High pressure exhausting silencing apparatus

A noise reduction device and high-voltage technology, which is applied in the direction of sound-emitting devices and instruments, can solve problems such as difficult control, strong air noise, and complex structure, and achieve the goal of reducing audible noise, reducing air noise, and eliminating air noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

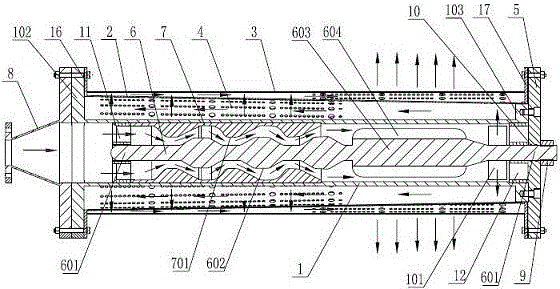

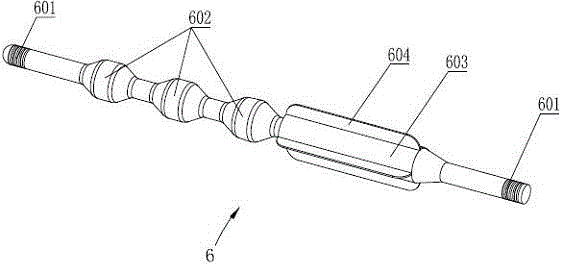

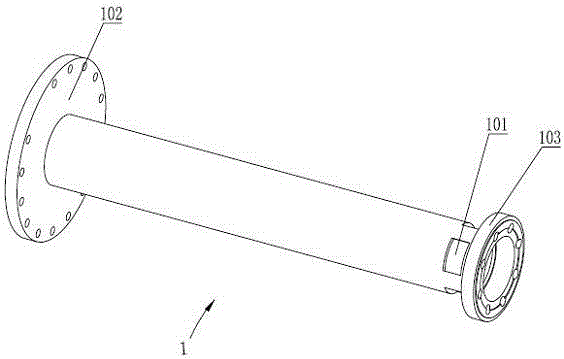

[0031] See figure 1 , figure 2 , image 3 , the present invention includes a throttling tube 1, a perforated inner tube 2 and a perforated outer tube 3 that are sequentially socketed from the inside to the outside, and the three are coaxially socketed, and the perforated inner tube 2 and the perforated outer tube 3 are provided with a plurality of diameters To the through microhole 4, one end of the throttle tube 1 is the air intake end, and the other end of the throttle tube 1 is provided with a radial through hole 101; The intake end is fixedly connected, the other ends of the throttle tube 1, the perforated inner tube 2 and the perforated outer tube 3 are all fixedly connected to the cover plate 5, the outer wall of the throttle tube 1 and the inner wall of the perforated inner tube 2, and the perforated inner tube 2 A cavity for ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com