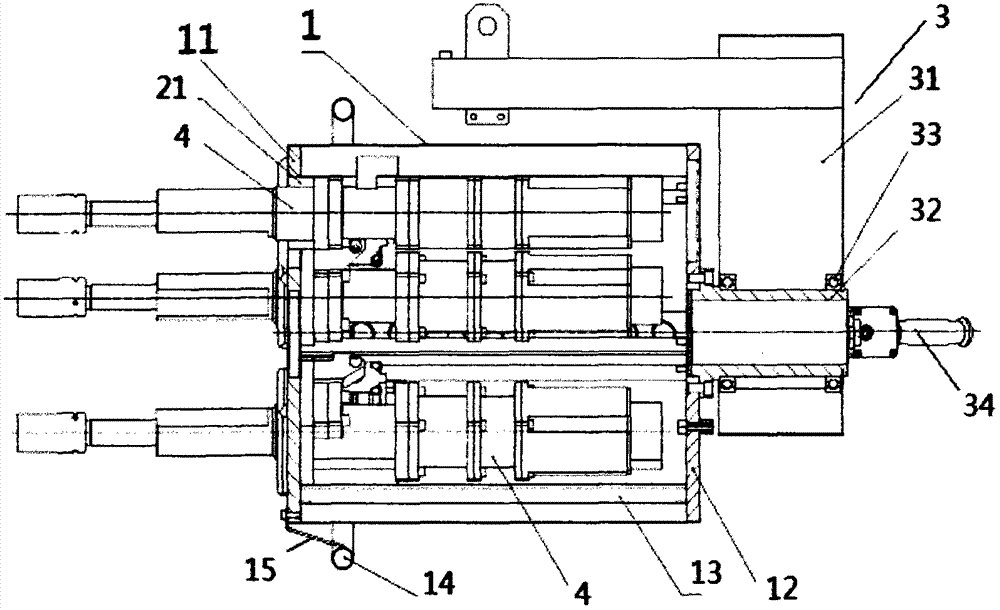

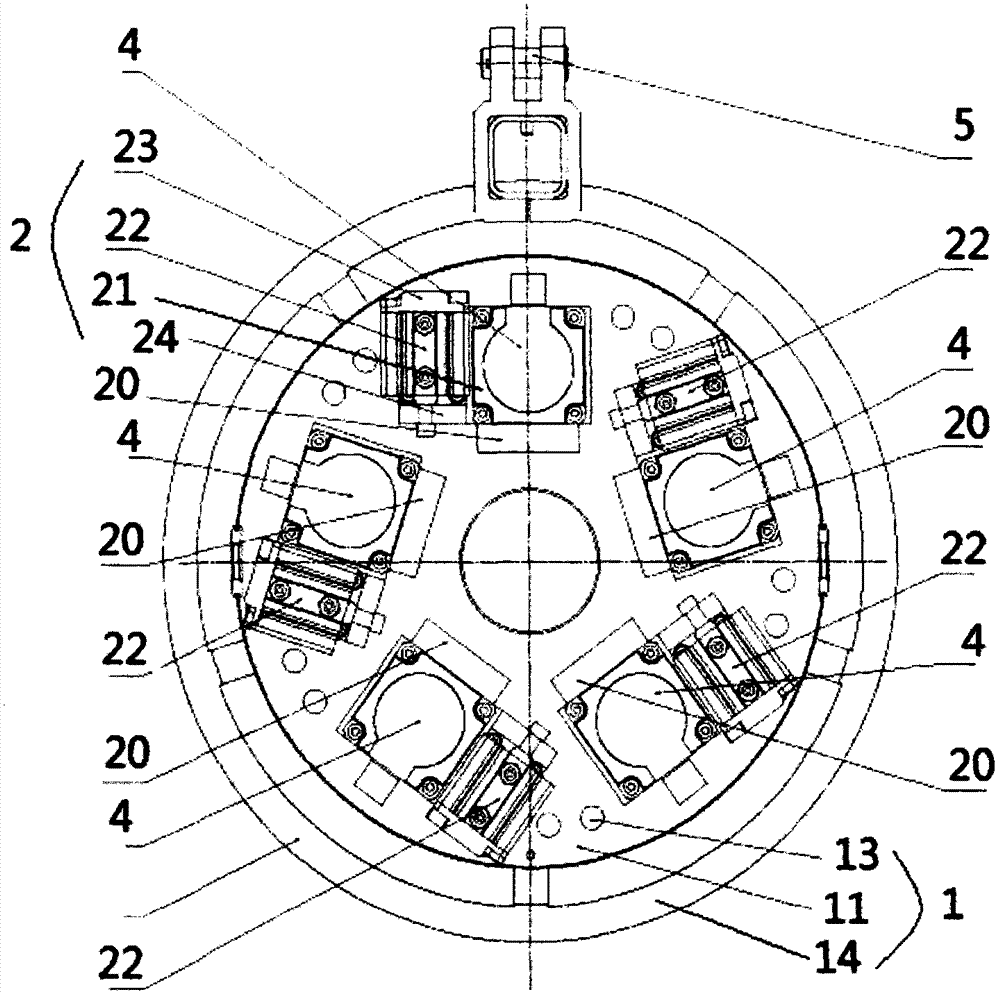

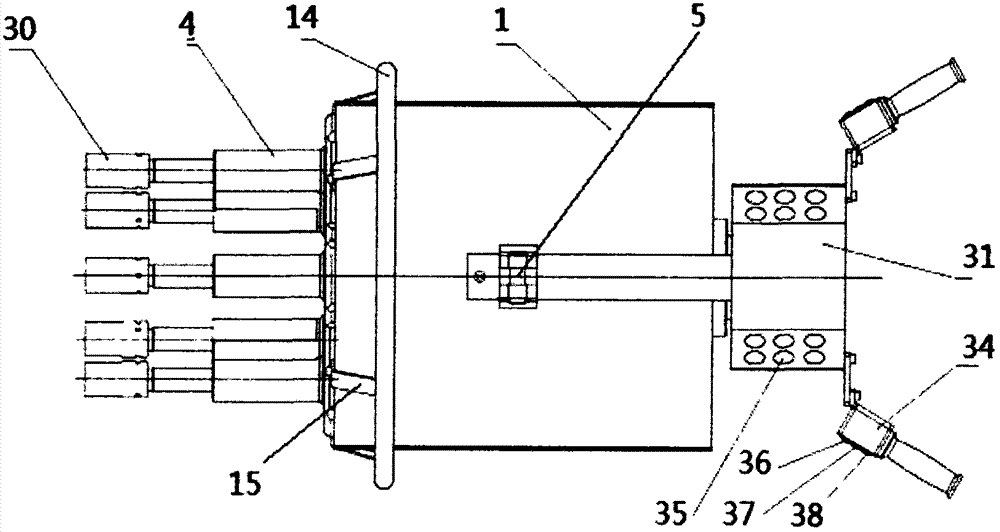

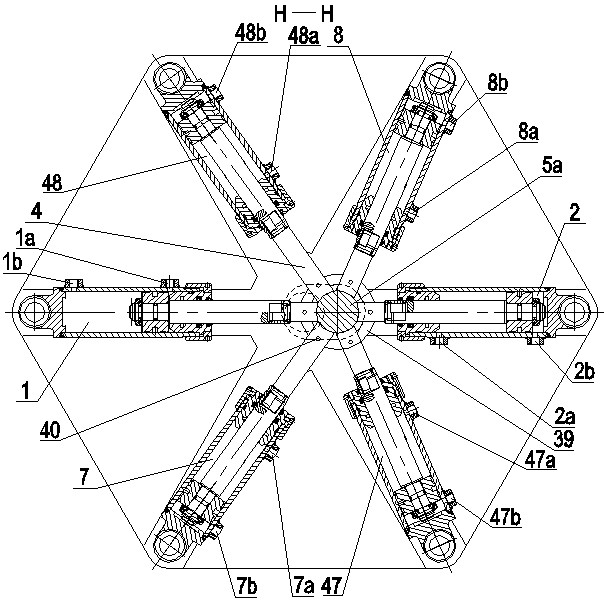

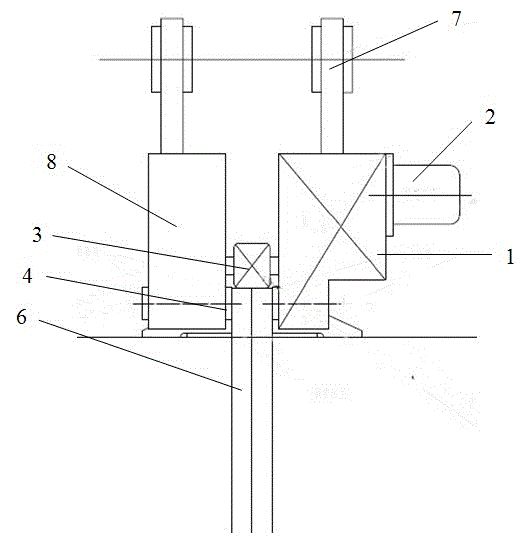

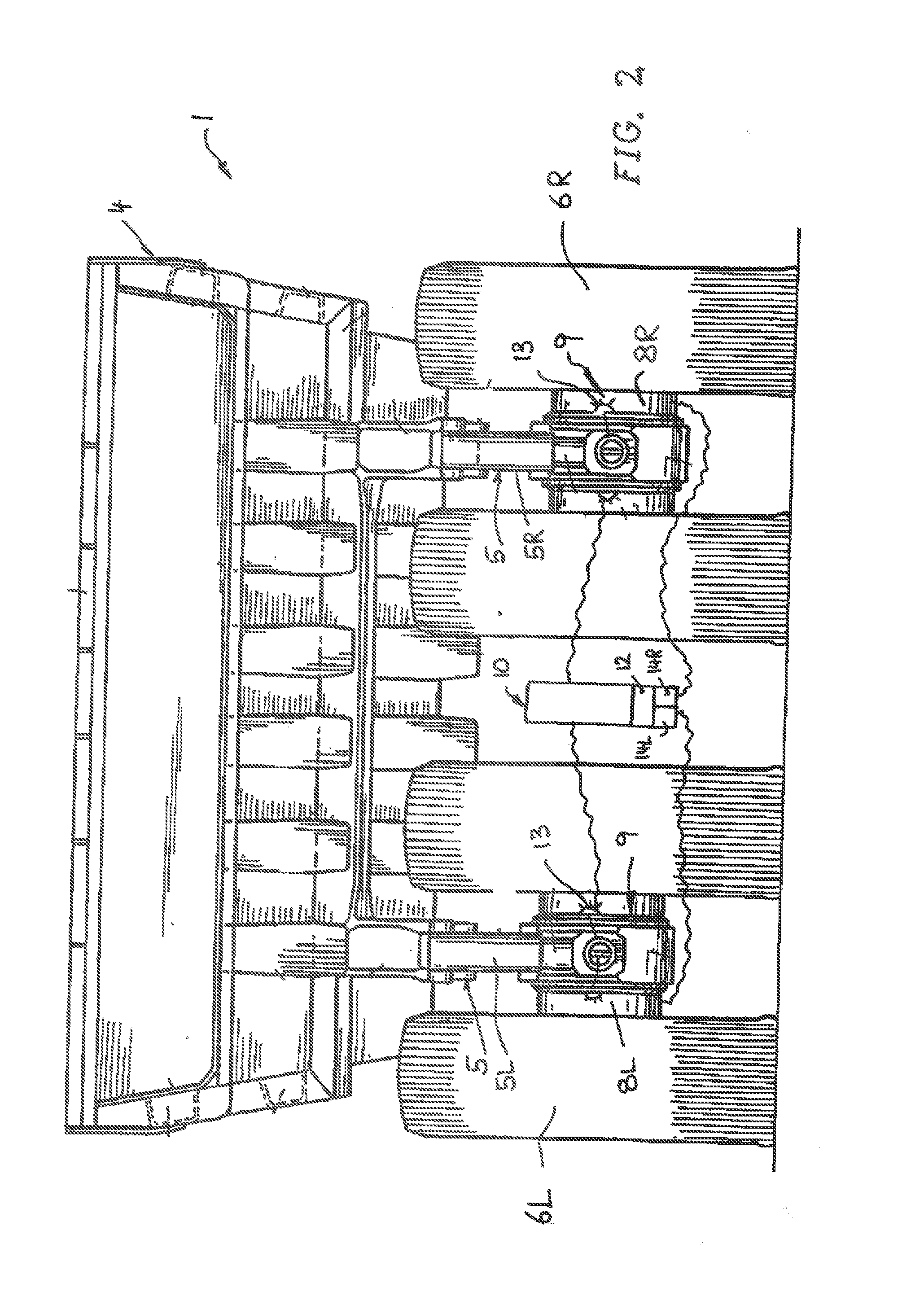

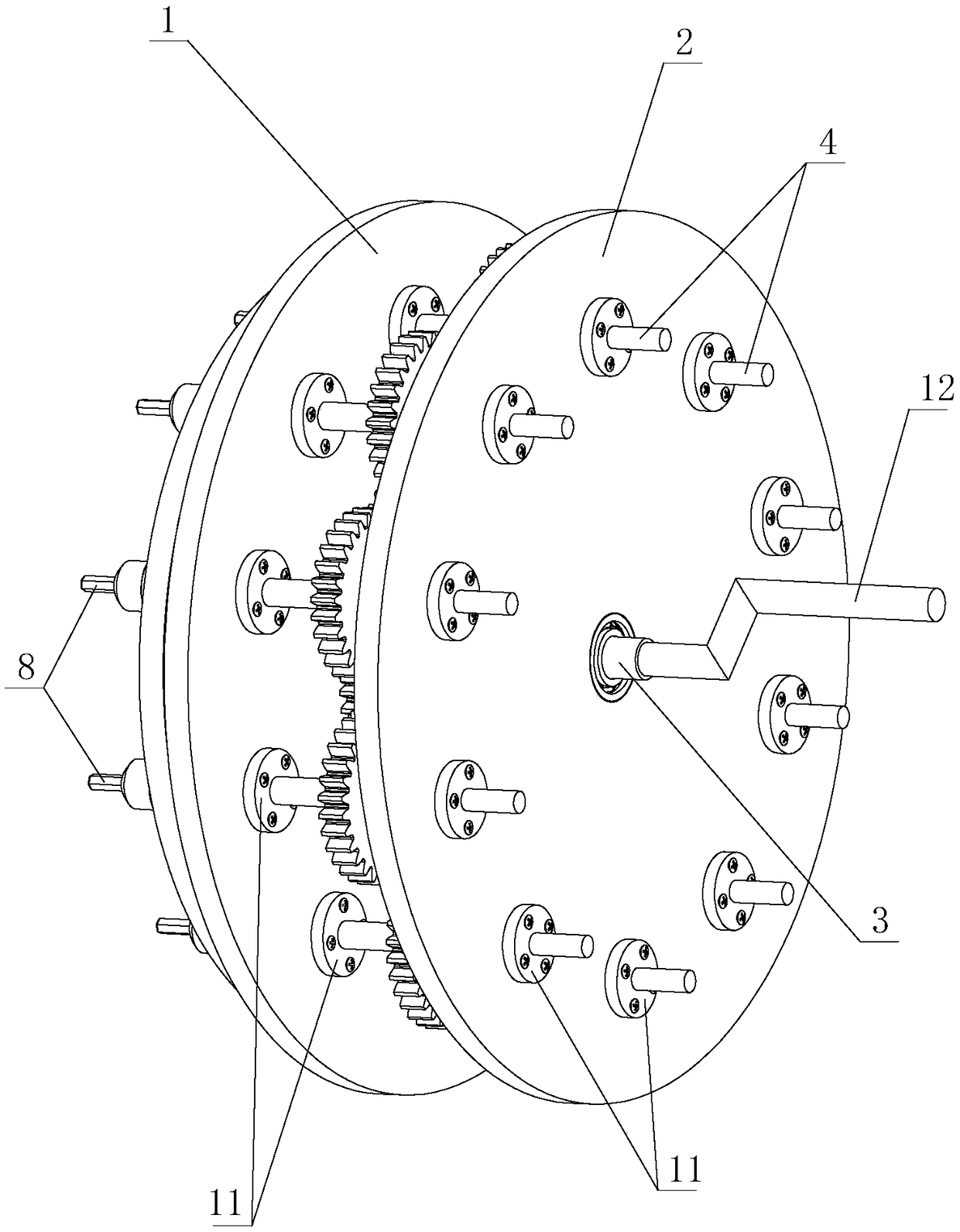

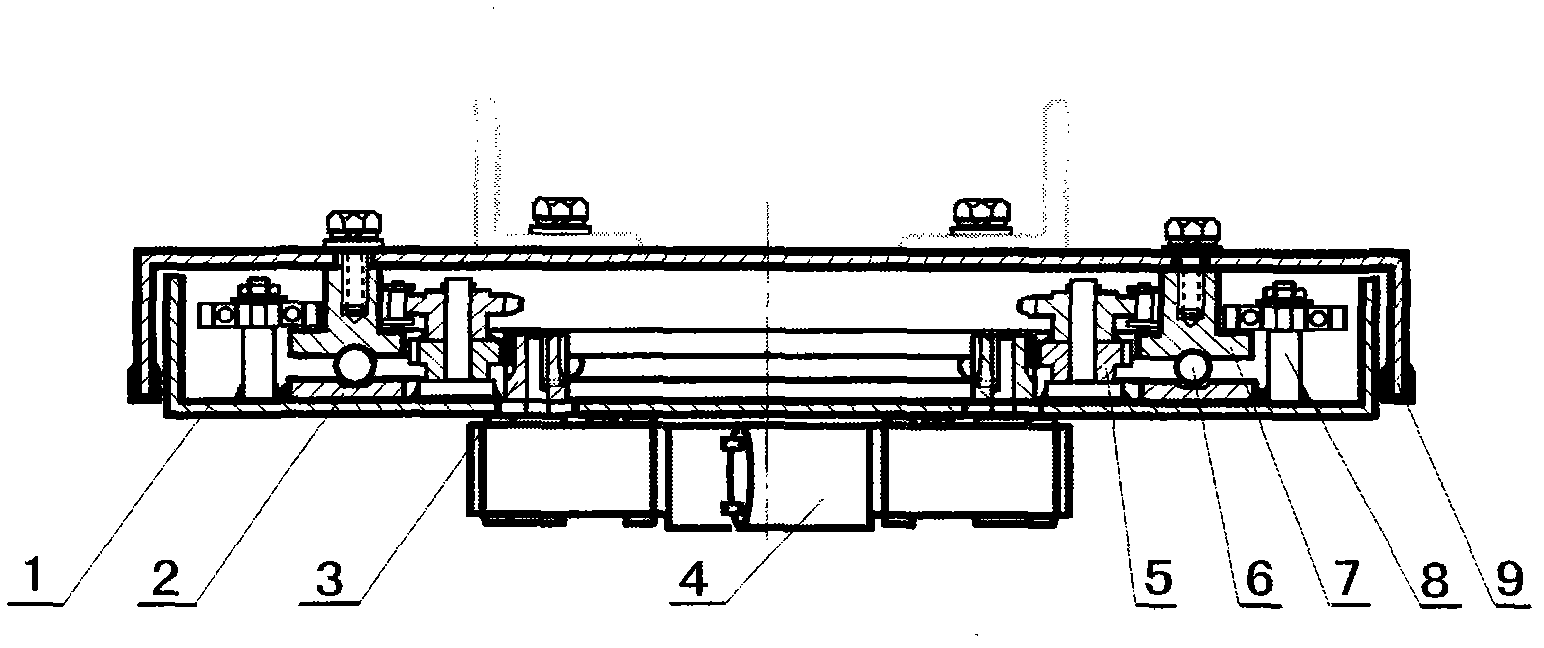

Distribution diameter automatic pitch-control five-axle wheel screwing equipment

ActiveCN102756267AUniform torqueReduce labor intensityMetal working apparatusAssembly linePiston rod

The invention discloses a distribution diameter automatic pitch-control five-axle wheel screwing equipment which comprises a screwing bracket, a hoisting mechanism and five screwing shafts, wherein a screwing shaft fixing plate is fixed at one end of the screwing bracket; five through holes positioned in the same circumference are distributed on the screwing shaft fixing plate; the screwing shafts are fixed on the screwing shaft fixing plate; the hoisting mechanism is fixed at the other end of the screwing bracket; multiple radial pitch-control adjusting mechanisms are arranged on the screwing shaft fixing plate; the radial pitch-control adjusting mechanisms are connected with the screwing shafts in a one-to-one correspondence manner and used for adjusting the radius of the circumference in which each screwing shaft is positioned; each radial pitch-control adjusting mechanism comprises a reducing air cylinder and a sliding block, the cylinder body end of the reducing air cylinder is fixedly connected with the screwing shaft fixing plate through a fixing bracket, and the piston rod end of the reducing air cylinder is connected with the sliding block through a connecting bracket; and the sliding blocks are fixedly connected with the screwing shafts, and each through hole is an elongated sliding chute hole extending along the radial direction of the circumference. The distribution diameter automatic pitch-control five-axle wheel screwing equipment has the advantages of high automation degree, simpleness and convenience in operation, and high efficiency, and is applicable to large-scale flow line production on an automotive assembly line.

Owner:大连嘉禾自控技术有限公司

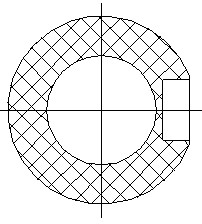

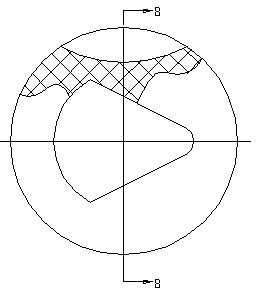

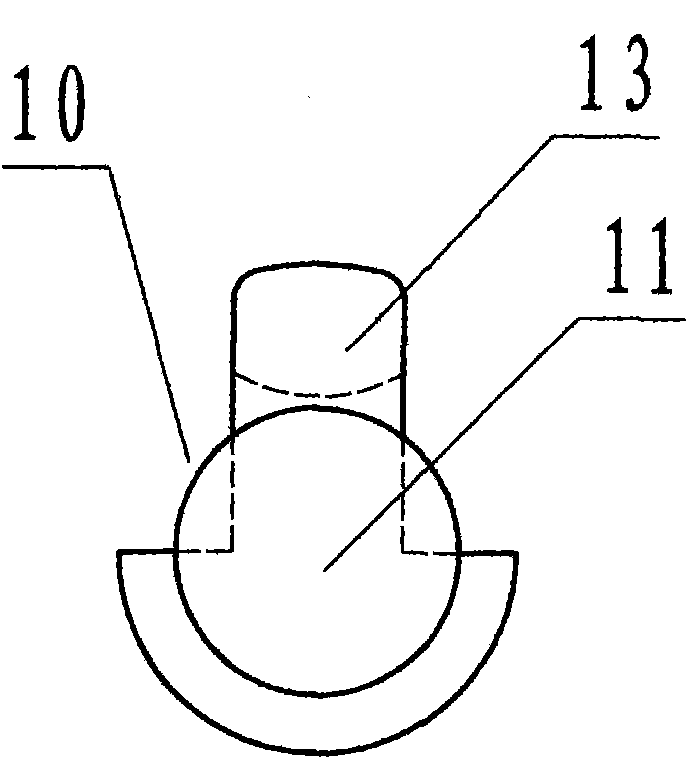

Ball body of rupture-preventing heavy-caliber composite ceramic ball valve, composite ceramic ball valve and manufacture methods thereof

ActiveCN102635700ASimple manufacturing processHigh hardnessPlug valvesValve housingsComposite ceramicUltimate tensile strength

The invention discloses a ball body of a rupture-preventing heavy-caliber composite ceramic ball valve, the composite ceramic ball valve and manufacture methods of the ball body and the composite ceramic ball valve. The ball body of the rupture-preventing heavy-caliber composite ceramic ball valve is formed by assembling a ceramic cylinder, a metal ring, a left ceramic spherical cap and a right ceramic spherical cap, the metal ring is fixed in the center of the outer wall of the ceramic cylinder, the metal ring is combined with the ceramic cylinder by adopting a hot charging process or cement process, the left and the right ceramic spherical caps are sleeved outside the ceramic cylinder and then transferred to a center line for covering the metal ring, end faces of the left and the right ceramic spherical caps are tightly fitted, high-temperature and high-strength glue is filled between the left and the right ceramic spherical caps and used for firmly adhering the left and the right ceramic spherical caps, and the metal ring is provided with an arc-shaped groove matched with a valve rod or milled with an elliptical hole matched with the valve rod. The invention also discloses the composite ceramic ball valve comprising the ball body, and the manufacture methods of the ball body and the composite ceramic ball valve. With the adoption of the composite ceramic ball valve, the difficulty of incapability of producing the heavy-caliber composite ceramic ball valve is solved.

Owner:郑州鼎盛工程技术有限公司 +1

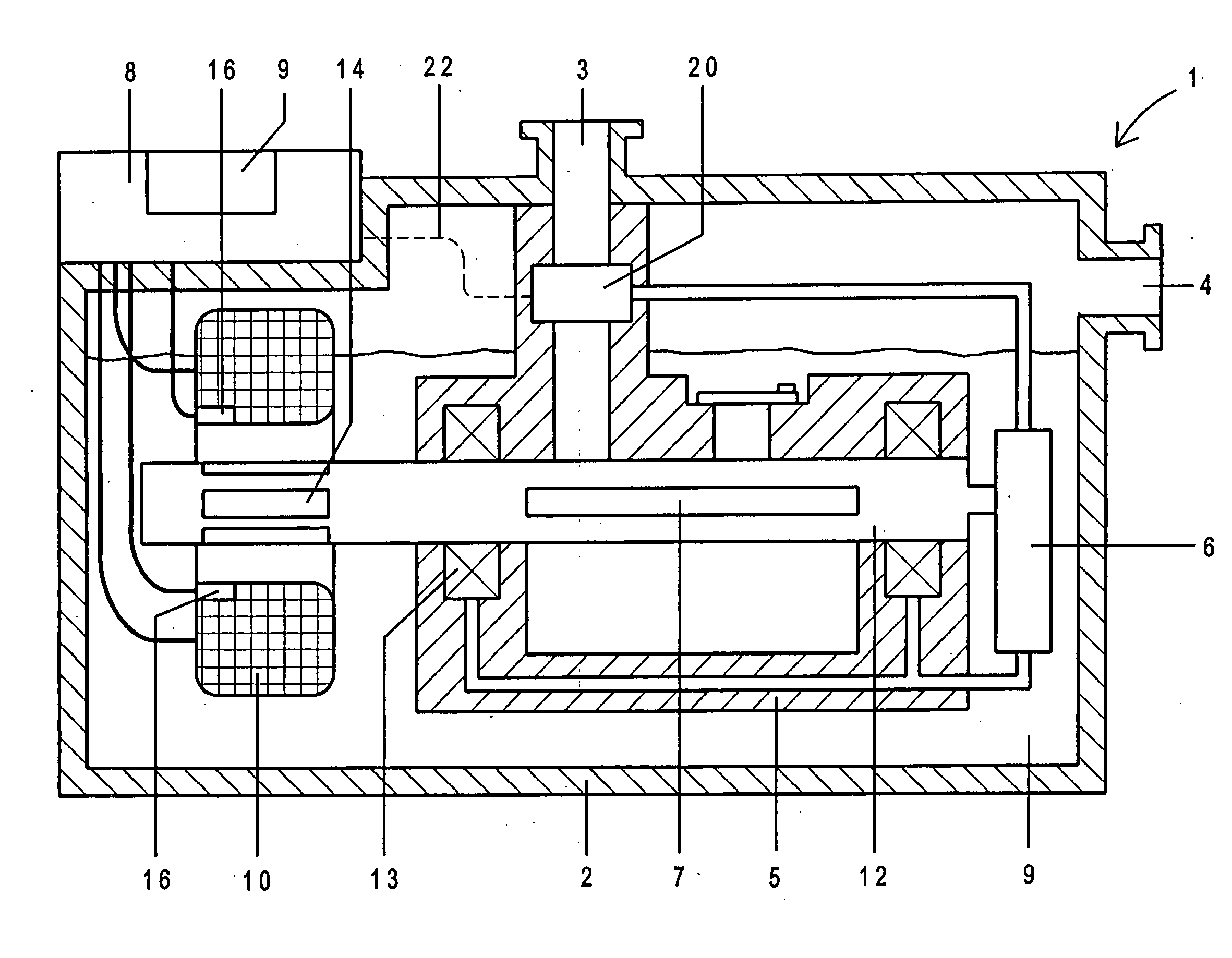

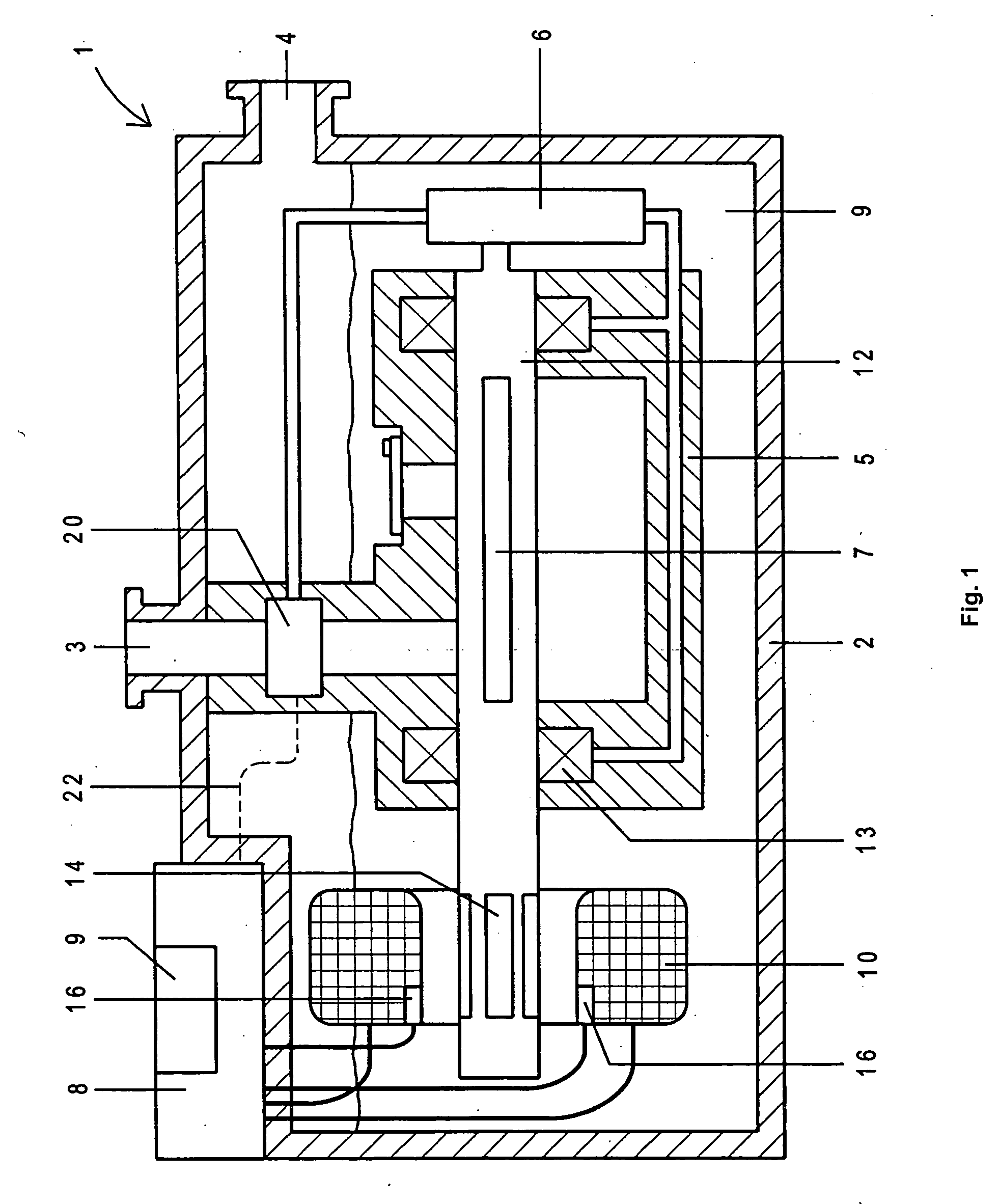

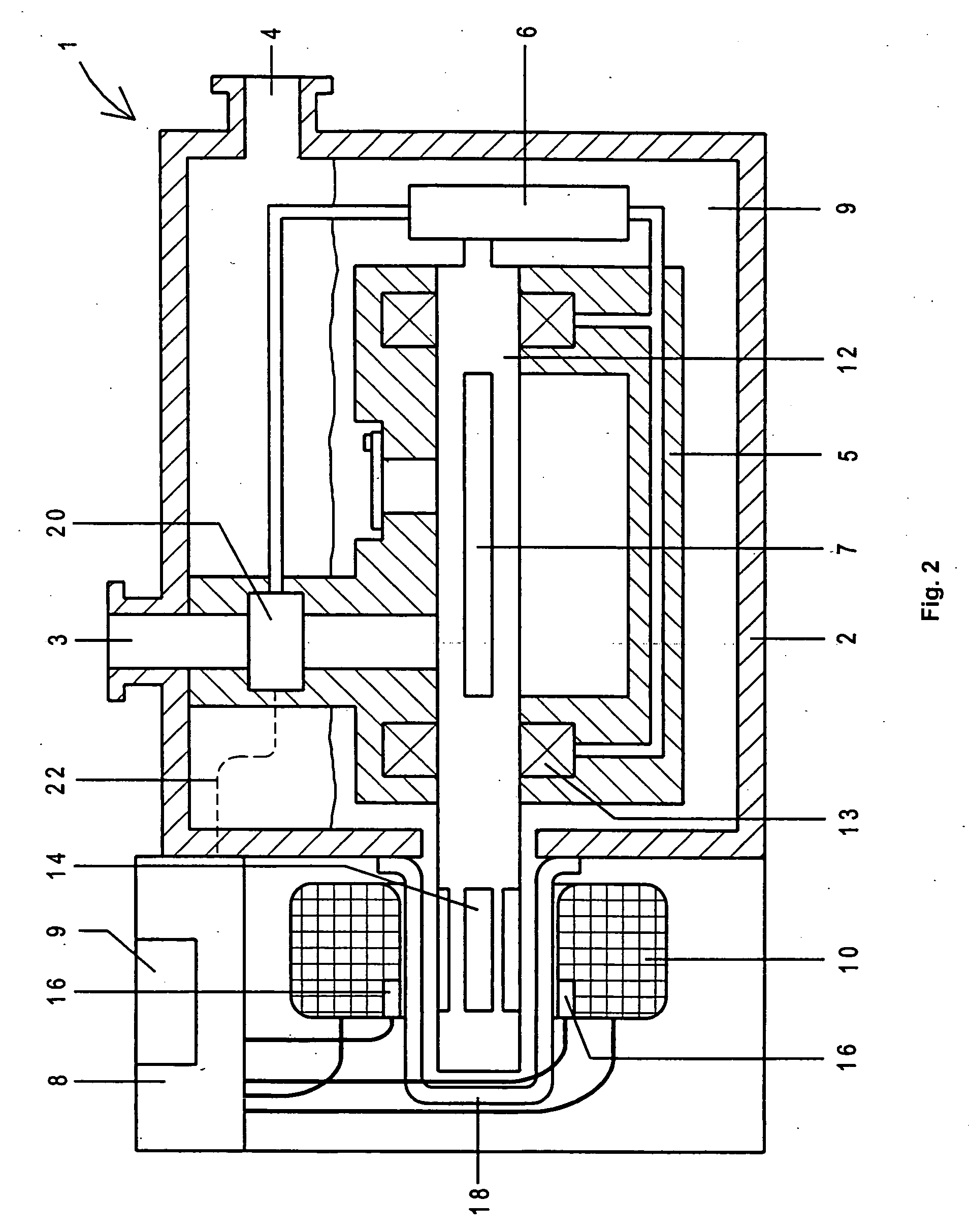

Oil-sealed vane rotary vacuum pump

InactiveUS20050260082A1Uniform relationshipReduce power consumptionMagnetic circuit rotating partsRotary piston pumpsEngineeringVacuum pump

An oil-sealed vane rotary vacuum pump includes at least one pump stage arranged in the housing and having a cylindrical chamber, a shaft excentrically arranged in the cylindrical chamber and provided with vanes, and a drive for driving the shaft and having a plurality of permanent magnets arranged on the shaft and stationary electrical coils surrounding the permanent magnets and producing a rotatable magnetic field, and control electronics for controlling the coils and arranged in a removable housing part of the pump.

Owner:PFEIFFER VACUUM GMBH

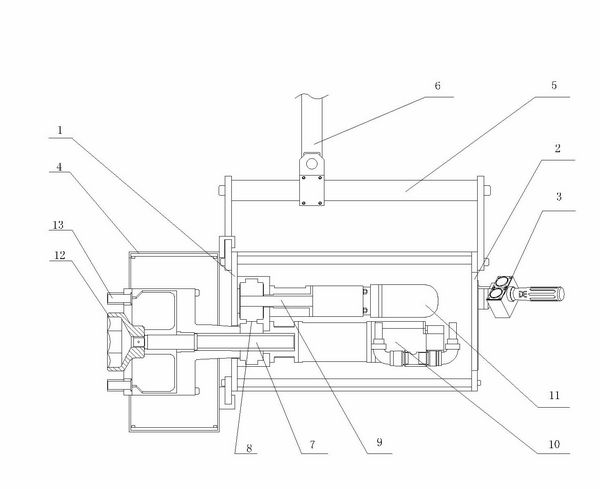

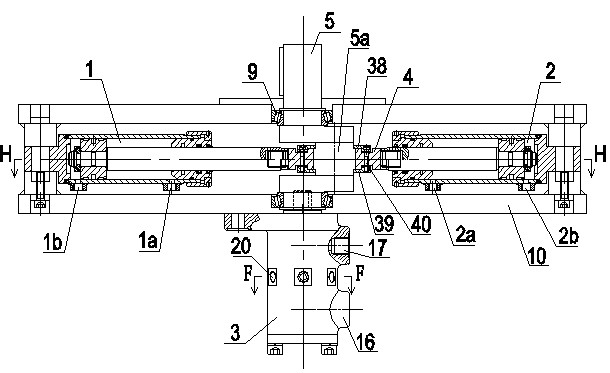

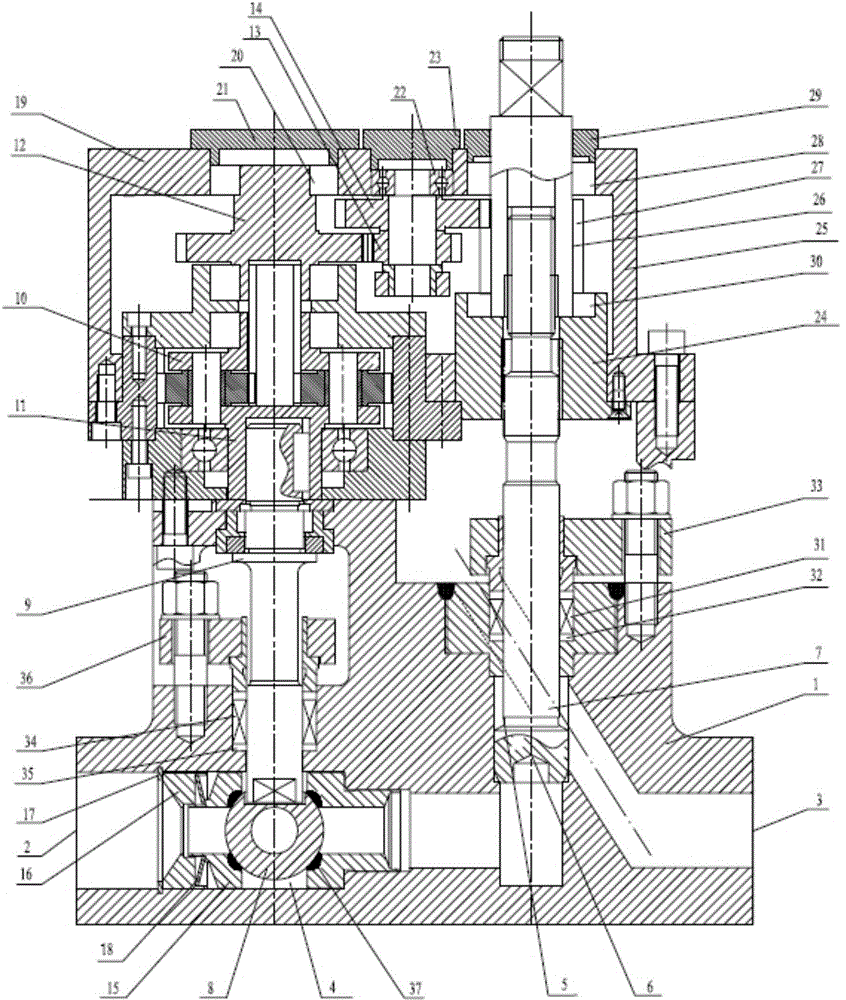

Hub main nut screwing and bearing pre-tightening force measuring machine and using method thereof

ActiveCN101979976AGuaranteed pressing forceSimple and fast operationMeasurement of torque/twisting force while tighteningWrench

The invention discloses a hub main nut screwing and bearing pre-tightening force measuring machine. The machine comprises a front sealing plate, a rear sealing plate, an operating handle, a protecting hood, a guide post, a suspension device, a nut screwing shaft, a gear, a revolution measurement rotating shaft, a first servo motor, a second servo motor, a special sleeve and a revolution measurement wrench; and the screwing of hub main nut and detection of bearing pre-tightening force can be simultaneously realized through one hub main nut screwing and bearing pre-tightening force measuring machine and various schemes for screwing and measurement are simultaneously provided for a user to select, so that the machine is easy and convenient to operate, has high assembly precision, uniform torque, and high measurement accuracy, is time-saving and labor-saving, achieves automatic unmanned operation and saves labor cost.

Owner:DALIAN DEXIN M&E TECH ENG

Generator with continuous variable volume compression ratio

InactiveCN101865025AAchieve economyReduce vibrationEngine controllersMachines/enginesEngineeringOrbit

The invention discloses a generator with continuous variable volume compression ratio, comprising a sensor, a box body, a bent axle, at least one connecting rod and a piston, wherein one end of the connecting rod is rotatablely connected with an outer shaft cervical collar installed on a shaft neck; the shaft neck of the bent axle is provided with a continuous variable volume compression ratio mechanism which is controlled by a circular ring orbit installed in the box body; a fixed mechanism which is arranged on the box body is provided with the control mechanism of the generator with the continuous variable volume compression ratio; the control mechanism controls the circular ring orbit to control different positions for the outer shaft cervical collar to be sheathed on an upper dead center and a lower dead center to realize different compressed heights and compression ratio so as to improve fuel economy and dynamic property.

Owner:高伟

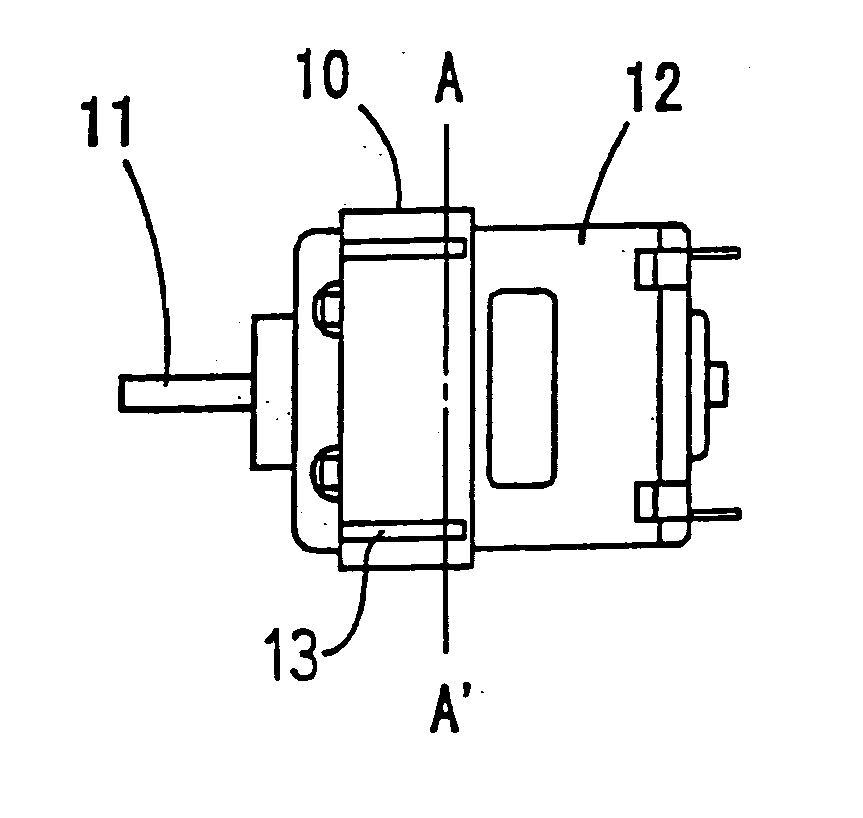

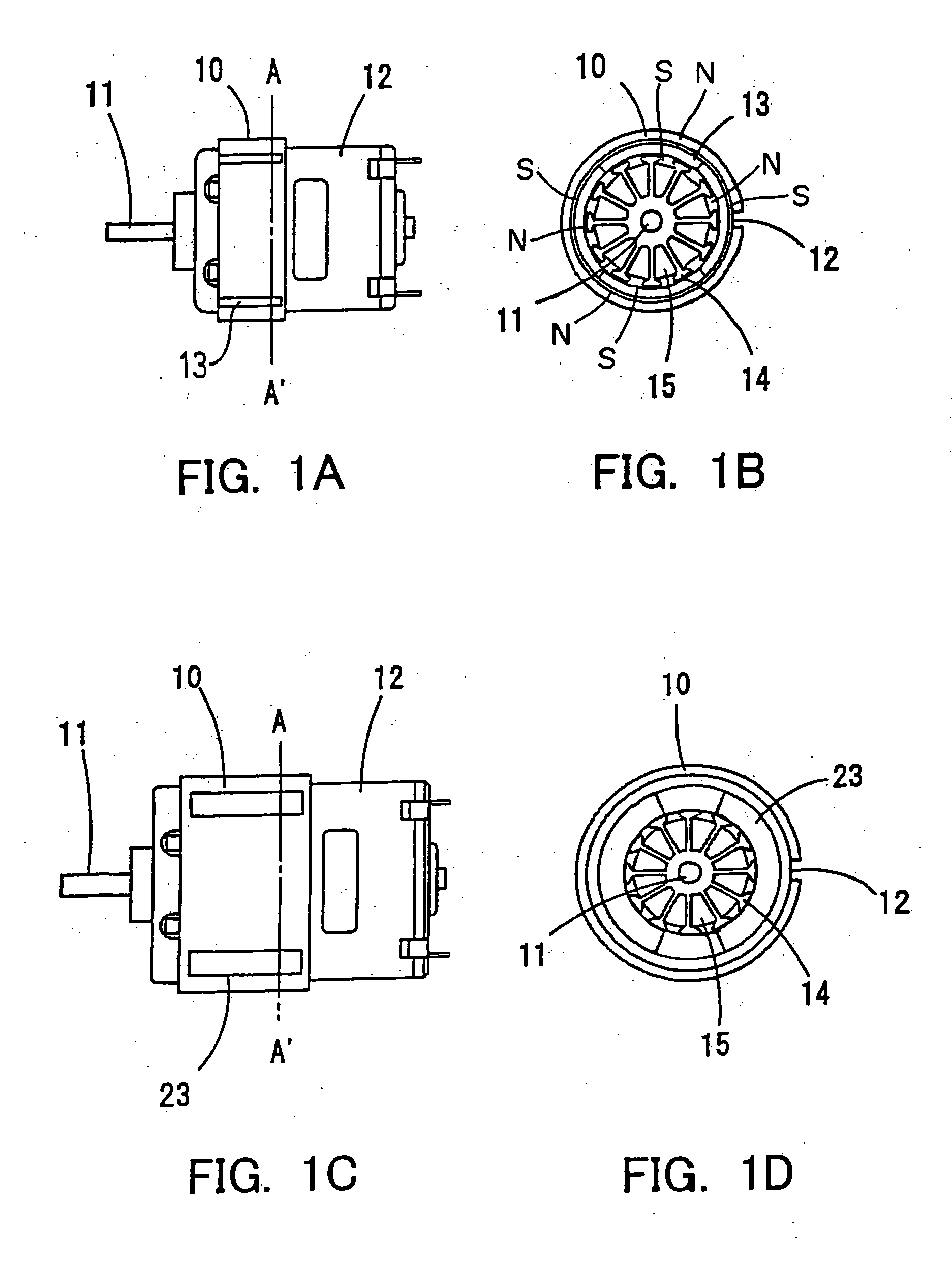

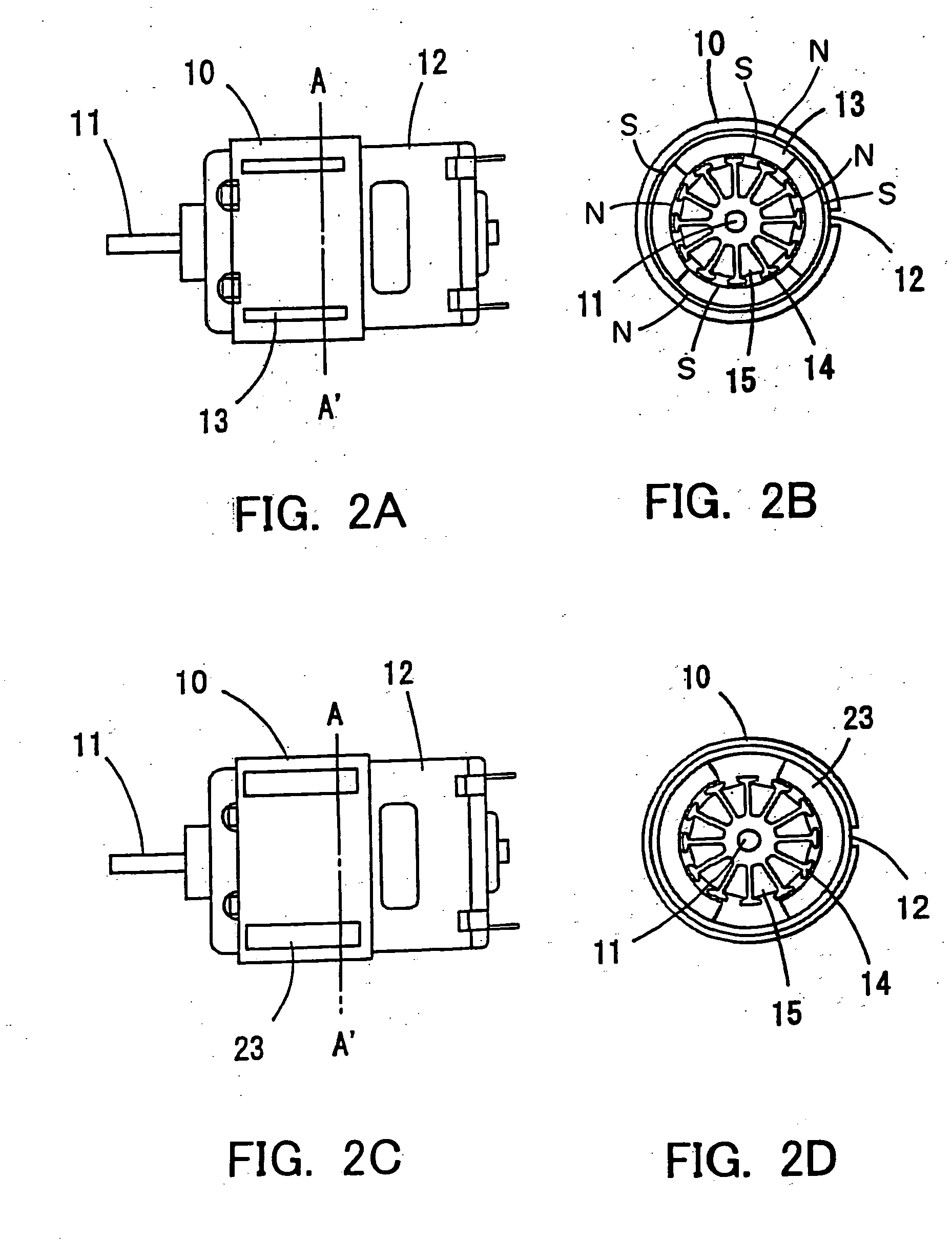

Motor and its permanent magnet

InactiveUS20040201300A1High propertyReduce thicknessPermanent magnetsMagnetic circuit stationary partsElectric machineMiniaturization

The challenge to be solved by the present invention is the miniaturization of a 1-300 W class of motor. This can be achieved by using a hollow-cylinder shaped anisotropic bonded magnet magnetized in a 4-pole configuration. The anisotropic bonded magnet has a maximum energy product approximately 4 times greater than the conventional sintered ferrite magnets. The use of a 4-pole configuration shortens the magnetic path length of the individual magnetic circuits and the magnetic force contributing to the torque is increased. When the torque is kept the same as in the conventional motor, the length of the electromagnetic rotor core and the axial magnet length can be reduced. In this fashion, 1-300 W class motors can be reduced in size.

Owner:AICHI STEEL

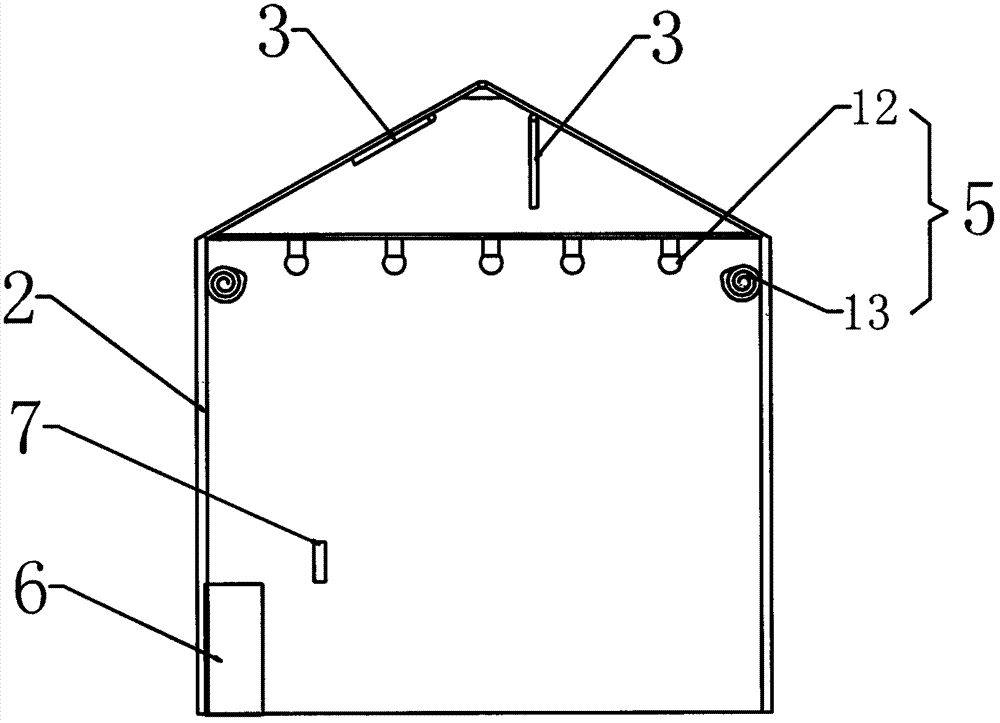

Automated shed light regulating and supplementing device

PendingCN106941945ARealize linkageImprove work efficiencyClimate change adaptationGreenhouse cultivationGreenhouseEffect light

The invention relates to the technical field of greenhouse shed regulation and control and provides an automated shed light regulating and supplementing device. The automated shed light regulating and supplementing device comprises a shed frame and shed walls, wherein skylights are arranged on the shed wall of the top of the shed frame. The automated shed light regulating and supplementing device further comprises a light regulating system, a light supplementing system, a controller and a lighting sensor, wherein the shed walls are made of a transparent material, and the skylights are opened downwards; the light supplementing system and the lighting sensor are arranged in a shed; and the light regulating system, the light supplementing system and the lighting sensor are all in electric signal connection with the controller, the lighting sensor is used for monitoring intensity of illumination in the shed and transmitting signals to the controller, and the controller controls actions of the light regulating system and the light supplementing system. According to the automated shed light regulating and supplementing device provided by the invention, the controller is used for controlling the actions of the light regulating system and the light supplementing system, so that the intensity of illumination in the shed is always in a state which is most beneficial to crop growth, and the growth of crops is promoted; and the device is high in work efficiency and good in light regulating effect.

Owner:ZHEJIANG JINSHI BIOTECH

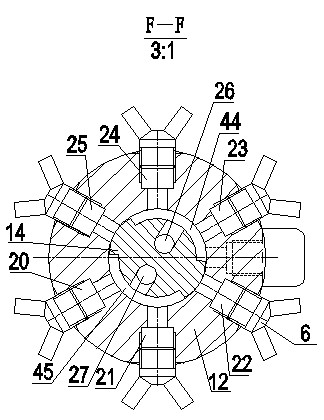

Open-type heavy hydraulic motor

The invention discloses an open-type heavy hydraulic motor which comprises a bracket, a spin valve and a crank shaft arranged at the center of the bracket, wherein one end of the crank shaft is connected with the outer end part of a valve core; more than four uniformly distributed double-acting oil cylinders are arranged around the eccentric section of the crank shaft; the bottom of each double-acting oil cylinder is hinged with the bracket, and the piston rod of each double-acting oil cylinder is connected with the eccentric section of the crank shaft through a rotatable connection structure; a valve body is provided with an oil inlet, an oil outlet and working oil ports of which the number is corresponding to that of the oil cylinders; all the working oil ports are uniformly distributed on the circumference of the valve body; the circumference of the valve core is provided with two annular grooves and two sectorial oil grooves; the corresponding central angles of the two sectorial oil grooves are greater than 90 degrees and less than 180 degrees; the two sectorial oil grooves are respectively connected with the corresponding annular grooves through connecting oil ways; and each working oil port is connected with the rod cavity oil port and rodless cavity oil port of each double-acting oil cylinder according to the corresponding relations. According to the invention, an extra-large torque can be easily realized, and the output torque and rotation speed are more uniform; and the open-type heavy hydraulic motor is convenient to install and maintain and has a wider application range.

Owner:南通艾德森机电设备有限公司

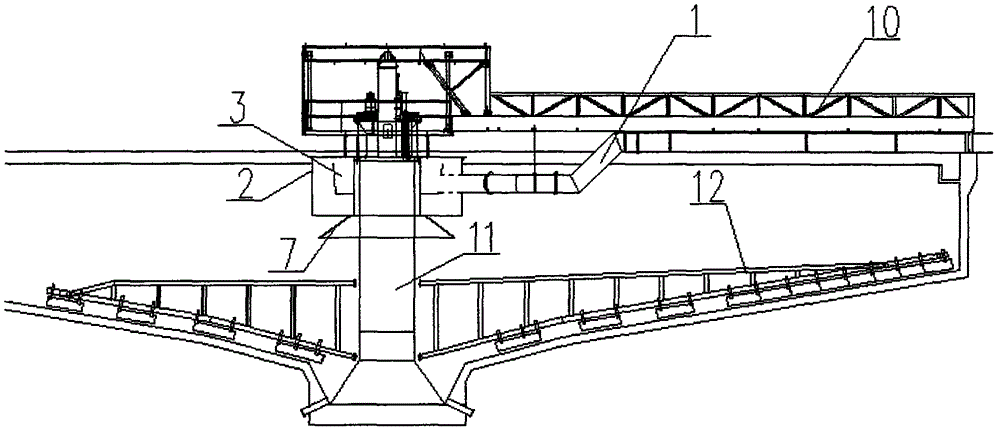

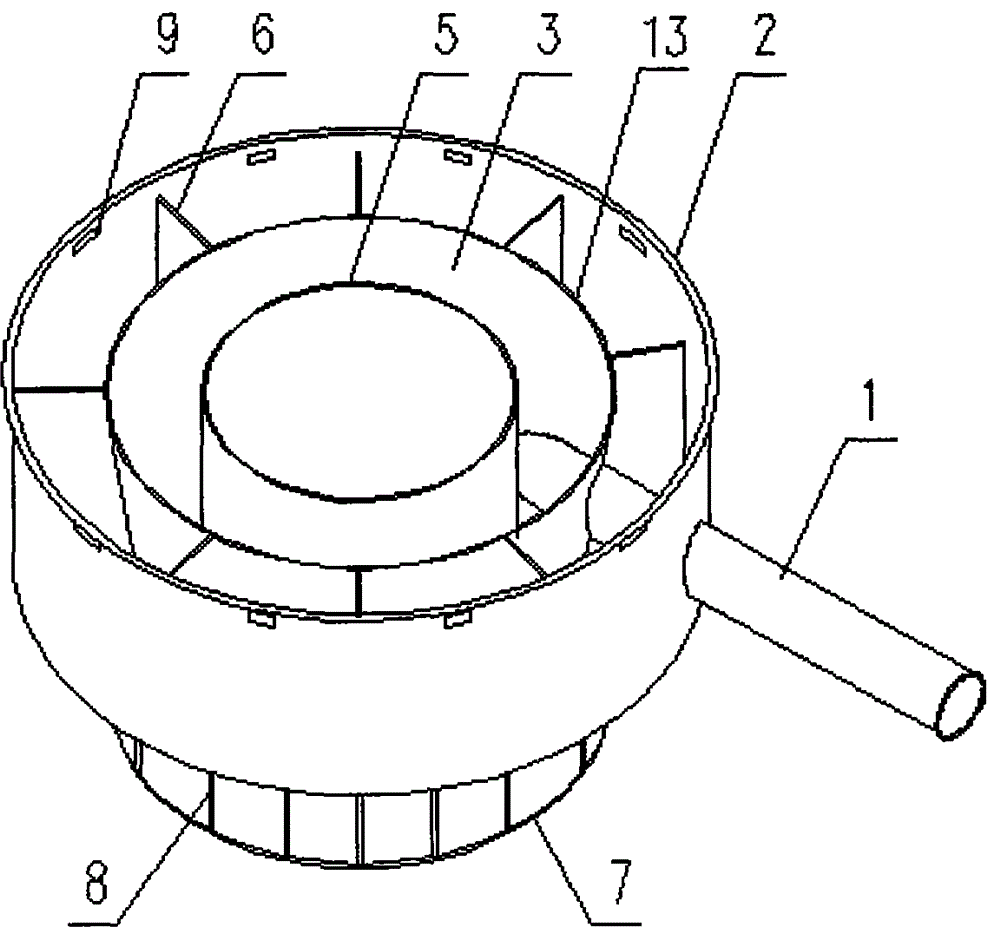

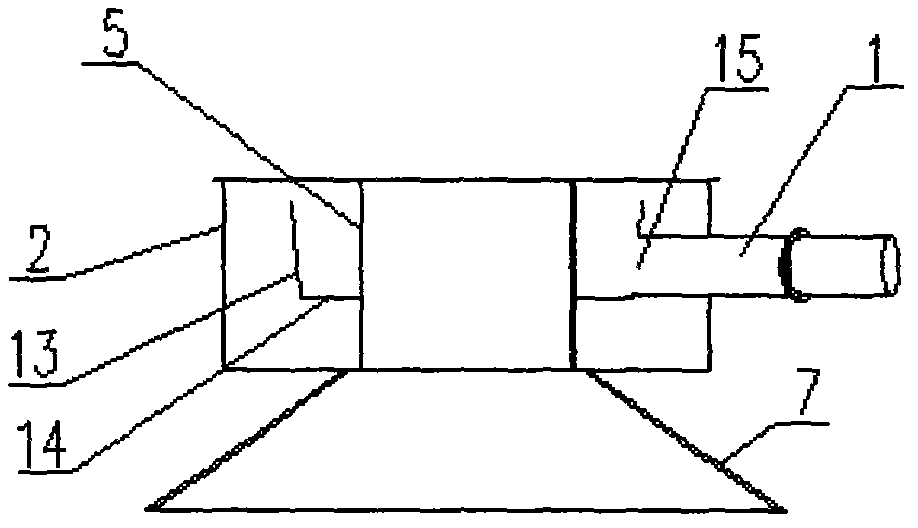

Material evenly distributing device of flow stabilizing cylinder of central transmission thickener

InactiveCN104826372AEvenly distributedEasy to handleSettling tanks feed/dischargeProviding materialCivil engineering

The invention discloses a material evenly distributing device of flow stabilizing cylinder of central transmission thickener, relates to the field of additional devices of central transmission thickener, and aims to solve the problem that the material settlement is non-uniform in the conventional thickeners. The material evenly distributing device comprises a material distributing tank and a plurality of fixed plate; the material distributing tank comprises a material distributing inner cylinder, a material distributing outer cylinder, and a material distributing bottom plate; the material distributing inner cylinder and the material distributing outer cylinder are connected through the material distributing bottom plate to form a circular groove; a material feeding pipe goes through an external flow guiding cylinder, and the opening of the material feeding pipe is fixed in the inner side of the material distributing outer cylinder. The provided material evenly distributing device can make materials evenly settle around the periphery of the material distributing tank, reduces the interference on the inner water and bed of thickening tank, and effectively improves the processing performance of a thickener.

Owner:HUAIBEI ZHONGFEN MINING MACHINERY

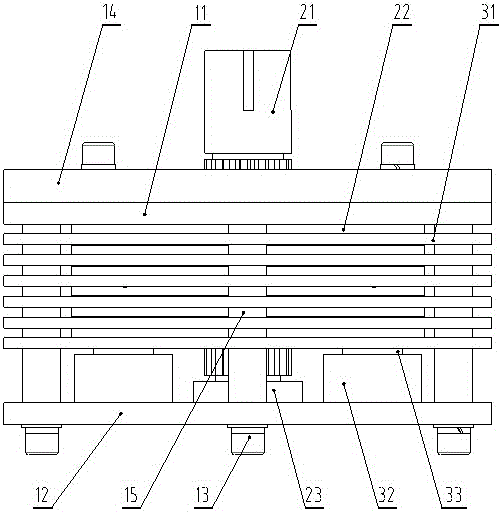

Testing apparatus for service life of load of valve execution mechanism and using method thereof

The invention provides a testing apparatus for a service life of a load of a valve execution mechanism and a using method thereof. The testing apparatus comprises a rack, a rotating mechanism and a loading mechanism. The rack is supported between a top plate and a bottom plate by support posts. A testing plate covers the top plate. Rotating shafts are installed in bearings between the top plate and the bottom plate and the upper ends of the rotating shafts pass out of the top plate and a mounting plate. More than one rotating plate is installed on the rotating shafts horizontally and rotates with the rotating shafts. The loading mechanism includes friction plates and hydraulic systems; through holes are formed in the friction plates and the friction plates sleeve the support posts through the through holes. One friction plate is arranged below each rotating plate; and the friction plates are separated by sleeving rings arranged on the support posts. The hydraulic systems are installed on the bottom plate and mandrils of the hydraulic systems support the bottom friction plates; under pushing of the mandrils, upward contact with the rotating plates is realized and the last friction plate is pushed upwardly by the sleeving ring and is in contact with the rotating plate arranged on the friction plate; and the rotating plates and the friction plates in close contact with the rotating plates respectively generate friction and the friction forces are transformed into torques by the rotating shafts, thereby realizing testing of the service life of the load of the valve execution mechanism.

Owner:TEFULONG SHANGHAI TECH CO LTD

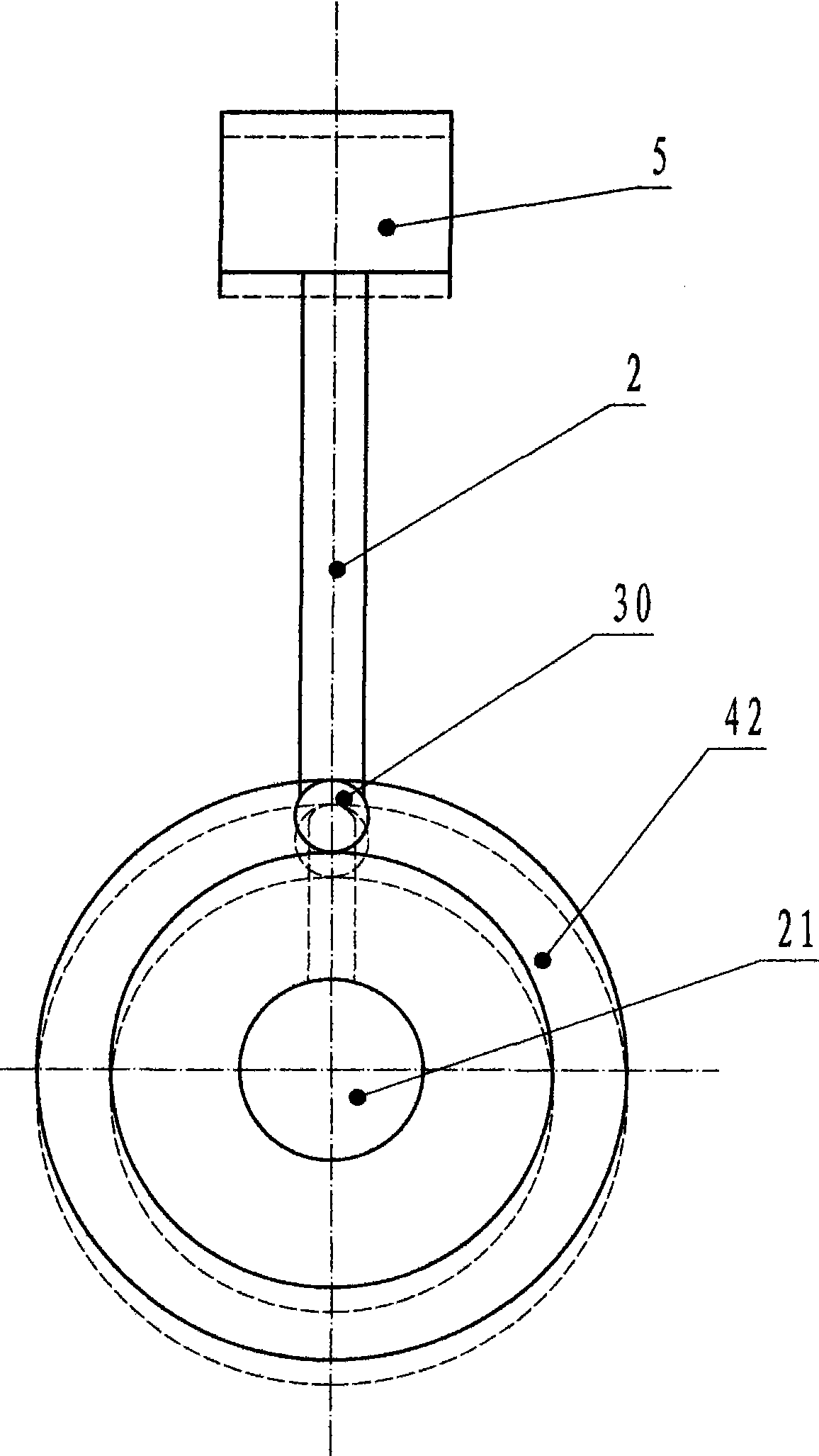

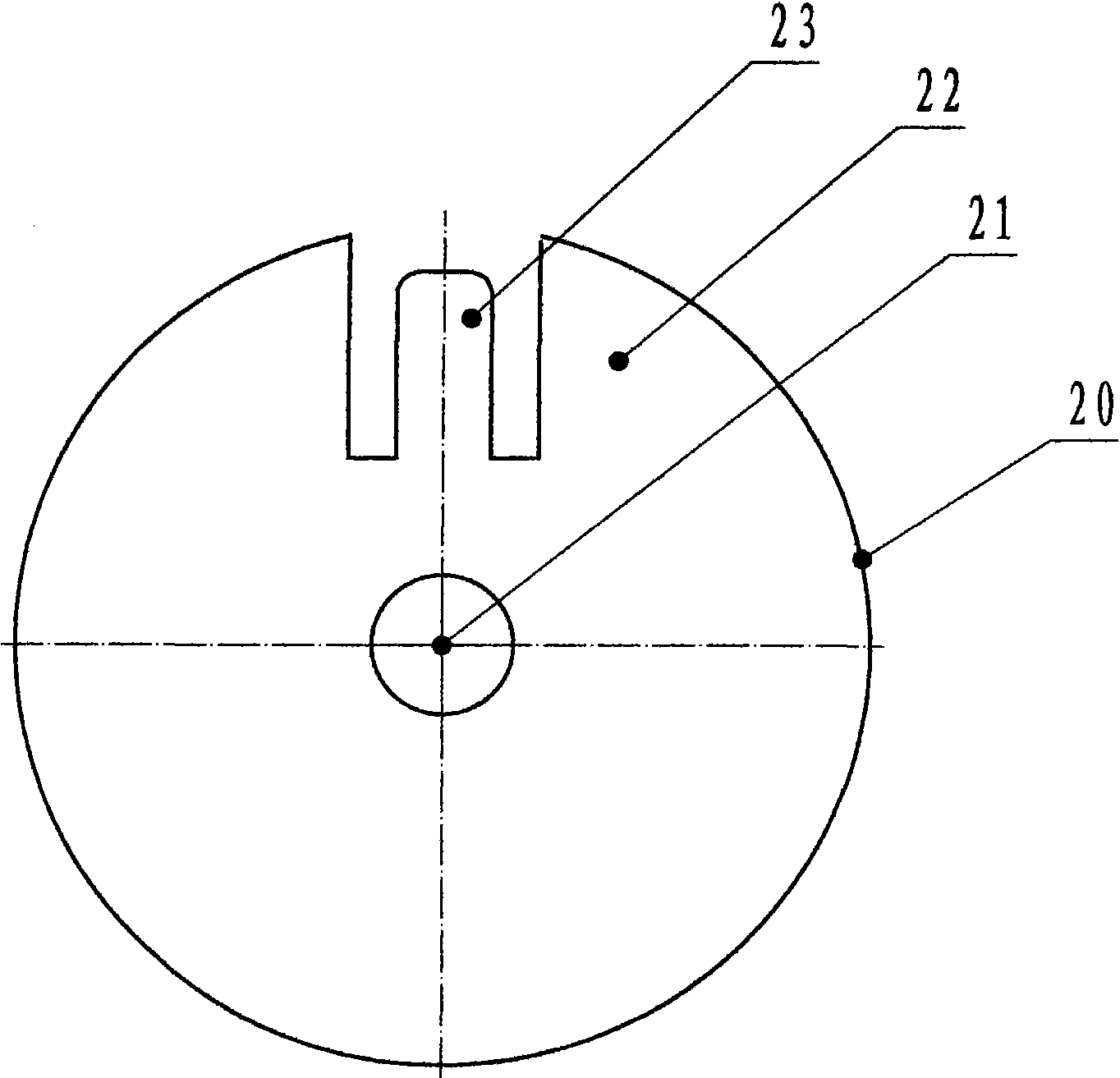

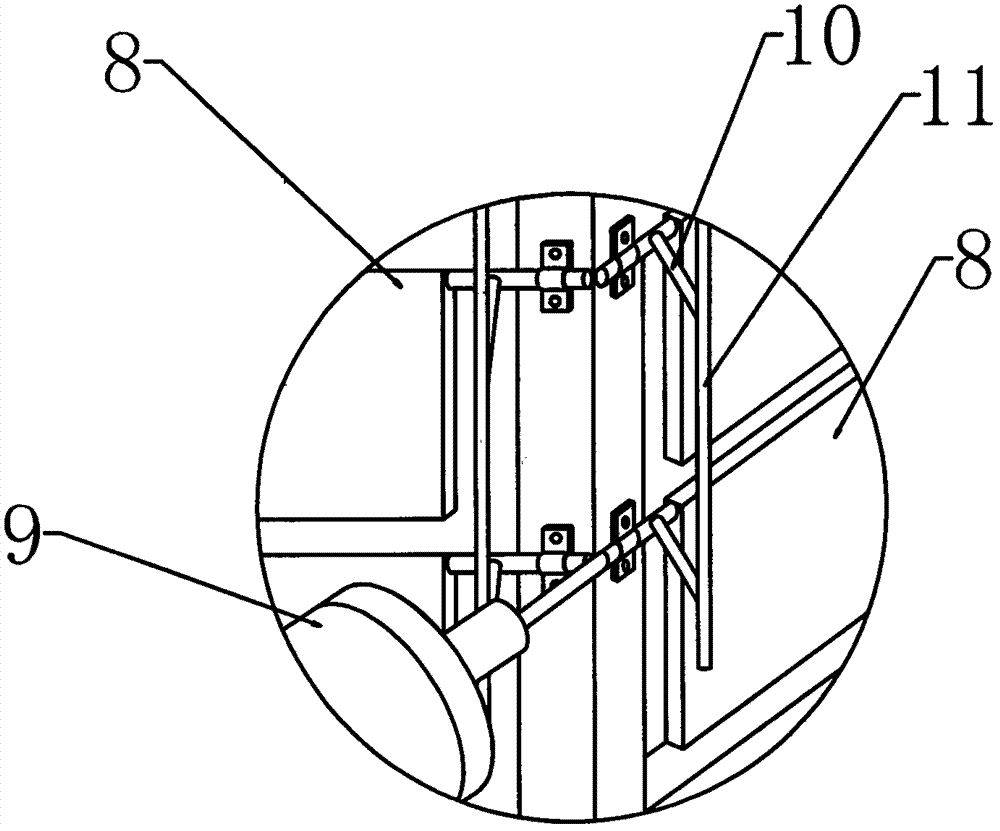

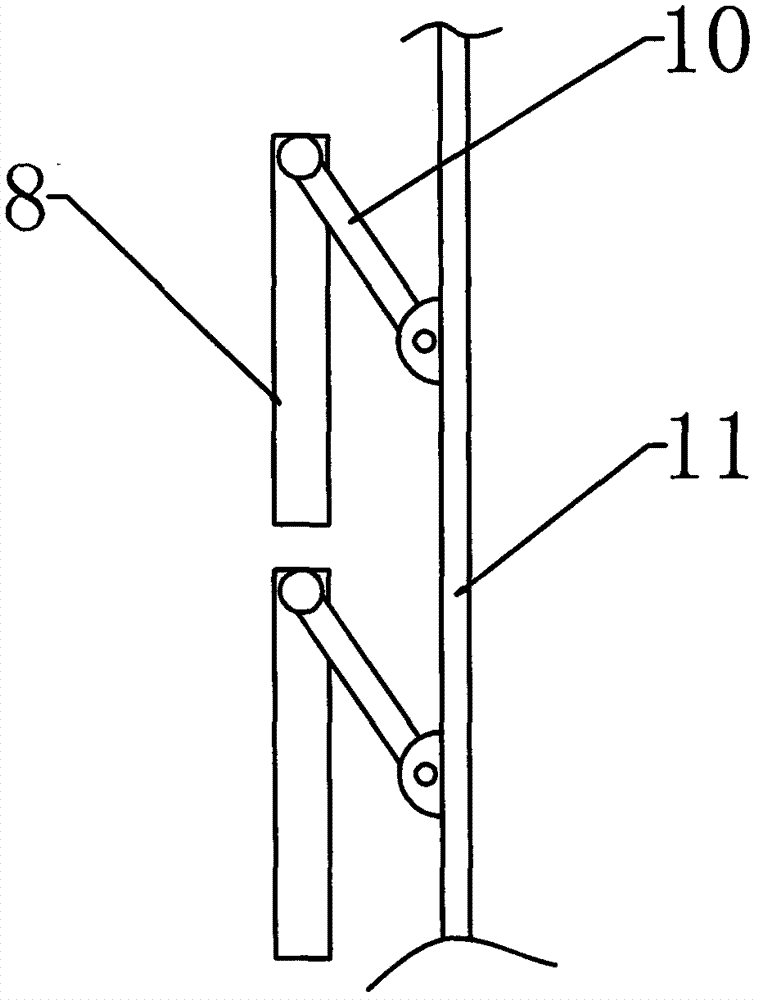

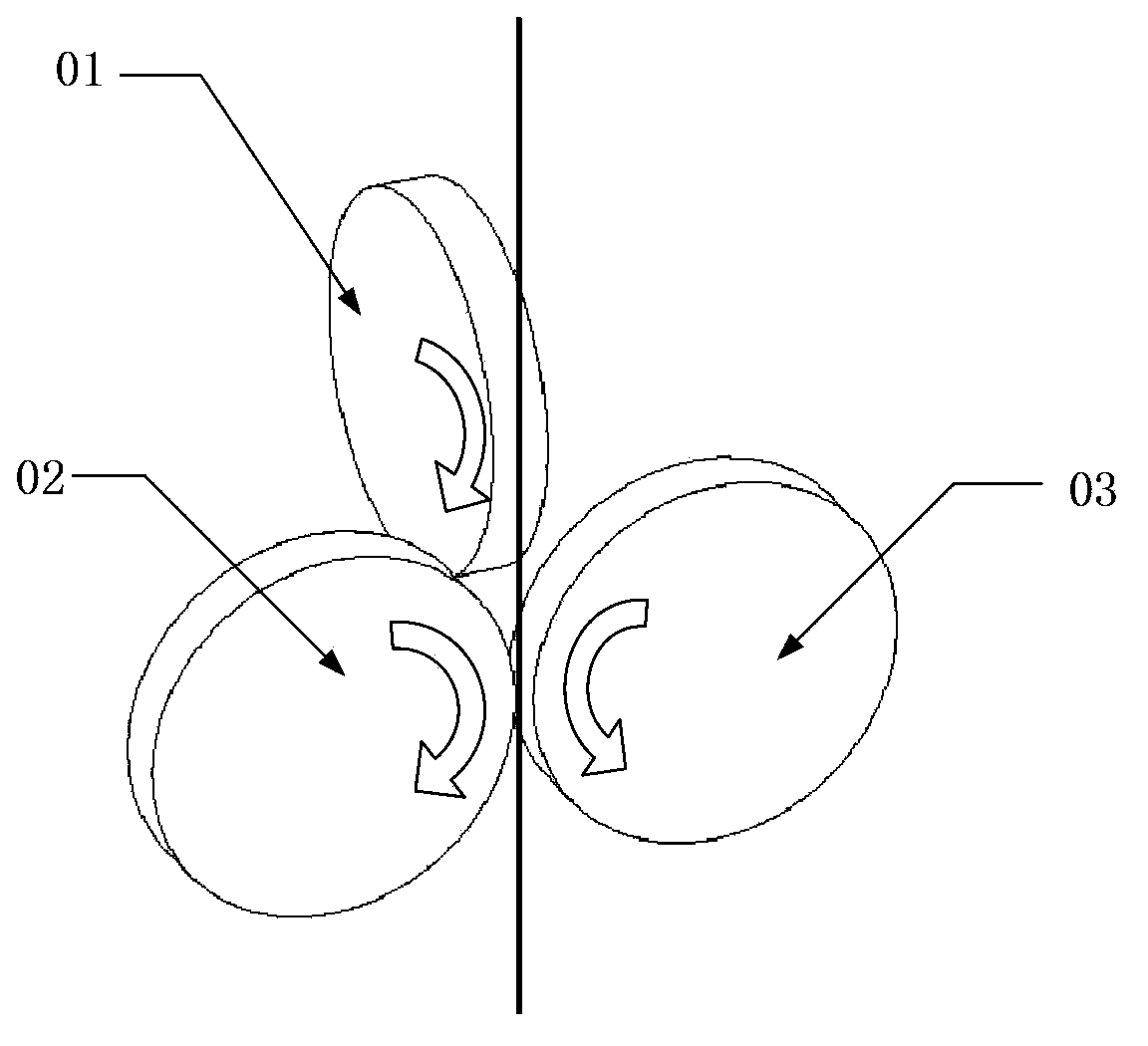

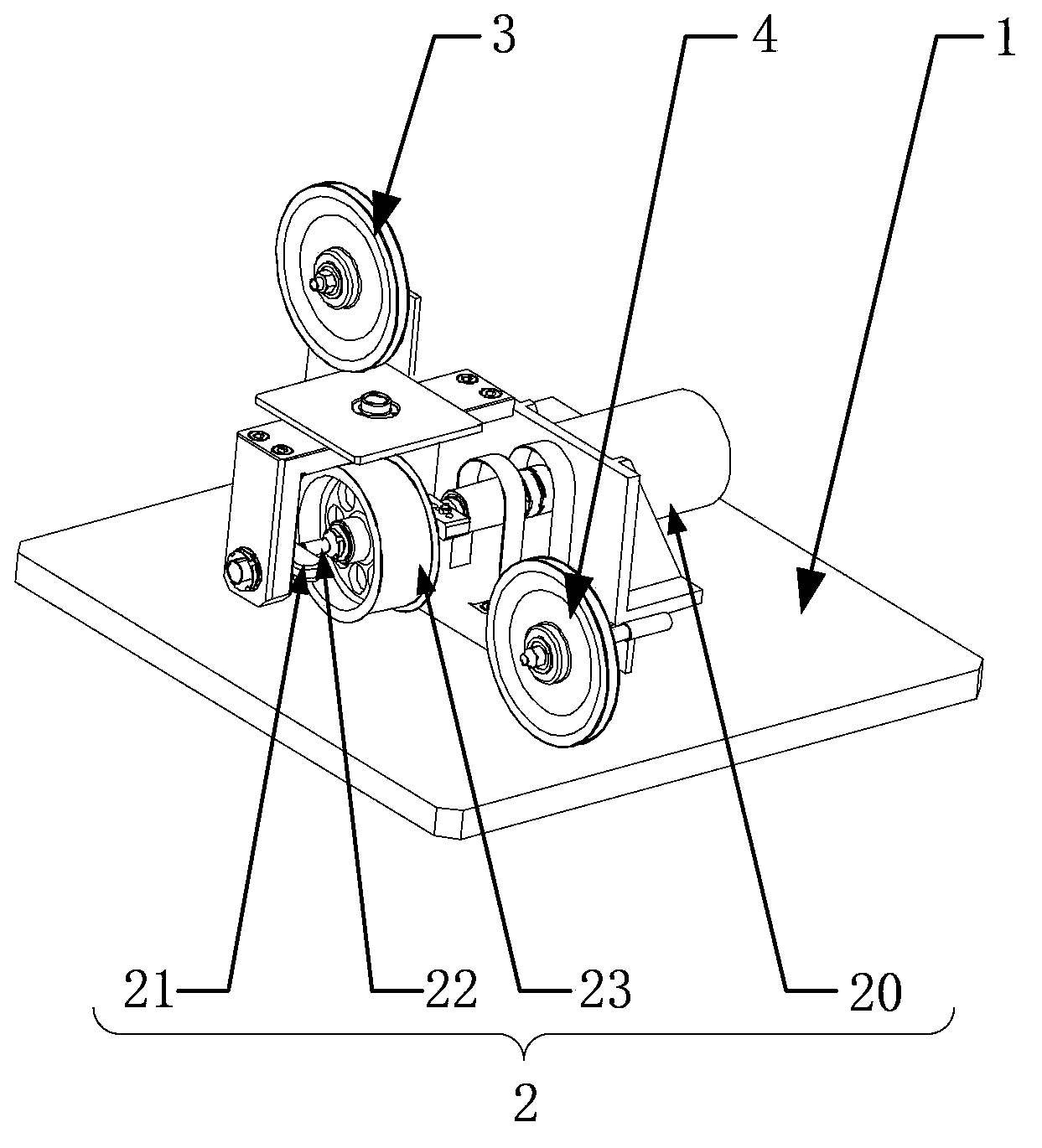

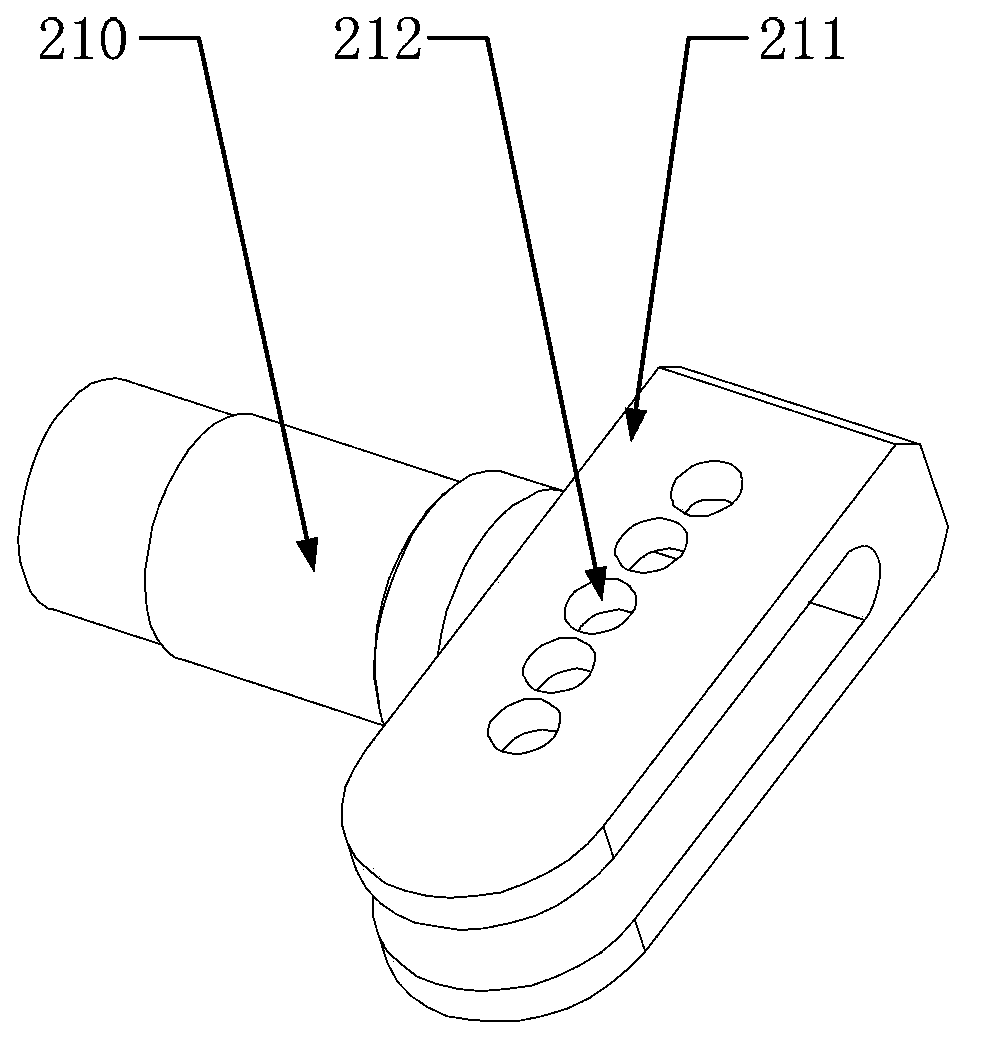

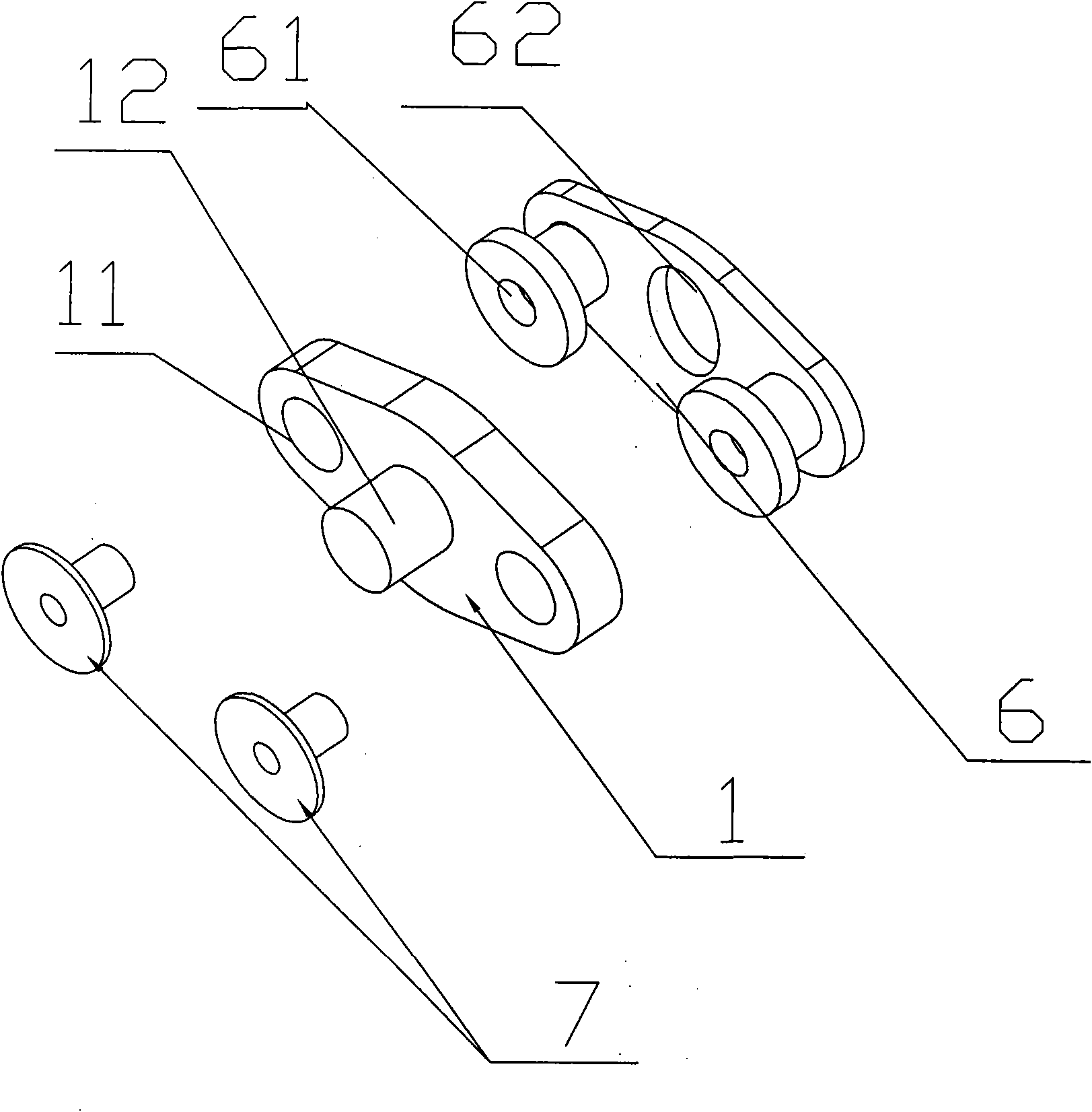

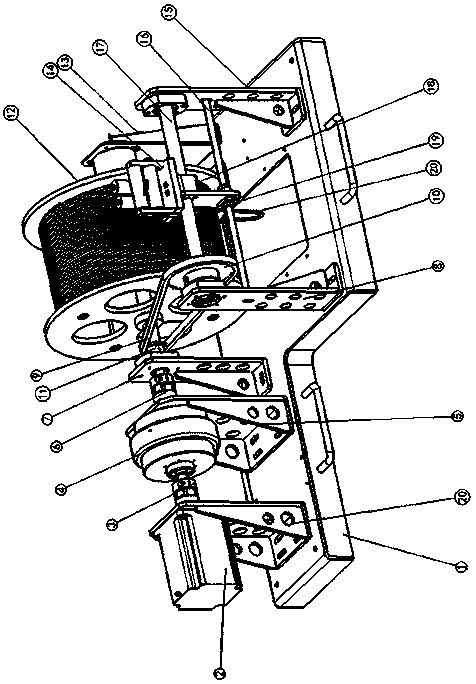

Optical fiber wringing equipment

InactiveCN103771699AReduce adverse effectsGuaranteed PMD valueGlass making apparatusEngineeringMechanical engineering

The invention discloses optical fiber wringing equipment. The equipment comprises a frame, a swing wheel device fixedly arranged on the frame, a front vibration-stopping wheel, and a rear vibration-stopping wheel, wherein the front vibration-stopping wheel and the rear vibration-stopping wheel are rotatingly arranged on the frame, and the rotation axes of the front vibration-stopping wheel and the rear vibration-stopping wheel are in a parallel relationship; the swing wheel device comprises a Z-shaped component, which is driven to rotate by a power device fixedly arranged on the frame; the Z-shaped component comprises two crank handles, wherein the rotation axes of the two crank handles are overlapped, one of the two crank handles is connected to the power device, a swing wheel shaft, whose two ends are respectively connected to the two crank handles, and a swing wheel fixedly arranged in the middle position of the swing wheel shaft; and the axis of the swing wheel shaft intersects with the rotation axis of the crank handles. When using the optical fiber wringing equipment, optical fibers carry out complete vibration between the front vibration-stopping wheel and the swing wheel, and between the swing wheel and the rear vibration-stopping wheel; thus the vibration buffering zone of optical fibers is increased, the wringing force on optical fibers is more even, the non-roundness degree of optical fiber is optimized, the reject rate caused by layering and damage of optical fibers is largely reduced, PMD of optical fibers is reduced, and the actual production speed of optical fibers is improved at the same time.

Owner:FUTONG GROUP CO LTD

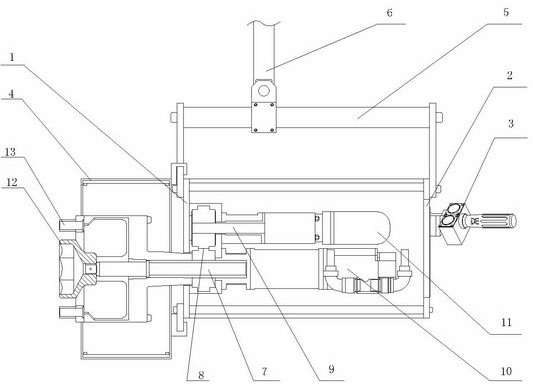

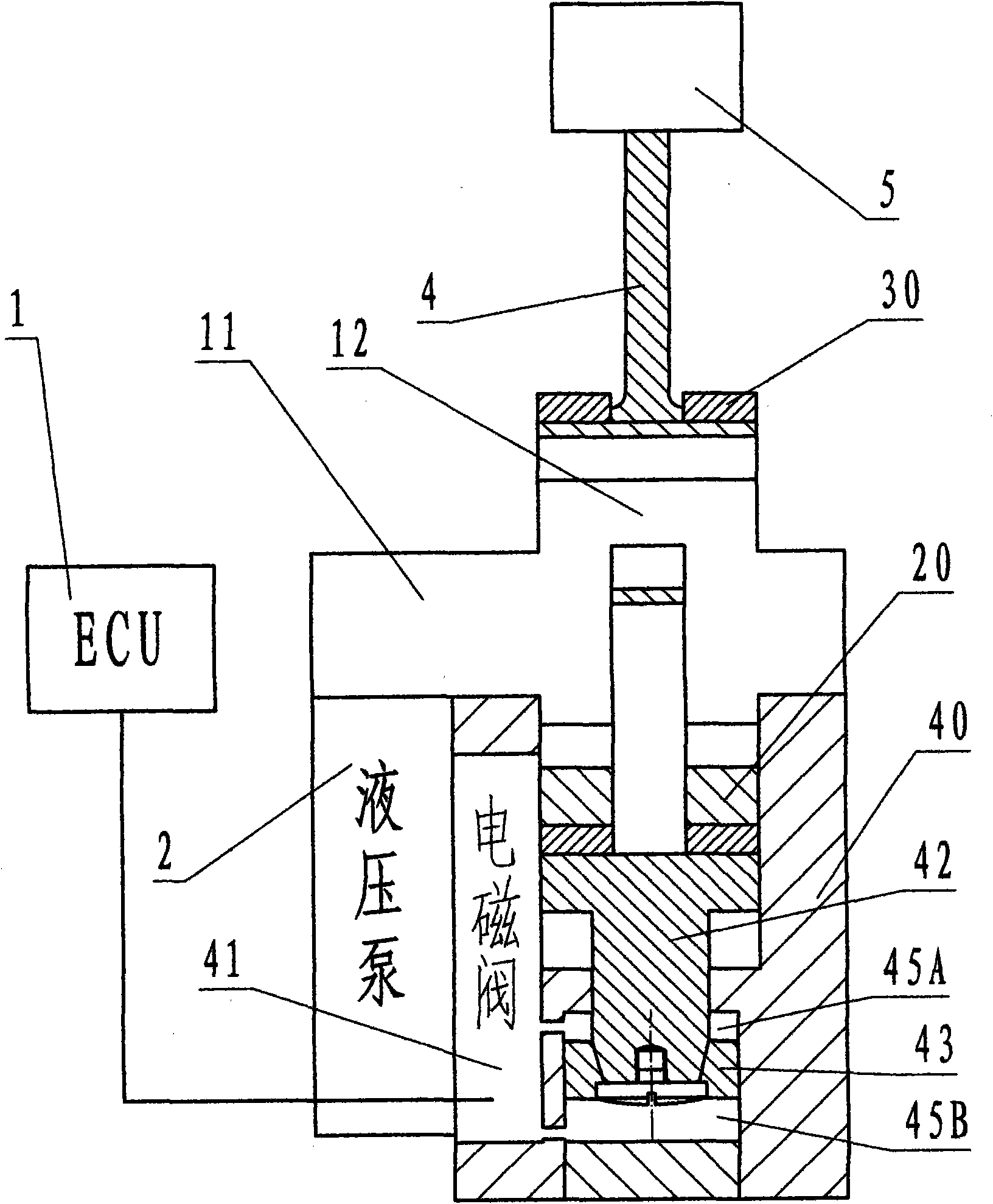

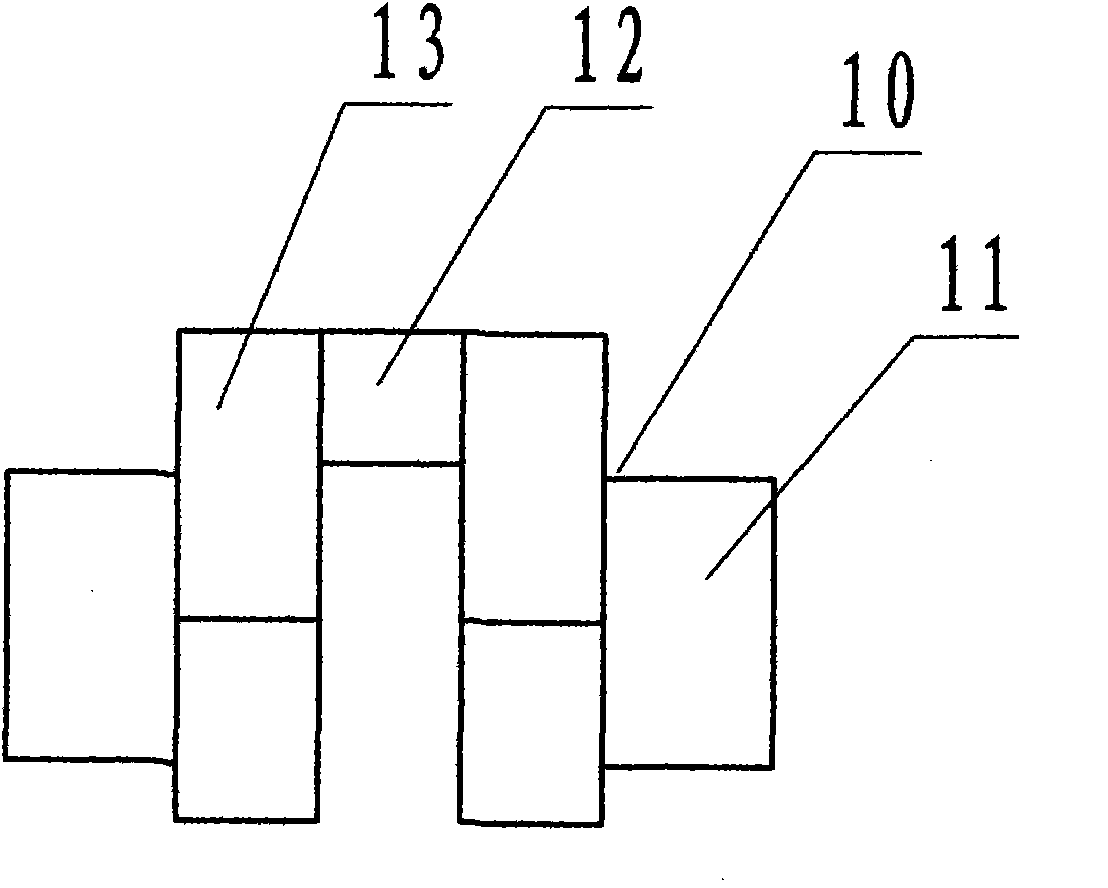

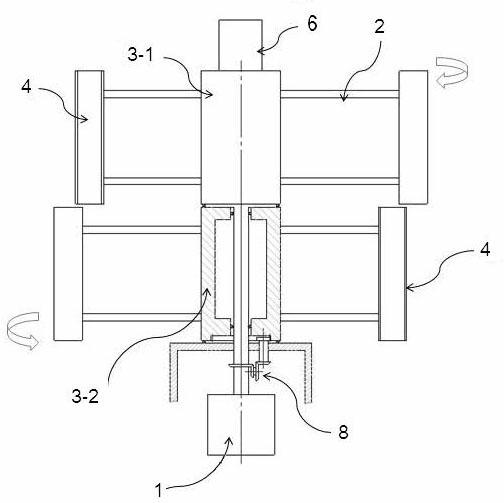

Variable volume compression ratio engine

InactiveCN101936229AReduce vibrationUniform torqueEngine controllersMachines/enginesEngineeringCylinder block

The invention discloses a variable volume compression ratio engine, comprising an ECU, a crankshaft, a connecting rod and a piston and the like, wherein the crankshaft is sheathed by a crankshaft sleeve composed of two crank sleeves and one shaft neck sleeve; one end of the connecting rod is ratably connected with the shaft neck sleeve and the other end is connected with the piston via a piston pin; two crank sleeves of each crankshaft sleeve group are respectively mounted in the operation holes on two operation sleeves; the crankshaft sleeve is controlled by adjusting the operation sleeves via an adjusting mechanism, to move downward or upward along the centerline of the cylinder to change the distance between the main journal and the shaft neck sleeve when the piston is at the upper dead center, thereby changing the compression height when the piston at the upper dead center to realize different compression ratios. In the technical scheme, the compression ratio of the engine can be controlled to satisfy the actual condition optimally according to gas intake, different load operating conditions and the compression ratios required by different fuels, in order to reach optimal fuel economy, dynamic property and discharge effects and realize wide selectivity of fuels of one engine.

Owner:高伟

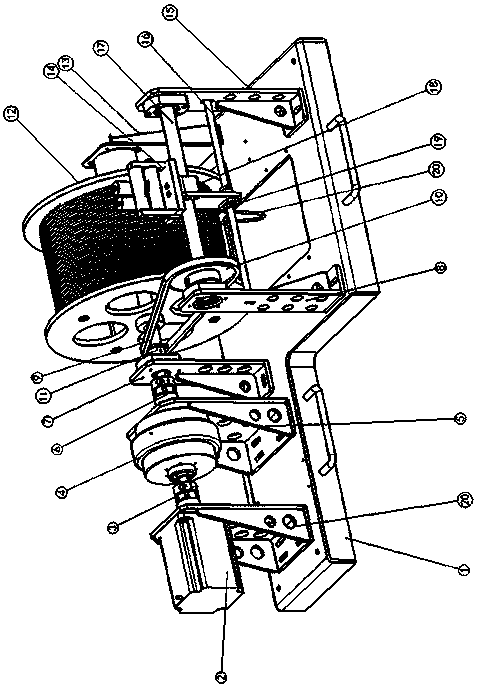

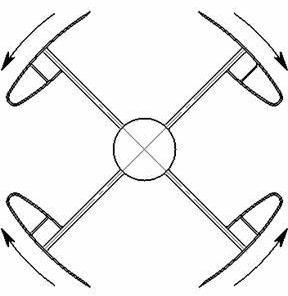

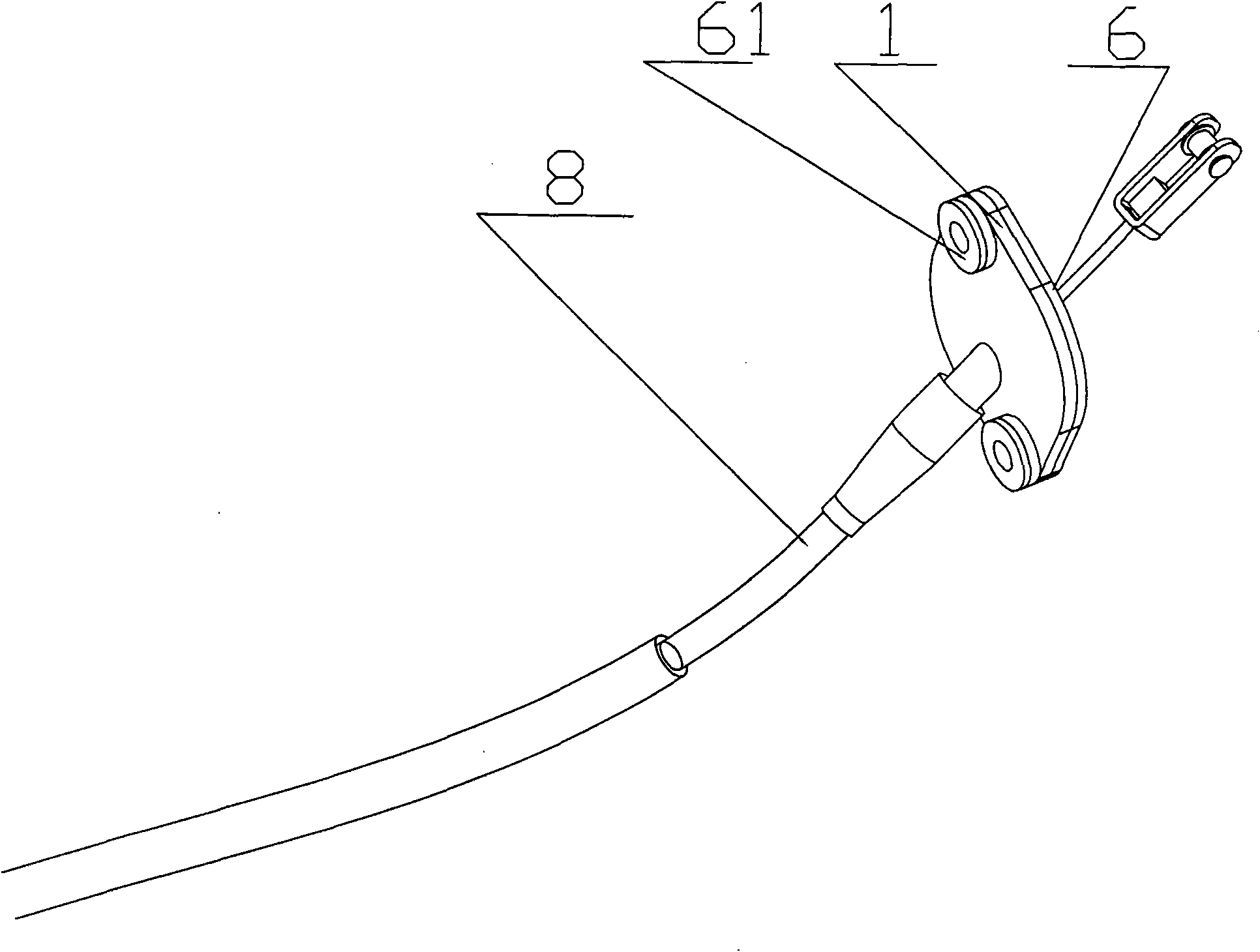

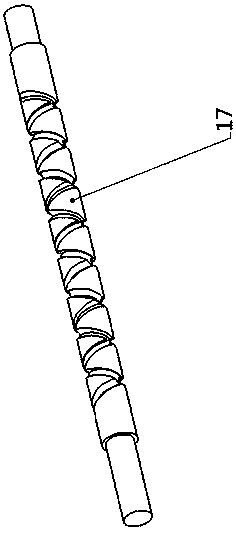

Variable-torque cable winding and unwinding device for mooring unmanned aerial vehicle and cable winding and unwinding method thereof

The invention provides a variable-torque cable winding and unwinding device for a mooring unmanned aerial vehicle and a cable winding and unwinding method thereof. The cable winding and unwinding device comprises a driving mechanism and a cable winding mechanism; the driving mechanism comprises a motor, a magnetic powder clutch and a driver, wherein the motor and the magnetic powder clutch are used for driving and controlling the rotation of a cable winding disc, and the driver is electrically connected to the magnetic powder clutch so as to adjust the torque of the magnetic powder clutch by controlling the current changes; and the cable winding mechanism comprises the cable winding disc, a reciprocating connecting rod, a sliding block and a creel stand, wherein the cable winding disc is used for allowing cables to be wound around the cable winding disc, the cable winding disc and the driving mechanism are coaxially arranged and are connected to the output end of the driving mechanism,the reciprocating connecting rod is arranged in parallel with the cable winding disc and is connected to the output end of the driving mechanism, a threaded groove is formed in the reciprocating connecting rod, the sliding block is arranged in the threaded groove of the reciprocating connecting rod and can move along the threaded groove, the cable arranging frame is arranged on the reciprocatingconnecting rod and can do reciprocating motion along the reciprocating connecting rod under the action of the sliding block, and the cables penetrate through the creel stand to be connected to a mainbody of the mooring unmanned aerial vehicle.

Owner:北京卓翼智能科技有限公司

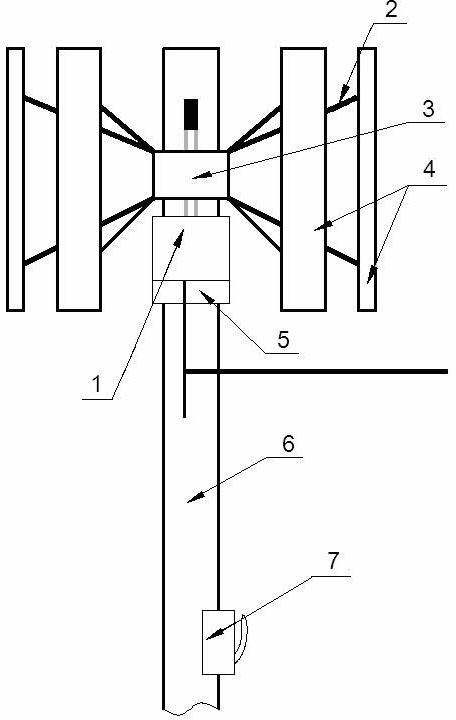

Vertical axis wind driven generator with balanced torque

InactiveCN102200097AImprove stabilityStructural Rigidity GuaranteeMachines/enginesWind motor combinationsImpellerWind driven

The invention provides a vertical axis wind driven generator with a balanced torque. The wind driven generator comprises a vertical column, impellors and a generator, wherein the impellor is axially and vertically arranged on the vertical column through a hub; the hub drives the main shaft of the generator; the hub is provided with a plurality of blades through connecting rods; the wind driven generator is provided with multiple stages of impellors which are classified into corotational impellors and couterrotational impellors; the rotation direction of the corotational impellors is the same as that of the main shaft of the generator; the hub is directly connected with the main shaft of the generator; the rotation direction of the couterroational impellor is opposite to the that of the main shaft of the generator; and the hub is connected with the main shaft of the generator through a synchronous reverse driving mechanism. According to the invention, two torques which are reversal and counteract mutually are generated uniformly on the vertical column, thus the stability is higher for the vertical axis wind driven generator in operation, the structure rigidity is ensured, and the possibility of device damage is reduced; and simultaneously, the generation efficiency is higher, the blades rotate smoothly, the structure is simple, the practical applicability is high, and the wind driven generator is easy to use and popularize in bulk.

Owner:DONGFANG TURBINE CO LTD

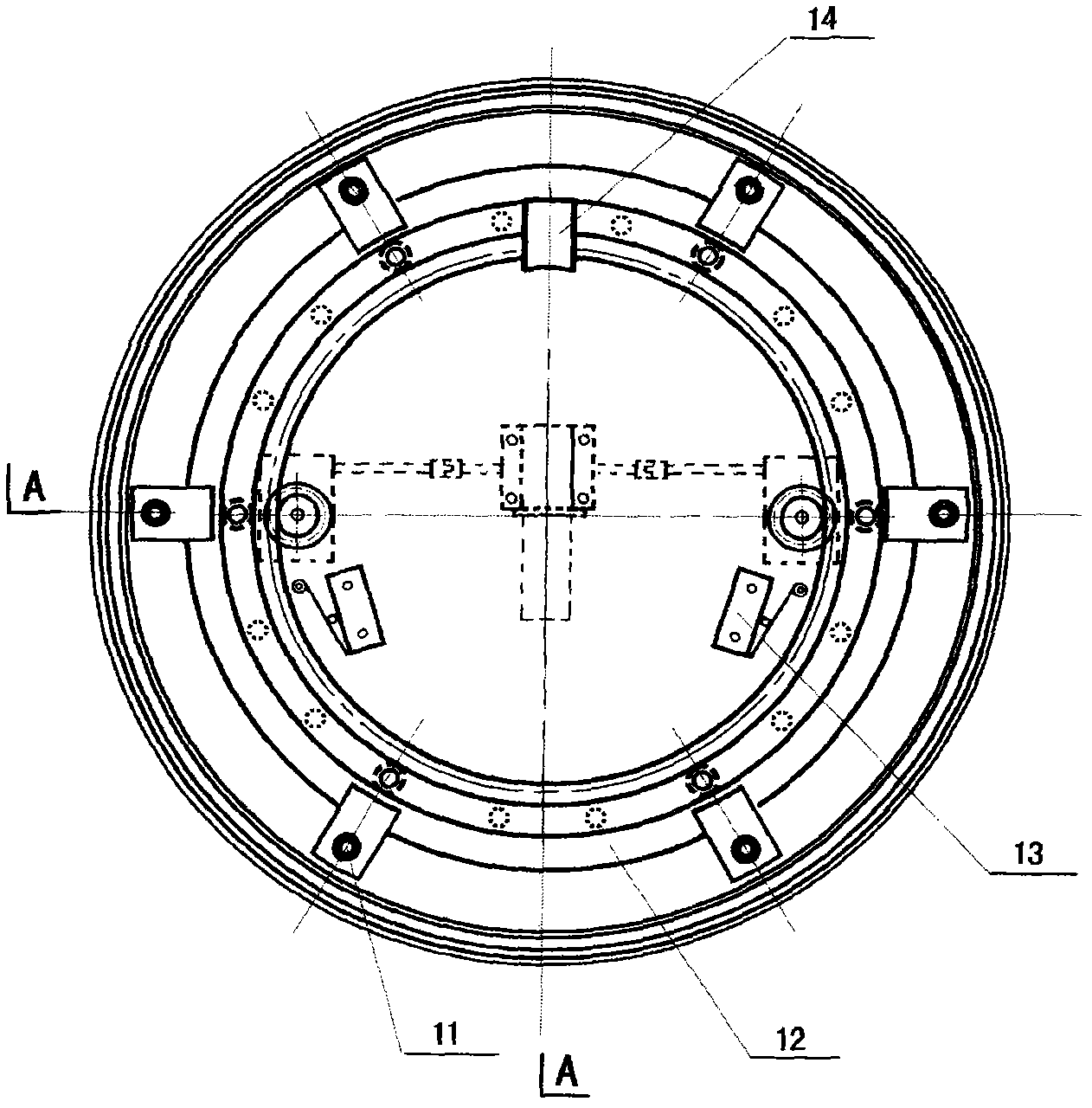

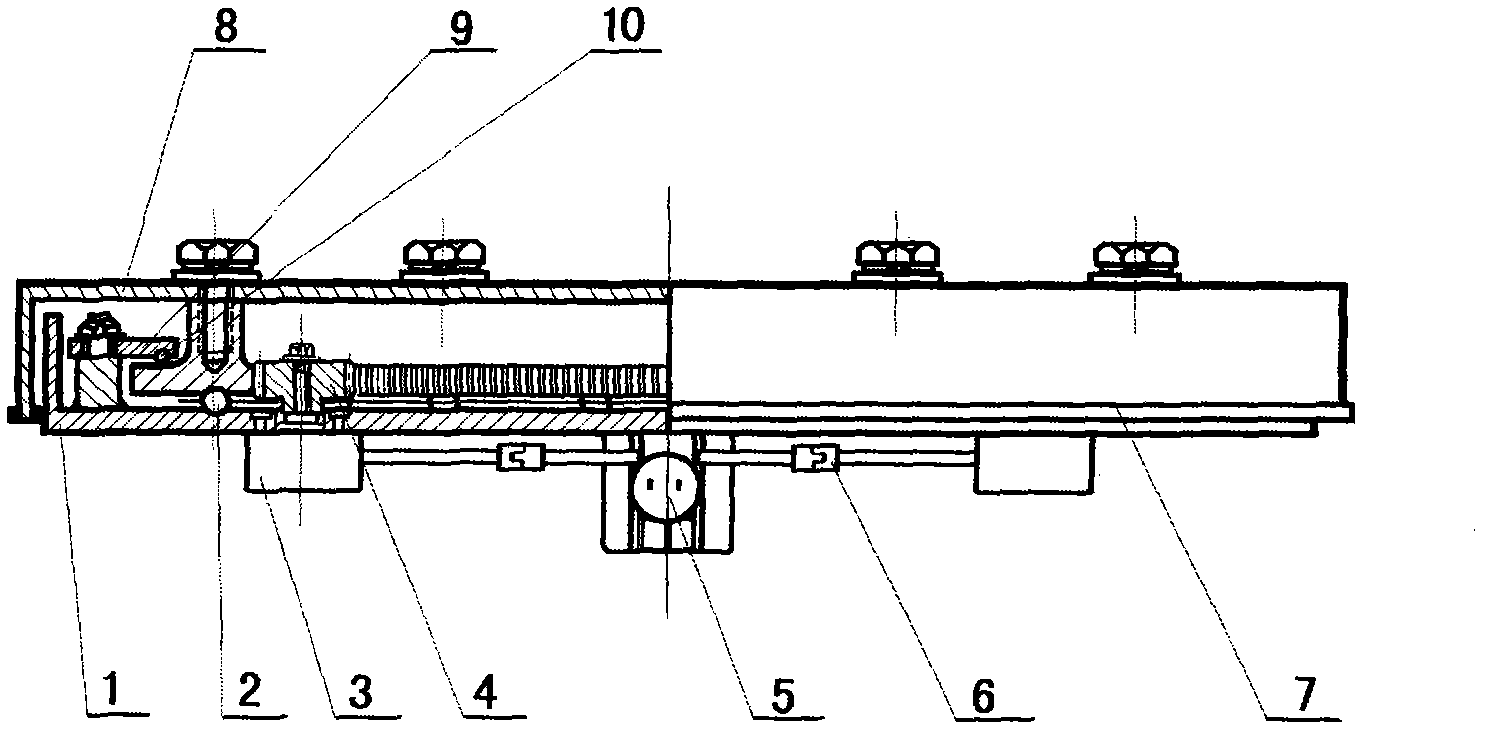

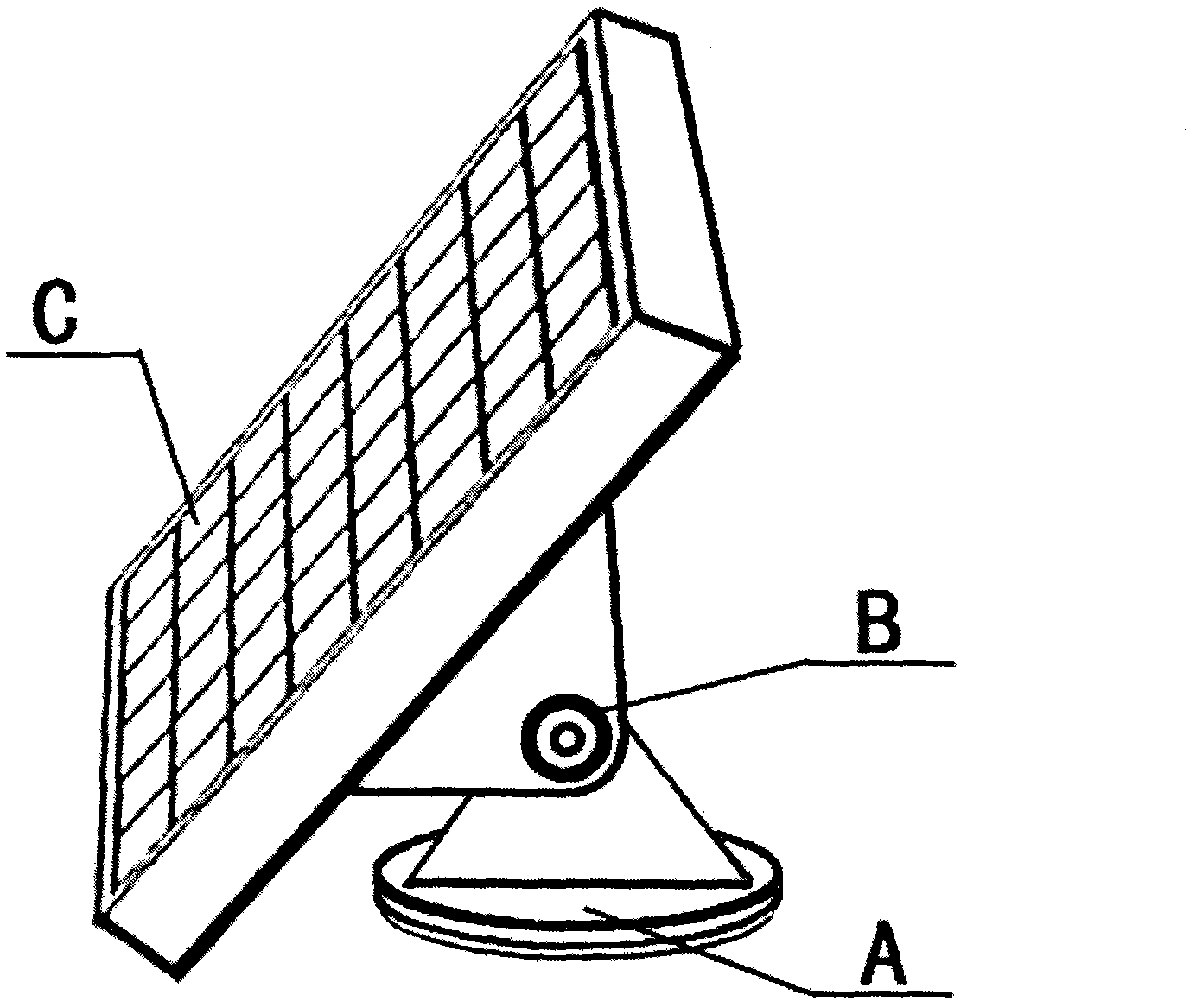

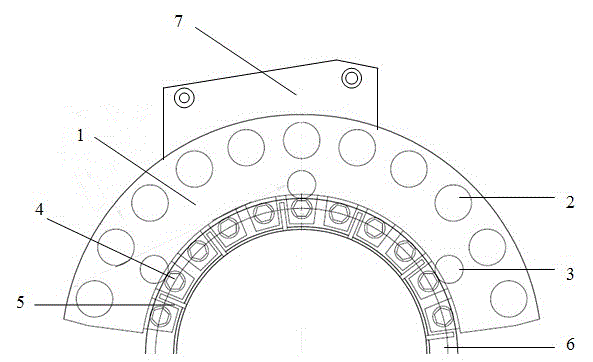

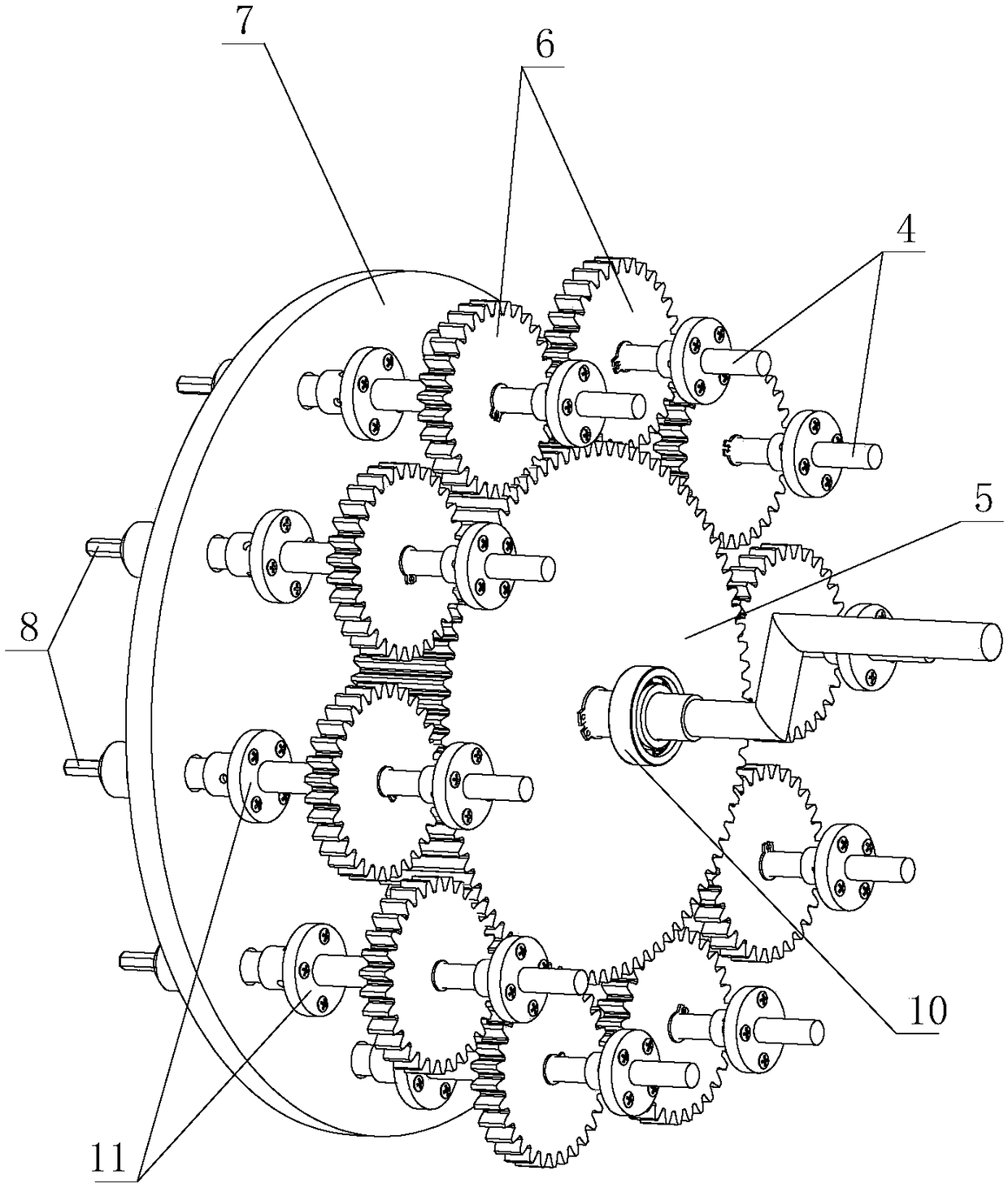

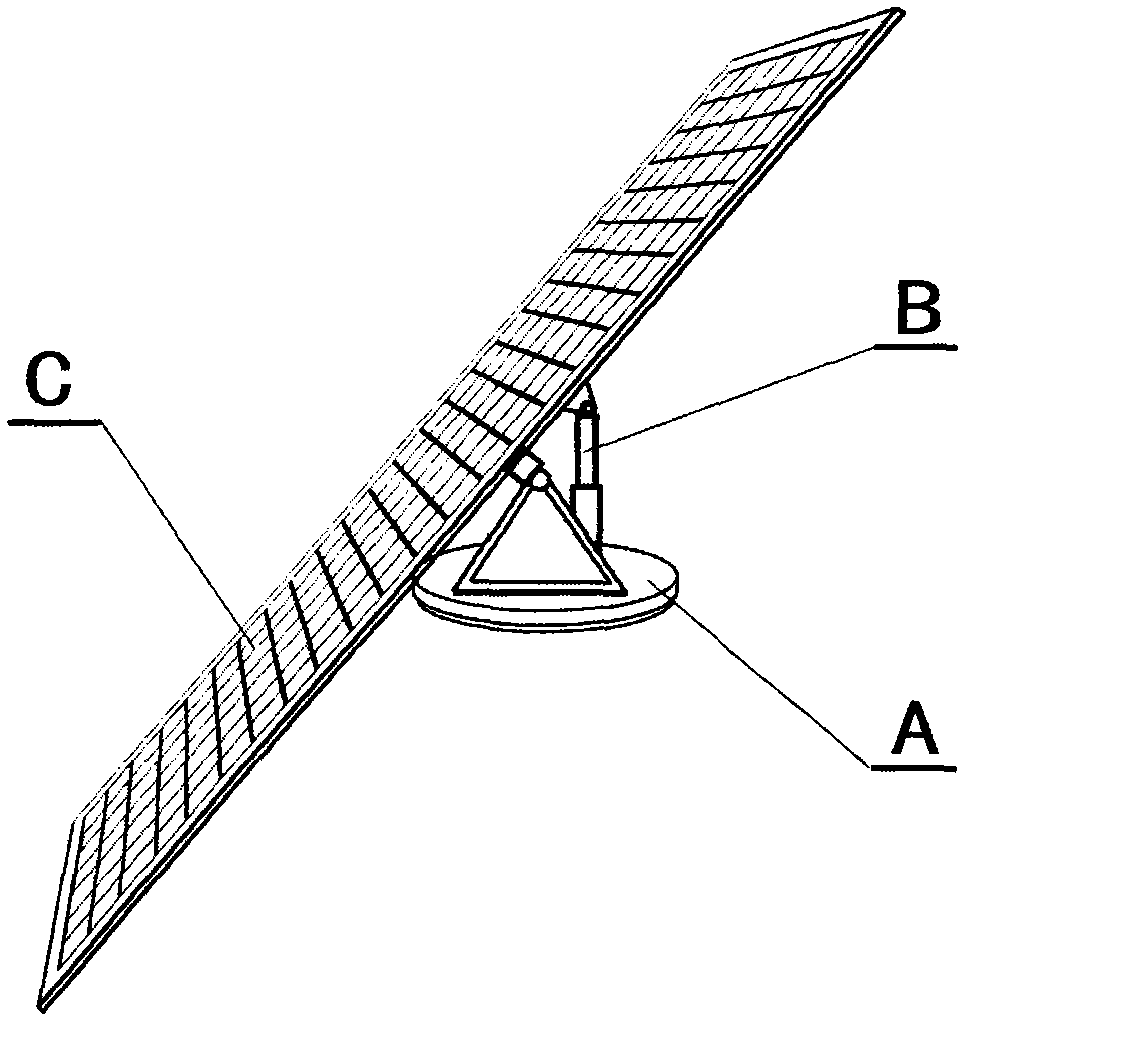

Condensation type solar power generation tracking rotating disc

InactiveCN103207624AImprove integrityImprove rigidityPhotovoltaic supportsControl using feedbackMotor driveDrive shaft

The invention provides a condensation type solar power generation tracking rotating disc which comprises a fixed part and a rotating part. The fixed part is composed of a chassis with a U-shaped guiding groove, a reduction motor fixed on the chassis, two worm and gear reduction boxes symmetrically fixed on the chassis, more than three studs evenly distributed on the outer side of the U-shaped guiding groove of the chassis and pressing plates assembled on the studs, wherein the reduction motor is respectively connected with driving shafts of the two worm and gear reduction boxes on the chassis through connection shafts. The rotating part is composed of a gear ring with a U-shaped guiding groove at the bottom, more than three steel balls rolling in the U-shaped guiding groove of the gear ring, and two driving gears. The two driving gears are connected with output shafts of the two worm and gear reduction boxes fixed on the chassis symmetrically, the reduction motor drives the driving shafts of the two worm and gear reduction boxes to enable the driving gears assembled on the output shafts of the worm and gear reduction boxes to rotate, and the driving gears are symmetrically meshed with inner teeth of the gear ring to drive the gear ring to rotate so as to enable the upper rotating disc integrated with the gear ring in a fixing mode to rotate.

Owner:陈永胜

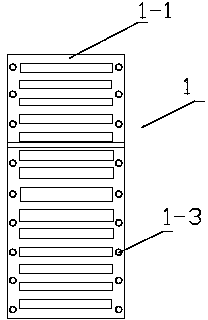

Hydraulic multi-axis screwing device for flange bolts

InactiveCN104551627AImprove construction efficiencyEasy to useMetal working apparatusHydraulic motorGear wheel

The invention discloses a hydraulic multi-axis screwing device for flange bolts. The hydraulic multi-axis screwing device comprises a main frame body and an assistant frame body, and is characterized in that connection seats are arranged on both the main and assistant frame bodies, and can be directly connected with a mechanical arm of an excavator; the main and assistant frame bodies are connected with each other through a plurality of connection oil cylinders and positioning wheels; a plurality of groups of reduction gears and a plurality of hexangular sleeves are arranged in the main frame body; a plurality of hydraulic motors are correspondingly mounted on the outer side of the main frame body; the hexangular sleeves arranged in the main frame body are used for placing of the bolts; a plurality of hexangular sleeves, which are used for placing of the bolts, provided with no without teeth and capable of rotating, are correspondingly arranged in the assistant frame body; through driving of the hydraulic motors, the reduction gear groups and the hexangular sleeves arranged in the main frame body, the bolts can be effectively screwed. The hydraulic multi-axis screwing device is suitable for the work condition of the connection through a bolt which has high screwing torque, simple to manufacture, low in production cost, high in work efficiency and low in labor intensity, and has the advantage that the operating efficiency of a dredger can be improved.

Owner:CCCC GUANGZHOU DREDGING +1

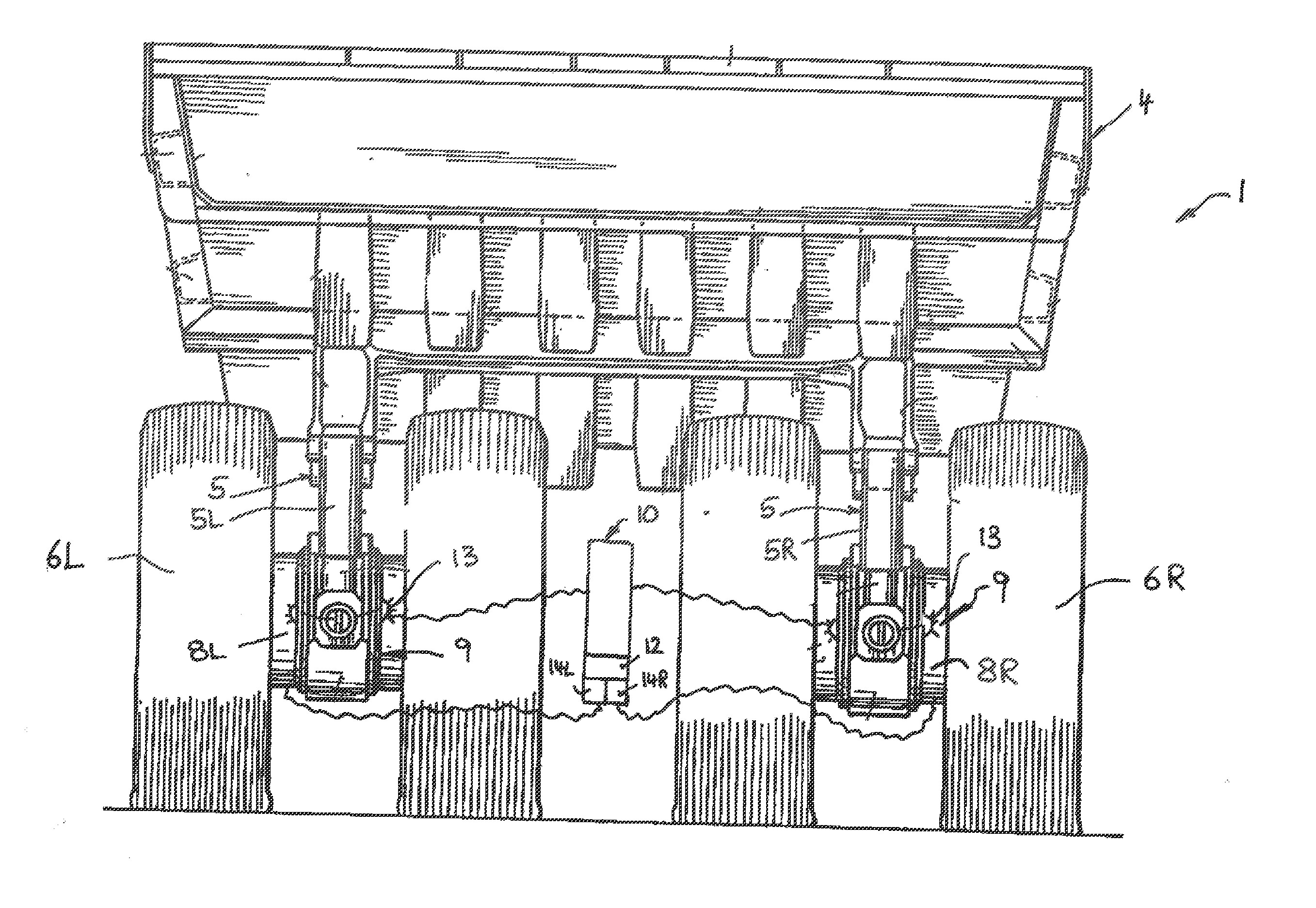

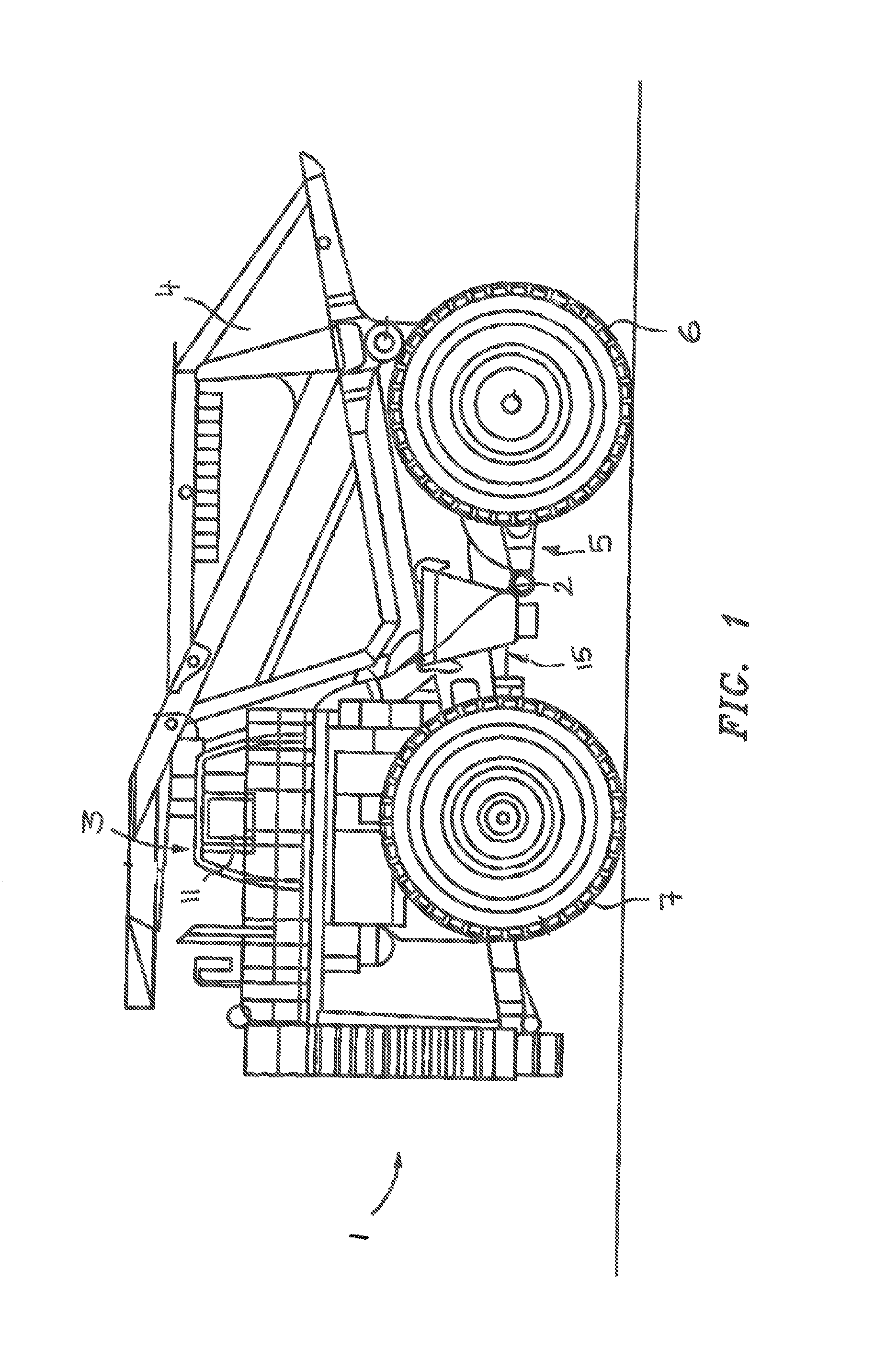

Method and Apparatus for Controlling the Drive System for Mobile Equipment such as a Mobile Construction and/or Mining Machine

ActiveUS20120130578A1Minimize stress and oscillationAvoid fatigueDigital data processing detailsMotor depositionControl theoryMobile device

The present invention relates to a method and an apparatus for controlling the drive system for mobile equipment, when the operator's drive commander is kept constant, electric traction motors are controlled by a torque controller to provide uniform torque, deviations in speeds of the electric traction motors are determined and electric motor power of at least one is varied relatively to the electric motor power of the other in response to a determined deviation in speed to keep the torques uniform. The power control balancing compensates for the torque differences previously encountered when the speeds of the traction motors differ at equal power supplied to the traction motors.

Owner:LIEBHERR MINING EQUIP

Combined valve

InactiveCN104482253ASolve bad working conditionsSolve the requestSpindle sealingsPlug valvesEngineeringVALVE PORT

The invention provides a combined valve. The combined valve can be free of leakage for a long time under severe working conditions. The combined valve comprises a combined valve body, wherein a medium inlet and a ball valve cavity communicated with the medium inlet are formed in one side of the combined valve body, a medium outlet and a stop valve cavity communicated with the medium outlet are formed in the other side of the combined valve body, the ball valve cavity is communicated with the stop valve cavity, a stop valve element arranged in the stop valve cavity a is connected with stop valve rod, a handle is connected to one end of the stop valve rod, a ball valve ball body arranged in the ball valve cavity is connected with a ball valve rod, the ball valve rod is connected with an output shaft at one end of a speed reduction mechanism, the other end of the speed reduction mechanism is connected with a driving gear for driving the speed reduction mechanism to rotate, the driving gear is meshed with a transition gear, and the stop valve rod drives the transition gear to rotate. The combined valve is integrally designed, has few leakage points, and is more reliable in pipeline installation, and more convenient to operate.

Owner:BEIJING OTE CONTROL VALVE

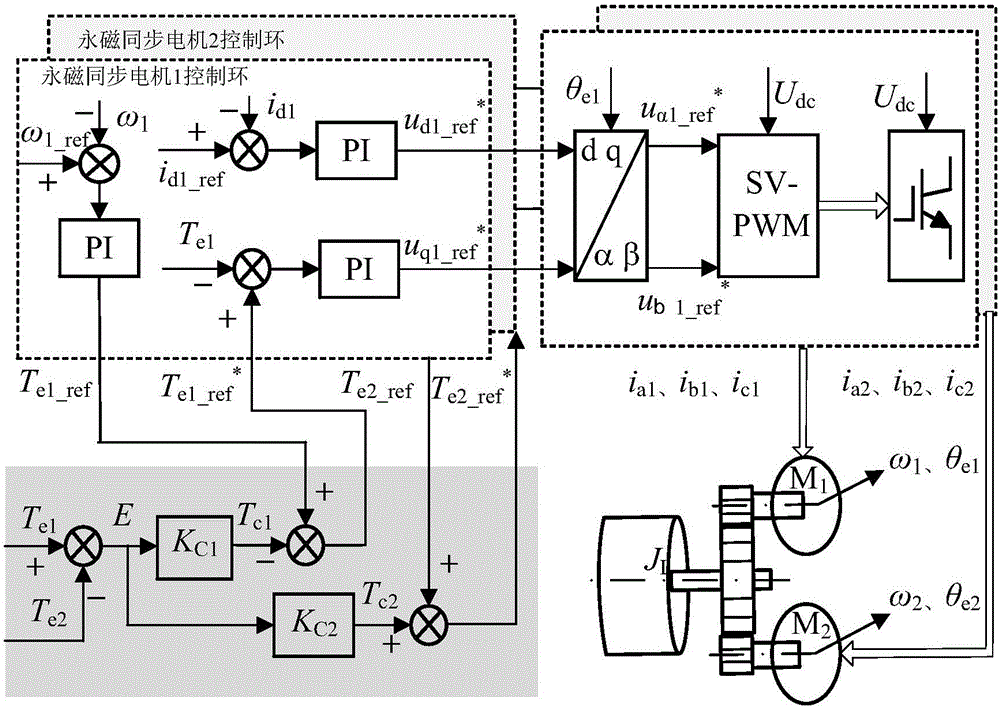

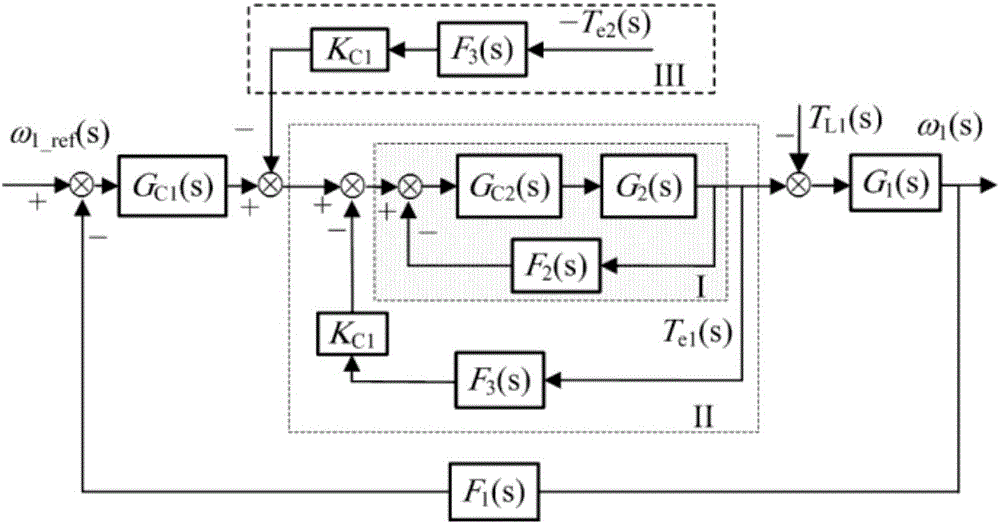

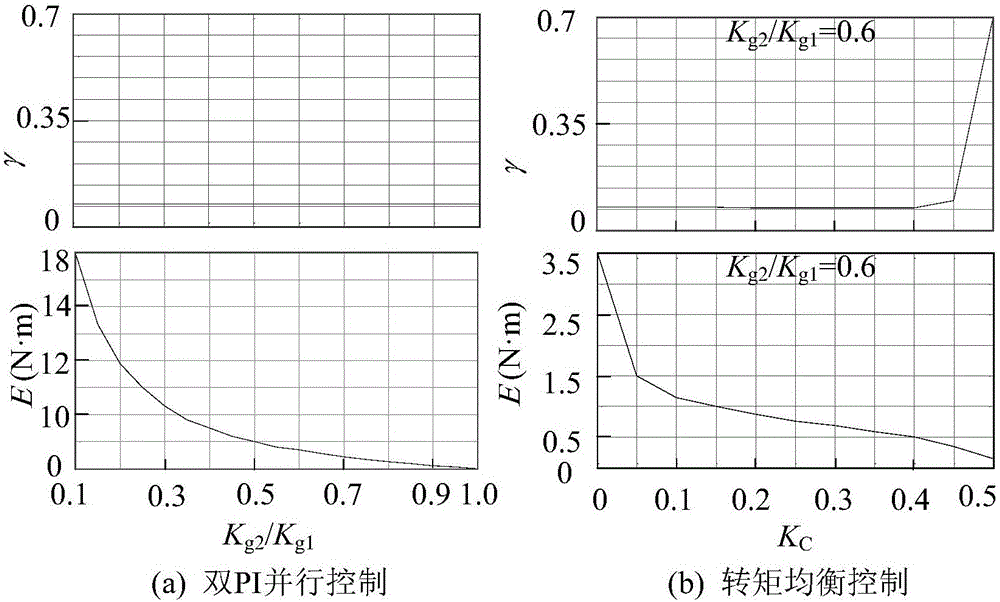

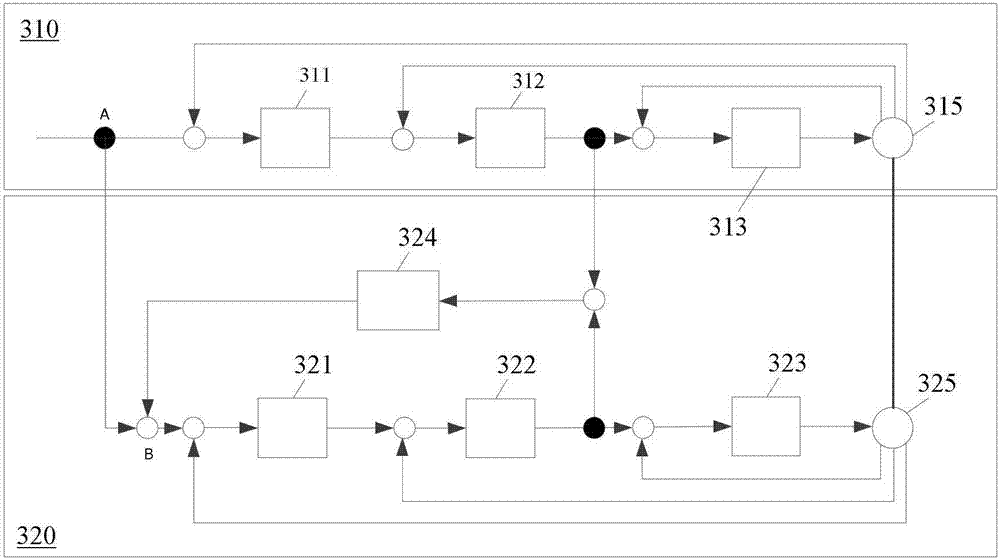

Dual-motor gear transmission system torque equalization control method

ActiveCN106230325AUniform torqueReduce synchronization errorElectric motor speed/torque regulationController designGear transmission

The invention relates to the field of dual-motor system control, and provides a dual-motor gear transmission system torque equalization control method so as to realize effective inhibition for output torque imbalance and control dual-synchronization in rotating speed and torque of the system. The invention adopts the following technical scheme: the dual-motor gear transmission system torque equalization control method comprises the steps of (1) a structural model of the system; (2) torque synchronization error calculation, wherein Te1 and Te2 are supposed to be electromagnetic torques of a motor 1 and a motor 2 respectively, a torque synchronization error of the system is defined as E(s)=Te1(s)-Te2(s), E serves as a feedback variable and acts on a synchronization controller, and the size of E reflects the performance of system torque equalization control; and (3) synchronization controller design. The method provided by the invention mainly applied to dual-motor control occasions.

Owner:TIANJIN POLYTECHNIC UNIV

Circumferential inhaul cable structure of vertical axis wind turbine

InactiveCN102135067APrevent circumferential jitterImprove sports performance and stressRenewable energy generationMachines/enginesWind forceDynamo

The invention discloses a circumferential inhaul cable structure of a vertical axis wind turbine. The wind turbine comprises a tower column and a wind wheel, wherein the wind wheel comprises a supporting wheel and blades as well as an inhaul cable, the supporting wheel is composed of a plurality of supporting bars, the blades are connected with the supporting bars; and the inhaul cable is respectively connected with two adjacent blades. In the invention, the inhaul cable structure is utilized to connect all the blades together, position change between adjacent blades is limited, and circumferential joggling of the blades in a rotating process is effectively prevented, thus torques provided for the turbine by all the blades are uniform and the service life of the turbine is prolonged. The inventor provides an optimal connection site of the inhaul cable and the blades, the stability of the connection site is the best, and the pneumatic characteristic of the wind wheel is not influenced. Compared with a rigid supporting wheel composed of rigid connection supporting bars in the prior art, the structure is greatly simplified, and the pneumatic characteristic of the wind wheel is not influenced; besides, the wind power coefficient can be effectively improved, thus the structure disclosed by the invention has good application prospect and market prospect.

Owner:NAT WIND ENERGY

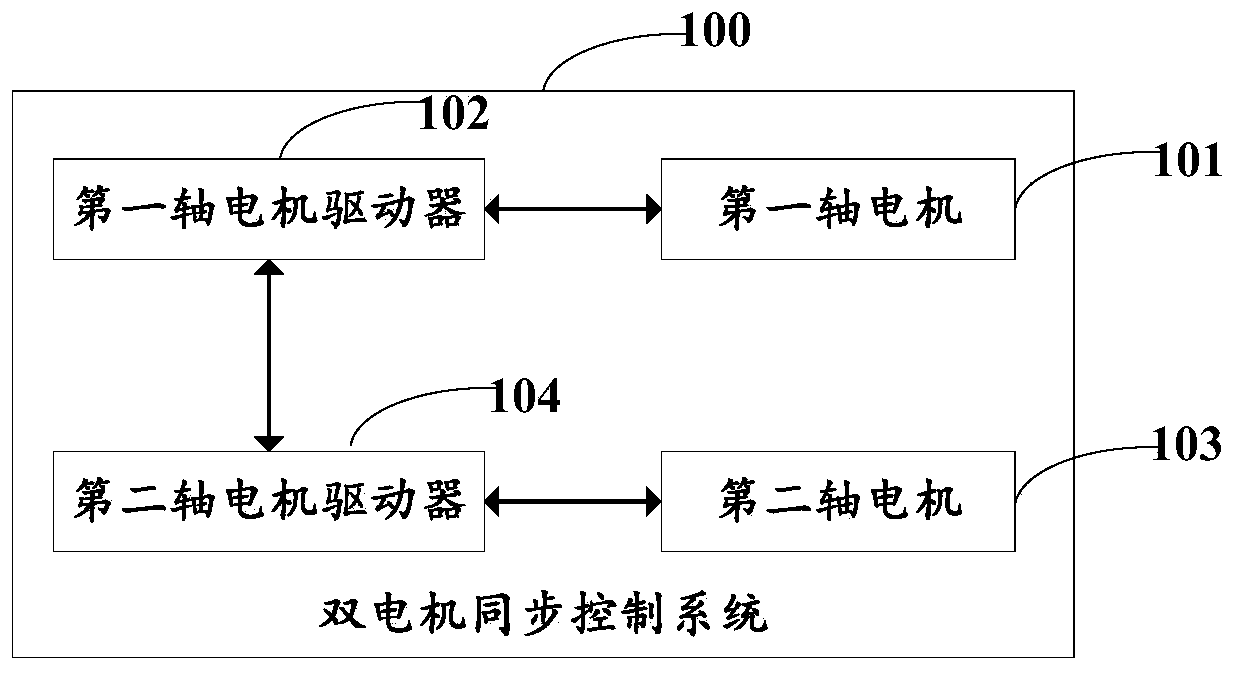

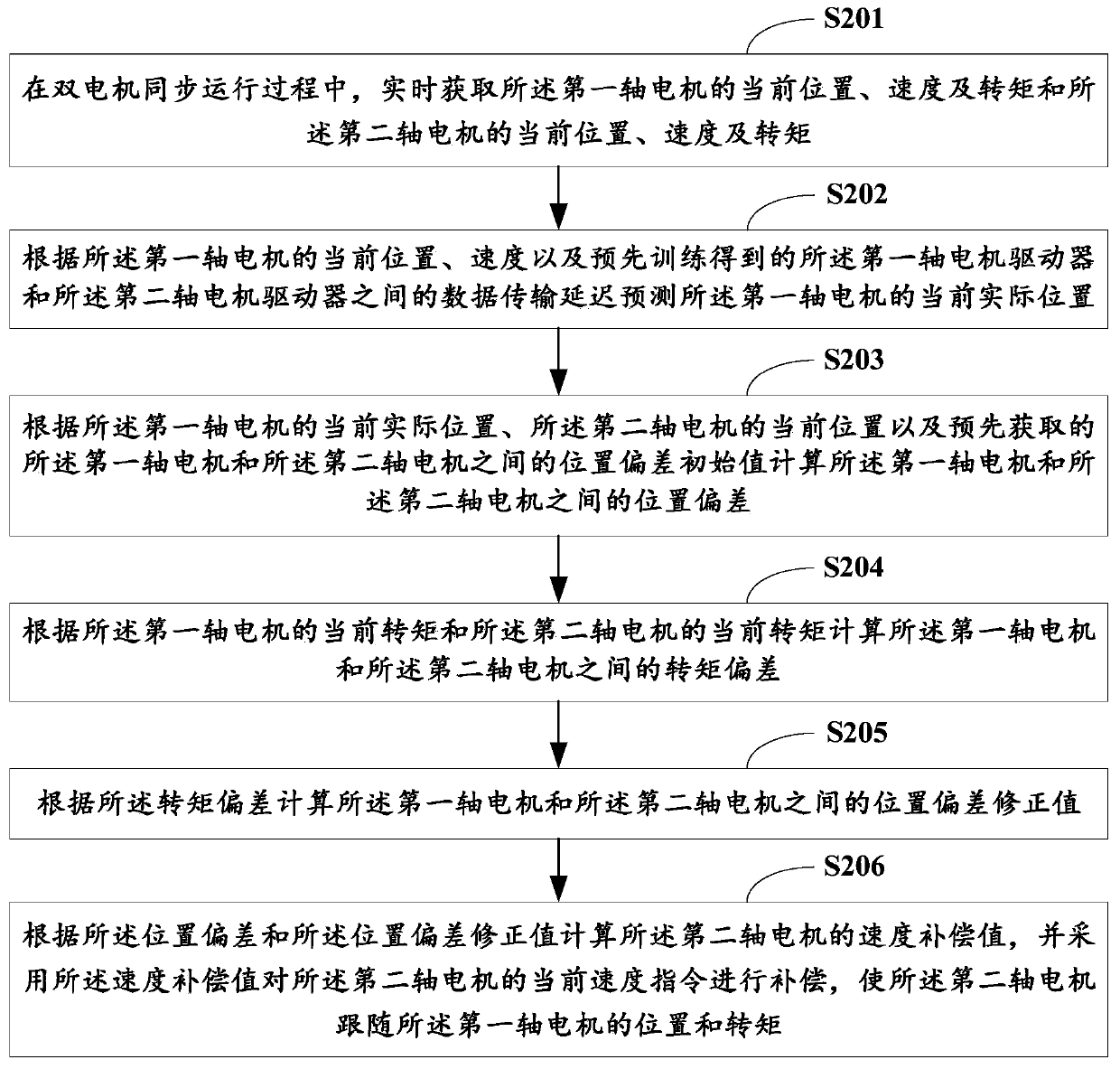

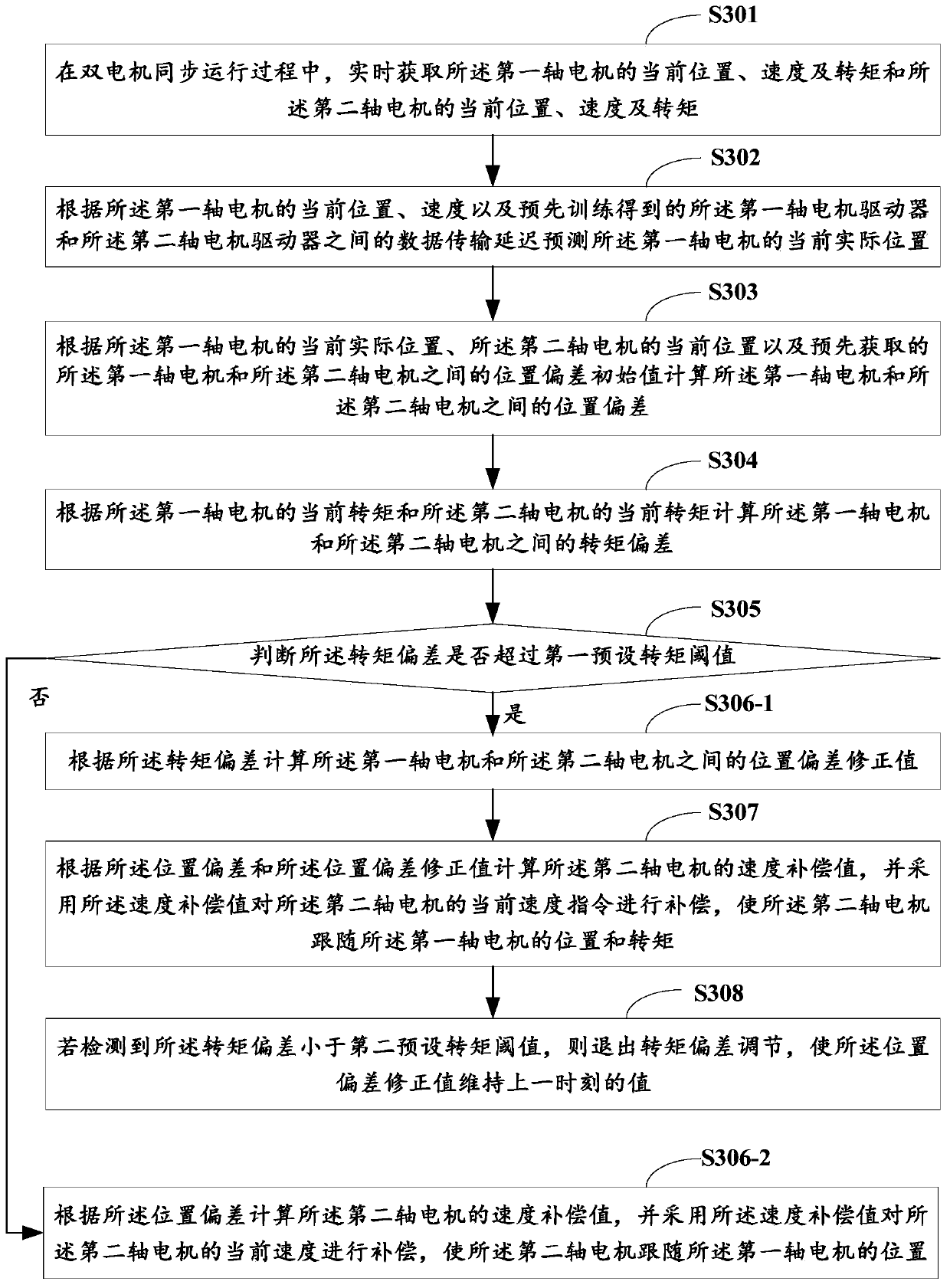

Dual-motor synchronization control method, system and computer readable storage medium

ActiveCN110311594AAvoid position deviationUniform torqueMultiple dynamo-electric motors speed regulationControl systemData transmission

The embodiment of the invention discloses a dual-motor synchronization control method, system and a computer readable storage medium, which relate to the technical field of industrial control. Synchronization control of dual motors is realized through adopting a control algorithm combining position prediction synchronization and torque synchronization control, the problem of position deviation ofthe dual motors caused by data transmission delay can be avoided, the torque balance of the dual motors can be kept in a position synchronization process, and the problem of uneven force of a mechanical device can thus be avoided; in addition, in comparison with the existing mode of realizing position synchronization control on dual motors through frequency division, a high-speed IO or a hardwarecircuit does not need to be added, and external interference does not happen; in comparison with the existing mode of realizing position synchronization control on dual motors through a high-performance PLC, no high-performance PLC is needed, the cost and the complexity of the synchronization control system are reduced, and the control performance of a simple PLC communicating with the dual-motorsynchronization control system is not affected.

Owner:SUZHOU INOVANCE TECH CO LTD

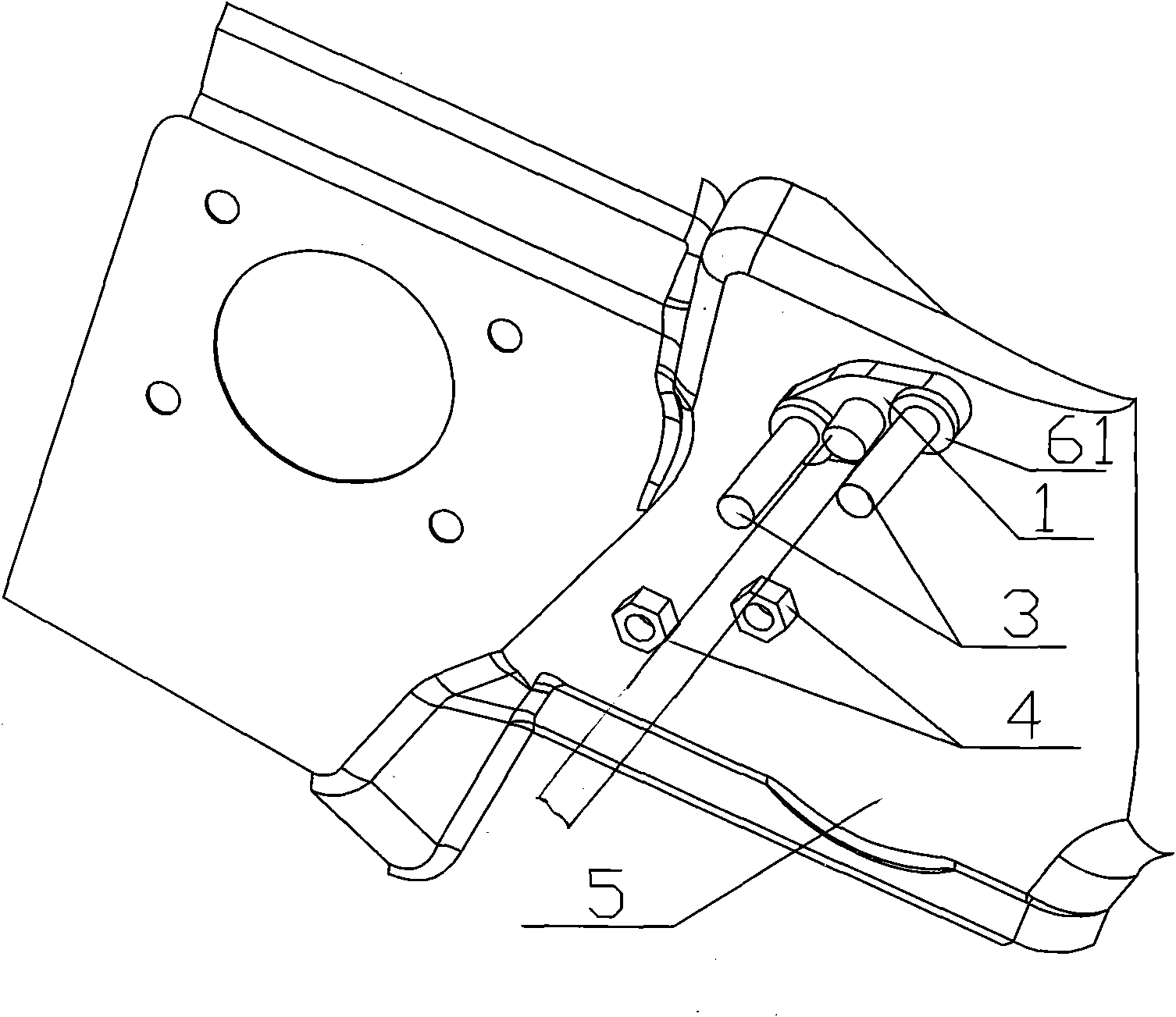

Assembly component of automobile clutch cable on front wall board of automobile

The invention provides an assembly component of an automobile clutch cable on a front wall board of an automobile. The assembly component comprises a metal cover plate, a rubber sealing gasket and bolt casings, wherein the centre of the metal cover plate is provided with a through hole through which a clutch cable passes, and the two ends of the metal cover plate are provided with mounting holes which are assembled with bolts on the front wall board of the automobile; the rubber sealing gasket has the same shape as that of the metal cover plate and is closely attached to one side of the metal cover plate close to the front wall board of the automobile; the centre of the rubber sealing gasket is also provided with the through hole, and the two ends of the rubber sealing gasket are provided with lug bosses with through holes and pressed into the mounting holes at the two ends of the metal cover plate; two bolt casings are pressed into the lug boss through holes at the two ends of the sealing gasket from the side of the metal cover plate respectively; and the outer ends of the bolt casings are attached to the edges of the orifices of the lug boss through holes of the sealing gasket. By increasing the bolt casing in the through hole of the rubber sealing gasket assembled with the front wall board of the automobile, the component reduces the wearing produced during the assembly of the sealing gasket to prevent the damage to the sealing property thereof.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Cable winding device for mooring unmanned aerial vehicle

The invention discloses a cable winding device for a mooring unmanned aerial vehicle. The cable winding device comprises a driving mechanism, a cable winding mechanism, a reciprocating connecting rod,a sliding block and a cable winding frame; the driving mechanism is used for driving and controlling rotation of a cable winding disc; the cable winding mechanism is used for winding a cable on a wire spool located on the cable winding mechanism, the cable winding disc and the driving mechanism are coaxially arranged, and the cable winding disc is connected to the output end of the driving mechanism; the reciprocating connecting rod is connected to the cable winding disc in parallel and is connected to the output end of the driving mechanism, and a threaded groove is formed in the reciprocating connecting rod; the sliding block is arranged in the threaded groove of the reciprocating connecting rod and can move along the threaded groove; and the wire arranging frame is arranged on the reciprocating connecting rod and can do reciprocating motion along the reciprocating connecting rod under the action of the sliding block; the cable penetrates through the cable winding frame to be connected to a mooring unmanned aerial vehicle body; and the driving mechanism and the cable winding mechanism are arranged on a base together.

Owner:北京卓翼智能科技有限公司

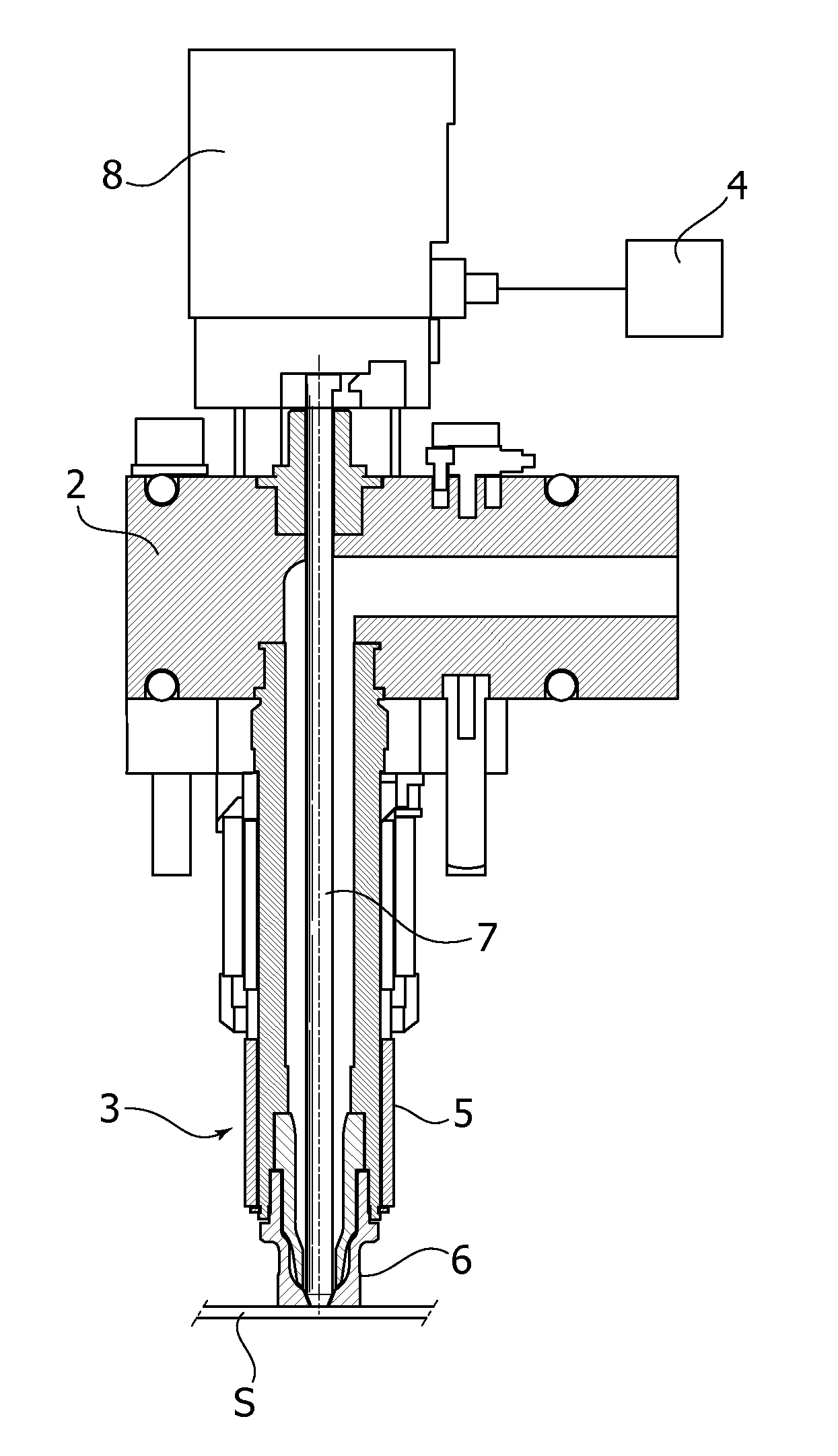

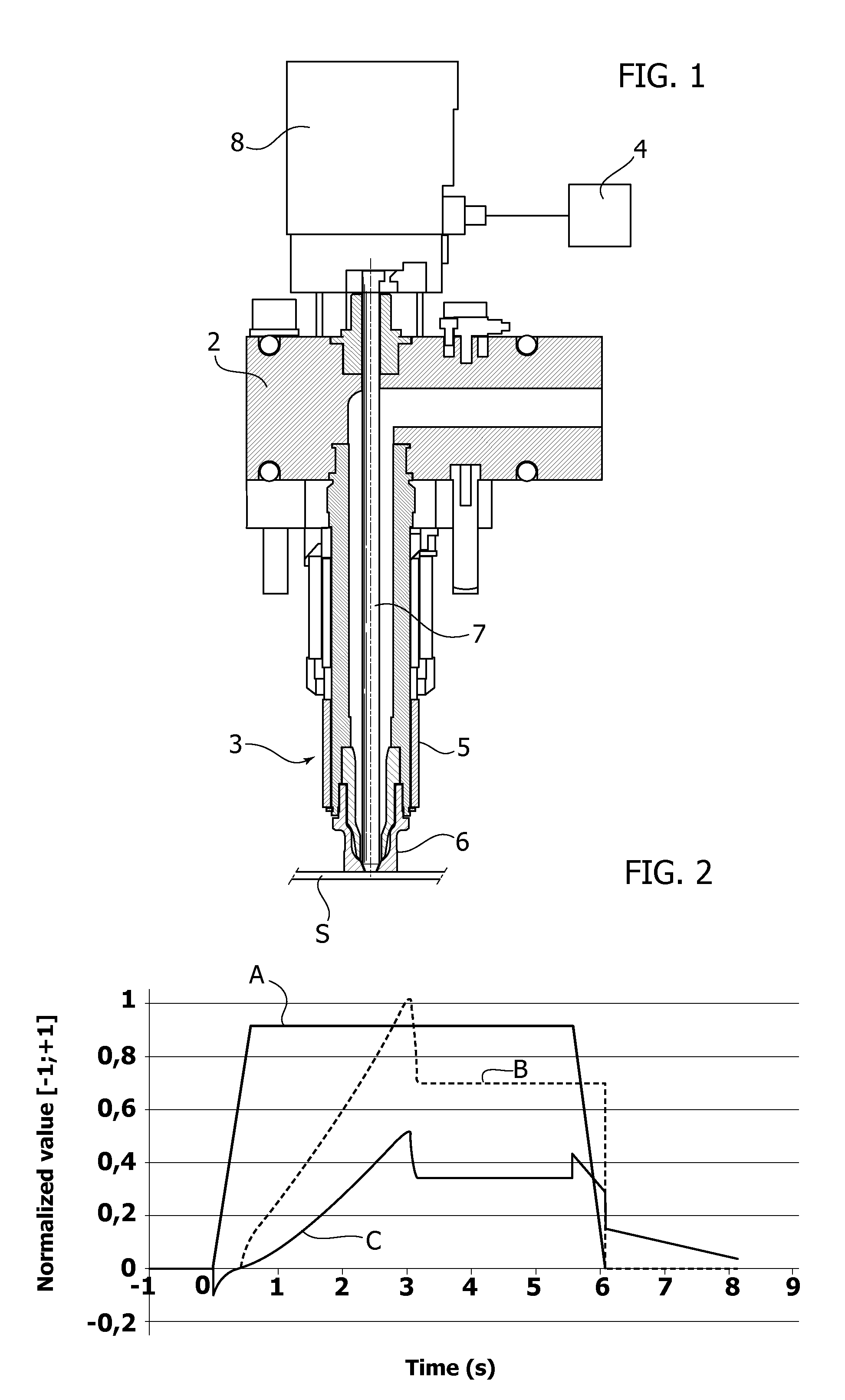

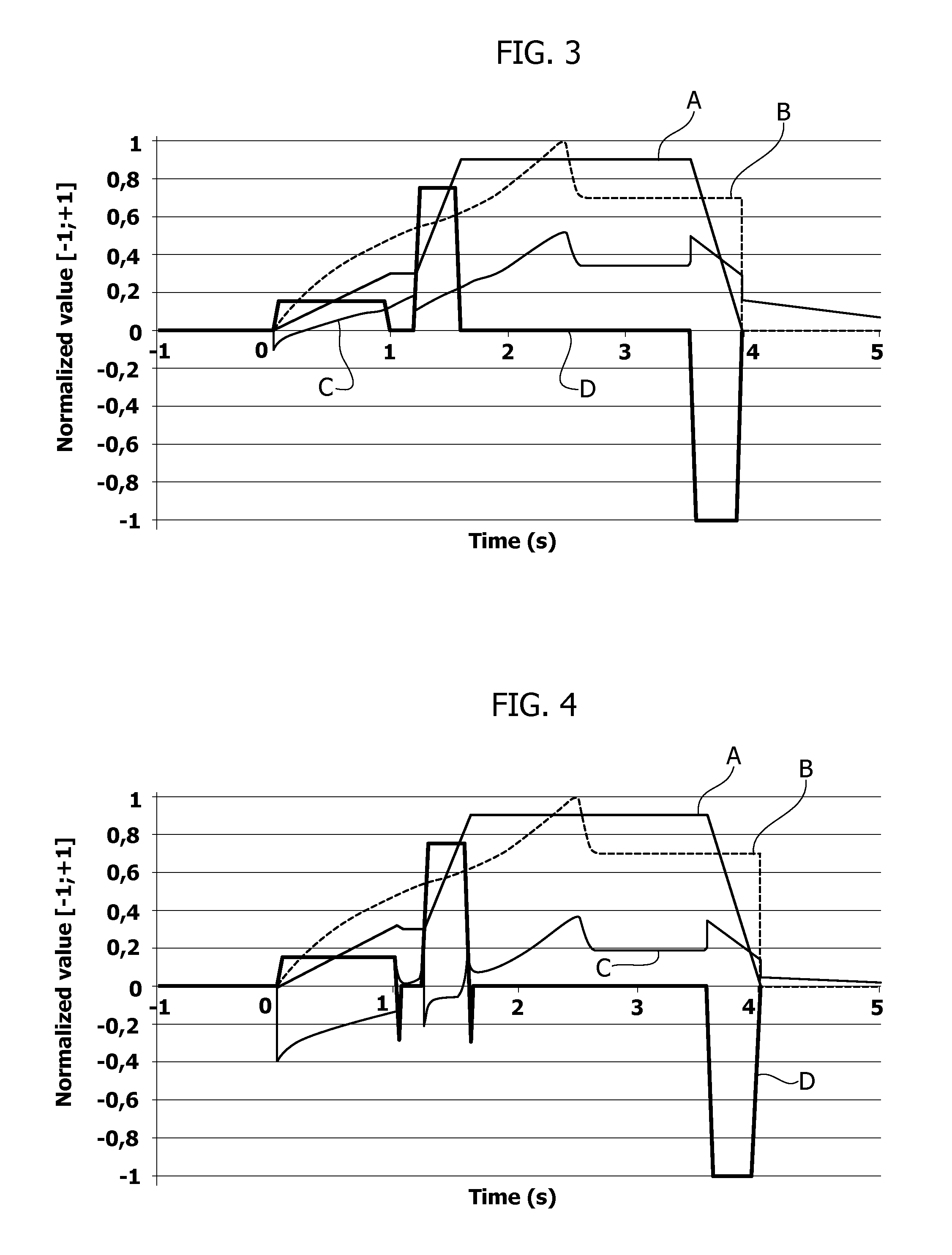

Method and apparatus for injection molding of plastic materials

ActiveUS20160067901A1Improve distributionImprove qualityAuxillary shaping apparatusPlastic materialsControl manner

Injection molding of plastic materials by an apparatus comprising at least one injector including a valve pin displaceable in a controlled manner between a closed position and an open position by an electric rotary actuator. At least one step is provided of detecting the value of the torque developed by the electric rotary actuator when the valve pin is in the path from the closed position to the open position, and the torque value detected is used to pilot the molding process.

Owner:INGLASS SPA

Device for quickly assembling and disassembling screws during inside diameter slicer cutter blade replacing

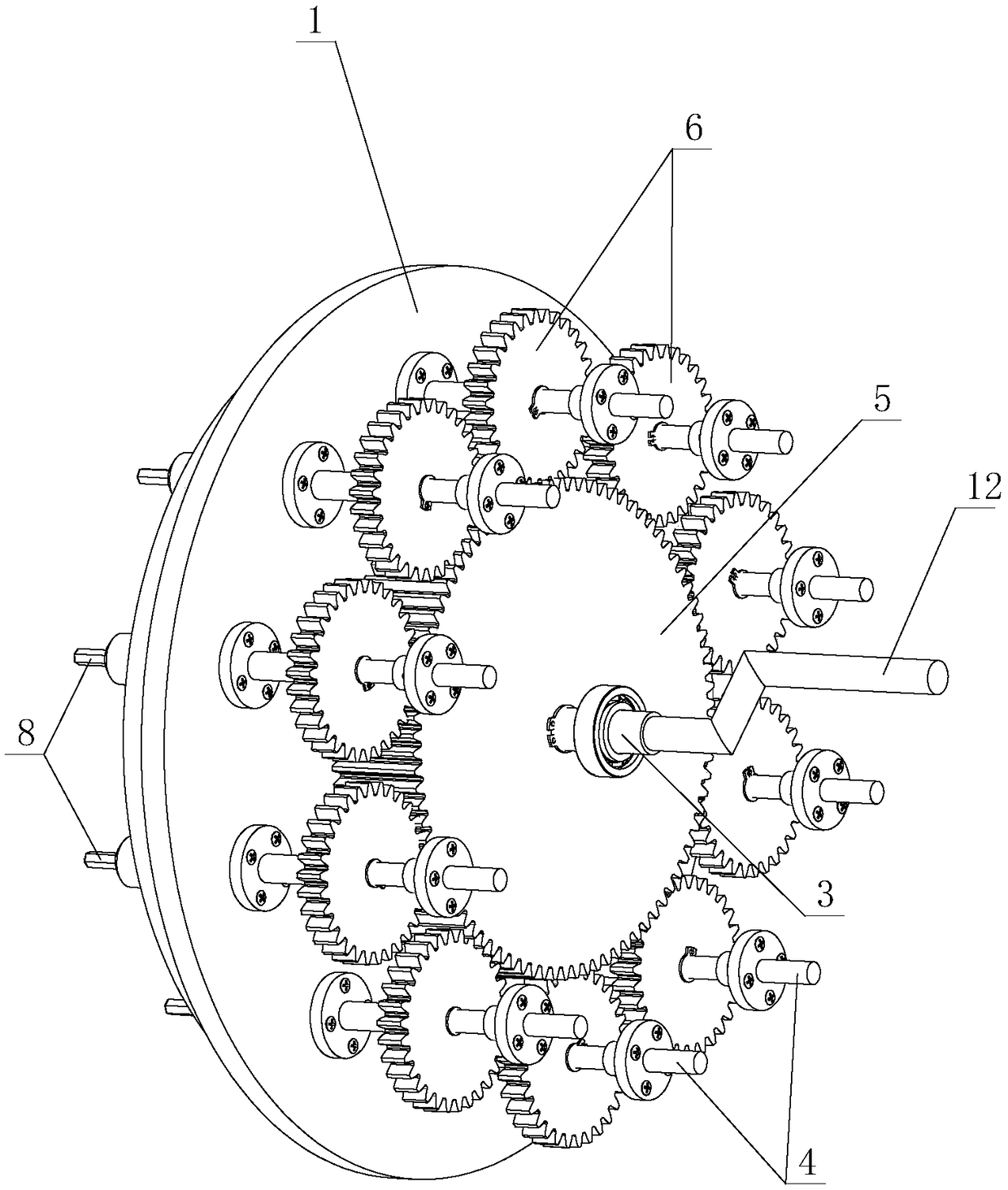

ActiveCN109277974AQuick loading and unloadingUniform torqueWrenchesScrewdriversGear transmissionDistortion

The invention provides a device for quickly assembling and disassembling screws during inside diameter slicer cutter blade replacing. The device comprises a rocking handle, an inner fixing disc, an outer fixing disc, a driving shaft, a plurality of driven shafts, a driving gear, a plurality of driven gears, a moving disc and a straight internal hexagonal wrench; the driving shaft drives the drivenshafts to rotate through gear transmission at first and finally drives the straight internal hexagonal wrench to rotate, meanwhile, the driving shaft drives the moving disc to move inwards through thread transmission, then, pushes the driven shafts to slide inwards in the axial direction and finally pushes the straight internal hexagonal wrench to move inwards, or the screws which are unscrewed outwards push the straight internal hexagonal wrench to move outwards, accordingly the driven shafts are pushed to slide outwards axially, and screw assembling and disassembling are achieved. The device can replace partial manpower, the torque borne by the screws in the tightening process is uniform, inside diameter slicing cutter blade distortion deformation is avoided, the cutter blade fasteningquality is improved, the assembling and disassembling time is shortened, and the efficiency of labor is improved.

Owner:SHANDONG JIANZHU UNIV

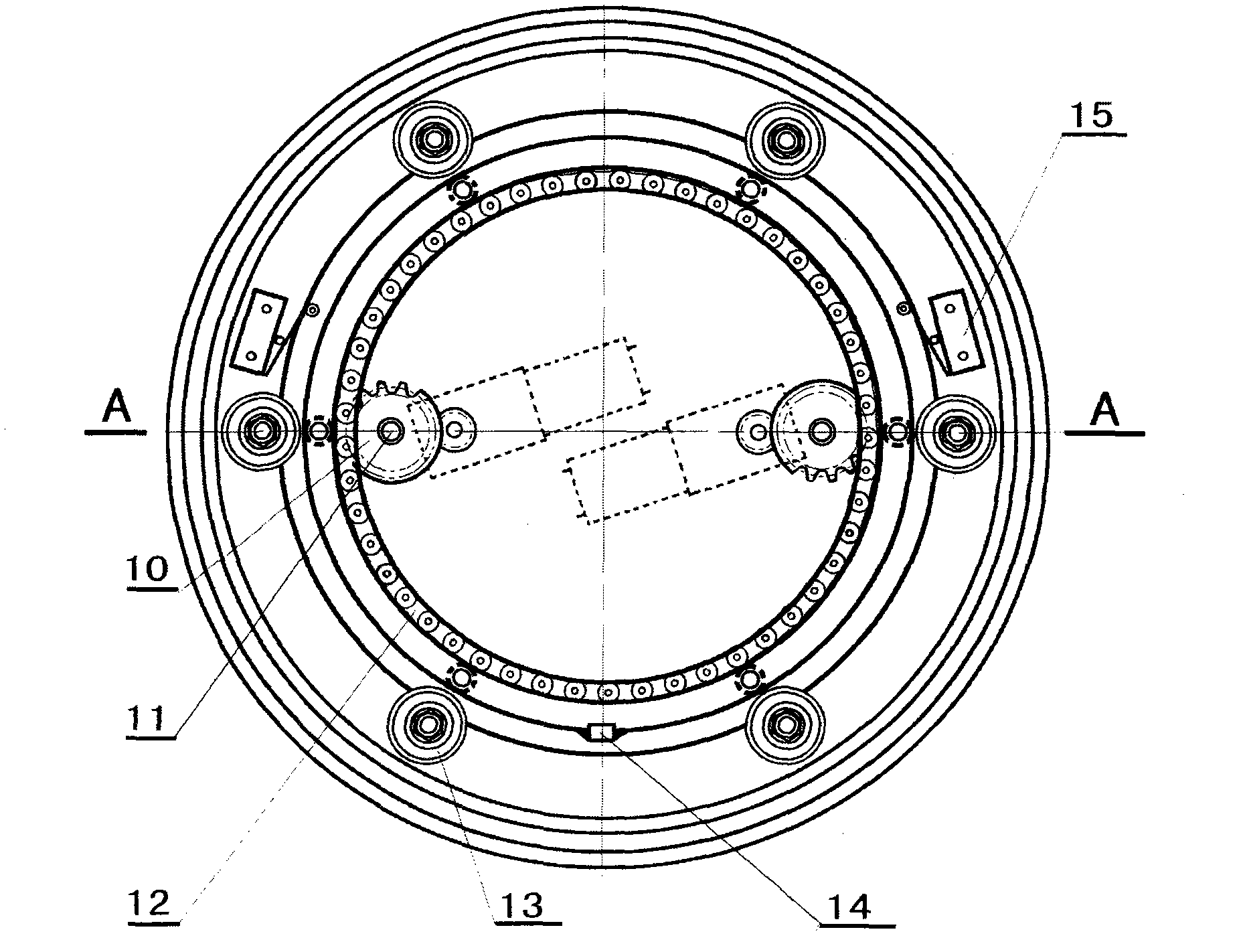

Solar power generation tracking rotating table

InactiveCN102999052ALow processing technology requirementsReduced precision requirementsControl using feedbackEngineeringSprocket

The invention provides a solar power generation tracking rotating table. The solar power generation tracking rotating table comprises a fixed portion and a rotating portion, the fixed portion comprises a flange ring with a V-shaped guide groove, two direct-current slowdown motors, two transmission shaft seats, more than three guide shafts and guide wheels, wherein the flange ring with the V-shaped guide groove is fixed on a base plate, the two slowdown motors are symmetrically fixed on the base plate, the two transmission shaft seats are symmetrically fixed in the flange ring with the V-shaped guide groove, the guide shafts are fixed outside the flange ring with the V-shaped guide groove, and the guide wheels are assembled on the guide shafts. The rotating portion comprises the rotating table, more than three steel balls rolling in the V-shaped guide groove, a rotating ring, a chain, two driving gears, two driven gears and sprockets, wherein the chain is fixed on the inner side of the rotating ring, and the sprockets are fixed on the driven gears. The two direct-current slowdown motors symmetrically fixed on the base plate are meshed with the driven gears on the transmission shaft seats through the driving gears to drive the sprockets to drive the chain fixed on the inner side of the rotating ring, so that the rotating portion rotates.

Owner:盐城无极电子照明有限公司

Method and device for multi-shaft coupling moment balance control based on position synchronization

ActiveCN106992720AUniform positionUniform torqueMultiple dynamo-electric motors speed regulationEqualizationControl theory

The present invention provides a method and device for multi-shaft coupling moment balance control based on position synchronization. The method comprises the following steps: controlling a main shaft and a slave shaft to perform synchronous operation through the given value of the same position; determining the given value of an additional position according to the moment deviation values of the main shaft and the slave shift; and regulating the moment equalization of the main shaft and the slave shaft based on the given value of the additional position. The method and device for multi-shaft coupling moment balance control based on position synchronization can ensure the position synchronization and the moment equalization of the main shaft and the slave shift based on position synchronization control, and are suitable for and include but not limited to the machinery coupling conditions of pure rigid connection, pure flexible connection and semi-rigid connection.

Owner:SIEMENS FACTORY AUTOMATION ENG

Multi-point applied force system equalizing regulation device

The invention discloses a multi-point applied force system equalizing regulation device. The multi-point applied force system equalizing regulation device is composed of a plurality of tension regulating modules coaxially installed between two end portion bearing seats. The number of the tension regulating modules is consistent with the quantity of applied force. Each tension regulating module comprises a shaft, an inner gear, a roller, a rope, a pinion and an intermediate gear. The shafts are provided with the inner gears, the rollers and the intermediate gears in sequence, the pinions on therollers and the rollers constitute a planet wheel train composite structure, and two sides of the pinions mesh with the inner gears and the intermediate gears separately. The adjacent tension regulating modules are connected by second connecting pieces to transfer torque, or the middles of the adjacent tension regulating modules are connected by intermediate bearing seats with slip-rings and fixed to lifting containers. The end portion bearing seats are installed on the shafts through bearings and fixedly connected with the tension regulating modules located on two end potions through first connecting pieces. The multi-point applied force system equalizing regulation device overcomes the problem that a multi-point applied force system with multiple ropes, chains or other elastic bars as load-bearing parts cannot be balanced, the structure is simple, and the regulating is fast and convenient.

Owner:CHINA UNIV OF MINING & TECH

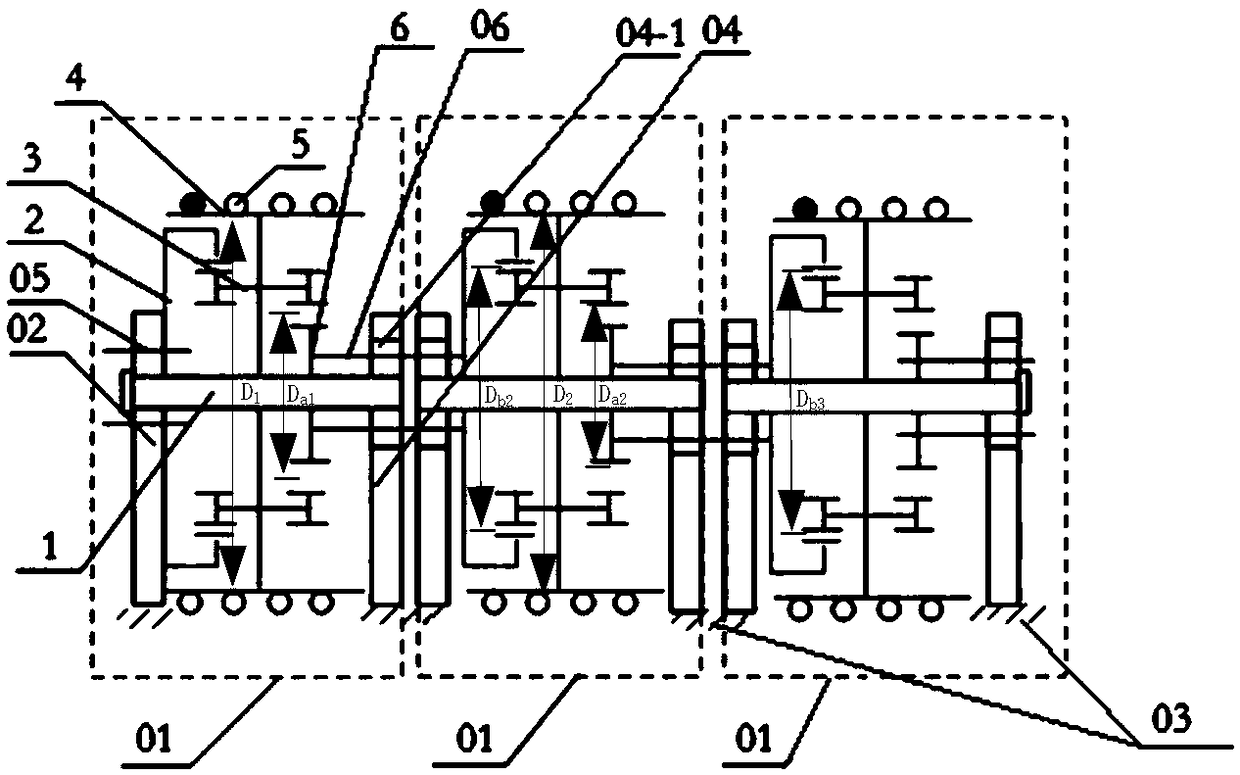

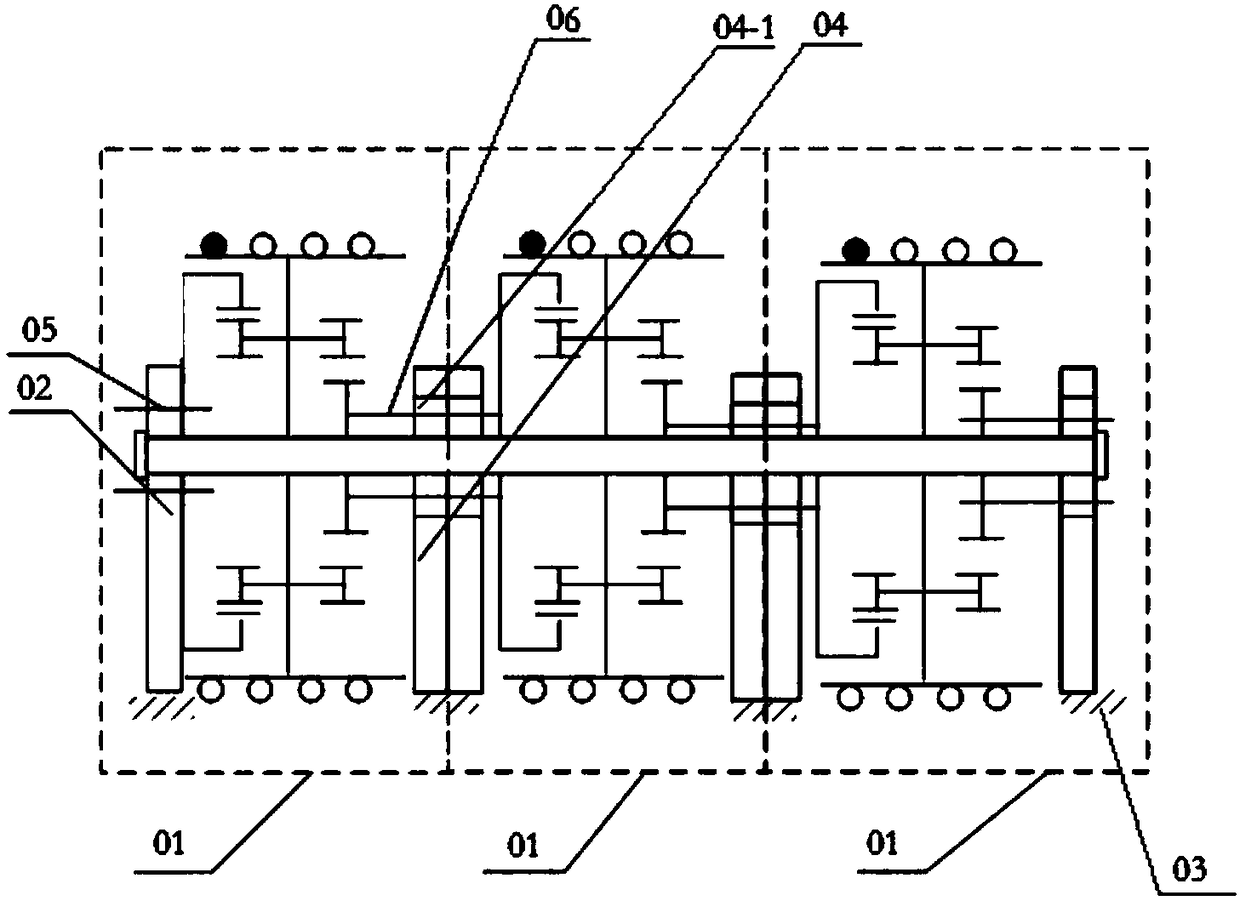

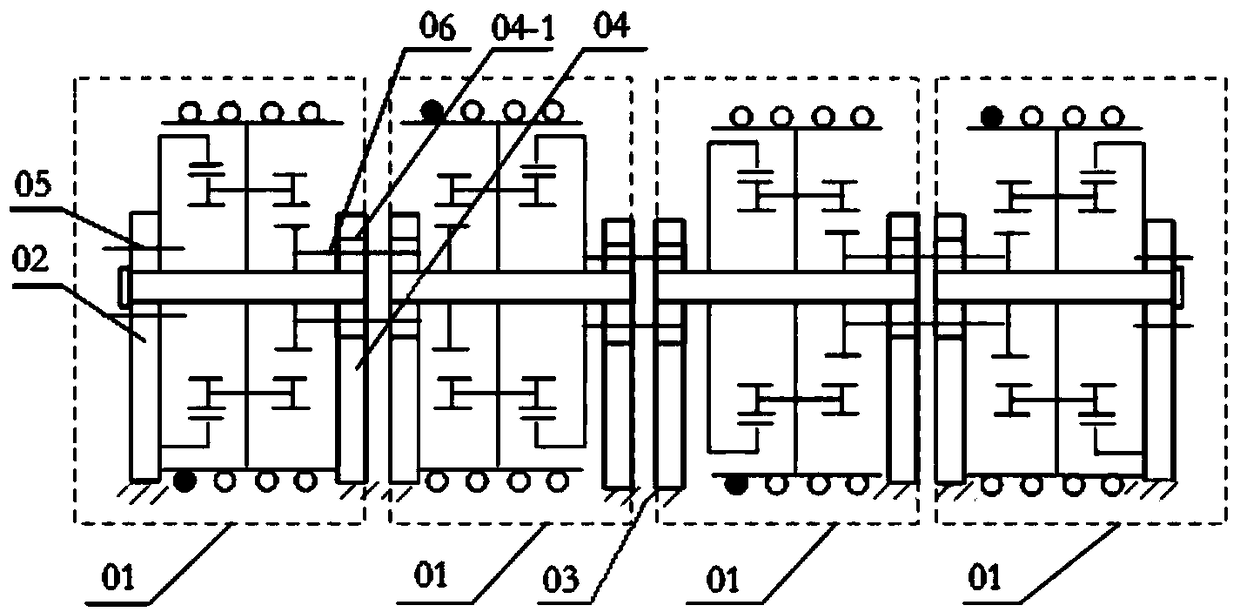

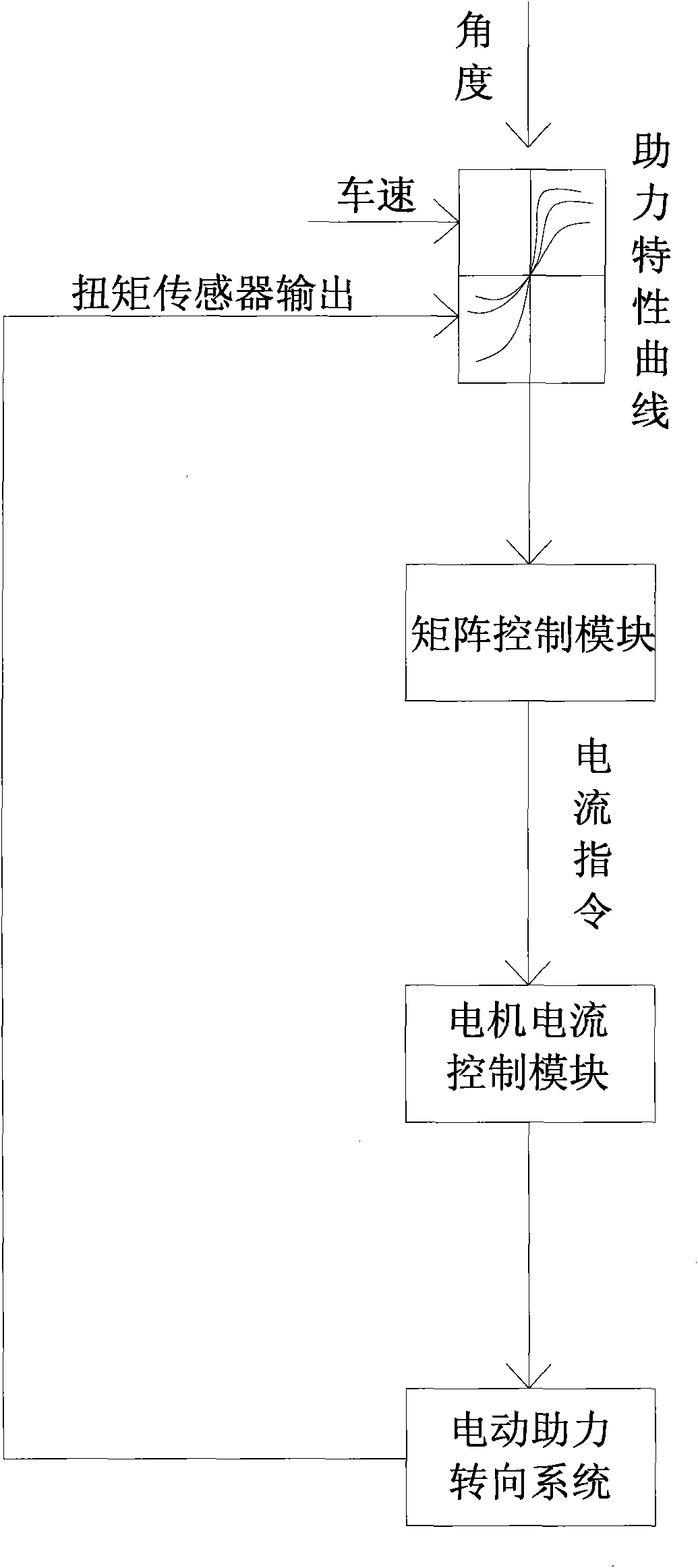

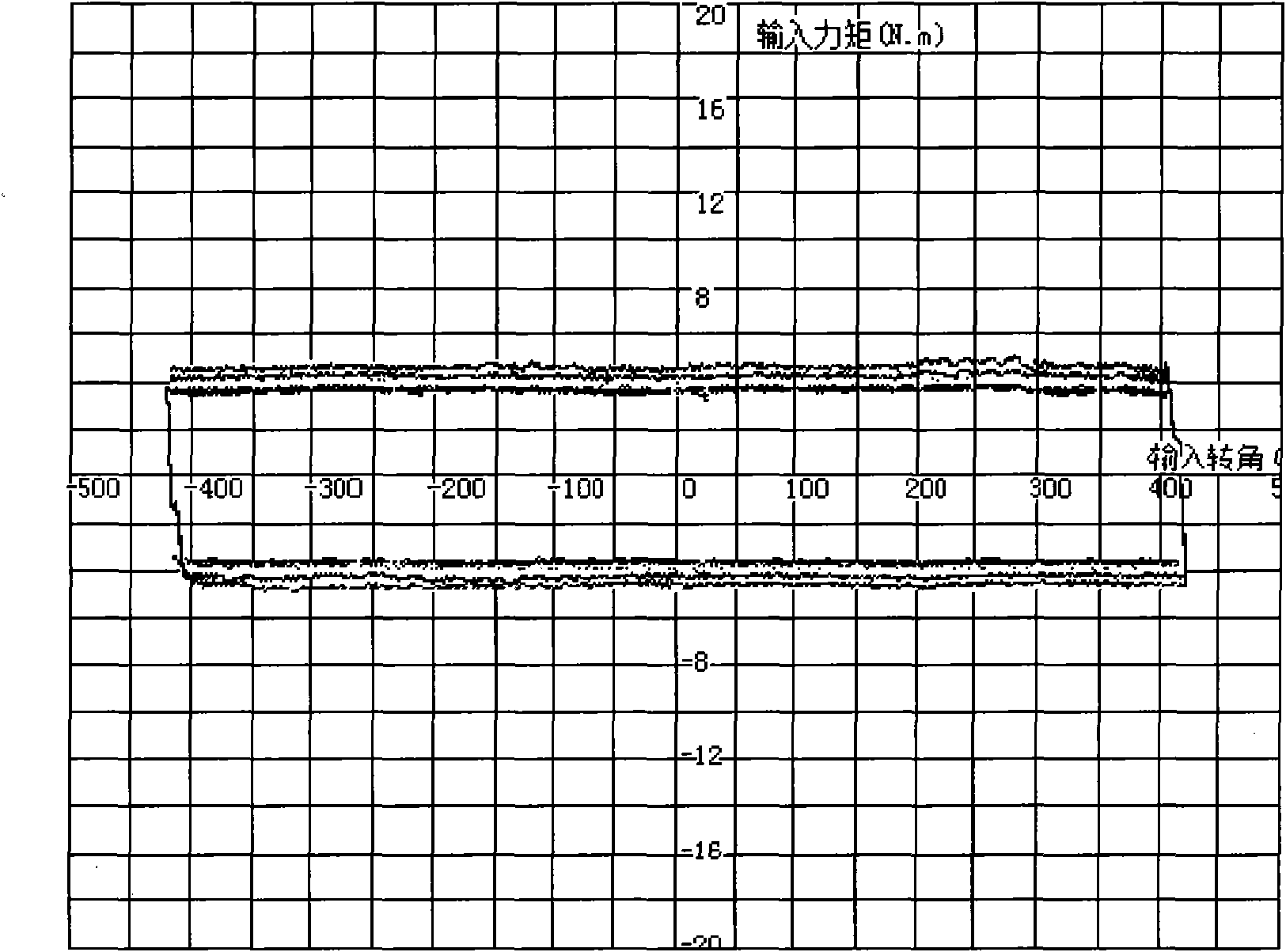

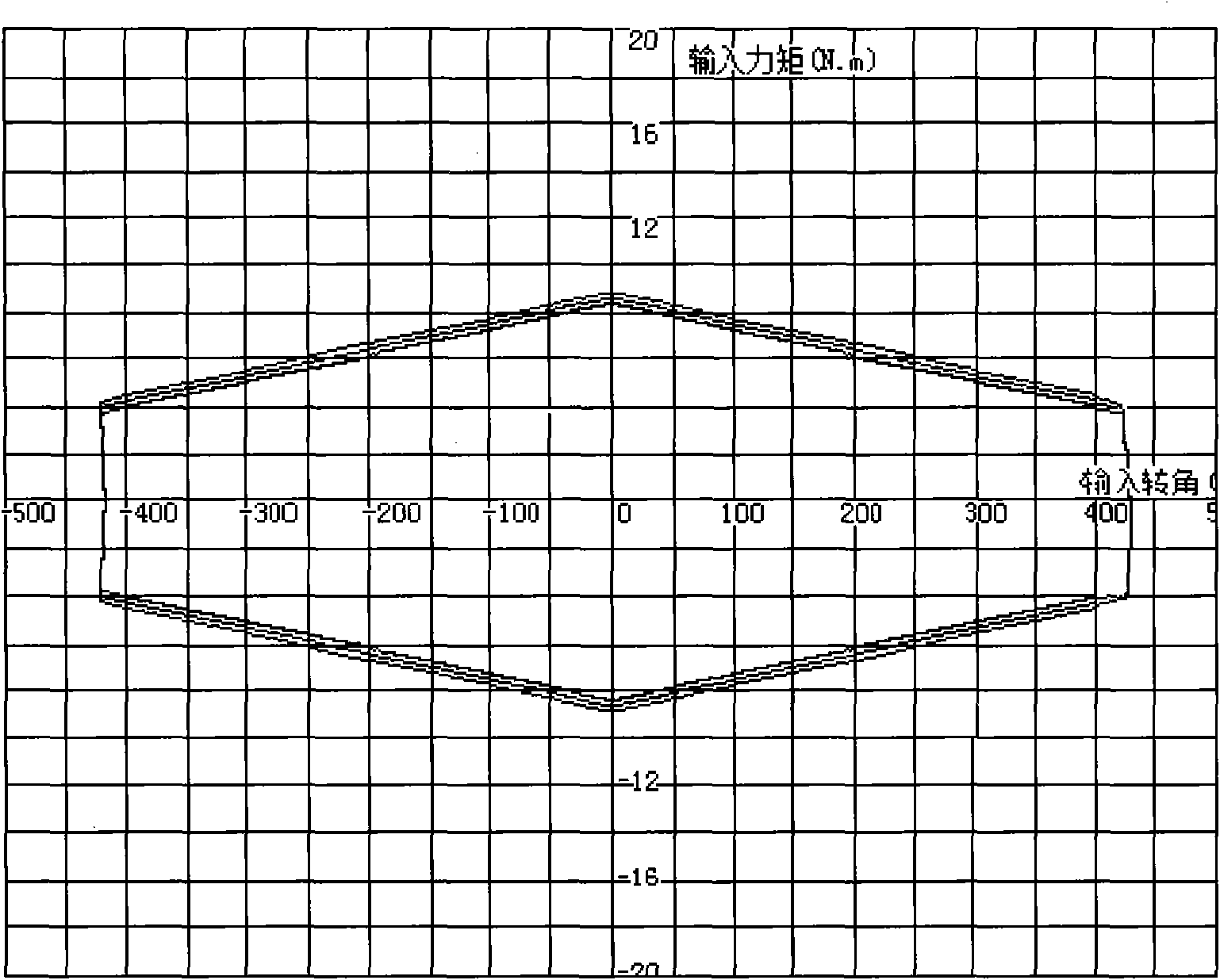

Angle signal-based electric power steering control method

InactiveCN101962036AUniform torqueGood sense of operationSteering linkagesAutomatic steering controlElectric machineryEngineering

The invention provides an angle signal-based electric power steering control method. On the basis that basic assisted motor current applied during the conventional electric power steering is based on torque and speed, angle is used as a third parameter of the basic assisted current to ensure that the basic assisted current changes along with changes of the torque, the speed and the angle. The method can solve the problem that a vehicle has different torques of the steering wheel under different steering angles, so the torques at different angles are uniform, and the operation sense becomes better.

Owner:HANGZHOU ZHENGQIANG ELECTRONICS TECH

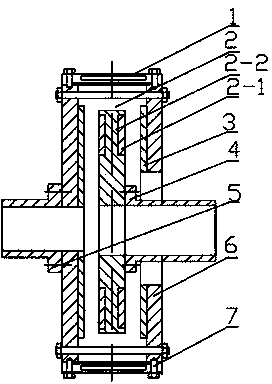

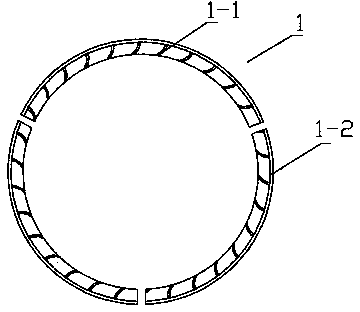

Permanent magnet transmission mechanism

InactiveCN103647433AImprove cooling effectPrevent flying outDynamo-electric gearsSupports/enclosures/casingsPermanent magnet rotorElectrical conductor

The invention relates to a permanent magnet transmission mechanism which comprises a conductor rotor and a permanent magnet rotor. The conductor rotor comprises a pair of rotor plates which are fixedly connected through bolts, and the permanent magnet rotor is arranged between the rotor plates. The permanent magnet transmission mechanism is characterized in that each rotor plate comprises a substrate and a conductor disk arranged on the substrate, a shield is arranged on the periphery of each substrate, wind wings are arranged on each shield, each shield at least includes two arc-shaped shields, and the permanent magnet rotor comprises a permanent magnet disk and magnetic steel blocks arranged on two surfaces of the permanent magnet disk. The permanent magnet transmission mechanism has the advantages that safety can be ensured, and the permanent magnet transmission mechanism has a fine cooling effect.

Owner:山东东朋自控仪表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com