Magnetic levitation overspeed test bed for impeller overspeed test

A technology of overspeed test and magnetic levitation, applied in pump control, non-variable capacity pump, machine/engine, etc., can solve the problems of low load and life, low motor output speed, difficult to control, etc., to achieve good dynamic balance performance, connection Simple structure and improved resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

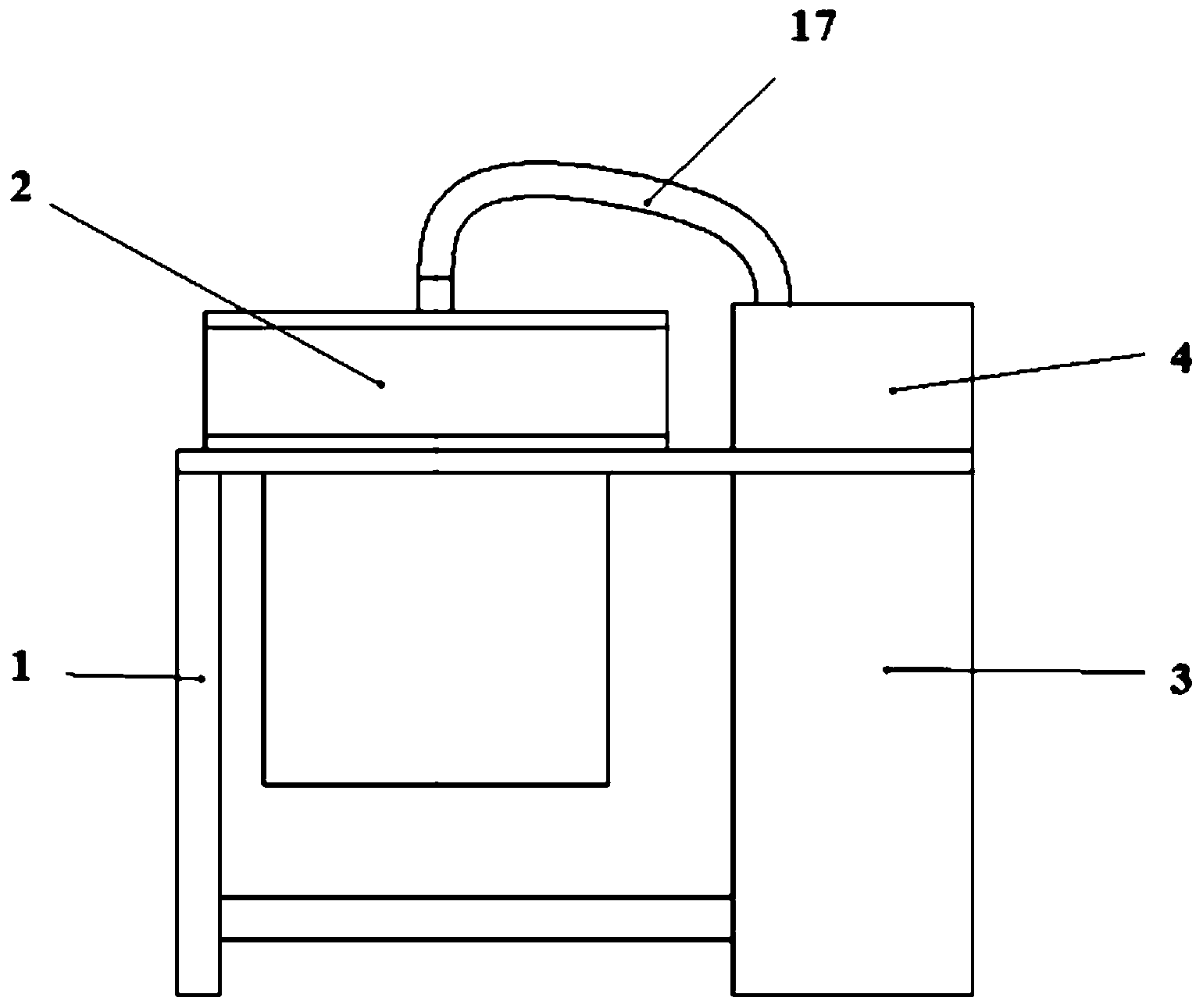

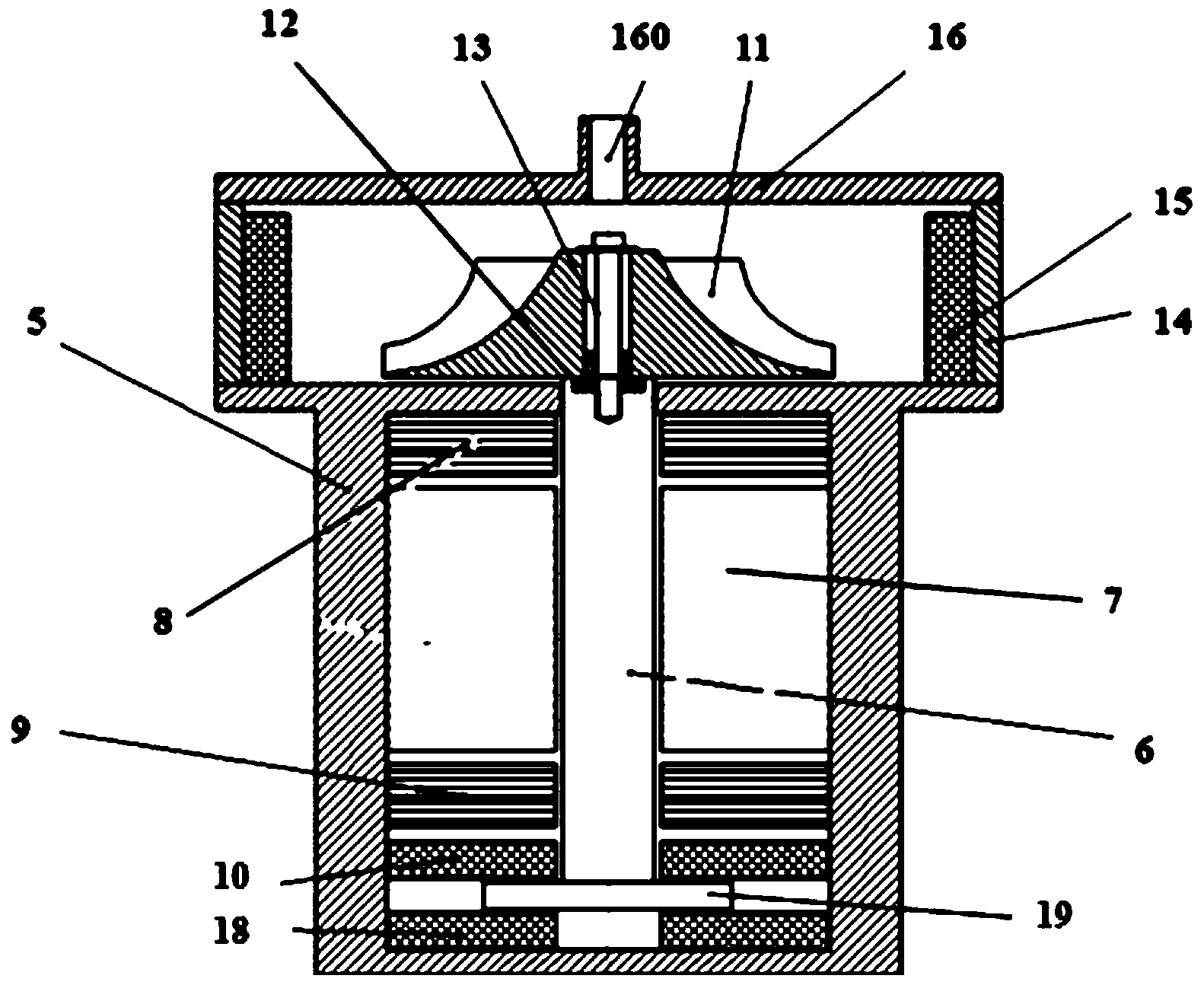

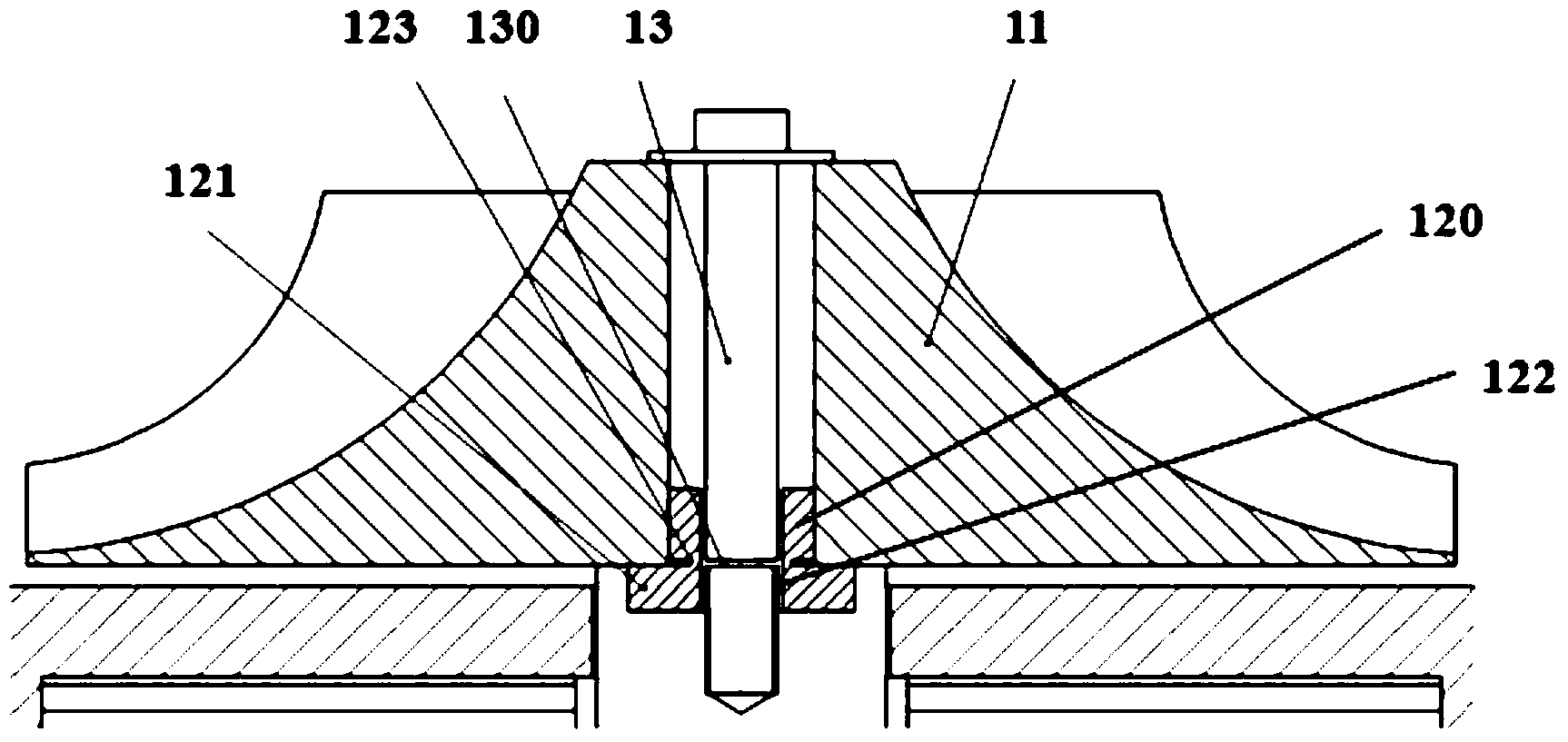

[0038] Please refer to Figure 1 to Figure 3 As shown, the magnetic levitation overspeed test bench for the impeller overspeed test of the present invention includes a support 1 and a host 2 installed on the support 1 , an electric control cabinet 3 and a vacuum pump 4 . The main engine 2 includes a motor housing 5, a motor rotor 6 installed in the motor housing 5, and an electronic stator 7, wherein the upper end of the motor rotor 6 extends beyond the upper end surface of the motor housing 5, and is located on the motor rotor 6. An upper radial magnetic bearing 8 and a lower radial magnetic bearing 9 are installed on the upper and lower positions of the stator 7, and an upper thrust magnetic bearing 10 and a lower thrust magnetic bearing 10 are installed on the motor rotor 7 below the lower radial magnetic bearing 9. The bearing 18 and the disc-shaped thrust disc 19 located between the upper thrust magnetic bearing 10 and the lower thrust magnetic bearing 18, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com