Material evenly distributing device of flow stabilizing cylinder of central transmission thickener

A technology of uniform material distribution and central transmission, which is applied to the feeding/discharging device of the settling tank, etc., can solve the problems of reducing the service life of rake racks, increasing production costs, and uneven torque, so as to improve processing capacity and prolong service life , the effect of increased processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

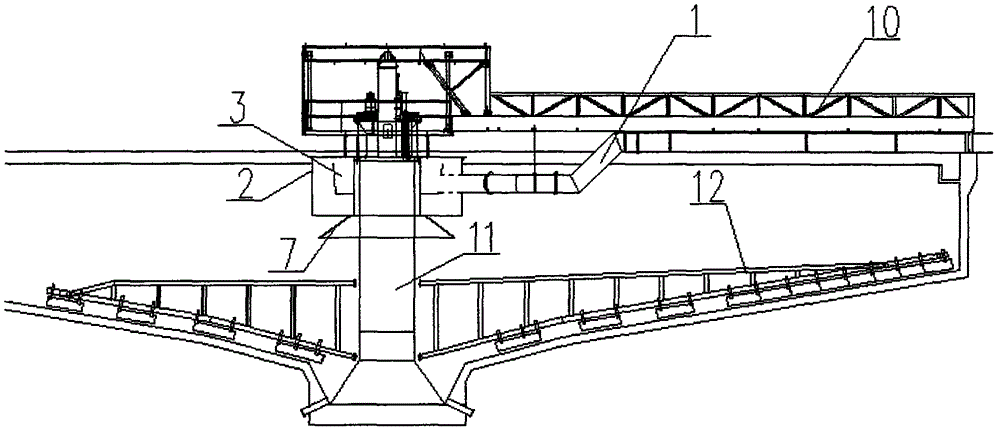

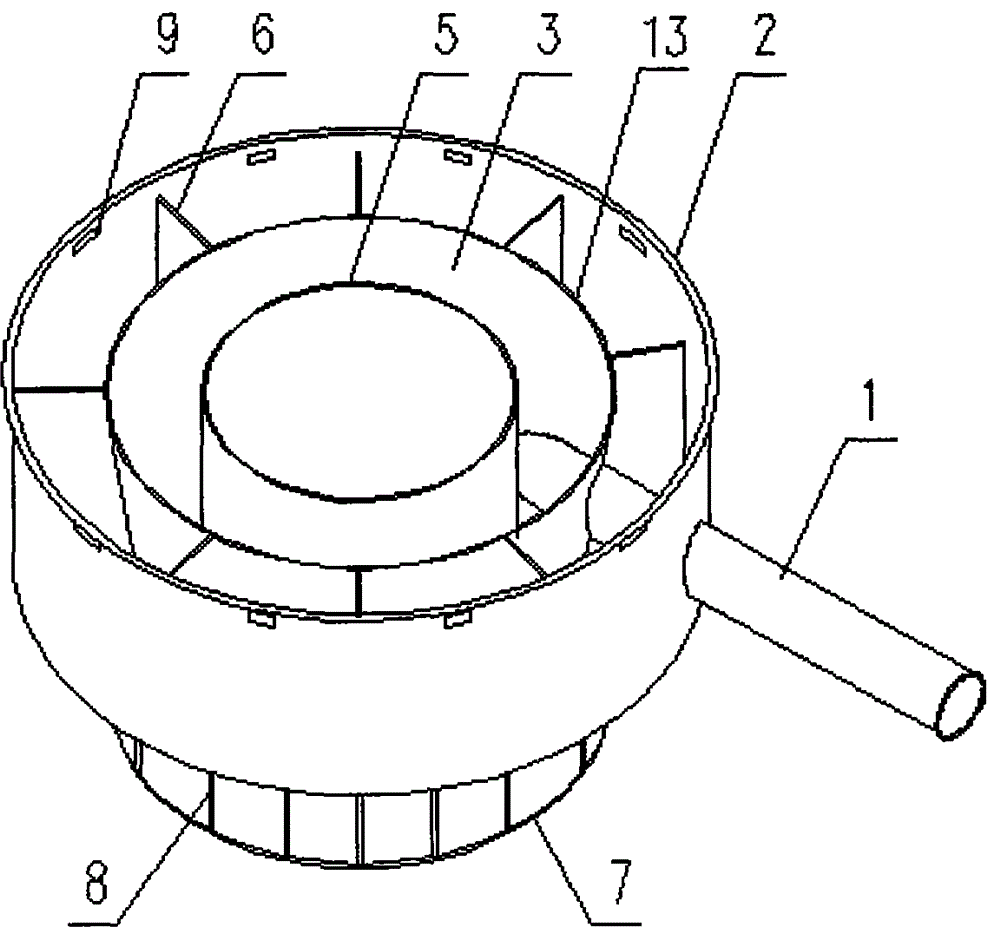

[0018] Example as figure 1 As shown, the central drive concentrator includes a feed pipe 1 , a bridge frame 10 , a rotating cage 11 and a rake frame 12 . Such as figure 1 and figure 2 As shown, the flow stabilizing cylinder includes an outer guiding cylinder 2 , an inner guiding cylinder 7 and a connecting plate 8 , and the upper end of the outer guiding cylinder 2 is equidistantly provided with dilution ports 9 .

[0019] Such as figure 2 , image 3 and Figure 4 As shown, a uniform distribution device is arranged in the outer guide tube 2, and the uniform distribution device includes a distribution tank 3 and 8 fixing plates 6, and a dilution port 9 is provided at the upper end of the outer guide tube 2 between adjacent fixing plates 6. The cloth trough 3 comprises a cloth inner cylinder 5, a cloth outer cylinder 13 and a cloth bottom plate 14, and the cloth outer cylinder 13 and the cloth inner cylinder 5 are fixedly connected through the cloth bottom plate 14 to for...

Embodiment 2

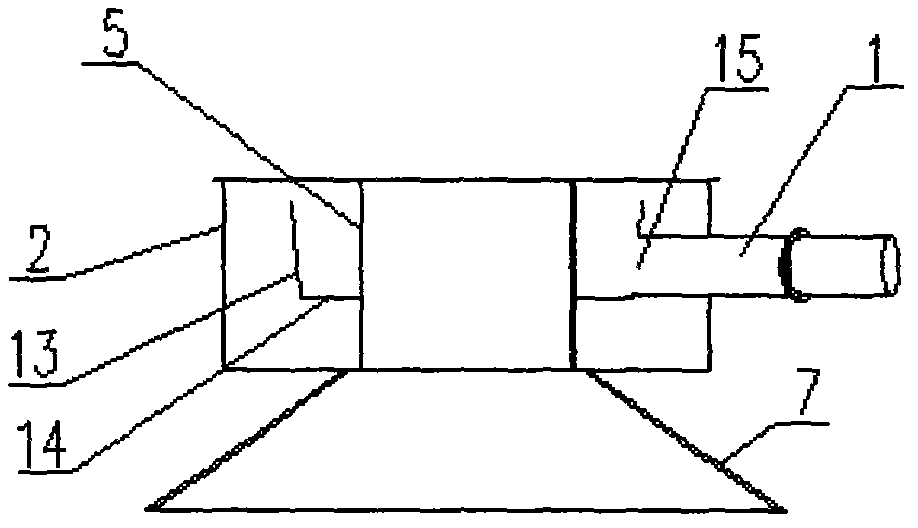

[0023] Example two such as Figure 5 As shown, a cloth control board 4 is fixedly connected between the cloth outer cylinder 13 above the feed nozzle 15 and the cloth inner cylinder 5. The cloth control board 4 is arc-shaped, and the width of the cloth control board 4 is equal to the cloth outer cylinder 13 and the cloth inner cylinder 5. The distance between the cloth inner cylinder 5, the radian of the cloth control board 4 is 90°, that is, the length of the cloth control board 4 is equal to 1 / 4 of the circumference formed by the cloth outer cylinder 13 and the cloth inner cylinder 5, other settings and embodiments together. The material distribution control plate 4 can effectively prevent the slurry flowing out from the discharge nozzle 15 from directly overflowing to the top of the material outer tube 13 and enter the inner side of the outer guide tube 2, so as to prevent the material in the flow stabilization tube from being biased toward the rotating cage 11 located at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com