Oil-sealed vane rotary vacuum pump

a vacuum pump and oil seal technology, applied in the direction of piston pumps, magnetic circuit rotating parts, magnetic circuit shapes/forms/construction, etc., can solve the problems of positive influence on vibration and noise, reduce manufacturing costs, and reduce failure danger, so as to reduce power consumption, uniform torque, and uniform relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

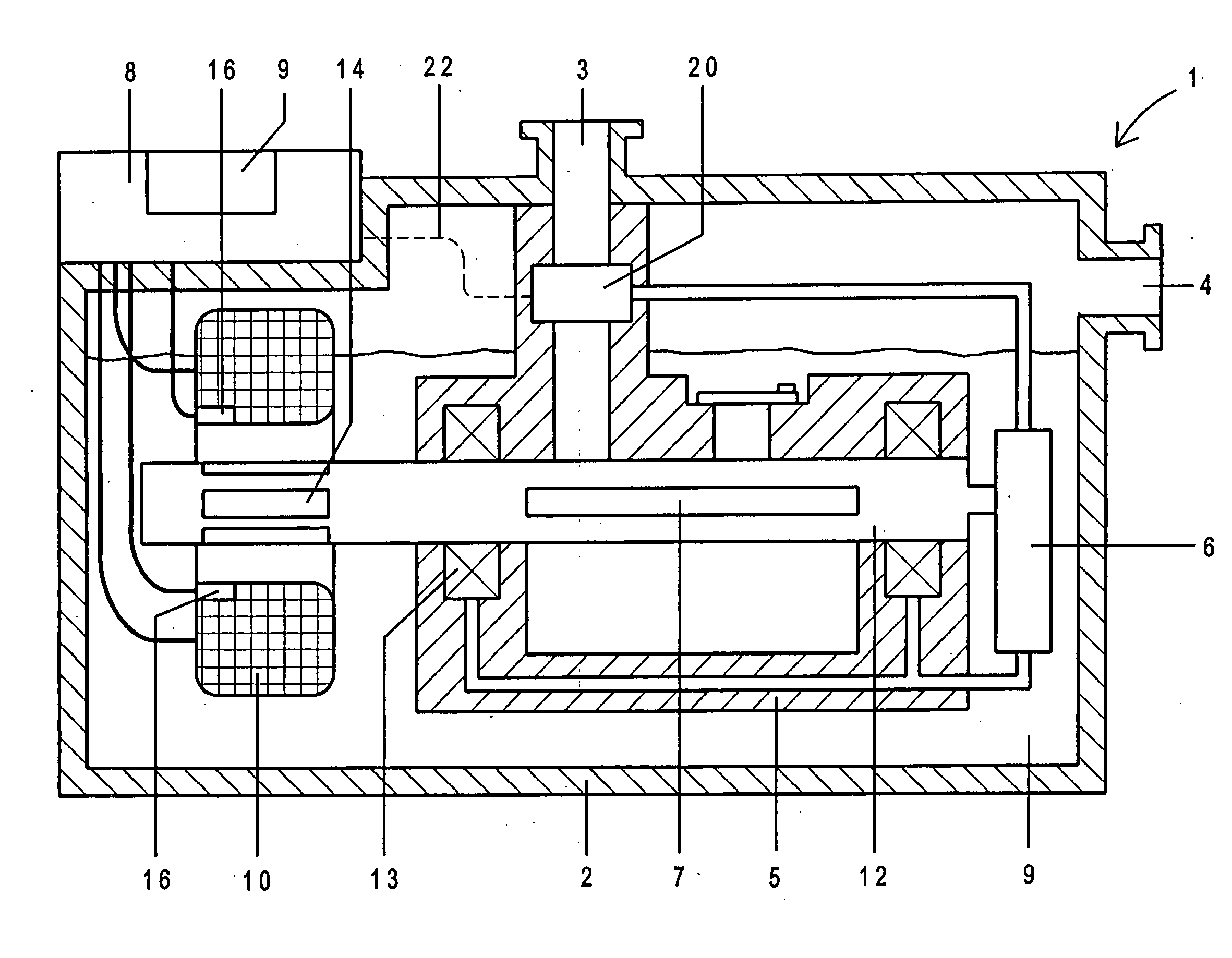

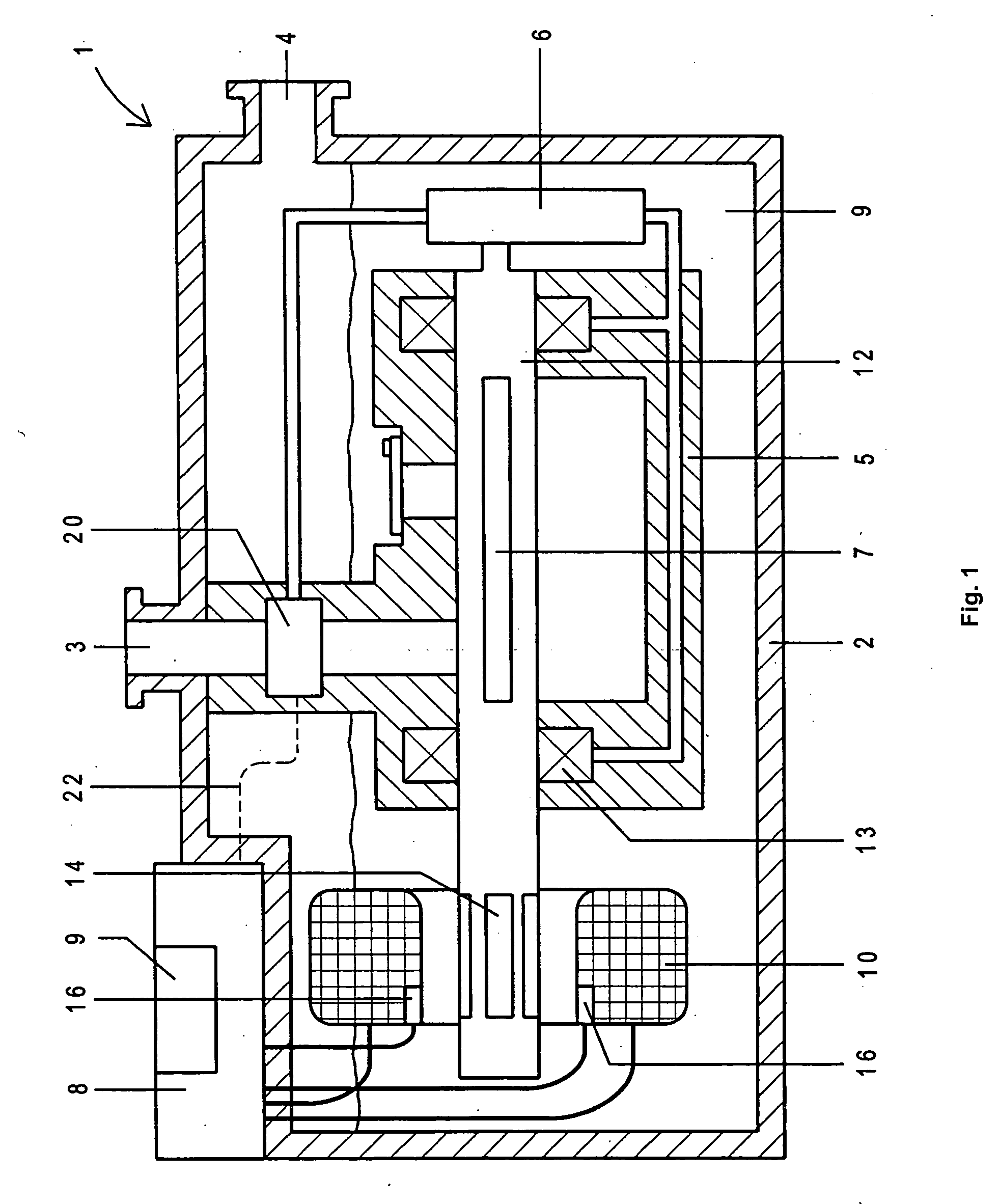

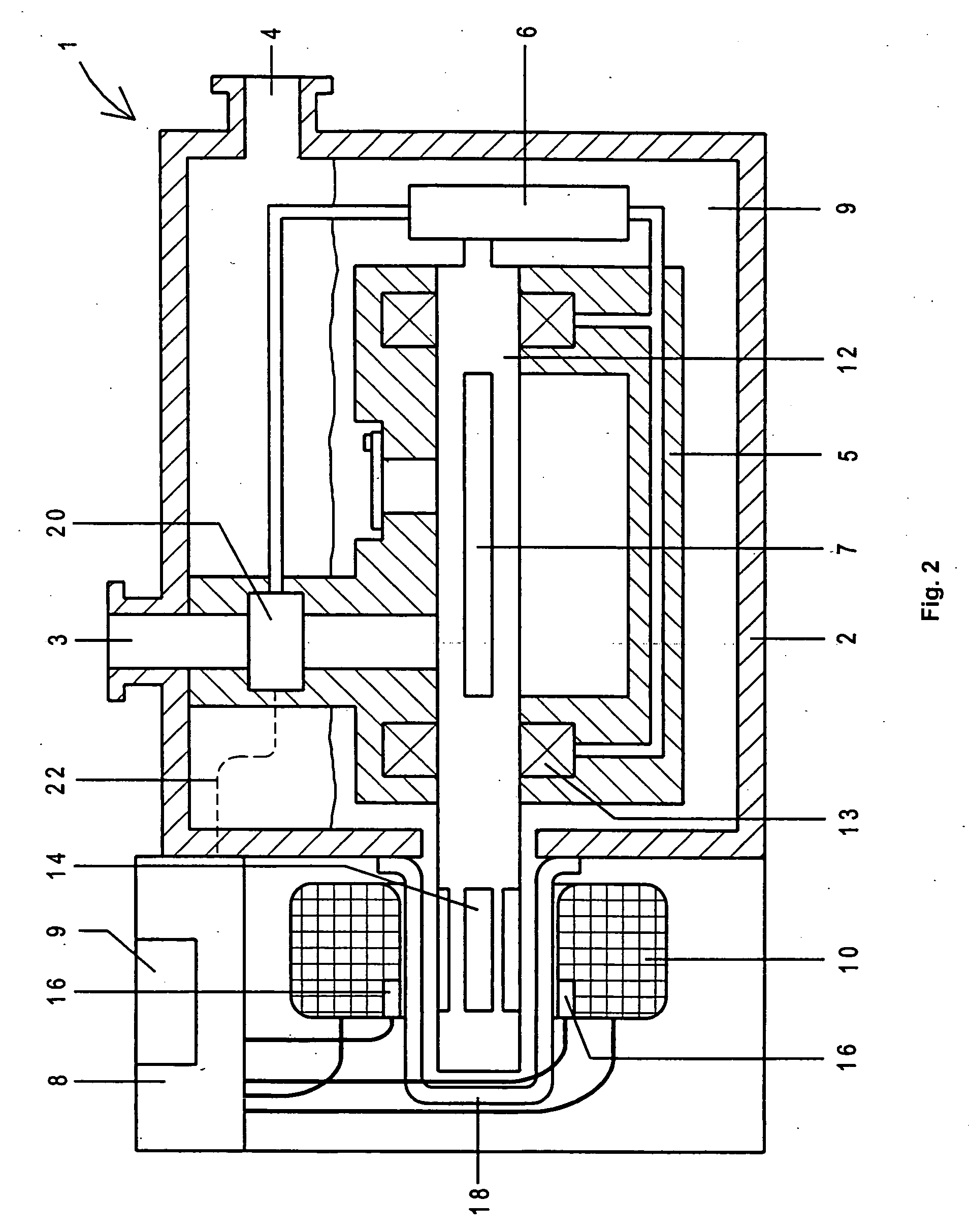

[0019] An oil-sealed, vane rotary vacuum pump 1 according to the present invention, which is shown in FIG. 1, includes a housing 2 having a gas inlet 3 and a gas outlet 4, and a pumping system 5 located in the interior of the housing 2. The pumping system 5 includes a shaft 12 which is supported in bearings 13. The pumping effect is produced by rotation of the shaft 12 together with rotary vanes 7. A hydraulic oil pump 6 provides for lubrication of the bearings 13 which are formed as bearings and supplies a high vacuum safety valve 20 with oil. This safety valve 20 is closed when the shaft 12 does not rotate any more, which leads to reduction in oil pressure provided by the oil pump 6.

[0020] On the shaft 12, there are arranged a plurality of permanent magnets 14 which are surrounded by coils 10. The coils 10 produce a rotatable magnetic field the position of which changes by an electronic commutation and thereby provides for rotation of the shaft 12. Instead of two shafts of conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com