Circumferential inhaul cable structure of vertical axis wind turbine

A wind turbine and cable structure technology, which is applied to wind turbines, wind turbines at right angles to the wind direction, motors, etc., can solve the problems of large vibration amplitude of the overall driving torque of the wind turbine, reduced power generation efficiency, and deteriorated aerodynamic characteristics, etc. Achieve the effect of improving sports performance and force, improving power generation efficiency, and preventing circumferential jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

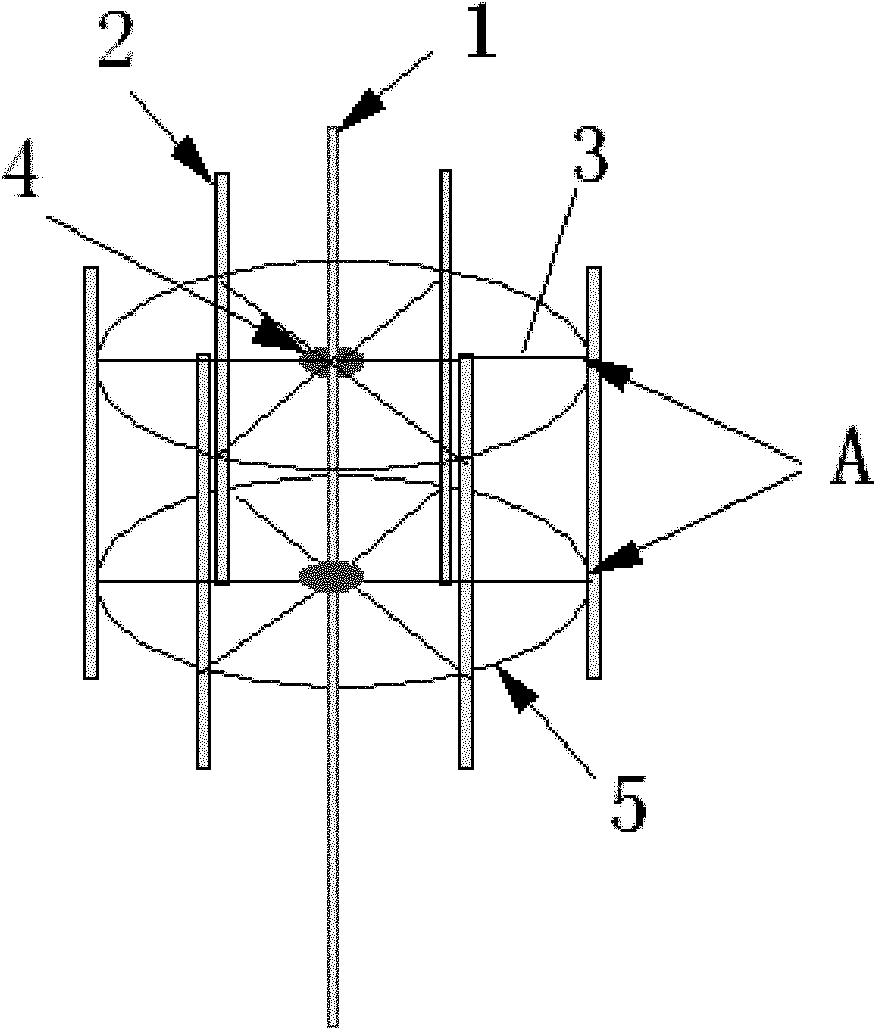

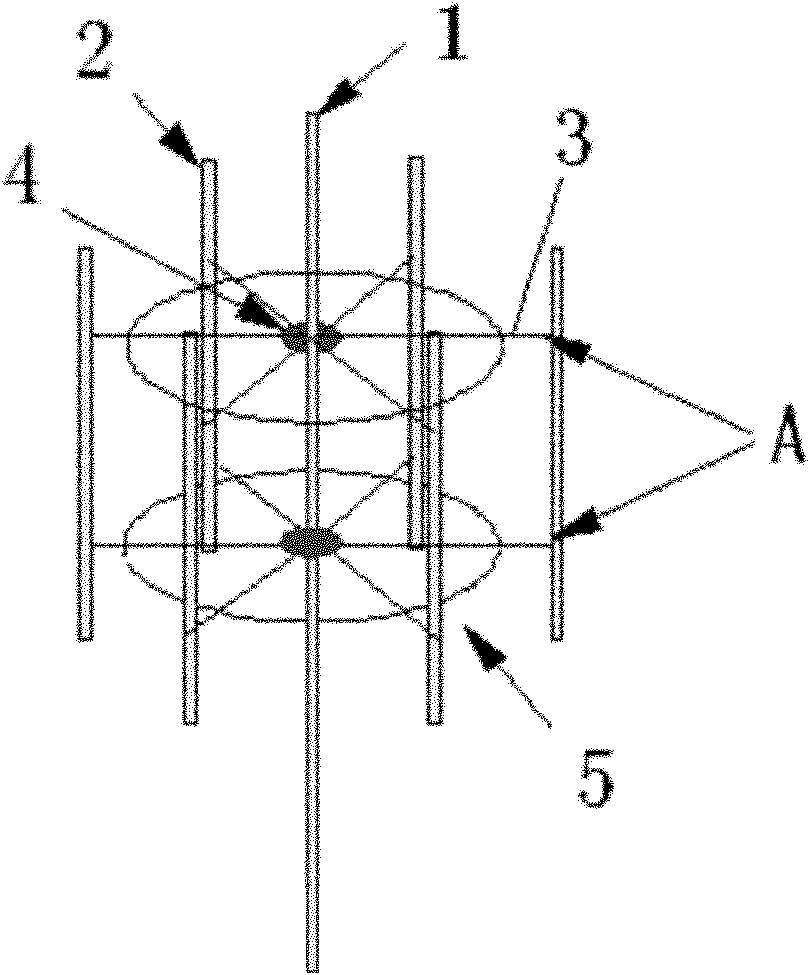

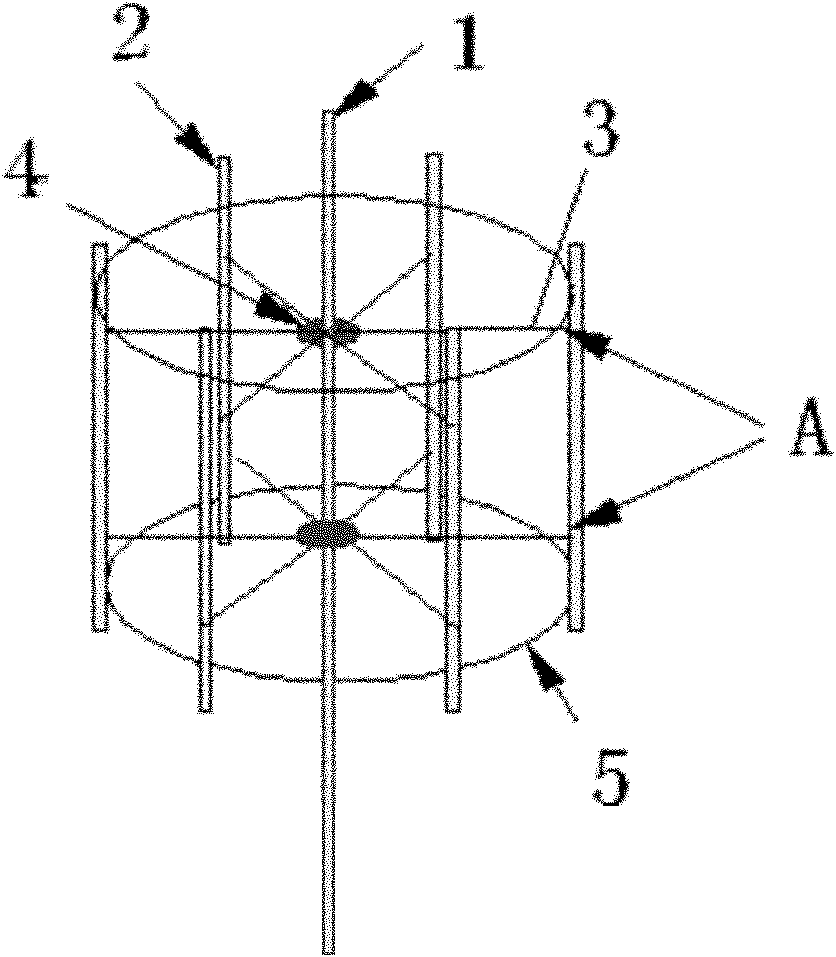

[0028] Such as figure 1 As shown, a circumferential cable structure of a vertical axis wind power generator, wherein the wind power generator includes a tower column 1, a wind wheel and a generator, the wind wheel includes a support wheel and blades 2, and the support wheel It includes a number of support rods 3, the support rods 3 are arranged radially and placed in the same horizontal plane, the inner ends of each support rod 3 are evenly distributed and fixed on the outer rotor 4 of the generator in the circumferential direction, the blades 2 and the The outer ends of the support rods 3 are fixedly connected; the support rods are fixed on the generator external rotor 4 on the tower column 1 to form support wheels; Cables are steel cables 5, each steel cable 5 is placed between two adjacent blades and / or support rods of the wind wheel, and the two ends of the flexible member are connected between the support rods 3 and the blades 2 The joint of the wind rotor is connected o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com