Ceramic tile production method

A production method and a technology for ceramic tiles, which are applied in the field of ceramic tile production, can solve the problems that the texture pattern of the embryo body does not correspond to the surface pattern, the texture pattern of the embryo body does not correspond to the surface pattern, and cannot meet the needs of the diversity of tile styles, and the like. Promoting production applications, enhancing harmony and artistry, enhancing the effect of textured pattern effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

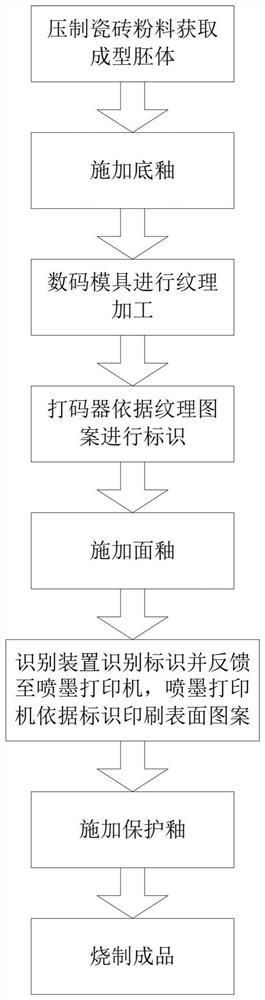

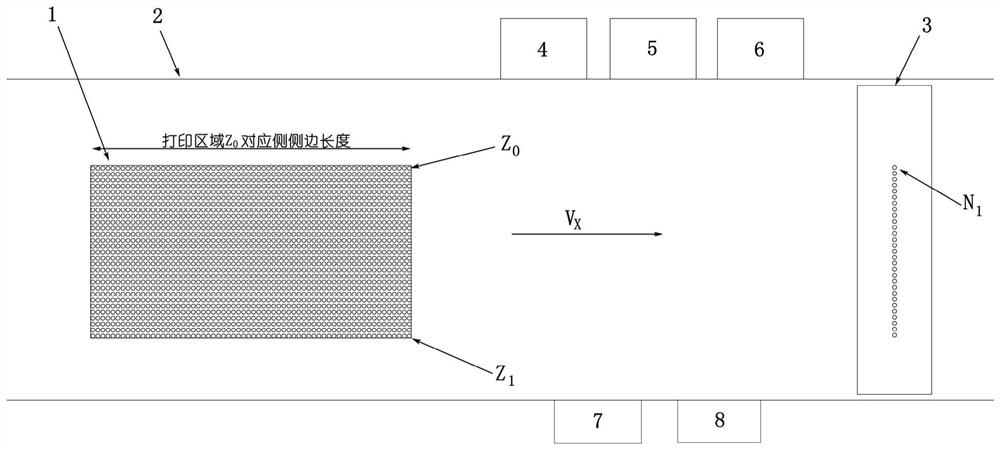

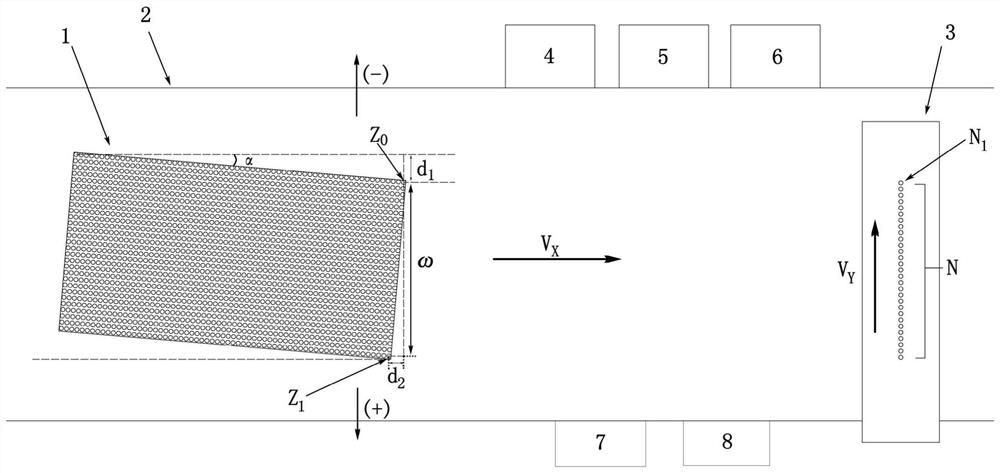

[0061] Such as figure 1 As shown, a ceramic tile production method includes steps: S1, processing the raw materials and performing compression molding treatment to obtain a compacted embryo body. In this embodiment, a press is used to press the tile powder to form an embryo, and after the embryo is formed Applying the primer; S2. Texturing the embryo body to which the primer has been applied to form a texture pattern comprising more than one concave texture and / or raised texture, the concave texture is formed by applying a reactive substance to corrode the surface to be textured, The raised texture is formed by stacking non-eroding substances on the surface to be textured. In this implementation, a digital mold is used for texture processing; S3. Mark the embryo body forming the texture pattern, and the logo at least reflects the current texture pattern information of the embryo body , in this embodiment, a coder is used to print an identification code, and the identification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com