Patents

Literature

100results about How to "Less agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

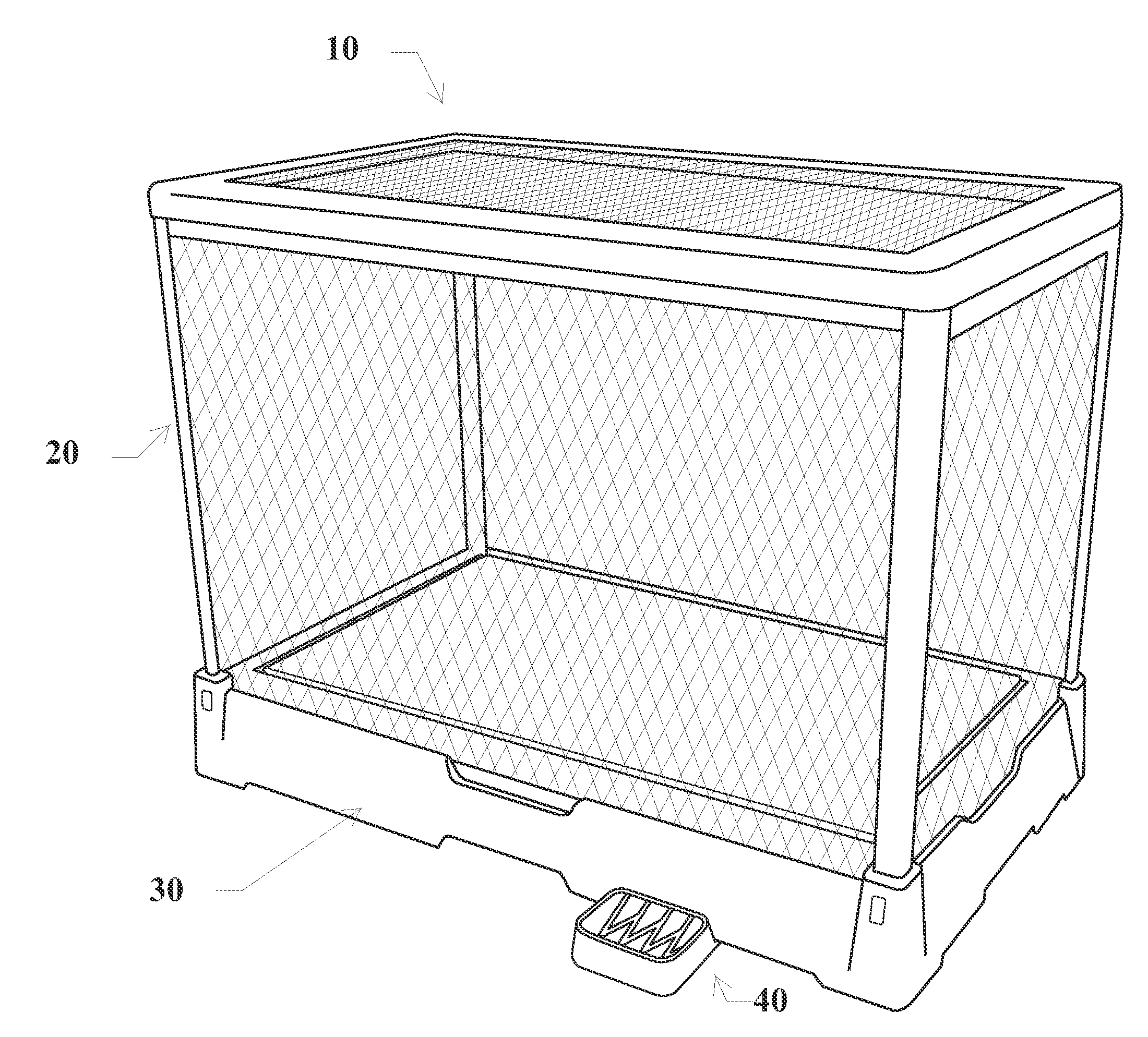

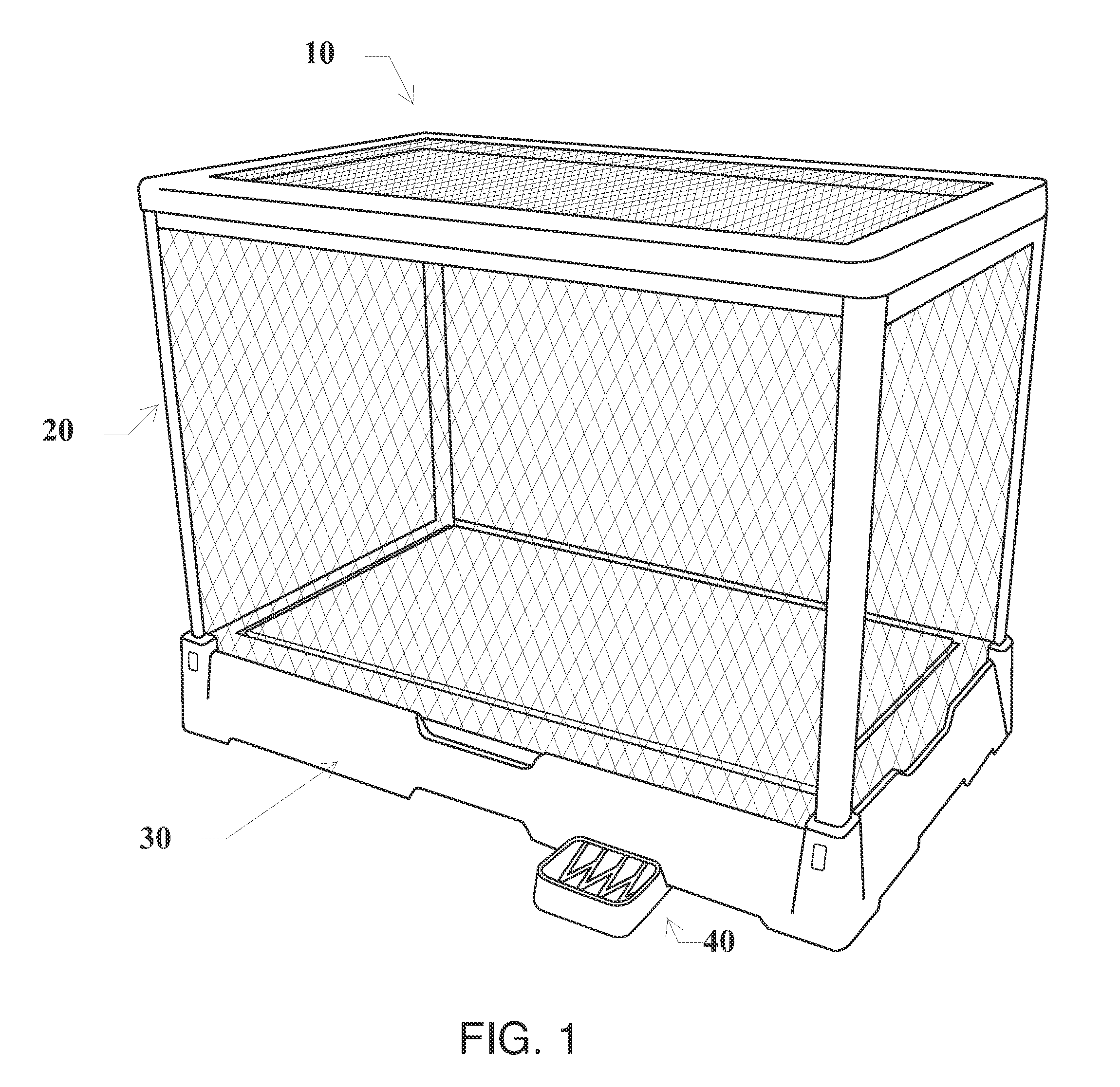

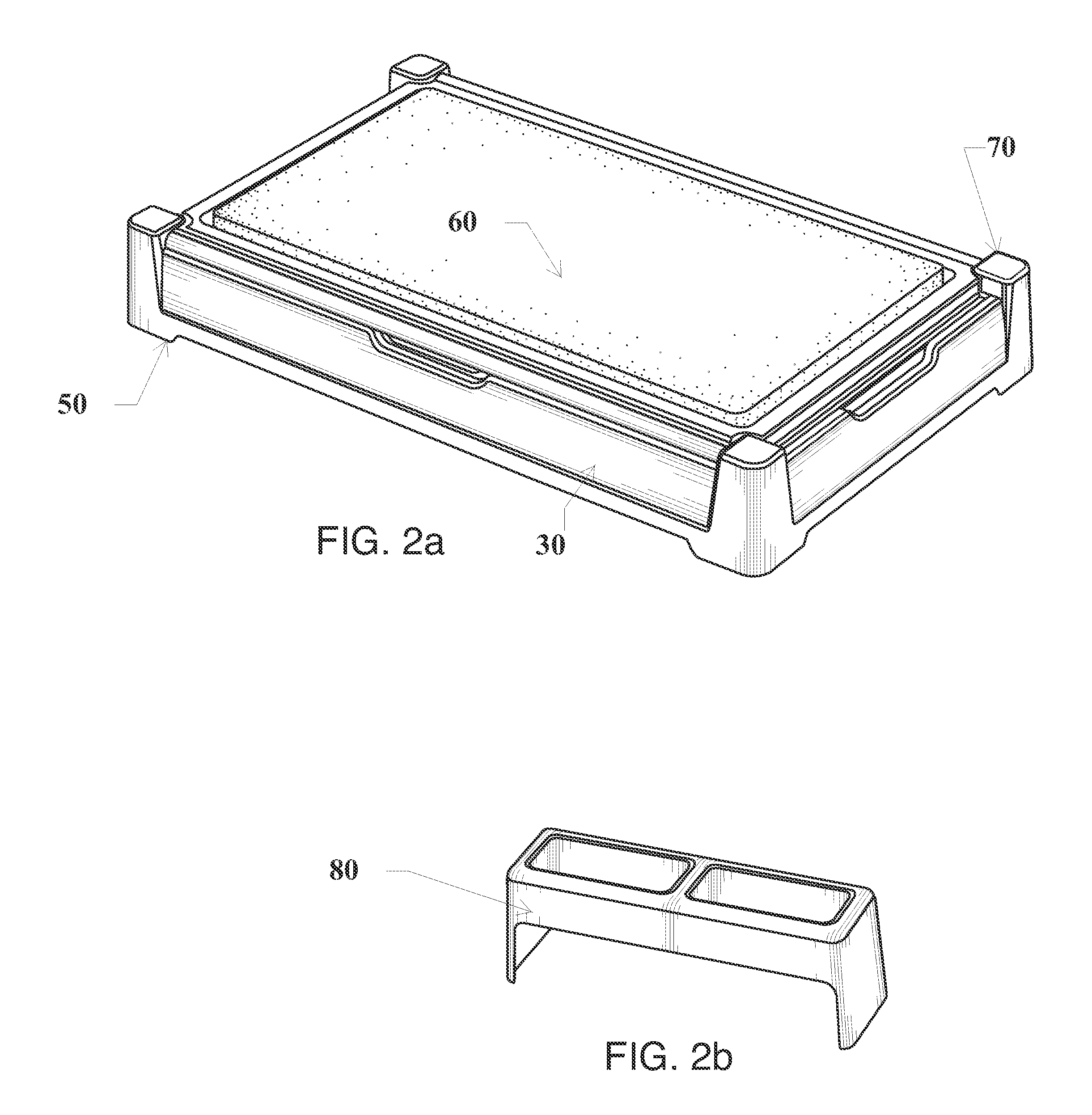

Collapsible combination pet bed and enclosure

InactiveUS20160192615A1Less agitationLess attentionAnimal watering devicesAnimal feeding devicesEngineeringCompanion animal

The invention relates to a novel multiple configuration enclosure and for pets—typically dogs. The enclosure can be configured to be an open bed, a “cuddle corner” with two panels up, a four-sided enclosure or an enclosure with a top. The carrier is outfitted with four support rails and mesh insert panels to create the sides or walls of the carrier. The soft panels have mesh inserts so that the dog may be able to receive sufficient airflow and see outside of the carrier. The molded base is indented to receive a removable padded bed which may then be easily removed for cleaning. The panels break down and are stored in a pull-out drawer in the base, and wheels are attached thereto for easy portability.

Owner:THE KYJEN CO LLC

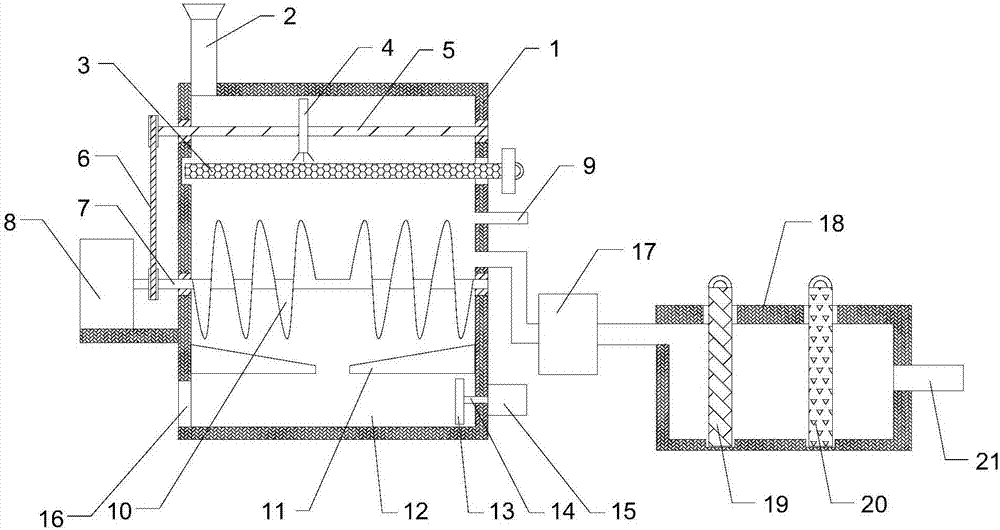

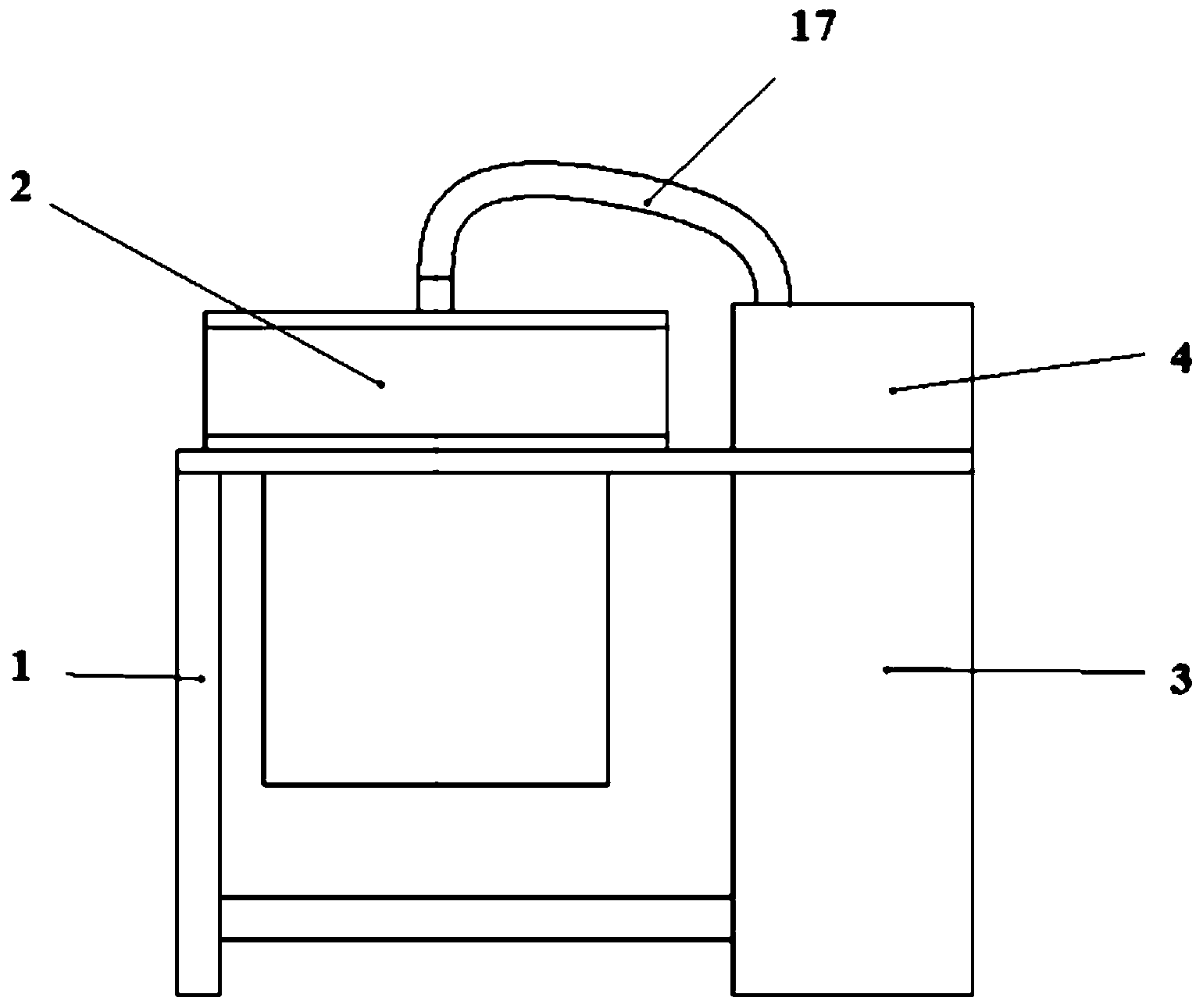

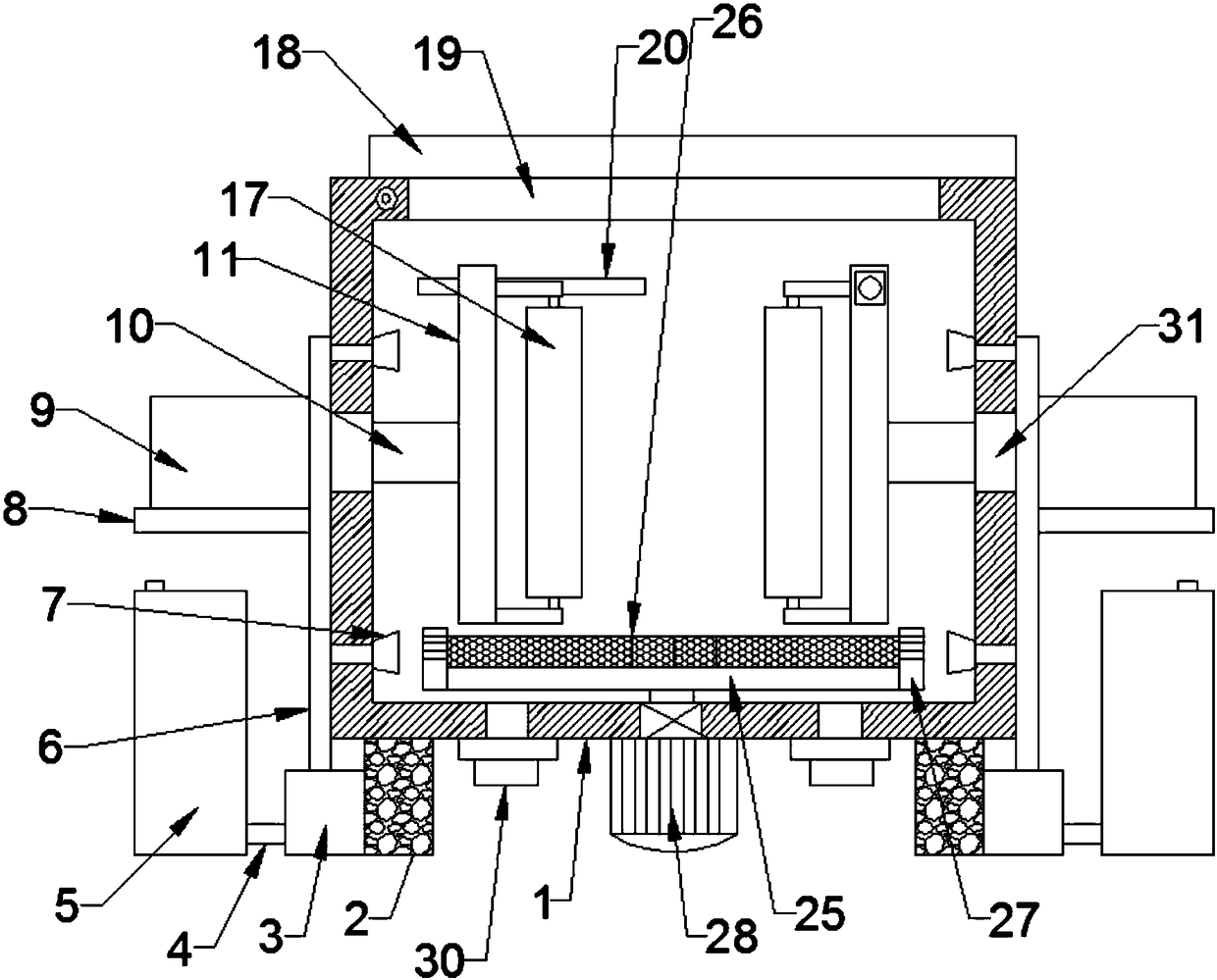

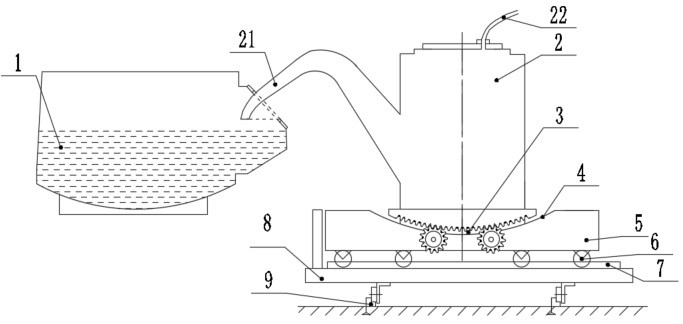

Small-sized rapid precipitation environment-friendly sewage treatment device

InactiveCN107226561ARapid diffusion mixingLess agitationTreatment involving filtrationMultistage water/sewage treatmentSludgeFiltration

The invention discloses a small-sized rapid-precipitation environment-friendly sewage treatment device, which comprises a sedimentation tank, a driving motor and a filter tank; A brush plate; a drive shaft is provided under the filter plate, and spiral blades in opposite directions are provided on the left and right sides of the drive shaft. The present invention is equipped with reverse spiral blades and trapezoidal material guide plates to horizontally stir and mix the sewage and flocculants, so that the flocculants can be rapidly diffused and mixed, improving the efficiency of flocculation and sedimentation, and at the same time reducing the impact on the settled sludge. Stir to improve the efficiency of sedimentation; the present invention is provided with a reciprocating brush to avoid clogging of the filter holes and ensure normal filtering; the present invention is provided with a filter plate, a sandstone packing plate and an activated carbon packing plate that are easy to disassemble, and has better Excellent purification effect, easy to disassemble and clean.

Owner:深圳市华帮国际商务服务有限公司

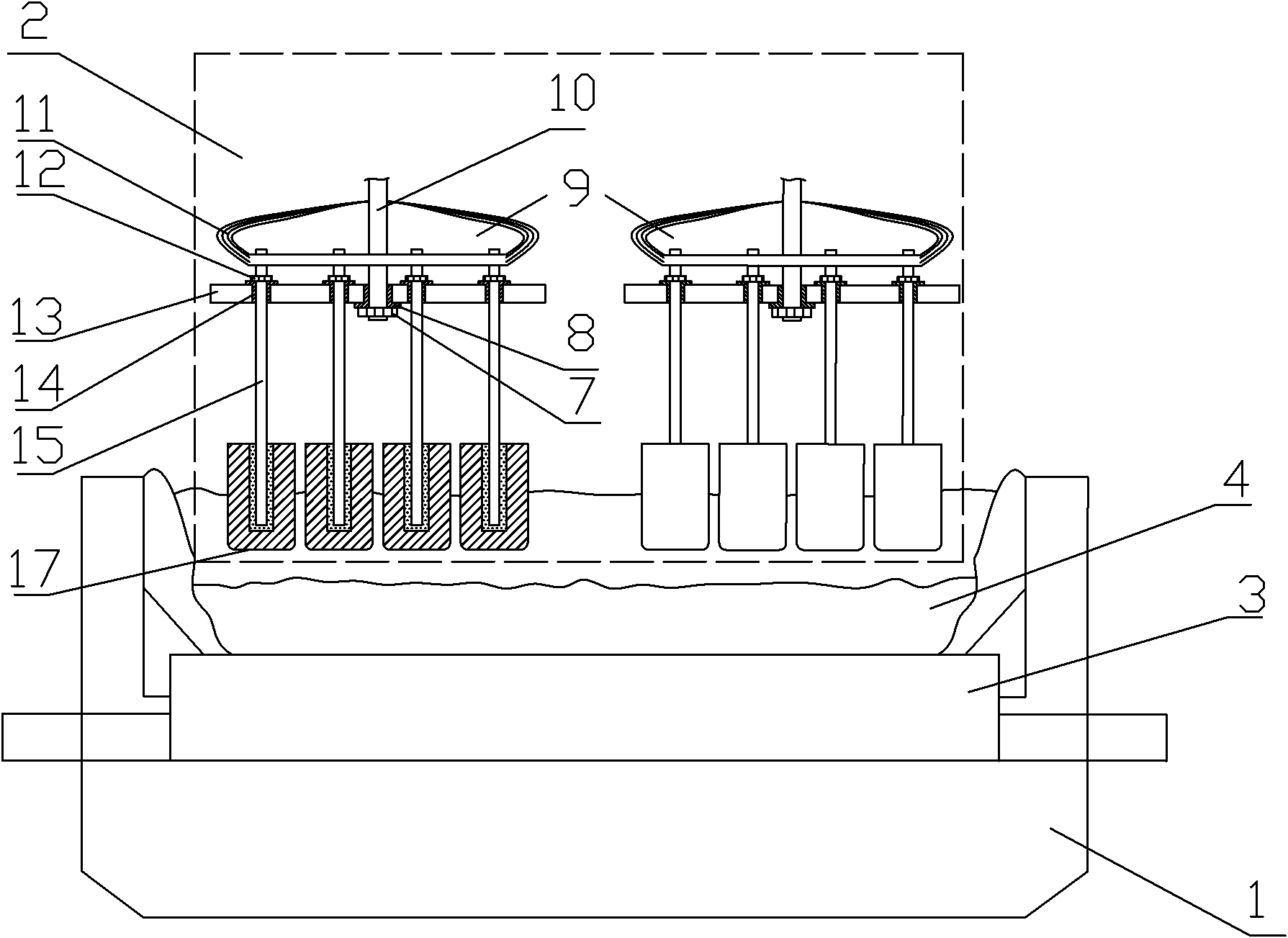

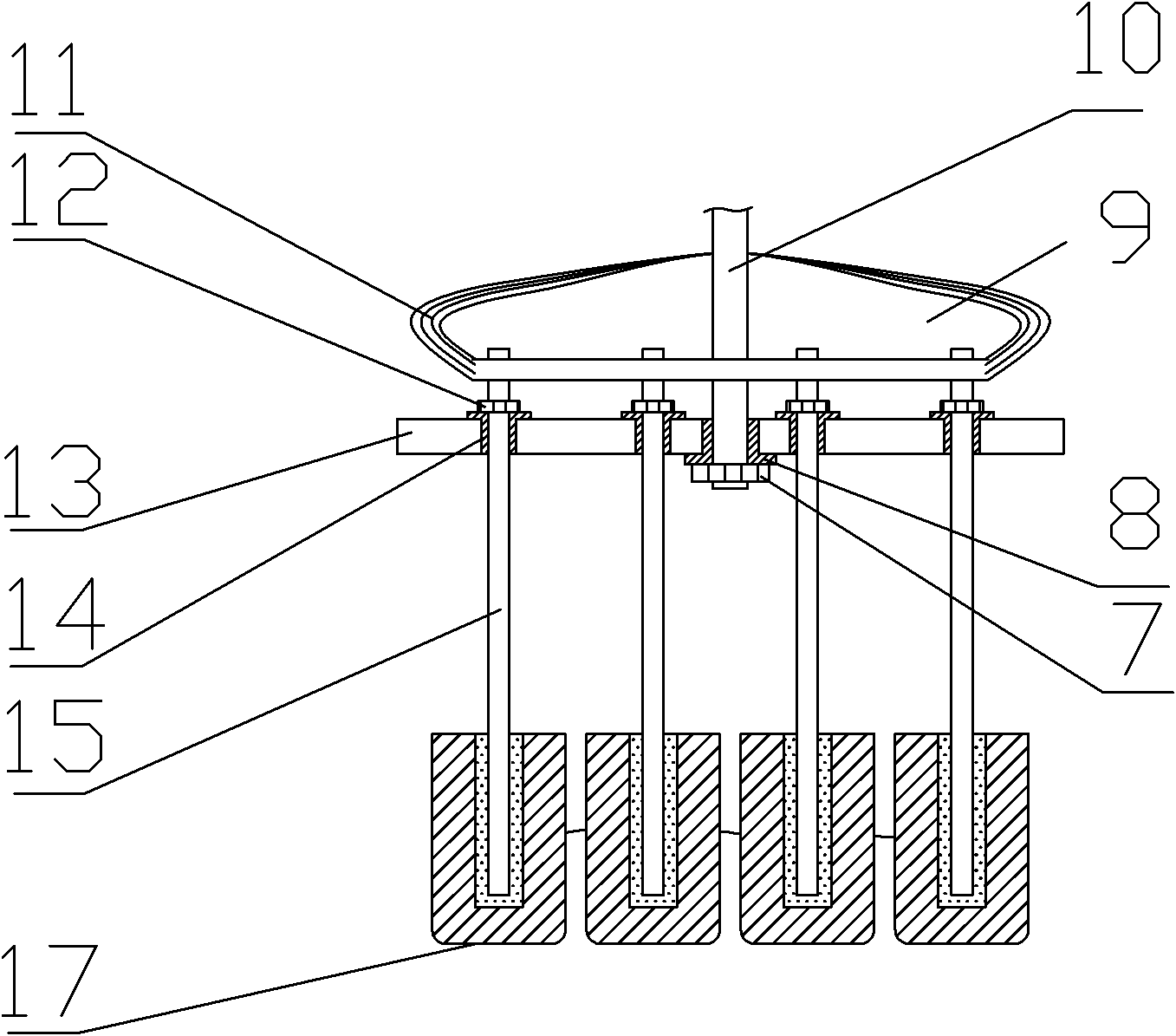

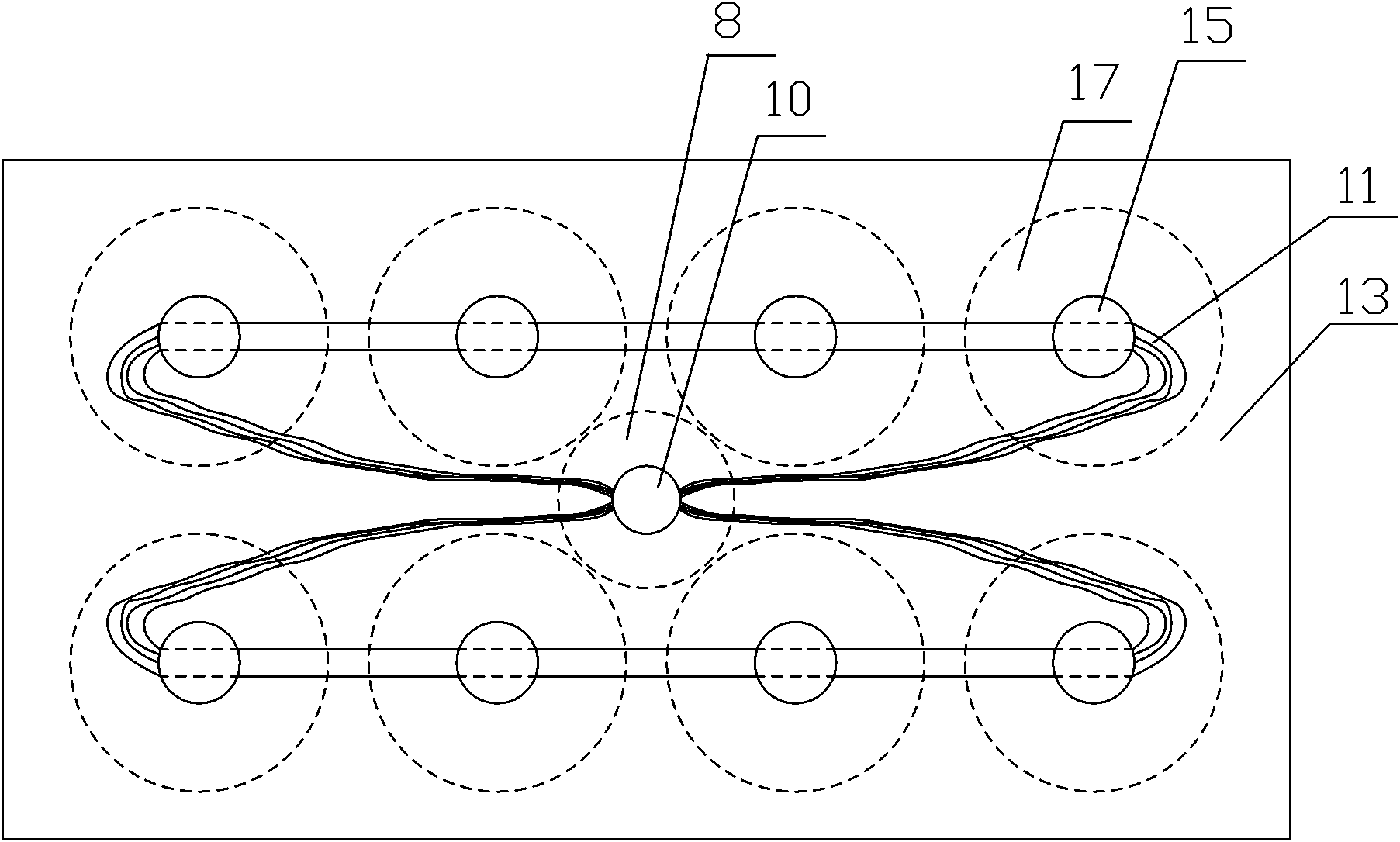

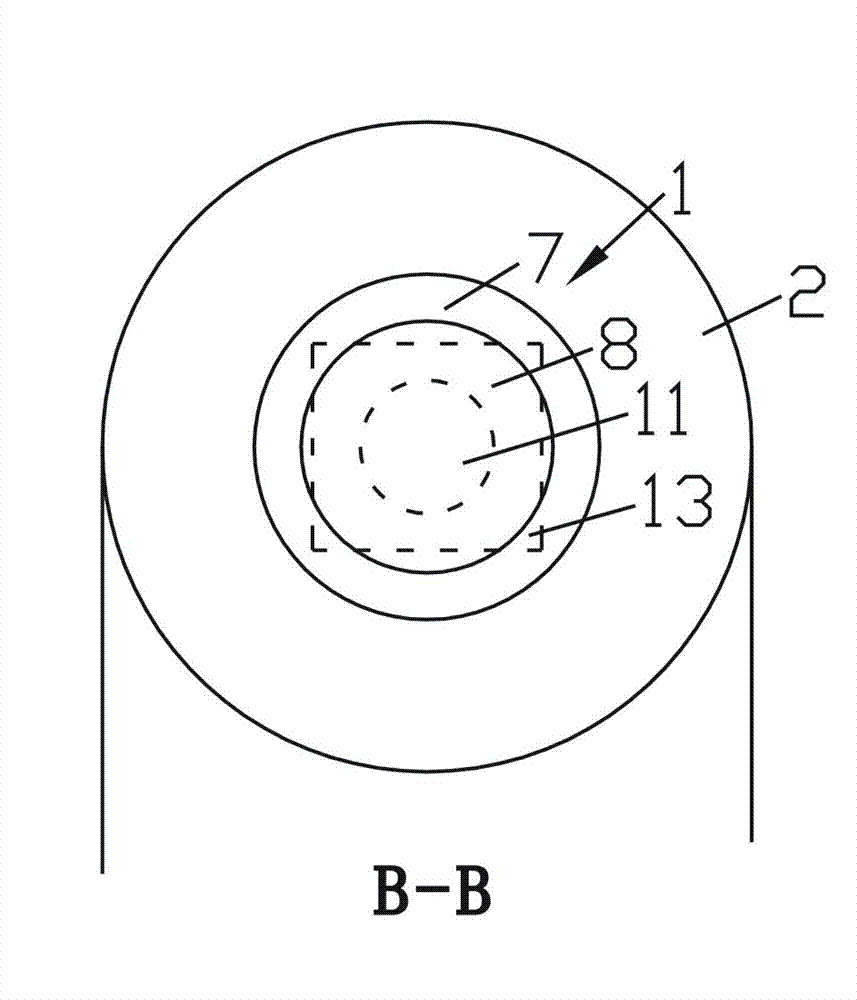

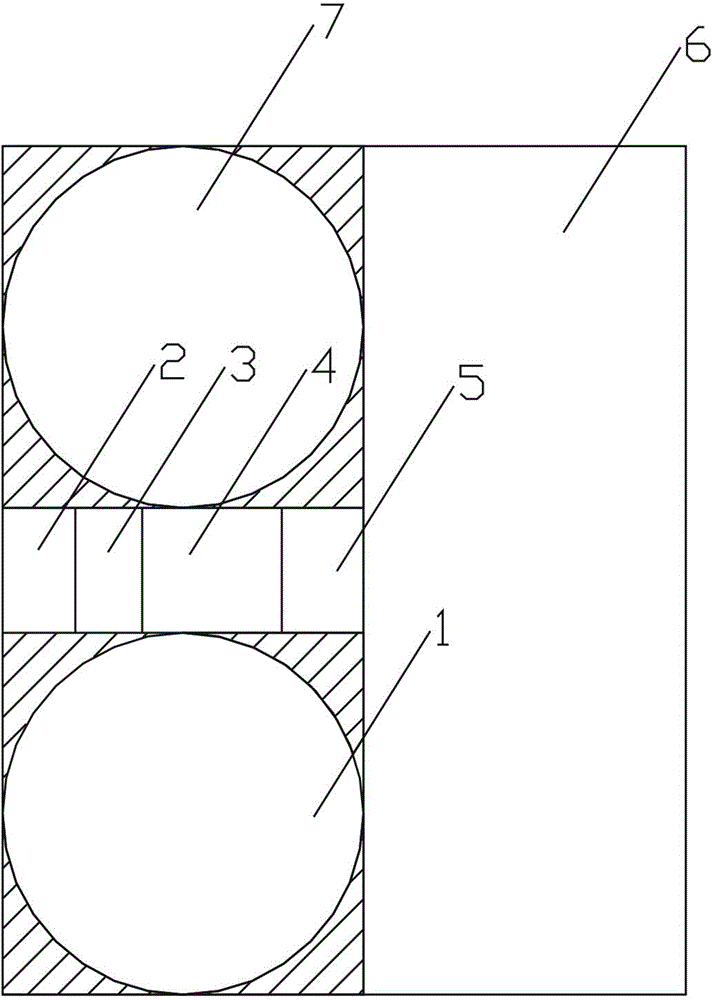

Inertial electrode low-temperature aluminium electrolytic cell

The invention discloses an inertial electrode low-temperature aluminium electrolytic cell comprising a electrolytic cell body, a metallic ceramic inertial anode, a wettable cathode and a low-temperature electrolyte, wherein, the wettable cathode is arranged at the bottom of the electrolytic cell body; the low-temperature electrolyte is arranged in the electrolytic cell body; the metallic ceramic inertial anode is arranged at the upper part of the electrolytic cell body, and end part of the metallic ceramic inertial anode extends into the low-temperature electrolyte; the metallic ceramic inertial anode is composed of at least two groups of metal ceramic inertial anode sets; each metallic ceramic inertial anode set is composed of at least two metallic ceramic inertial anode monomers; the metallic ceramic inertial anode sets and the metal ceramic inertial anode monomers in the same metal ceramic inertial anode sets are both in electrical parallel connection. The inertial electrode low-temperature aluminium electrolytic cell has reasonable structure, simple and convenient operation, stable operation, less oxygen discharge and small aluminium liquid fluctuation, low electrolytic cell voltage, low operation temperature and less energy consumption, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

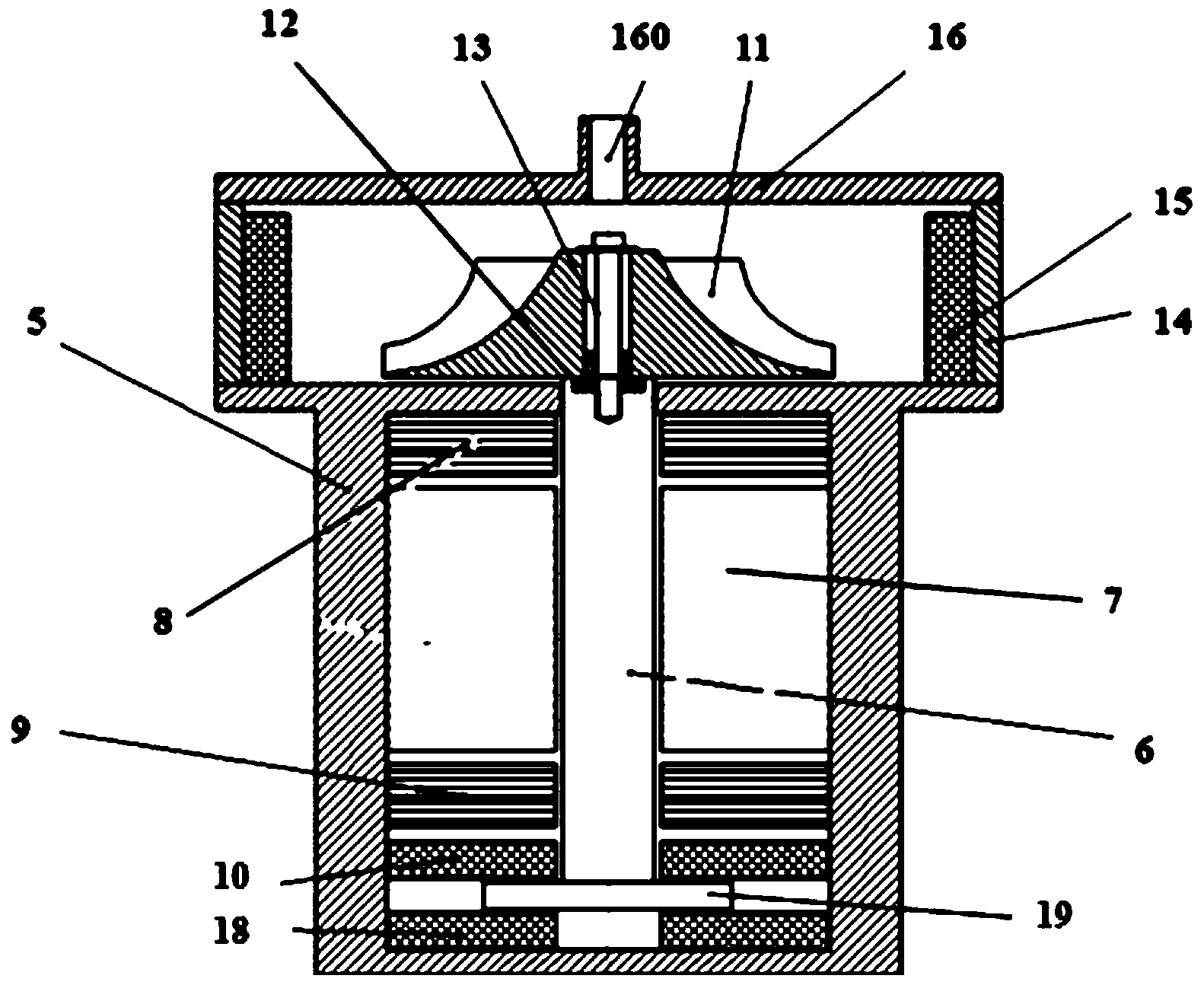

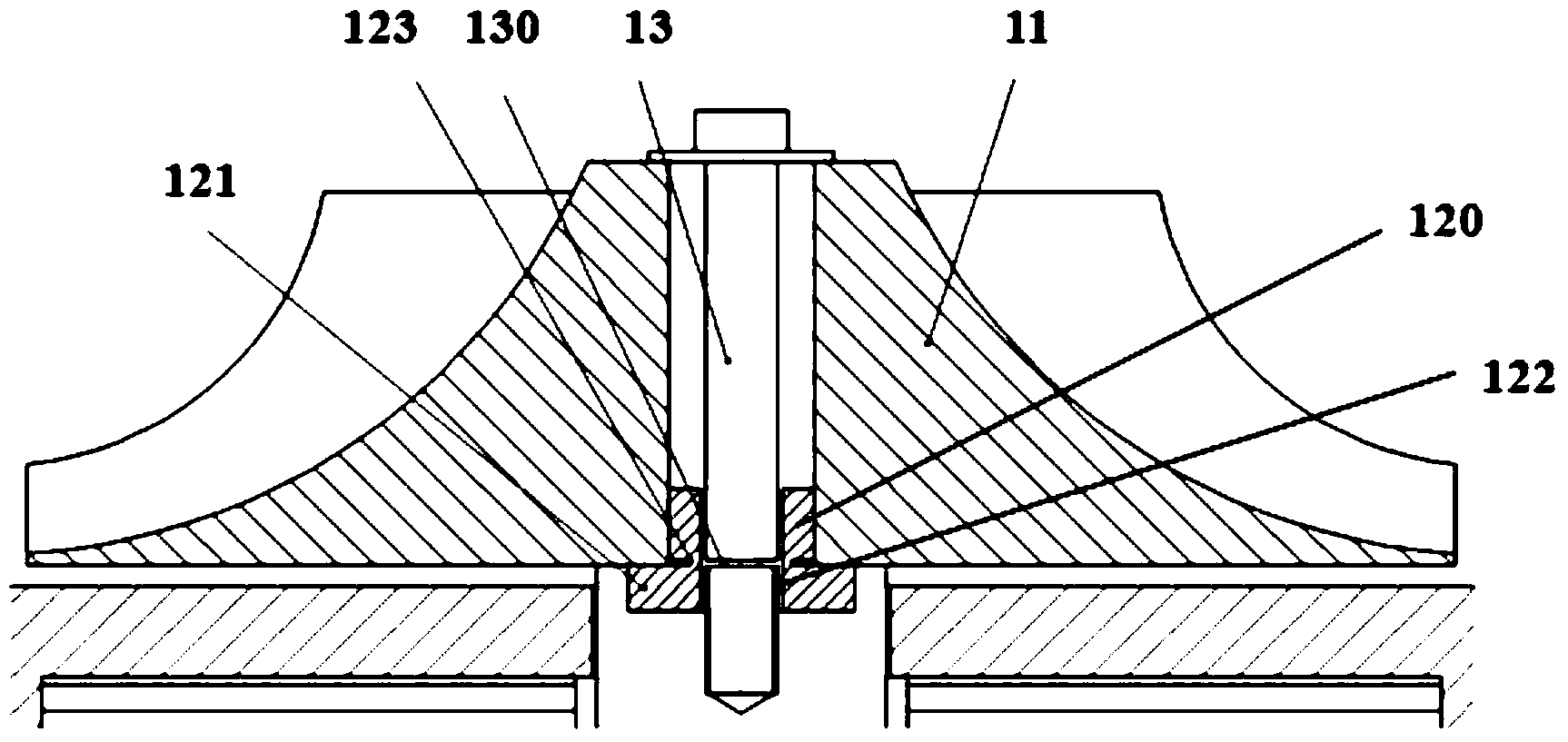

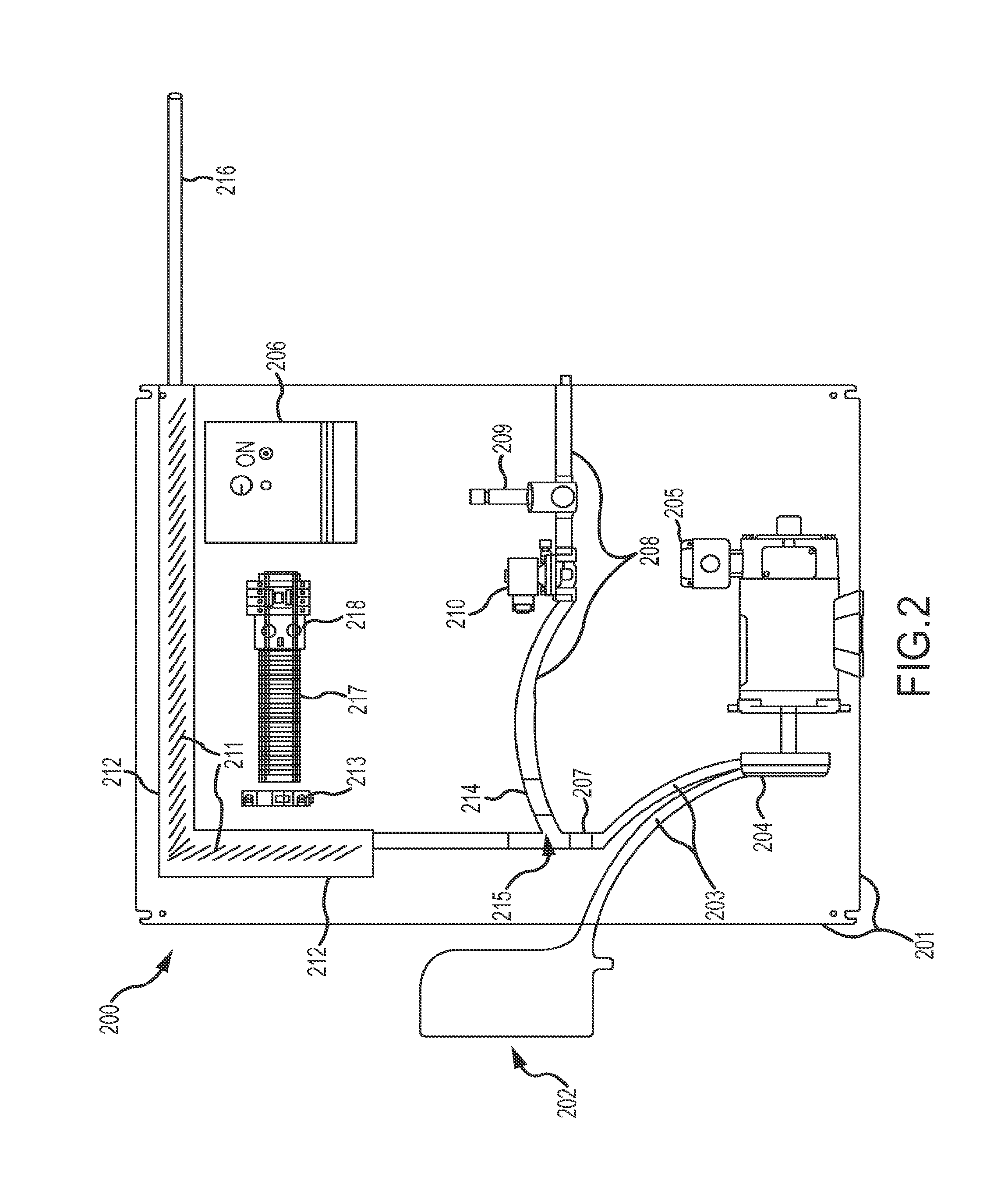

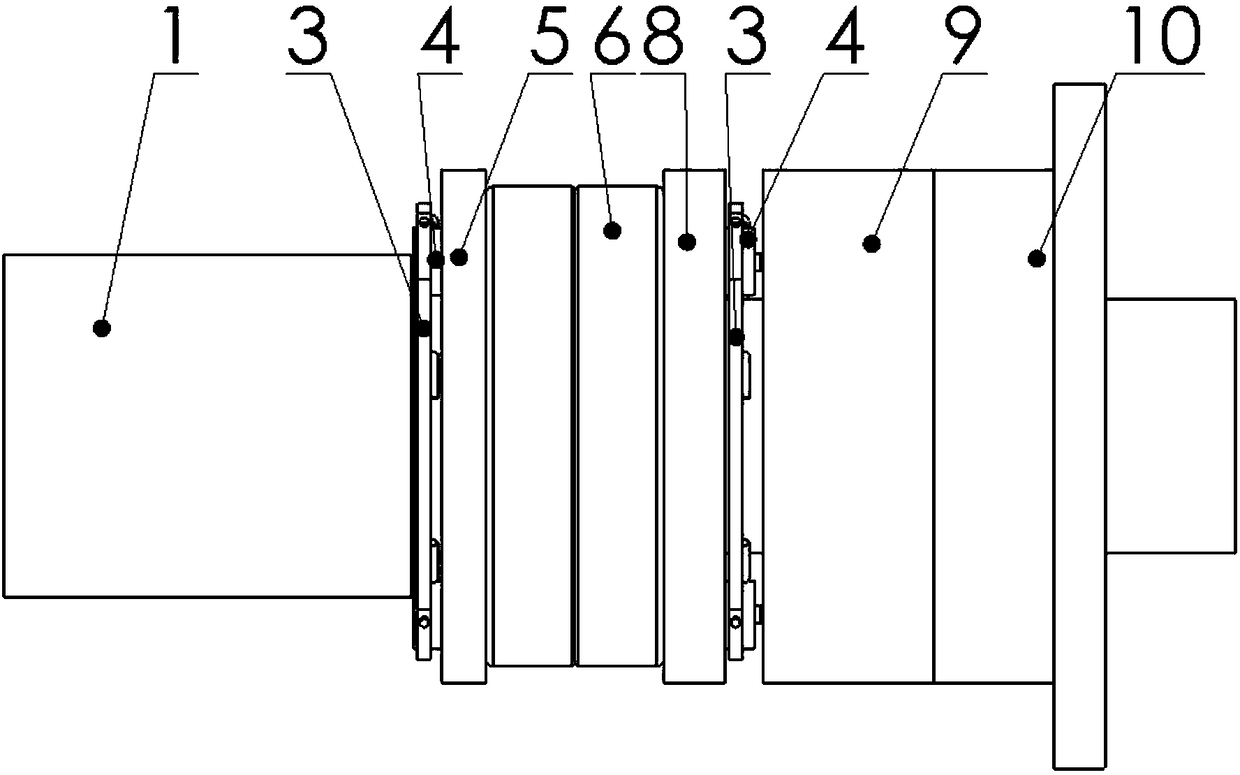

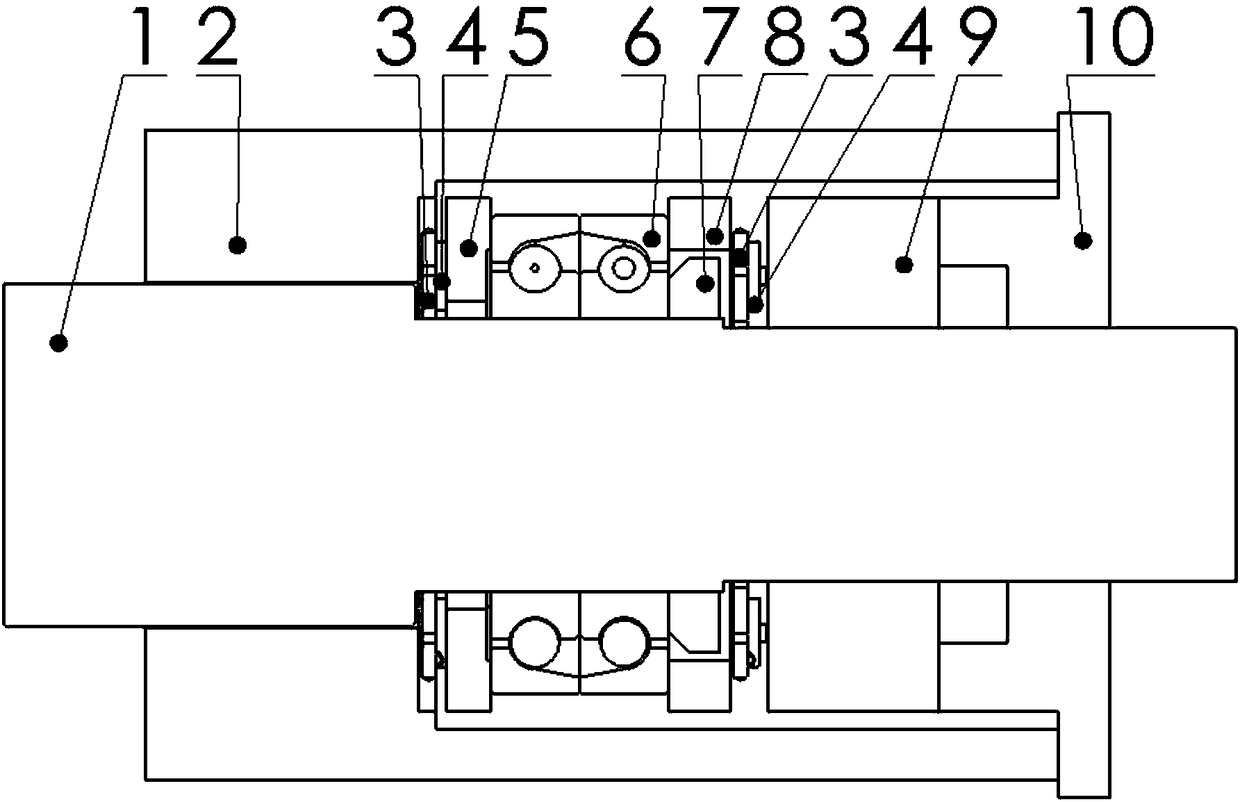

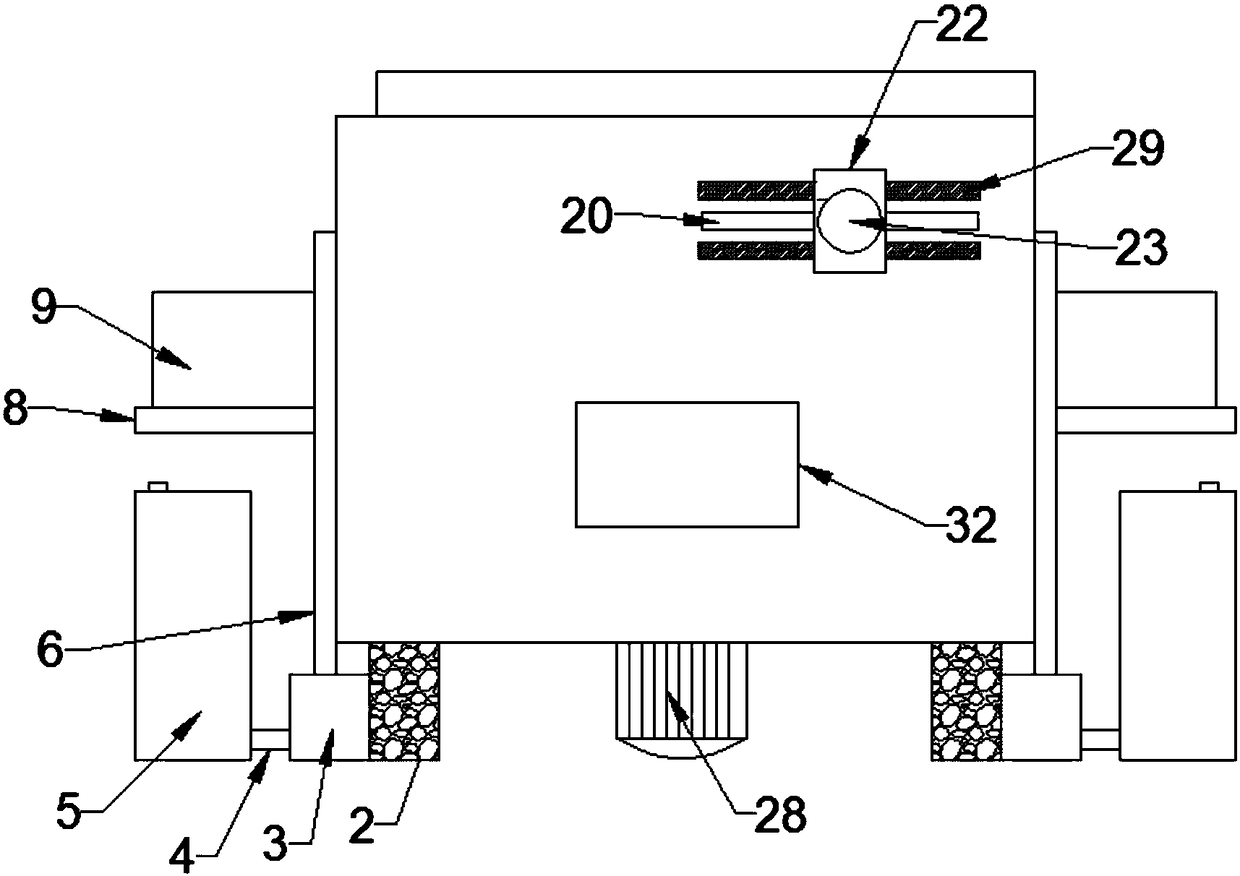

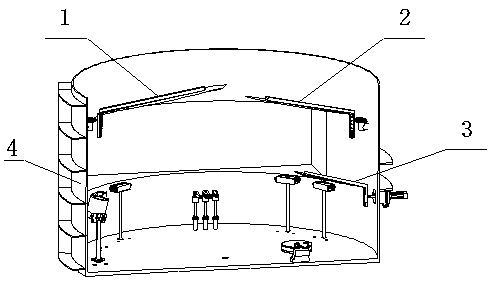

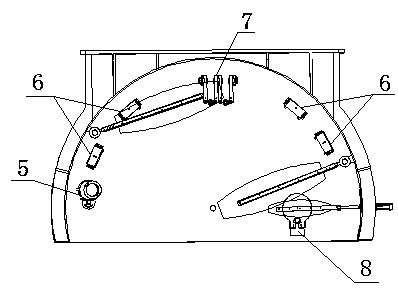

Magnetic levitation overspeed test bed for impeller overspeed test

ActiveCN104295518ASimple structureClean structurePump controlNon-positive displacement fluid enginesImpellerMagnetic bearing

The invention discloses a magnetic levitation overspeed test bed for an impeller overspeed test. The magnetic levitation overspeed test bed comprises a support, a main machine, an electric control cabinet and a vacuum pump. The main machine, the electric control cabinet and the vacuum pump are installed on the support. The main machine comprises a motor shell, a motor rotor and a motor stator, wherein the motor rotor and the motor stator are installed in the motor shell. The upper tail end of the motor rotor extends out of the upper end face of the motor shell. The motor rotor is provided with an upper radial magnetic bearing, a lower radial magnetic bearing, an upper thrust magnetic bearing, a lower thrust magnetic bearing and a thrust disc. The upper tail end of the motor rotor is connected with a safety connector and a pull rod screw which are used for fixing an impeller to the upper end of the motor rotor. A protective cover is arranged at the position, around the impeller, of the motor shell. A protective cover lid is installed on the protective cover. The upper surface of the motor shell, the protective cover and the protective cover lid jointly form a closed contained wrapping the impeller. A buffer block is installed on the inner wall of the protective cover. A vacuumizing connector is formed on the protective cover lid. A vacuumizing pipe is installed on the vacuumizing connector. The other end of the vacuumizing pipe is connected to the vacuum pump.

Owner:NANJING CIGU TECH CORP LTD

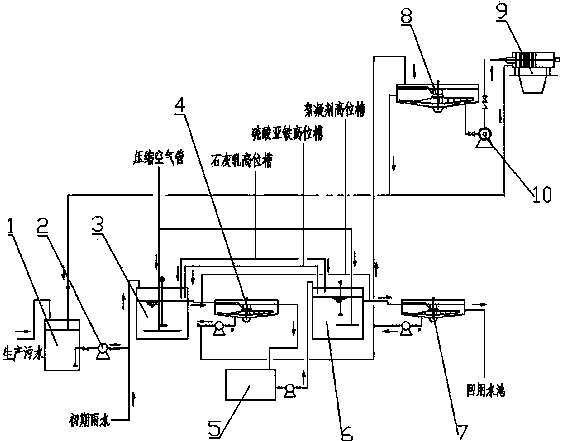

Sewage treatment system

ActiveCN103539287AReduce processingReduce processing costsSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSewageFilter press

The invention discloses a sewage treatment system. The sewage treatment system is characterized in that a sludge adjusting pond is connected with an inlet pipeline of a first-order neutralization reaction tank through a lift pump; an outlet pipeline of the first-order neutralization reaction tank is connected with the inlet pipeline of a primary thickener; a sludge outlet of the primary thickener is connected with a sludge concentrating pond through the lift pump; the outlet pipeline of the primary thickener is connected with the inlet pipeline of a second-order neutralization reaction tank; the outlet pipeline of the second-order neutralization reaction tank is connected with the inlet pipeline of a secondary thickener; the sludge outlet of the secondary thickener is connected with the sludge concentrating pond through the lift pump; a supernate pipe orifice on the sludge concentrating pond is connected with the sludge adjusting pond; the sludge outlet of the sludge concentrating pond is connected with a filter press through a mortar pump; a liquid outlet of the filter press is connected with the sludge concentrating pond; the outlet pipeline of the secondary thickener is connected with a recycling pool. By adopting the sludge treatment system, the handling capacity of the filter press is greatly reduced; the sludge treatment cost is also reduced.

Owner:江西自立环保科技有限公司

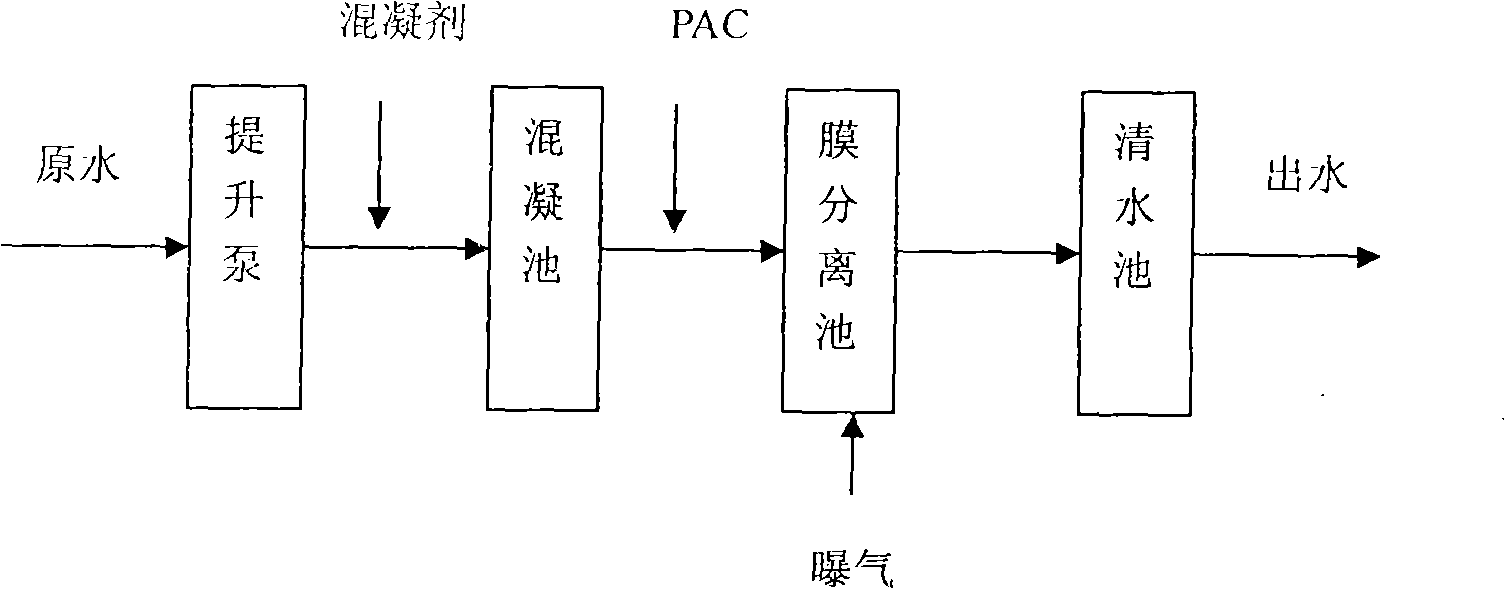

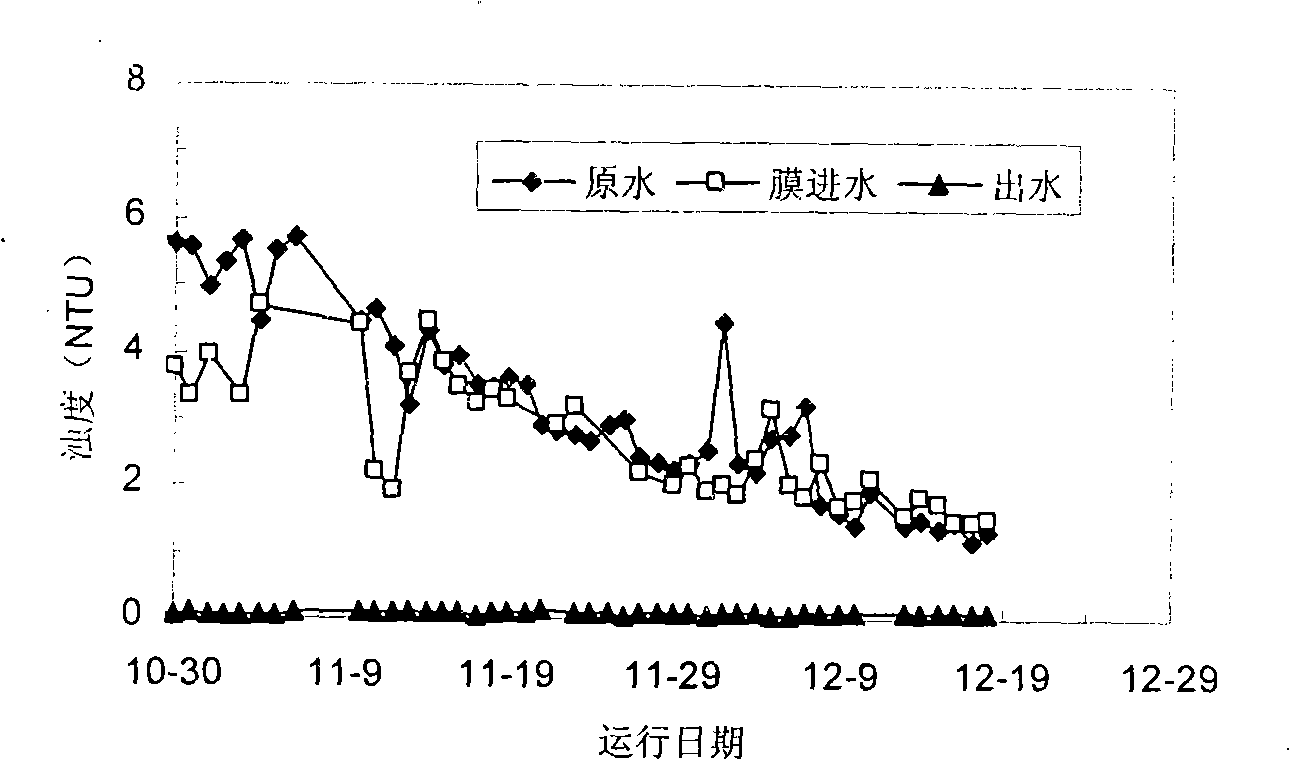

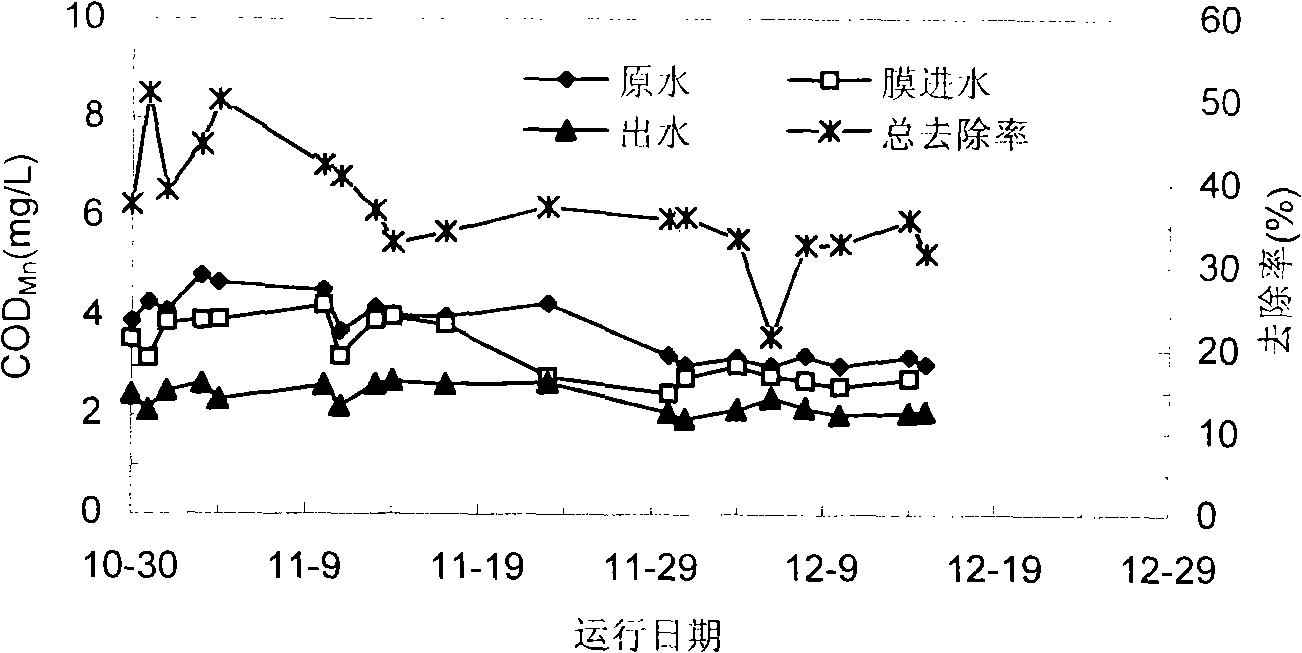

Technological process and apparatus for drinking water treatment by film method

InactiveCN101279805AEfficient removalImprove water qualityWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSuspended particlesFiltration

The invention provides a film method drinking water treatment equipment and a treatment method thereof. According to the treatment equipment of the invention, the film method drinking water treatment equipment comprises: a pretreatment unit, a coagulation tank and a film separation tank; a wide grille and a Y-shaped pipeline filter, etc. are arranged in the pretreatment unit for pre-treating the raw water and avoiding the blockage to a water pump and an inlet water meter by impurities in the raw water; the coagulation tank is a mechanical coagulation tank for coagulating the raw water; and the film separation tank adopts a curtain type membrane module structure to filter the raw water. The raw water is put with a coagulant after going through the pretreatment unit and then enters the coagulation tank, and the water treated by coagulation is treated by components of the curtain type membrane module. The drinking water treatment equipment adopts the combination of coagulation and membrane filtration to treat the micro-polluted surface water, and can fully prevent bacteria and effectively remove various suspended particles, bacteria, algae, COD and organic matters in water, thereby ensuring the excellent water quality with nearly zero water suspended substance.

Owner:TIANJIN POLYTECHNIC UNIV +1

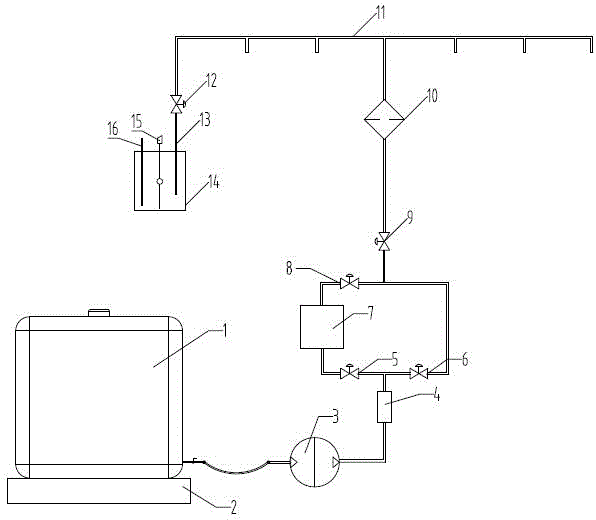

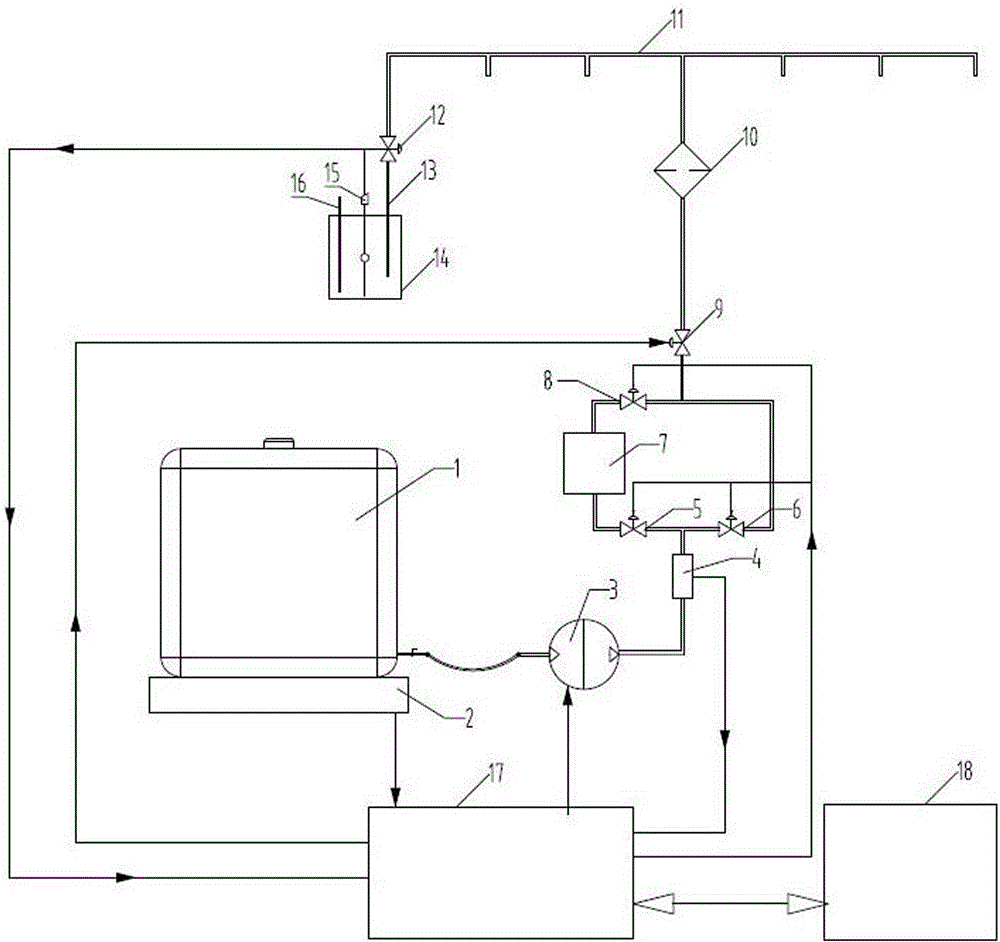

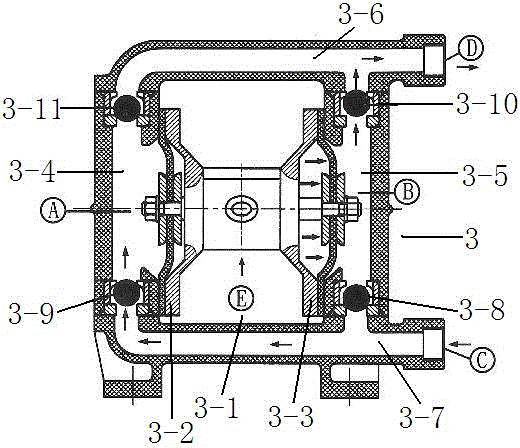

Concentrated automatic control switching type feeding system and control method thereof

ActiveCN105327839AReduce the temperatureNo dischargeLiquid surface applicatorsCoatingsDiaphragm pumpAutomatic control

The invention relates to a concentrated automatic control switching type feeding system and a control method thereof in the field of manufacturing of optical fiber. The system comprises a central material tank, a weighing device, a diaphragm pump, an air bubble early warning device, a control valve I, a control valve II, a control valve III, a control valve IV, a defoaming device, a coating filter, a main pipeline, a control valve V, a coating barrel, a charging pipe, a coating liquid level sensor, a discharging pipe, a central controller and an upper computer; the central material tank is placed on the weighing device and is connected with the diaphragm pump by a hose through a connector, the outlet of the diaphragm pump is connected with the air bubble early warning device, the coating filter is connected with the main pipeline, branches of the main pipeline are respectively connected with the coating barrel in each line, and the central controller is jointed with the upper computer.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

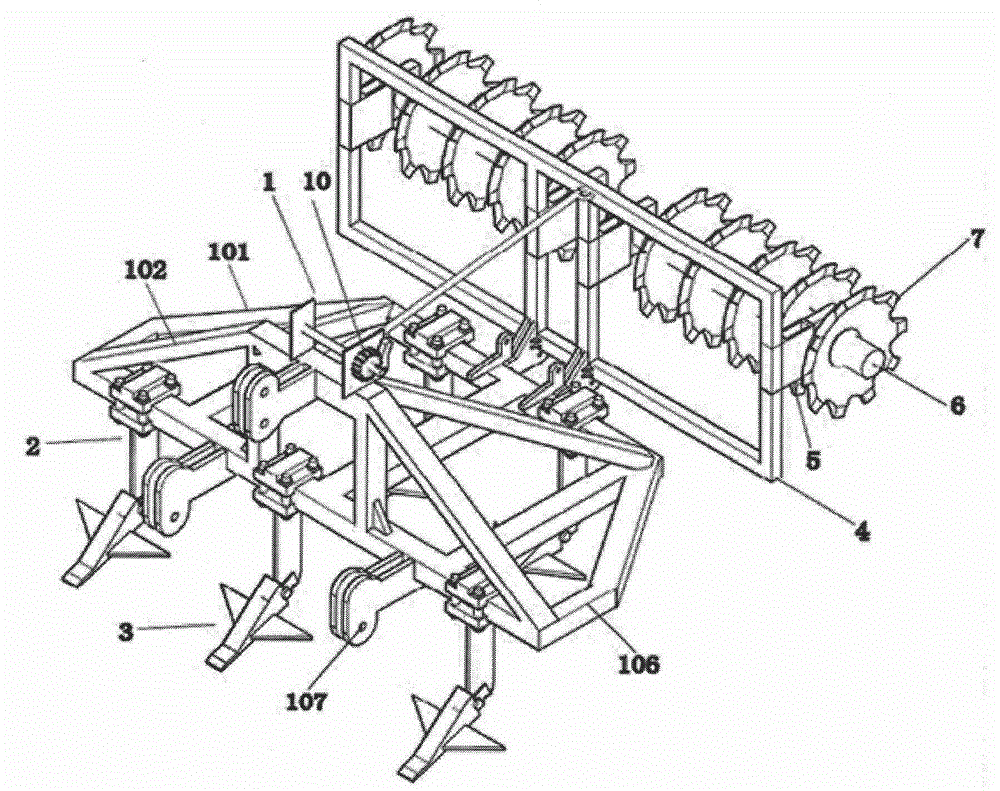

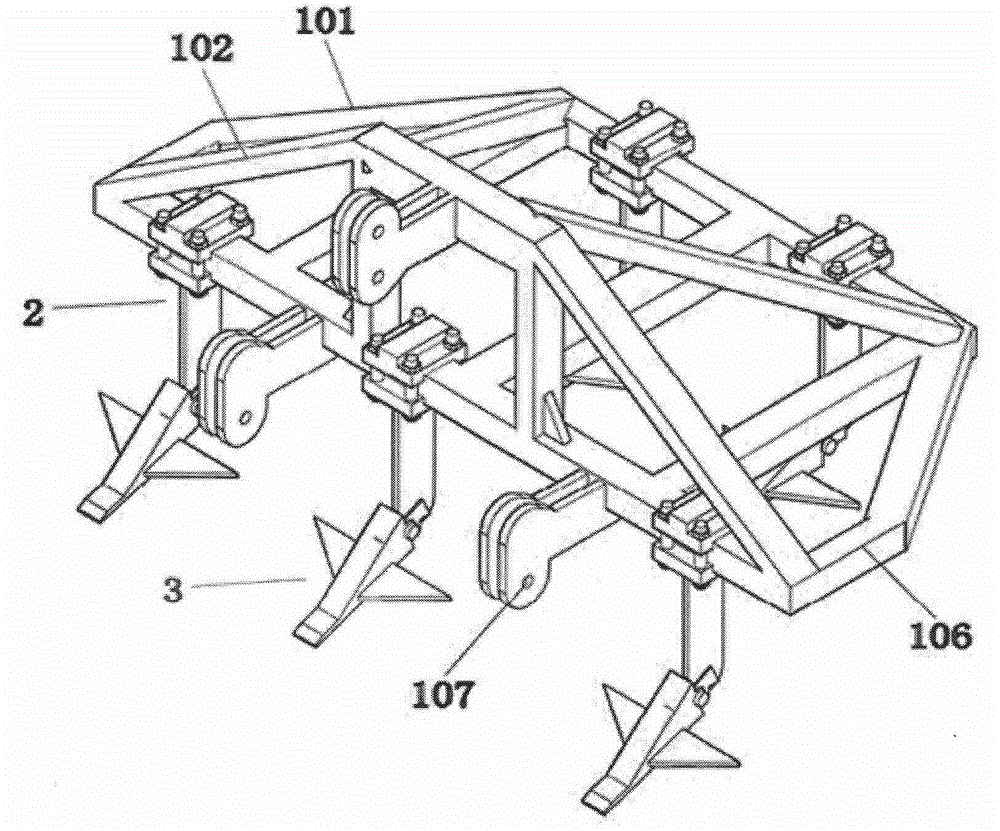

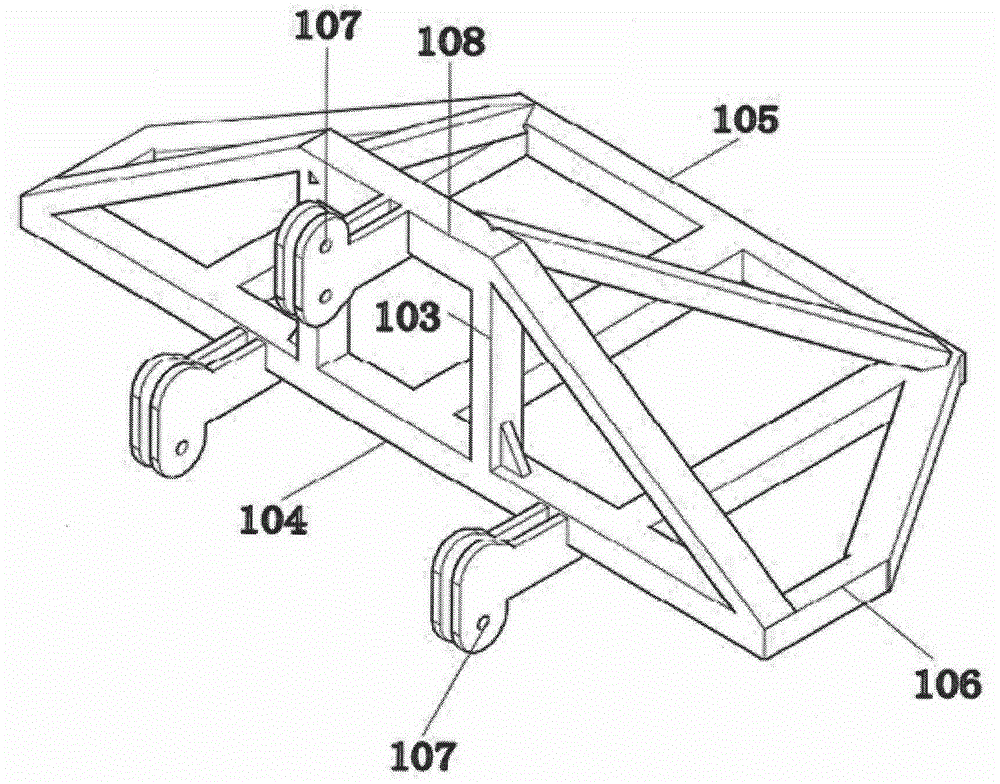

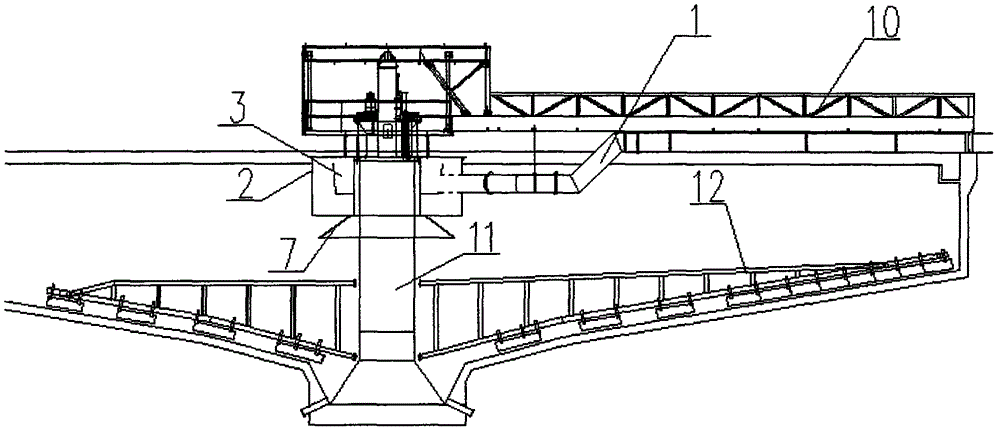

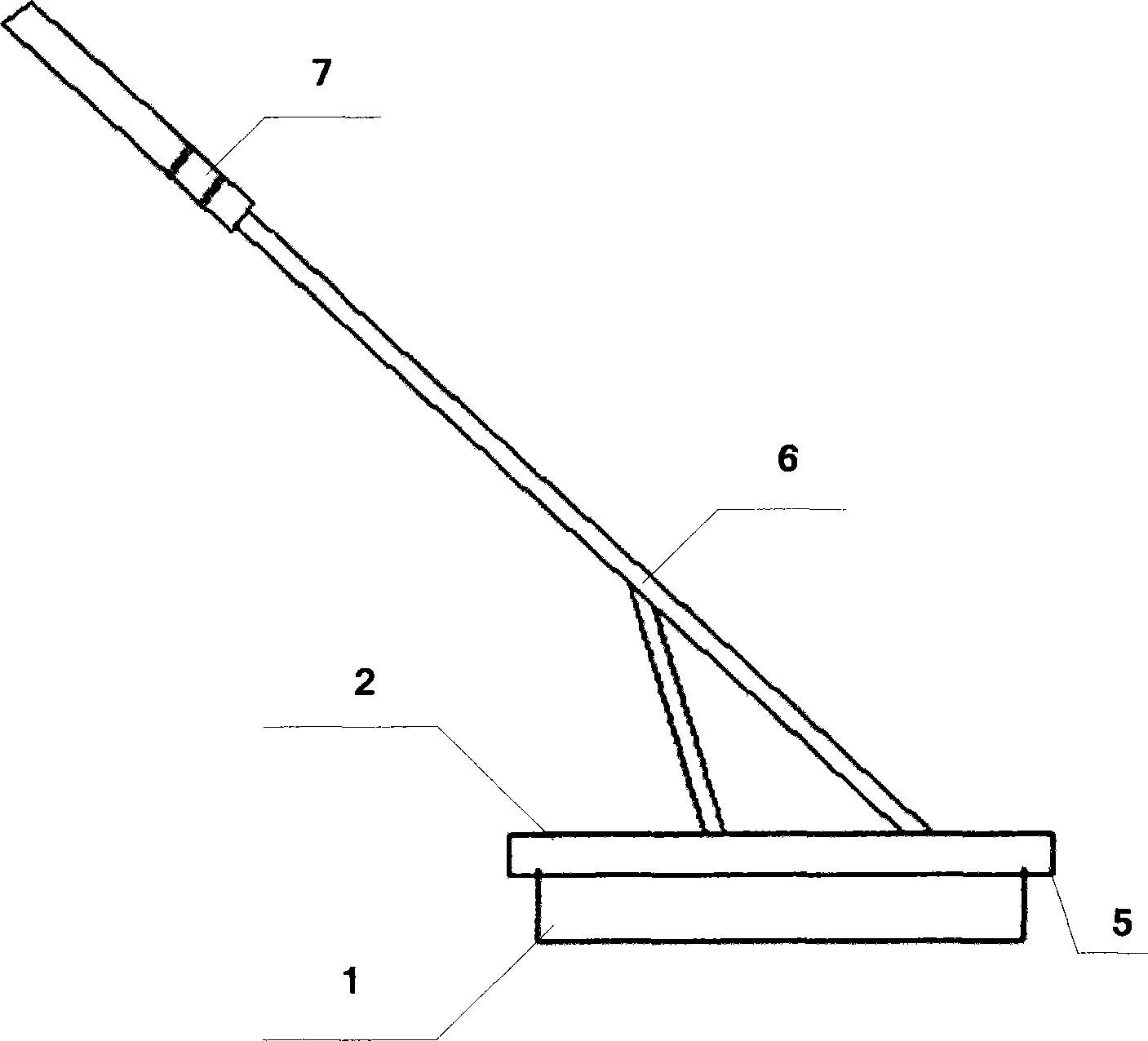

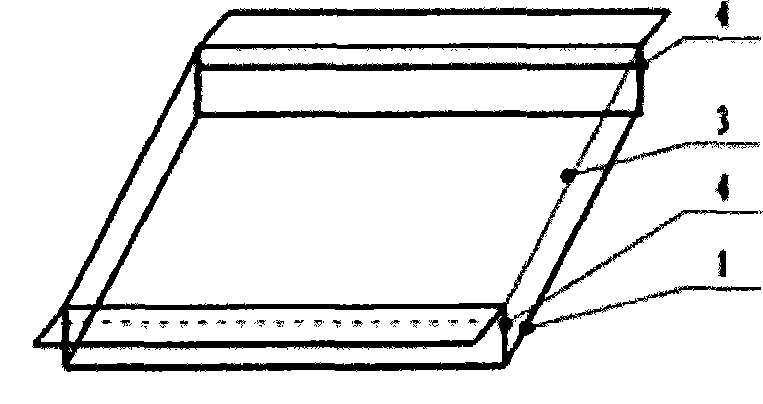

Soil tillage device with deep scarification and harrow smashing and leveling functions

The invention provides a soil tillage device with deep scarification and harrow smashing and leveling functions, and belongs to the technical field of agricultural machinery. The soil tillage device comprises a deep scarification device, a harrow smashing and leveling device, a connection mechanism of the deep scarification device and the hollow smashing and leveling device, and a lifting mechanism controlling the working height of the harrow smashing and leveling device. The deep scarification device is arranged on the front part, and the harrow smashing and leveling device is arranged on the rear part. By means of the soil tillage device, the deep scarification device and the harrow smashing and leveling device are organically combined together, the operation cost is reduced, soil compaction caused by repetitive work of agricultural machinery is reduced, and the operation depth is adjusted through the dead weight of the connection mechanism of the deep scarification device and the harrow smashing and leveling device and the dead weight of the harrow smashing and leveling device.

Owner:XINPING ZI YAN AGRI MACHINERY ENG CO LTD

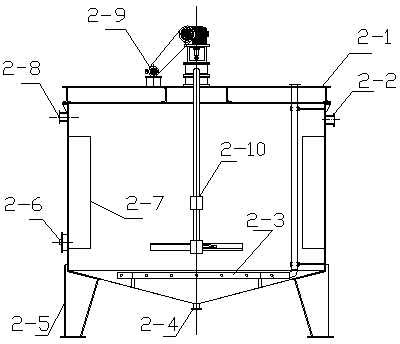

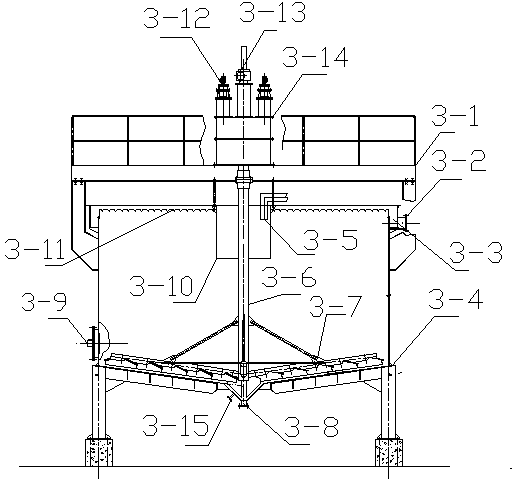

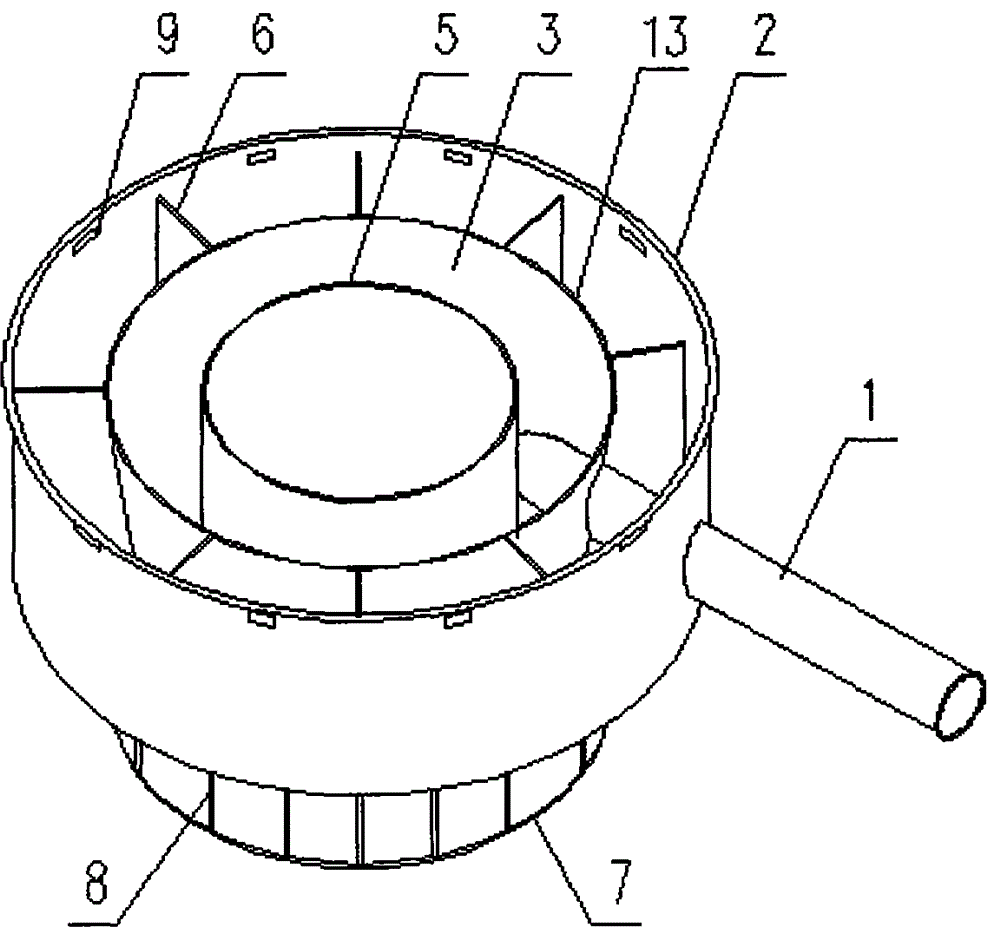

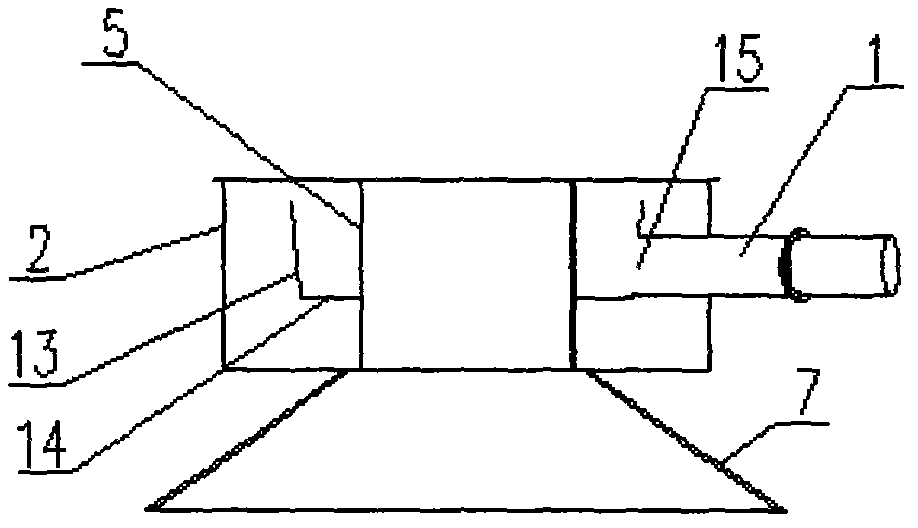

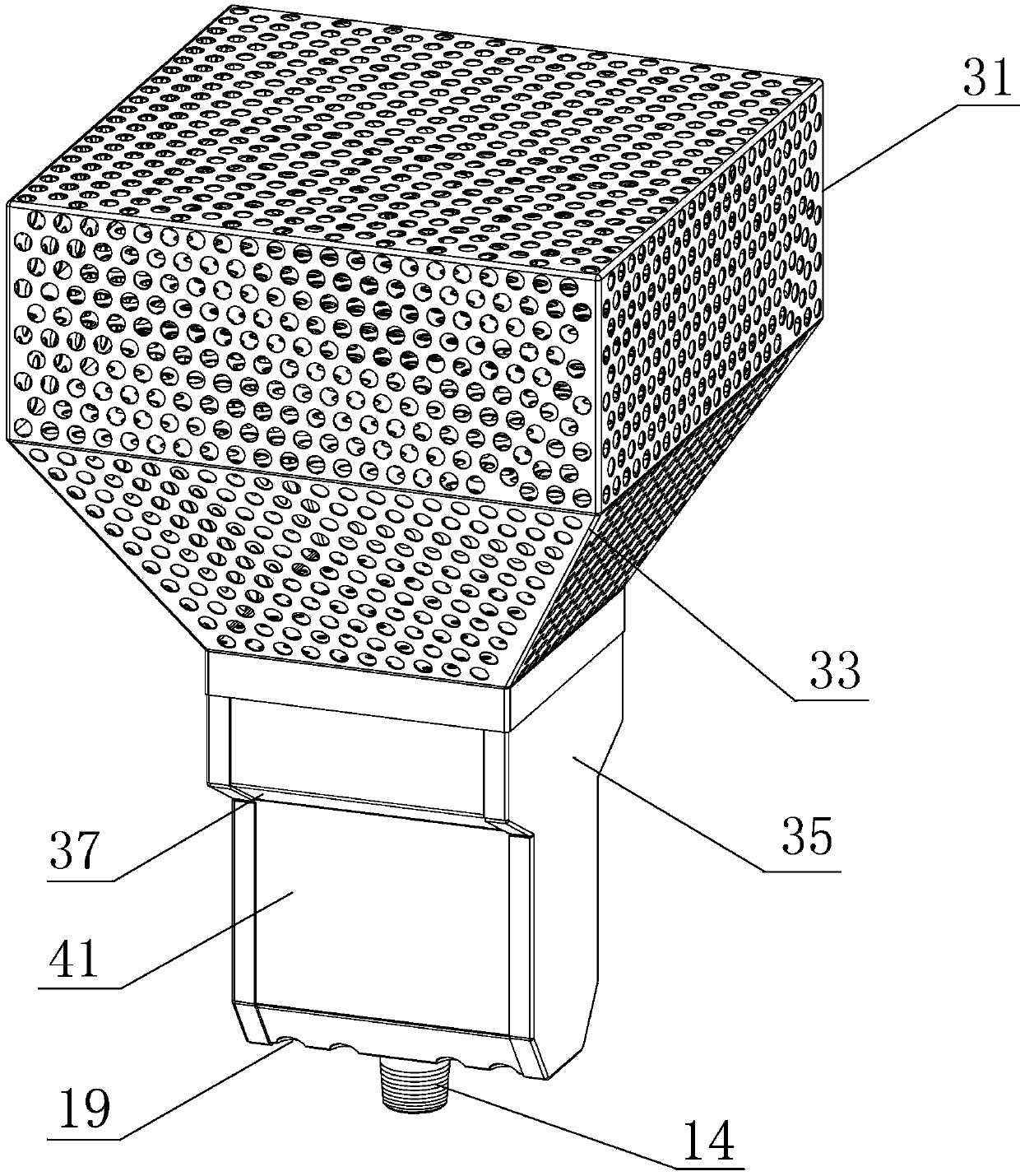

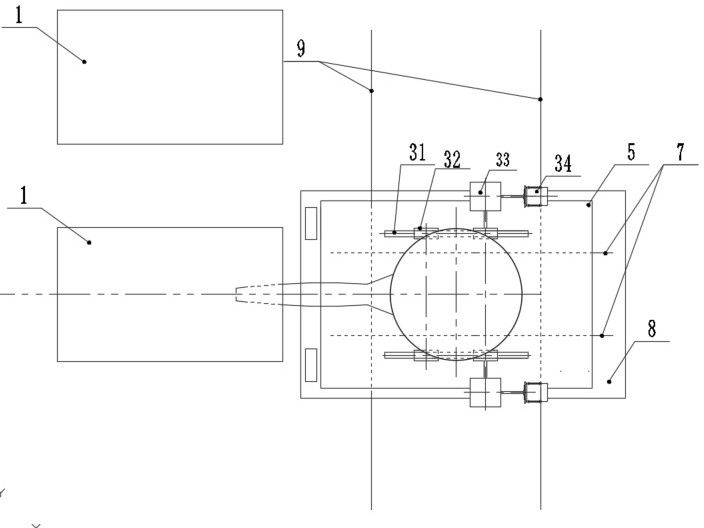

Material evenly distributing device of flow stabilizing cylinder of central transmission thickener

InactiveCN104826372AEvenly distributedEasy to handleSettling tanks feed/dischargeProviding materialCivil engineering

The invention discloses a material evenly distributing device of flow stabilizing cylinder of central transmission thickener, relates to the field of additional devices of central transmission thickener, and aims to solve the problem that the material settlement is non-uniform in the conventional thickeners. The material evenly distributing device comprises a material distributing tank and a plurality of fixed plate; the material distributing tank comprises a material distributing inner cylinder, a material distributing outer cylinder, and a material distributing bottom plate; the material distributing inner cylinder and the material distributing outer cylinder are connected through the material distributing bottom plate to form a circular groove; a material feeding pipe goes through an external flow guiding cylinder, and the opening of the material feeding pipe is fixed in the inner side of the material distributing outer cylinder. The provided material evenly distributing device can make materials evenly settle around the periphery of the material distributing tank, reduces the interference on the inner water and bed of thickening tank, and effectively improves the processing performance of a thickener.

Owner:HUAIBEI ZHONGFEN MINING MACHINERY

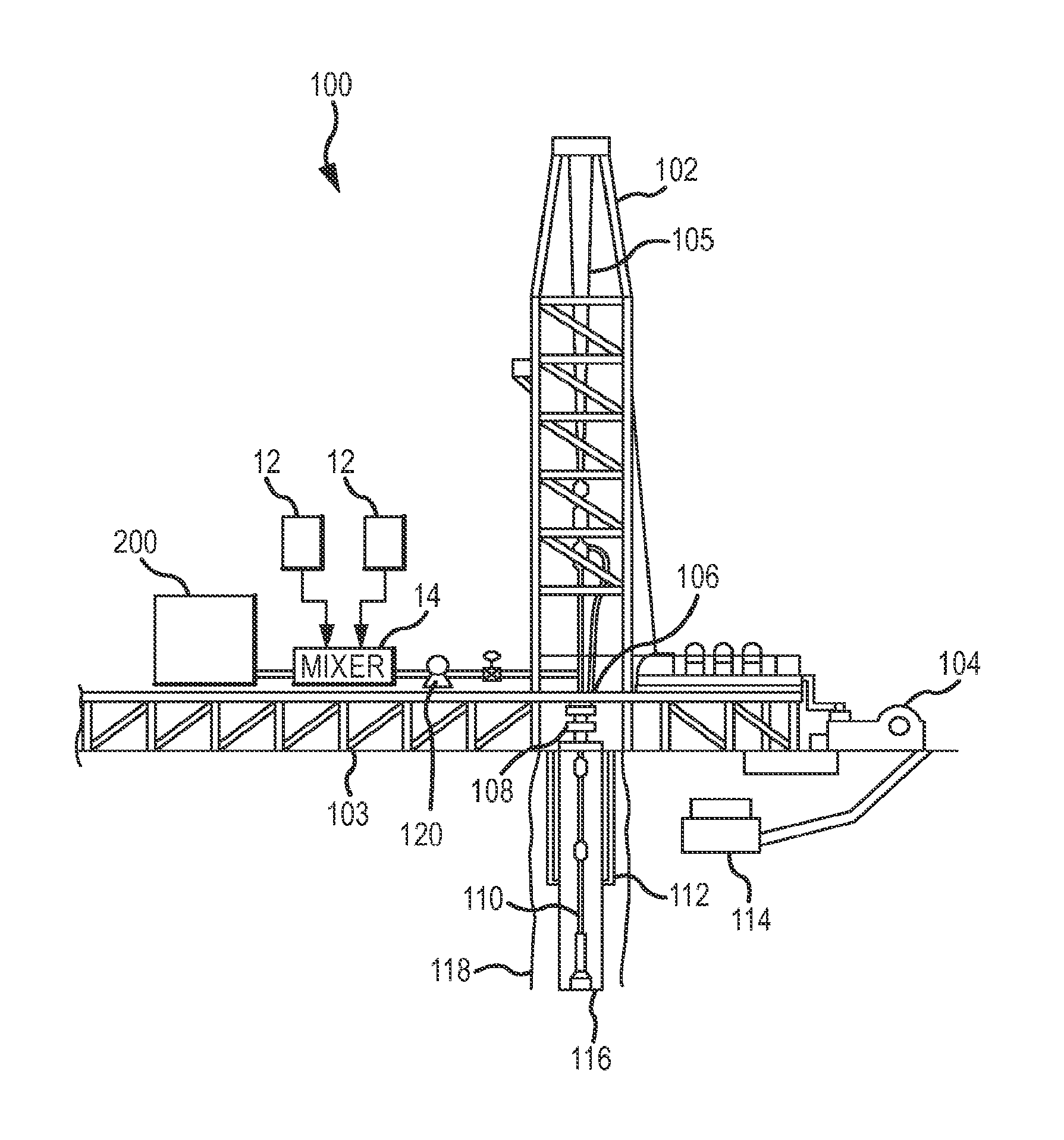

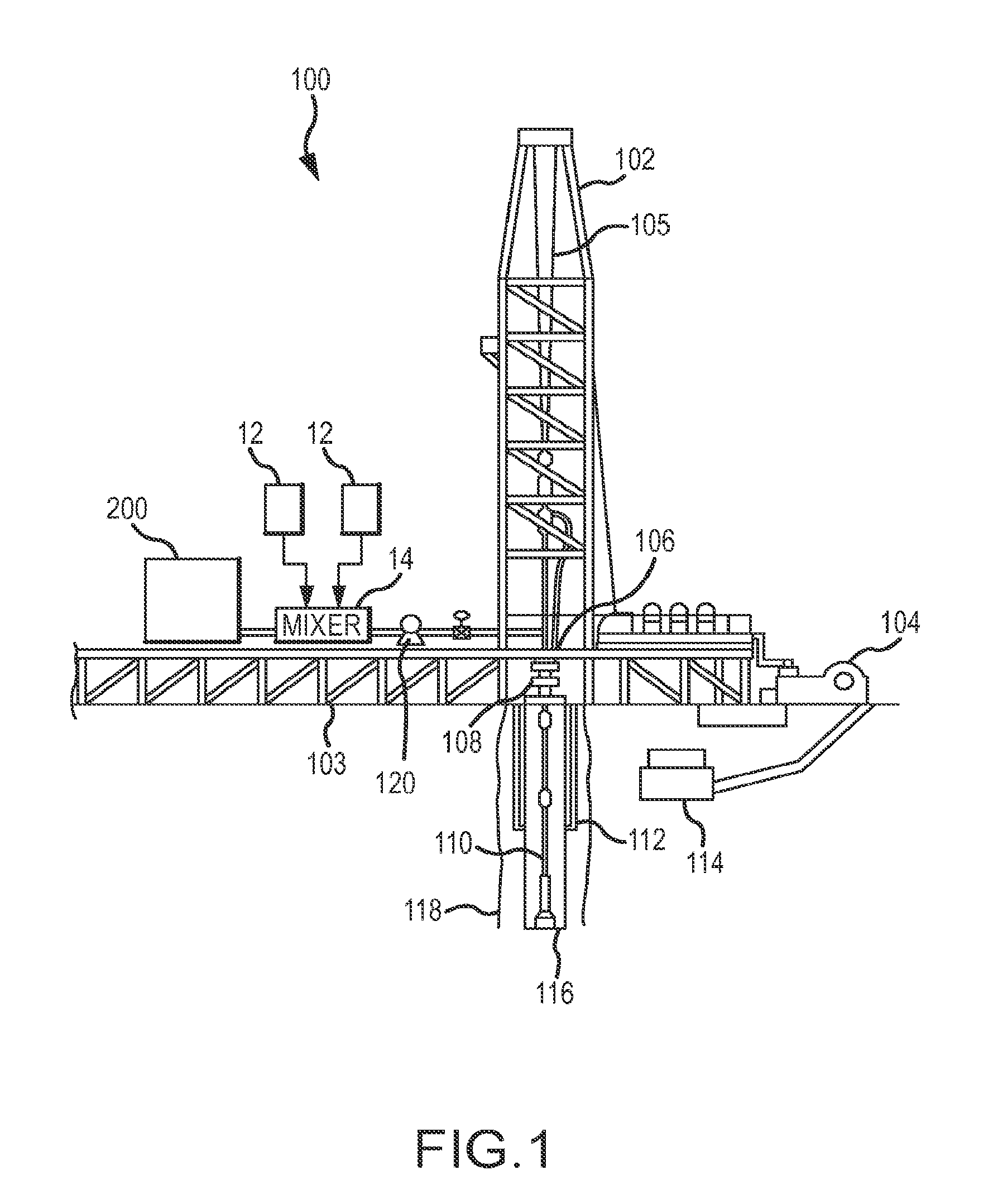

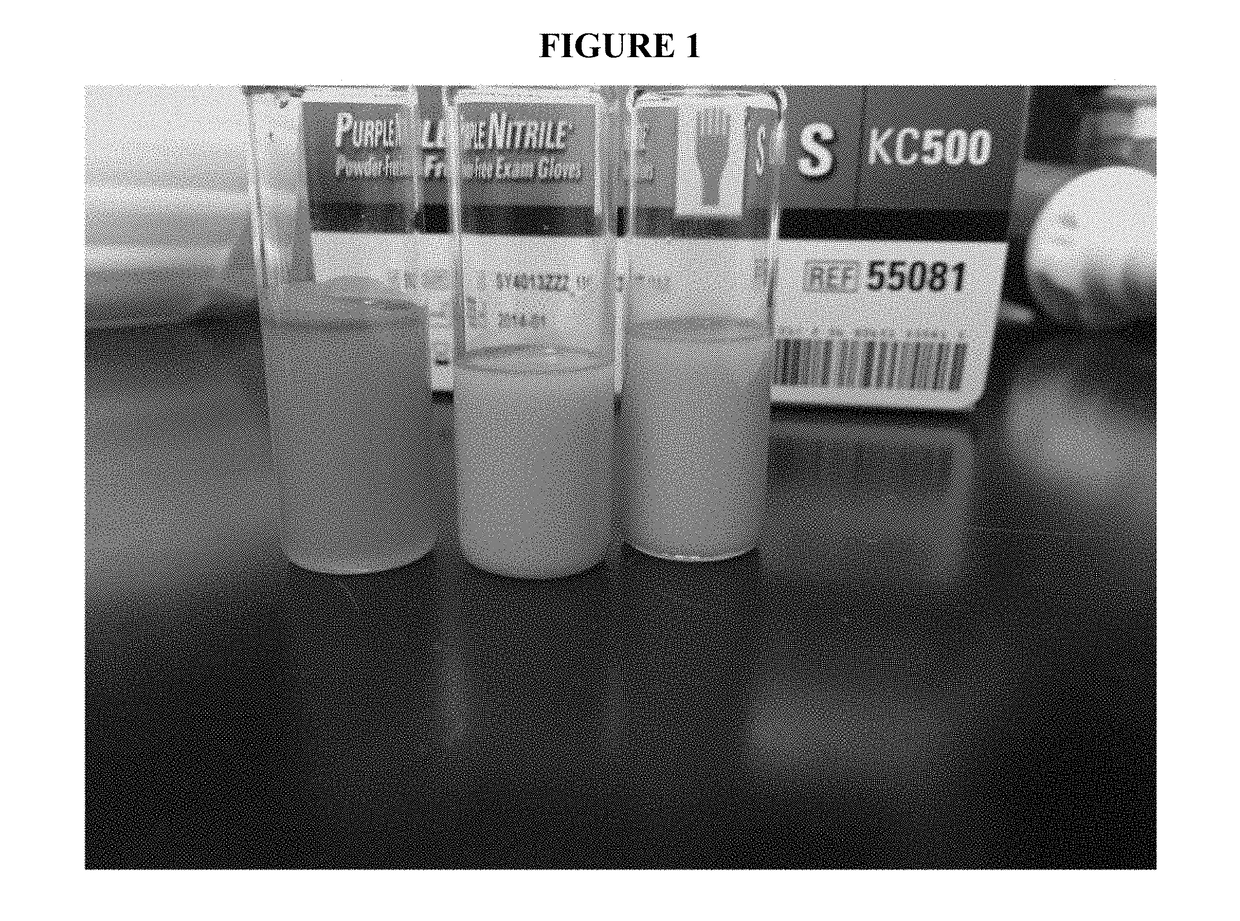

System, method and apparatus for manufacturing stable cement slurry for downhole injection

InactiveUS20140238665A1Low densityIncrease pressureSurveyDrilling rodsCement slurryMaterials science

A method for manufacturing stable lightweight cement slurry in a continuous manner for downhole injection comprising the steps of manufacturing a foamed gas having desired density ranging from about 2.15 to about 2.35 lb / cubic ft. and utilizing foam stabilizing nonionic surfactant. And, an apparatus for carrying out the method.

Owner:MACH IV L L C

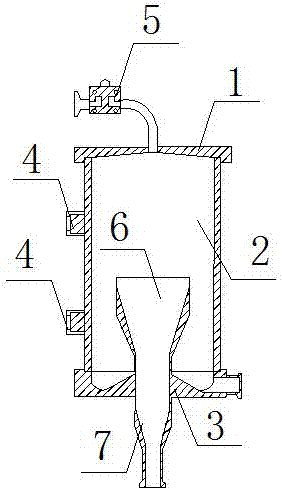

Bubble trap for separating gas and liquid and stabilizing flow rate of fluid

InactiveCN106861243AEasy to operateEfficient and smooth removalLiquid degasification regulation/controlFoam dispersion/preventionTransfer procedureReducer

The invention discloses a gas-liquid separation and a stable fluid flow rate bubble trap, which comprises a top plate, a glass cylinder, a bottom plate, a liquid level detector, a top valve, a two-stage deceleration variable diameter and a one-stage deceleration variable diameter. The beneficial effects of the present invention are: the bubble trap can efficiently and smoothly remove the bubbles in the fluid in biopharmaceuticals, the liquid level detector can accurately transmit the fluid gas-liquid boundary line to the PC or PLC with digital signals, and the separated bubbles are discharged The final liquid level height adjustment ensures the high precision of removing air bubbles; the use of multi-stage fluid deceleration and diameter reduction effectively reduces the fluid flow rate inside the device and improves the stability of fluid delivery; the device is mainly used for fluid transfer in biopharmaceuticals The gas-liquid separation in the process realizes stable fluid delivery. The device can be operated manually, semi-automatically or fully automatically. The operation steps are simple and can meet the needs of process characteristics. The air bubble trap is easy to operate, and the connection of each component is flexible.

Owner:上海东富龙海崴生物科技有限公司

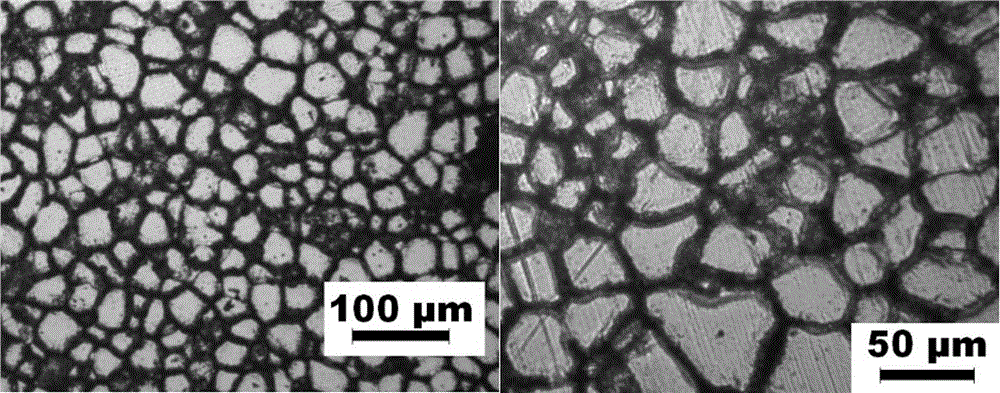

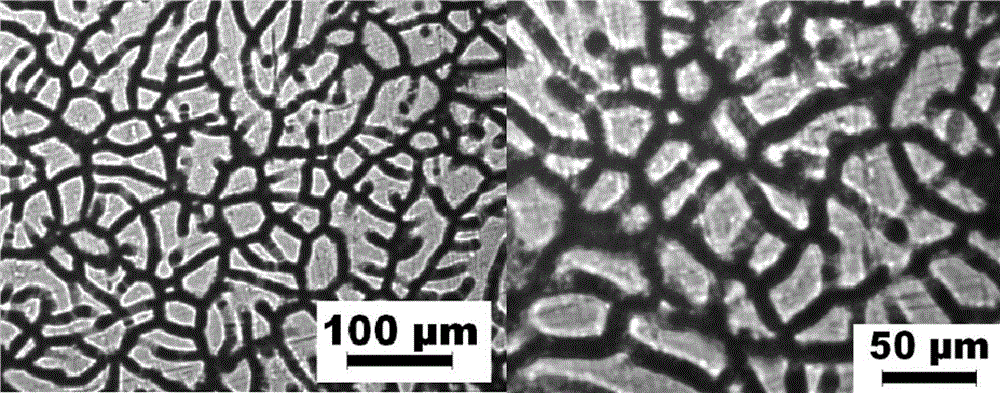

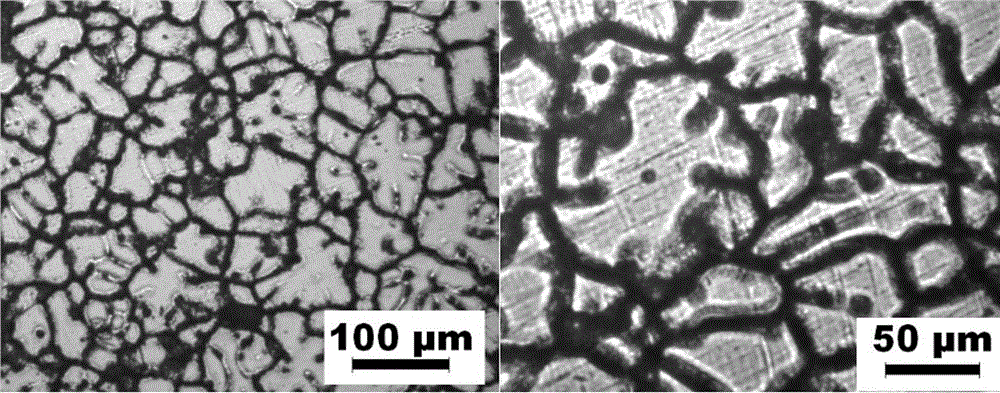

High-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc wrought aluminum alloy and manufacturing method thereof

The invention provides a high-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc wrought aluminum alloy. The alloy is composed of, by mass, 7% of Zn, 2% of Mg, 2.3% of Cu, 0.1% of Ce, 0.5% of Y, 0.1% of Er, 0.01% of La, 0.2% of Sc and the balance Al, wherein Al, Zn, Mg and Cu are added in a form of industrial pure Al, Zn, Mg and Cu with purity larger than 99.99wt.%, and Ce, Er, Y, Sc and La are added respectively in a form of powdery rare earth alloy with Al and 30wt.% of Ce, Mg and 30wt.% of Er, Mg and 20wt.% of Y, Al and 30wt.% of La, Al and 2wt.% of Sc. The invention further provides a manufacturing method of the alloy. Good composition homogenization effect is realized by adding rare earth elements and utilizing helium to blow rare earth alloy powder in, and a protecting atmosphere is formed through helium in the process of manufacturing, so that oxidizing reaction in the process of smelting is reduced as much as possible, the formed alloy is more accurate in composition, and the problem that conventional Al-Zn-Mg-Cu alloys are insufficient in performance and have product defects is solved effectively.

Owner:SHENYANG POLYTECHNIC UNIV

Measuring device and method for rotor axial force of double-screw compressor

ActiveCN108534940AStable and real-time measurementStable and real-time monitoringApparatus for force/torque/work measurementGas compressorThrust bearing

The invention discloses a measuring device and method for rotor axial force of a double-screw compressor. The measuring device mainly comprises two groups of stress sensors arranged on two sides of athrust bearing at an exhaust end of the double-screw compressor, each group of stress sensor assembly comprises three standard stress sensors, stress is uniform, stable measurement and real-time monitoring can be realized, and the three standard stress sensors are fixed on a corresponding bracket and are mounted and positioned by through holes. The measuring device adopts two-way force measurementdesign, can accurately measure the direction and magnitude of axial force without interference to operation of a rotor.

Owner:XI AN JIAOTONG UNIV

Horizontal layered shallow water bottom mud sampler

InactiveCN103267655ALayered clearlyEnhance layeringWithdrawing sample devicesEarth material testingEnvironmental protection

Owner:YANTAI UNIV

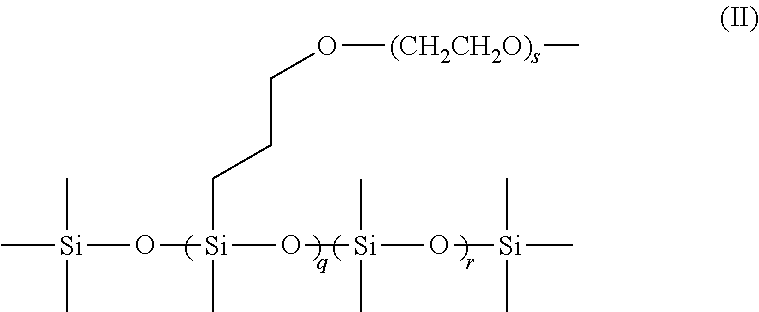

Silicone copolymers as emulsification additives for quantum dot resin premix

InactiveUS20180327661A1Creation of smaller heterogeneous domainsLess agitationLuminescent compositionsQuantum dotQuantum

The present invention provides quantum dot compositions and methods of producing quantum dot compositions. The quantum dot compositions comprise a population of quantum dots, a siloxane polymer, an emulsification additive, and an organic resin. The present invention also provides quantum dot films comprising a quantum dot layer and methods of making quantum dot films.

Owner:NANOSYS INC

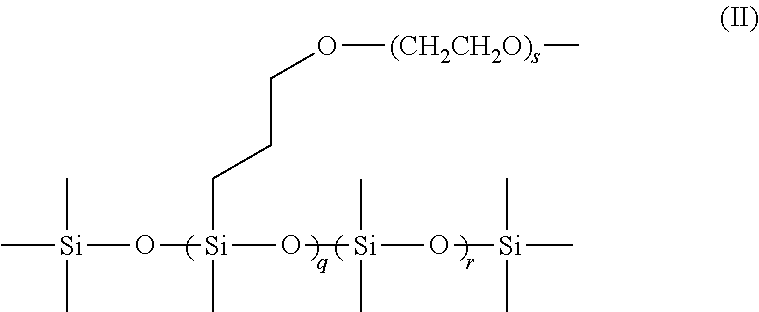

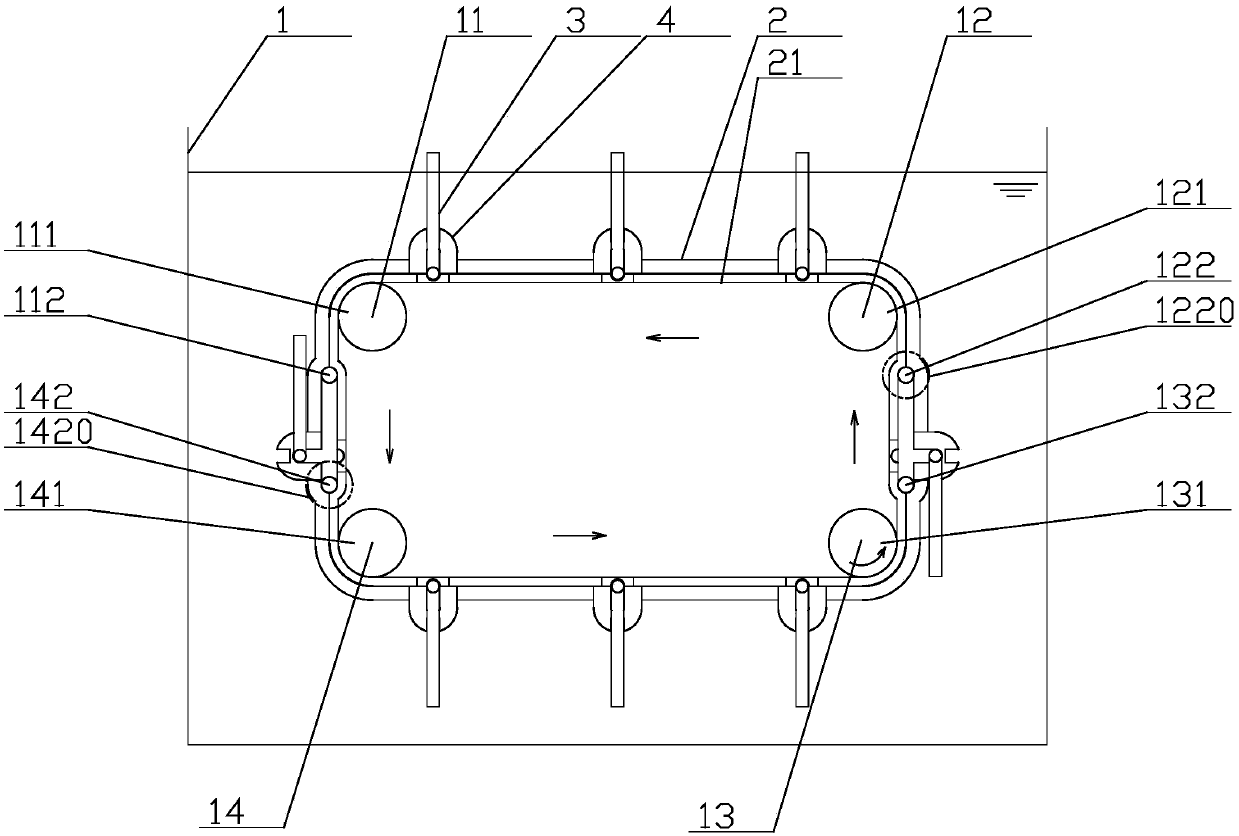

Skimming and mud scraping device

ActiveCN107670346AAvoid stirringHigh precipitation efficiencySedimentation settling tanksEngineeringSewage treatment

The invention discloses a skimming and mud scraping device, relates to the field of sewage treatment equipment, and particularly relates to improvement on skimming and mud scraping machines. The skimming and mud scraping device is exquisite in structure, good in stability and high in reliability and is good in structural strength during mud scraping and skimming, and false triggering can be prevented. The skimming and mud scraping device is arranged in a settling pond and comprises a first belt pulley, a second belt pulley, a third belt pulley, a fourth belt pulley, a conveyor belt, a plurality of scraping plates and a plurality of connecting assemblies. The first belt pulley and the second belt pulley are arranged at two ends of a location which is positioned below the internal liquid level of the settling pond, the third belt pulley and the fourth belt pulley are arranged at two ends of the upper portion of the bottom surface of the settling pond, and the conveyor belt is annularly sequentially wound on the first belt pulley, the second belt pulley, the third belt pulley and the fourth belt pulley. The skimming and mud scraping device integrally has the advantages that the skimming and mud scraping device is exquisite in structure, good in stability and high in reliability and is good in structural strength during mud scraping and skimming, the false triggering can be prevented, and the stirring degree of pond water can be lowered to a great extent.

Owner:扬州青青环保成套设备有限公司

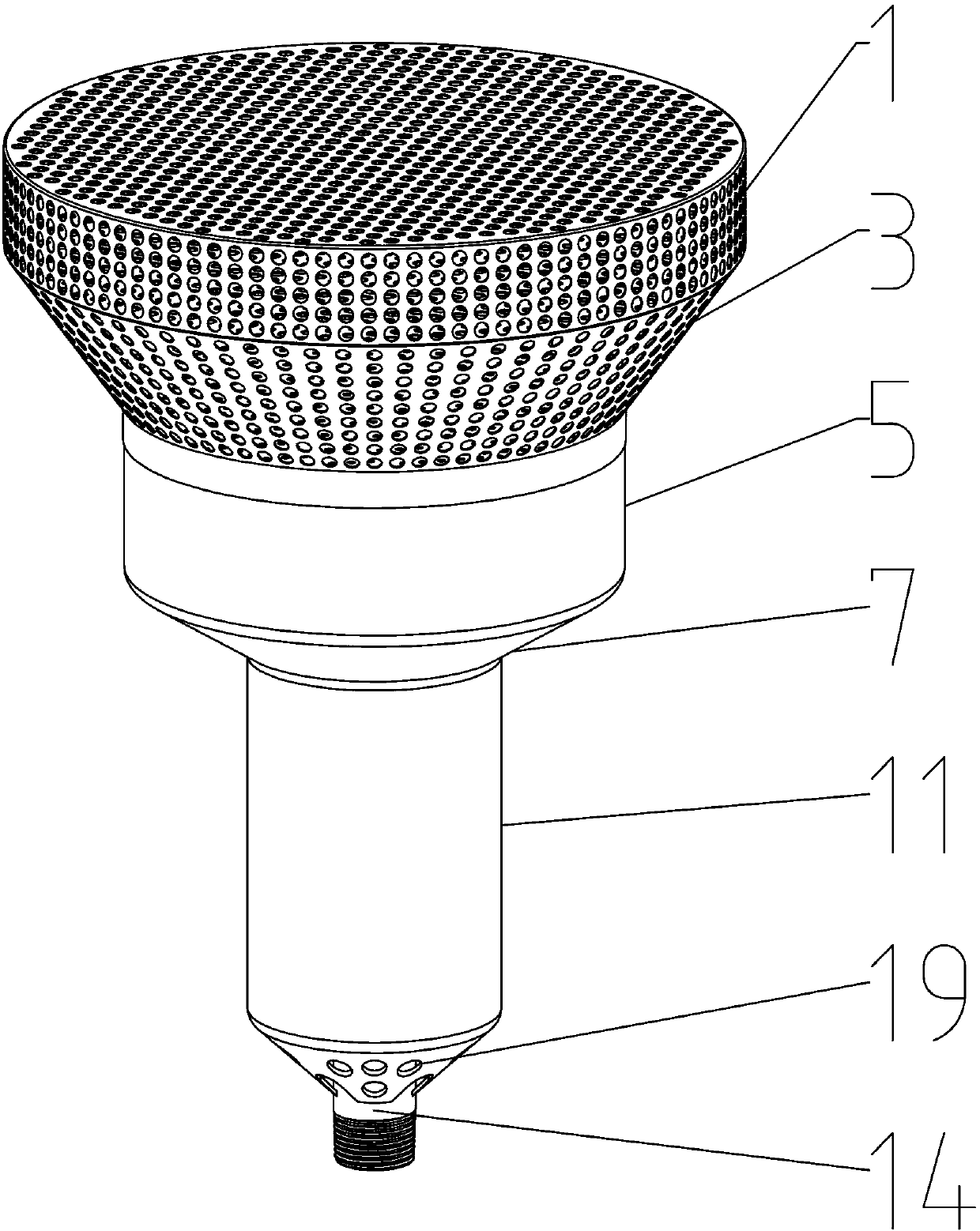

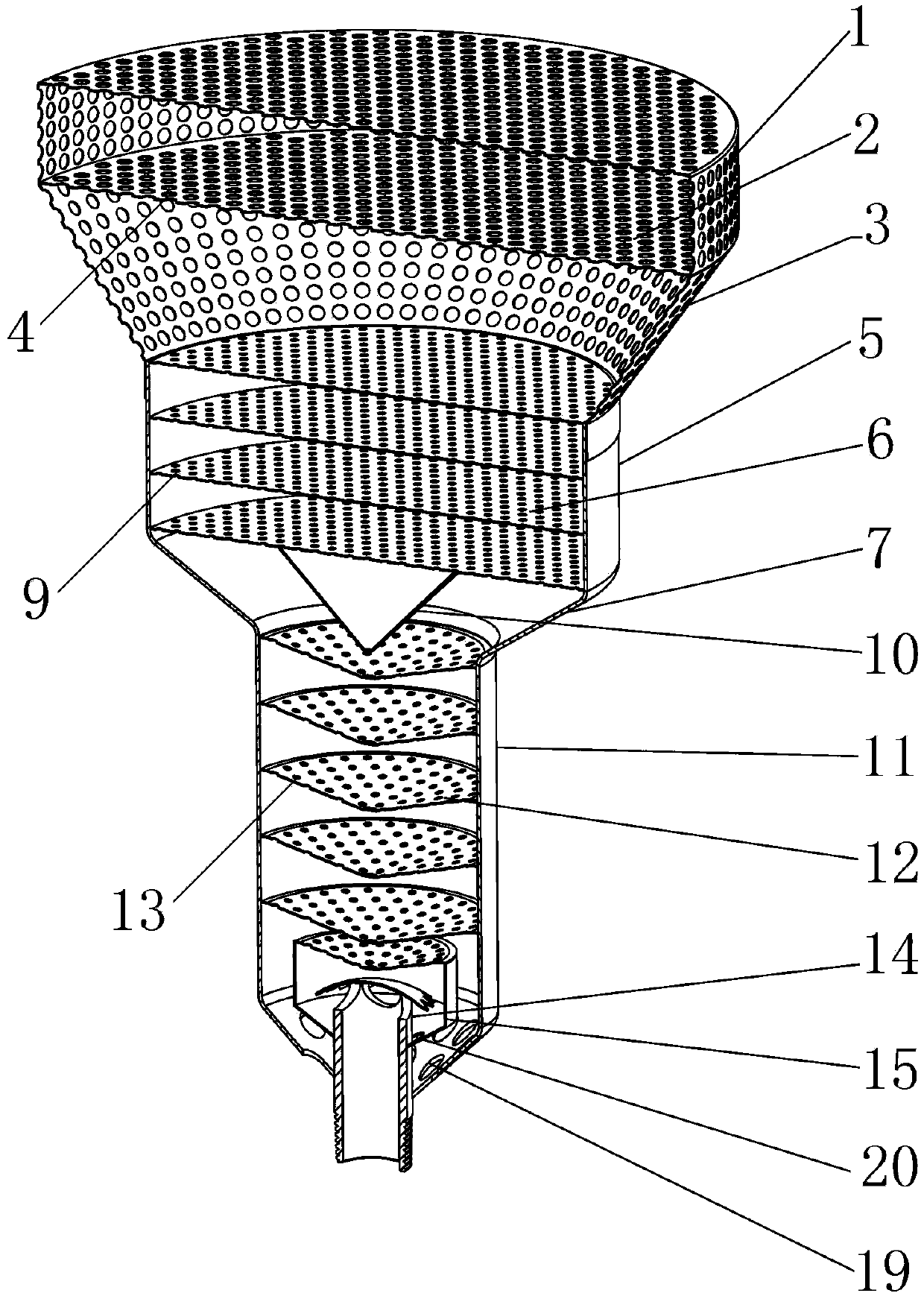

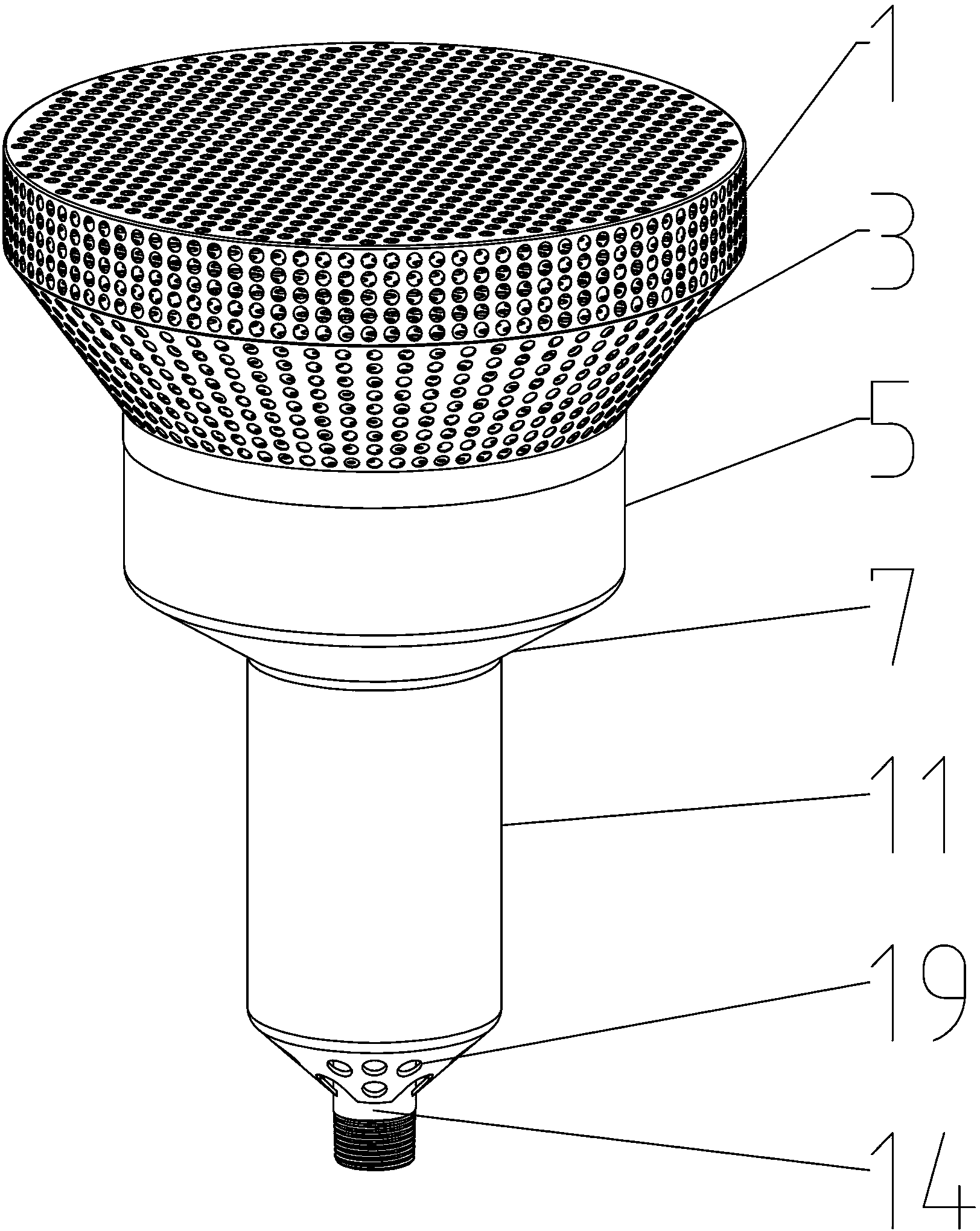

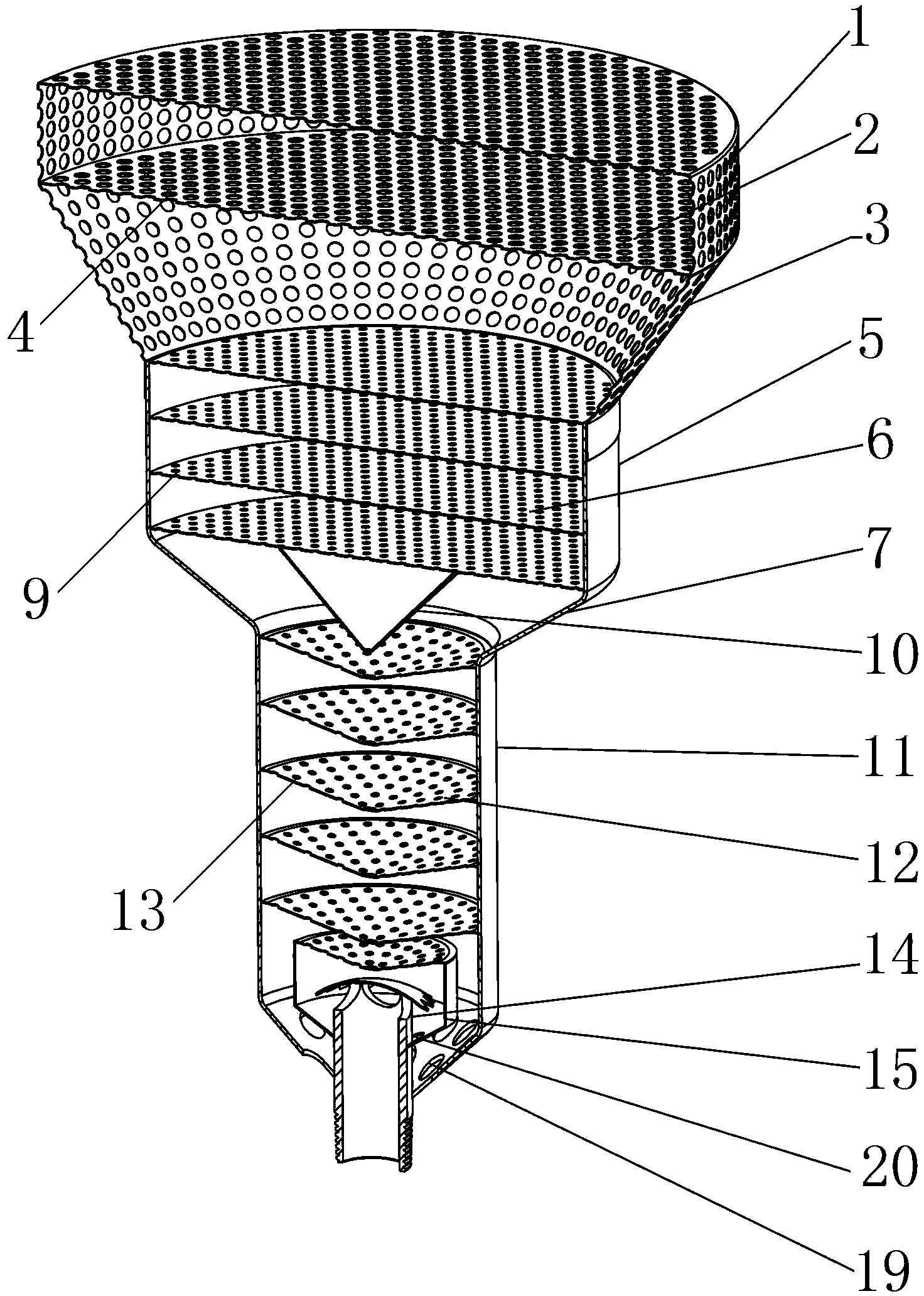

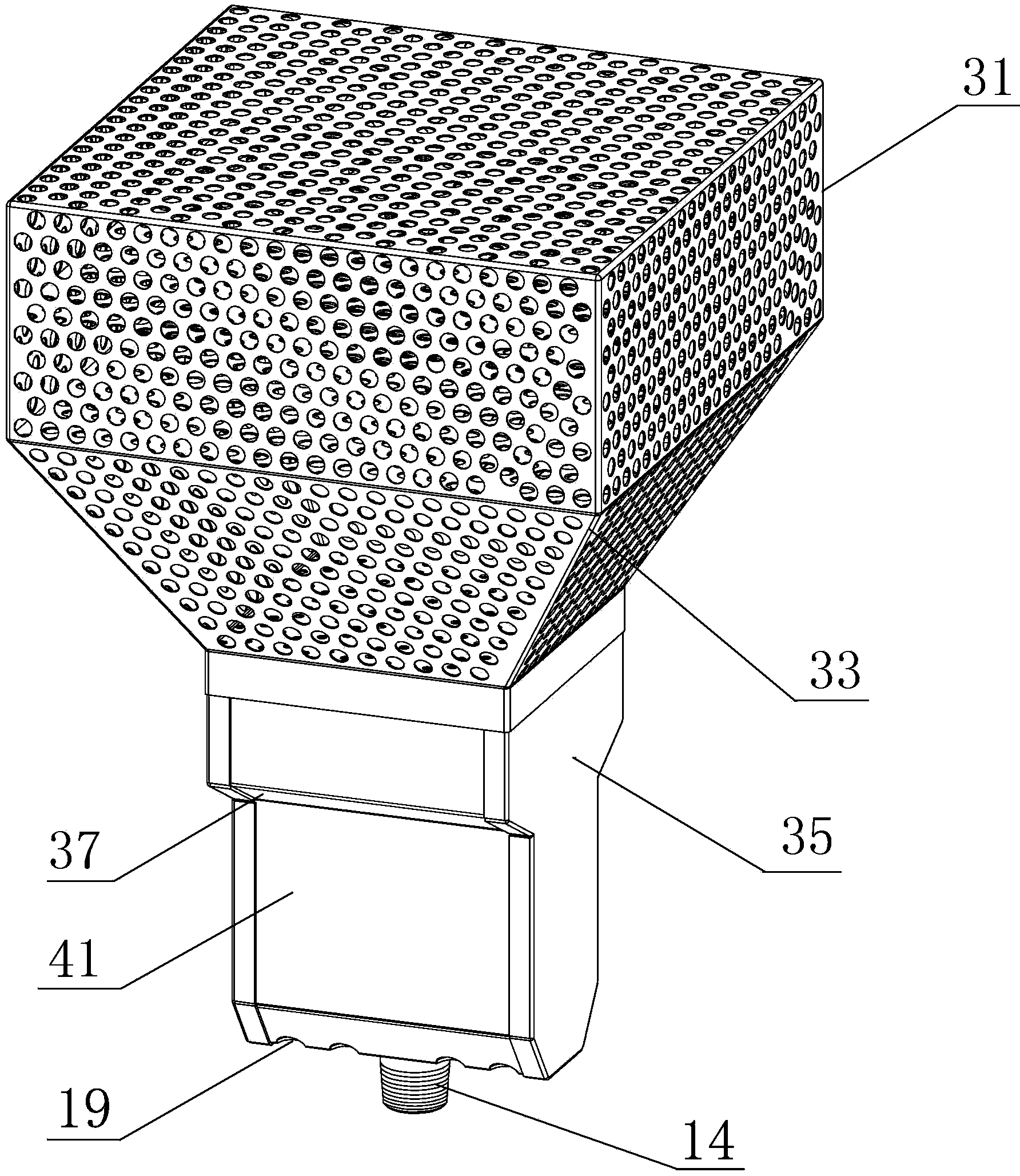

Anti-clogging aerator

ActiveCN103435120AReduce the gas flow rateLarge service areaTreatment using aerobic processesSustainable biological treatmentGas bubbleMechanics

The invention relates to an anti-clogging aerator which comprises an upper bubble rectifying device, a middle bubble cutting device, a lower bubble cutting device and an air intake component, wherein the upper bubble rectifying device comprises a cowling, a rectifying plate and a funneled cowling transitional connection casing; the middle bubble cutting device comprises a middle casing, a middle cutting plate and a middle funneled transitional connection casing; the lower bubble cutting device comprises a lower casing and a lower cutting plate; the air intake component comprises an air inlet pipe, a cover body and a baffle plate. According to the invention, gas is smashed into bubbles through cutting holes in the gas and liquid mixing process, after being cut at each stage, the bubbles become smaller in size and are increased in number, meanwhile, the gas flow rate is lowered so as to enlarge the service area of the bubbles. Blowdown holes are formed in the lower casing and the lower part of the cover body, the cutting holes are formed in the cutting plates and are not blocked easily or required to be cleaned, and the use is not influenced even the cutting plates scale slightly. The anti-clogging aerator is simple in structure and convenient to operate; procedures for cleaning the aerator frequently are reduced, and the production efficiency is improved.

Owner:石家庄金钛净化设备有限公司

Scrubbing wash device for wool

InactiveCN108570715ALess agitationReduce dispersionWool fibre washing/scouringReciprocating motionAir pump

The invention discloses a scrubbing wash device for wool. The scrubbing wash device comprises a cleaning box, wherein water pumps are fixed on the outer side walls of support columns; water tanks arearranged on the outer sides of the water pumps; extrusion air pumps are arranged in the middles of two side walls of the cleaning box; extruding expansion links penetrate into the cleaning box throughpenetrating rings; scrubbing plates are fixed at the inner side ends of the extruding expansion links; scrubbing grooves are formed in the top and the bottom of each scrubbing plate; a drive slider and a following slider are clamped in each scrubbing groove, and roller supports are fixed on the outer side surfaces of the drive sliders and the following sliders; a scrubbing roller is fixed rotationally between the roller supports located on the two sides; a scrubbing air pump is fixed on the outer side wall of a scrubbing base; drive rods of the scrubbing air pump are fixed with the side wallsof the drive sliders; a control box is fixed on a front panel of the cleaning box. According to the scrubbing wash device, the scrubbing air pump drives the scrubbing roller to perform reciprocatingmotion in the cleaning box to scrub and wash the wool repeatedly, so that the problem that the wool is prone to breaking and dispersing in the cleaning process and the cleaning box is easily blocked by the wool are solved.

Owner:王少平

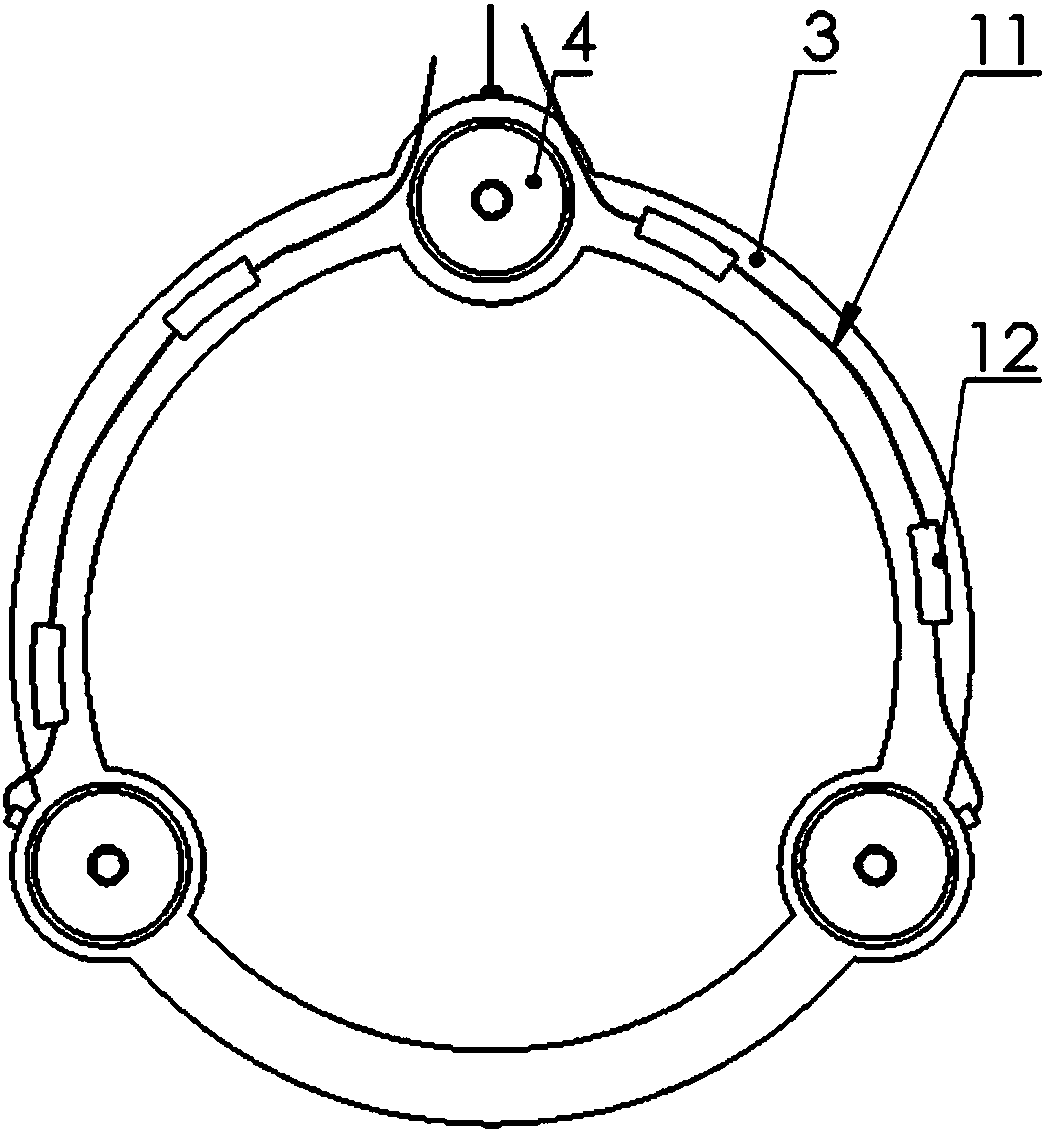

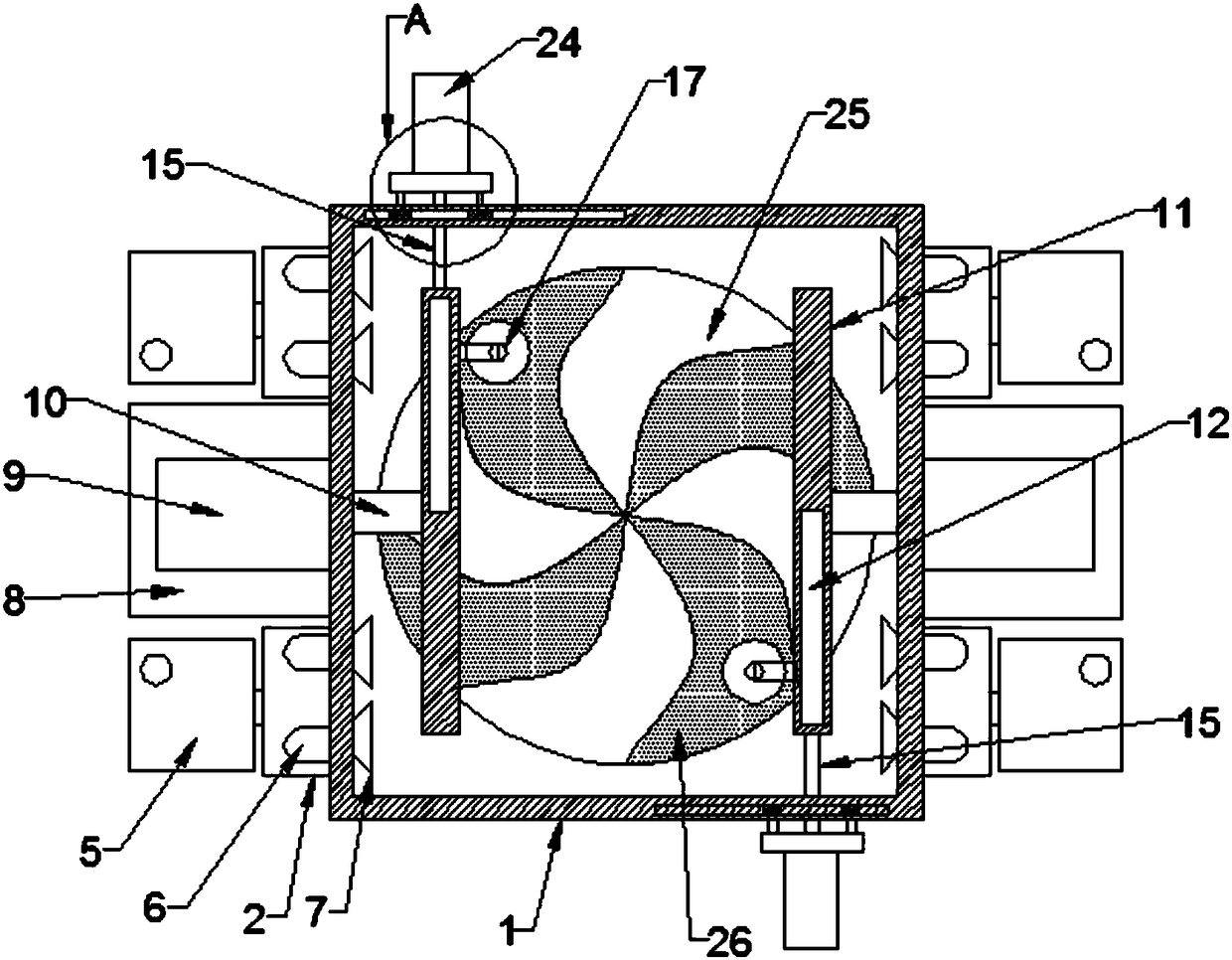

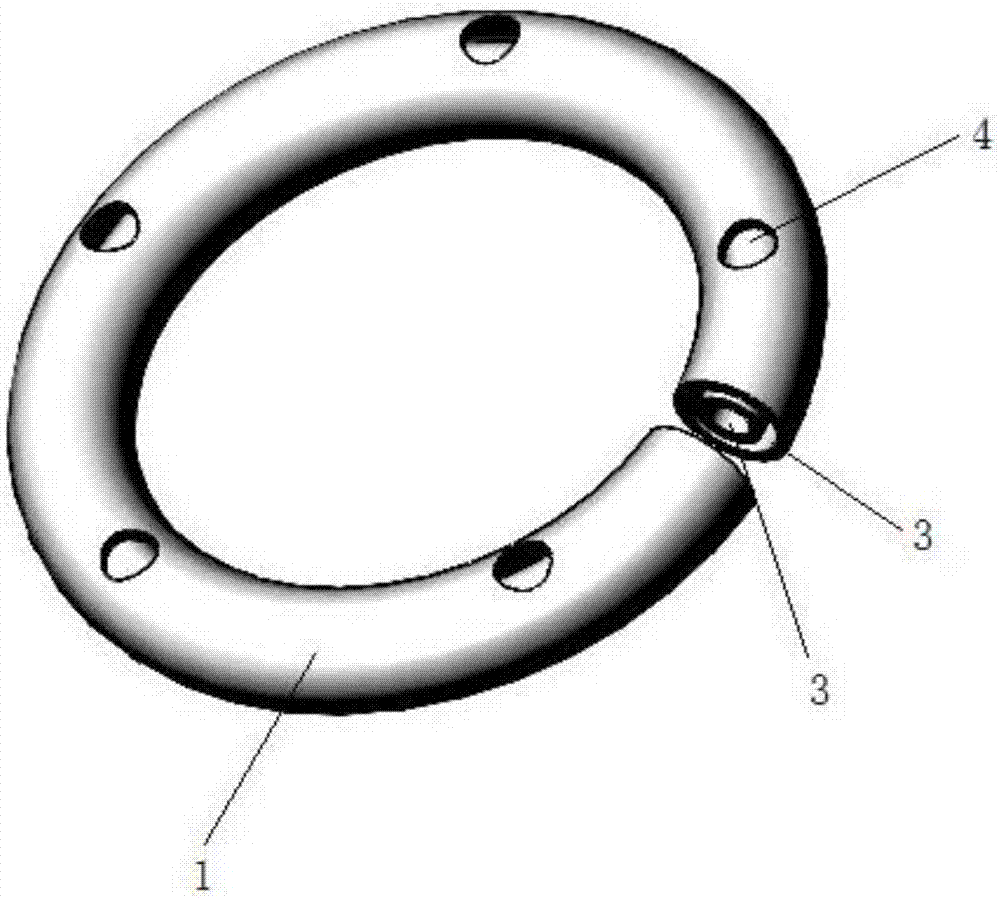

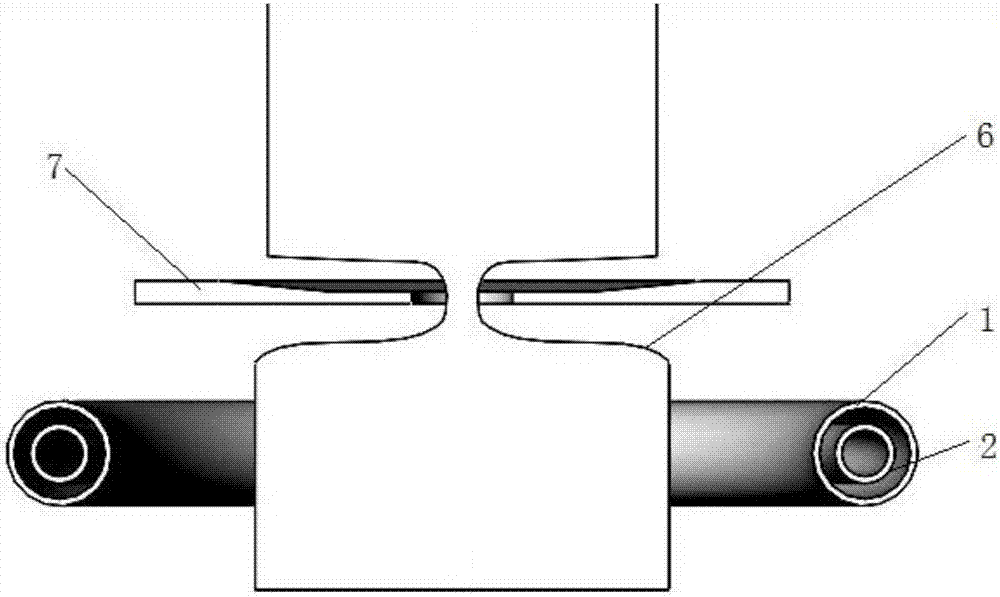

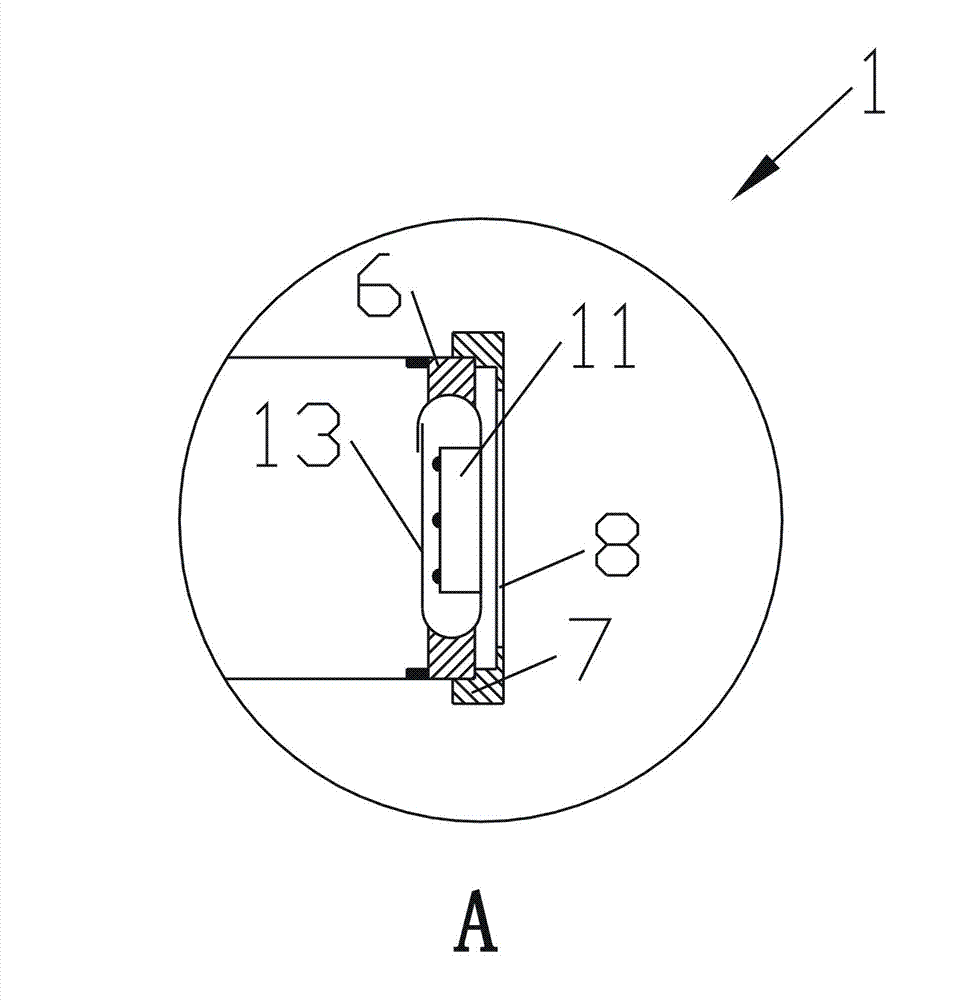

Doping device for improving radial resistivity distribution of float-zone single silicon crystals

ActiveCN106995935AUniform concentrationLess agitationPolycrystalline material growthFinal product manufacturePhysical chemistryEngineering

The invention creatively provides a doping device for improving the radial resistivity distribution of float-zone single silicon crystals. The doping device comprises a main annular pipe and a doped gas annular pipe nested in a pipe cavity of the main annular pipe; mutually independent air inlets are arranged on the main annular pipe and the doped gas annular pipe respectively; a plurality of main gas outlets are formed in the main annular pipe in a circumferential direction; a plurality of doped gas outlets are arranged on the doped gas annular pipe in the circumferential direction; and the main gas outlets and the doped gas outlets are distributed in a staggering manner. The doping device created by the invention can effectively improve the uniformity and the stability of a concentration of the doped gas in a furnace body and ensures the radial resistivity distribution of the grown float-zone single silicon crystals to be more uniform.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

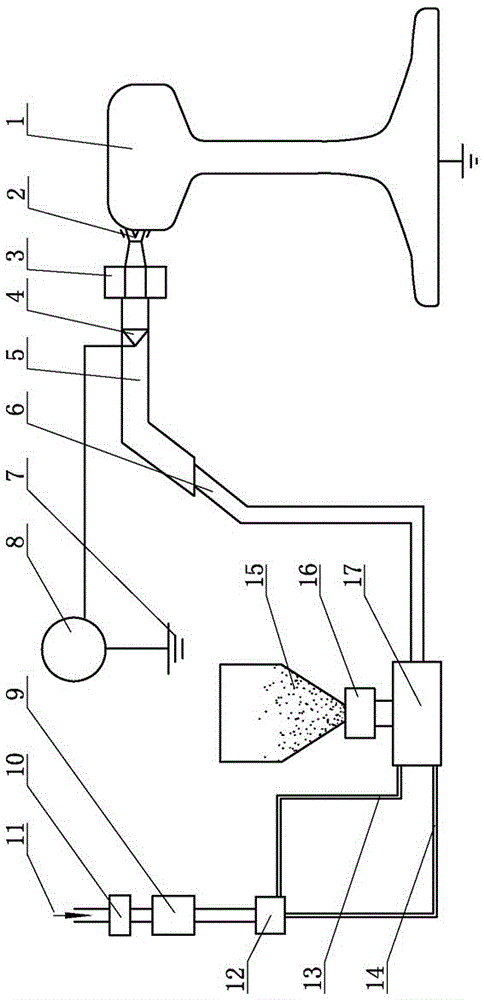

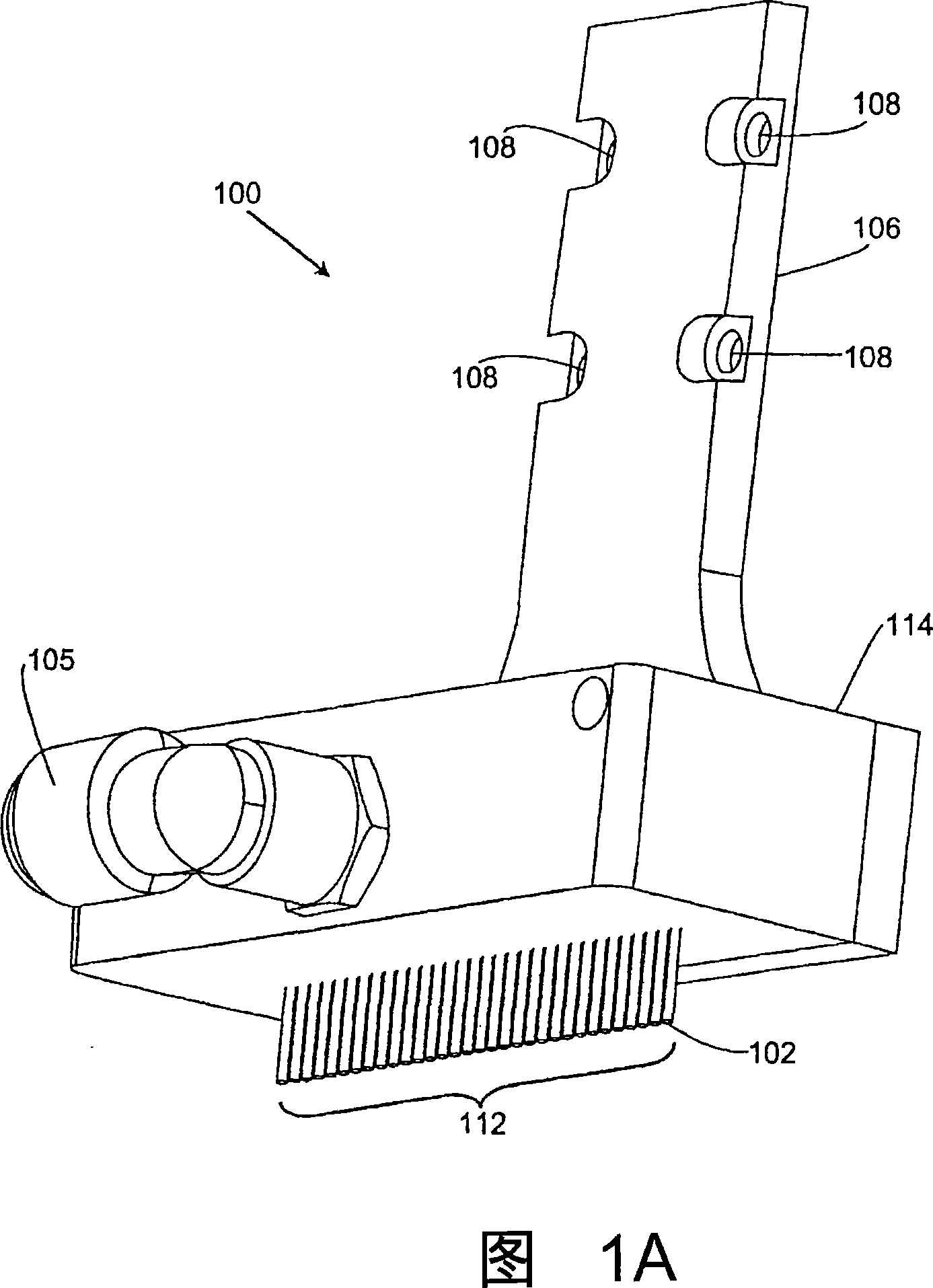

Electrostatic coating device of locomotive-mounted wheel rail friction control material

InactiveCN105728218AIncrease profitDensity controllableRail lubricationRail wetting/lubricationElectrostatic coatingEngineering

The invention discloses an electrostatic coating device of a locomotive-mounted wheel rail friction control material. The electrostatic coating device comprises a high-voltage electrostatic generator, a high-voltage electrode and a powder pump; the powder pump is provided with a secondary wind pressure pipe and a primary wind pressure pipe; a feed port of the powder pump is connected with a supply electromagnetic valve; the supply electromagnetic valve is connected with a storage tank; a discharge port of the powder pump is connected with a powder-air mixing pipe; the powder-air mixing pipe is connected with a nozzle; and the high-voltage electrode is arranged in the nozzle, and is connected with the high-voltage electrostatic generator. The electrostatic coating device has the following advantages: the electrostatic coating device saves such links as heating, stirring and insulation transportation in a solid-liquid-solid coating mode, so that the caused defects are prevented, the device is compact in structure, small in size and more convenient for installation, largely increases the material utilization rate, realizes controllability of coating thickness and density, and can adjust the coating thickness and density through a mode of adjusting primary and secondary wind pressure and voltage of the electrostatic generator according to specific conditions of different curves; and a coating method is more scientific and precise, and greatly improves the coating effect.

Owner:张峰

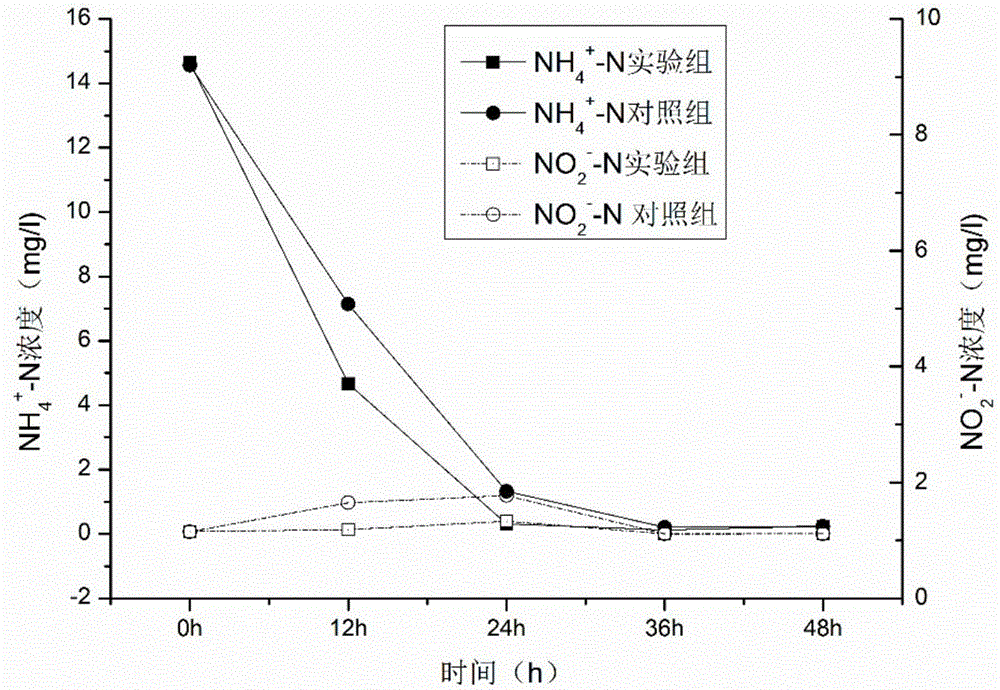

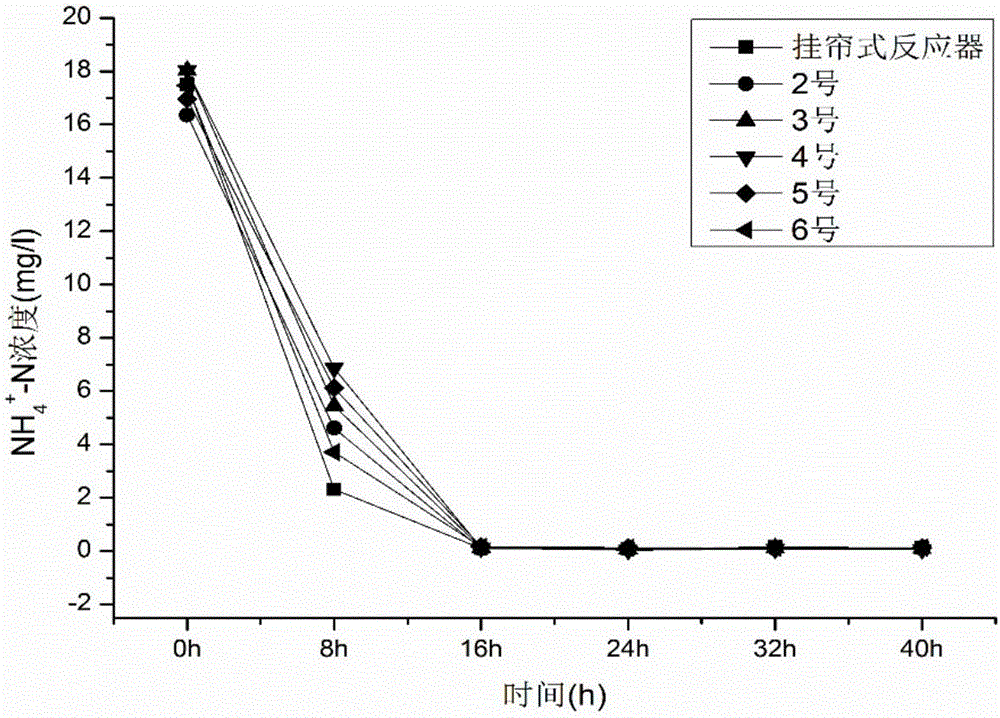

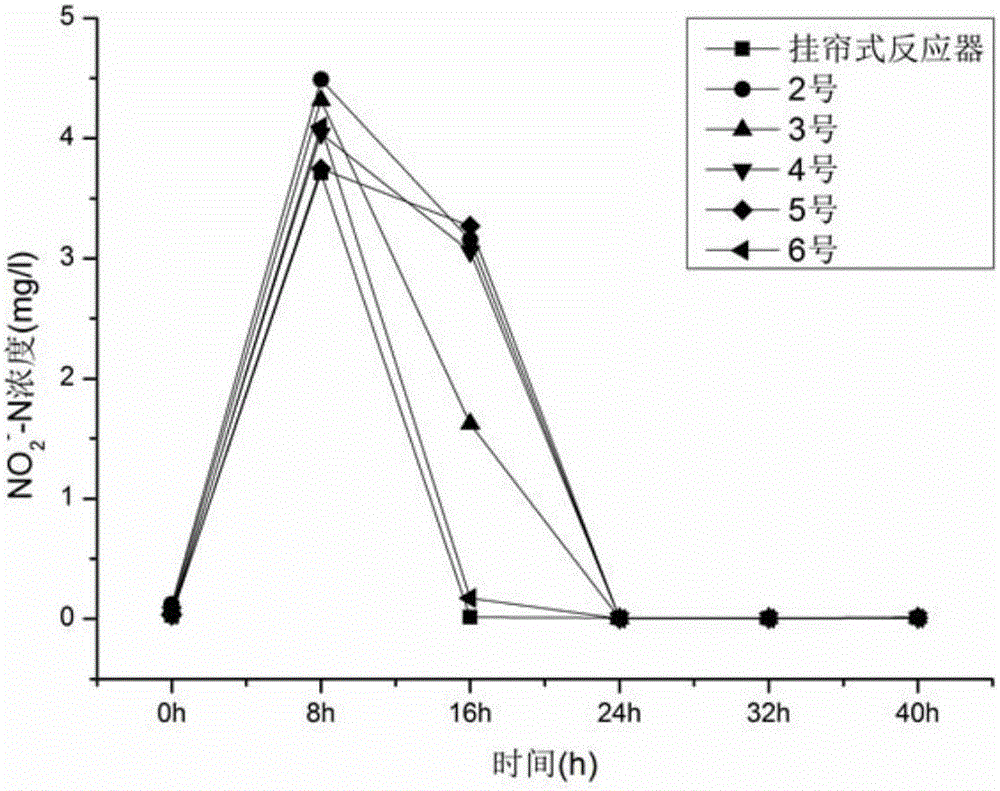

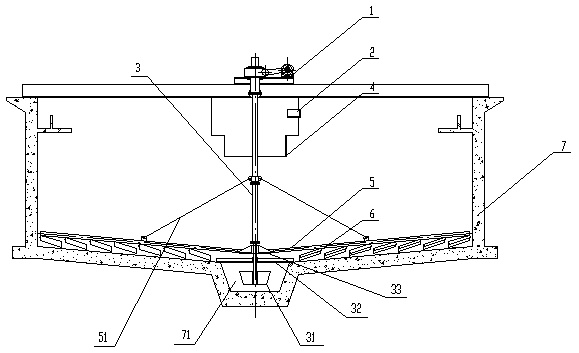

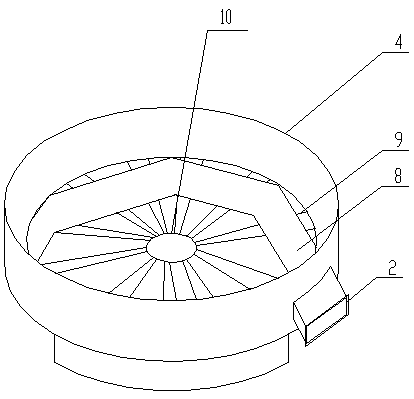

Hanging curtain type biological filtering pool and application thereof to recirculating aquaculture

ActiveCN105693022AFavorable for attachment growthLess agitationWater/sewage treatment by irradiationWater contaminantsFiberCarbon fibers

The invention provides a hanging curtain type biological filtering pool which comprises a container, carbon fiber felt, a water inlet pipe and a water outlet pipe; the carbon fiber felt is inserted into the container side by side at the interval of 2-4 cm, the water inlet pipe is arranged on the upper portion of the container, the water inlet pipe is connected with water distribution pipes, the water distribution pipes are connected with a water distribution device, and the water distribution device is located above the carbon fiber felt; the water outlet pipe is located at the bottom of the container. The invention further provides application of the hanging curtain type biological filtering pool. The hanging curtain type biological filtering pool enables microorganisms to be attached to the carbon fiber felt, stirring of water flow is reduced, the microorganisms can grow more easily in an attached mode, pollutants in water are further removed, and quality of outlet water is improved; meanwhile, an aged biological membrane falls along with water and is removed through a physical filtration system, backwash equipment is not needed, and cost is saved while removal efficiency of ammonia nitrogen and nitrite nitrogen is guaranteed.

Owner:BEIJING AGRO BIOTECH RES CENT

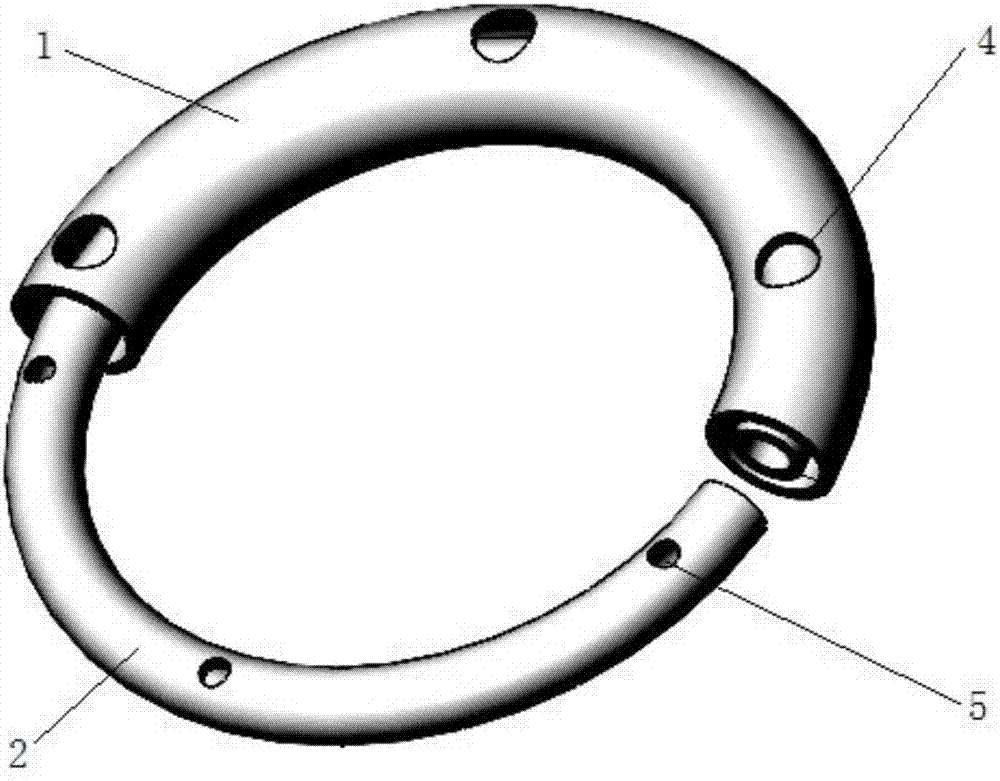

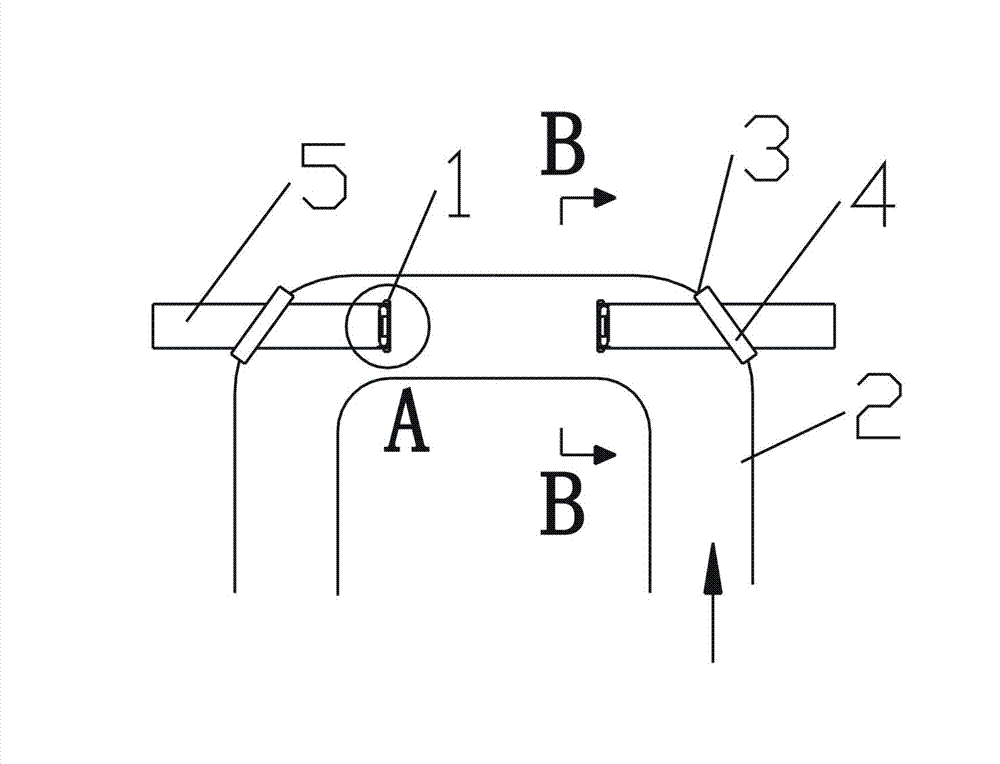

Mud scraper

InactiveCN111097204ALess agitationInto a stableSettling tanks feed/dischargeSedimentation settling tanksEngineeringSewage

A mud scraper relates to the field of sewage treatment, in particular to an improvement of a mud scraper for sewage treatment. According to the mud scraper, inflow water stirring is reduced, and the contact time of sewage and a flocculating agent is prolonged, so that the effluent efficiency is guaranteed. The mud scraper comprises a tank body and a working bridge fixed above the tank body. A flowstabilizing cylinder is fixedly arranged on the bottom surface of the working bridge; a water inlet is formed in the upper portion of the flow stabilizing cylinder; a plurality of stabilizing plateslocated below an outlet of a water inlet channel are arranged on the inner wall of the upper portion; one end of each stabilizing plate is evenly fixed to the inner wall of the upper portion, and theother end of the stabilizing plate is fixed to the outer wall of a connecting ring; the connecting ring is arranged on a mud scraping shaft in a sleeving mode; and the stabilizing plates are arrangedobliquely to the horizontal plane. The flocculation effect is improved, and the effluent efficiency is finally ensured.

Owner:YANGZHOU XINYA ENVIRONMENTAL ENG

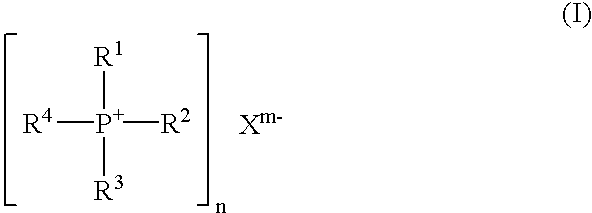

Product stability enhancement with phosphonium salts

InactiveUS7018561B2Improve stabilityReduce icingBiocideScale removal and water softeningChemistrySURFACTANT BLEND

The present invention provides a beverage surfactant composition that includes a surfactant, a phosphonium compound, and a carrier; wherein the beverage surfactant composition exhibits stability as a solution or as a dispersion at a temperature of about 0° C. to about 8° C. The present invention also provides a container or a conveyor for a container having a surface that is at least partially coated with the composition. The present invention also provides a process for lubricating a container that includes contacting at least a portion of a surface of the container and the composition together. The present invention also provides a process for lubricating a conveyor that includes contacting at least a portion of a surface of the conveyor and the composition together. The present invention also provides a method for enhancing stability as a solution or a dispersion of a composition containing a surfactant and a carrier, involving incorporating a phosphonium compound into the composition.

Owner:ECOLAB USA INC

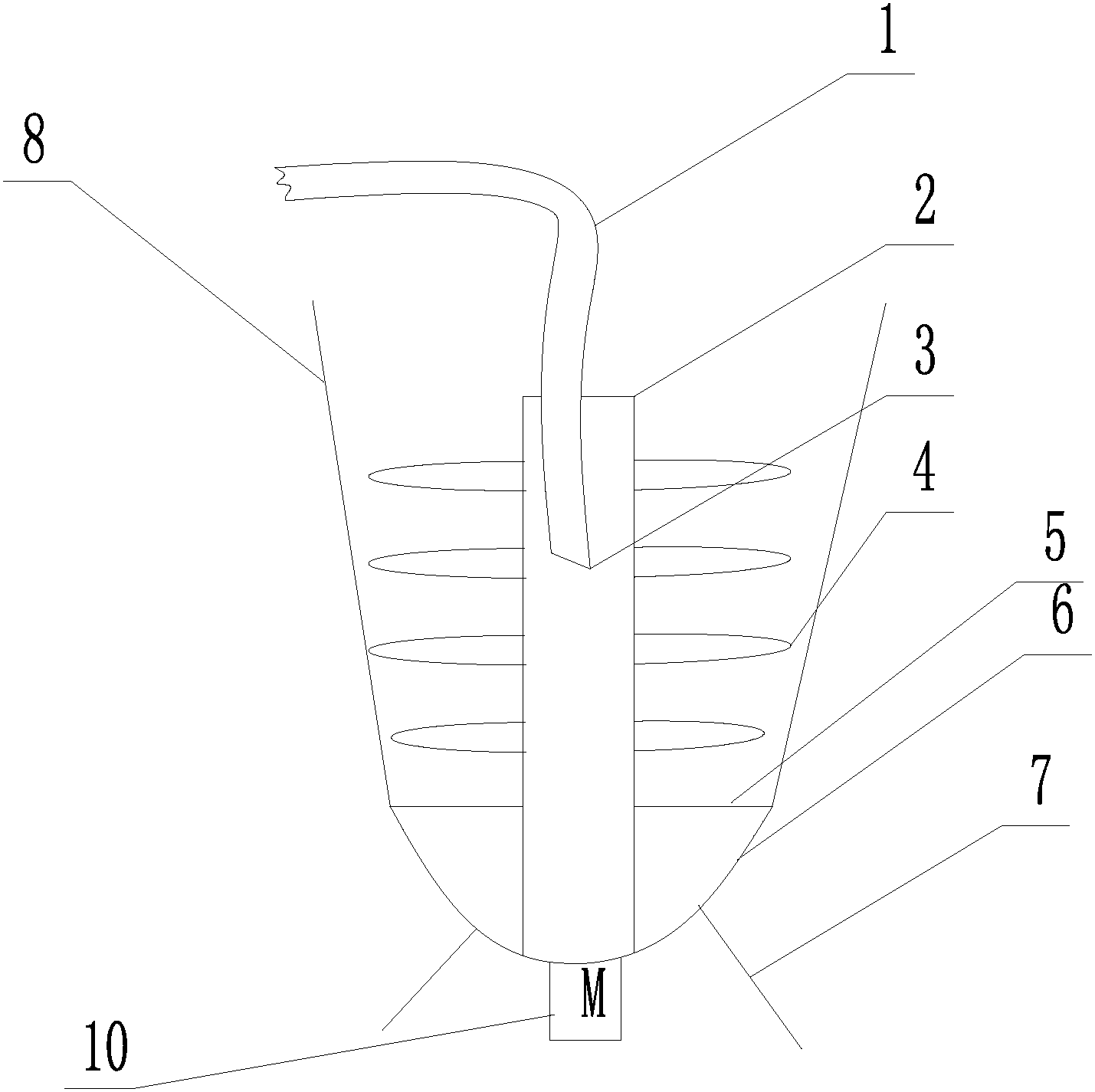

Deslagging filter

InactiveCN104307242AImprove performanceExtended service lifeCentrifugal force sediment separationFiltration separationSlurryPulp and paper industry

The invention relates to a deslagging filter, and in particular relates to a deslagging filter which is used for removing solid particles in slurry of cereals. The deslagging filter comprises a slurry delivery passage, a centrifugal filtering module and a drainage tube, wherein the centrifugal filtering module comprises a roller with an open upper end, and a stirring shaft fixed at the bottom of the roller, wherein a stirring paddle is arranged on the stirring shaft, the bottom of the roller is a concave spherical surface, the stirring shaft is a hollow barrel with open upper end, and penetrates through the axial central shaft of the roller, and the inlet of the drainage tube extends into the stirring shaft. By virtue of the deslagging filter, the defects that the filtering material is expensive, high in cost and short in service life in the prior art are overcome, and the deslagging filter provided by the invention is low in cost and long in service life.

Owner:CHONGQING DAWOSI FOOD

Anti-clogging aerator

ActiveCN103435120BLarge service areaReduce flow rateTreatment using aerobic processesSustainable biological treatmentEngineeringCowling

The invention relates to an anti-clogging aerator which comprises an upper bubble rectifying device, a middle bubble cutting device, a lower bubble cutting device and an air intake component, wherein the upper bubble rectifying device comprises a cowling, a rectifying plate and a funneled cowling transitional connection casing; the middle bubble cutting device comprises a middle casing, a middle cutting plate and a middle funneled transitional connection casing; the lower bubble cutting device comprises a lower casing and a lower cutting plate; the air intake component comprises an air inlet pipe, a cover body and a baffle plate. According to the invention, gas is smashed into bubbles through cutting holes in the gas and liquid mixing process, after being cut at each stage, the bubbles become smaller in size and are increased in number, meanwhile, the gas flow rate is lowered so as to enlarge the service area of the bubbles. Blowdown holes are formed in the lower casing and the lower part of the cover body, the cutting holes are formed in the cutting plates and are not blocked easily or required to be cleaned, and the use is not influenced even the cutting plates scale slightly. The anti-clogging aerator is simple in structure and convenient to operate; procedures for cleaning the aerator frequently are reduced, and the production efficiency is improved.

Owner:石家庄金钛净化设备有限公司

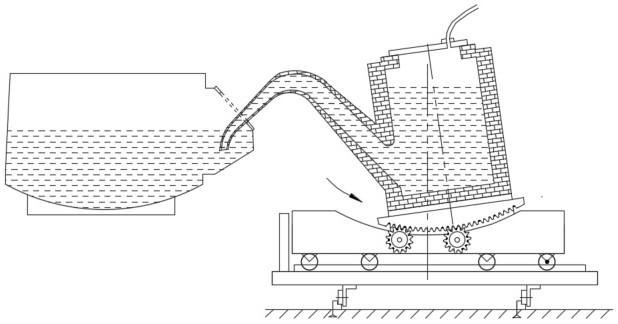

Molten aluminum transfer system

PendingCN112222378ALess agitationQuality improvementMelt-holding vesselsMolten metal supplying equipmentsMaterials scienceCompressed air

The invention discloses a molten aluminum transfer system. The molten aluminum transfer system comprises a casting ladle arranged on a supporting platform, an n-shaped molten aluminum pouring gate andan air inlet are formed in the casting ladle, the molten aluminum pouring gate can extend into the position below the molten aluminum level in a heat preservation furnace, and compressed air can be introduced into the air inlet. According to the molten aluminum transfer system, molten aluminum stirring during direct pouring can be relieved, impurities at the bottom of the heat preservation furnace are prevented from being brought into molten aluminum, and the quality of the molten aluminum is improved; and quantitative filling is achieved by controlling the compressed gas introducing time andcontrolling the adding amount of the molten aluminum.

Owner:CITIC DICASTAL

Ultrasonic heat meter

The invention relates to the technical field of acoustic sensors, and discloses an ultrasonic heat meter. The ultrasonic heat meter comprises ultrasonic transducers and a sensor casing, and is characterized in that the sensor casing is U-shaped, two ends of the sensor casing are connected with a water inlet pipe and a water outlet pipe, two through holes are arranged at the bend of the sensor casing, sealing caps are arranged on the through holes and provided with pipes, one end of each pipe extends to the inside of the sensor casing, the other end of each pipe is positioned outside the sensor casing, each ultrasonic transducer is arranged at the end, inside the sensor casing, of the corresponding pipe, and the two pipes are located on the same straight line. The ultrasonic heat meter has the advantages that the ultrasonic heat meter is simple in structure with a reflection device omitted, convenient to detach, accurate in measurement, easy and convenient to maintain and low in pressure loss, and the transducers are mounted with high tightness.

Owner:SHAOXING UNIVERSITY

Electron beam evaporation coating machine coating film correcting device

PendingCN109609916ASimple structureLow costVacuum evaporation coatingSputtering coatingPhysicsHalogen

The invention relates to an electron beam evaporation coating machine coating film correcting device which comprises a fixed correcting device I, a fixed correcting device II, a movable correcting device, one evaporation source, four halogen lamps, one ion source and one electronic gun. The one evaporation source, the four halogen lamps and the one ion source are on one same divided circle; the four halogen lamps are divided into two groups and are symmetrical along two sides of the center position; the evaporation source is located in the central symmetry position of a furnace body; the ion source is located on the left side of the furnace body; the electronic gun is located on the right side of the furnace body; the fixed correcting device I is located in the middle position between thetwo halogen lamps on the left side, and is arranged on the inner wall of the furnace body; the fixed correcting device II is located in the middle position between the halogen lamps on the right sideand the electronic gun, and is arranged on the inner wall of the furnace body; the installation heights of the fixed correcting device I and the fixed correcting device II are consistent; and the movable fixed correcting device is located on the right side of the furnace body and is located above the electronic gun. The electron beam evaporation coating machine coating film correcting device provided by the invention has the advantages of simple structure, less number of correcting devices, good effect and the like.

Owner:湖南宇诚精密科技有限公司

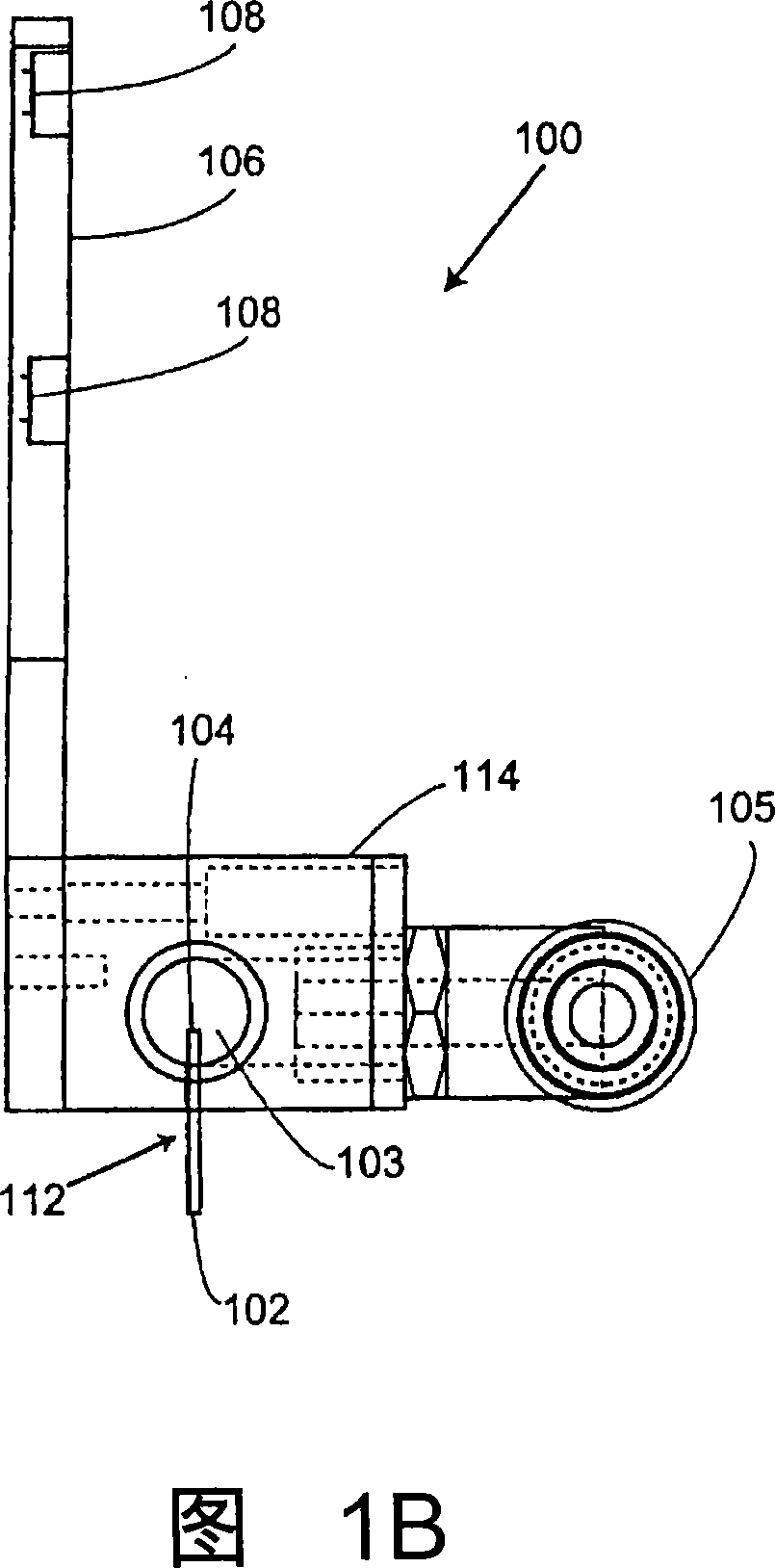

Multi-well container processing systems, system components, and related methods

The present invention provides fluid removal heads and related multi well container processing systems for the efficient removal of fluids from multi-well containers. Methods of removing fluid from multi-well containers are also provided.

Owner:IRM

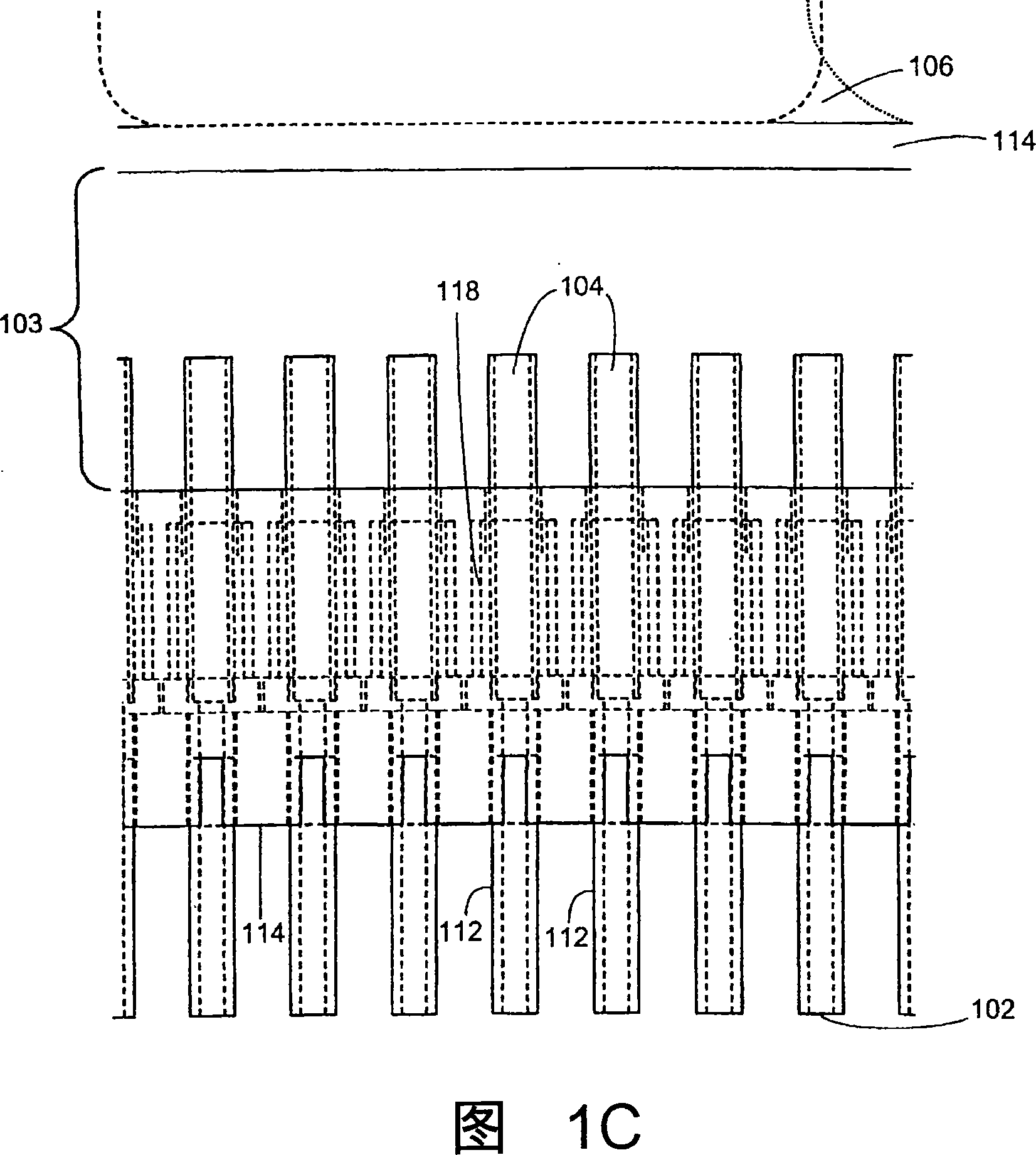

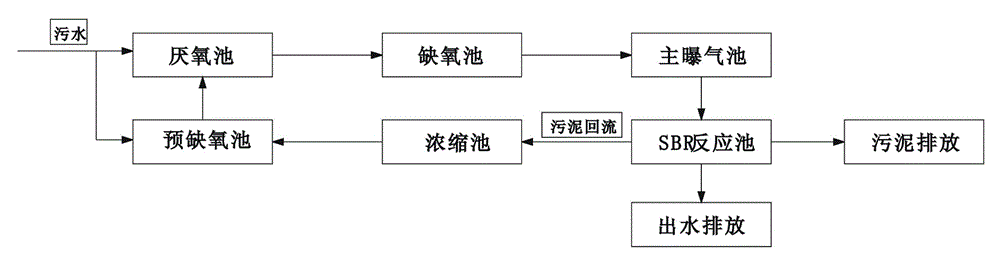

Process control method of modified sequencing batch reactor (MSBR) system

ActiveCN102745811AWell mixedAeration time is sufficientTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesSequencing batch reactorAutomatic control

The invention relates to a wastewater treatment method and discloses a process control method of a modified sequencing batch reactor (MSBR) system. The process control method includes that sequencing batch reactor (SBR) reaction tanks are operated alternately and intermittently and correspondingly regulate the process control method according to ambient temperatures or inflow water quality conditions. The process control method of the MSBR system has the advantages of being concise in operation modes, sufficient in aeration time and pre-setting time and capable of facilitating sediment and reducing suspended substance (SS) in discharged water, and the whole system performs continuous water inflow and continuous backflow to guarantee full mixing of backflow sludge and inflow water, so that automatic control and daily production management are facilitated; and the process control method is capable of achieving the best treatment effect under conditions of different temperatures and different inflow water qualities.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com