Patents

Literature

42results about How to "Improve pattern quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

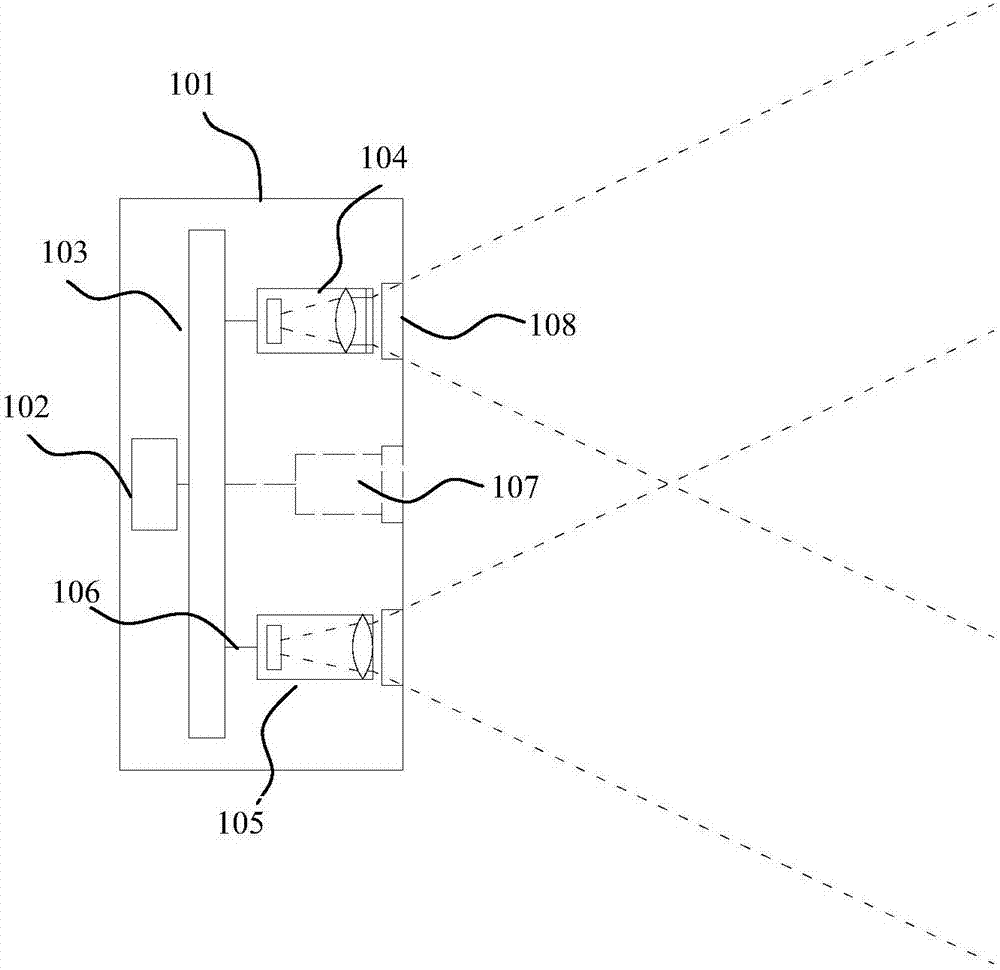

Laser projection device

InactiveCN106990659AReduce magnificationImprove pattern qualityProjectorsOptical pathImaging quality

The invention provides a laser projection device and a depth camera thereof. The laser projection device comprises a VCSEL array, a micro-lens array, a main lens and a pattern generation optical element. Micro-lens units receive and focus light beams emitted by corresponding VCSEL units. The main lens carries out secondary focusing imaging on the light beams of the micro-lens array. Through a secondary imaging optical path consisting of the micro-lens array and the main lens, quite low magnification times is achieved, so imaging quality of a laser projection module is improved and the laser projection device is quite small in size. In addition, according to the difference application scene requirements, the distance between the micro-lens array and the main lens can be adjusted in the installation to increase or decrease the magnification times, thereby satisfying the size of required spot patterns at a long distance or a small distance.

Owner:SHENZHEN ORBBEC CO LTD

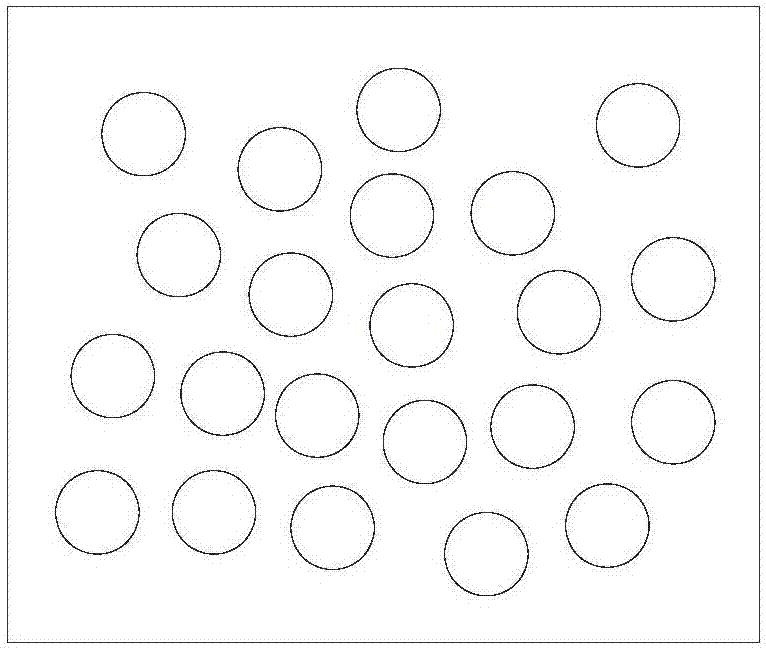

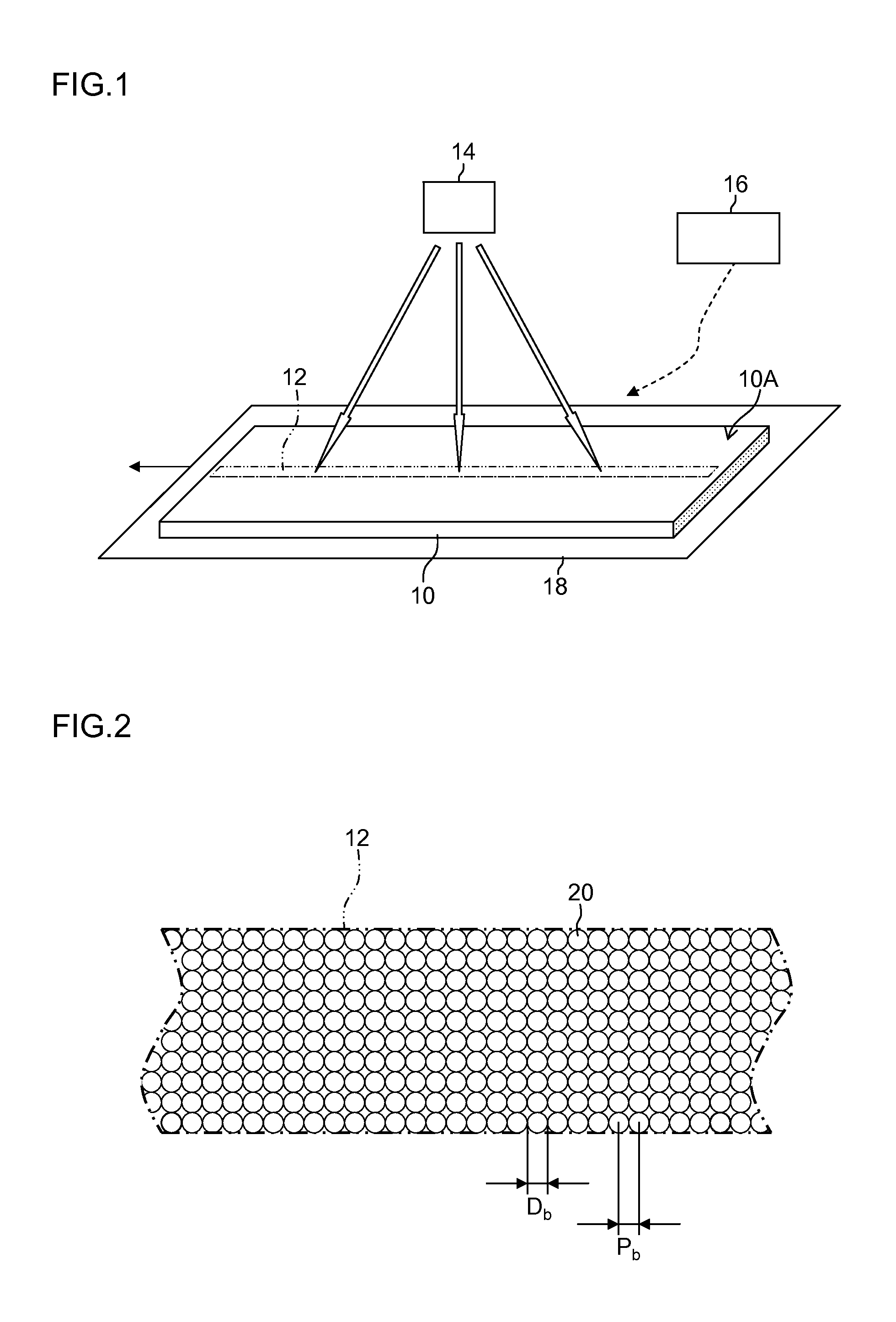

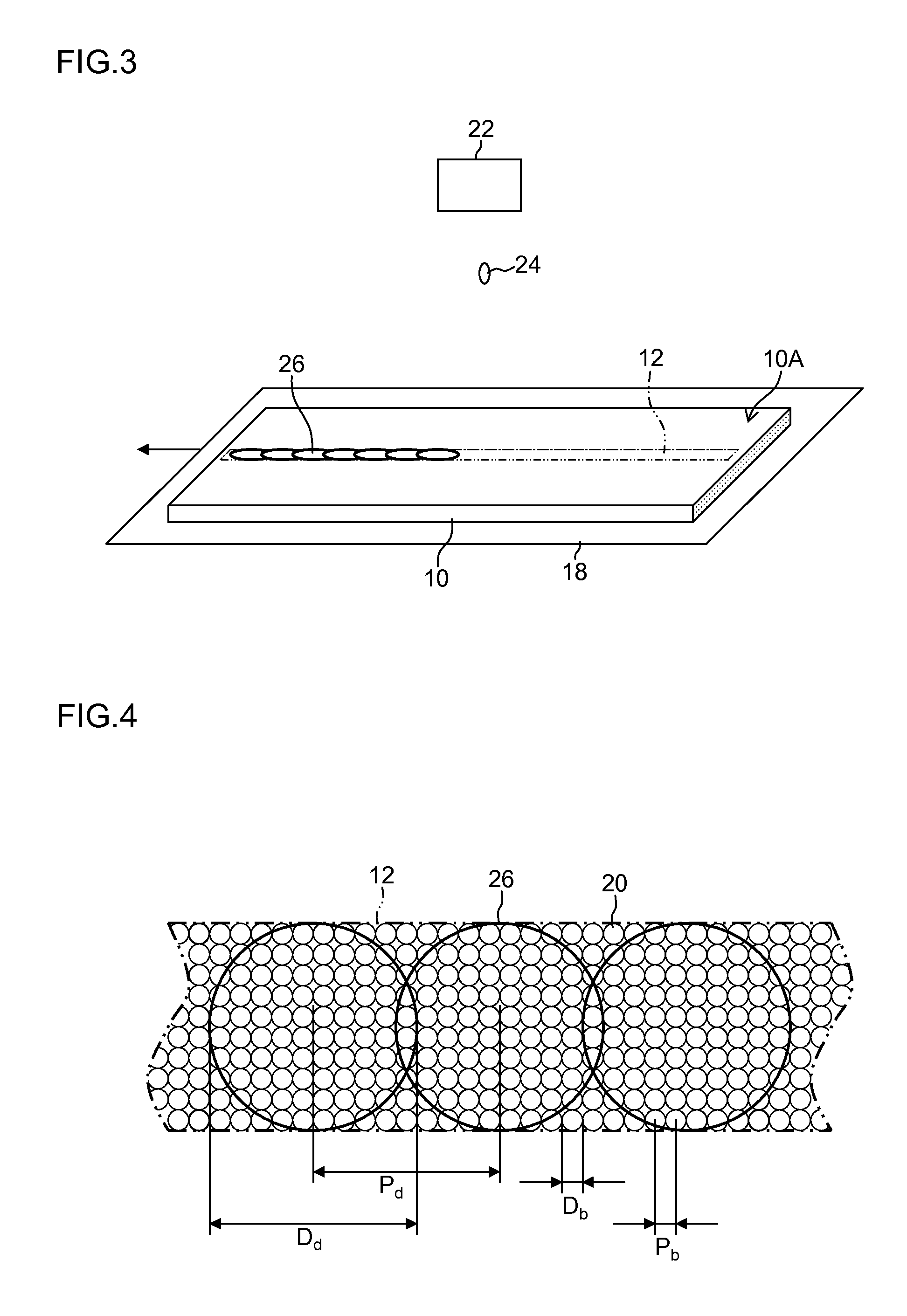

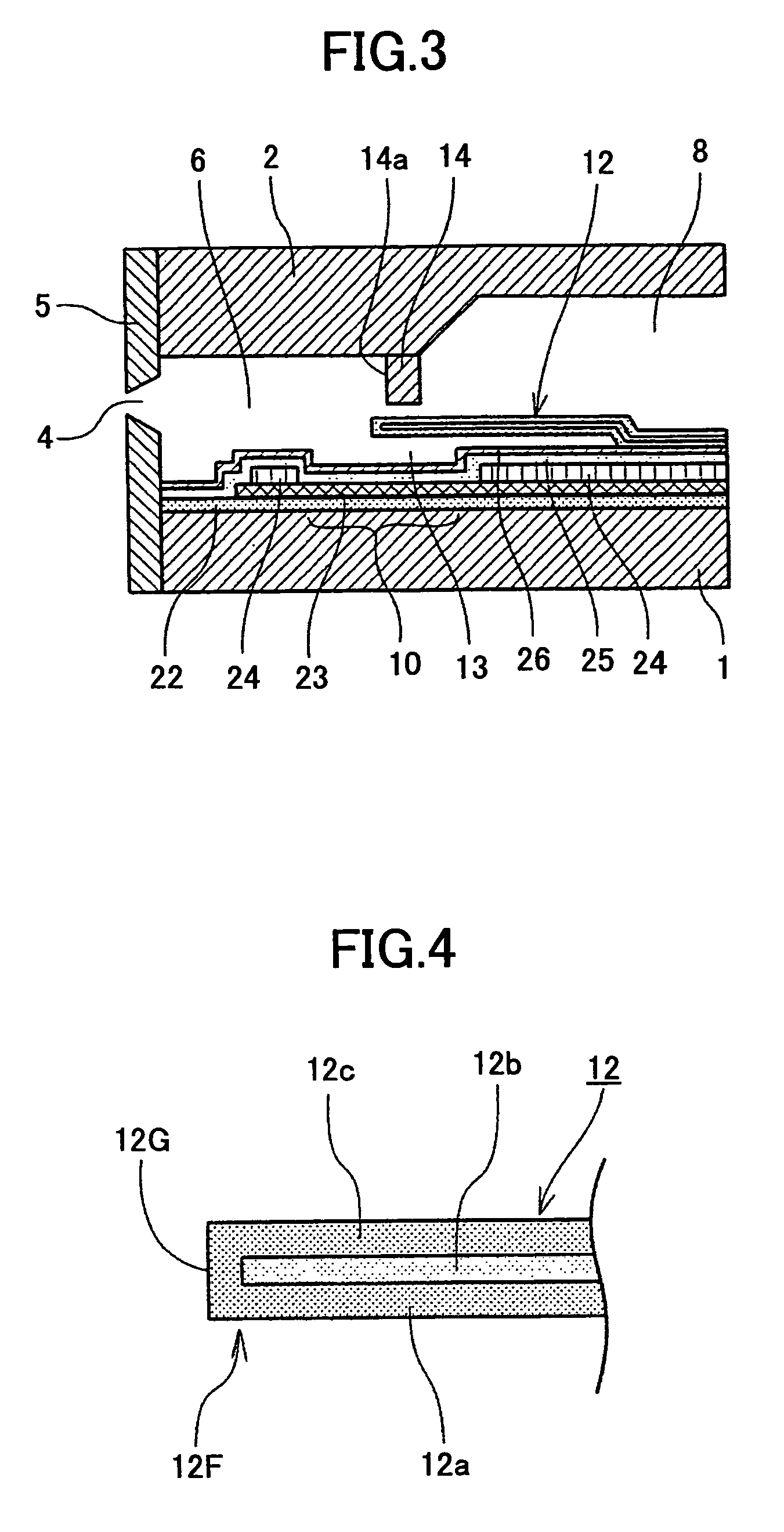

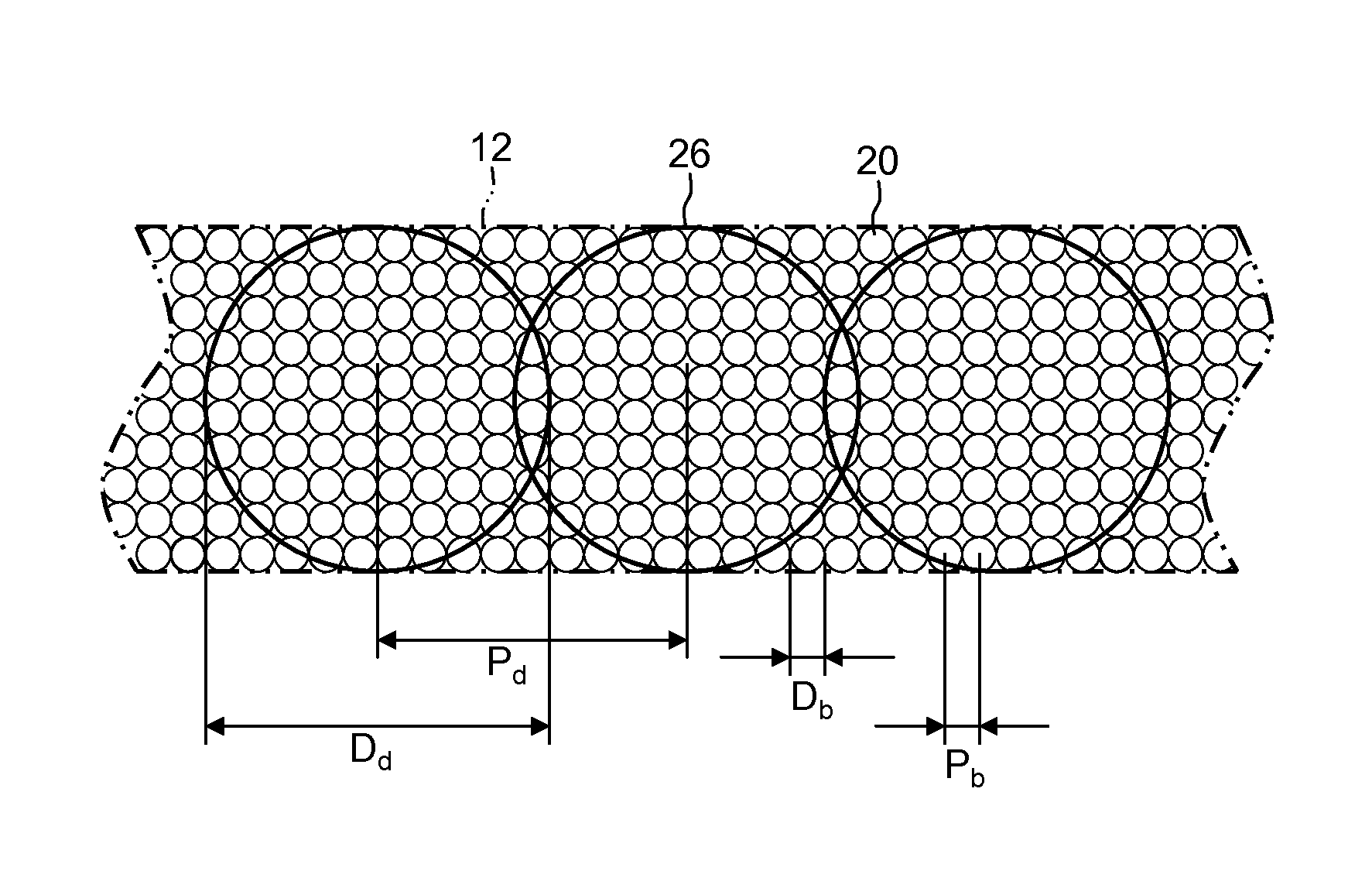

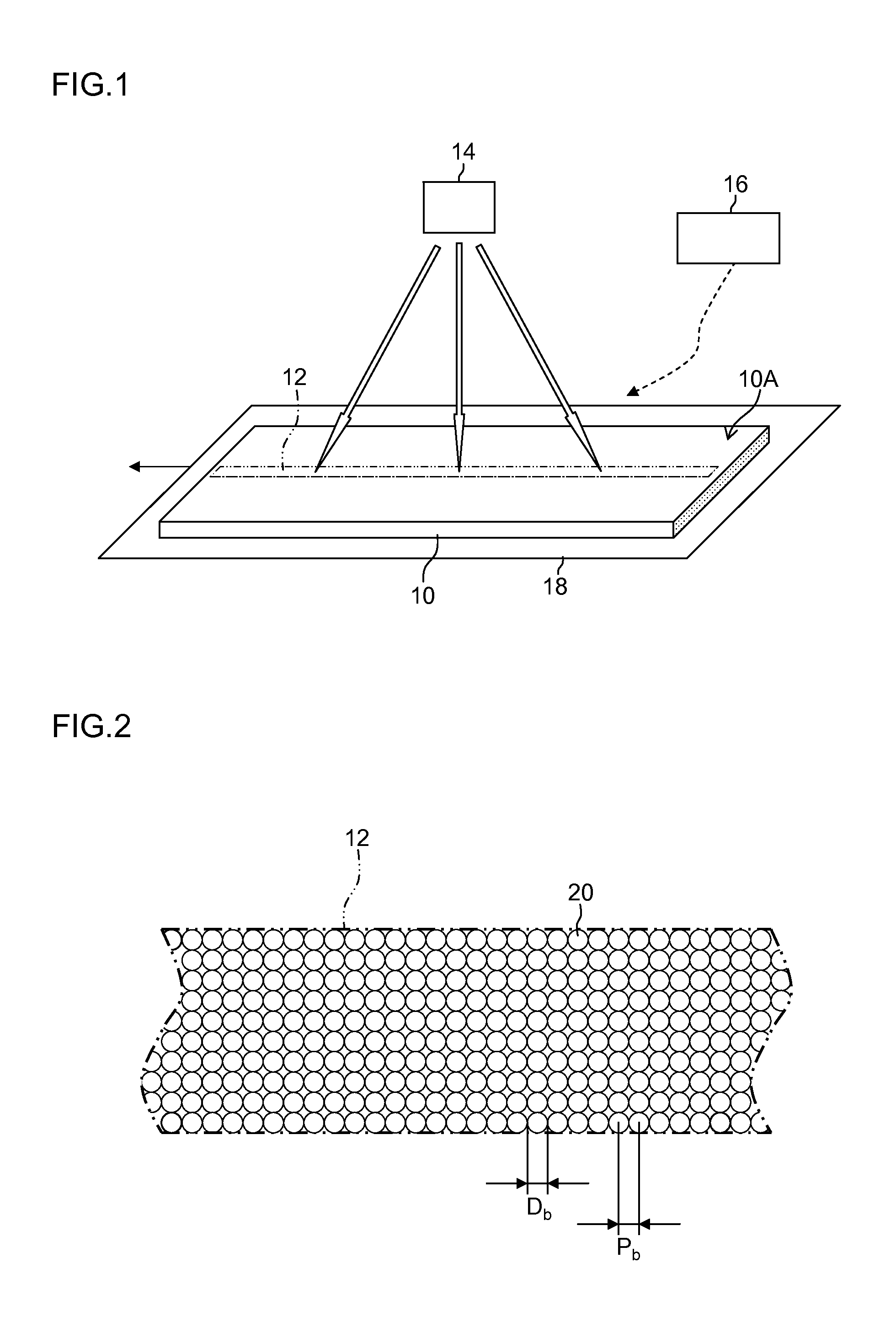

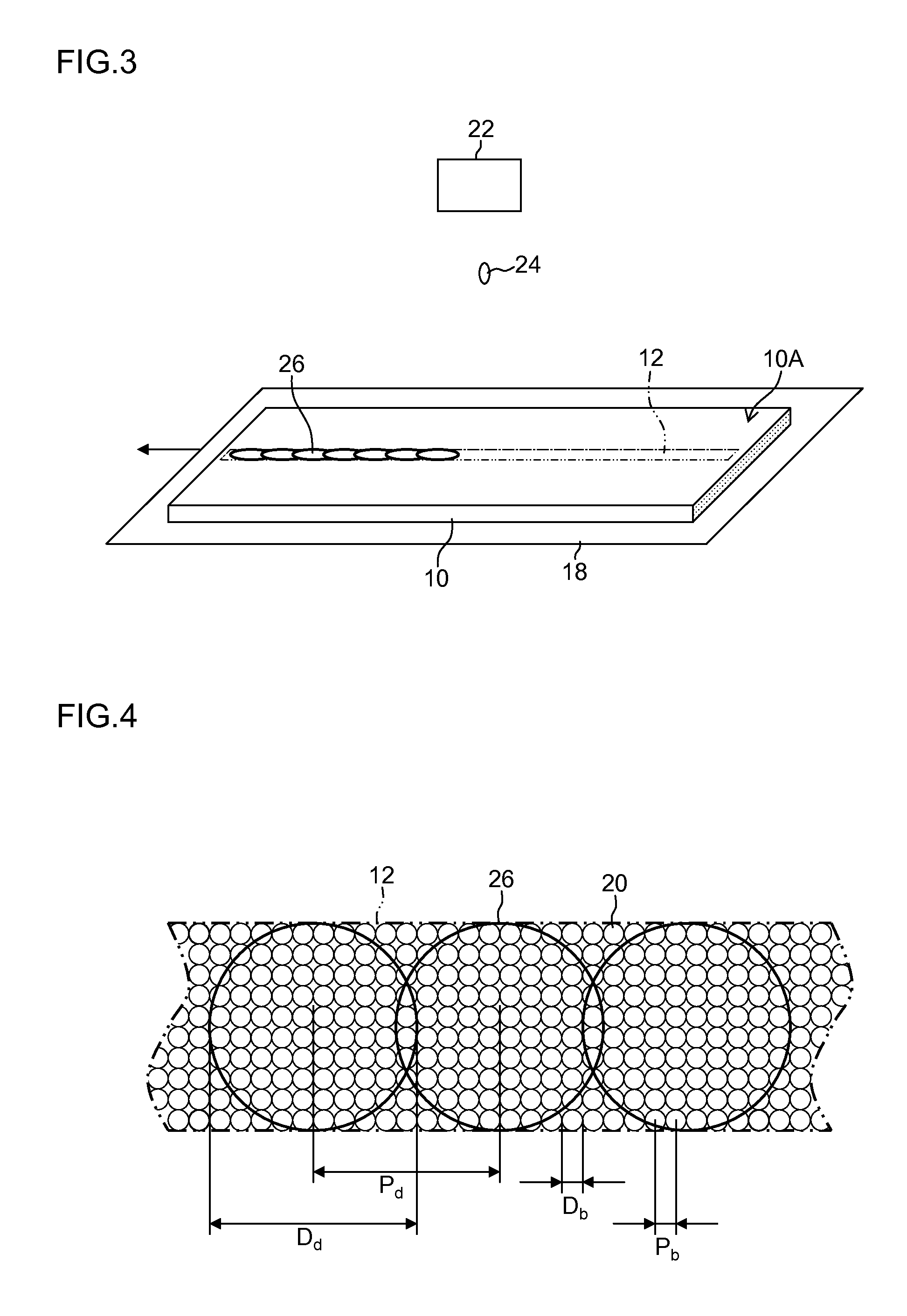

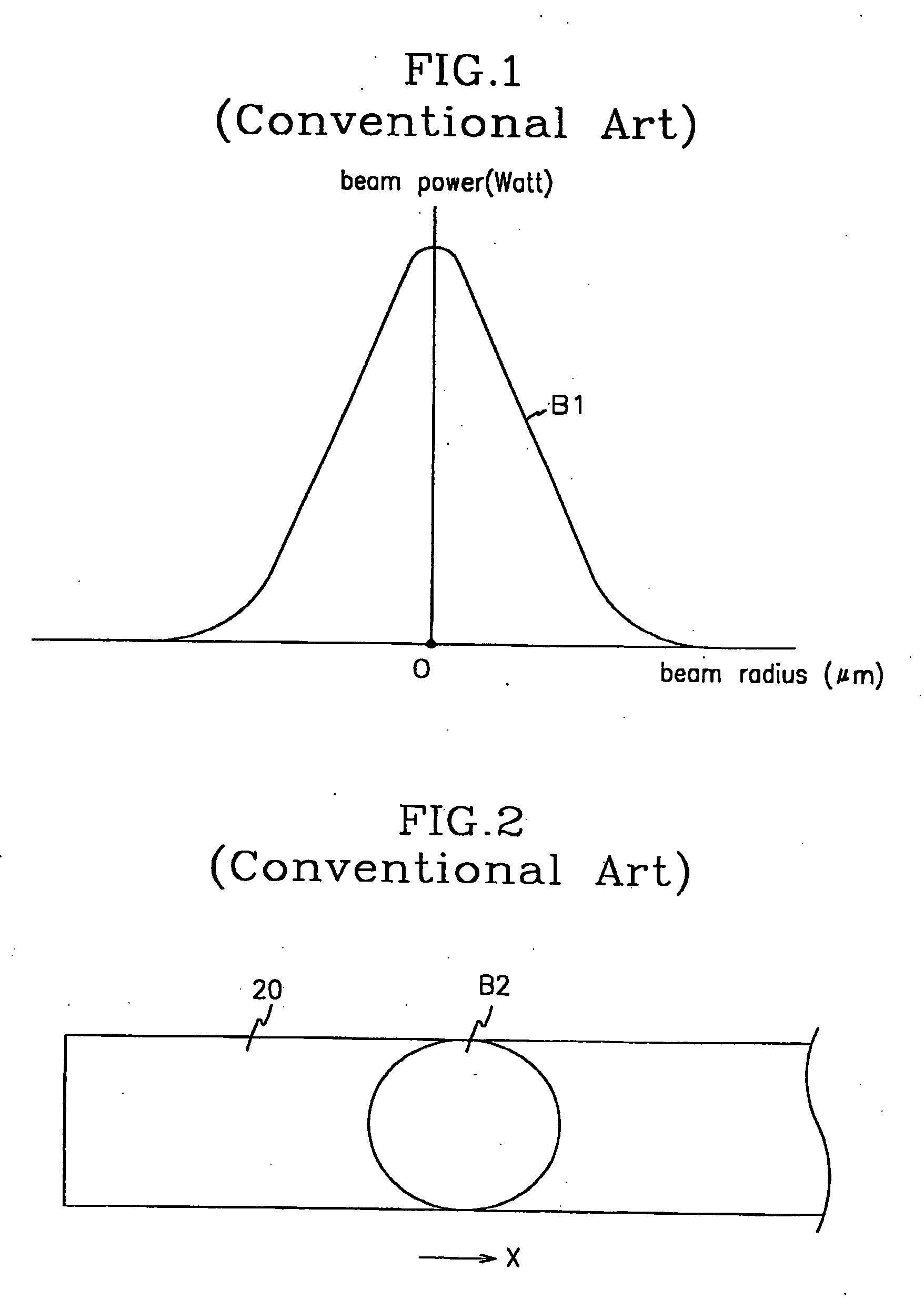

Pattern forming method and pattern forming apparatus

InactiveUS20130201240A1Avoid position deviationImprove pattern qualityPretreated surfacesTypewritersLight beamEngineering

A pattern forming method includes: a modification treatment step of, in accordance with a pattern to be formed on a pattern forming surface of a base body, applying a light beam having a width smaller than a diameter of each of dots to constitute the pattern, onto a treatment target region including at least outer edges on both sides in a width direction of a region where the pattern is to be formed in the pattern forming surface, thereby carrying out modification treatment on the treatment target region; and a droplet deposition step of ejecting and depositing droplets of a functional liquid by an inkjet method onto the region where the pattern is to be formed including the treatment target region where the modification treatment has been carried out.

Owner:FUJIFILM CORP

Liquid ejection head having improved durability against liquid, liquid cartridge having such a liquid ejection head, liquid ejection apparatus having such a liquid cartridge, image forming apparatus having such a liquid ejection apparatus, and manufacturing method of liquid ejecting head

Owner:RICOH KK

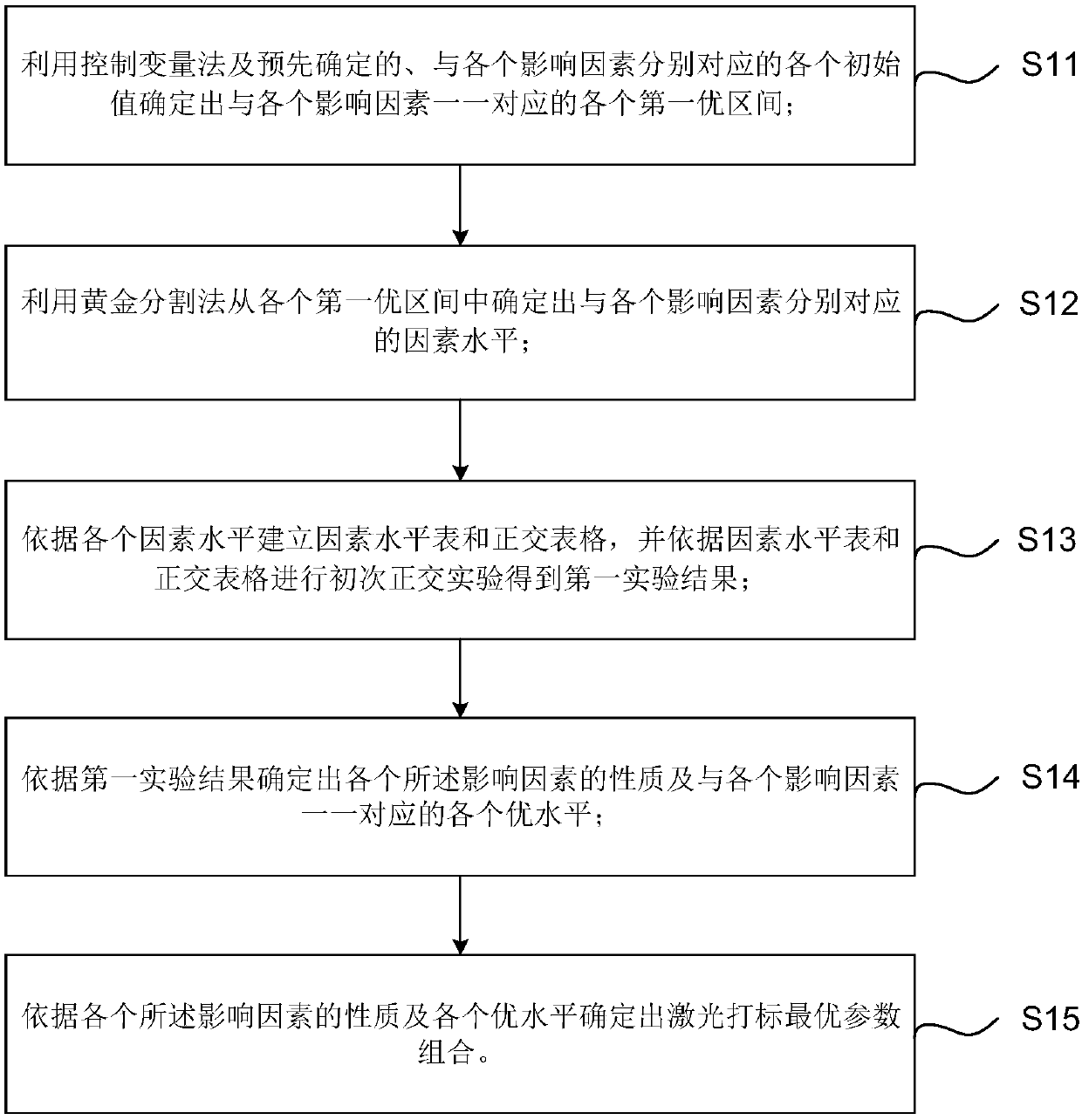

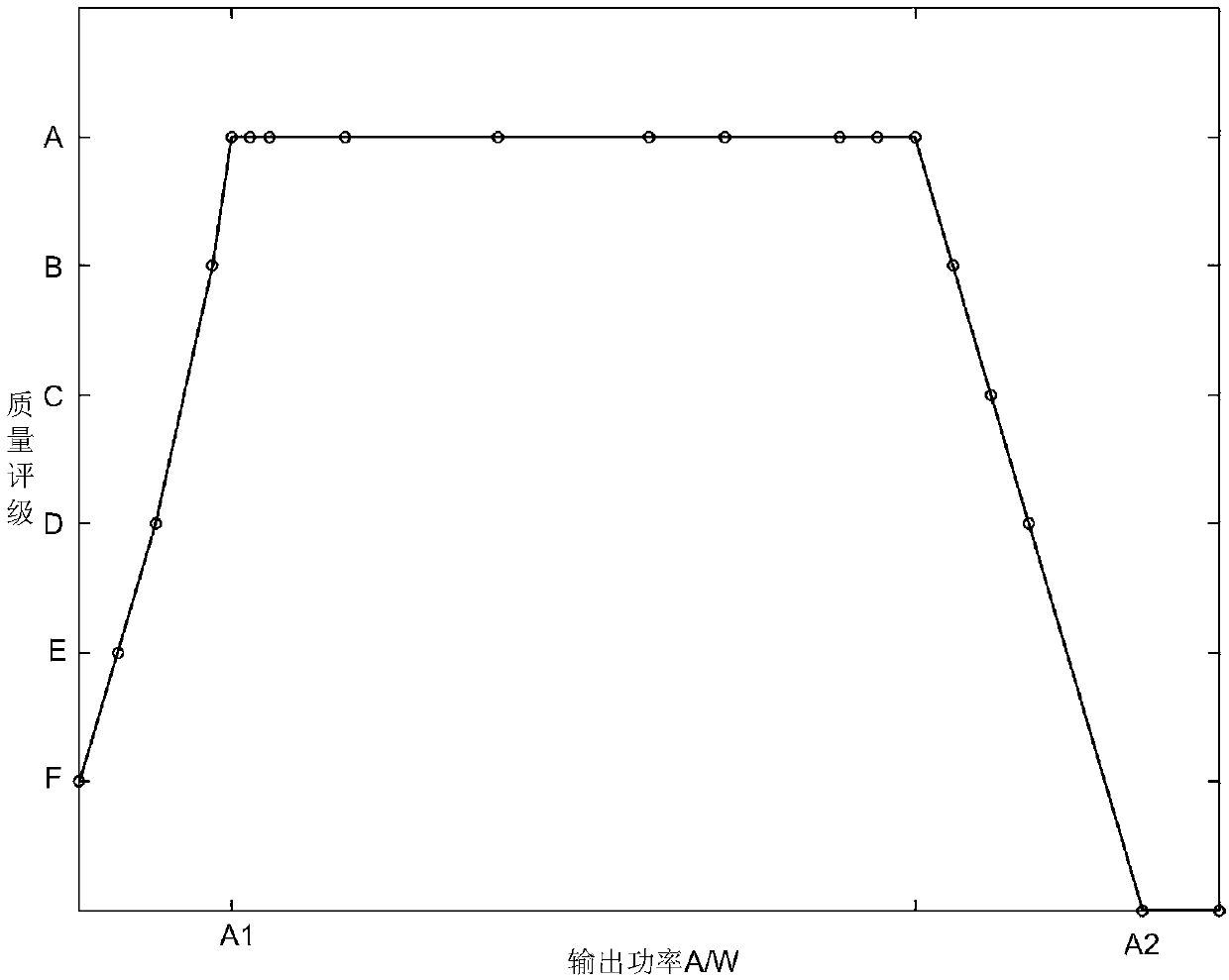

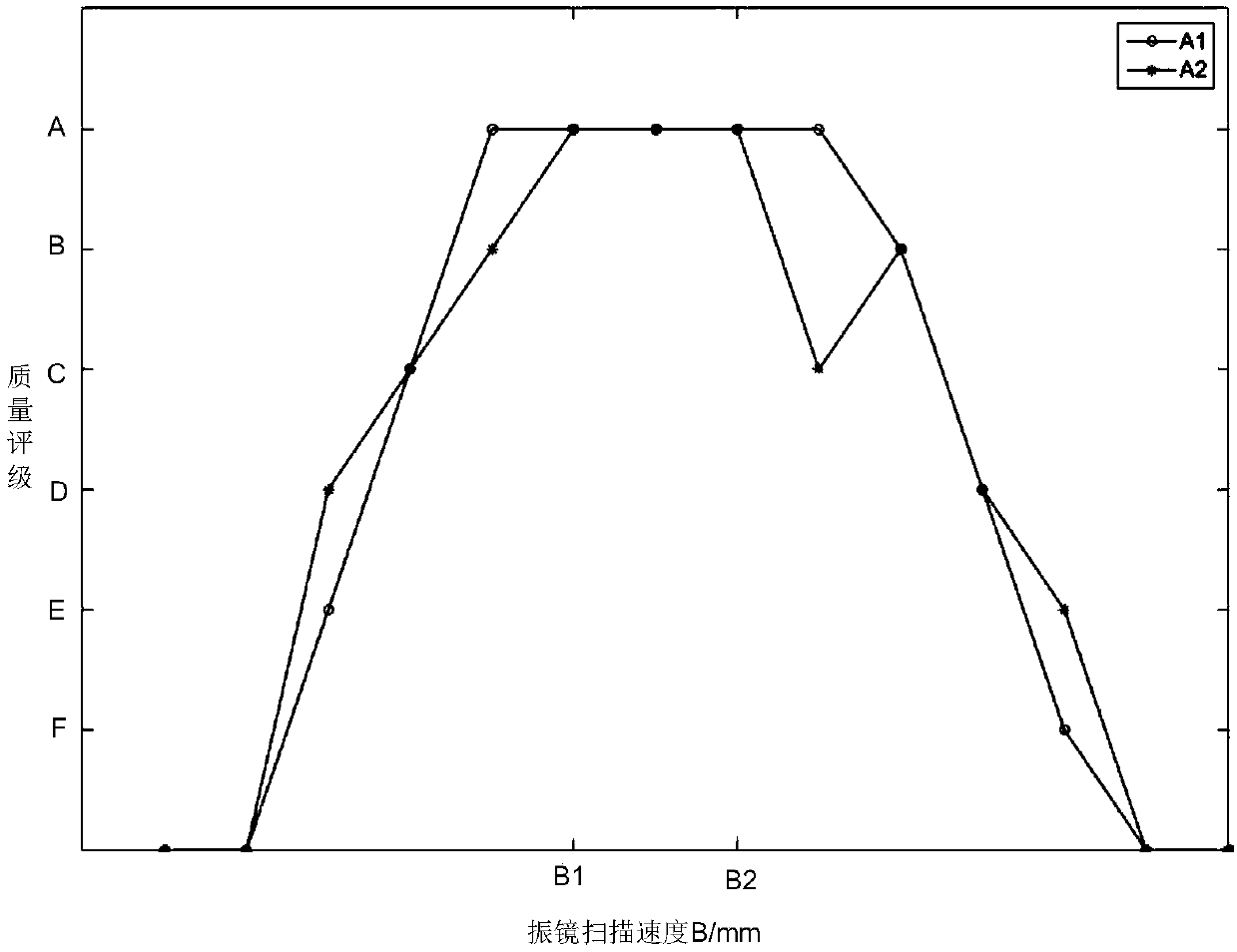

Method, device and system for calculating laser processing system technological parameters

ActiveCN108038297AHigh precisionImprove pattern qualityMulti-objective optimisationSpecial data processing applicationsLaser processingComputational physics

The embodiment of the invention discloses a method, device and system for calculating laser processing system technological parameters. The method for calculating the laser processing system technological parameters includes the steps of adopting a control variable method and various initial values to determine all first good intervals which are in one-to-to correspondence with all influence factors, wherein all the initial values correspond to all the influence factors; adopting a golden section method to determine factor levels which correspond to all the influence factors respectively fromall the first good intervals; according to all the factor levels, establishing a factor level list and a orthogonal form, and according to the factor level list and the orthogonal form, carrying out an orthogonal experiment for the first time to obtain first experiment results; according to the first experiment results, determining characteristics of all the influence factors and all good levels,wherein all the good levels are in one-to-one correspondence with all the influence factors; according to the characteristics of all the influence factors and all the good levels, determining an optimal technical parameter combination. By the adoption of the method, device and system for calculating the laser processing system technological parameters, the accuracy of the factor levels, the accuracy of the factor level list and the accuracy of the orthogonal form are improved, and therefore the accuracy of the optimal technical parameter combination is improved.

Owner:GUANGDONG ZHENGYE TECH

Pattern forming method and pattern forming apparatus

InactiveUS8845077B2Avoid position deviationImprove pattern qualityPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringDroplet deposition

A pattern forming method includes: a modification treatment step of, in accordance with a pattern to be formed on a pattern forming surface of a base body, applying a light beam having a width smaller than a diameter of each of dots to constitute the pattern, onto a treatment target region including at least outer edges on both sides in a width direction of a region where the pattern is to be formed in the pattern forming surface, thereby carrying out modification treatment on the treatment target region; and a droplet deposition step of ejecting and depositing droplets of a functional liquid by an inkjet method onto the region where the pattern is to be formed including the treatment target region where the modification treatment has been carried out.

Owner:FUJIFILM CORP

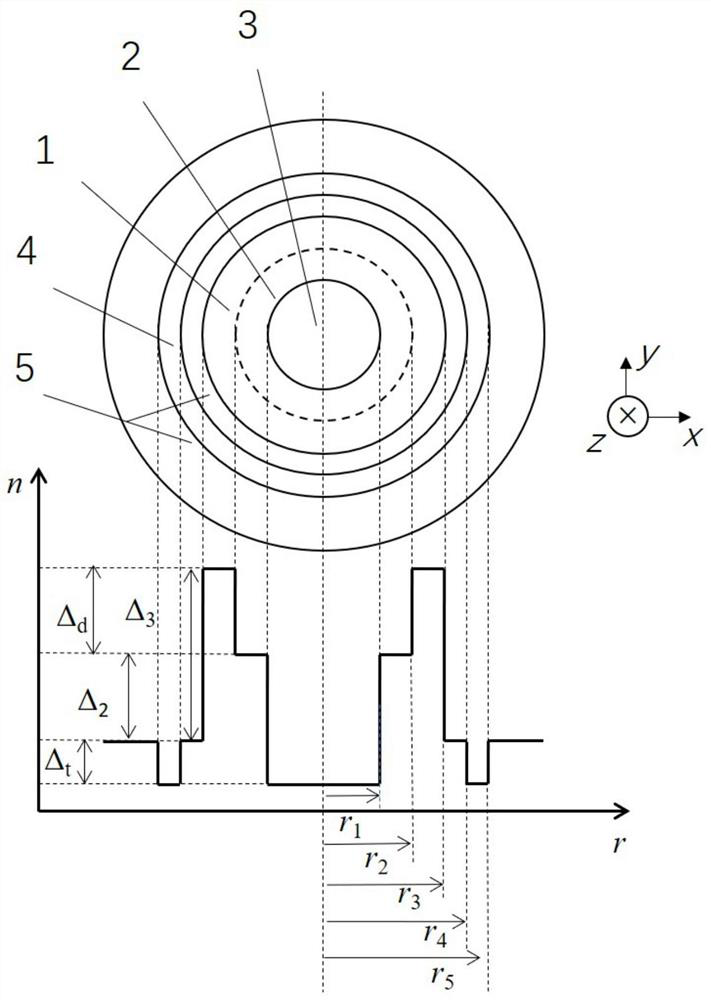

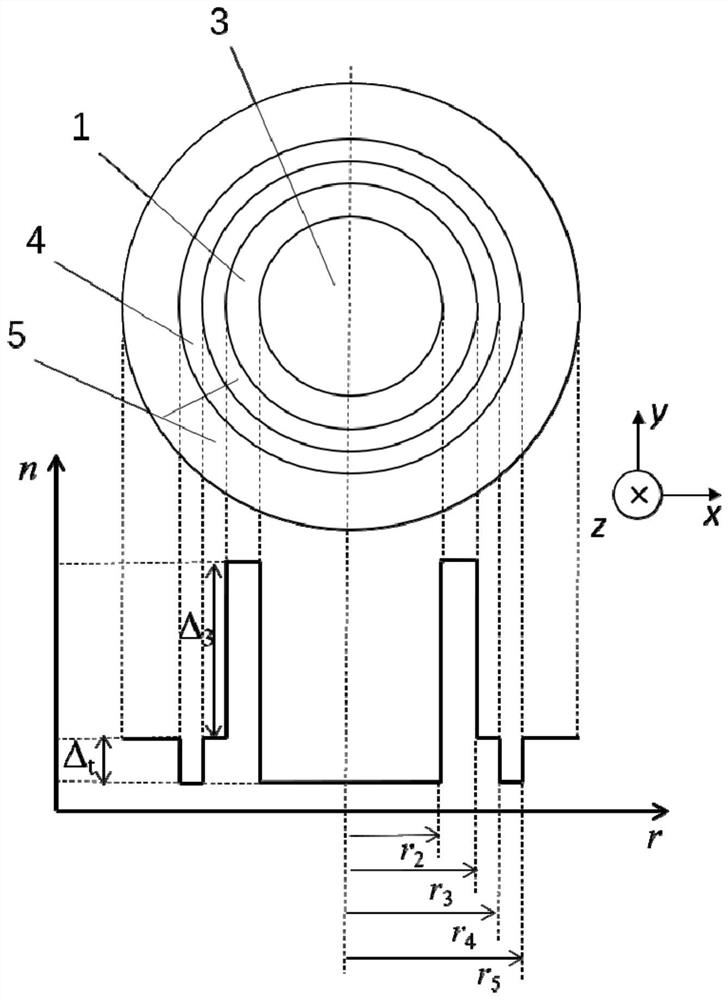

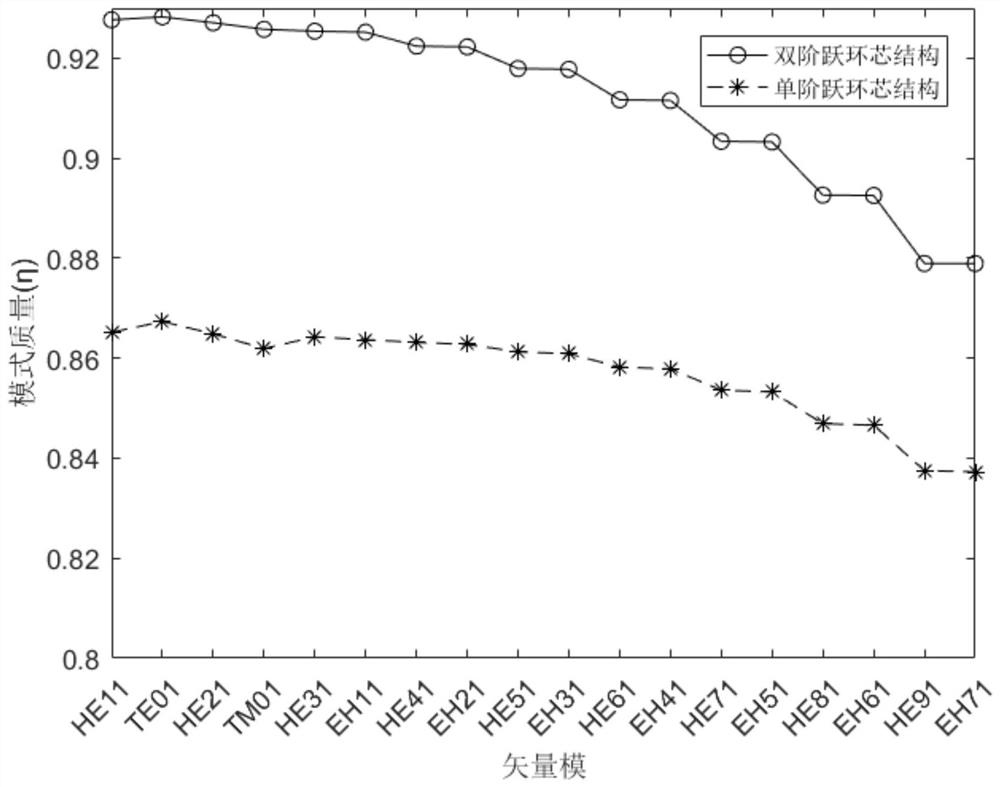

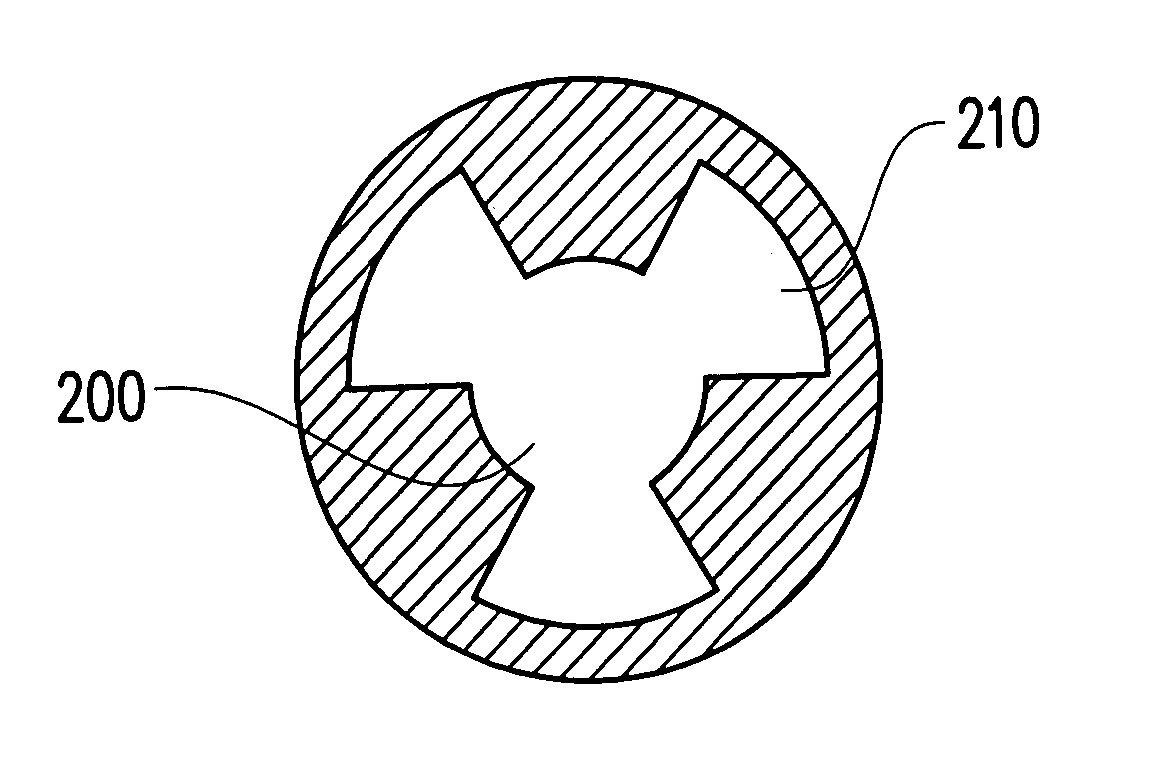

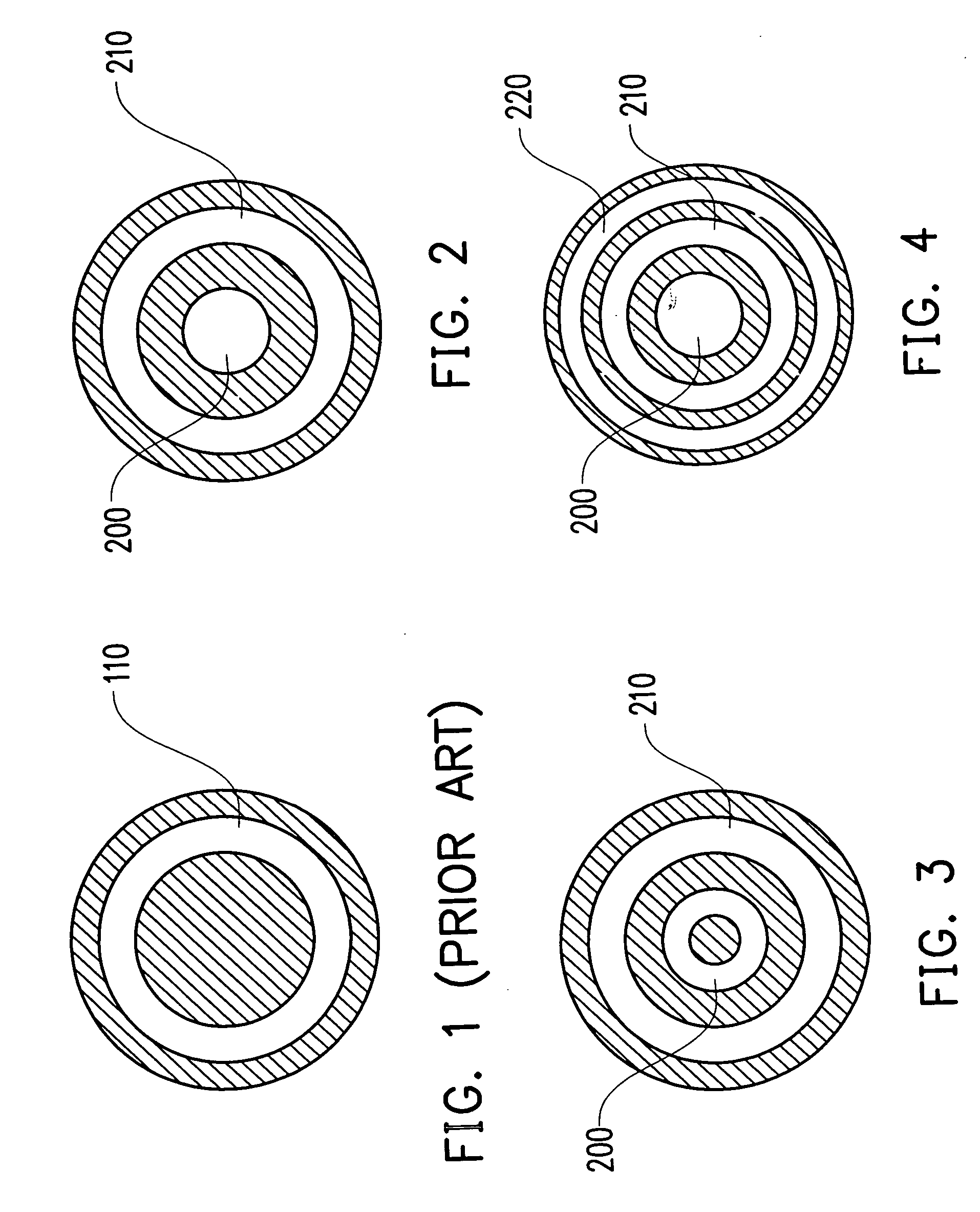

Groove-assisted double-step ring core optical fiber

ActiveCN112363271ANot affected by bendingBig Design DimensionsOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingEngineeringMechanical engineering

The invention discloses a groove-assisted double-step ring core optical fiber. The groove-assisted double-step ring core optical fiber comprises a ring core and an outer cladding; the ring core sequentially comprises a central cladding, a second-layer step ring, a first-layer step ring and an annular groove from inside to outside; refractive indexes of the first-layer step ring core and the second-layer step ring core are distributed in a double-step ring core shape; the first-layer step ring core is used for controlling optical fiber normalization frequency so as to regulate and control the number of modes; the second-layer step ring core is used for increasing the effective area of the modes so as to reduce the nonlinear coefficient of each mode of the optical fiber and suppress a radialhigh-order mode; and the double-layer step structure is used for mode regulation and control with higher degree of freedom. The optical fiber can support eight-order OAM modules, the effective refractive index difference between the modules is larger than 10<-4>, and module weak coupling transmission can be adopted. Four modes in the modules are in a degenerate state, and a fixed 4*4-scale MIMO algorithm can be used. OAM modes supported by the optical fiber are all radial first-order modes.

Owner:JINAN UNIVERSITY

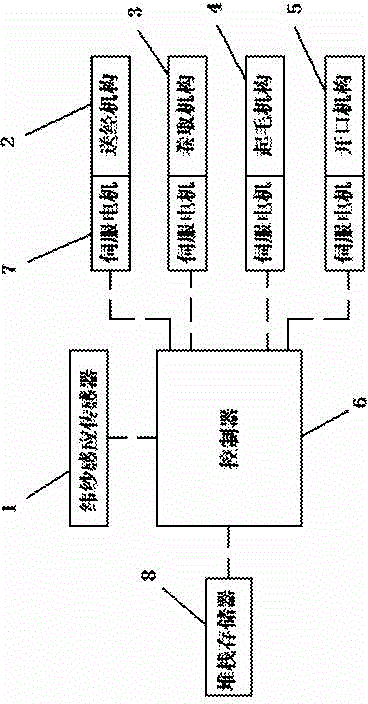

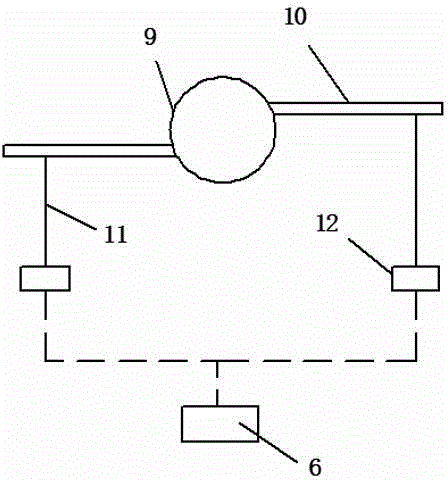

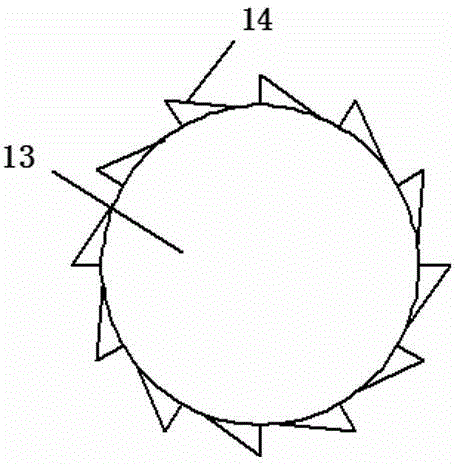

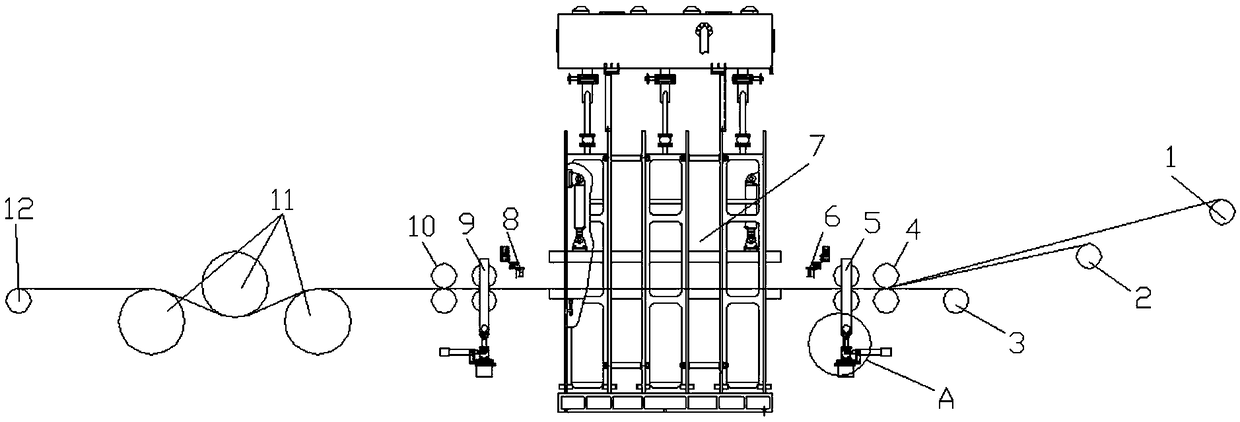

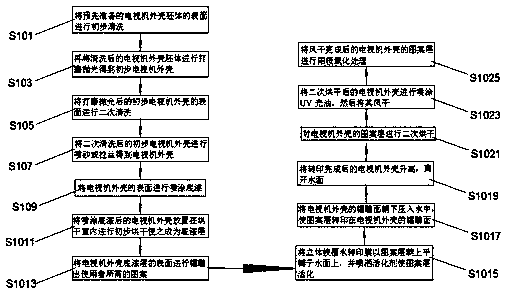

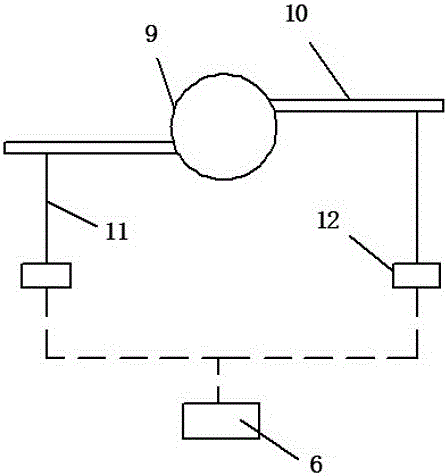

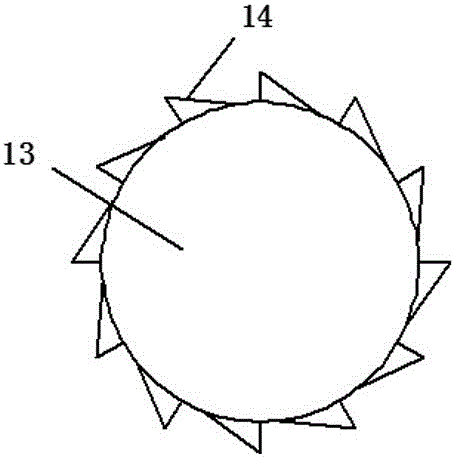

Automatic weft finding device and method for rapier loom

The invention discloses an automatic weft finding device for a rapier loom. The automatic weft finding device comprises a weft sensor, a warp let-off mechanism, a reeling mechanism, a fluffing mechanism, an opening mechanism and a controller. The warp let-off mechanism, the reeling mechanism, the fluffing mechanism and the opening mechanism are provided with four variable frequency motors, respectively. The input end of the controller is connected with the weft sensor. The output end of the controller is connected with the four variable frequency motors; the controller is further connected with a stack storage. The invention further discloses an automatic weft finding method for the rapier loom. If weft breakage occurs, weft finding is performed at low equipment speed through a reversing program. The automatic weft finding device and method has the advantages that the defects of the prior art can be overcome, the structure of the rapier loom is simplified, and failure rate is reduced.

Owner:GAOYANG HUIQIANG TEXTILE MACHINERY MFG CO LTD

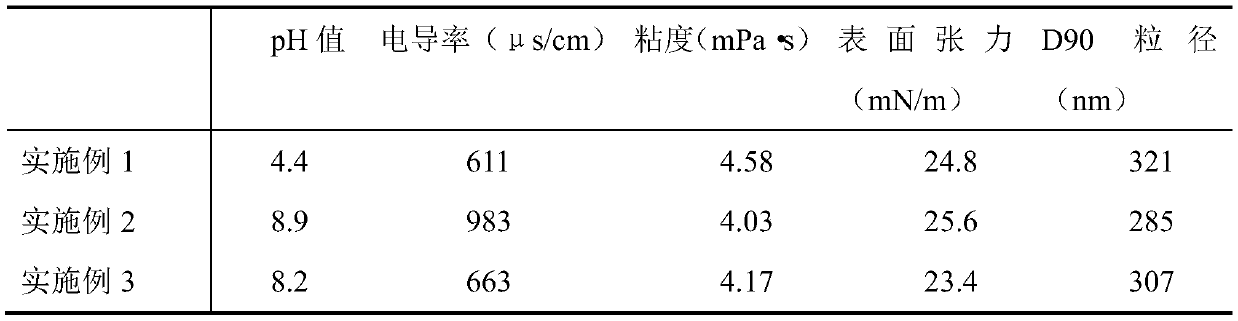

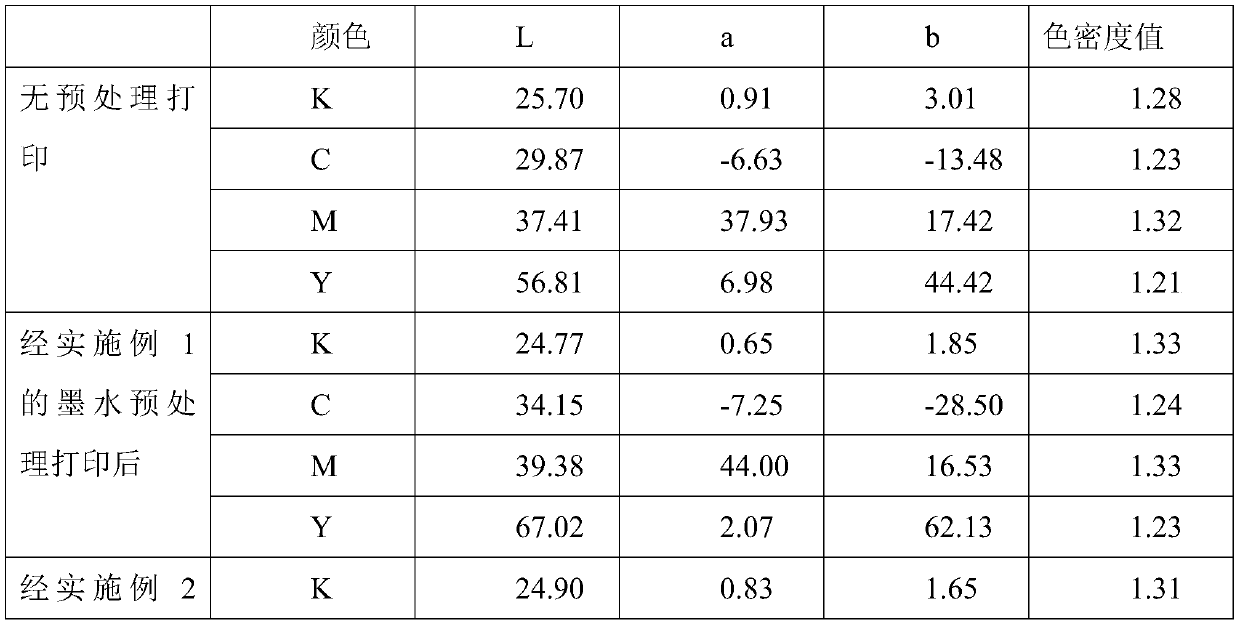

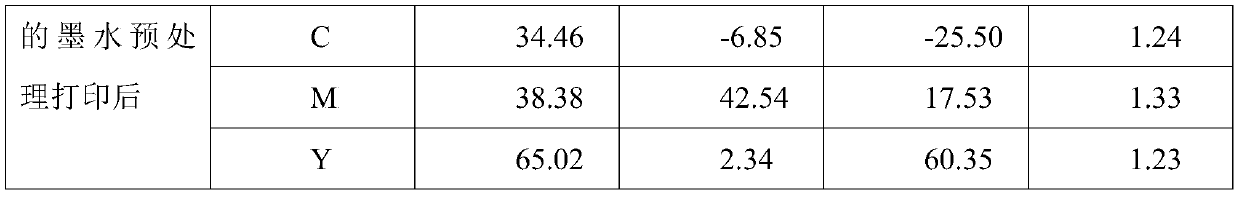

Pretreatment inkjet ink for digital printing and application method thereof

InactiveCN110862715ASolve the problem of dim color, even colored media can not display color, etc.Improve pattern qualityDuplicating/marking methodsInksColored whiteDigital printing

The invention discloses a pretreatment inkjet ink for digital printing. The pretreatment inkjet ink is prepared from the following components by weight percentage: 20-40% of white color paste, 2.0-20%of a color improver, 10-35.0% of a viscosity regulator, 0.1-5.0% of a surface tension control agent, 0.1-1% of a bactericide and the balance deionized water. Specifically, the white color paste is prepared by high speed grinding of the following components by weight percentage: 2-30% of a white color developing agent, 1.0-10% of a dispersing agent, 0.1-1.0% of a defoaming agent, 0.1-3.0% of a pHcontrol agent and the balance deionized water. In addition, the invention also discloses a preparation method of the pretreatment inkjet ink, and the method includes the steps of: adding deionized water, the color improver, the viscosity regulator, the surface tension control agent and the bactericide sequentially into the white color paste under a stirring state, performing stirring until all thecomponents are uniformly mixed, and then conducting filtering. The pretreatment inkjet ink is printed on a printing medium before printing with digital printing ink, so that the color and covering power of a printed pattern can be obviously improved.

Owner:HONGSAM DIGITAL SCI & TECH

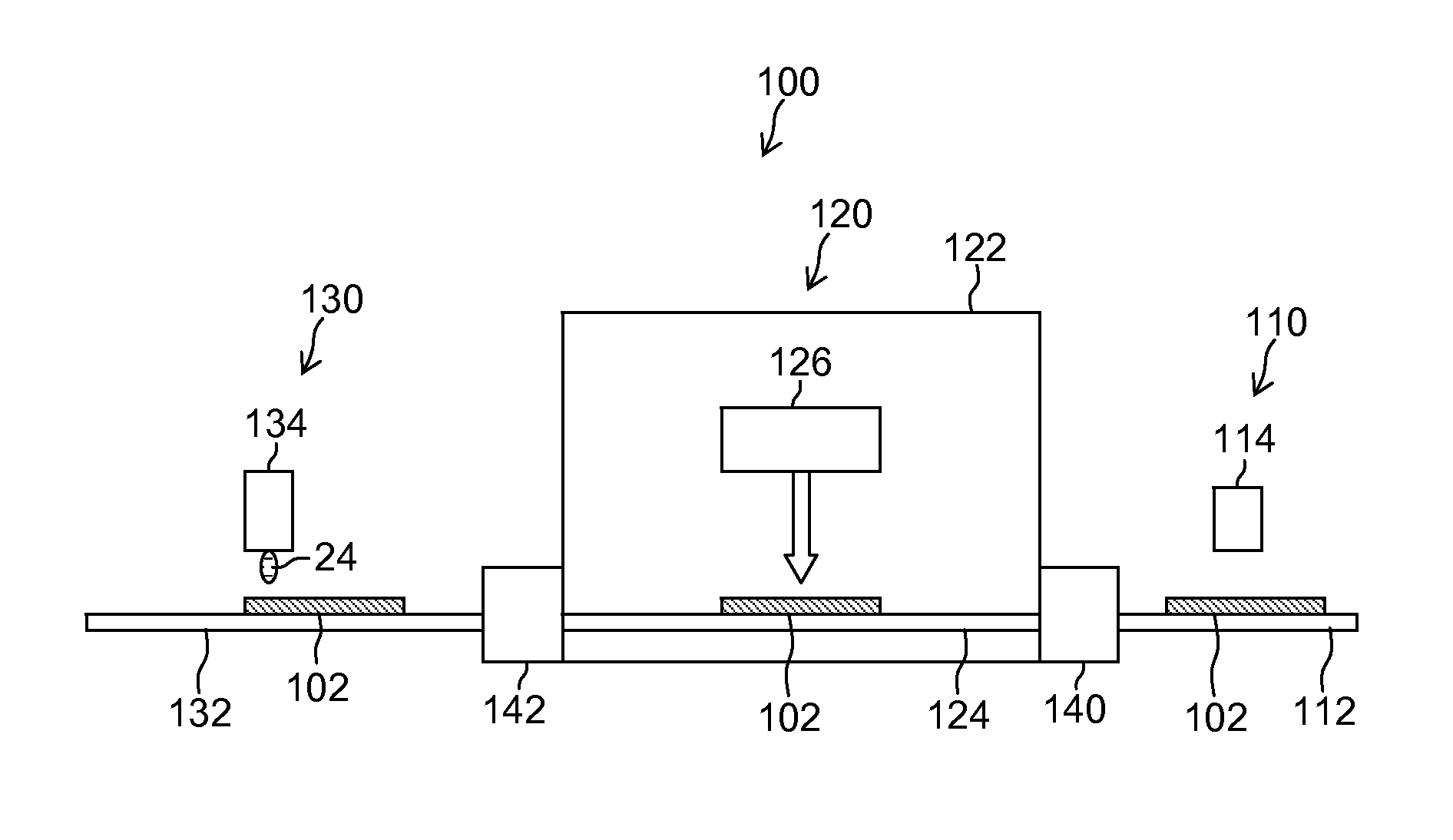

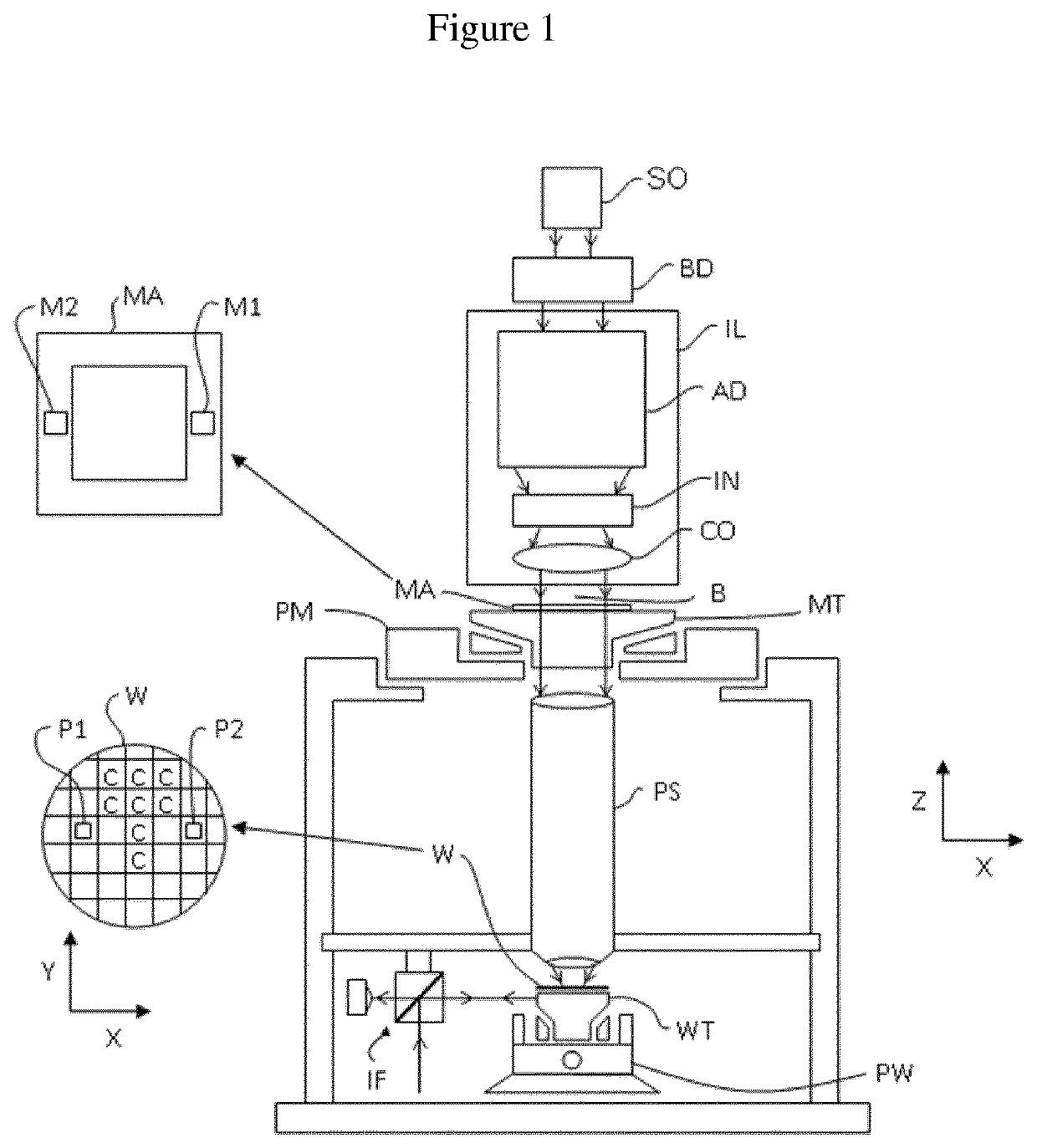

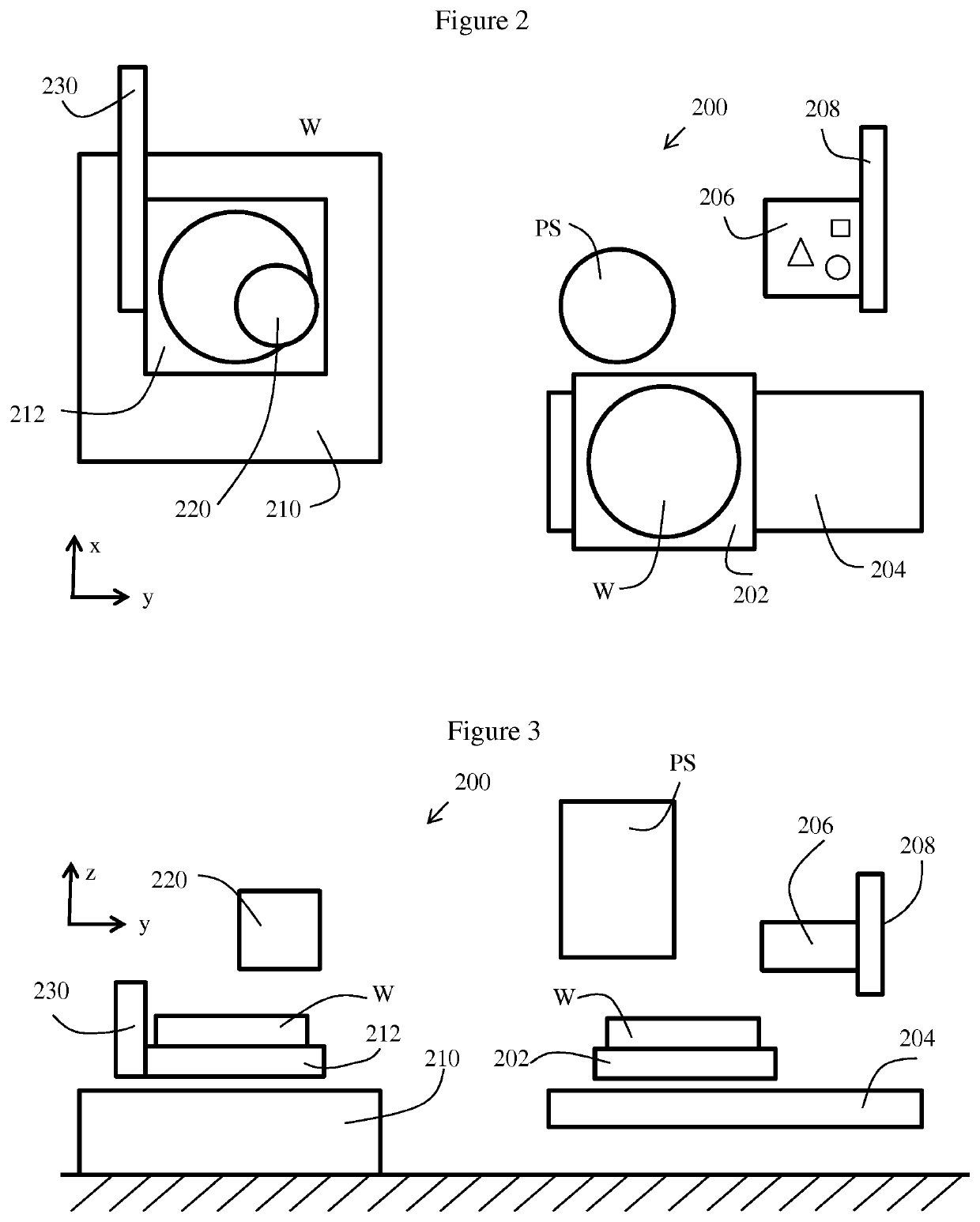

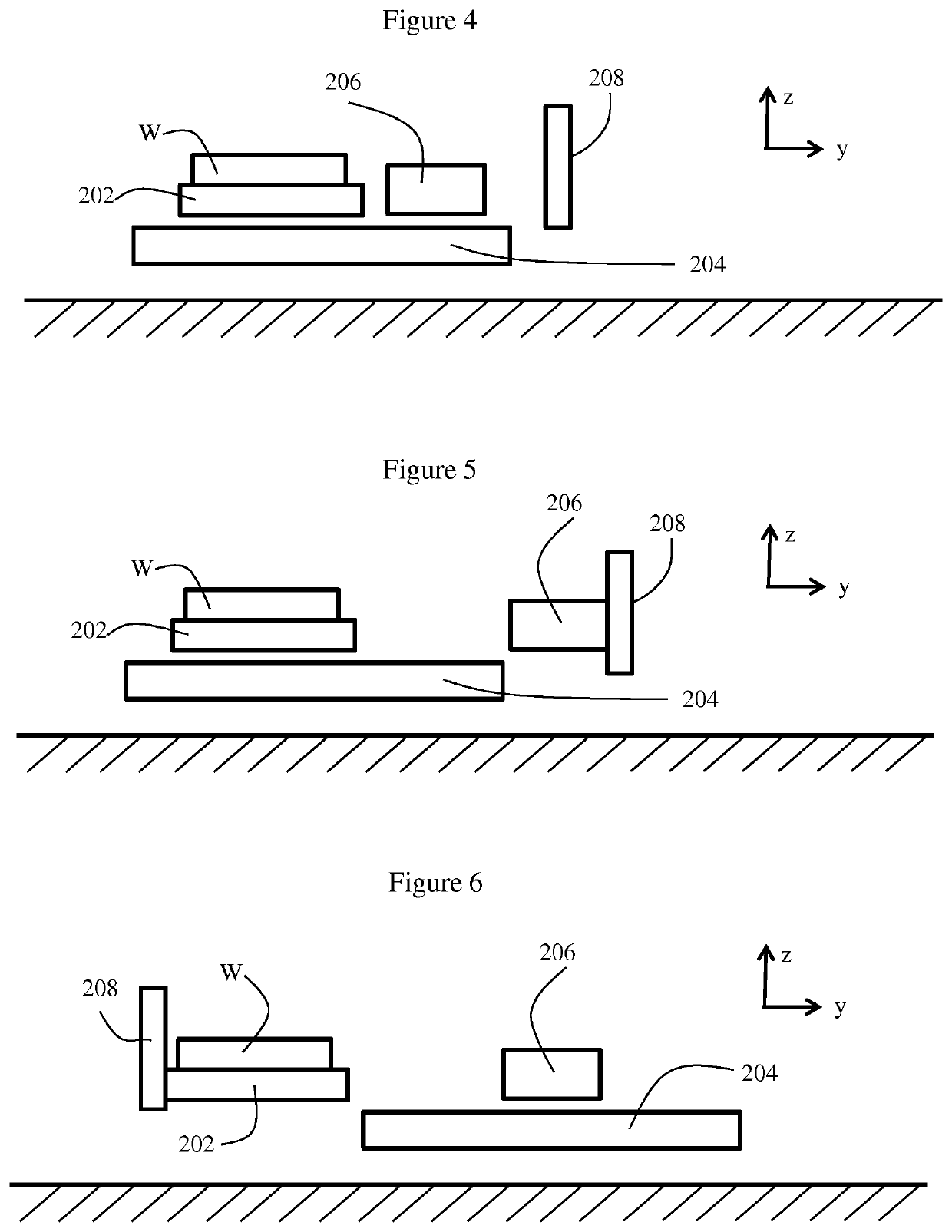

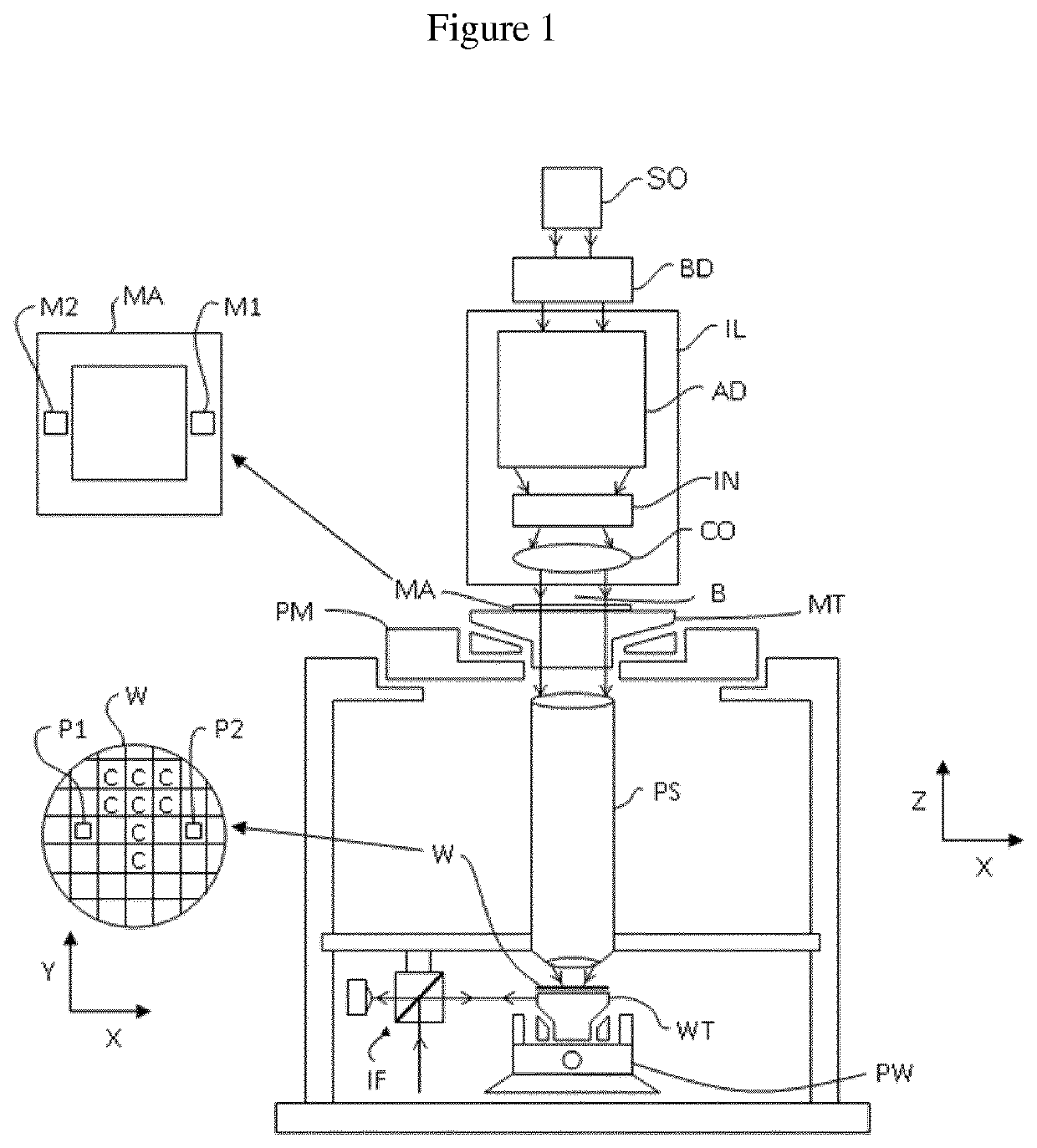

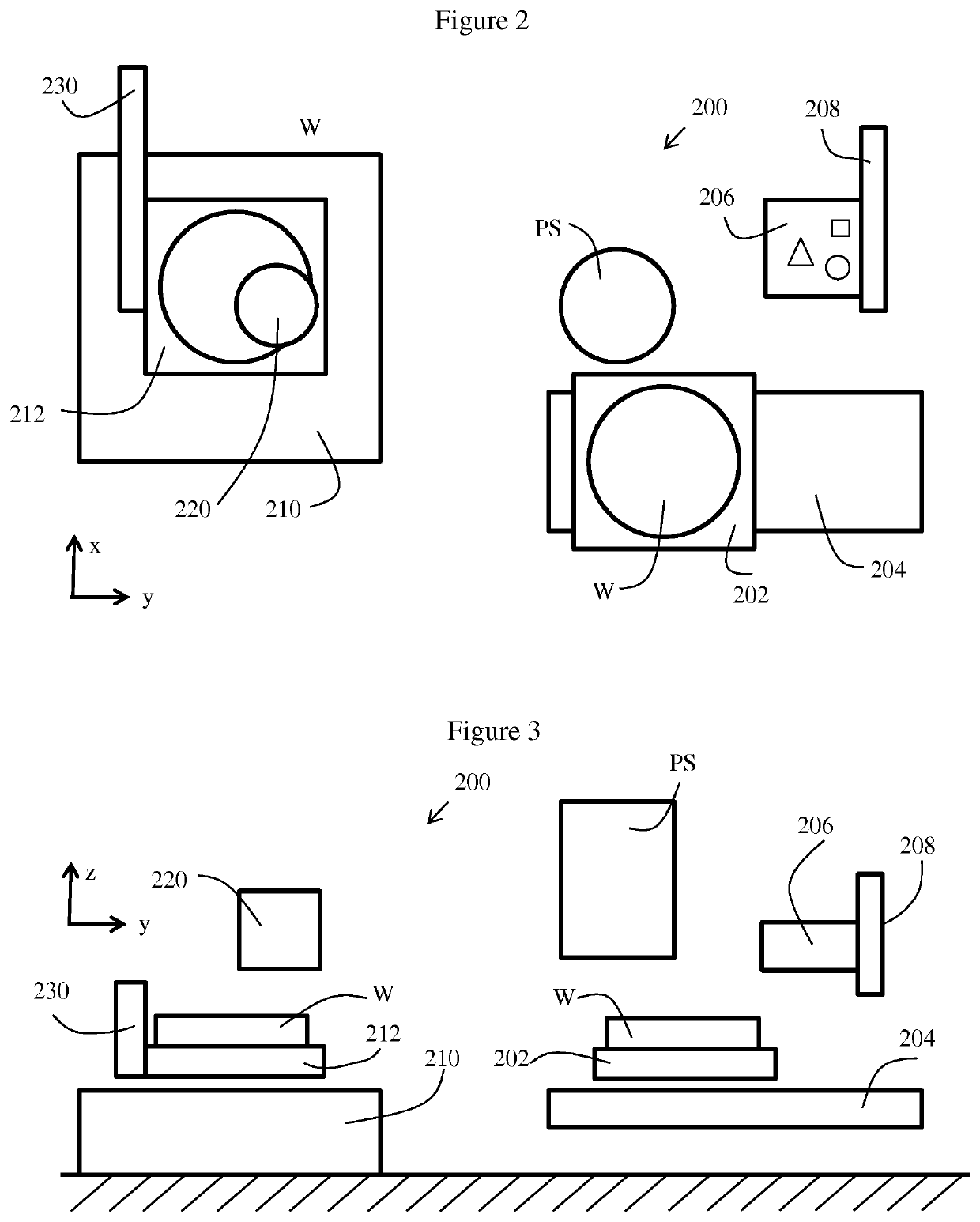

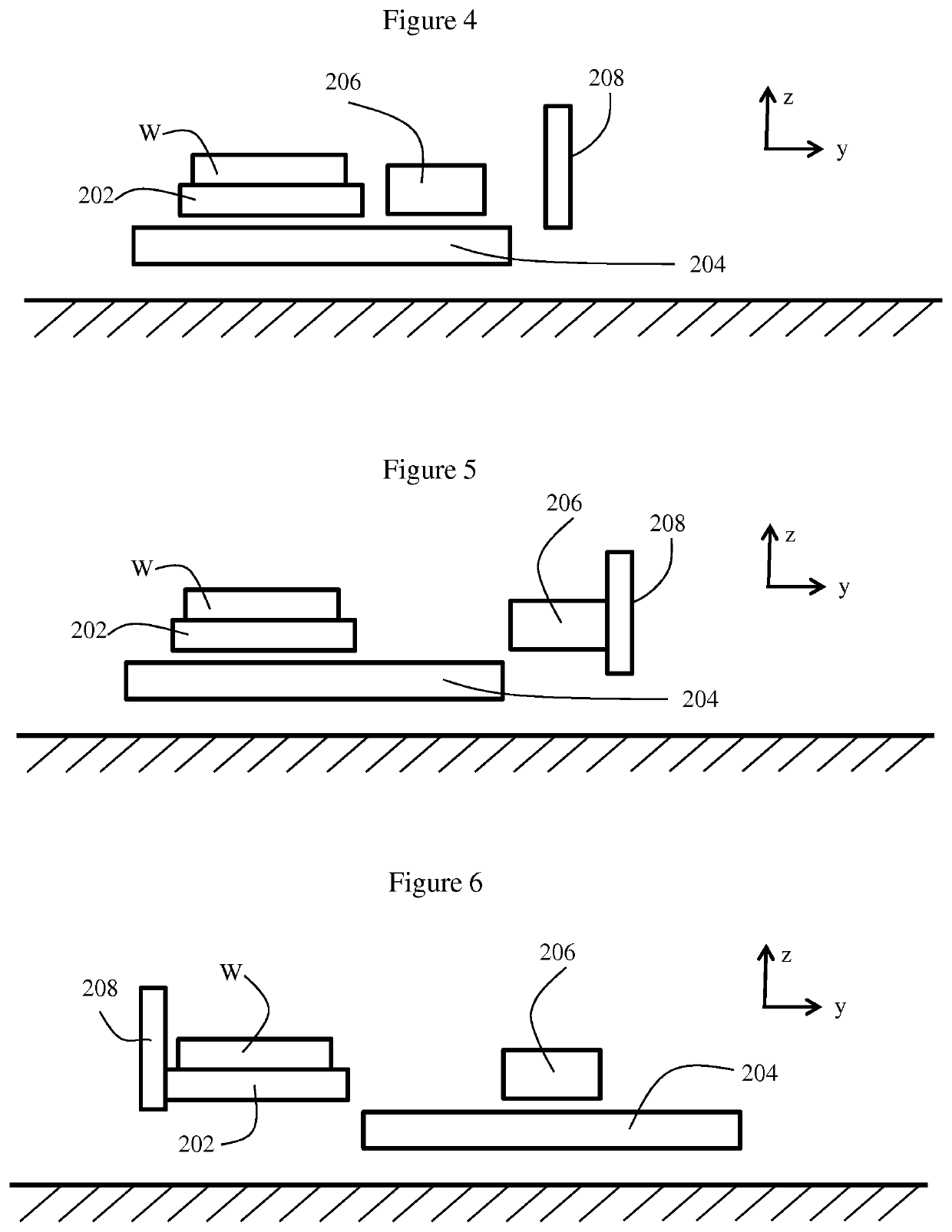

Exposure apparatus

ActiveUS20190377270A1Improve pattern qualityLow production costPhotomechanical exposure apparatusMicrolithography exposure apparatusMeasurement deviceSensor holder

An exposure apparatus arranged to project a radiation beam onto a target portion of a substrate, the exposure apparatus having: a first substrate holder configured to hold the substrate; a second substrate holder configured to hold the substrate; a sensor holder configured to hold a sensor and / or detector; a first measurement device having a first alignment system having an alignment sensor configured to measure positions of a substrate alignment mark on the substrate; a second measurement device having a second alignment system having a further alignment sensor configured to measure positions of the substrate alignment mark on the substrate; a first scale arranged on a lower surface of the first substrate holder; and a first encoder head arranged to cooperate with the first scale, the first encoder head located beneath the first alignment system and held by a stationary support.

Owner:ASML NETHERLANDS BV

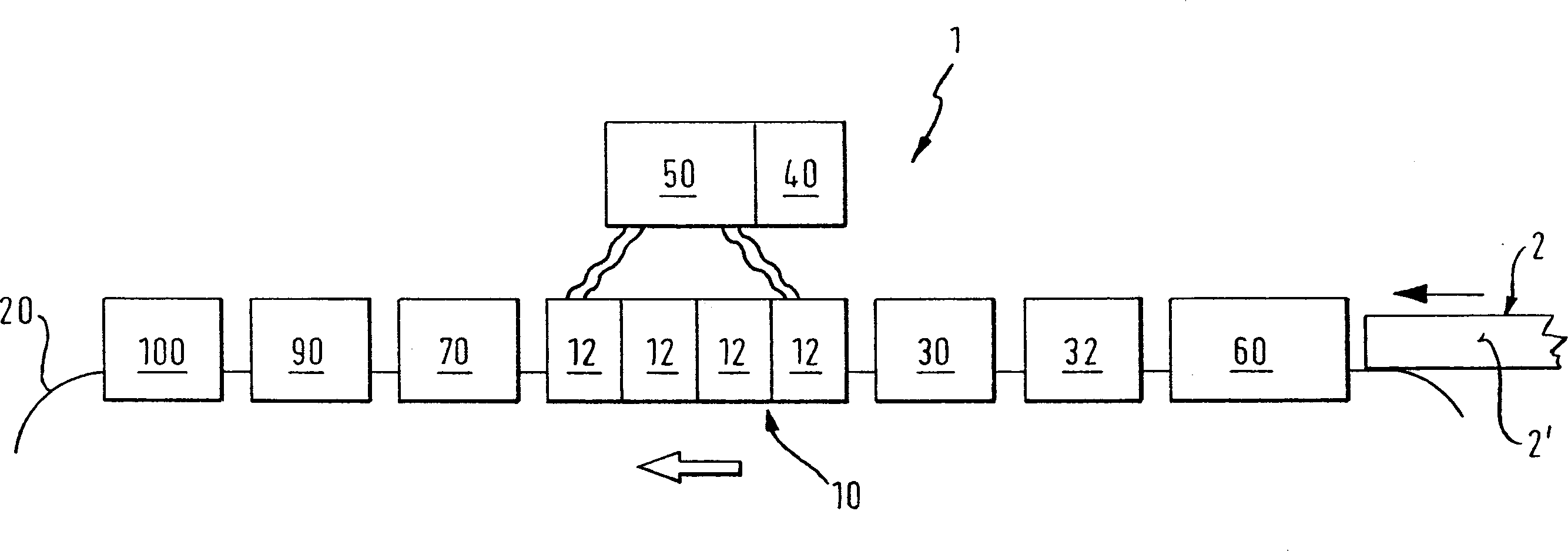

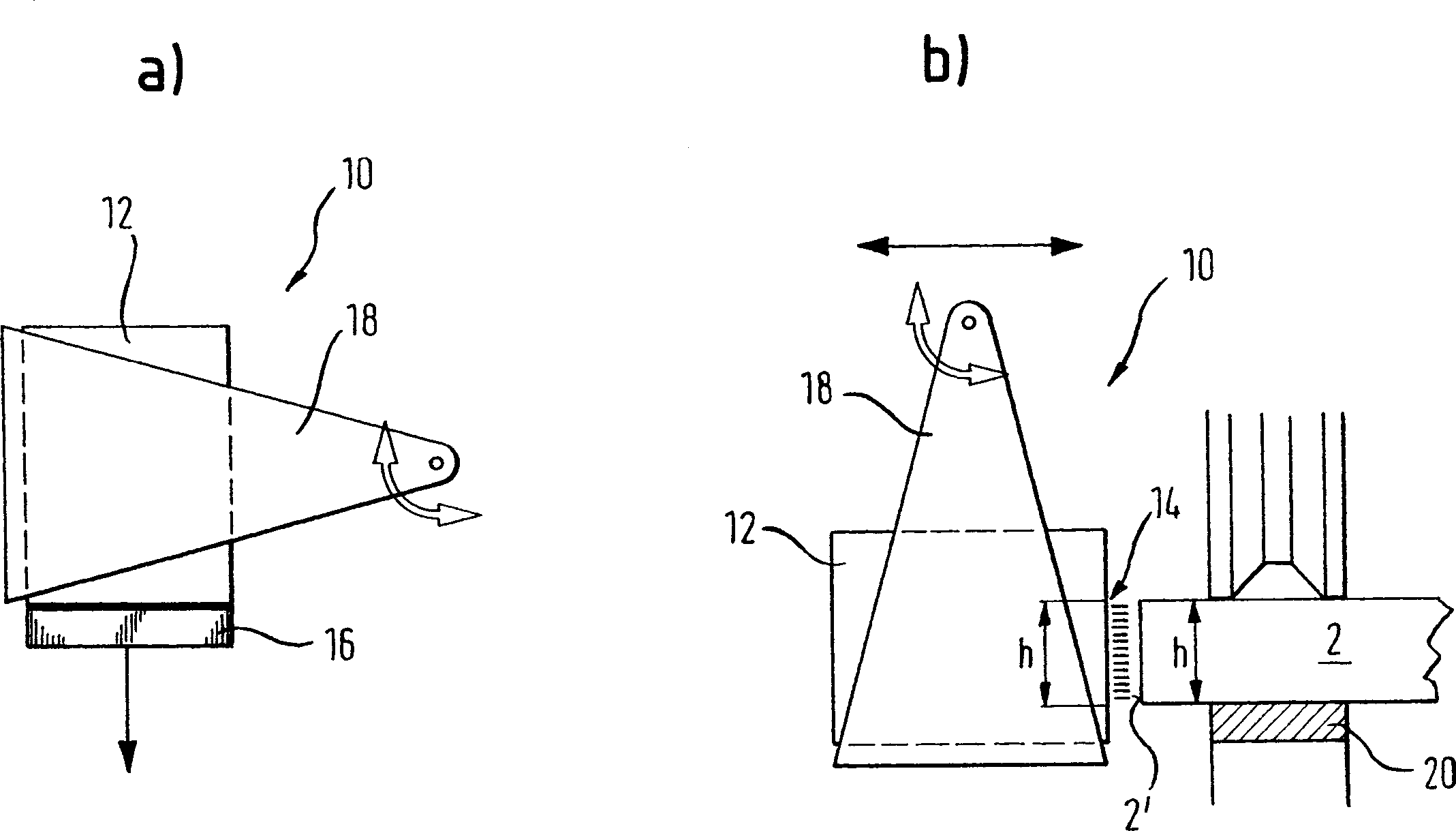

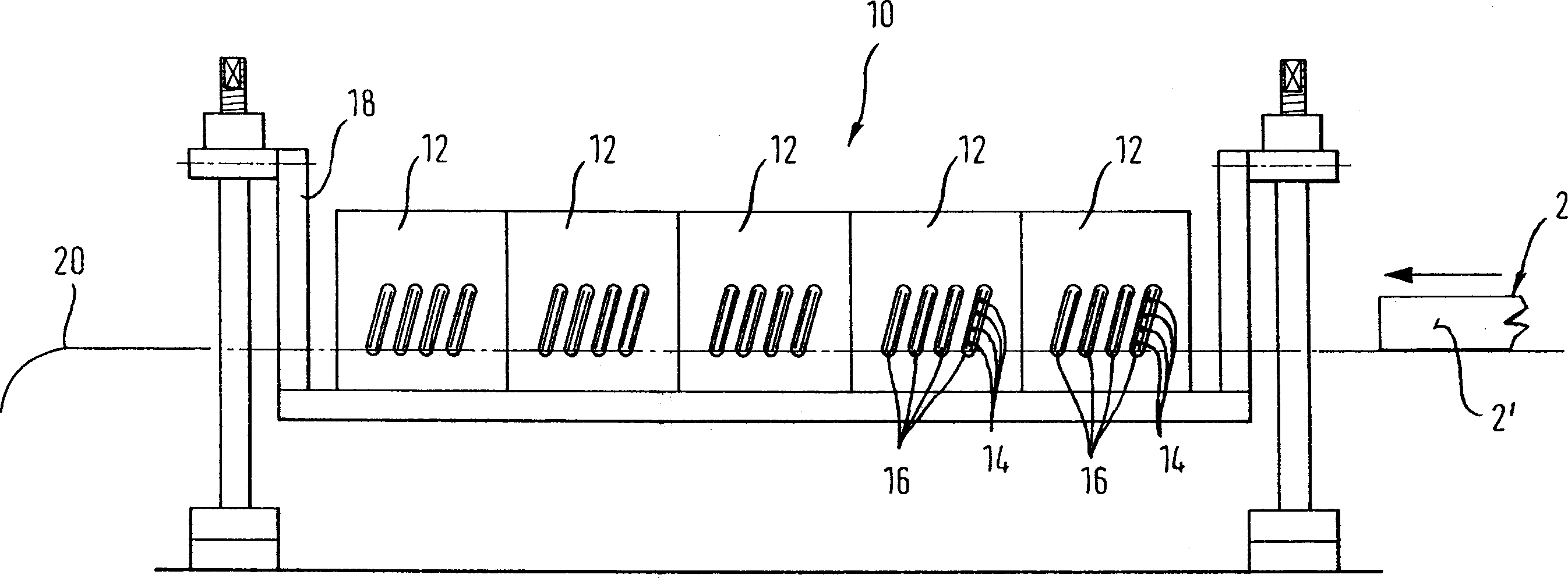

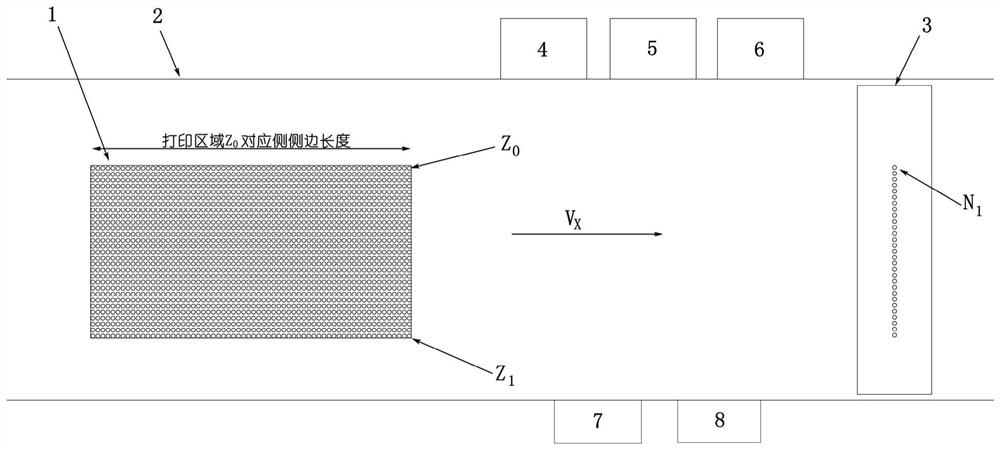

Device and method for implementing patterns on the narrow side of the plate workpieces

ActiveCN1853944ALow costImprove pattern qualityOther plywood/veneer working apparatusTypewritersElectrical and Electronics engineeringNozzle

The invention discloses a pattern exerting device (1) and method of narrow side (2') of board-shaped workpiece (2) through wood, which comprises the following parts: static printing unit (10), which possesses multiple static ink-injecting heads (12) with multiple sprayers (14); transmitting device (20), which transmits workpiece (2) to printing unit (10); detecting devices (30, 32) on the upstream of printing unit, which detect narrow side (2') and or position and or transmitting speed of workpiece (2) on the transmitting device (20); reserving device (40), which stores image data of narrow side (2'); control device (50), which interconnects printing head (12), detecting devices (30, 32) and reserving device (40) to spray ink from sprayer (14) in the printing region (D), wherein the height of printing region equals the height of pattern narrow side (2') relatively.

Owner:豪迈木材加工系统公司

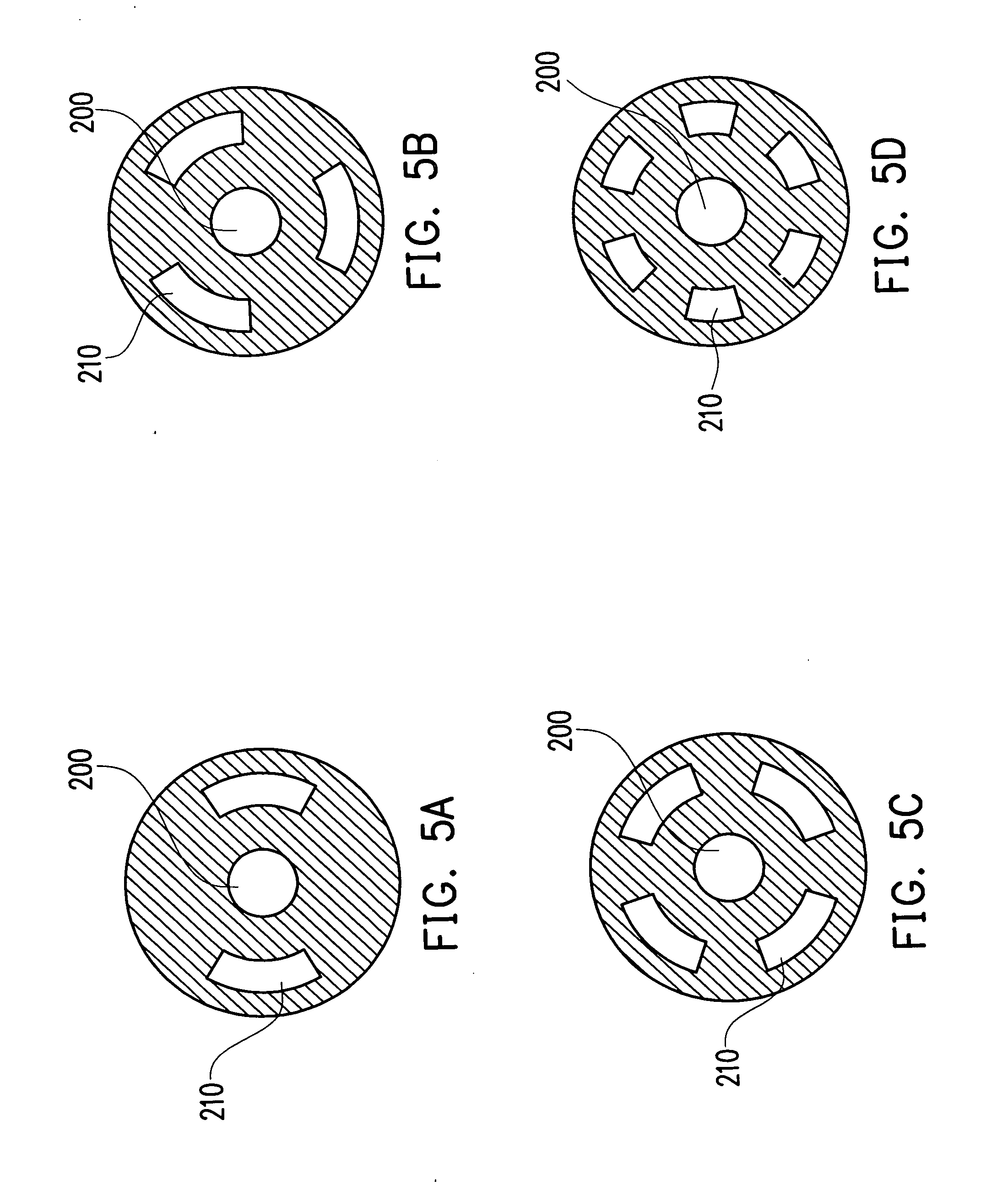

Customer illumination aperture structure

InactiveUS20070053077A1High resolutionImprove pattern qualityPhotomechanical apparatusOptical elementsPhysics

A customer illumination aperture (CIA) structure for lithographic exposure is disclosed, including a central part and at least one off-axis part around the central part. The off-axis part of the CIA is disposed in a symmetric manner with respect to the central part.

Owner:UNITED MICROELECTRONICS CORP

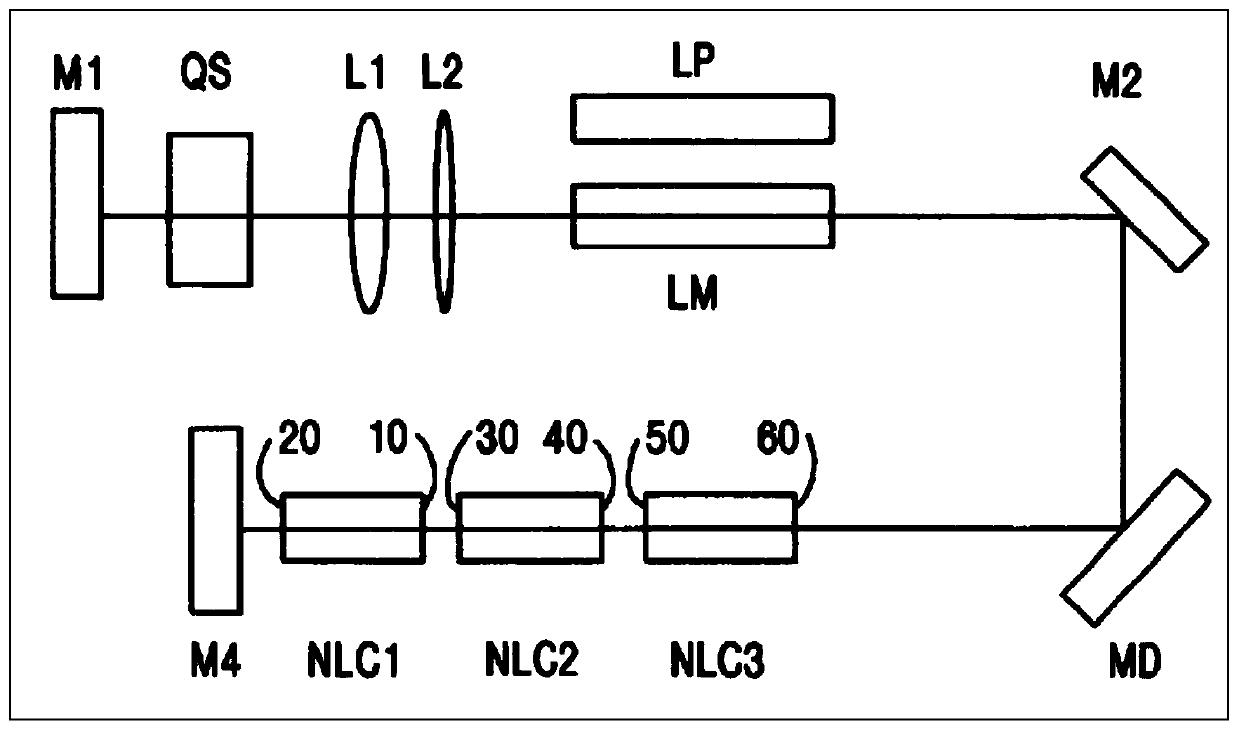

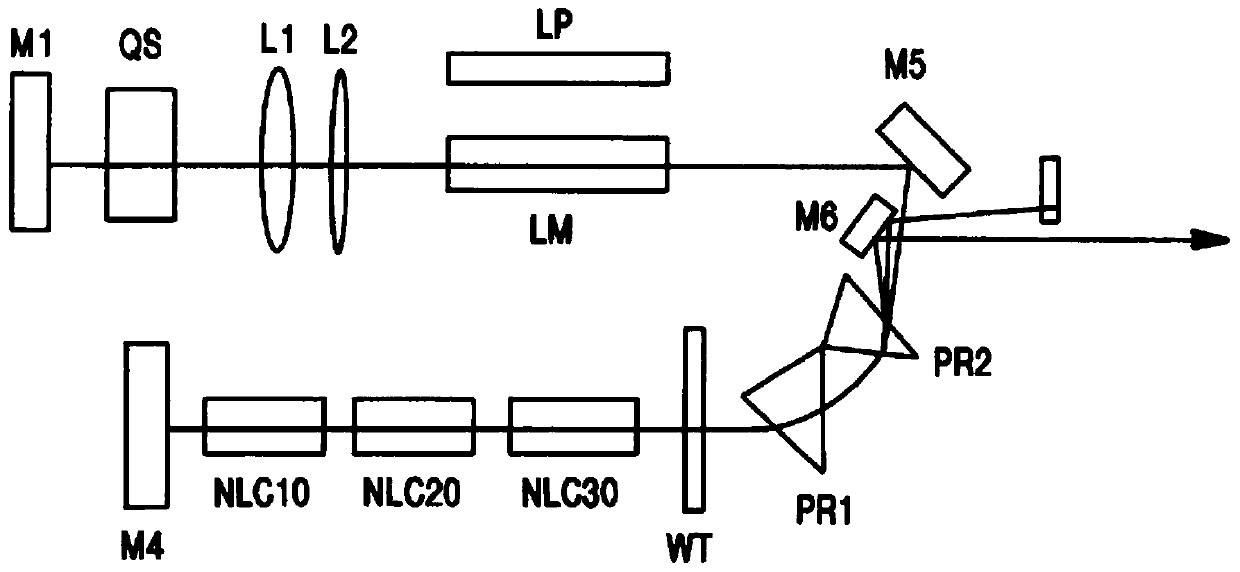

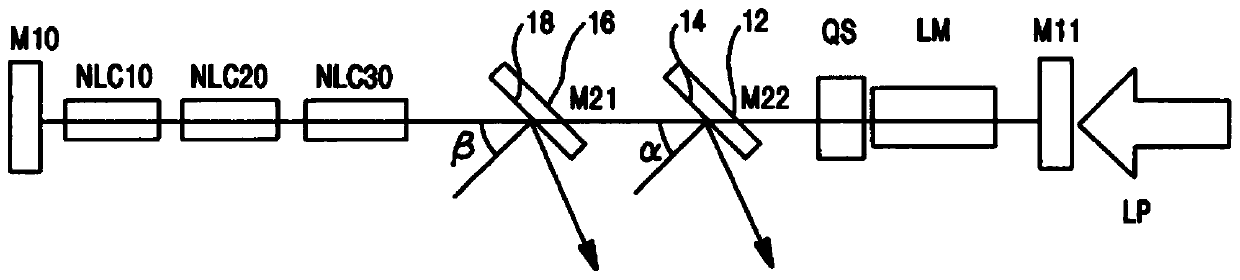

Device for generating fourth harmonic beam

The invention relates to a device for generating a fourth harmonic light beam. The system comprises an active laser medium in an optical cavity, and a second harmonic generator for generating a secondharmonic frequency of fundamental frequency light directly generated by the laser medium. The fundamental wave light beam is guided to the second harmonic generation crystal, wherein one part of fundamental wave light beams are converted into second harmonic light beams; before the second harmonic light beam is converted into the higher harmonic light beam, the second harmonic wave and the unconverted fundamental wave light beam are reflected back to the second harmonic wave generator by a reflecting surface and pass through the second harmonic wave generator again; an independent reflectingsurface can also be used for reflecting an unconverted fundamental wave light beam and a second harmonic light beam respectively; and the unconverted second harmonic light beam can be guided into a laser medium to serve as an additional pump, and almost all ultraviolet light beams with the wavelength exceeding 99% or even more can be output from a laser cavity. The laser of the invention has significantly improved conversion efficiency and improved mode quality.

Owner:富通尼激光科技(东莞)有限公司

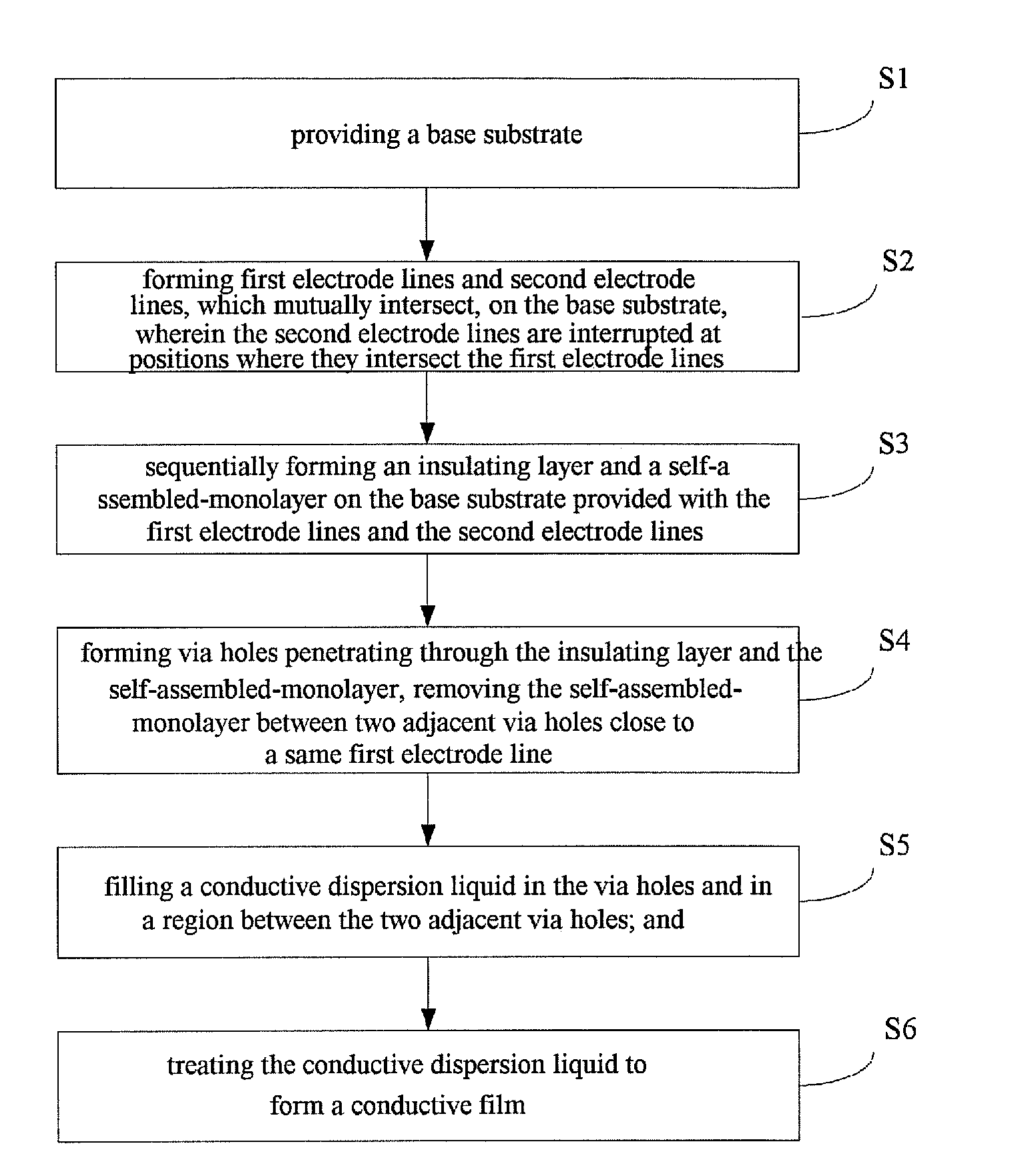

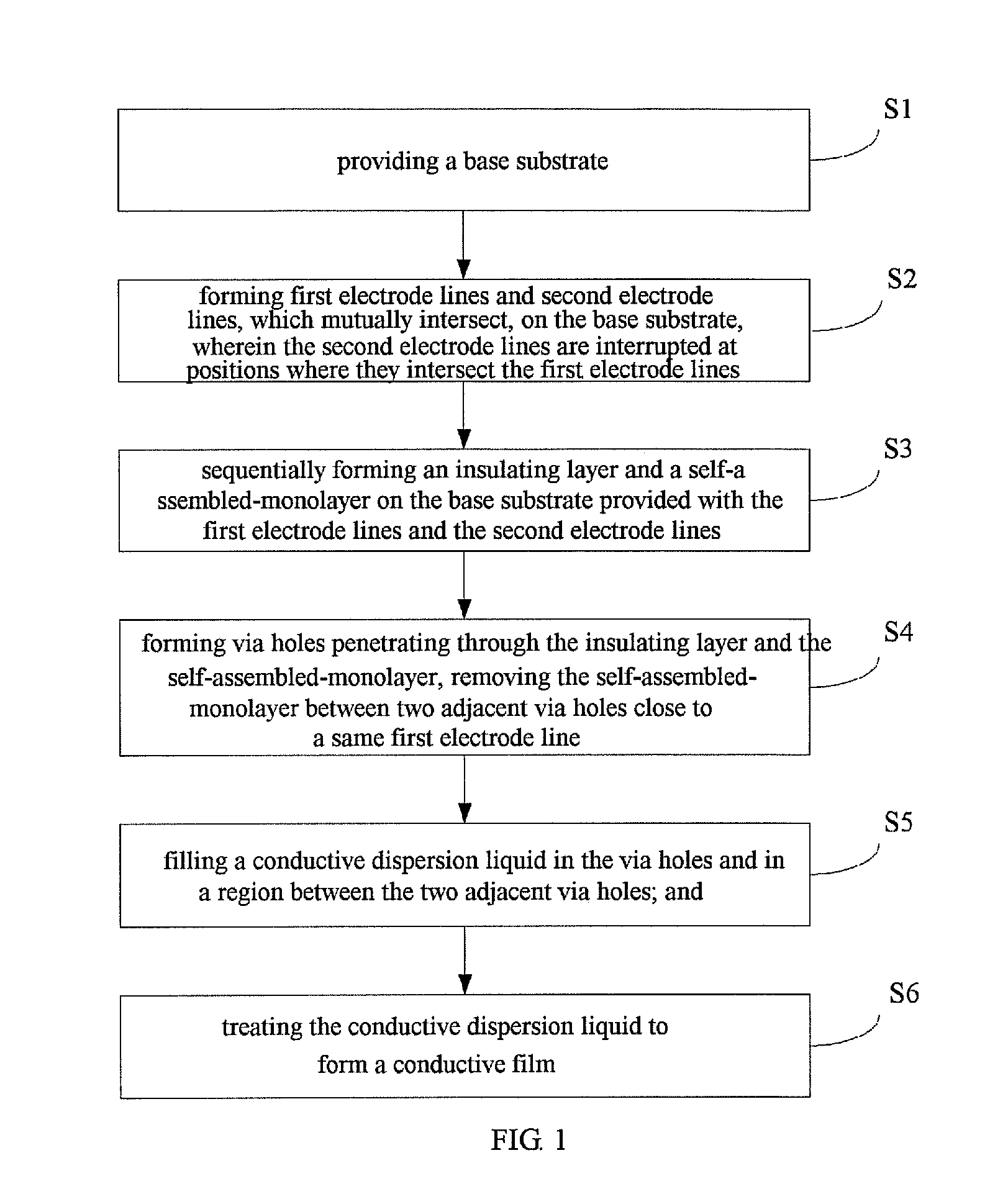

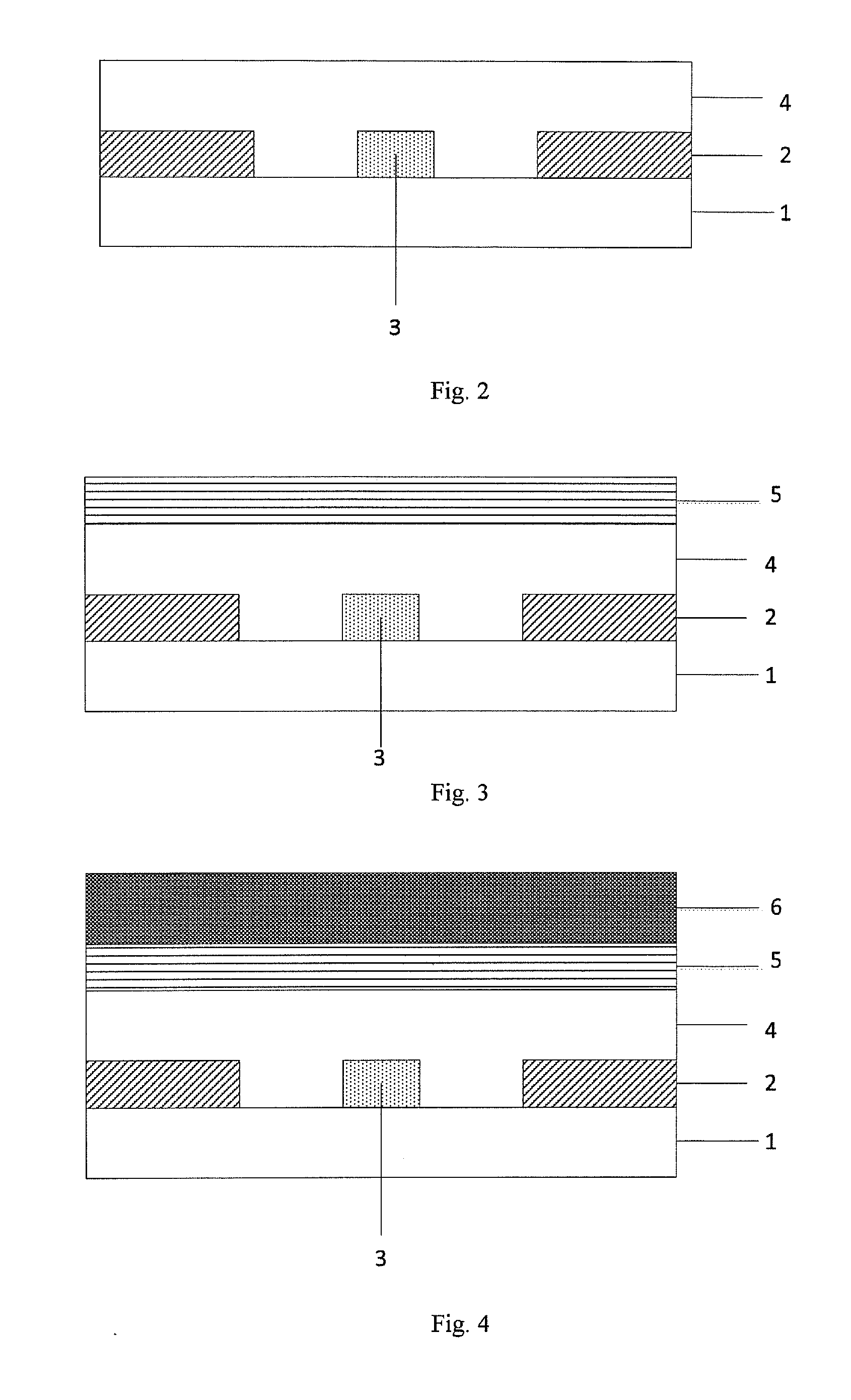

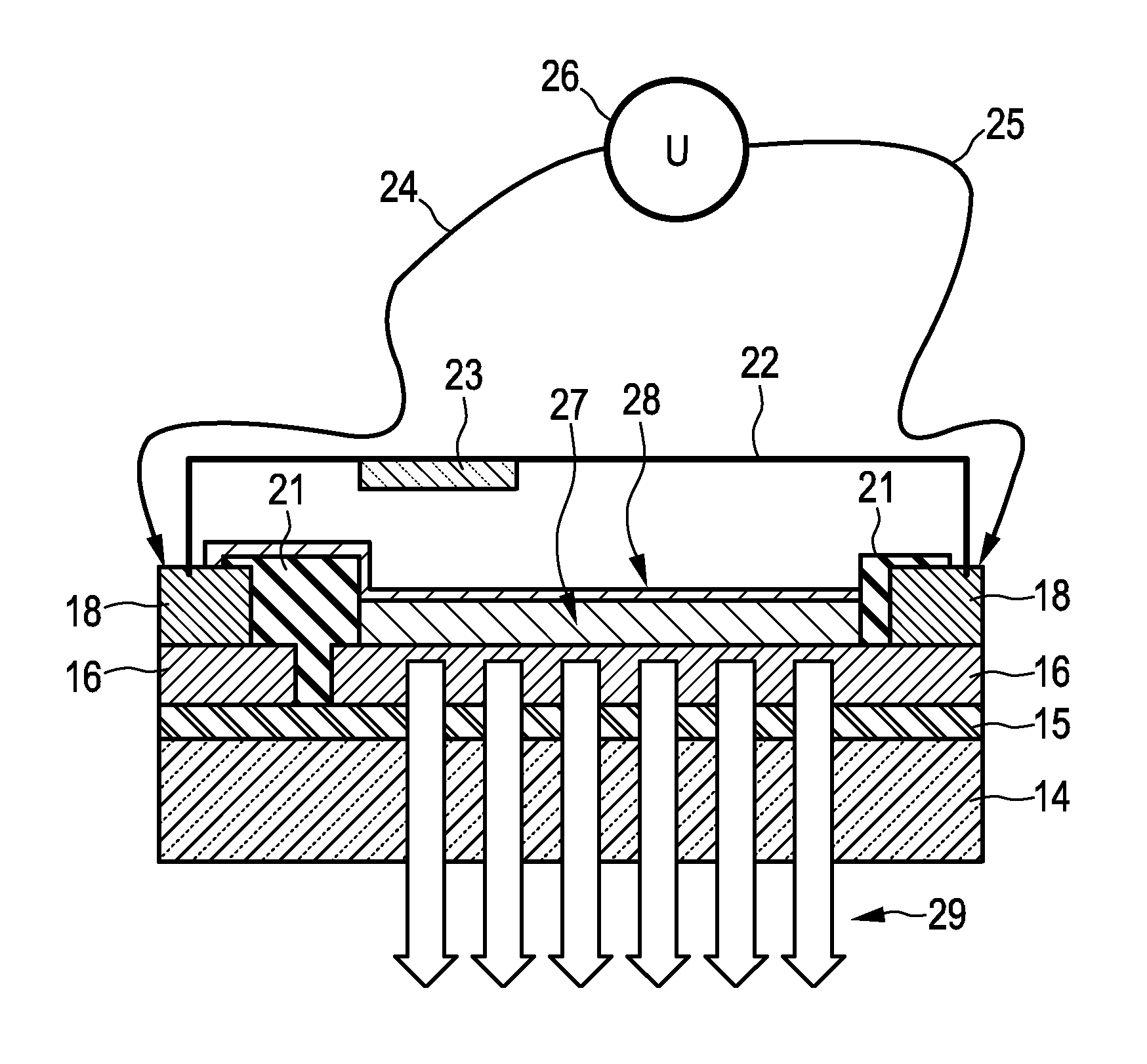

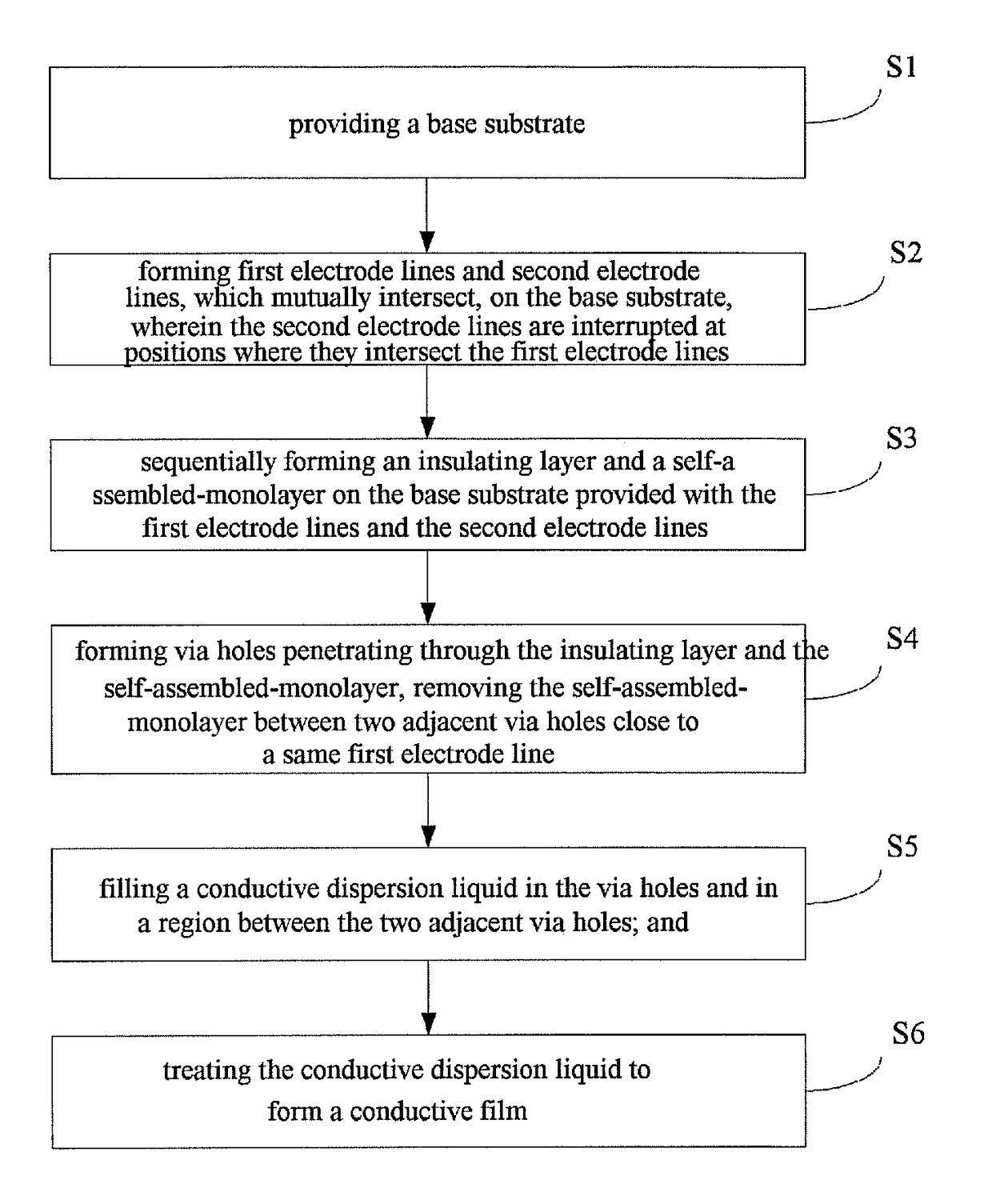

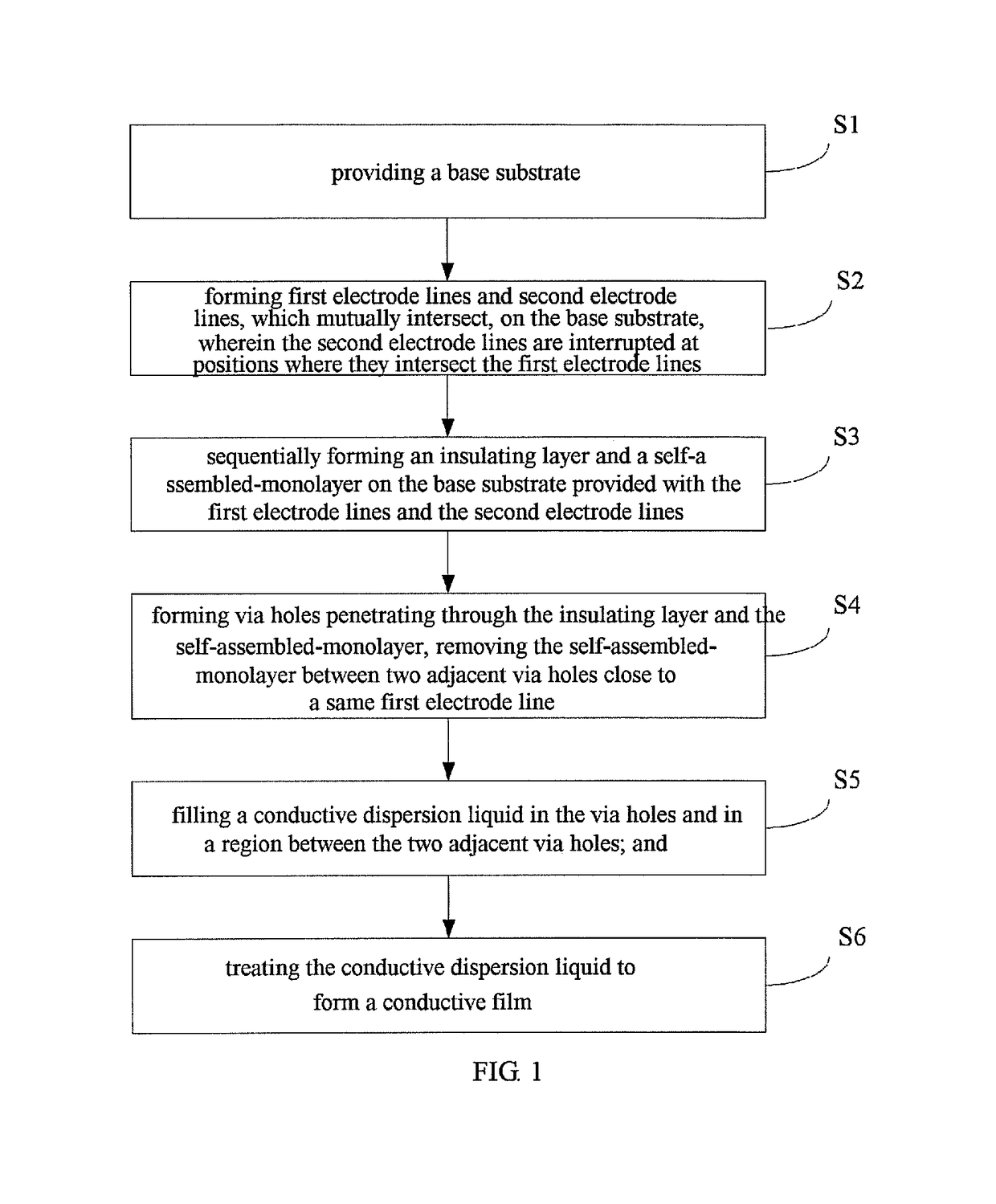

Conductive bridging method, bridging structure, touch panel and touch control display apparatus

ActiveUS20170038865A1Easy to operateReduce processing costsInput/output processes for data processingSelf-assembled monolayerEngineering

The present invention relates to the technical field of display by a touch screen, and particularly relates to a conductive bridging method, a bridging structure, a touch panel and a touch control display apparatus. The conductive bridging method comprises: sequentially forming an insulating layer and a self-assembled-monolayer on the base substrate provided with first electrode lines and second electrode lines which mutually intersect; forming via holes penetrating through the insulating layer and the self-assembled-monolayer; removing the self-assembled-monolayer between two adjacent via holes close to a same first electrode line; and forming a conductive film in the via holes and in a region between two adjacent via holes. In this way, a bridging connection is achieved with the help of the electrical conductivity of the conductive film.

Owner:BOE TECH GRP CO LTD +1

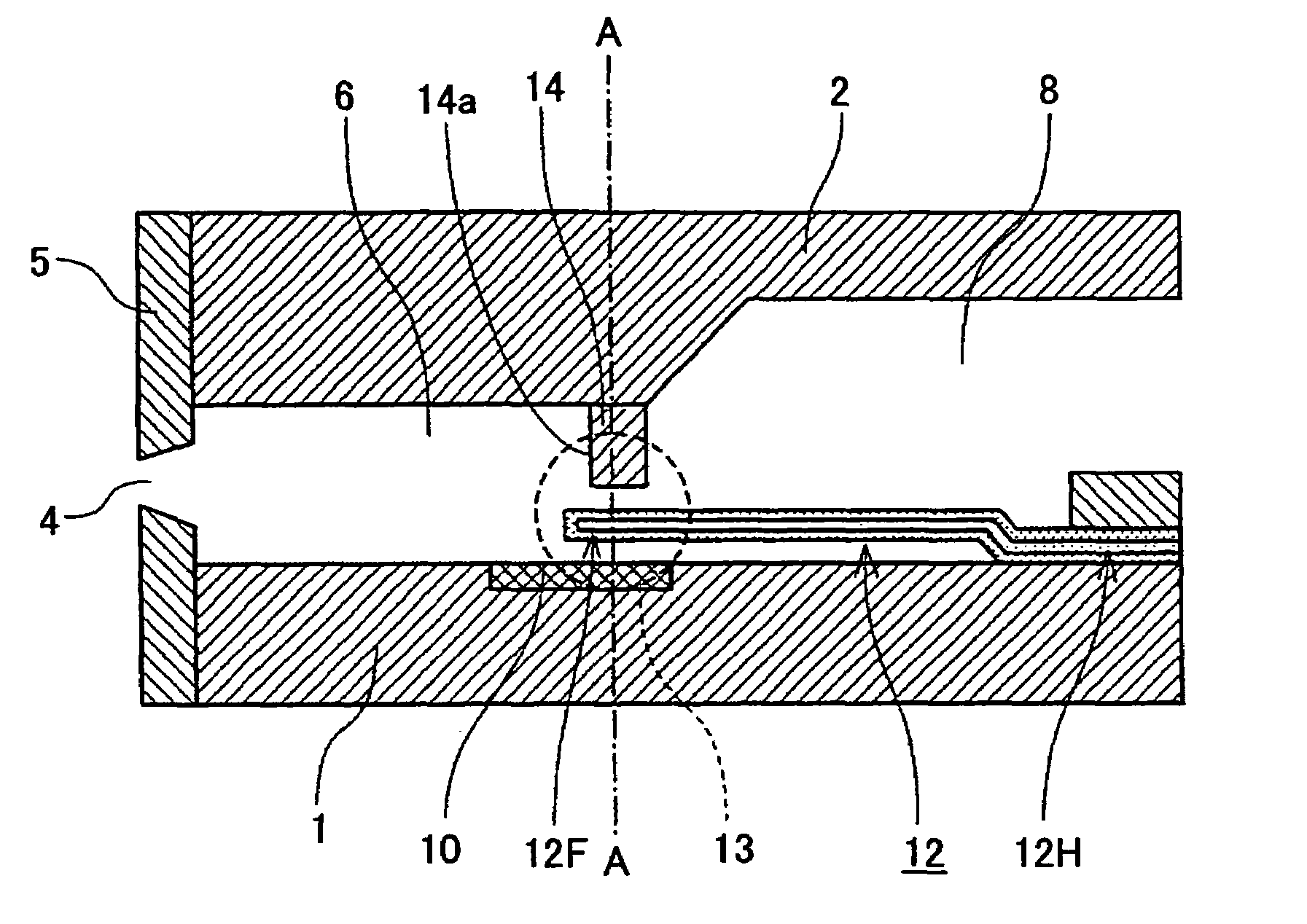

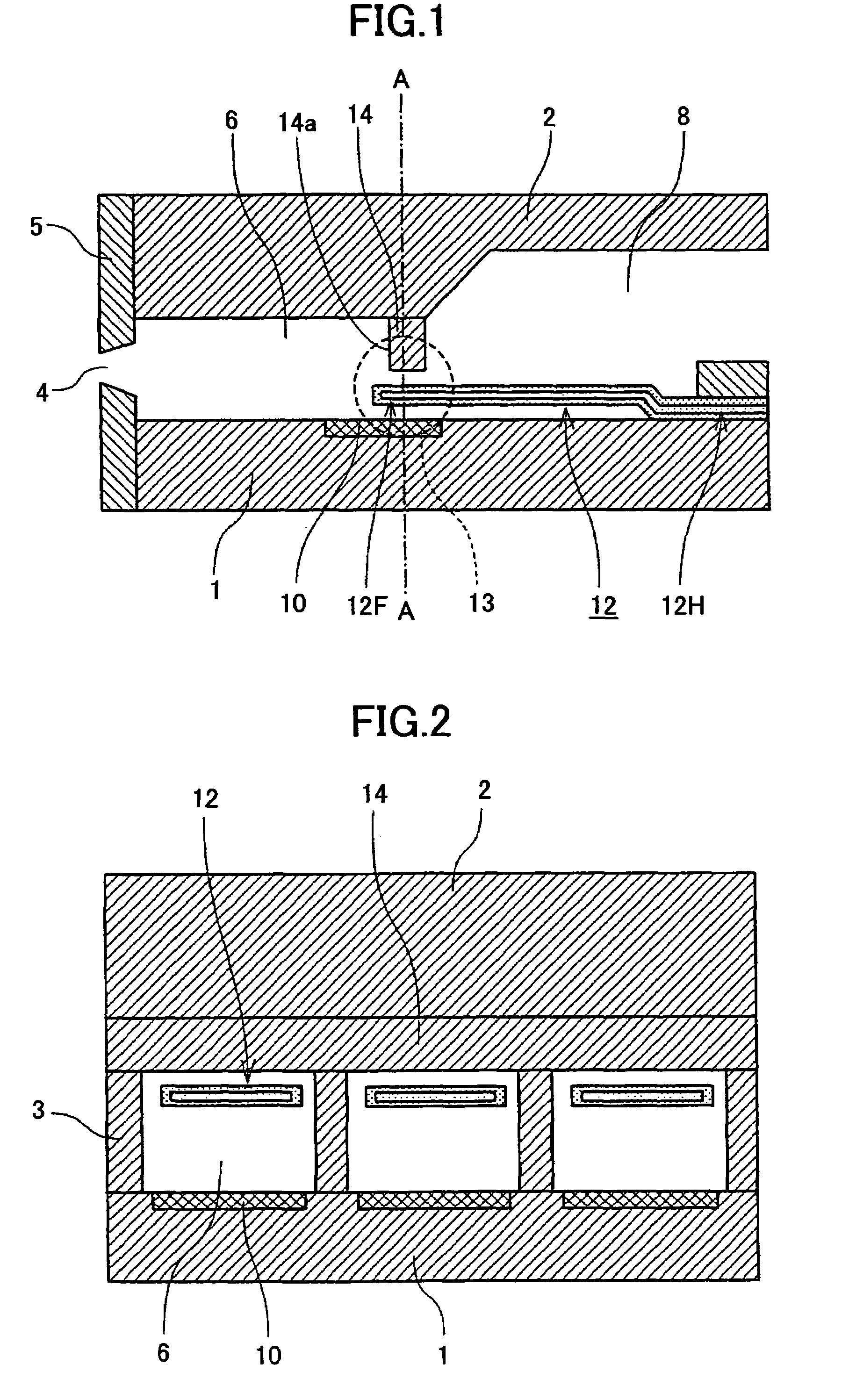

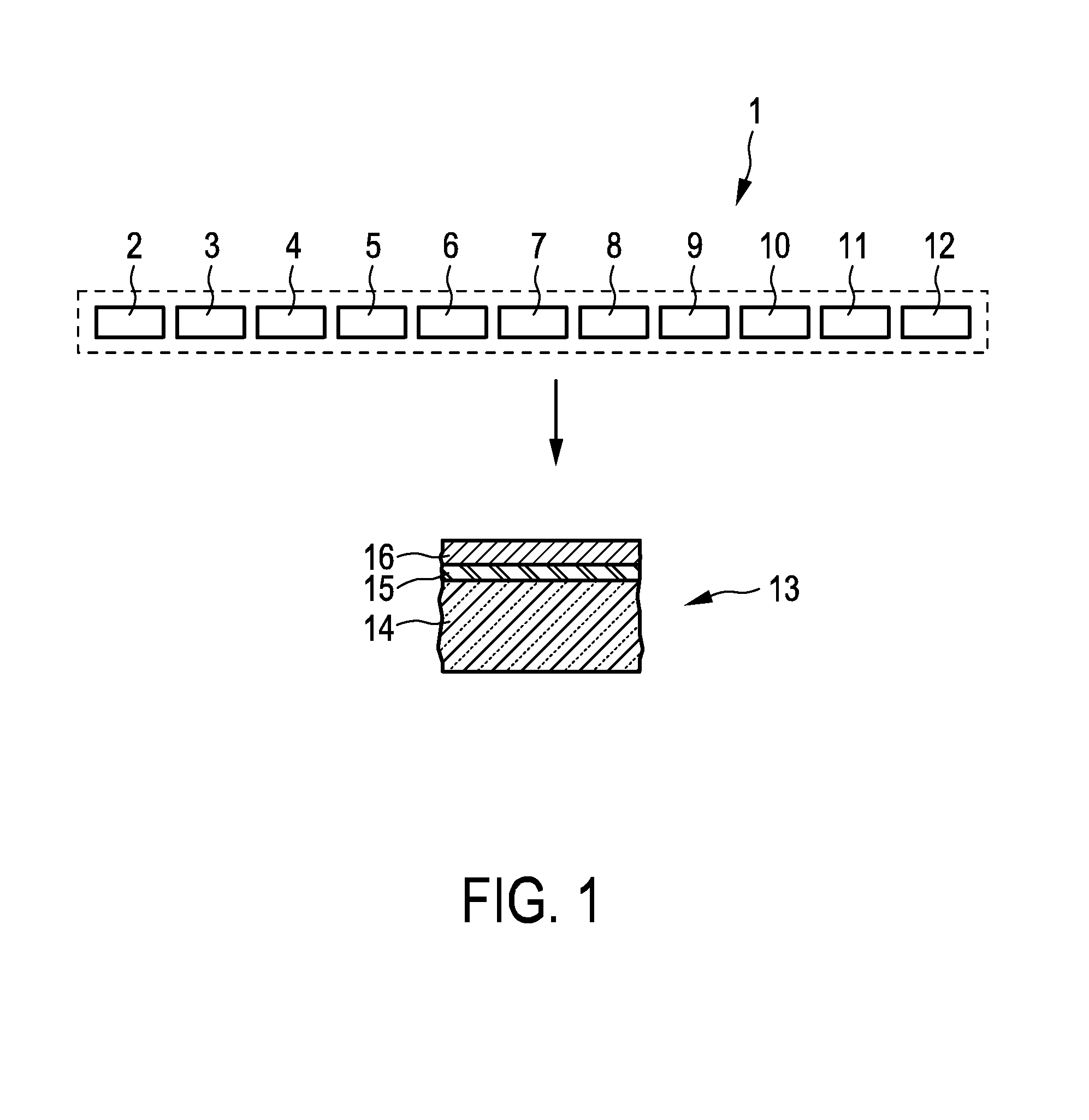

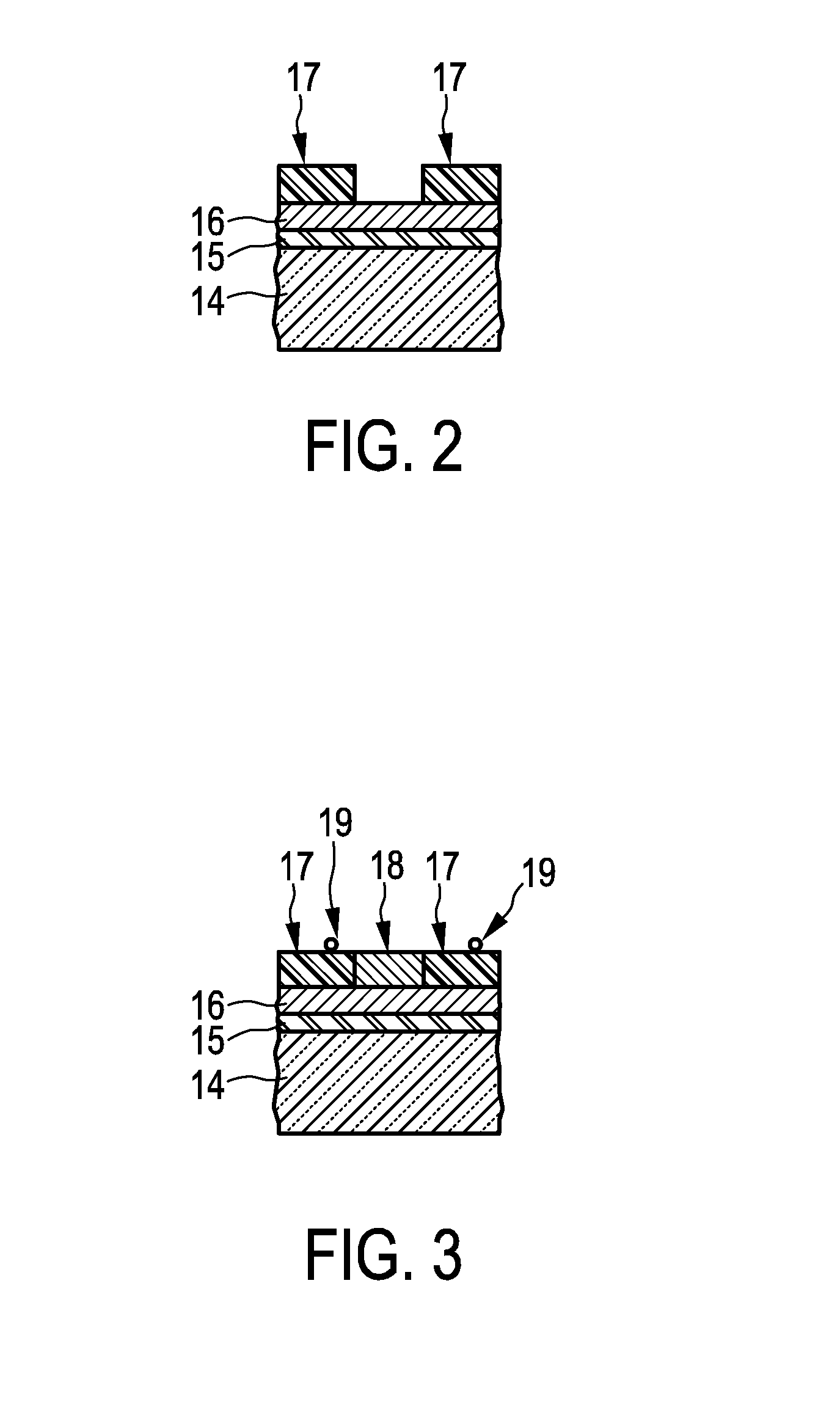

Fabrication apparatus for fabricating a patterned layer

InactiveUS20140203250A1Improve accuracyLarge spreadConfectionerySolid-state devicesLiquid layerMelt temperature

The invention relates to a fabrication apparatus for fabricating a patterned layer (18) on a substrate (14). Protective material (17) is applied in second regions on the substrate (14) and liquid layer material (18) is then printed in first regions being different to the second regions on the substrate (14). The layer material (18) is dried by heating the layer material (18) to a drying temperature being smaller than a melting temperature of the protective material (17), before removing the protective material (17) from the substrate (14) by using a removing temperature being larger than the melting temperature of the protective material (17). A patterned layer (18) can therefore be produced, without using, for example, a costly photolithography process, and because of the use of the protective material (17) the layer material (18) is present in the desired first regions only and not in the second regions. This improves the quality of the patterned layer, which may be used for producing an OLED.

Owner:OLEDWORKS GMBH

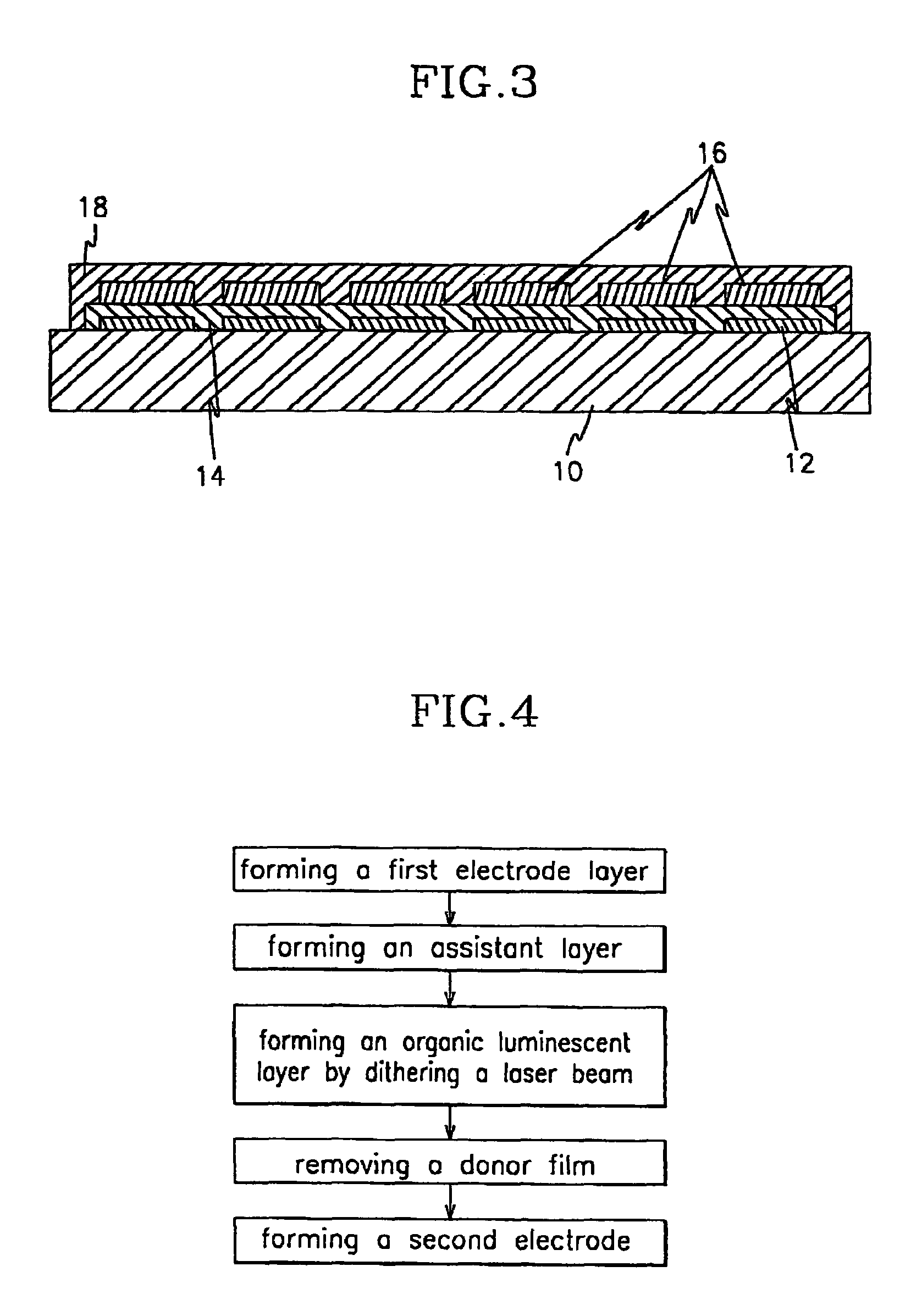

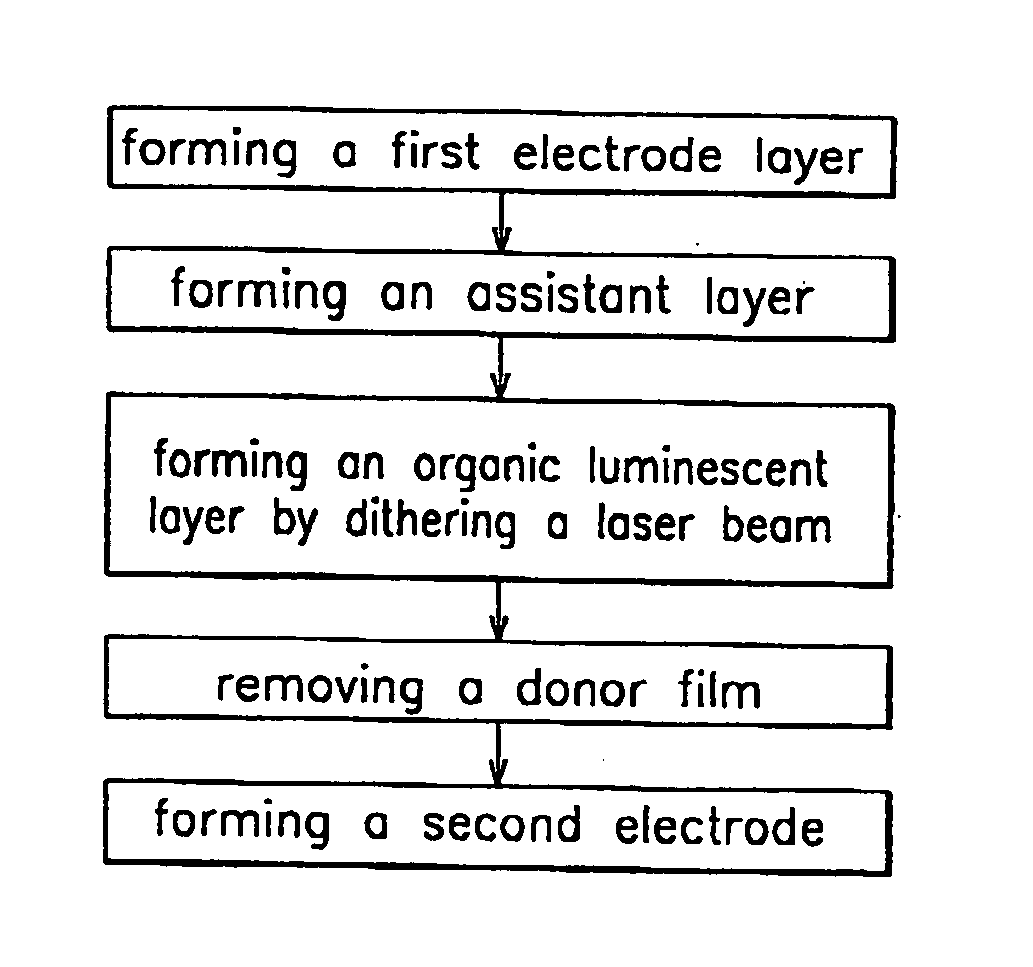

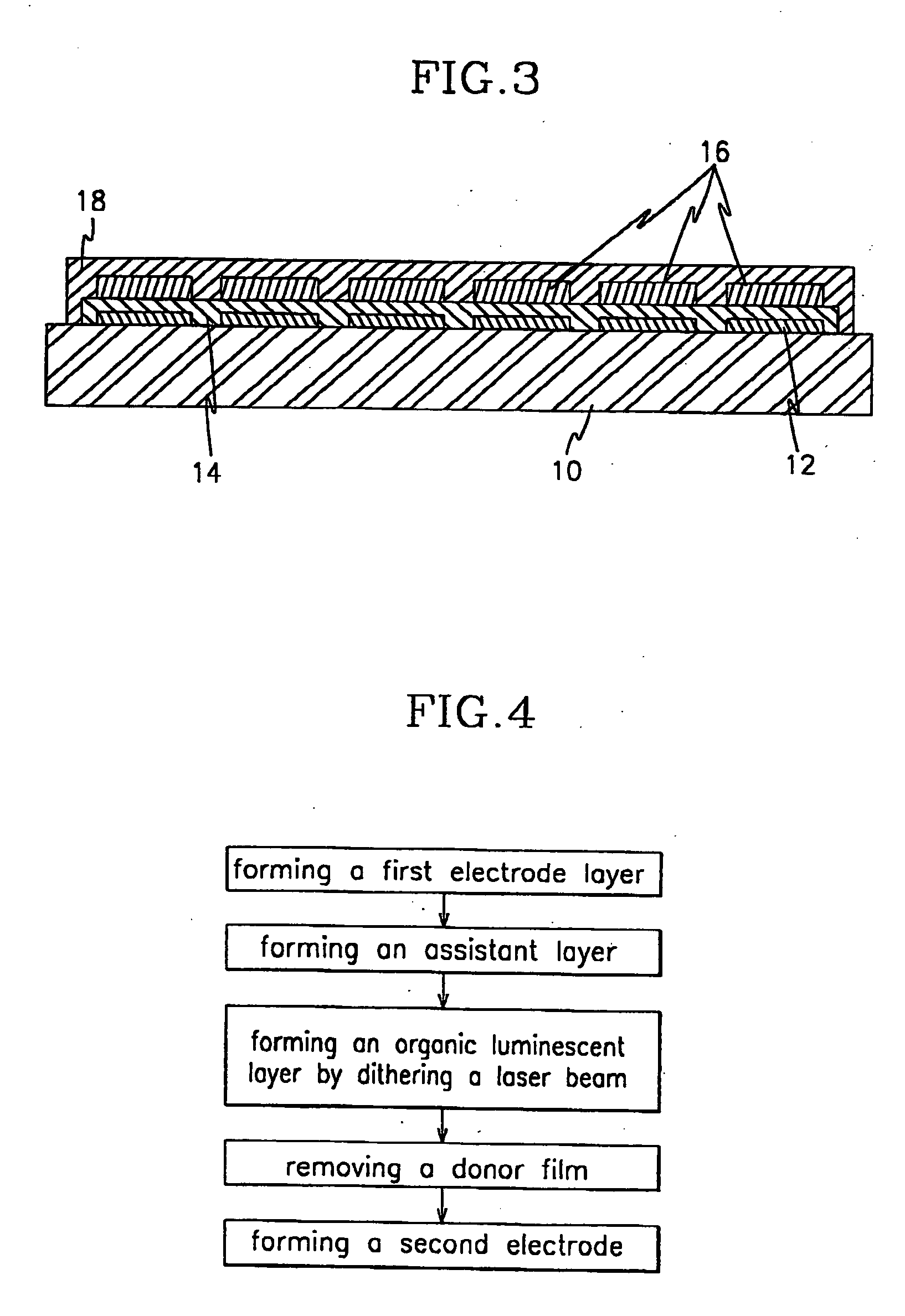

Method for fabricating organic electroluminescent display

InactiveUS7563477B2Improve pattern qualityDiffusion transfer processesElectric discharge heatingOptoelectronicsOrganic electroluminescence

Owner:SAMSUNG DISPLAY CO LTD

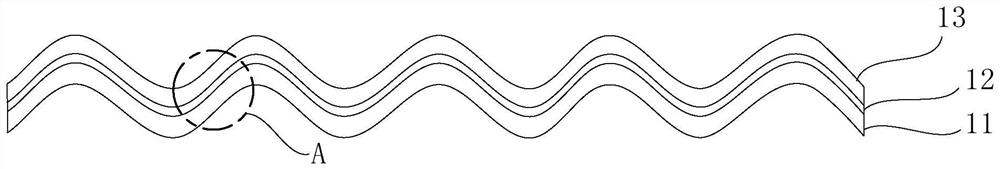

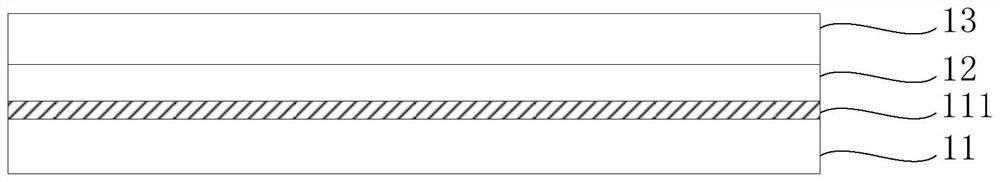

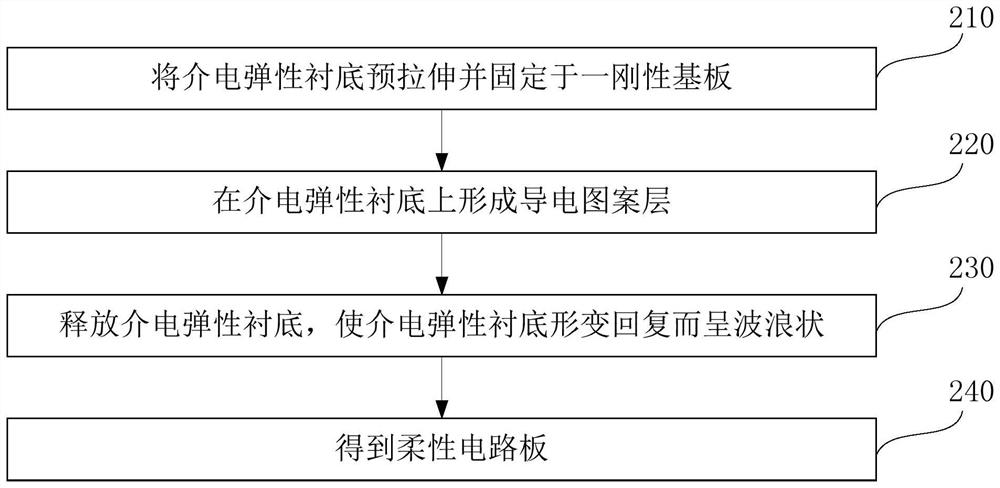

Flexible circuit board and manufacturing method thereof

PendingCN112867238AImprove bending resistanceImprove pattern qualityPrinted circuit manufactureCircuit susbtrate materialsFlexible circuitsElastic substrate

The invention relates to a flexible circuit board and a manufacturing method thereof. The flexible circuit board comprises a dielectric elastic substrate and a conductive pattern layer, the dielectric elastic substrate is wavy, and the conductive pattern layer is located on one side surface of the dielectric elastic substrate. The manufacturing method of the flexible circuit board comprises the following steps of pre-stretching a dielectric elastic substrate and fixing the dielectric elastic substrate on a rigid substrate, forming a conductive pattern layer on the dielectric elastic substrate, releasing the dielectric elastic substrate to enable the dielectric elastic substrate to deform and restore to be wavy, and obtaining the flexible circuit board. According to the flexible circuit board, the dielectric elastic substrate is adopted and is wavy, so that the whole flexible circuit board can be stretched, and the number of times of bending resistance is high. In addition, the dielectric elastic substrate is pre-stretched and fixed on the rigid substrate to manufacture the conductive pattern layer, so that the dielectric elastic substrate can form a regular wavy structure, and the pattern quality of the conductive pattern is good.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

Printing ink

A printing ink belongs to the technical field of an ink. The printing ink comprises the following components, by weight part, sodium alginate, glycerin, triglycol, urea, triethylene glycol monobutyl ether, a mildew inhibitor, polyurethane-modified epoxy resin, polyester resin, a polyether-modified organosilicon antifoaming agent, a nanometer alumina emulsion and cyclohexanone. Through adoption of components including solid epoxy resin, polyester resin and a wear-resisting emulsion, the printing ink is greatly improved in adhesion force and wear resistance, is good in chemical resistance, becomes fine, and is greatly saved in consumption during use. The ink is good in stability and effect, is clear, has no undissolved substance appeared, is long in retention period, and good in light, cold, acid and water resistance, thermal resistance and stability. The prepared ink-jet printing ink is good in quality of printed patterns, has no bleeding or deckle edges, doesn't block the printing head, and ensures uniform printing.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

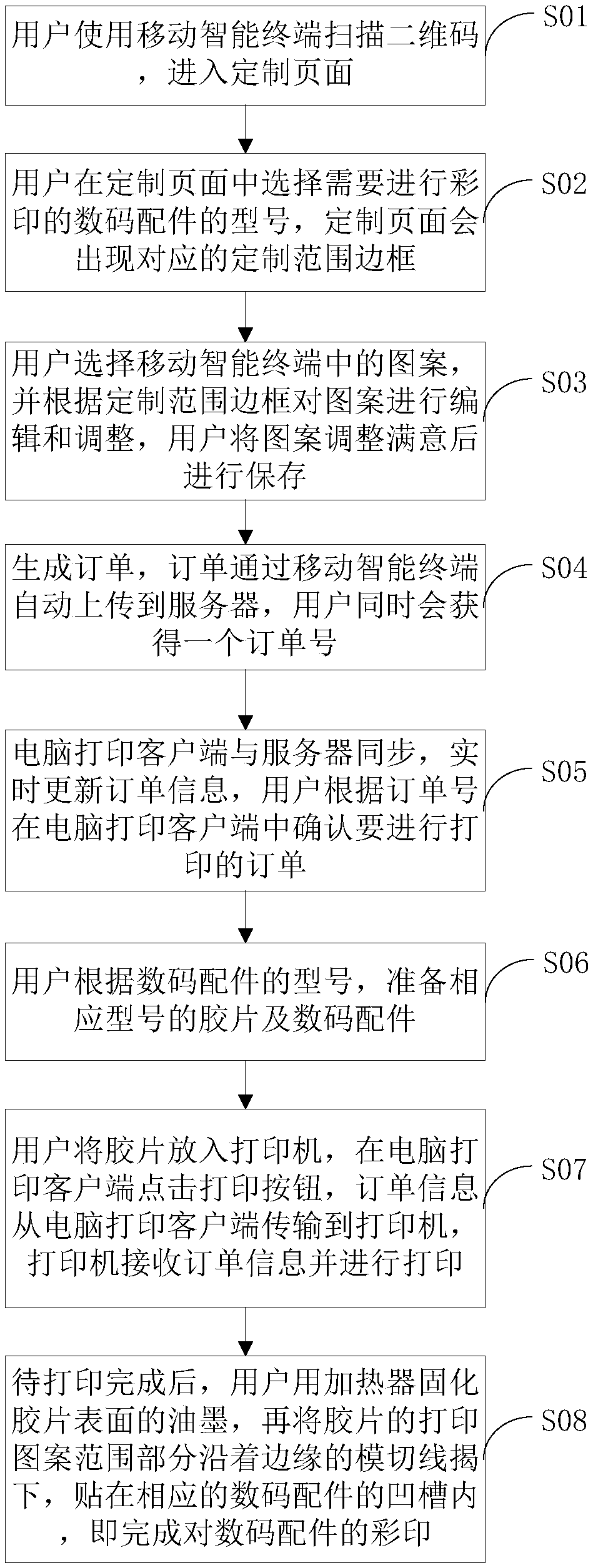

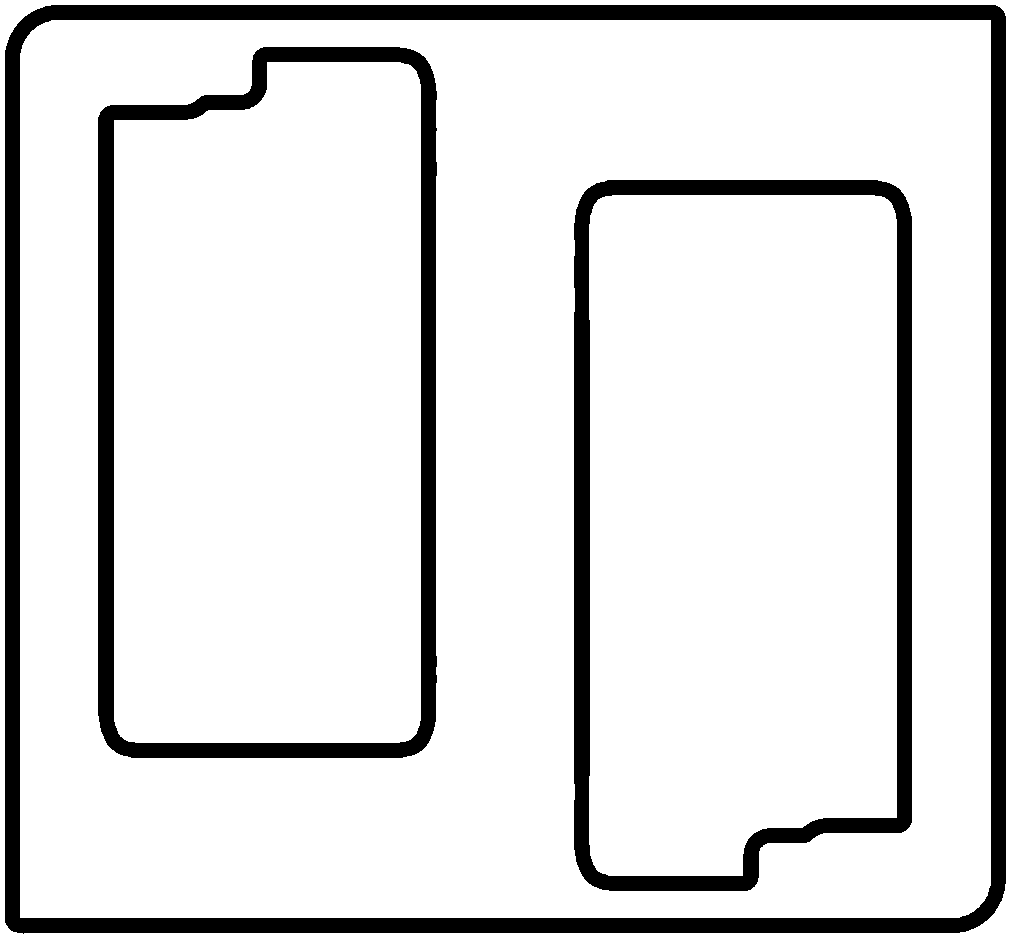

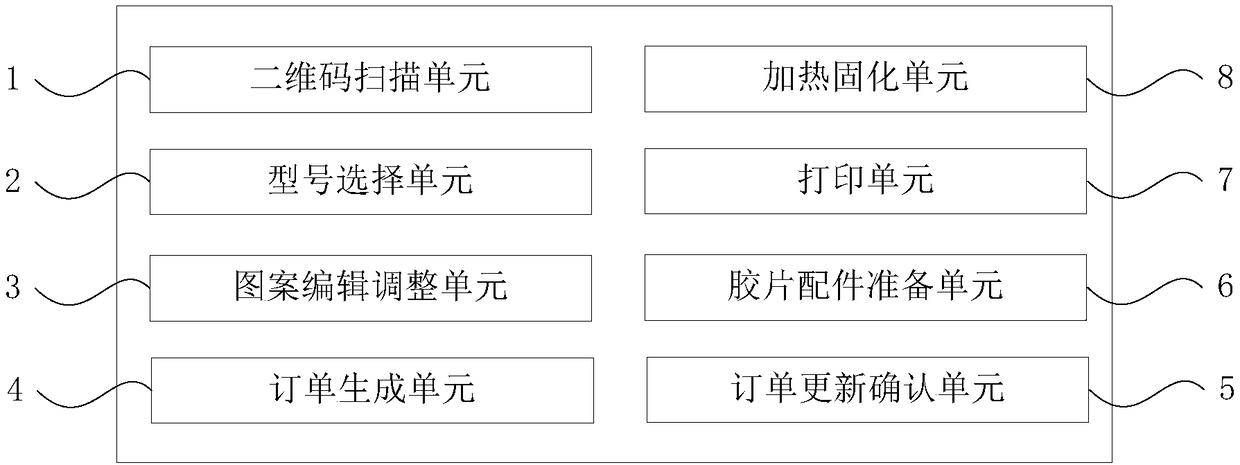

Method of on-site color printing on digital accessory and device

PendingCN108564436AQuality improvementEasy to handleTypewritersBuying/selling/leasing transactionsComputer printingTransfer procedure

The invention discloses a method of on-site color printing on a digital accessory and a device. The method comprises: scanning a two-dimensional code to enter a customization page; selecting a model of the digital accessory of color printing, and giving a customization range frame; selecting a pattern in a mobile intelligent terminal, and editing and adjusting the pattern; generating an order, automatically uploading the order to a server through the mobile intelligent terminal, and obtaining an order number; updating order information in real time by a computer printing client, confirming theorder, of which printing needs to be carried out, by a user in the computer printing client; preparing a film of a corresponding model and the digital accessory by the user; putting the film into a printer by the user, receiving the order information by the printer, and carrying out printing; and using a heater by the user to solidify ink of a surface of the film, then removing a printed patternrange portion of the film along a die-cut line of an edge, and attaching the same in a groove of the corresponding digital accessory to complete color printing on the digital accessory. According to the method, a data processing and transmission process is relatively convenient, a printing process is relatively simple, and pattern quality is better.

Owner:ACECA GUANGZHOU TECH CO LTD

Exposure apparatus

ActiveUS11092903B2Improve pattern qualityLow production costPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringExposure

An exposure apparatus arranged to project a radiation beam onto a target portion of a substrate, the exposure apparatus having: a first substrate holder configured to hold the substrate; a second substrate holder configured to hold the substrate; a sensor holder configured to hold a sensor and / or detector; a first measurement device having a first alignment system having an alignment sensor configured to measure positions of a substrate alignment mark on the substrate; a second measurement device having a second alignment system having a further alignment sensor configured to measure positions of the substrate alignment mark on the substrate; a first scale arranged on a lower surface of the first substrate holder; and a first encoder head arranged to cooperate with the first scale, the first encoder head located beneath the first alignment system and held by a stationary support.

Owner:ASML NETHERLANDS BV

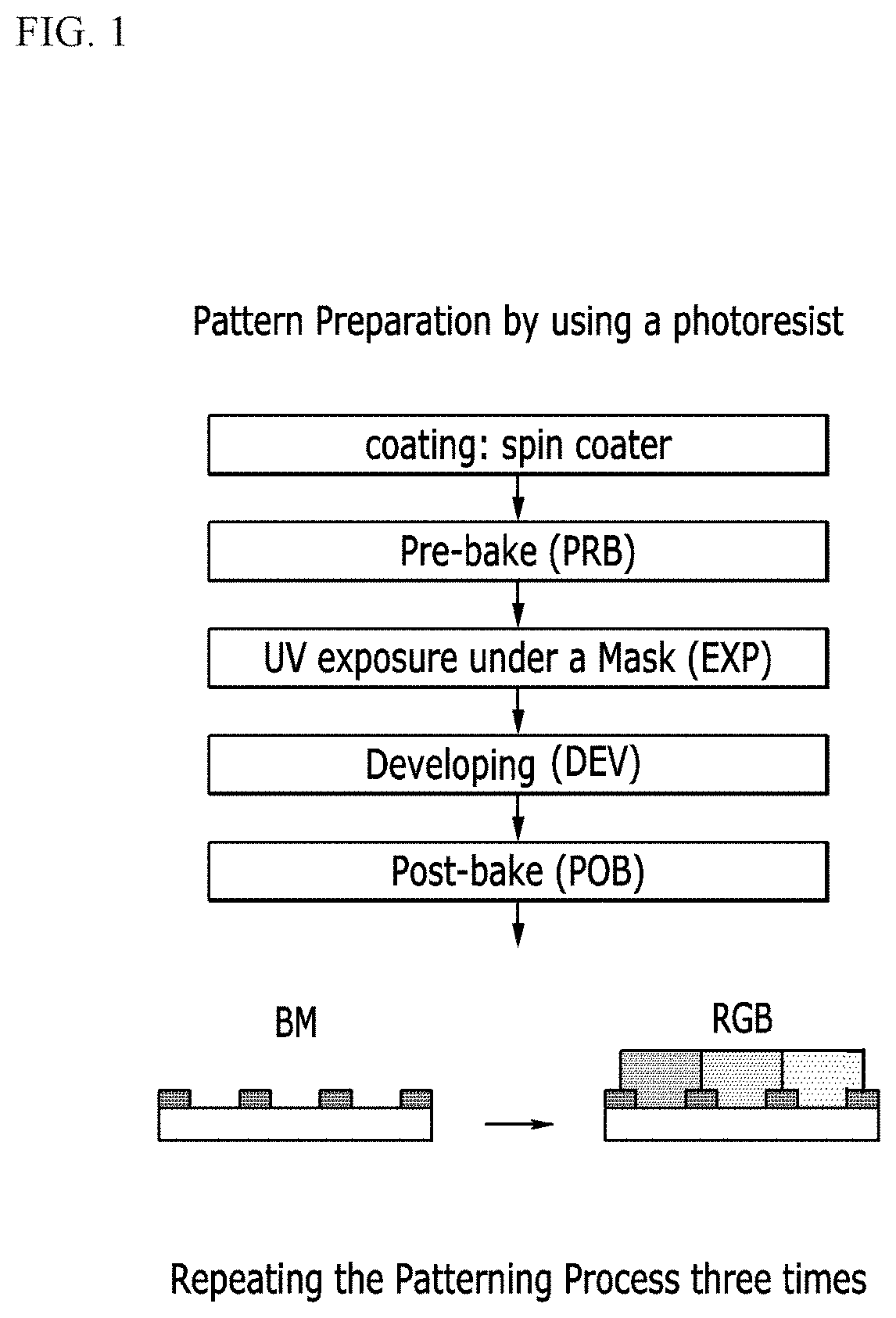

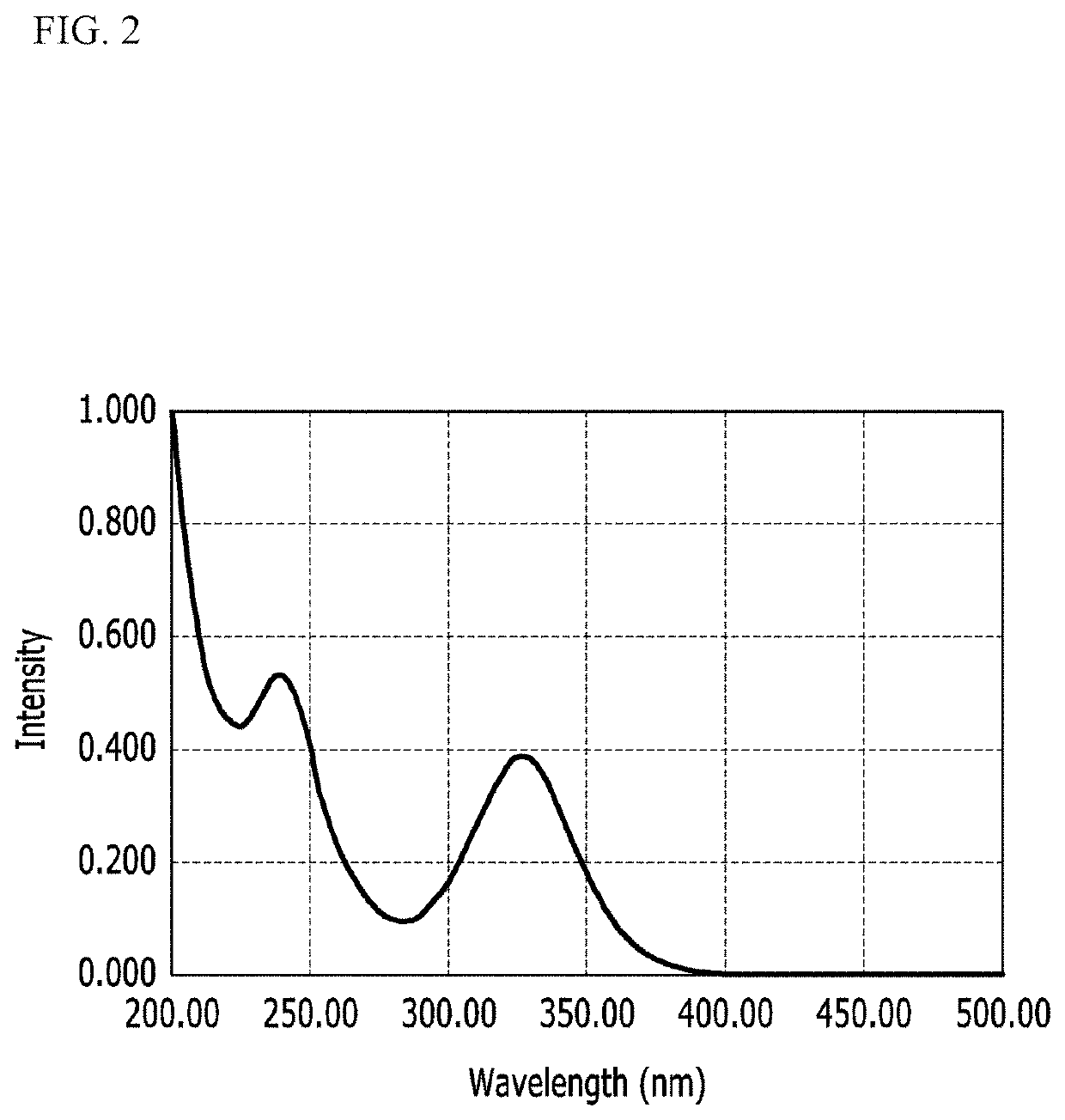

Photosensitive compositions, preparation methods thereof, and quantum dot polymer composite pattern produced therefrom

ActiveUS10990006B2Improve pattern qualityPhotosensitive materials for photomechanical apparatusLuminescent compositionsPolymer scienceCarboxylic acid

A photosensitive composition including: a plurality of quantum dots, wherein the quantum dot includes an organic ligand bound to a surface of the quantum dot; a photoinitiator; a binder including a carboxylic acid group; a photopolymerizable monomer having a carbon-carbon double bond; and a solvent, wherein the photoinitiator includes a first photoinitiator including an oxime compound and a second photoinitiator including at least one selected from a phosphine oxide compound and an amino ketone compound.

Owner:SAMSUNG ELECTRONICS CO LTD +2

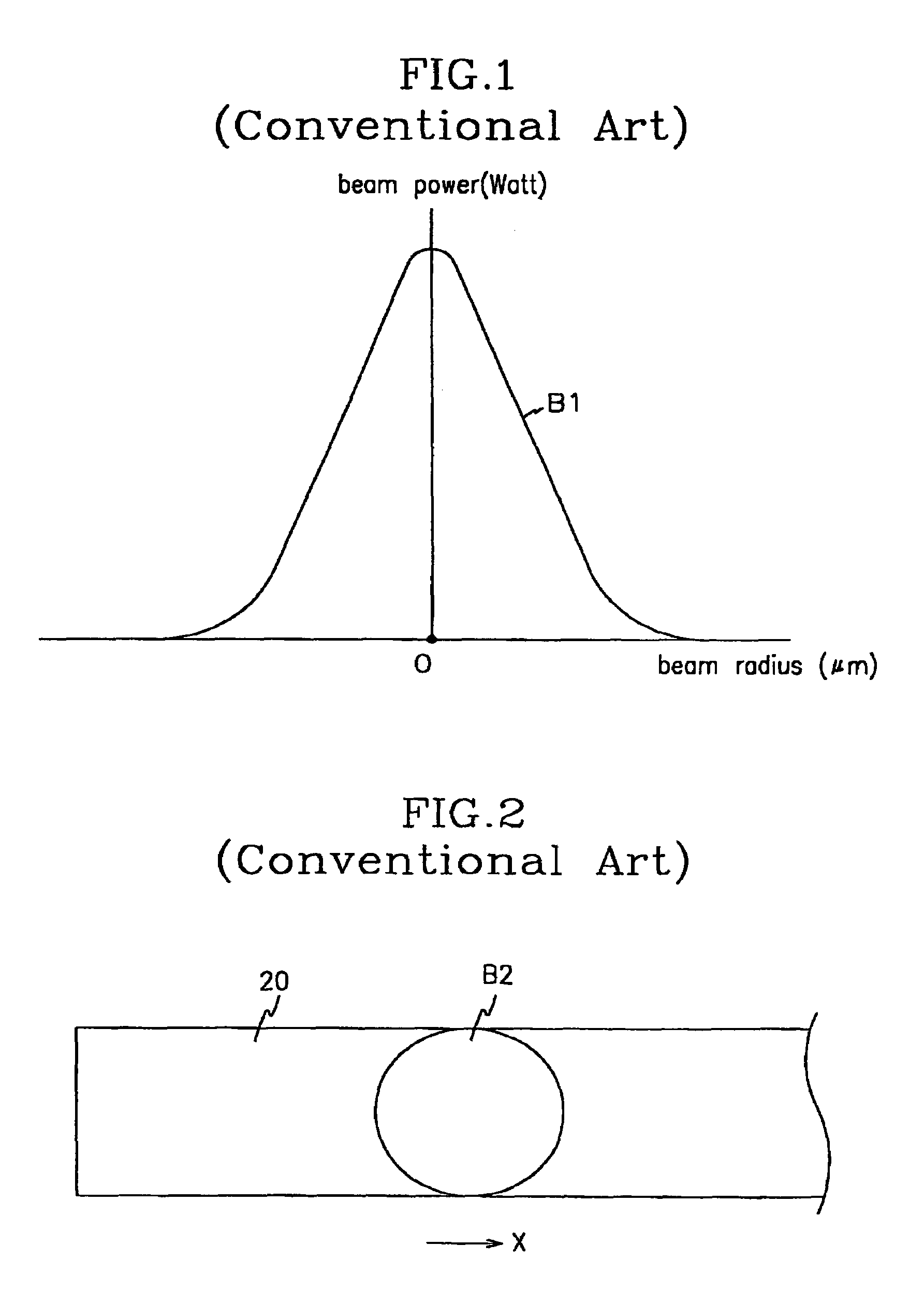

Method for fabricating organic electroluminescent display

InactiveUS20050227568A1Improve pattern qualityElectroluminescent light sourcesSolid-state devicesOptoelectronicsOrganic electroluminescence

In a method for fabricating an organic electroluminescent display, a first electrode layer is formed on a transparent substrate, and a hole transport layer is formed on the first electrode layer. After an organic luminescent layer is formed on the hole transport layer by scanning a donor film disposed on the substrate using a laser beam, the donor film is removed and then a second electrode is formed on the organic luminescent layer. The laser beam dithers while performing the scanning operation to make the energy distribution uniform.

Owner:SAMSUNG DISPLAY CO LTD

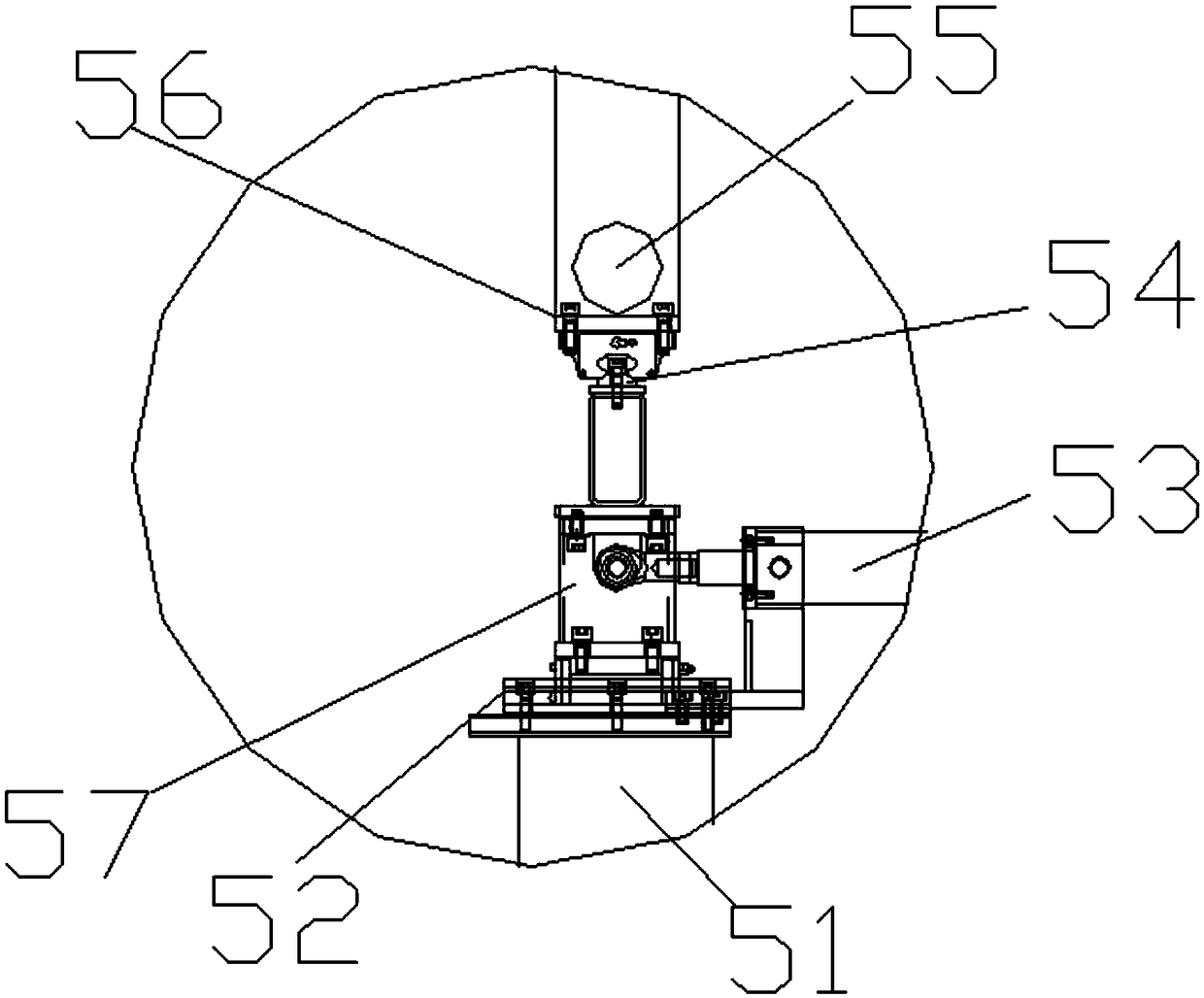

Coating material register hot-pressing production device

PendingCN109049932AEnsure alignment accuracyImprove pattern qualityControlling laminationLaminationEngineeringHot pressing

The invention discloses a coating material register hot-pressing production device, comprising a controller, a winding roller, a hot press, a first visual detection device, a second visual detection device, a first clamping component, a second clamping component, a first loosing component, a second loosing component and a plurality of unwinding rollers, wherein the plurality of unwinding rollers,the first loosing component, the first clamping component, the first visual detection device, the hot press, the second visual detection device, the second clamping component, the second loosing component and the winding roller are arranged in a production line way from front to back, and are separately connected with a controller in linear way. The coating material register hot-pressing production device guarantees the register accuracy between plane patterns on decorative paper and three-dimensional patterns on a stainless steel template, thus improving the pattern quality and reducing the production of wastes.

Owner:苏州伍得人造板设备有限公司

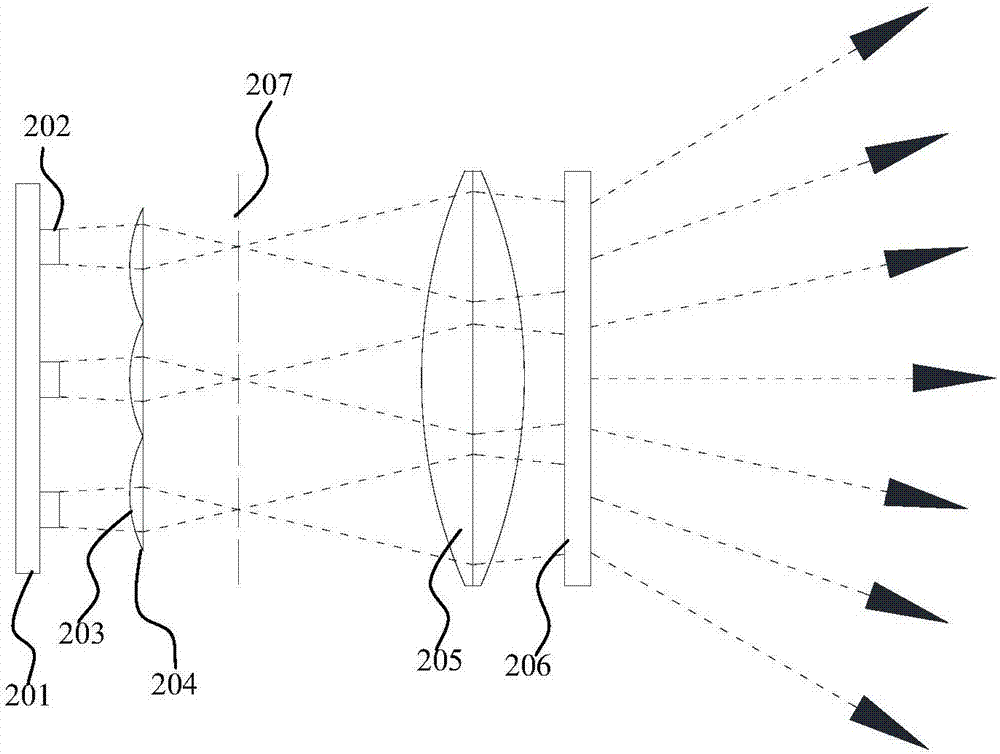

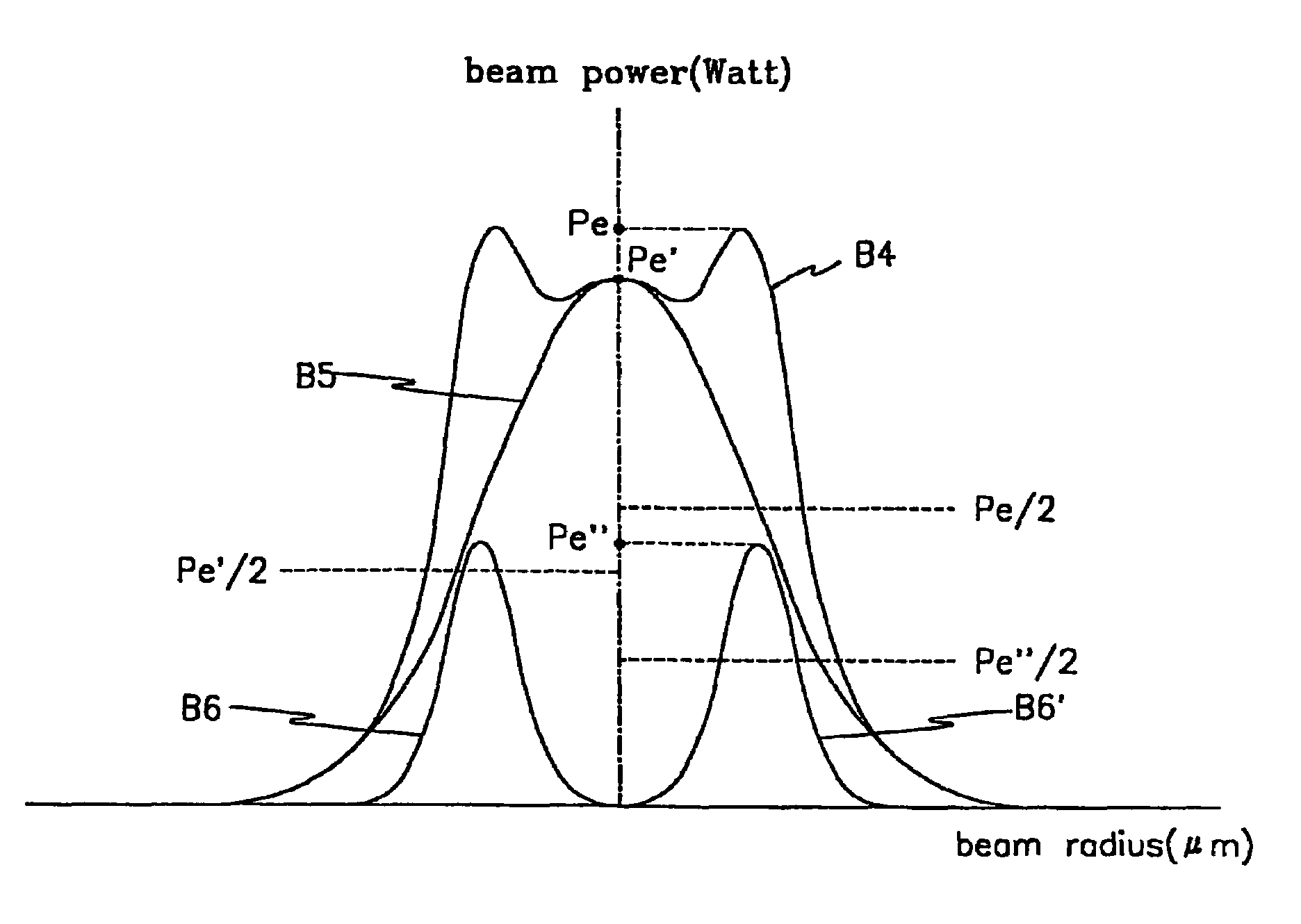

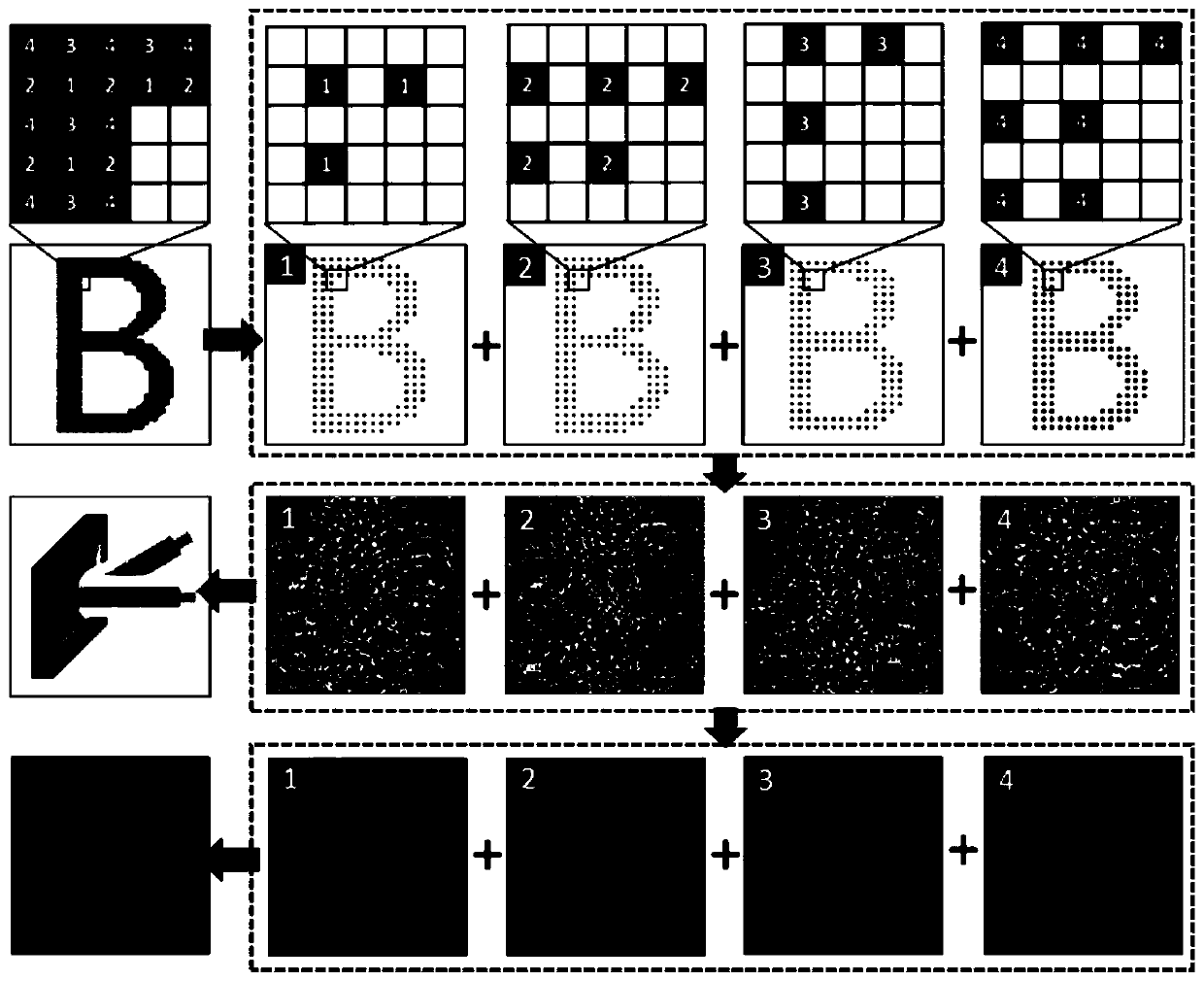

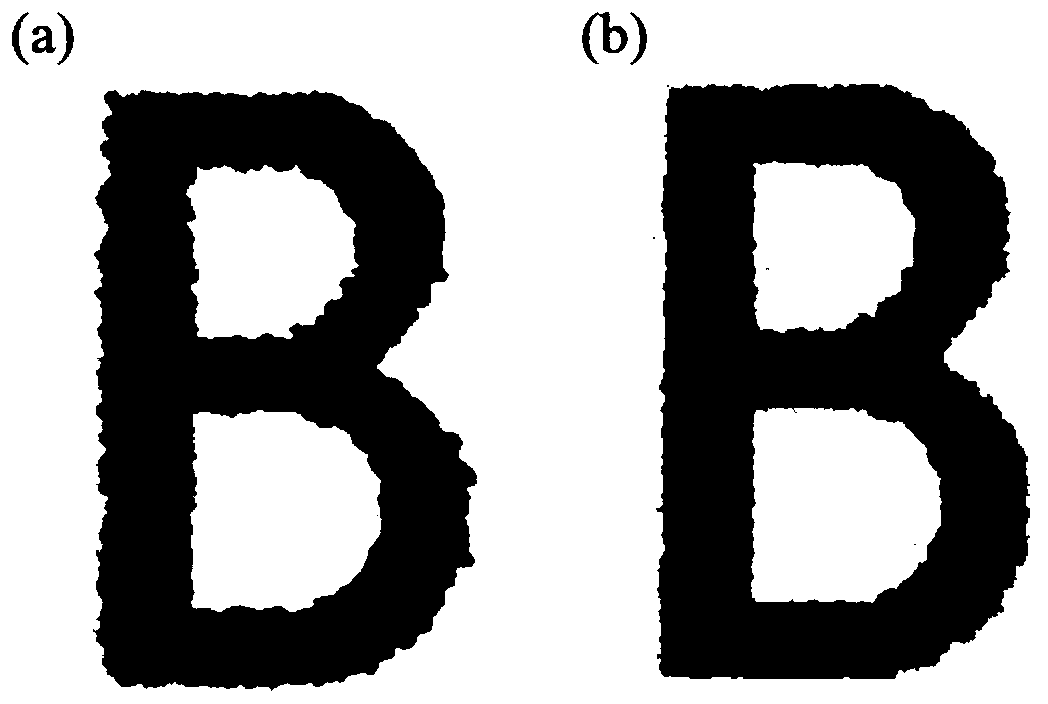

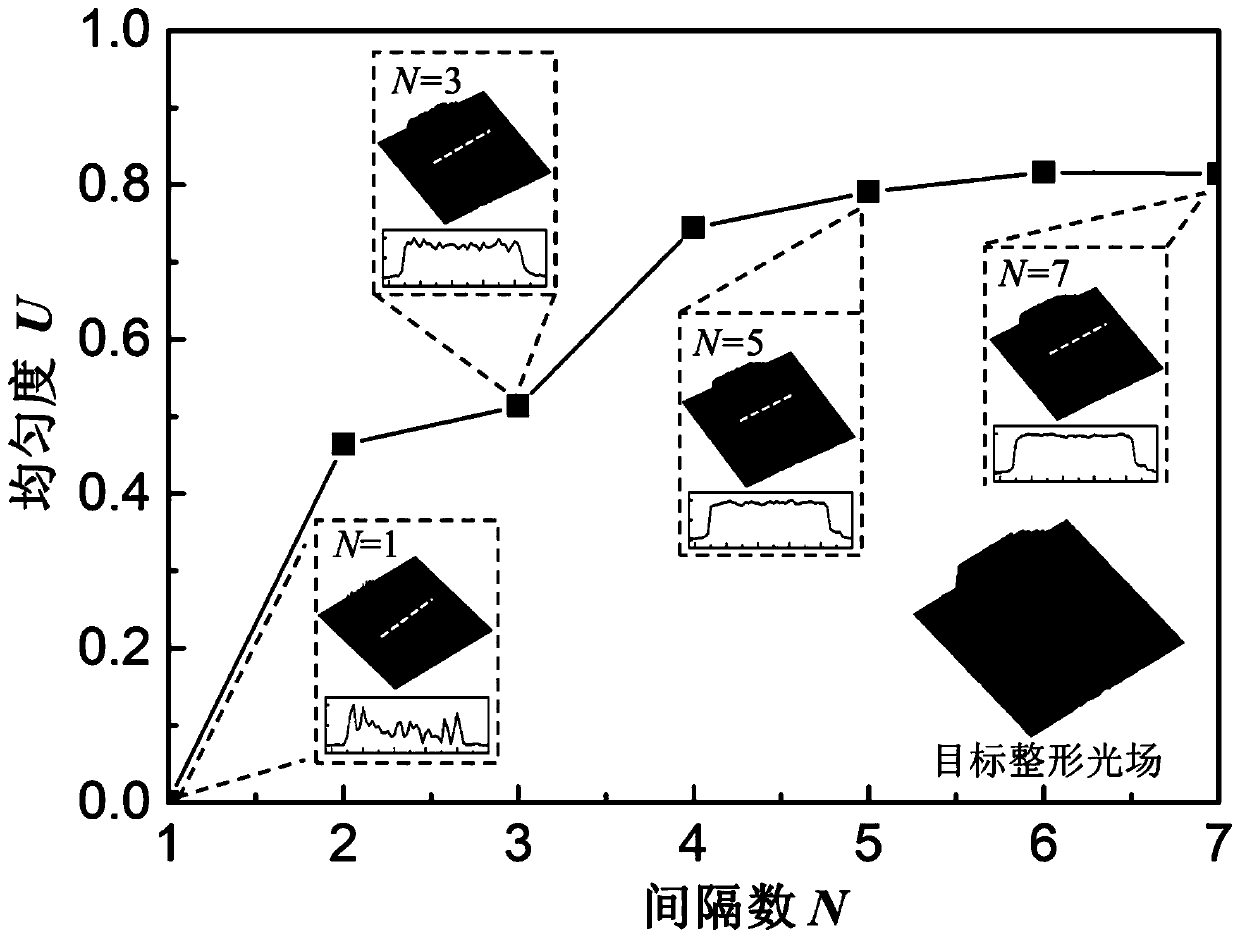

A method for improving the uniformity of laser patterning

ActiveCN109590604BReduce speckle noiseImprove pattern qualityLaser beam welding apparatusOptical elementsSpatial light modulatorLaser patterning

The invention relates to a method for improving the laser patterning processing uniformity, and belongs to the technical field of laser application. According to the method for improving the laser patterning processing uniformity, a to-be-processed pattern is disassembled into a series of sub-patterns by adopting an interlacing splitting method, a phase diagram of each sub-pattern is calculate according to a Fourier iterative algorithm, then the phase diagrams are sequentially loaded into a spatial light modulator to obtain shaping light fields, the sub-pattern corresponding to each shaping light field is processed on a material by using the shaping light fields, and the sub-patterns are finally combined into the complete processing pattern. In this way, the problem of uneven energy deposition caused by spot noise of the light field when a single phase diagram is adopted for carrying out laser space light field shaping processing is solved, and then the purpose of improving the laser patterning processing uniformity is achieved. The method is simple in principle, the uniformity of a processing result is remarkably improved, and the method has strong practicability; and the method for improving the energy deposition uniformity by performing interlacing splitting on the to-be-processed pattern can play an important role in laser space light field shaping and patterning processingbased on the spatial light modulator.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Conductive bridging method, bridging structure, touch panel and touch control display apparatus

ActiveUS9665228B2Poor robustnessComplicated processInput/output processes for data processingSelf-assembled monolayerEngineering

The present invention relates to the technical field of display by a touch screen, and particularly relates to a conductive bridging method, a bridging structure, a touch panel and a touch control display apparatus. The conductive bridging method comprises: sequentially forming an insulating layer and a self-assembled-monolayer on the base substrate provided with first electrode lines and second electrode lines which mutually intersect; forming via holes penetrating through the insulating layer and the self-assembled-monolayer; removing the self-assembled-monolayer between two adjacent via holes close to a same first electrode line; and forming a conductive film in the via holes and in a region between two adjacent via holes. In this way, a bridging connection is achieved with the help of the electrical conductivity of the conductive film.

Owner:BOE TECH GRP CO LTD +1

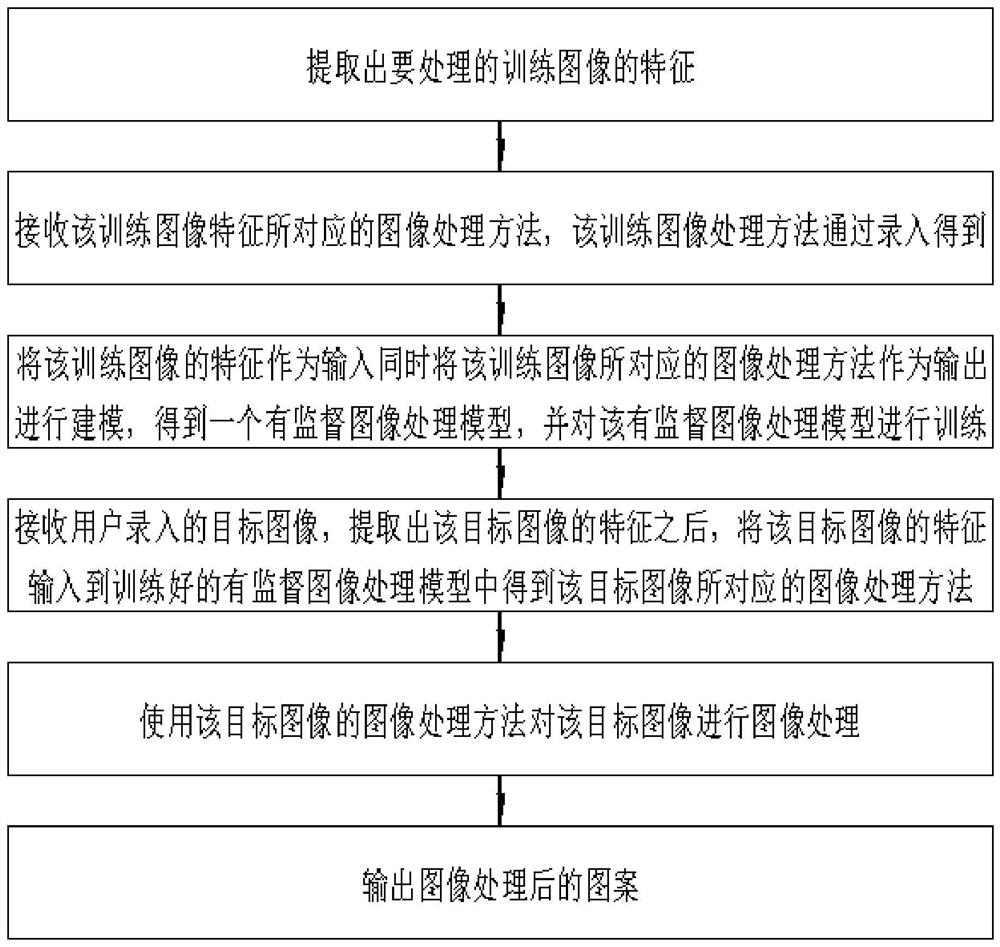

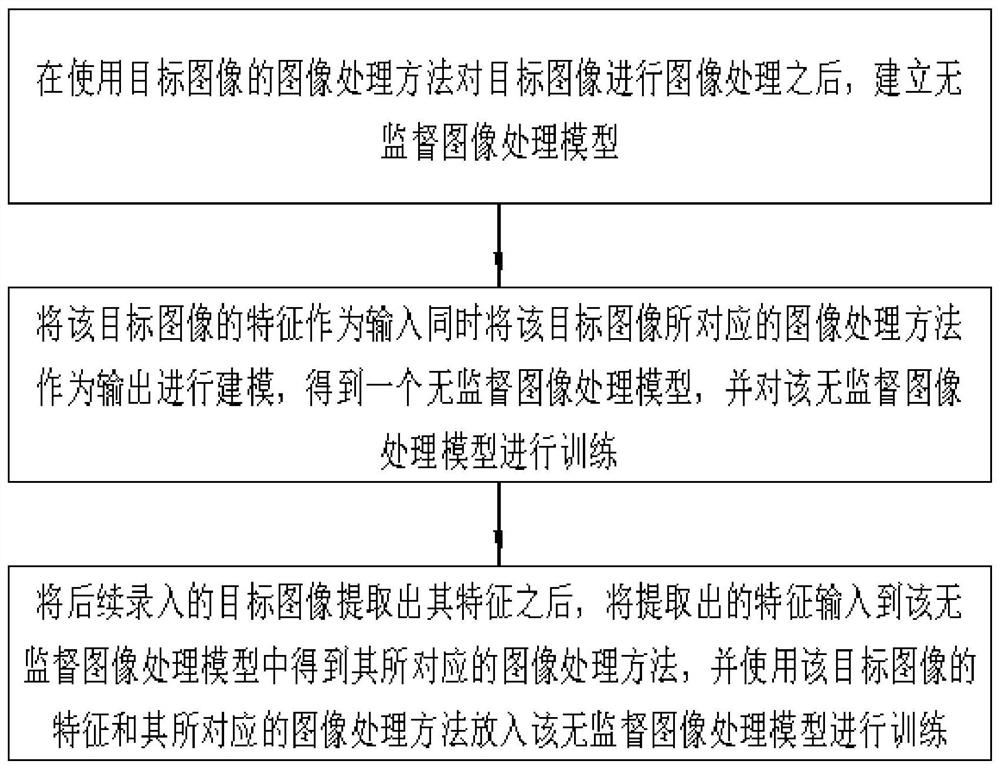

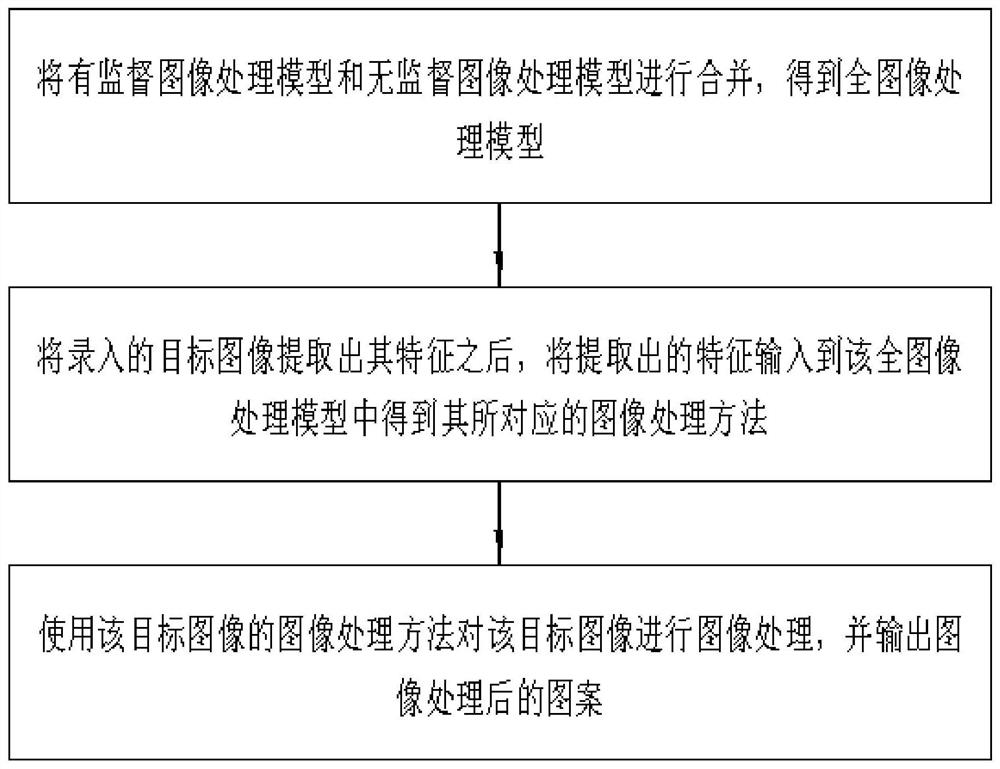

Image processing method based on machine learning

PendingCN112070099AChoose accuratelyImprove pattern qualityCharacter and pattern recognitionMachine learningPattern recognitionImaging processing

The invention discloses an image processing method based on machine learning. The method comprises the following steps: extracting features of a training image to be processed; receiving an image processing method corresponding to the training image features, wherein the training image processing method is obtained through input; modeling by taking the features of the training image as input and taking an image processing method corresponding to the training image as output to obtain an image processing model; receiving a target image input by a user, extracting features of the target image, and inputting the features of the target image into the trained image processing model to obtain an image processing method corresponding to the target image; performing image processing on the targetimage by using an image processing method of the target image; and outputting the pattern after image processing. According to the invention, a user inputs the image, the image processing method of the image is obtained in the image processing model by identifying the characteristics of the image, and finally the extracted pattern is obtained.

Owner:JIANGXI UNIVERSITY OF FINANCE AND ECONOMICS

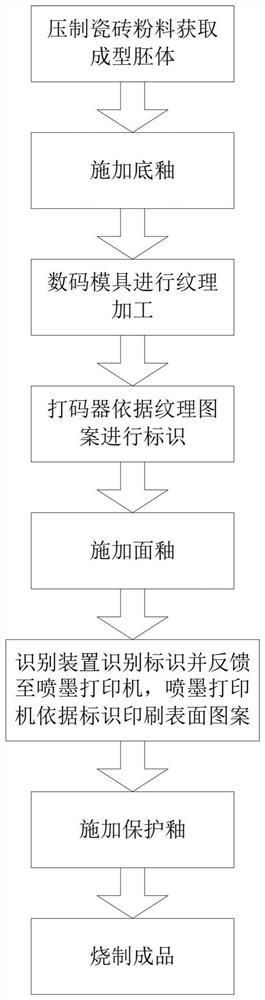

Ceramic tile production method

ActiveCN114074374AImprove the decorative effectRich styleCeramic shaping apparatusCompression moldingTexture processing

The invention discloses a ceramic tile production method which comprises the steps: S1, processing raw materials, and performing compression molding treatment to obtain compression molded blank bodies; S2, carrying out texture processing on the blank bodies, and forming texture patterns comprising one or more concave textures and / or convex textures, wherein the concave textures are formed by applying reaction substances to erode a surface to be subjected to texture applying, and the convex textures are formed by stacking non-erosion substances on the surface to be subjected to texture applying; S3, identifying the blank bodies with the texture patterns, wherein the identification at least reflects the texture pattern information of the current blank bodies; S4, applying overglaze to the identified blank bodies, and printing a corresponding pattern according to the identification; and S5, firing a finished product. The texture formed by erosion or stacking is more natural and attractive, different texture patterns between the blank bodies can be formed in the production process, the patterns of the texture patterns of the blank bodies are enriched, meanwhile, the printed patterns correspond to the texture patterns on the basis of the identification, and the decoration effect of the final ceramic tile finished product can be remarkably improved.

Owner:GUANGZHOU KINGTAU MACHINERY & ELECTRONICS EQUIP CO LTD

Waste construction material soil conversion method

InactiveCN100337761CSatisfied with elasticityNo resistanceSolid waste managementSolid waste disposalCalcium silicateMaterials science

A soil conversion method of waste building materials is provided. The waste building materials of building materials molded by a building material composition are converted into soil by crushing or steam treatment. The building material composition is formed by blending calcium silicate-based building materials with non-expanded vermiculite.

Owner:MITSUBISHI SHOJI CONSTR MATERIALS CORP

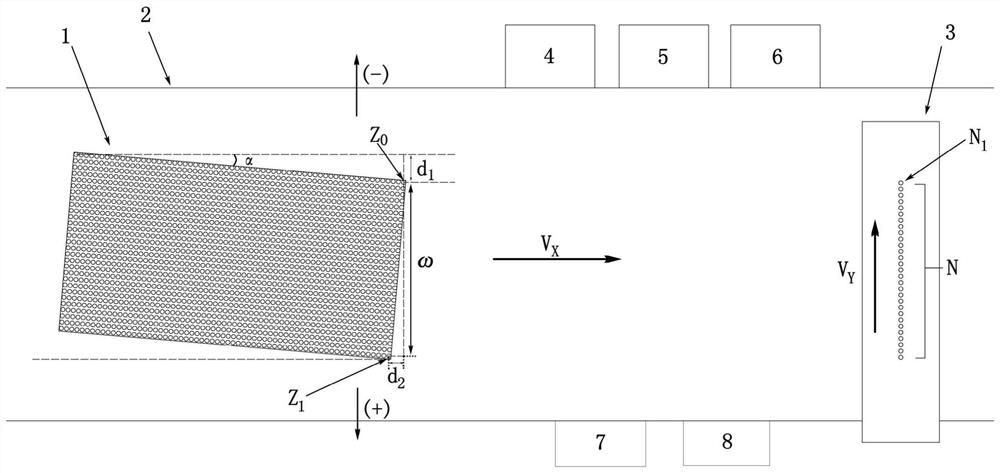

Machining method for TV set shell pattern

InactiveCN109015215AExcellent surface hardnessImprove wear resistancePretreated surfacesGrinding machinesAbrasive blastingEconomic benefits

The invention discloses a machining method for a TV set shell pattern. The machining method for the TV set shell pattern includes the following steps that the surface of a TV set shell blank body prepared in advance is subjected to preliminary cleaning; the TV set shell blank body after being cleaned is ground and polished so that a preliminary TV set shell can be obtained; the surface of the preliminary TV set shell after being ground and polished is subjected to secondary cleaning; the preliminary TV set shell after secondary cleaning is subjected to abrasive blasting or wire drawing so thata TV set shell can be obtained; primer is sprayed on the surface of the TV set shell; the TV set shell subjected to primer spraying is placed in a drying chamber to be subjected to preliminary dryingso that a primer layer can be formed by the primer; and the surface of the primer layer of the TV set shell is subjected to laser carving so that the pattern needed by a user can be formed. The machining method has the beneficial effects that the production efficiency is substantially improved, remarkable economic benefits are achieved, a pattern layer can be firmly attached to the surface of theTV set shell, and the pattern on the TV set shell is clear, attractive, free of breakage, long in service life and not prone to fall off.

Owner:航嘉电器(合肥)有限公司

An automatic weft-seeking device and method for a rapier loom

The invention discloses an automatic weft finding device for a rapier loom. The automatic weft finding device comprises a weft sensor, a warp let-off mechanism, a reeling mechanism, a fluffing mechanism, an opening mechanism and a controller. The warp let-off mechanism, the reeling mechanism, the fluffing mechanism and the opening mechanism are provided with four variable frequency motors, respectively. The input end of the controller is connected with the weft sensor. The output end of the controller is connected with the four variable frequency motors; the controller is further connected with a stack storage. The invention further discloses an automatic weft finding method for the rapier loom. If weft breakage occurs, weft finding is performed at low equipment speed through a reversing program. The automatic weft finding device and method has the advantages that the defects of the prior art can be overcome, the structure of the rapier loom is simplified, and failure rate is reduced.

Owner:GAOYANG HUIQIANG TEXTILE MACHINERY MFG CO LTD

Red printing ink for wash label printing and preparation method thereof

The invention discloses red printing ink for wash label printing, which comprises the following components according to mass percent: 0.8% of C.I. acid red 52, 0.7% of C.I. acid red 289, 16-19% of diethylene glycol, 6-9% of triethylene glycol monobutyl ether, 0.4-0.5% of surfactant and the balance of deionized water. The invention further discloses a preparation method of the red printing ink for wash label printing. A pattern printed by the red printing ink prepared by the method is good in quality, unlikely to bleed, free of bur and good in fastness to rubbing, and the pattern has certain light fastness.

Owner:张家港市杨舍丝印工艺厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com