Dual-motor synchronization control method, system and computer readable storage medium

A synchronous control and dual-motor technology, which is applied in the direction of multiple motor speed adjustment, can solve the problems of increased cost and complexity, excessive torque deviation of the master-slave shaft motor, and the position frequency division output signal is susceptible to external interference, etc., to achieve The effect of reducing cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

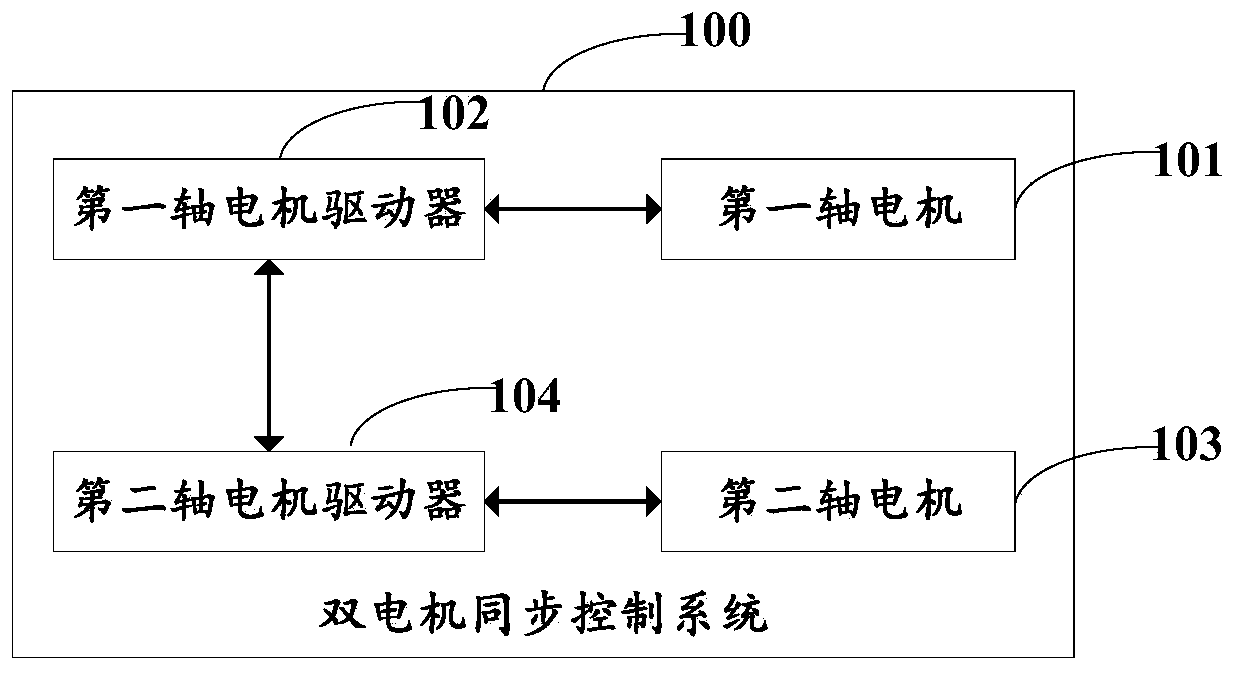

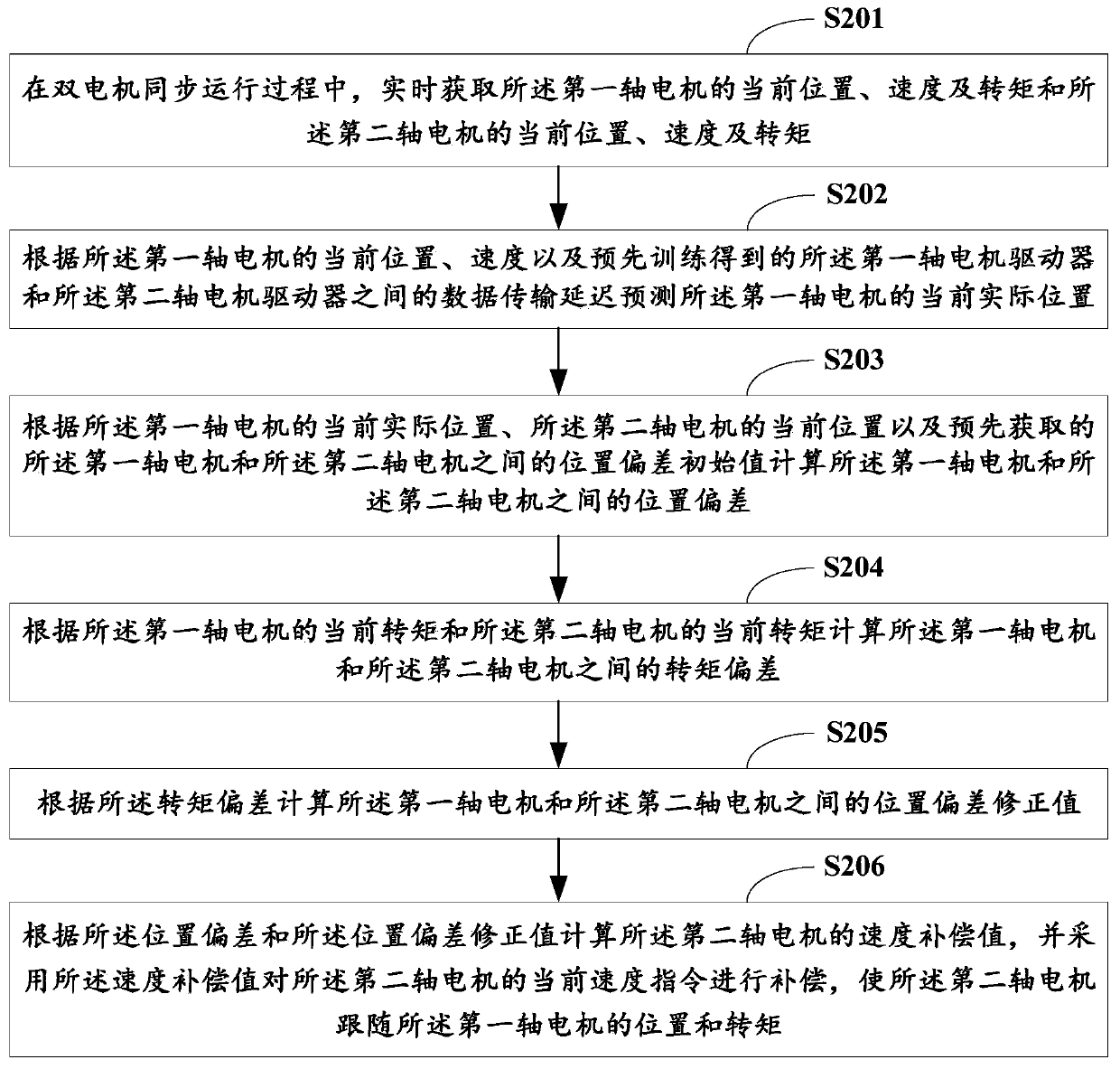

[0055] figure 2 It is a schematic flow chart of the implementation of the dual-motor synchronous control method provided in Embodiment 1 of the present invention, which is applied to figure 1 The dual-motor synchronous control system 100 is executed by figure 1 The second axis motor driver 104 in the dual motor synchronous control system 100 is shown. see figure 2 As shown, the dual-motor synchronous control method provided in this embodiment may include the following steps:

[0056] Step S201 , during the synchronous operation of the two motors, the current position, speed and torque of the first shaft motor 101 and the current position, speed and torque of the second shaft motor 103 are acquired in real time.

[0057] In a specific implementation manner, the first shaft motor 101 and the second shaft motor 103 will feed back their respective The current position, speed and torque of the first shaft motor driver 102 need to send the first motor to the The current posit...

Embodiment 2

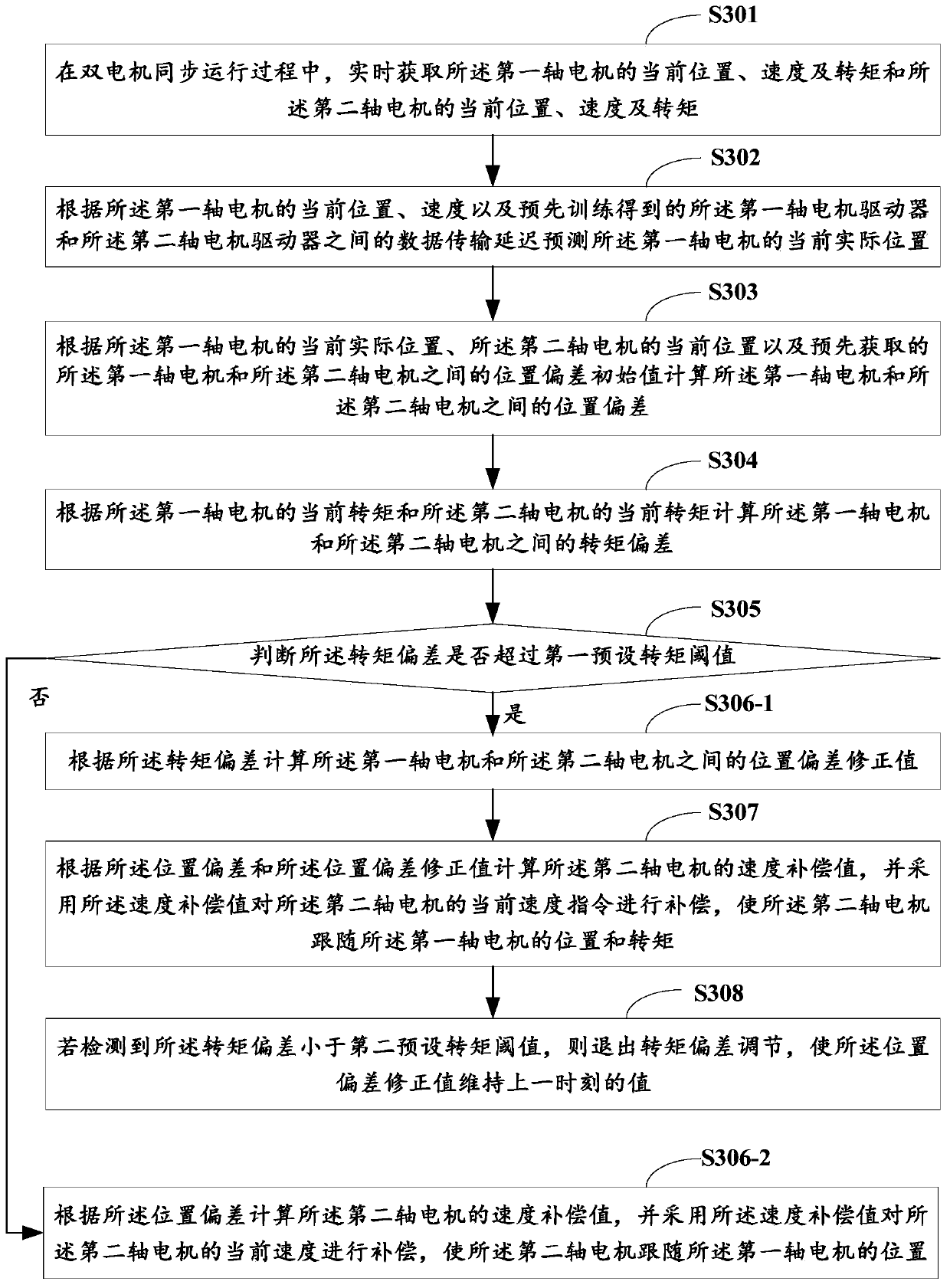

[0094] image 3 It is a schematic flow chart of the implementation of the dual-motor synchronous control method provided in Embodiment 2 of the present invention. This method is applied to figure 1 The dual-motor synchronous control system 100 is executed by figure 1 The second axis motor driver 104 in the dual motor synchronous control system 100 is shown. see image 3 As shown, the dual-motor synchronous control method provided in this embodiment may include the following steps:

[0095] Step S301, acquiring the current position, speed and torque of the first shaft motor 101 and the current position, speed and torque of the second shaft motor 103 in real time during the synchronous operation of the dual motors;

[0096] Step S302, predicting the first axis according to the current position and speed of the first axis motor 101 and the data transmission delay between the first axis motor driver 102 and the second axis motor driver 104 obtained through pre-training The cu...

Embodiment 3

[0122] Figure 4 It is a schematic structural diagram of the second-axis motor driver 104 in the dual-motor synchronous control system 100 provided by Embodiment 3 of the present invention. For convenience of description, only the parts related to this embodiment are shown.

[0123] see Figure 4 As shown, the dual-motor synchronous control system 100 provided in this embodiment includes a first-axis motor driver 102 for driving the first-axis motor 101 and a second-axis motor driver 104 for driving the second-axis motor 103. The first shaft motor driver 102 is communicatively connected with the second shaft motor driver 104, and the second shaft motor driver 104 includes:

[0124] The motor operation parameter acquisition unit 41 is used to obtain the current position, speed and torque of the first shaft motor 101 and the current position, speed and torque of the second shaft motor 103 in real time during the synchronous operation of the dual motors ;

[0125] The first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com