Electron beam evaporation coating machine coating film correcting device

A technology of electron beam evaporation and coating machine, which is applied in the directions of vacuum evaporation coating, ion implantation coating, sputtering coating, etc., which can solve the problems that are difficult to meet at the same time, and the influence of the cavity pumping coating uniformity is not considered. Achieve the effect of small structural limitations, simple structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

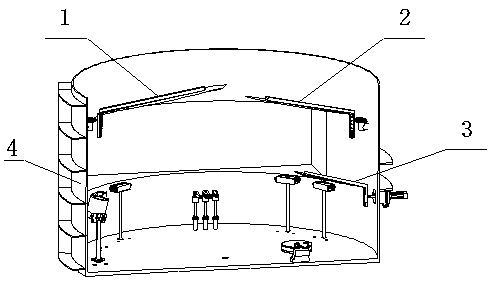

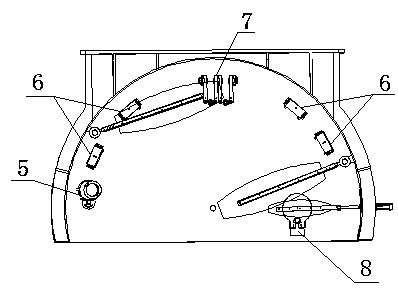

[0019] refer to Figure 1-Figure 2 , a coating correction device for an electron beam evaporation coating machine, including a fixed correction device I1, a fixed correction device II2, a movable correction device 3, an evaporation source 7, four halogen lamps 6, an ion source 5, and an electron gun 8 , the fixed correction device I1, the fixed correction device II2 and the movable correction device 3 are all fixed on the furnace body 4 of the coating machine;

[0020] The 1 evaporation source 7, the 4 halogen lamps 6, and the 1 ion source 5 are on the same graduation circle, and the 4 halogen lamps 6 are divided into two groups, which are symmetrical on both sides along the central position; the evaporation source 7 is located at a symmetrical position in the center of the furnace body, close to the air outlet of the furnace body; the ion source 5 is located on the left side of the furnace body close to the furnace door; the electron gun 8 is located on the right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com